Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

408 results about "Double support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

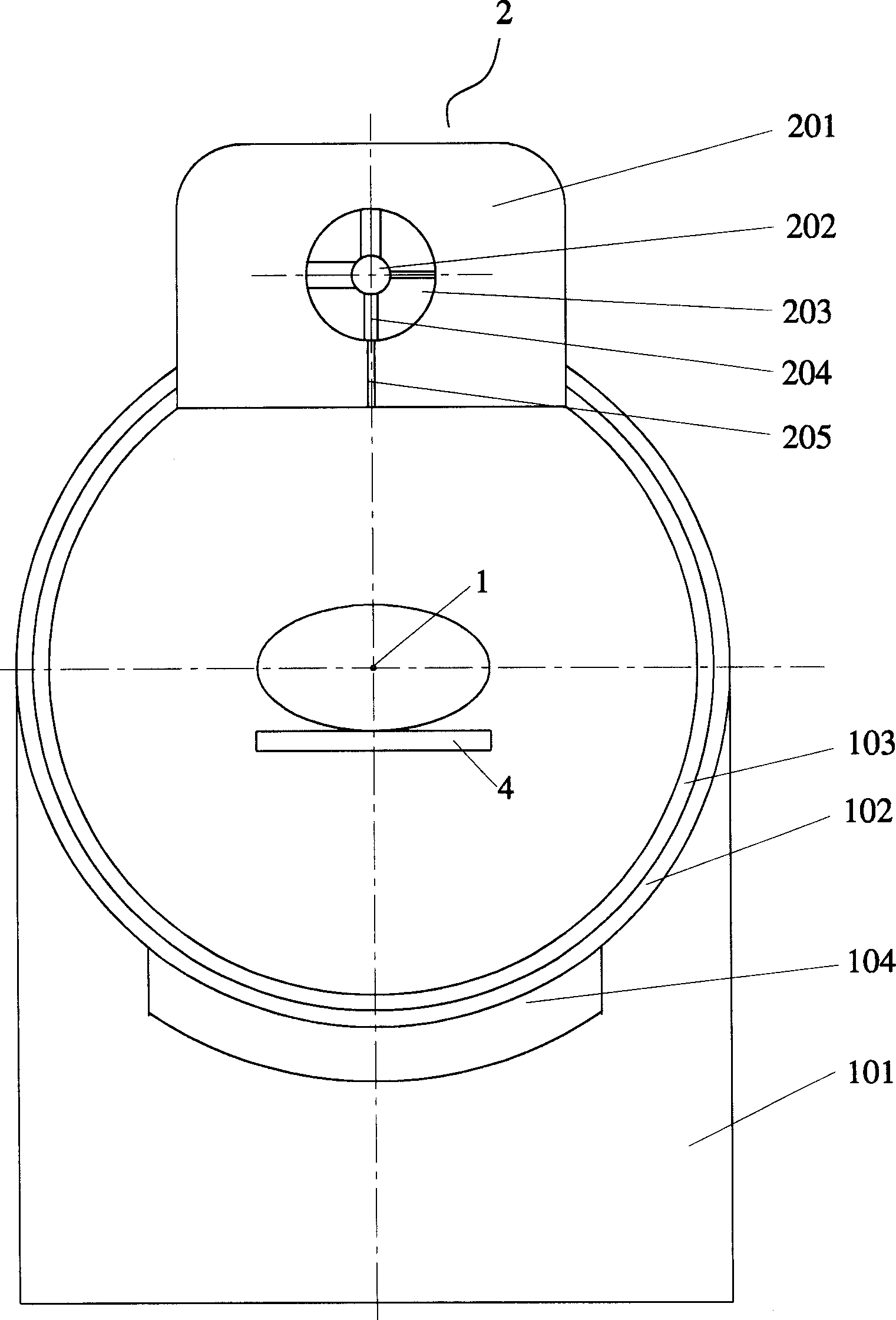

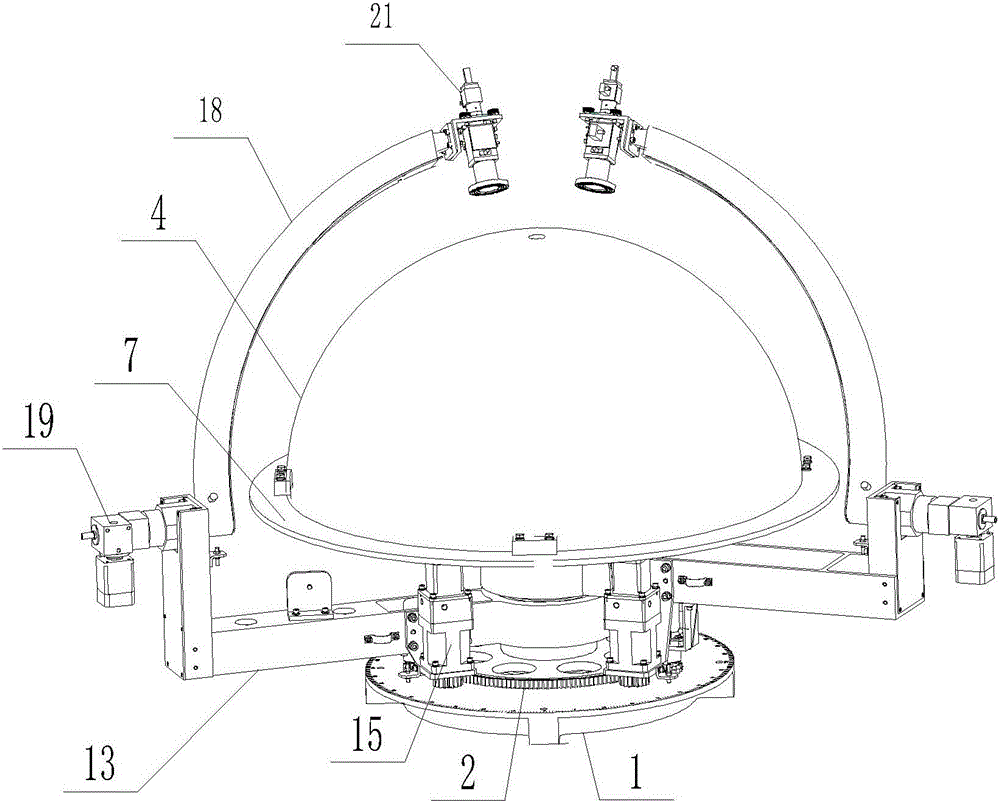

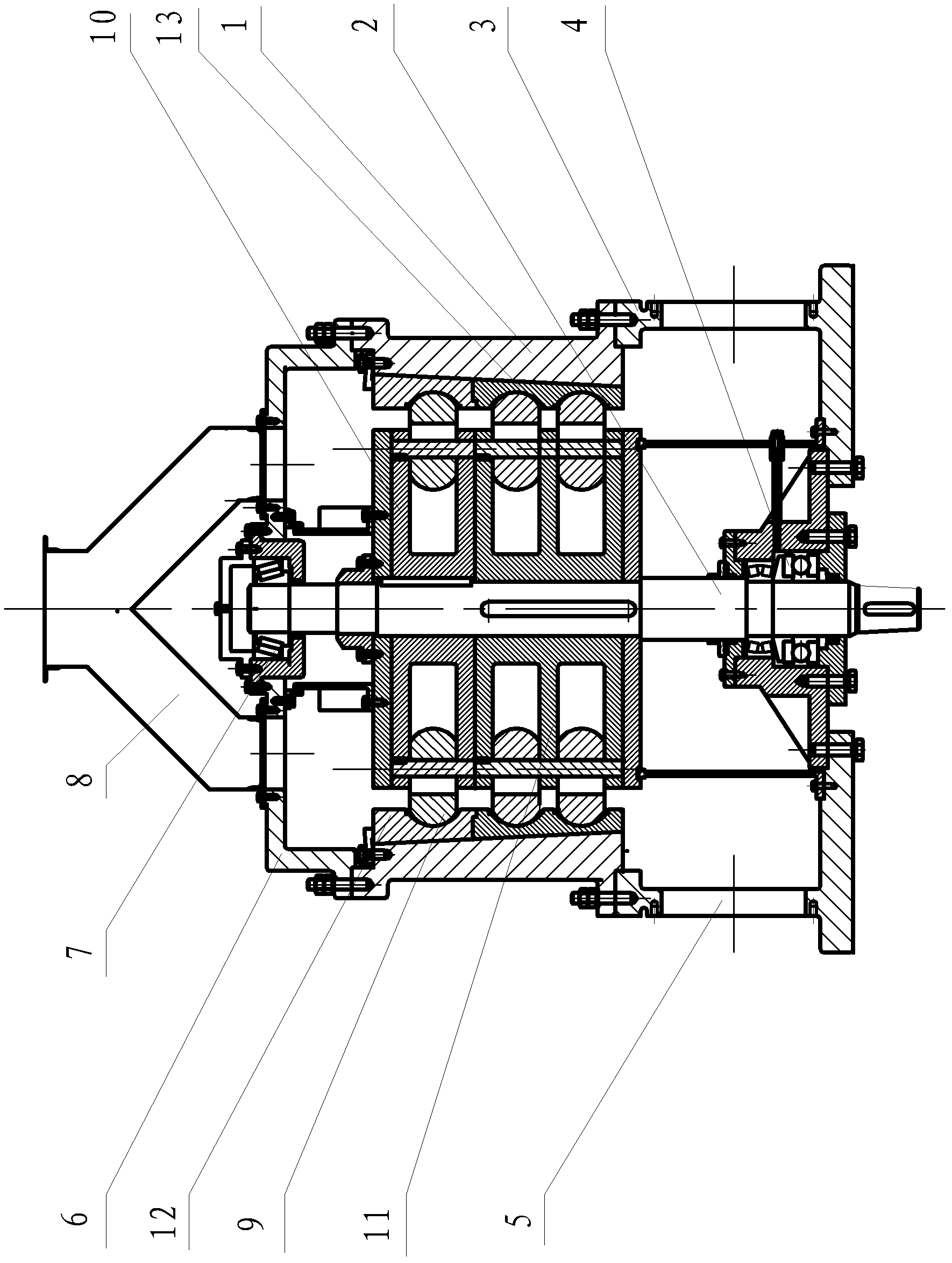

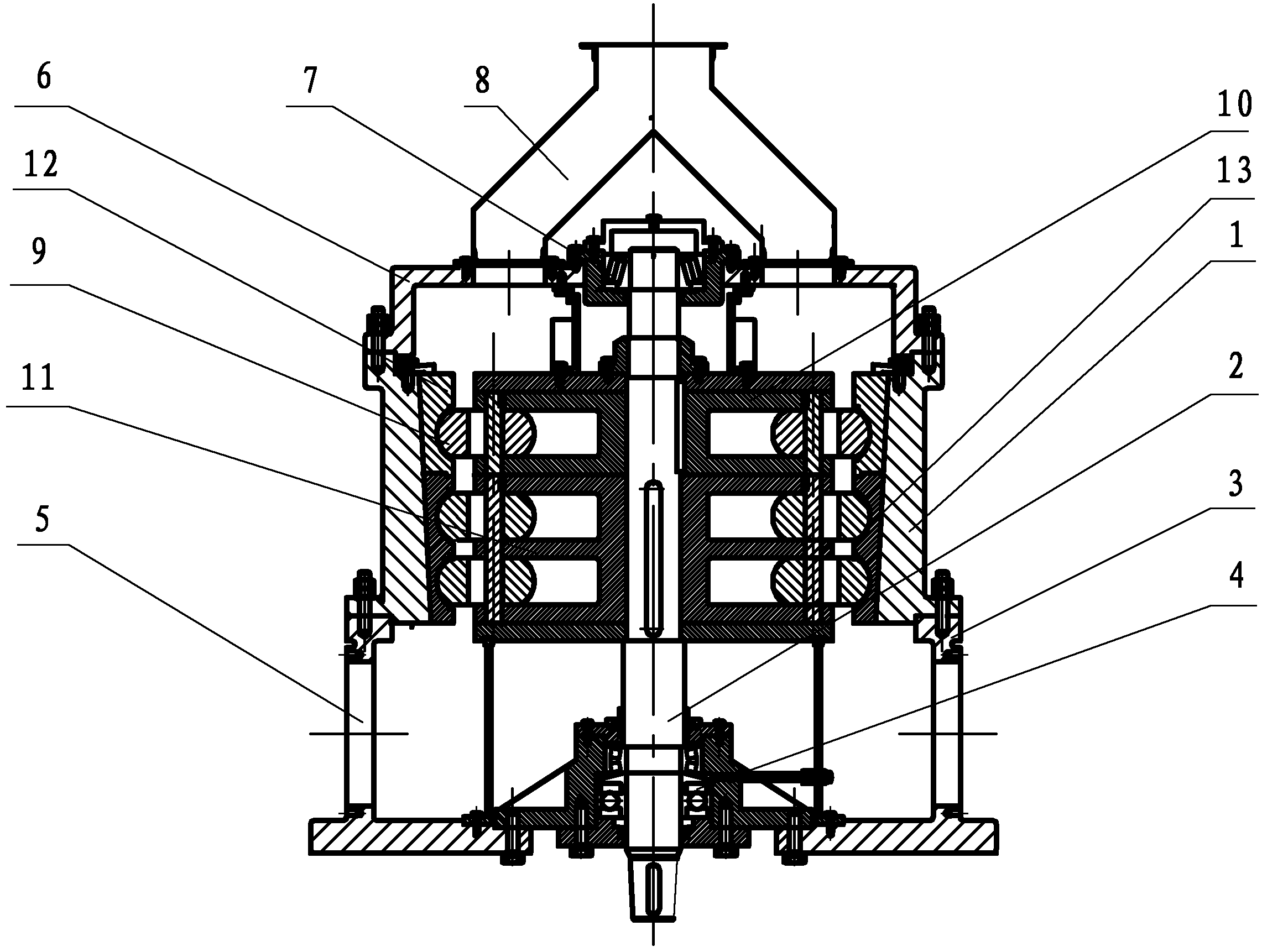

