Liquid level measuring device for double-chamber balance container

A technology of a liquid level measuring device and a balancing container, which is applied to the display of liquid level indicators, components of steam boilers, and accessories of steam boilers through pressure measurement, which can solve the problems of easily polluted environment, low safety factor, and poor measurement accuracy. , to achieve the effect of improving the operational safety factor, improving the measurement accuracy and reducing the measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

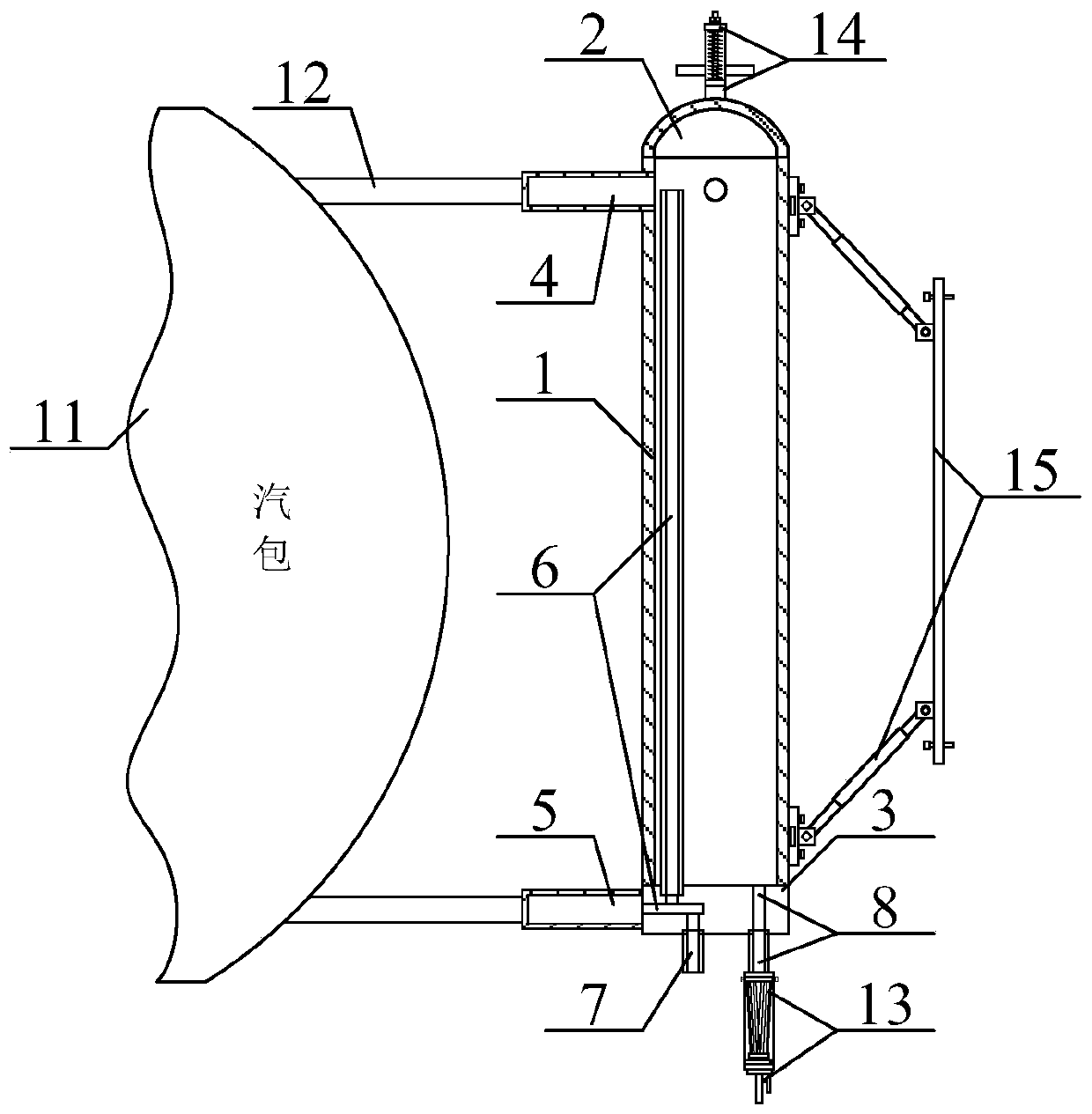

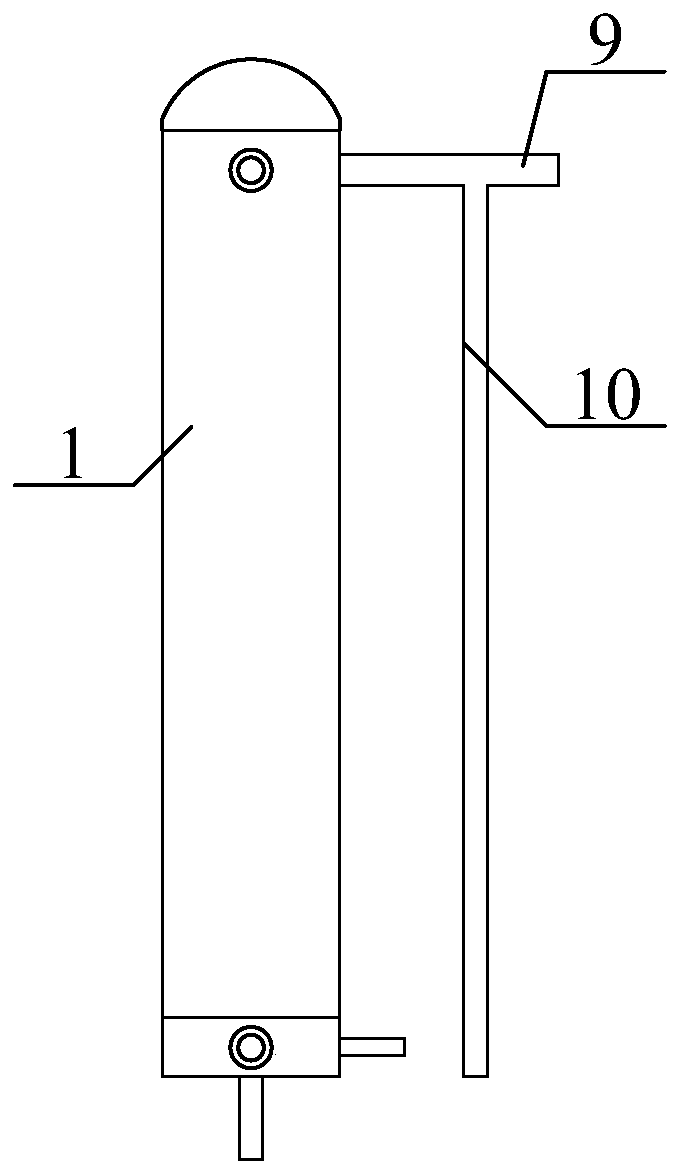

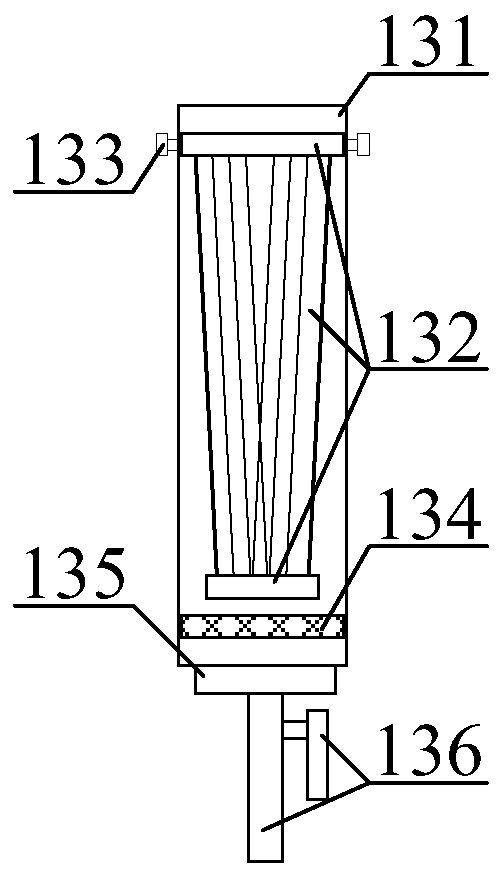

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, the liquid level measuring device of the double-chamber balance vessel includes a double-chamber balance vessel body 1, an upper head 2, a lower head 3, an upper connecting pipe 4, a lower connecting pipe 5, a T-shaped connector 6, and a positive pressure pipe 7. Sewage pipe 8, condensing coil 9, negative pressure pipe 10, boiler 11, steam drum vapor phase conduit 12, sewage treatment anti-pollution discharge pipe structure 13, anti-steam pressure excessive self-control release pipe structure 14 and adjustable support The mounting frame structure 15, the upper end of the double-chamber balance container cylinder 1 is threadedly connected with the upper head 2, and the lower end of the double-chamber balance container cylinder 1 is threadedly connected with the lower head 3; The upper and lower connecting pipes 4 and 5 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com