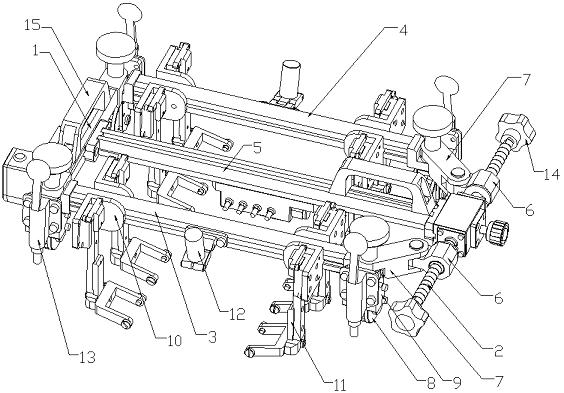

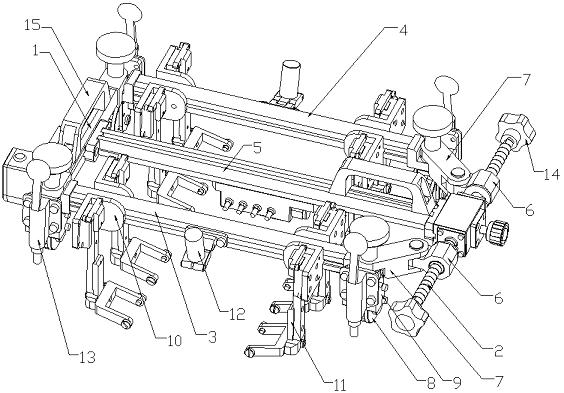

Combined TOFD and phased array imaging scanner for weld of seal head for pressure vessel

A pressure vessel and phased array technology, which is applied in the detection field of straight seams and other circular seams, and can solve problems such as the influence of the reliability of detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] see figure 1 , the present invention provides a combination weld TOFD and phased array imaging scanner of a pressure vessel head, comprising a main frame composed of a front beam 1, a rear beam 2, a left beam 3, a right beam 4 and a middle beam 5, preferably The rear beam is longer than the front beam, and the lengths of the left and right beams are equal, so that when the scanner is pushed to walk, the extension lines of the left, right, and middle beams always intersect at one point, and this point is set as If it is set as the center of the measured circular seam, the scanner’s walking route can be in the same circle (or arc shape) as the measured circular seam, ensuring that the probe installed on the scanner can move along the circular seam. Detection, the front ends of the left and right beams are respectively hinged with the two ends of the front beam to facilitate relative rotation, the front part of the middle beam is fixedly connected to the middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com