Radiotherapy Device

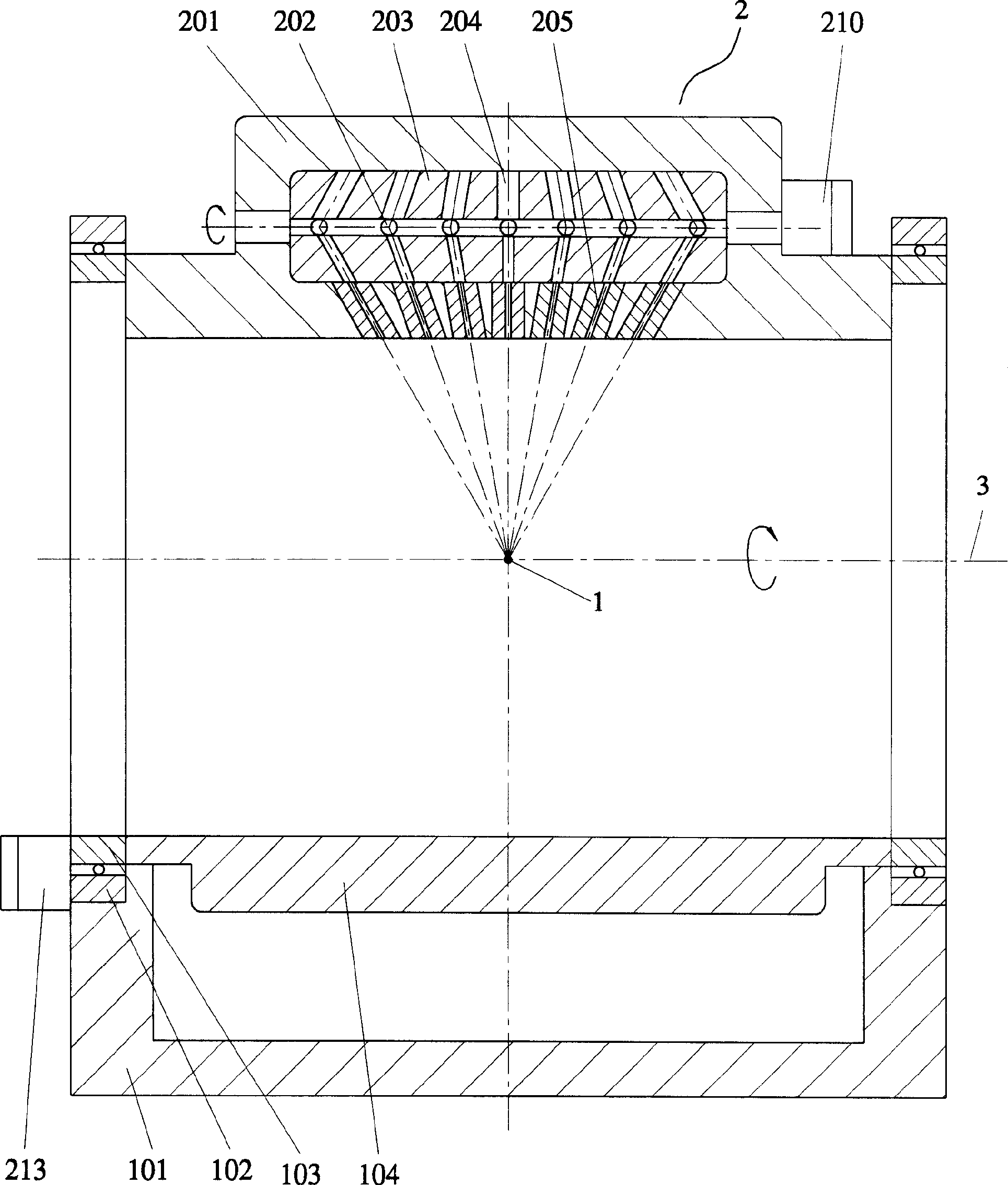

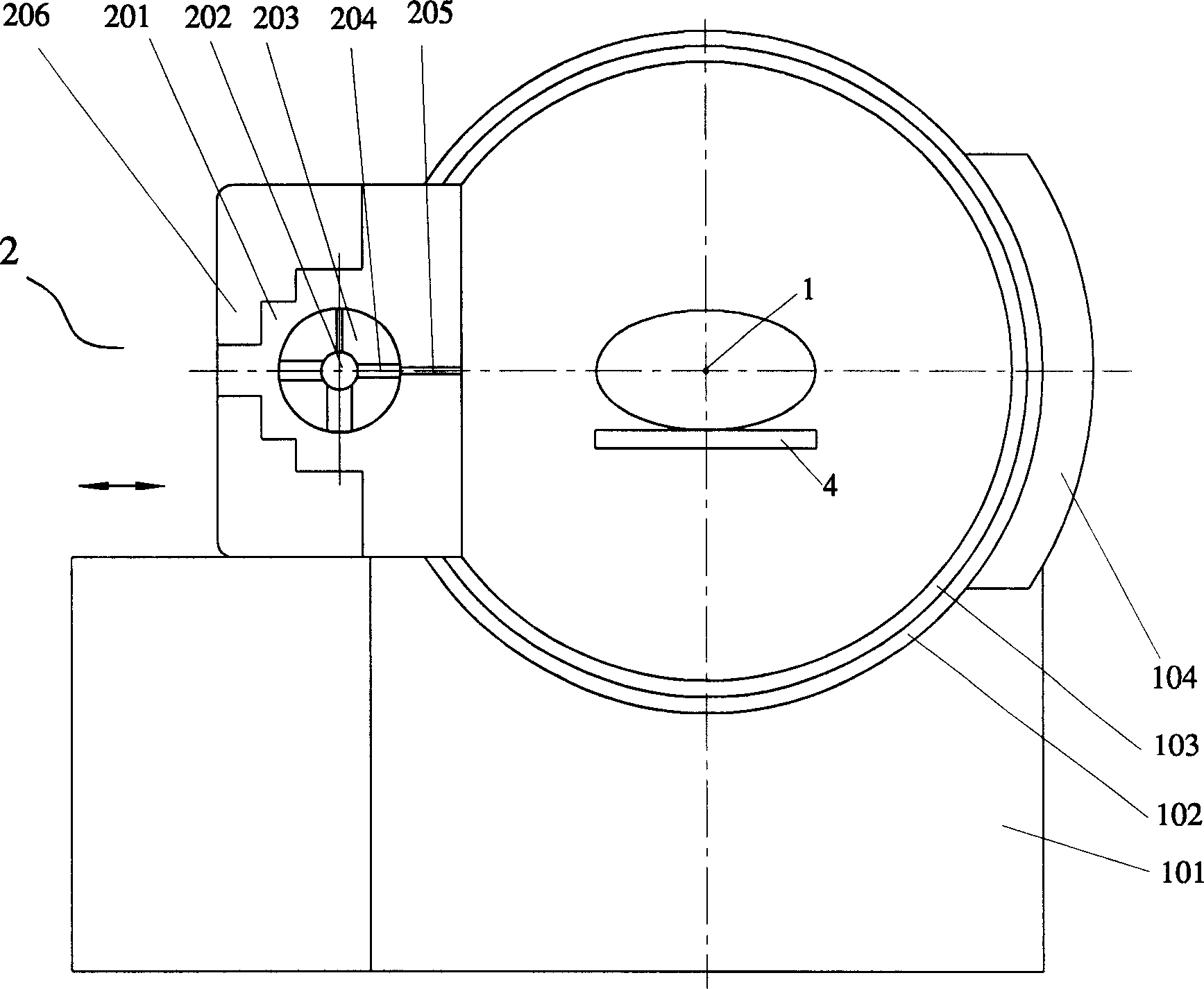

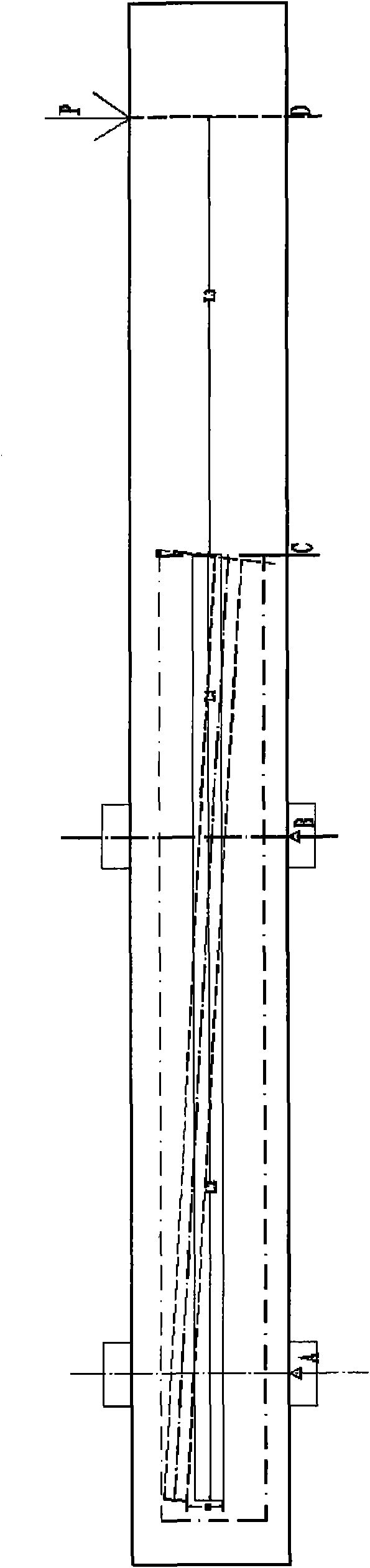

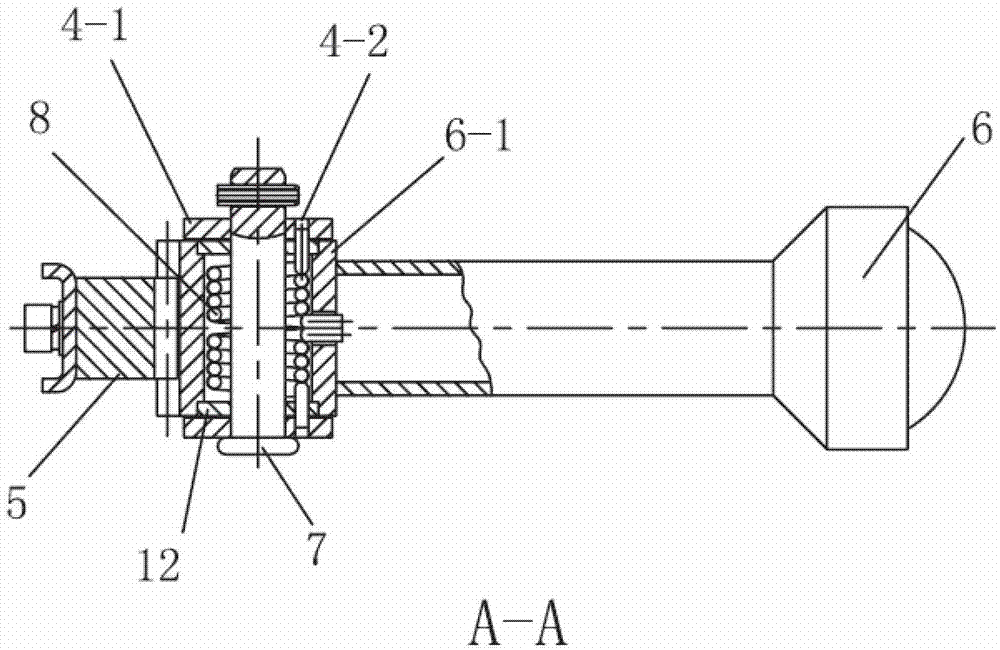

ActiveUS20090086909A1Expand the treatment spaceLow costHandling using diaphragms/collimetersX-ray apparatusRotational axisLight beam

