Reactor pressure vessel lower sealing head surfacing welding layer detection tool and method

A pressure vessel and detection tool technology, applied in the field of nuclear power plant maintenance, can solve the problems of reduced service life of the vessel, thinning of the thickness of the surfacing layer, damage, etc. The effect of collision risk and arm-folding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment this patent is described in detail:

[0037] It mainly includes the following technologies:

[0038] 1. Terminal monitoring technology

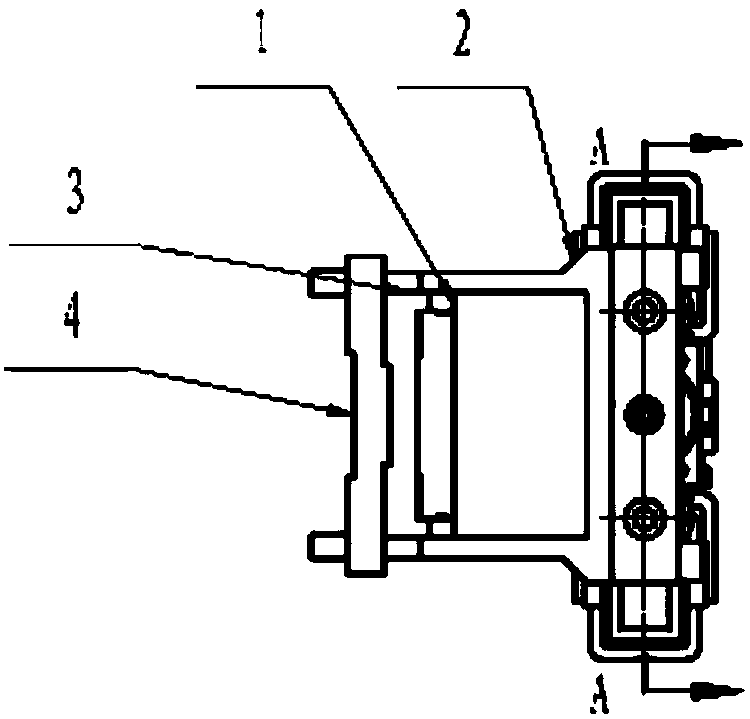

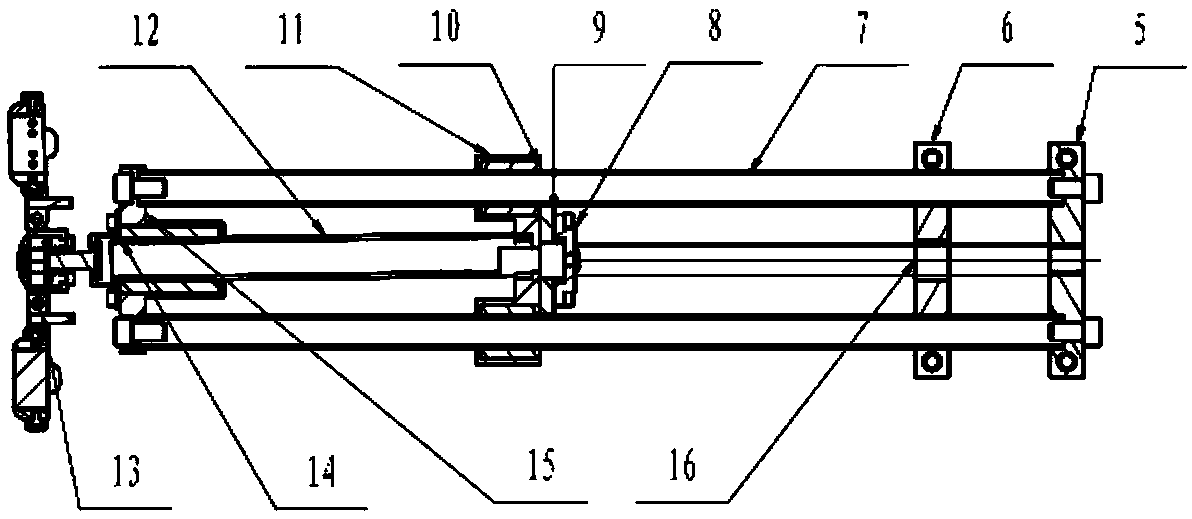

[0039] like figure 1 As shown, the terminal monitoring device includes: a connection block, a camera 1 , and an adapter base 2 . The distance between the two rows of penetrating parts in the surfacing layer area of the lower head of the reactor pressure vessel is 200.3 mm, and the vertical heights are not completely consistent. Due to the influence of the J-shaped weld, the detection range is relatively small. The detection environment is complex and the light is weak. The monitoring method for the detection of other parts of the pressure vessel relies on the monitoring on both sides of the central box of the robot or the monitoring of the long rod camera. Both monitoring methods are far away and it is difficult to ensure long-term real-time monitoring. collis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com