Production process of iron-removing filter

A production process and filter technology, which is applied in the field of iron removal filter production process, can solve the problems of delayed delivery, high price, long delivery time of composite boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

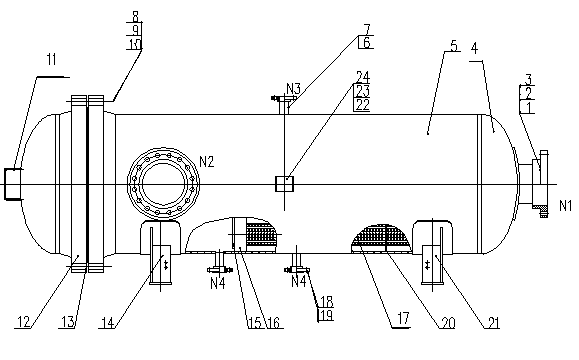

[0196] A production process of iron removal filter, the main processing steps are: head, cylinder, filter element casing, flange, orifice plate, tube plate, connecting pipe, component assembly, product assembly, pressure test.

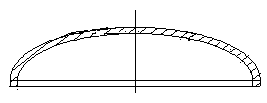

[0197] The described head is composed of an inner head and an outer head, and its processing steps are as follows:

[0198] 1). Material preparation: the material is made of Q345R steel plate and S30408 steel plate, and there should be a quality assurance certificate, and the material marking should be clear and complete;

[0199] 2). Scribing: The inner head is made of S30408 steel plate, the outer diameter blank is ф1150mm, and the thickness is 3mm; the outer head is made of Q345R steel plate, the outer diameter blank is ф1170mm, and the thickness is 14mm, two pieces each;

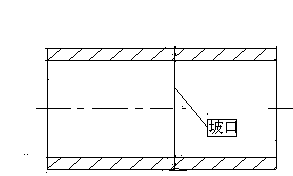

[0200] 3). Blanking: plasma and gas cutting cutting according to the marking requirements, to remove cutting residues and burrs;

[0201] 4). Drilling: On the stainless s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com