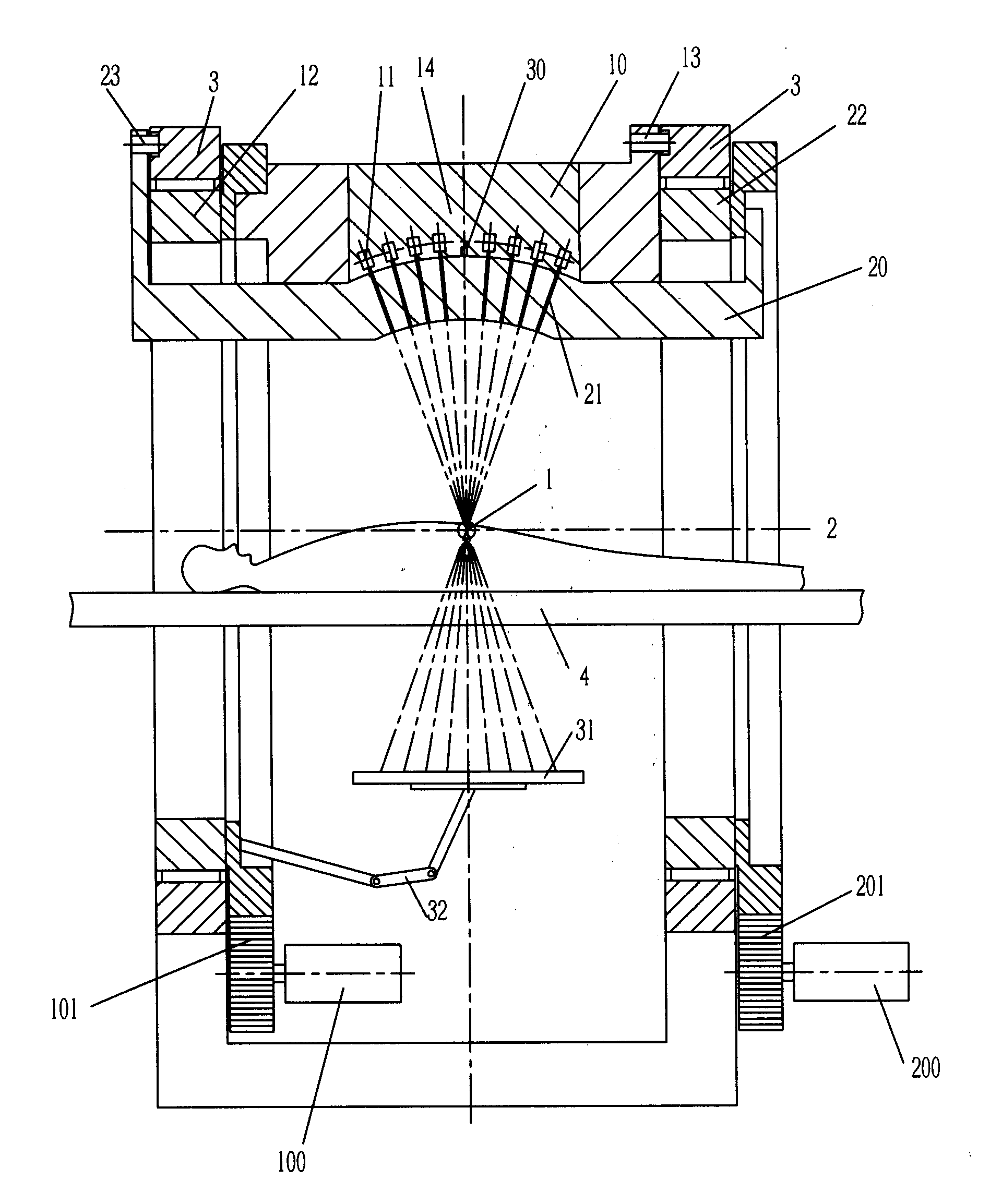

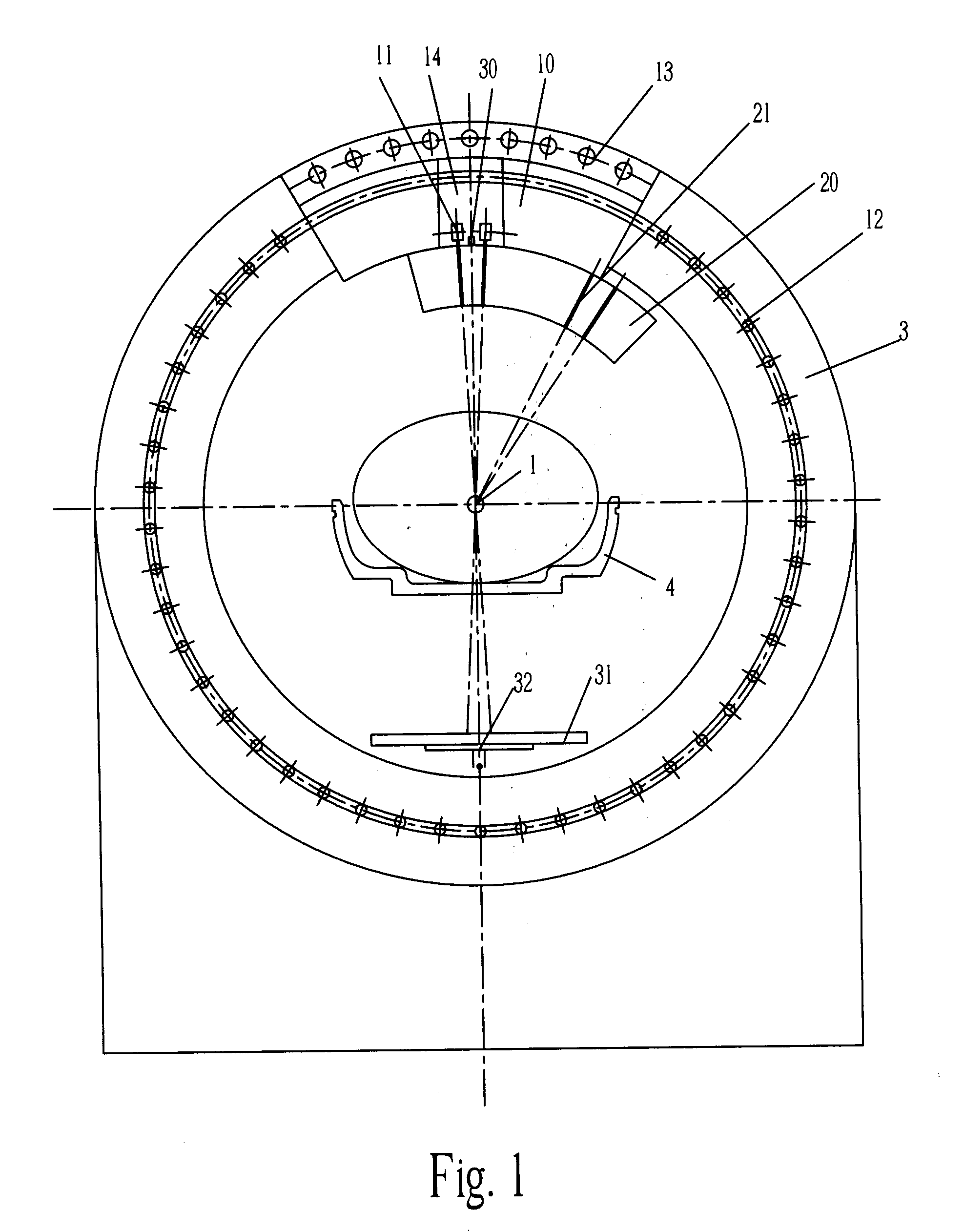

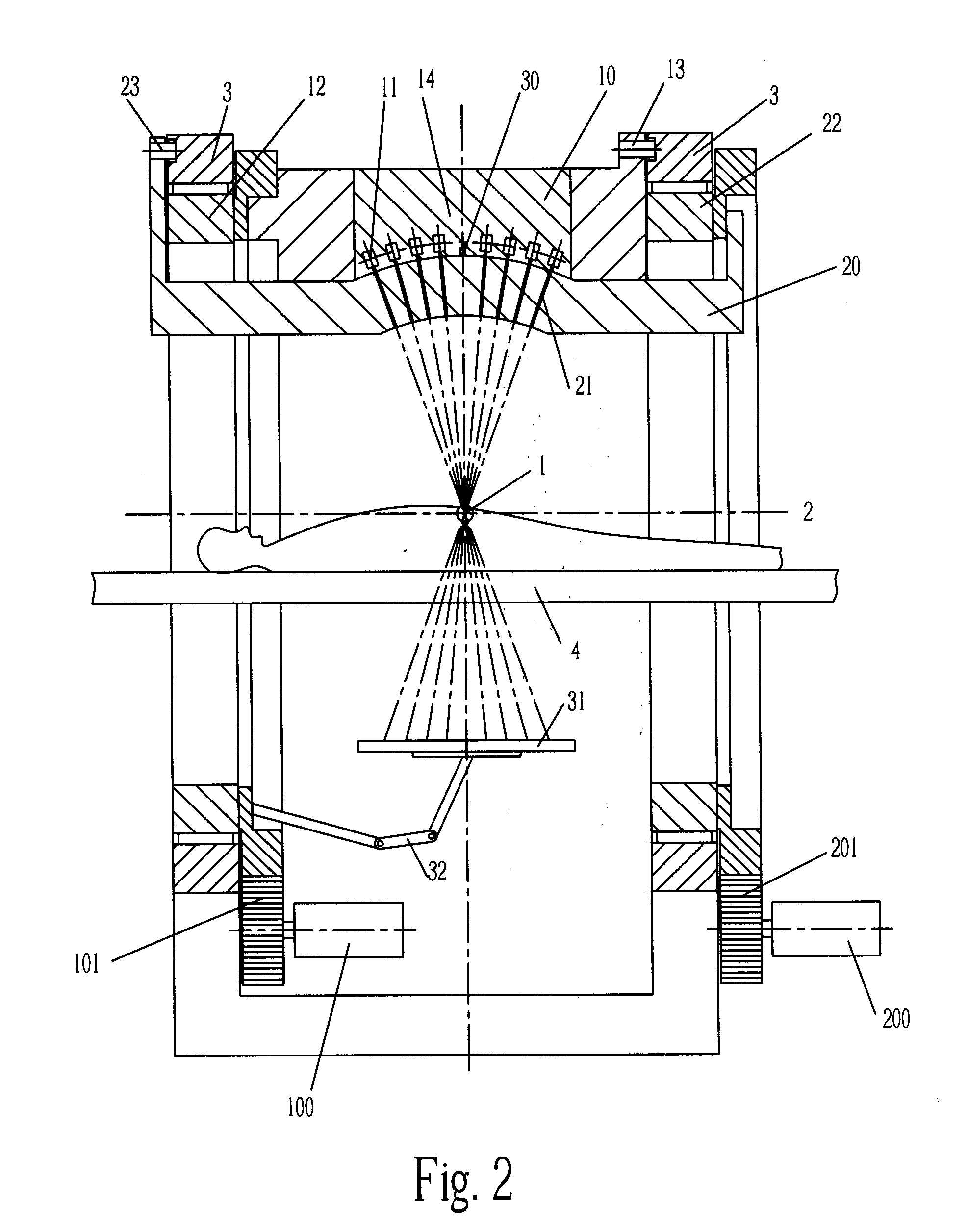

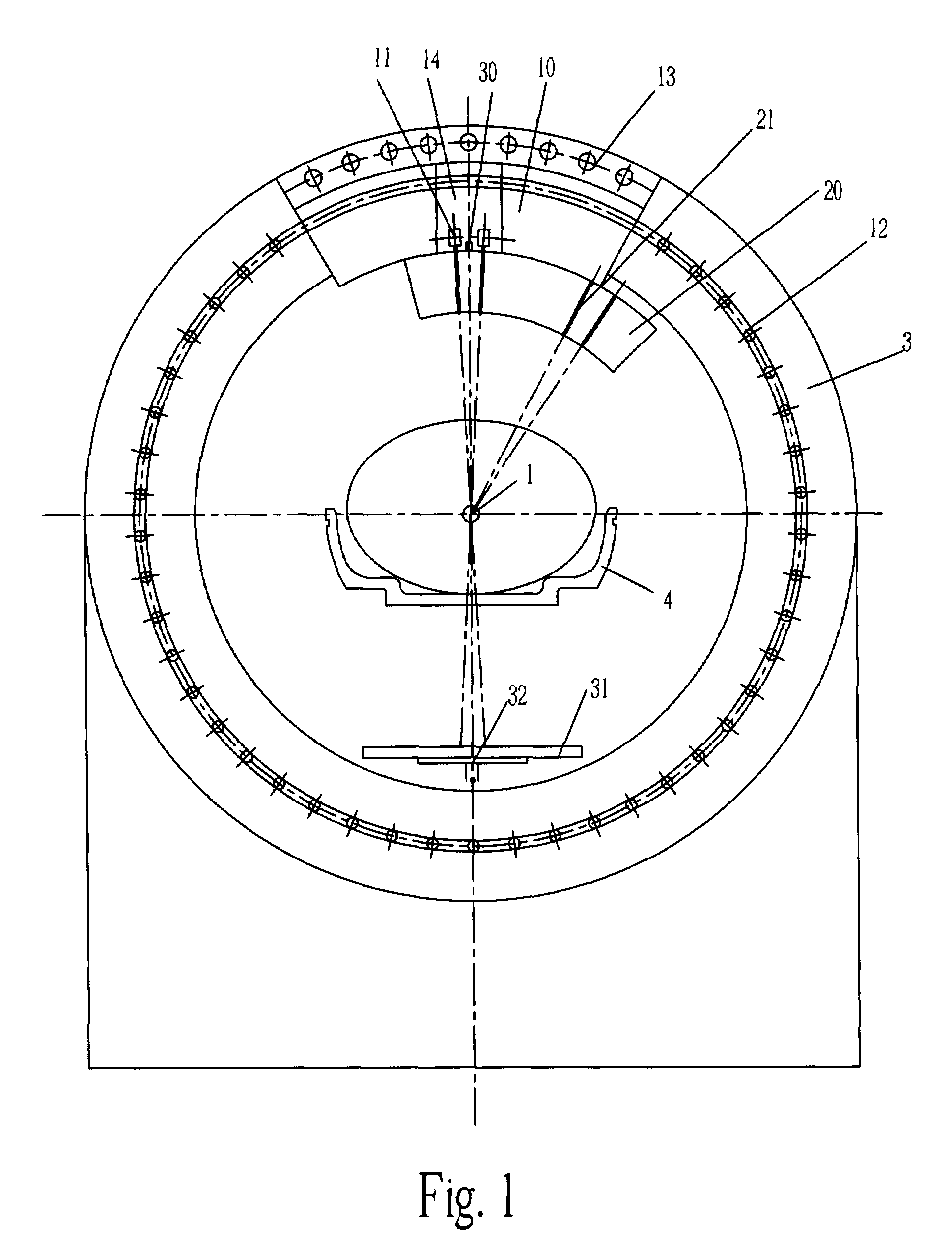

The invention involves a rotary focused gamma-ray radiotherapy device. The invention includes a frame, a rotary ring positioned at the frame, and a source carrier and a collimator carrier that can rotate around a rotary axis respectively. The source carrier is equipped inside with multiple radiation sources. The collimator carrier is equipped inside with a corresponding beam channel to the radiation sources, which focus at a shared focus of the rotary axis through the beam channel. The source carrier and the collimator carrier are connected at both ends with the rotary ring and the frame, respectively. The single-layer and double-support structure of the source carrier and the collimator carrier adopted in the invention enlarges the treatment space, lowers manufacturing cost and difficulty, simplifies the mechanical structure, increases support rigidity of the source carrier and the collimator carrier, ensuring long-lasting and steady coaxial rotation of source carrier and collimator carrier, as well as position accuracy of the focusing center in the therapeutic system. Therefore, a precision radiotherapy is realized with improved radiotherapy effect.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

Radiotherapy device

ActiveUS7656999B2Expand the treatment spaceLow costHandling using diaphragms/collimetersX-ray apparatusRotational axisLight beam

The invention involves a rotary focused gamma-ray radiotherapy device. The invention includes a frame, a rotary ring positioned at the frame, and a source carrier and a collimator carrier that can rotate around a rotary axis respectively. The source carrier is equipped inside with multiple radiation sources. The collimator carrier is equipped inside with a corresponding beam channel to the radiation sources, which focus at a shared focus of the rotary axis through the beam channel. The source carrier and the collimator carrier are connected at both ends with the rotary ring and the frame, respectively. The single-layer and double-support structure of the source carrier and the collimator carrier adopted in the invention enlarges the treatment space, lowers manufacturing cost and difficulty, simplifies the mechanical structure, increases support rigidity of the source carrier and the collimator carrier, ensuring long-lasting and steady coaxial rotation of source carrier and collimator carrier, as well as position accuracy of the focusing center in the therapeutic system. Therefore, a precision radiotherapy is realized with improved radiotherapy effect.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

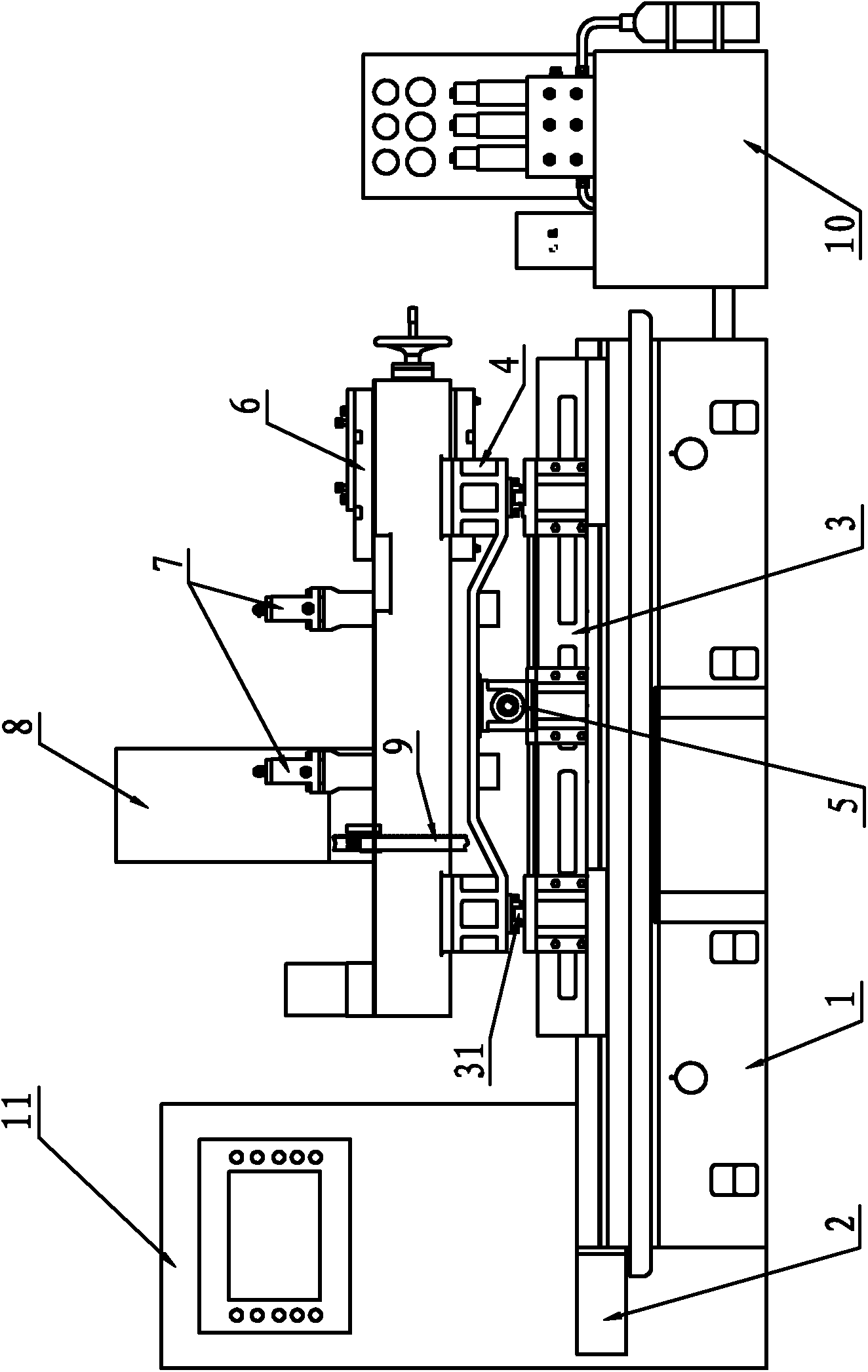

Ultrasonic-assisted laser material additive manufacturing device and realization method thereof

ActiveCN106363173AImprove bonded stateGood mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlCavitation

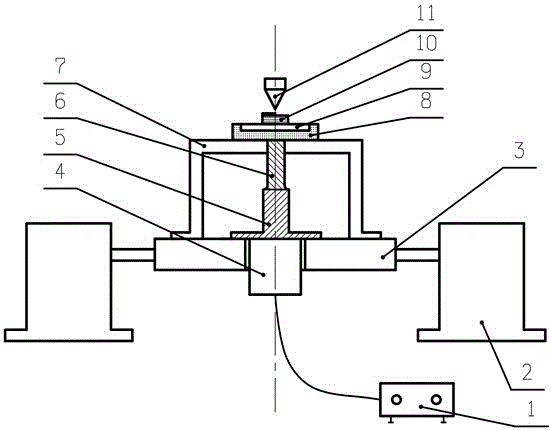

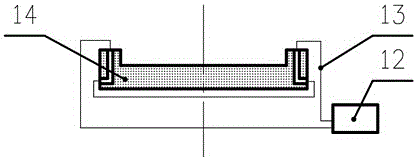

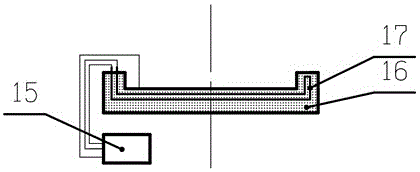

The invention discloses an ultrasonic-assisted laser material additive manufacturing device, which comprises a precise double-shaft numerical control rotating table, a support fastening base, a mold, an ultrasonic device, a base plate and a powder supply spray nozzle, wherein the precise double-shaft numerical control rotating table mainly consists of a double-support rotating table and a processing table; the support fastening base is arranged on the processing table; the mold is arranged on the support fastening base and is provided with a groove; the ultrasonic device is arranged in a way of passing through the processing table and the support fastening base and is connected with the bottom of the mold; the base plate is arranged in the groove formed in the mold; the powder supply spray nozzle is positioned above the base plate. The invention also provides a realization method of the ultrasonic-assisted laser material additive manufacturing device. The ultrasonic vibration is transmitted to the base plate, so that the base plate generates resonance; ultrasonic vibration stirring is performed in a molten pool formed under the laser effect in the laser material additive manufacturing process; a cavitation effect and a mechanical effect are generated; the combination state between layers can be improved; the formation probability of microsegregation and air holes inside forming elements can be reduced; meanwhile, crystal grains are refined; the residue stress is reduced; the forming elements with the good mechanical property are obtained.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

