Expanding device of moving block

A technology of moving blocks and expanding blocks, which is applied in the processing or treatment of steel pipes, can solve the problems of small heat transfer coefficient, large thermal expansion coefficient, and large shrinkage of stainless steel plates, and achieve low manufacturing costs, reduce or weld deformation, and eliminate The effect of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

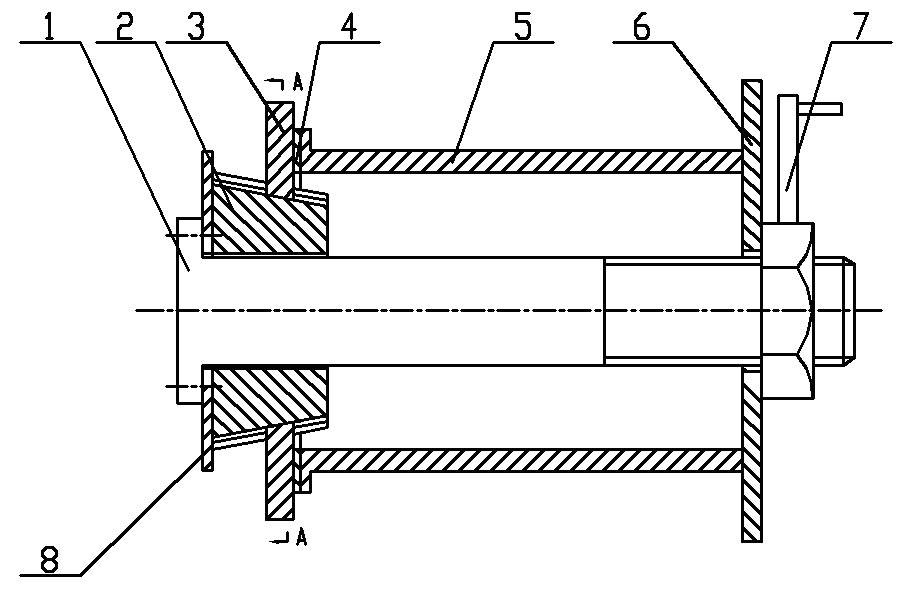

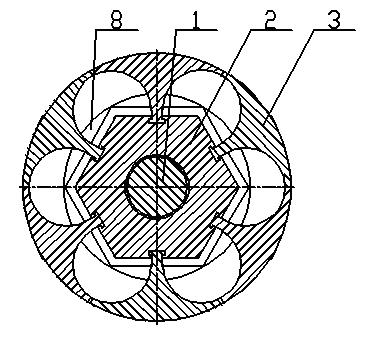

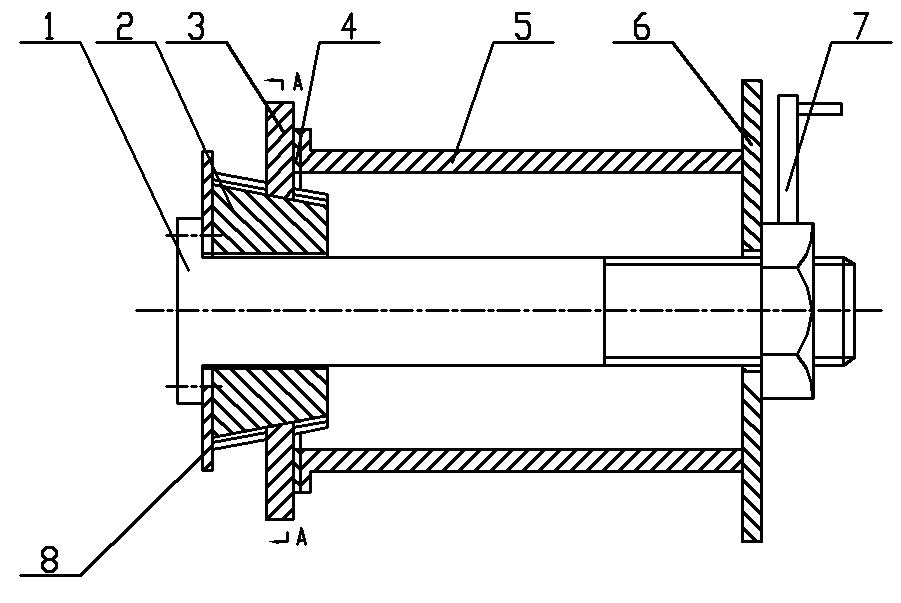

[0015] An expansion device for a moving block of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 with figure 2 As shown, an expansion device for a moving block of the present invention consists of a pull rod 1, an expansion head 2, an expansion block 3, a guide plate 4, a sleeve 5, a positioning block 6, a locking handle 7 and a stop plate 8 Composition; the pull rod 1 is placed in the T-shaped sleeve 5, and one end of the pull rod 1 protruding from the T-shaped sleeve 5 is sequentially fitted with a circular stop disc 8 with a central hole, and a regular hexagonal cone The expansion head 2 and the circular guide plate 4; the pull rod 1 stretches out from the T-shaped sleeve 5 and the other end of the threaded end passes through the hole provided by the positioning block 6 and is threadedly connected with the locking handle 7; the regular hexagon The connection between the expansion hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com