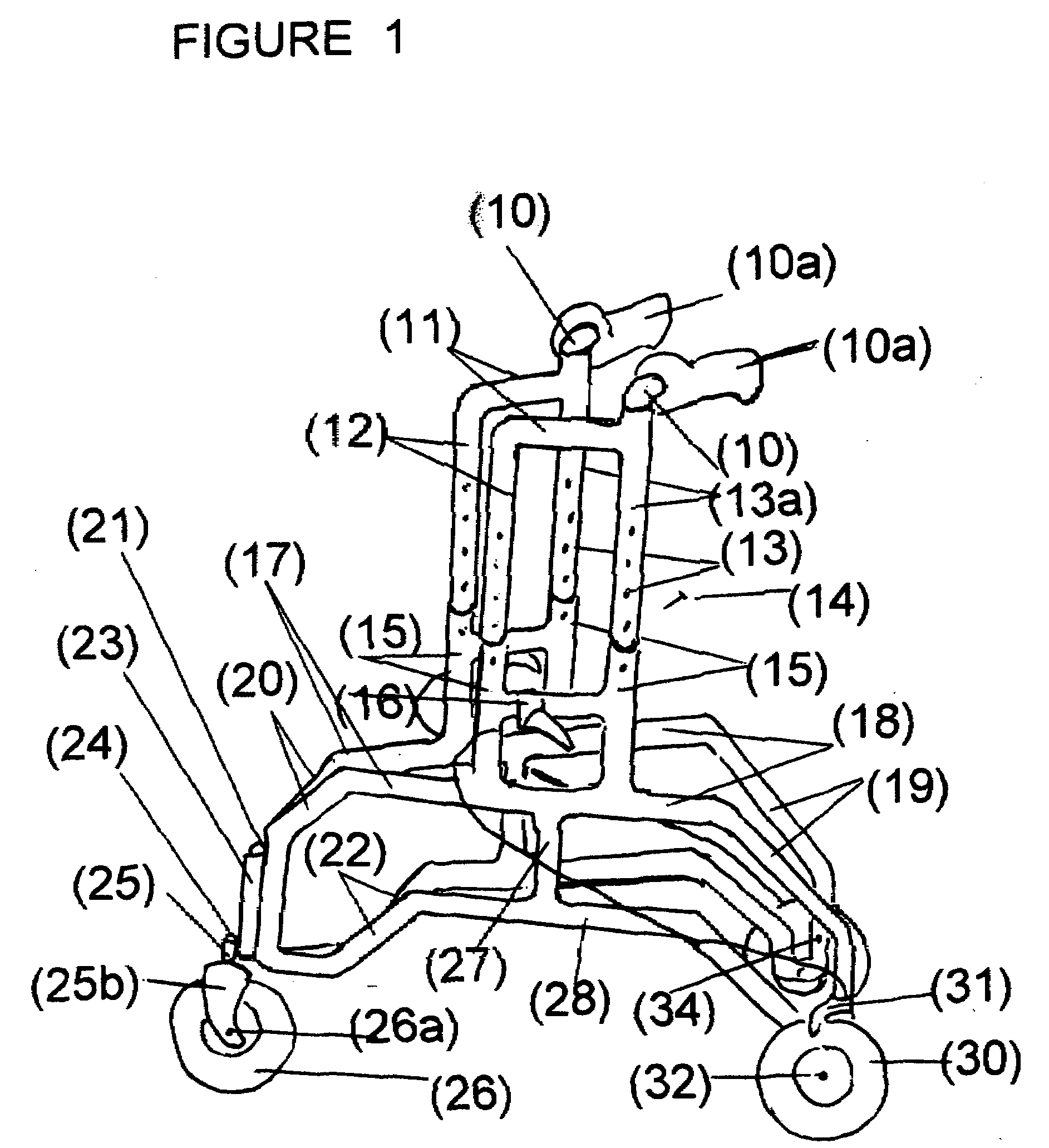

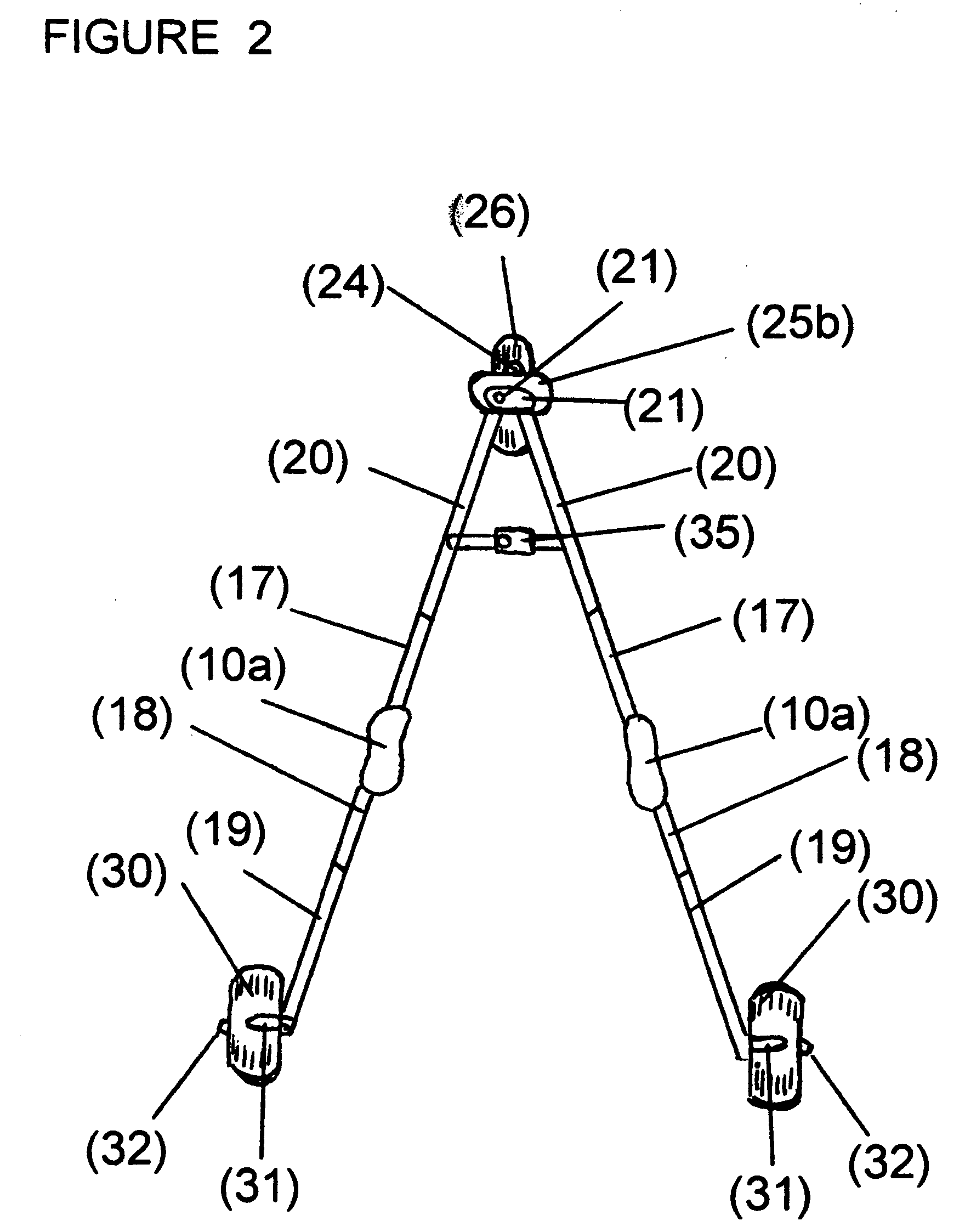

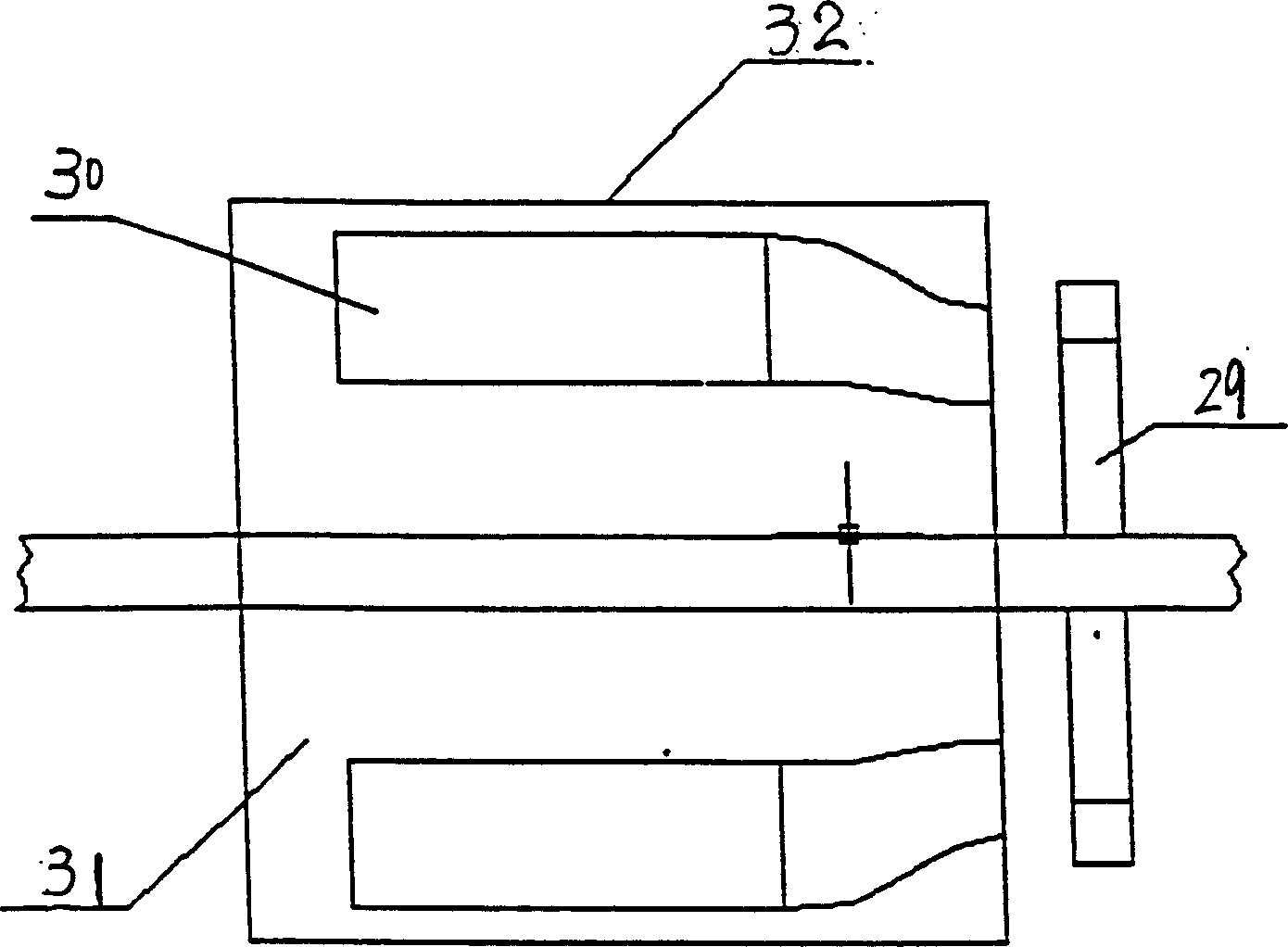

Crutch stroller

InactiveUS20080174084A1Solve the lack of durabilityWalking sticksChildren furnitureEngineeringAids walking

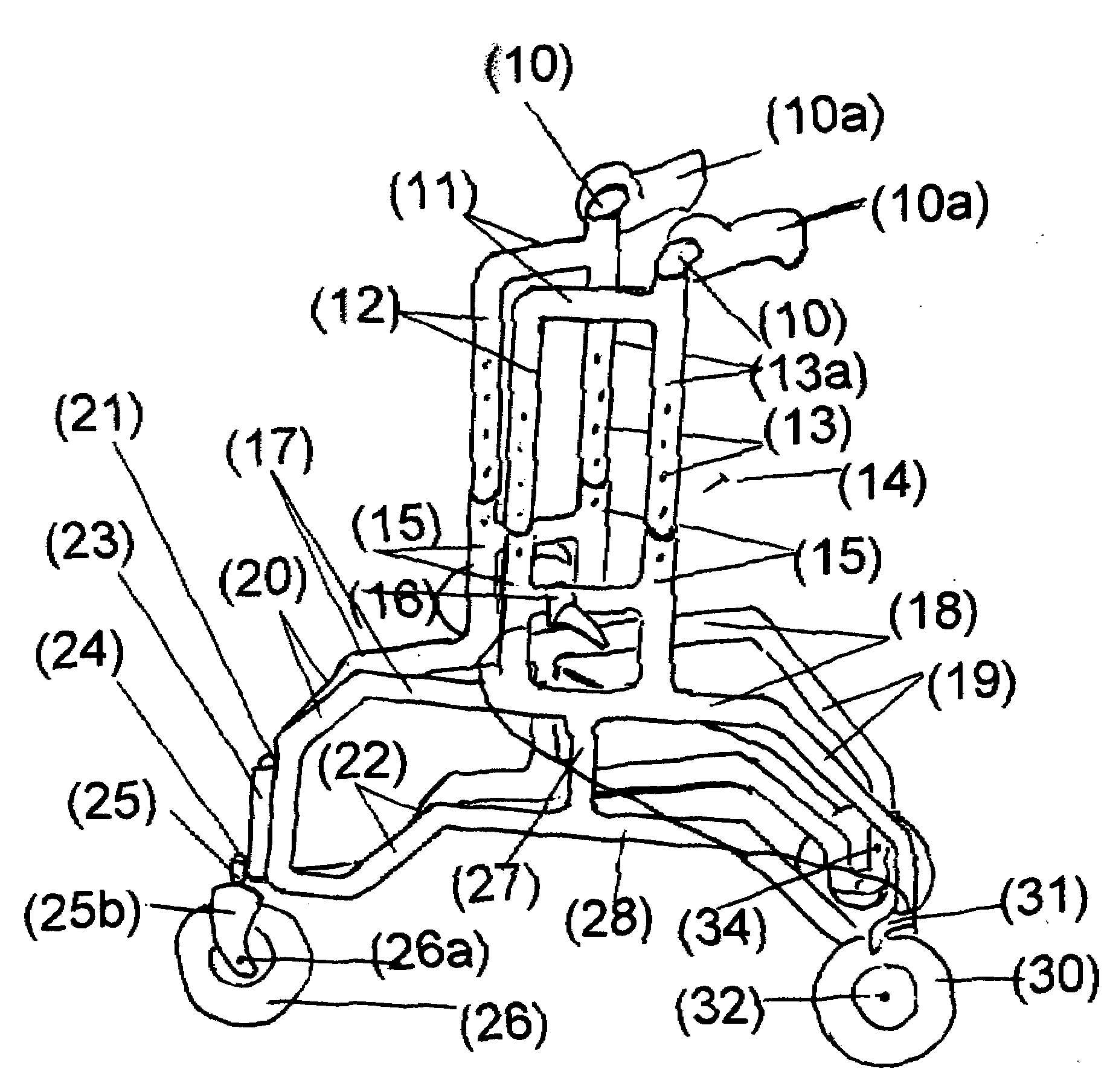

A mobility aid (FIG. 1) design for providing stabilized mobility support by the practical use of a two sided vertically supported rigid frame comprising front and rear bilaterally double support members (12), (12a), (13), (13a), (15), and (15a), and not limited to but preferably of aluminum construction to include a plurality of upper and lower substantially identical bilaterally horizontal and vertical tubular main frame members (17), (18), (19), (20), (22), (27), (28), and (29), supported on a plurality of sufficiently sized wheels (26), and (30), attached to the underside of the main frame (26), and (30), with predetermined spacing. Base members (22), (28), and (29), are sufficiently elevated-providing for unhindered foot movement during mobilization. A guide wheel assembly (23), (25), (25b), (26), and (26a), is vertically attached at a contiguously anterior junction surface of the two sided main frame assembly (20), and (23), thereby providing selective directional steering. Hand brake controls (16), secure by clamps to riser connectors (15), activate brakes (31).

Owner:GEE SR LARRY ELLIS

Heavy gas turbine

The heavy gas turbine consists of air admission casing, air admission adjustable guide vane, air pump, diffusor, combustor, turbine and air exhaust casing. The air admission casing has inner casing and outer casing cast integrally with the commuting support plate, and the casings for different parts are connected via axial screw bolts. The air pump and turbine rotor are in disc-drum structure connected firmly via axial screw bolts to constitute drum type air pump-turbine rotor, which is supported on front and back sliding plain bearings to form a double-support and single-stator structure with front output shaft connected via elastic coupling to the generator. The present invention has air pump with high compression ratio, combustor with low pollution exhaust, multi-stage air-cooled turbine capable of bearing high burning gas temperature and relatively light complete machine.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Liquefied natural gas tanker container nesting method

InactiveCN101187442APrecise positioningSwallowing process is smoothPressure vesselsInsulation layerEngineering

The invention discloses a package packing method of a liquefied natural gas tanker container. An inner tank is set up on the positions of assembly process pipes on the two ends through special supports, the lower section of each support is provided with four concave wheels which are engaged with outer cylinder guide rails, two support pipe which are engaged with the assembly process pipes on the two ends of the inner tank are arranged on the upper end of the support, the support is arranged on the outer cylinder guide rails whose heights are decided by the center shaft of the inner tank overlapping the center shaft of the outer cylinder. The inner tank and the support are pushed by a truss hoist and other devices on the far end from the inner tank to the outer cylinder, and the inner tank is slowly sleeved in the outer cylinder to the assembly position. The invention can precise the center positioning of the inner tank through adopting double supports, and the axialities of the inner tank and the outer cylinder are high, which are specially used to pack assembly under the condition that the distance between the outer surface of the inner tank and the inner surface of an outer cylinder is smaller. The double support enables the inward swallowing process of the inner tank much smoother, which avoids that the inner tank skews to hit the outer cylinder result in damaging an insulation layer in the packing process, and largely reduces the packing operation time, and the safety is much higher.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

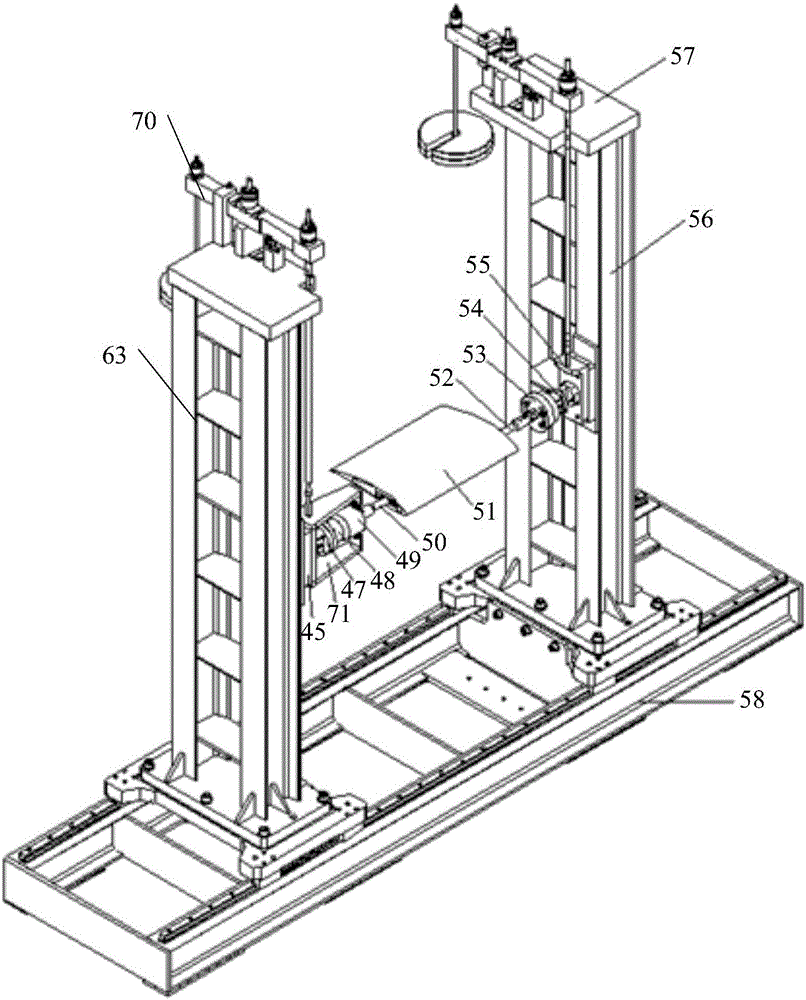

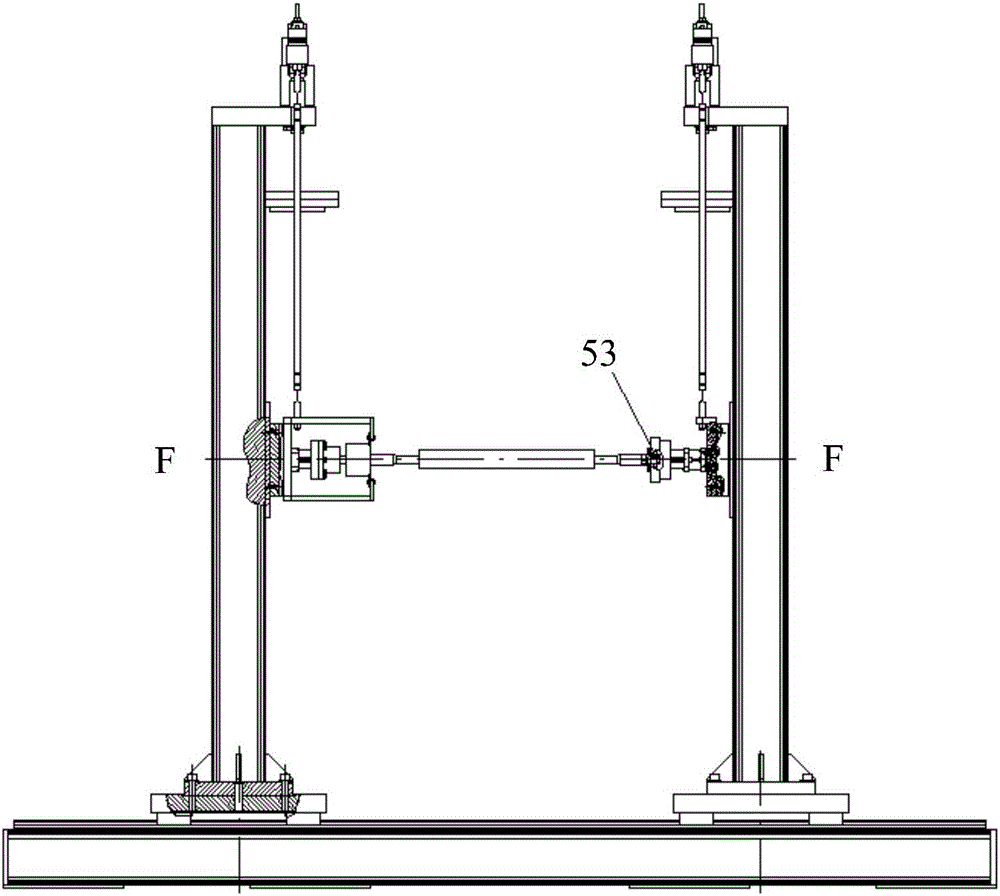

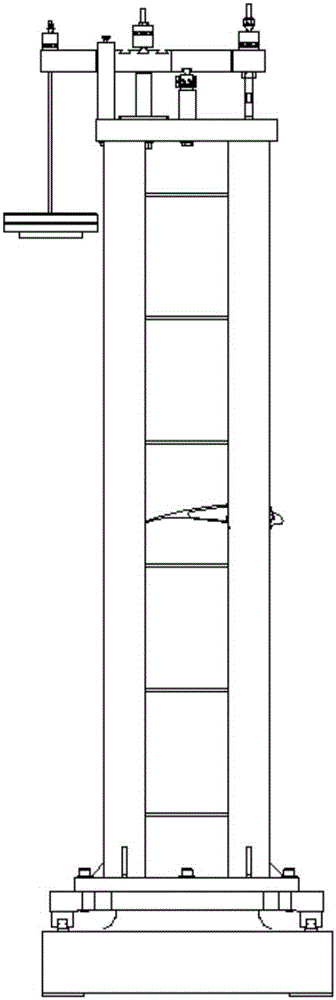

Airfoil model force measurement system

InactiveCN106289710AReduce distortionImprove support stiffnessAerodynamic testingMeasurement deviceFriction loss

The invention discloses an airfoil model force measurement system comprising a pair of supports, a pair of connecting bases, a drag measurement scale, a drag and pitch moment measurement scale, a pair of connecting rods, and a pair of lift measurement devices. The supports are arranged vertically. The connecting bases are respectively arranged on the supports in such a way that the connecting bases can slide along the supports without friction loss. The drag measurement scale is connected to one connecting base. The drag and pitch moment measurement scale is connected to the other connecting base. One end of one connecting rod is connected to the drag measurement scale, one end of the other connecting rod is connected to the drag and pitch moment measurement scale, and the other ends of the connecting rods are connected to the front end of an airfoil model to support the airfoil model between the supports. The lift measurement devices are respectively arranged on the supports, and the lift transfer components of the lift measurement devices are respectively connected to the connecting bases. A double-support system is adopted, and the airfoil model is supported between the supports. The system is of high support rigidity, and the airfoil model has little deformation under the action of gravity and wind load.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

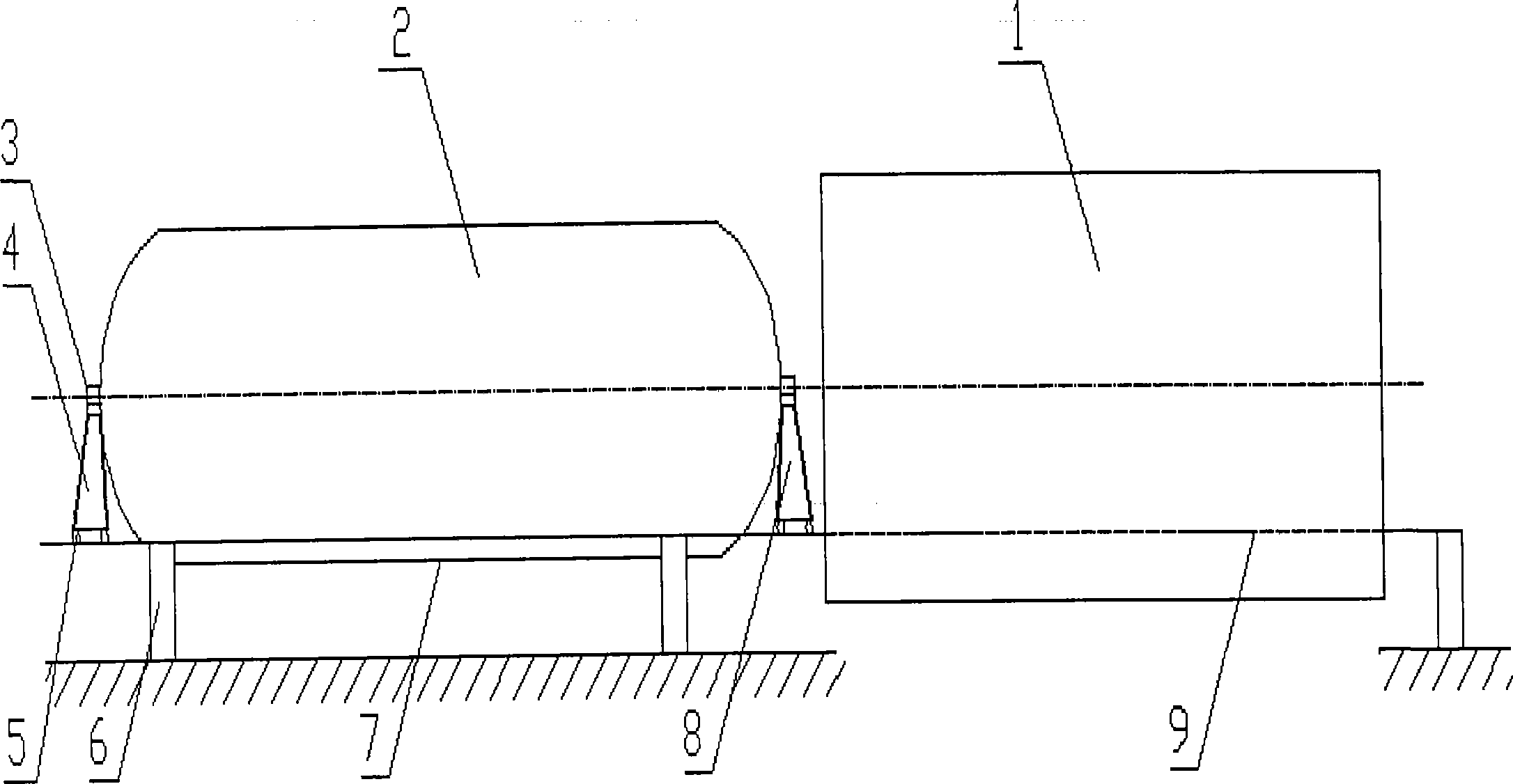

Radiotherapy apparatus and method for changing radiation beam diameter thereof

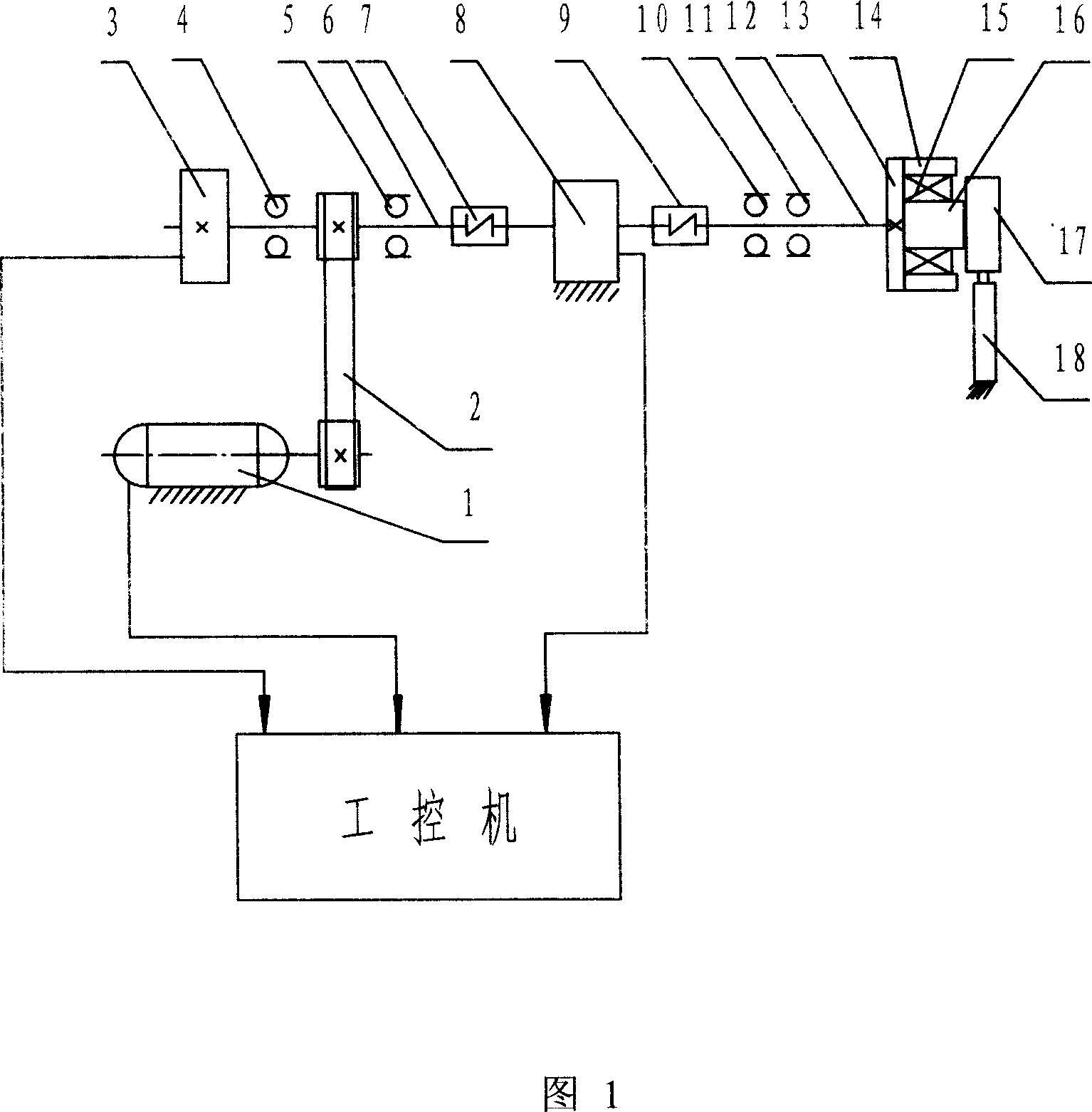

ActiveCN1736510AExtended range of movementEasy to recycleX-ray/gamma-ray/particle-irradiation therapyTherapeutic bedGamma ray

The invention relates to a radiotherapy device and method of gamma ray rotation and focusing, which comprises the following steps: main control unit, driver, radiation device, therapeutic bed and so on, wherein the therapeutic bed and rotatable barrier are set in the rotating ring and radiation device separately; the rotating support ring is fixed on two ends of rotating stand with the axial of rotating support ring matching rotating ring positionally; the relating radiation device is set between two rotating rings, whose the rotatable barrier center fixes a rotatable cylindrical alignment. The character of the invention in comparison with the present technique comprises the following: the cylindrical alignment and source bulk rotate in the radiotherapy device simultaneously; the single-layer and double-support structure augments the range of rotating ring in comparison with the present double-rotating rings and double-support structure. The device expands the mobile range of the therapeutic bed in the rotating ring, which expands the treatment space and reduces the making cost and difficulty.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

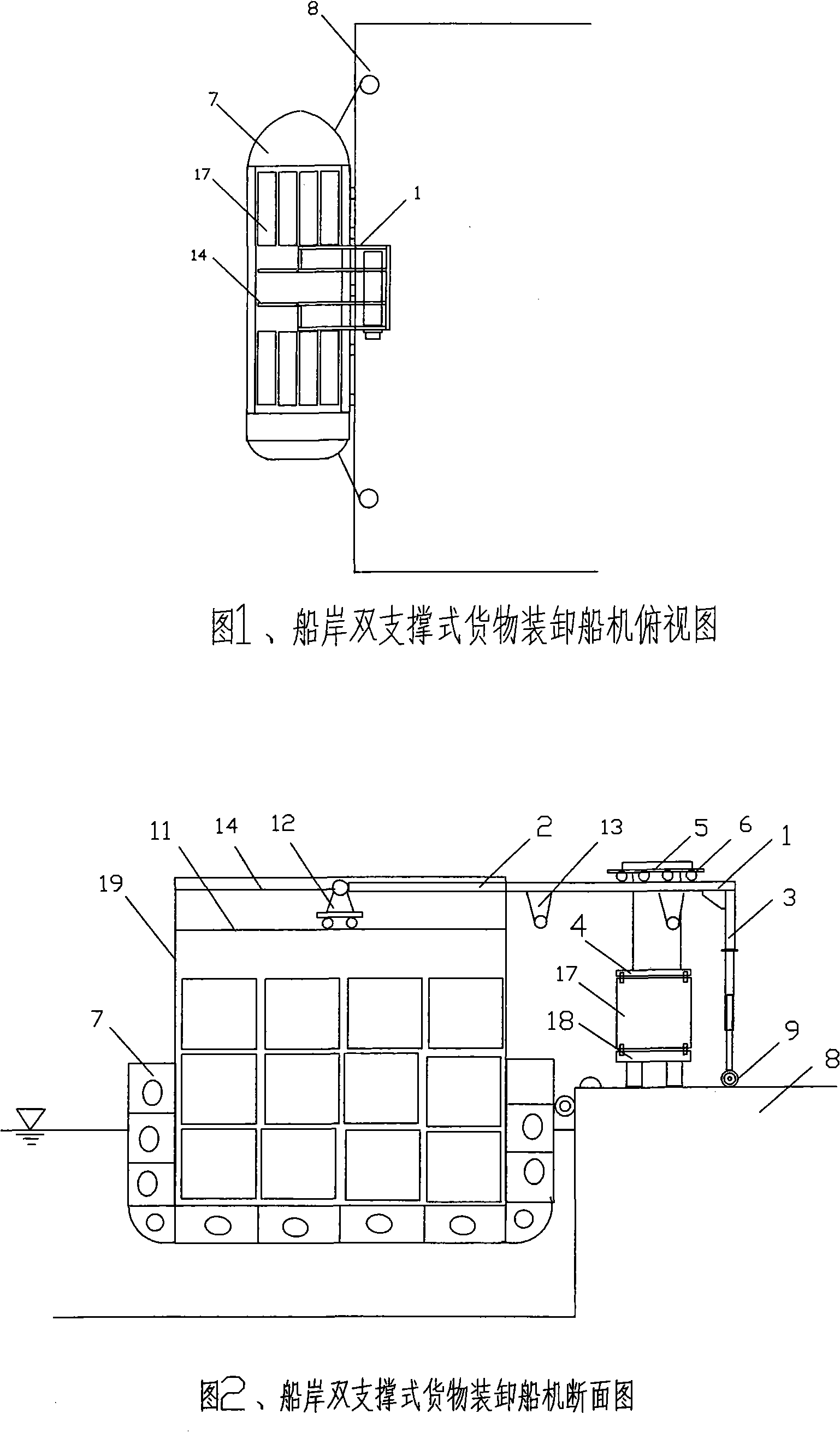

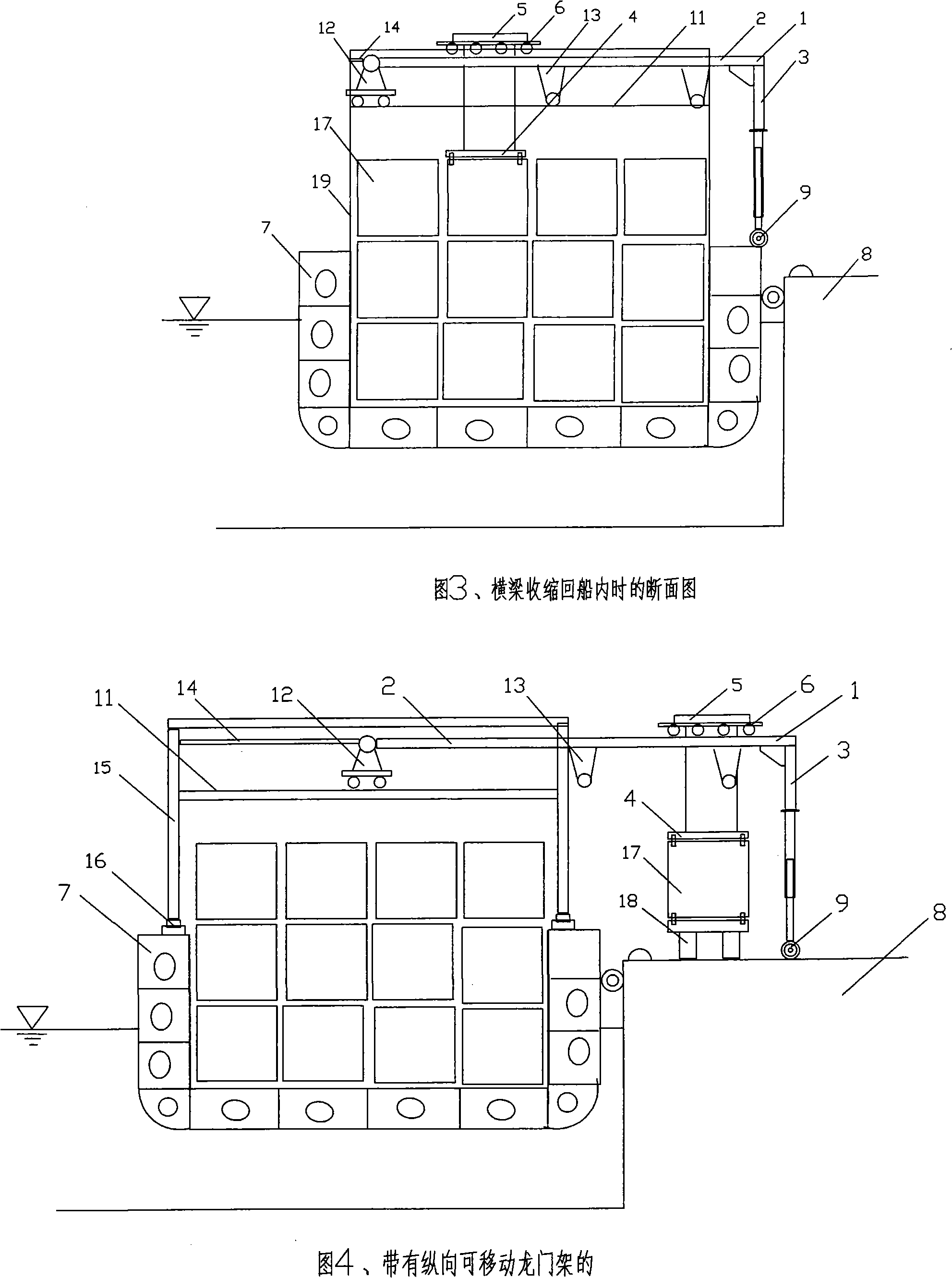

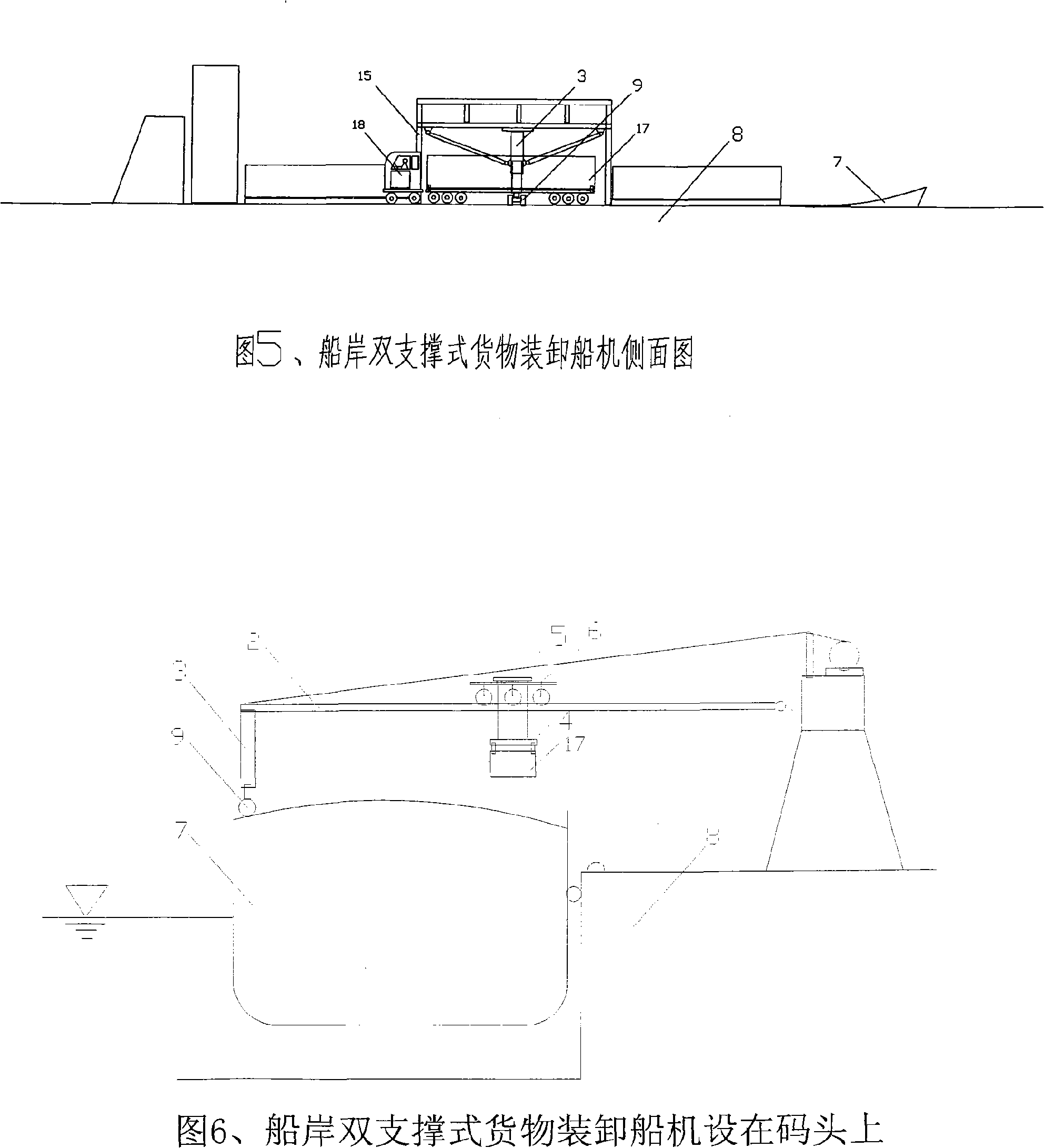

Ship-shore double supporting type cargo handling machine

ActiveCN101279640AReduce loading and unloading costsReduce insecurityCargo handling apparatusPassenger handling apparatusMarine engineeringControllability

The invention relates to a boat-bank double-support cargo loading and unloading ship machine with support points placed both on a boat and a bank, overcoming the disadvantages of various cantilevered slings used in the past for transferring cargos between the boat and a dock. The invention adopts the method of the boat-bank double-support cargo loading and unloading ship with one support point placed on the boat and the other placed on the bank, forming a freely supported beam mechanism, simplifying the structure of a loop wheel machine, reducing weight, and reducing the air lifting distance of cargos; the cargo travels along a straight line in air, thus greatly increasing the controllability and stability of cargo in air, greatly improving the efficiency and safety, and realizing the quick transfer of cargos between the boat and the dock; meanwhile, the simplified structure is favorable to be carried in boats, in particular small boats, and the ship machine is convenient and flexible, economical and practical.

Owner:游勇

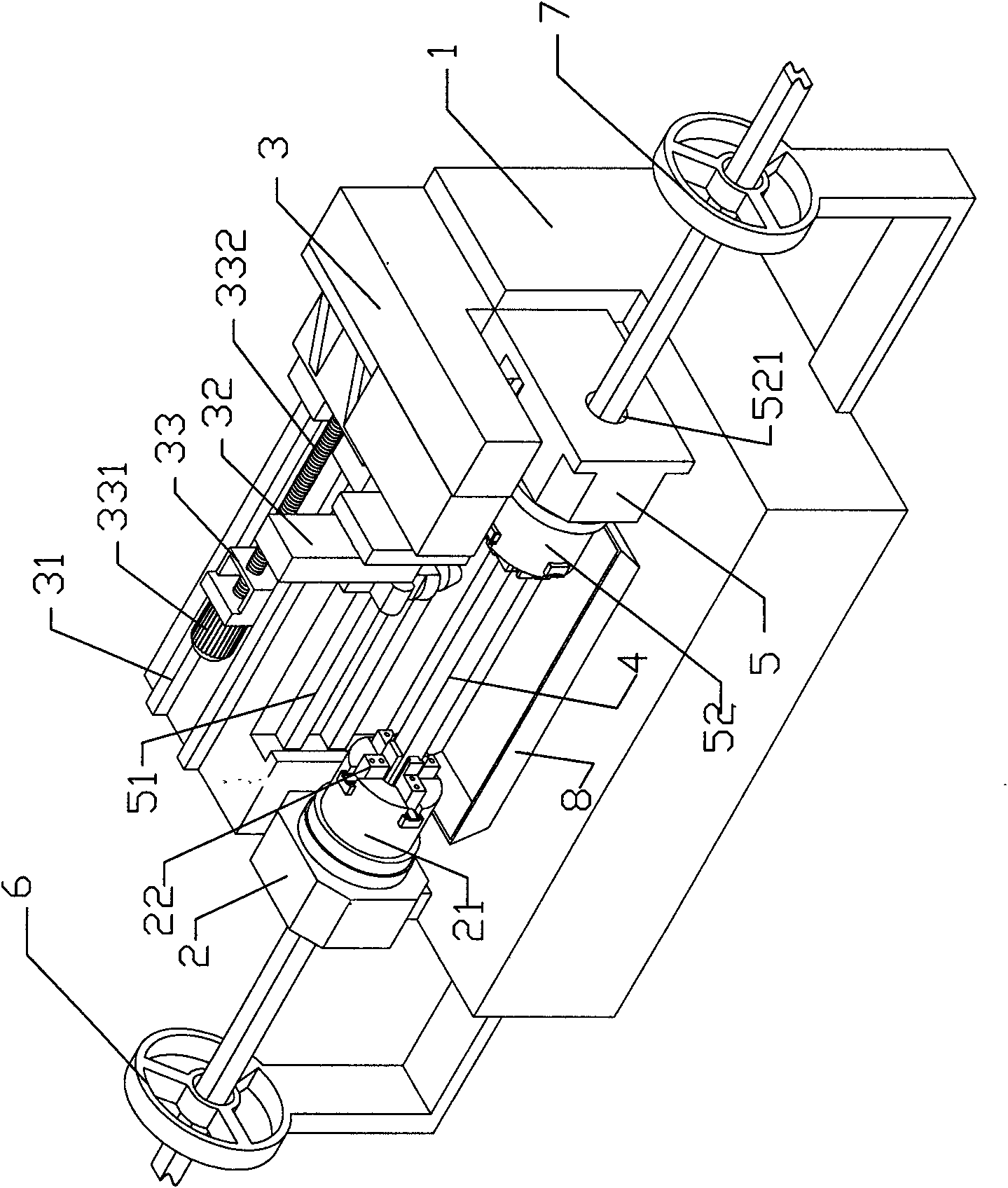

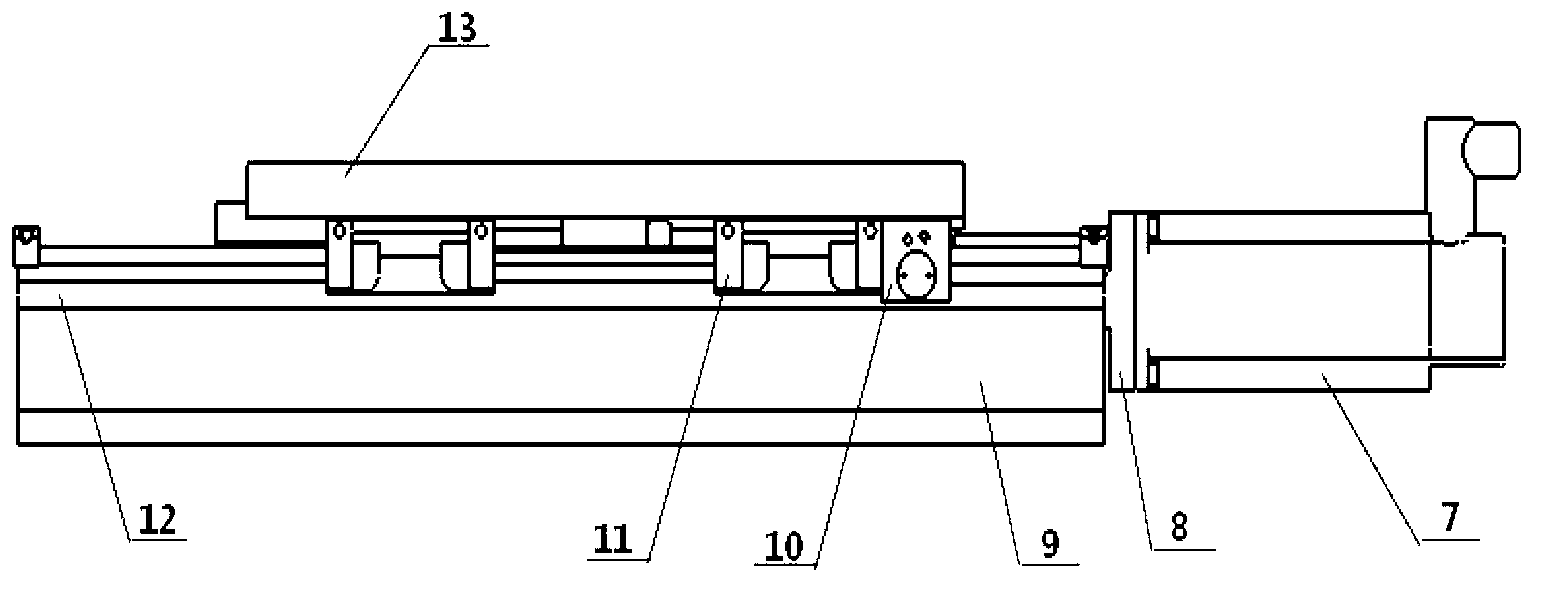

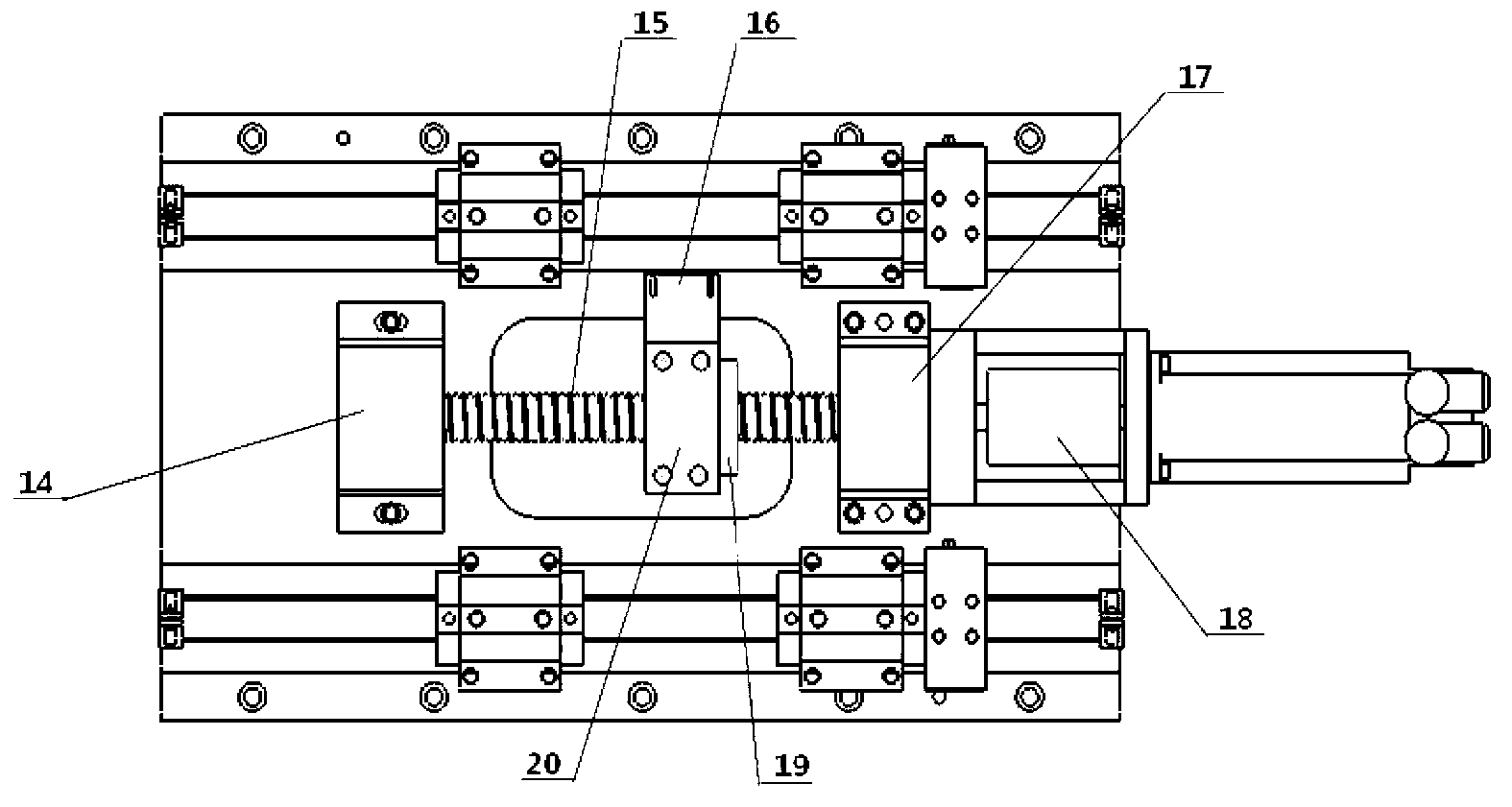

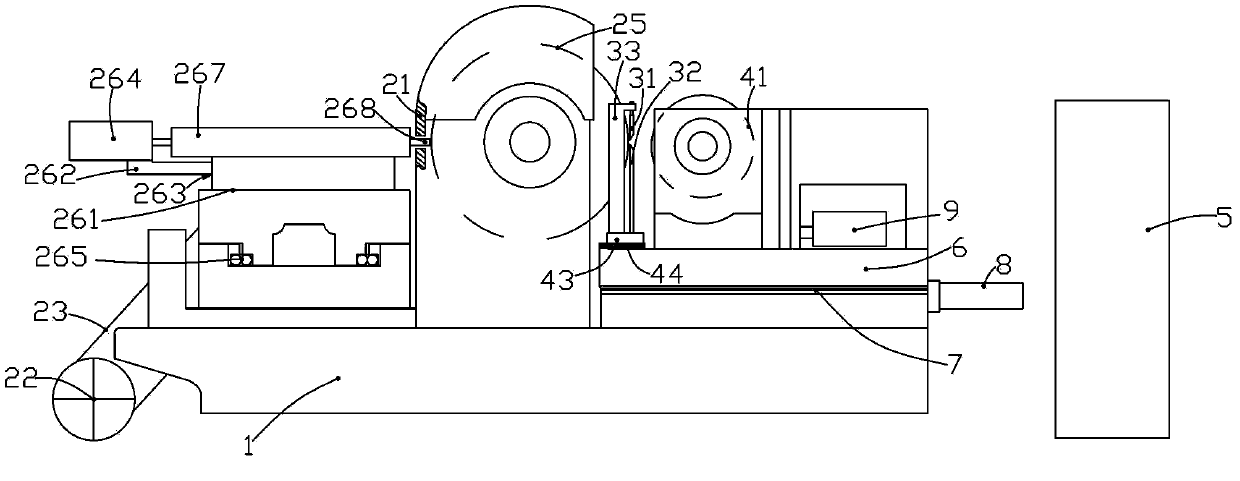

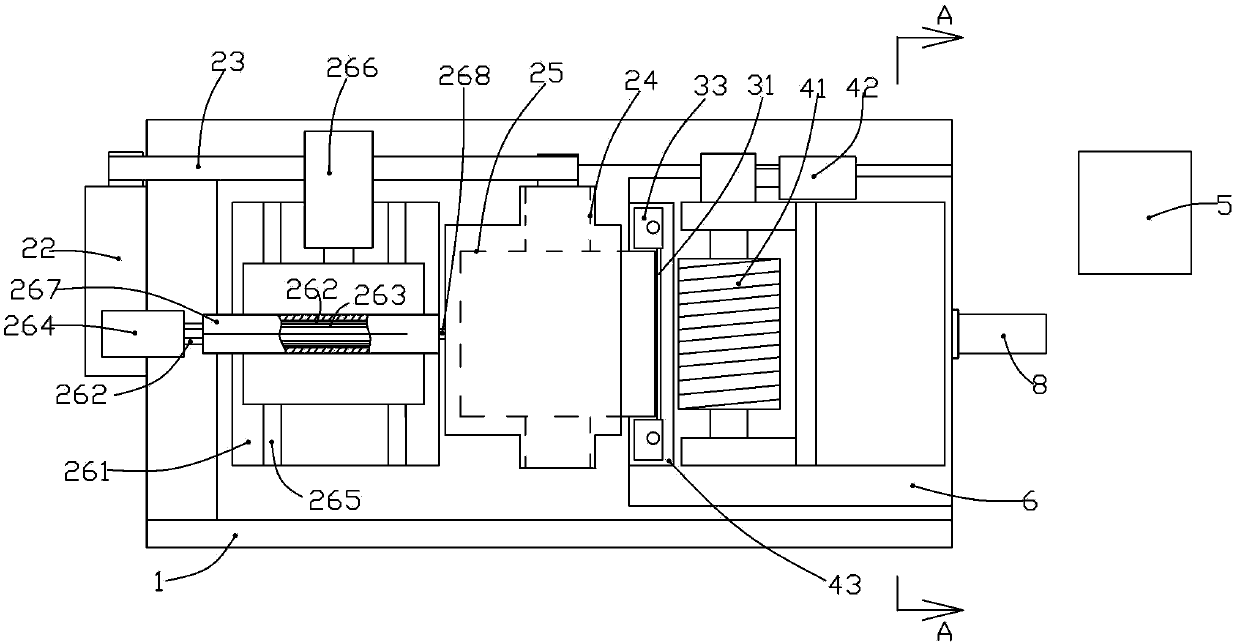

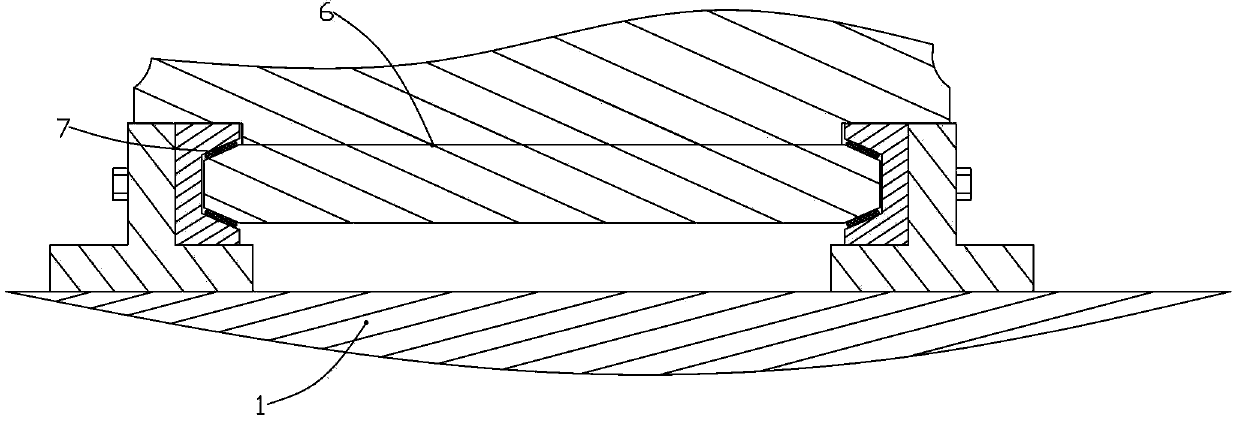

Double support pipe cutting equipment

InactiveCN101642852AImprove machining accuracyIncrease productivityLaser beam welding apparatusTubular articlesEngineeringMachining process

The invention relates to a double support pipe cutting equipment, comprising a frame and a feeding mechanism; the frame is provided with a supporting mechanism for bearing incoming materials of the pipe and a cutting mechanism for processing the cutting seams of the pipe; the supporting mechanism comprises a first supporting seat fixed on the frame and a first clamp for clamping the pipe; the cutting mechanism comprises a cutting guide rail, a cutting bracket and a pushing mechanism; the cutting bracket is provided with a laser cutting head positioned above the pipe; the feeding mechanism comprises a feeding guide rail fixed on a machine tool and a second supporting seat arranged on the feeding guide rail in a sliding manner; the supporting seat is provided with a second clamp which is strictly aligned with the first clamp and rotates synchronously with the first clamp; and when the second clamp moves forward and backward, the first clamp and the second clamp alternatively clamp the cut pipe. The double support pipe cutting equipment can keep constant for the central position of the pipe in the processing process, can lead the pipe to be fed automatically, can carry out processingto a whole pipe without pipe waste materials, and has high processing precision and high production efficiency.

Owner:李路平

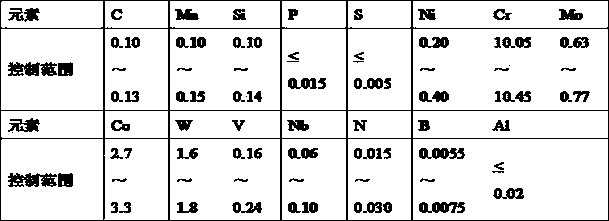

Method for manufacturing steel ingots through ultra-supercritical steam turbine blade steel electro-slag remelting

The invention discloses a method for manufacturing steel ingots through ultra-supercritical steam turbine blade steel electro-slag remelting. Specifically, a smelting method adopting an electric-arc furnace, LF,VOD / VHD, double-supporting-arm electro-slag furnace remelting is adopted, components Si, Al and B of a consumable electrode is strictly controlled, the adding amount of Al powder or Fe-Si powder mixture is strictly controlled in the electro-slag slagging process, the oxidation burning loss of elements in the electro-slag remelting process is reduced by evenly and strictly controlling the adding amounts of the Al powder and the Fe-Si powder in a slag bath in the remelting process of the consumable electrode, and even and uniform integral chemical components, gaseous oxygen content and purity degree of electro-slag ingots are ensured. The method is suitable for smelting of common electro-slag furnaces, device input is reduced, and smelting cost is reduced. The low-Si, low-Al ultra-supercritical steam turbine blade steel gaseous oxygen content obtained by means of the method is smaller than or equal to 30*106, and non-metallic inclusions conform to assessment stipulations of ASTM E45 standard A law and accordingly meets the blade steel purity degree requirement for an ultra-supercritical steam turbine.

Owner:FUSHUN SPECIAL STEEL SHARES

Double-spiral-arm type luneberg lens antenna

PendingCN106785444AGuaranteed centripetalIncrease travel distanceAntennas earthing switches associationDouble supportPhysics

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Fin rotating mechanism capable of dynamically measuring fin lift force

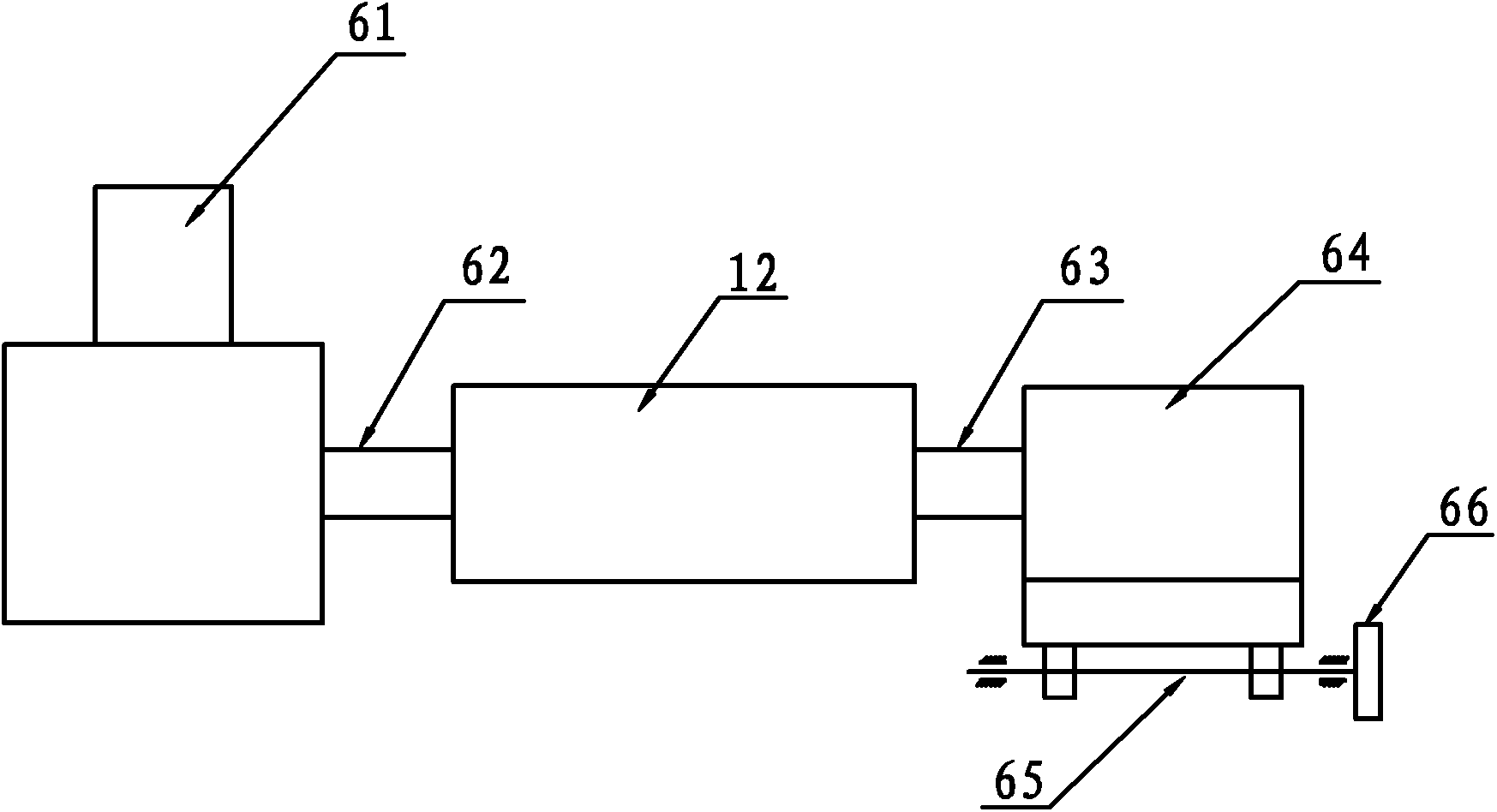

InactiveCN101792017ASolving Nonlinear RelationshipsSolve engineering implementation problemsForce measurementVessel movement reduction by foilsTransducerLinear relationship

The invention provides a fin rotating mechanism capable of dynamically measuring fin lift force, which comprises a fin shaft, wherein an end fin sleeve of the fin shaft is provided with an anti-rolling fin; an end circle center position at the other end of the fin shaft is provided with a potentiometer type fin angle measuring transducer to form a fin angle feedback box to serve as a fin angle feedback mechanism; the fin shaft realizes double-support fixation through two bearings; a box body realizes dynamic seal with the fin shaft and is welded on a boat hull; the fin shaft is a hollow fin shaft, and a solid shaft core is arranged in the hollow fin shaft, is firmly connected with a jacket of the fin shaft close to a fin mounting position and can rotate along with the fin shaft; and a lift force measuring transducer is fixedly arranged at the tail end of the solid shaft core. The fin rotating mechanism designed by the invention can directly acquire the dynamic lift force of a fin, avoid the non-linear relationship between an angle of attack and the lift force, and reduce the phase lag caused by the angle of attack in an angle servo.

Owner:哈尔滨哈船减摇自动化设备有限公司

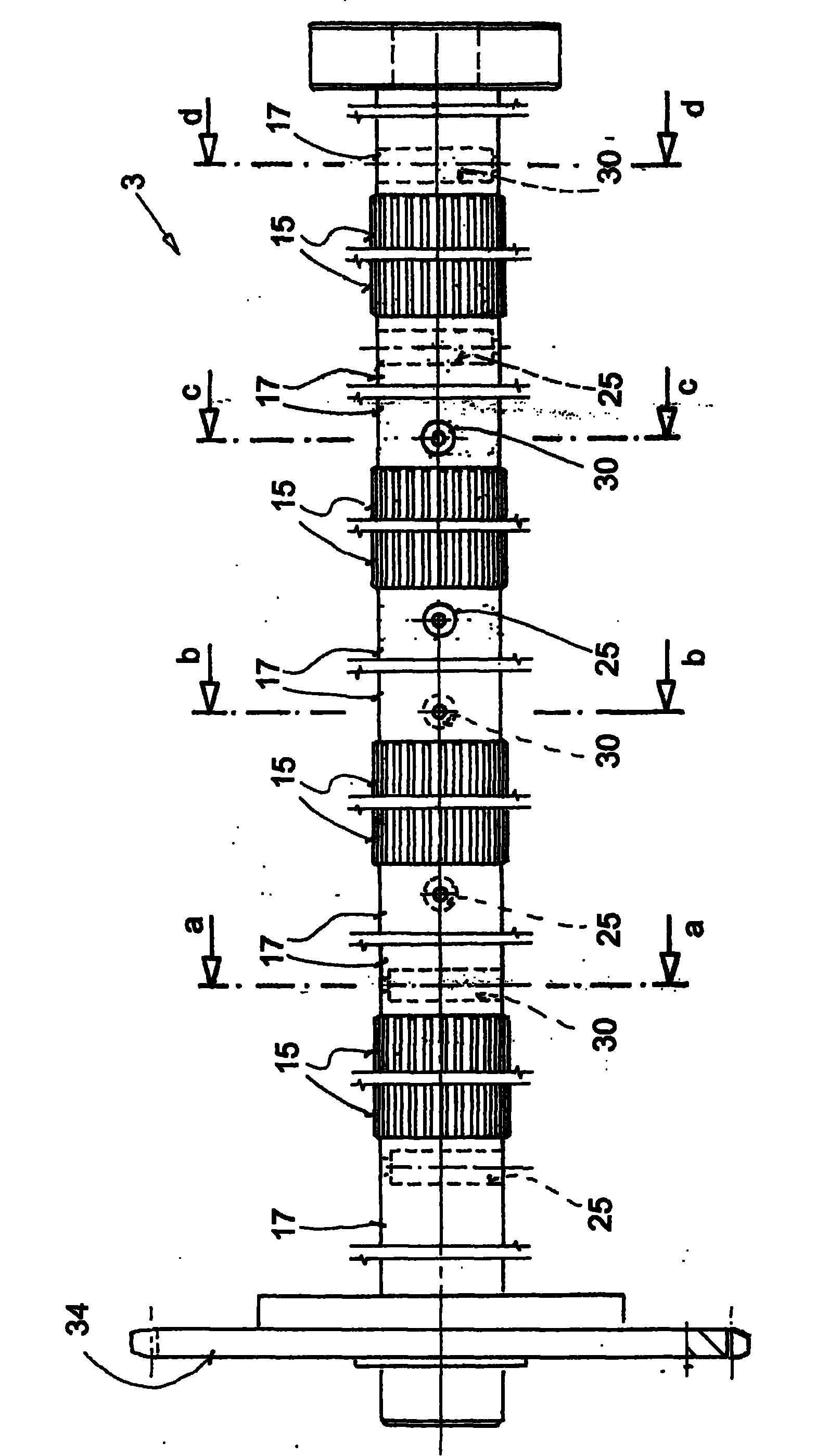

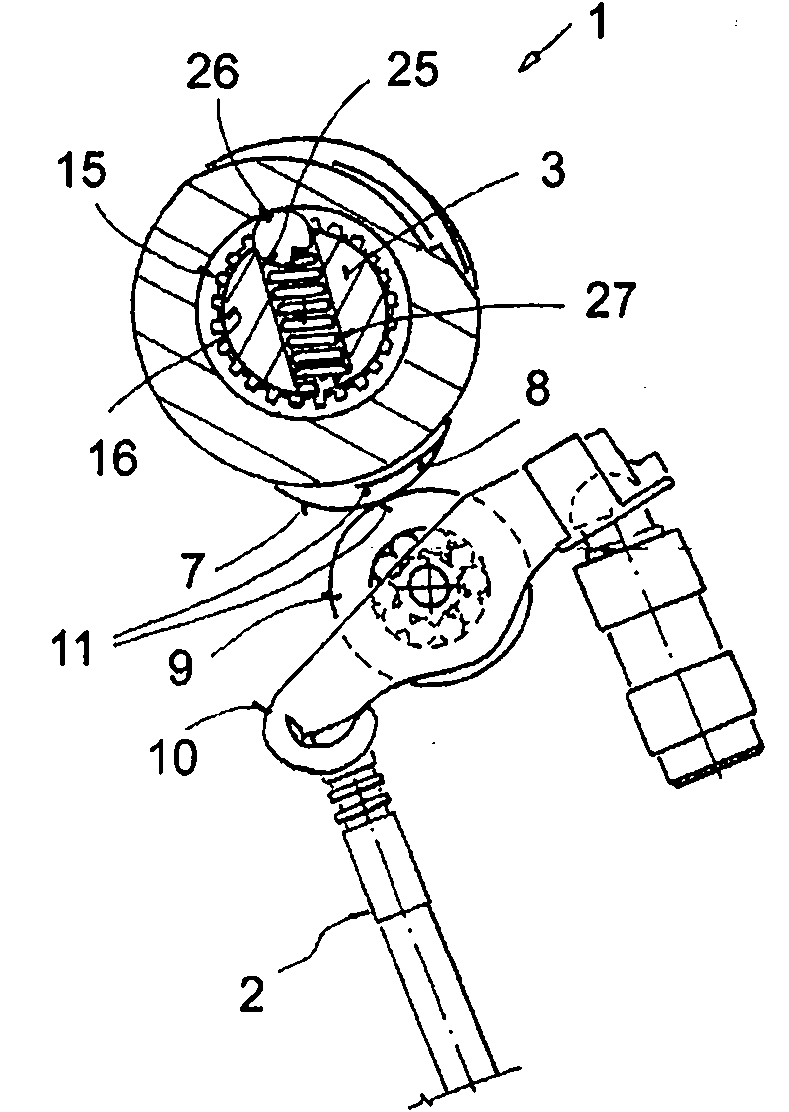

Valve train for gas exchange valves of an internal combustion engine having double-supported cam carriers

ActiveCN102132014AAvoid leaningThe force acts in the same directionValve arrangementsMachines/enginesExternal combustion engineGas exchange

The invention relates to a valve train (1) for gas exchange valves (2) of an internal combustion engine, having a base camshaft (3), a plurality of cam carriers (4) arranged on the base camshaft (3) in a rotationally fixed and axially displaceable way, and locking devices (24) for retaining the cam carriers (4) in defined displacement positions along the base camshaft (3). The locking devices (24) each comprise a pressing element (26), which is inserted into a recess (25) of the base camshaft (3) and pressed in the radial direction of the base camshaft (3) against an opposing inner circumferential section of the cam carrier (4). In order to counteract noise development in the valve train, according to a first variant of the invention, a further pressing element (31) is provided at an axial distance to the pressing element (26) and is pressed against an opposing inner circumferential section (33) of the cam carrier (4). According to a second alternative or additional variant scheme of the invention, the pressing elements (26, 31) of different cam carriers (4) are offset from each other in the circumferential direction of the base camshaft (3).

Owner:AUDI AG

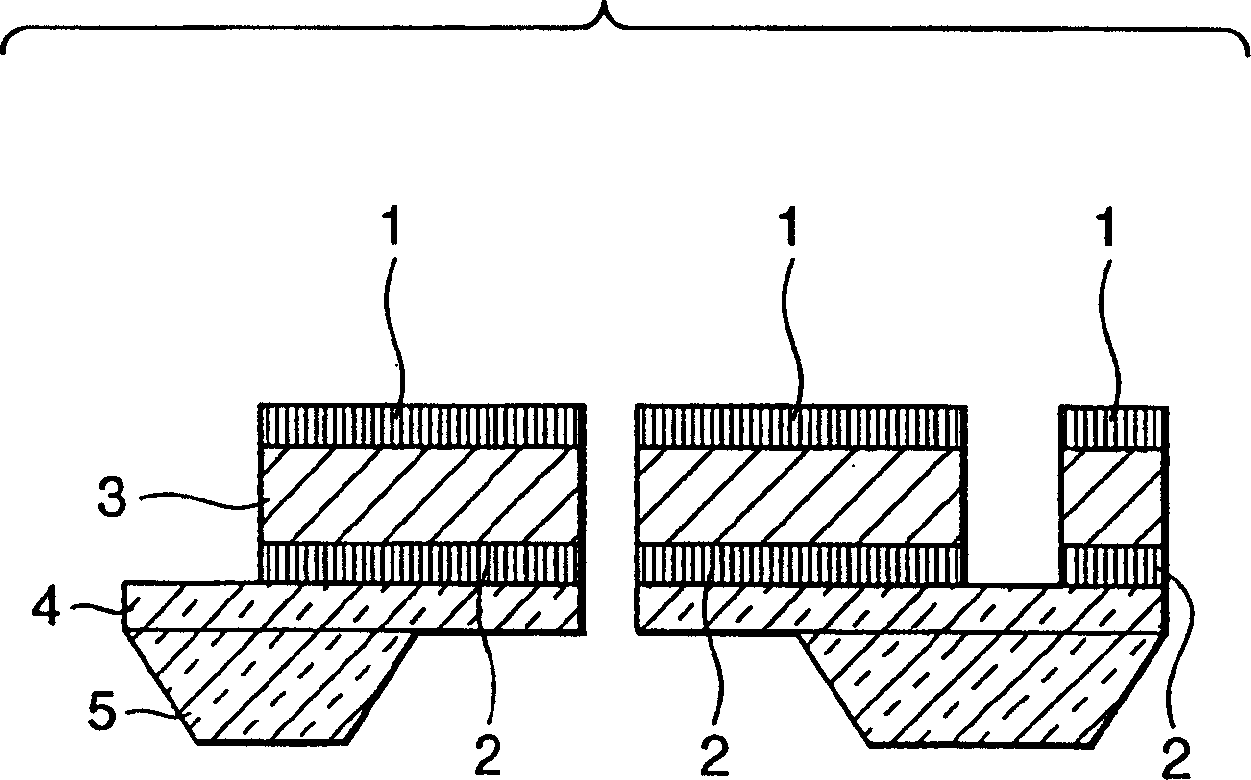

Complex function device, producing method thereof , touch information system and information inputting device

InactiveCN1727858AInput/output for user-computer interactionThermometers using electric/magnetic elementsInformation processingHuman–computer interaction

The invention provides a composite functional device and manufacturing method, a touch sensation information system and an information input device. Regarding various touch sensation information like temperature, pressure, etc., the invention enables an touch sensation information processing similar to human beings with low cost without damaging elements in the wide applications in different fields such as the surface states of various concave convex graphics, paper, etc., the input device of an information machine. For this, strong dielectric substance or pyroelectrics capable of responding both to temperature and pressure is adopted, and one touch sensation information element can detect various temperature pressure information simultaneously. In addition, the invention can not only detect the information but also change part of or all of the detected touch sensation information into physical quantities equal to or different from the detected signal for reappearance through building the strong dielectric substance or pyroelectrics into a hollow structure of a cantilever beam or double supporting beam and electrifying the strong dielectric substance or pyroelectrics via an external power supply and the electrode.

Owner:CANON KK

Electric double-supporting foot

The invention relates to an electric double-supporting foot which comprises a screw rod, a motor connected with the screw rod in a driving way, a beam in threaded match with the screw rod, supporting rods fixedly connected with the two ends of the beam, and supporting foot rods articulated with the bottom ends of all the supporting rods, wherein the outer side surface of the top end of each supporting foot rod is a tooth surface, and a rack suitable for being meshed with each tooth surface is fixedly arranged adjacently to the outer side of the tooth surface of each supporting rod. When the electric double-supporting foot is in use, the motor is controlled to control the screw rod to rotate, so as to control the up-and-down synchronous displacement of all the supporting rods through the beam; when all the supporting rods displace synchronously downwards, all the supporting foot rods swing downwards in place to be in an approximate reversed-V shape under the matching action of the racks and the tooth surfaces; and then, all the supporting rods continue to displace synchronously downwards till all the supporting rods are in contact with the ground and support the rear end part of an electric car or a motorcycle, so as to fix the vehicle. According to the electric double-supporting foot, the whole process can be completed through electric control without manpower, thereby facilitating the use of users. When the users want to use the electric car or the motorcycle, the supporting foot can be retracted automatically only in a way that the motor is controlled to act reversely.

Owner:常州市爱多动力科技有限公司

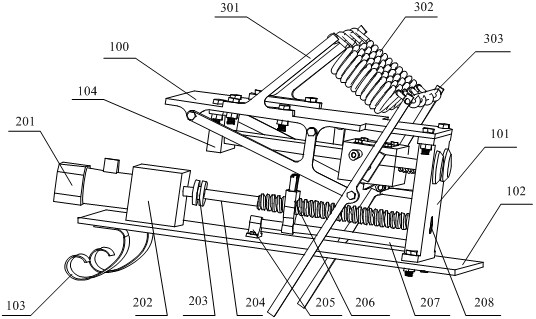

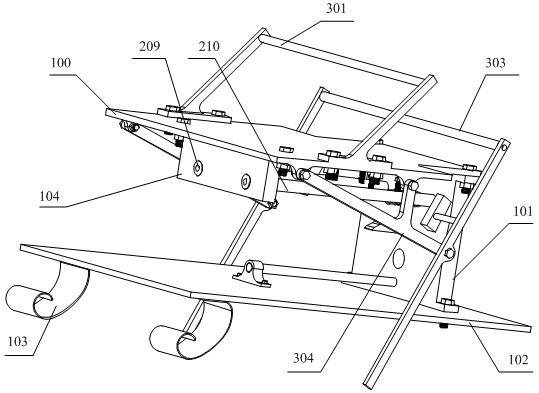

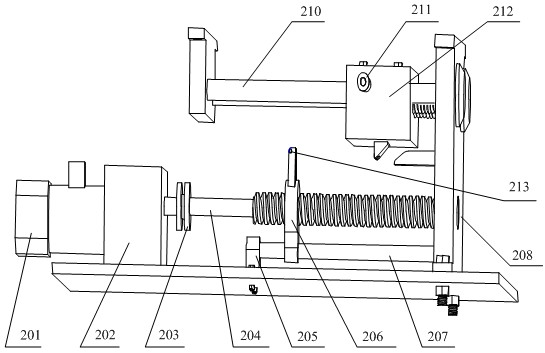

Jumping robot imitating ejection mechanism of locust

The invention discloses a jumping robot imitating the ejection mechanism of a locust. The jumping robot comprises a machine body, a front leg connected with the front end of the machine body, and a rear leg mechanism connected with the back end of the machine body. The machine body comprises a motor, a speed reducer, a coupler, a transmission lead screw, a feed rod support seat, a lead screw nut, a transmission feed rod, a rolling bearing, fixing screws for support rods, double support rods, an extension bar of a compression block, the compression block, a rolling wheel on the lead screw nut, and two deflector rods at the upper end of the lead screw nut; and the rear leg mechanism comprises a connecting spring support, a spring group, an inverted U-shaped rear leg, a connecting rod part, a spring pressure plate, a spring in the compression block, the rolling wheel on the compression block, a first wedge-shaped block, a rolling wheel on the first wedge-shaped block, a second wedge-shaped block and a rear leg power transmission rod. A compression device can complete the function of automatic triggering through the compression block, and the spring is further arranged between the compression block and a rear plate for realizing the function of fast release. The jumping robot is used as a motion carrier of a detection instrument, and remote control of the mechanism can be realized by adding a sensor and a control circuit board.

Owner:ZHEJIANG UNIV

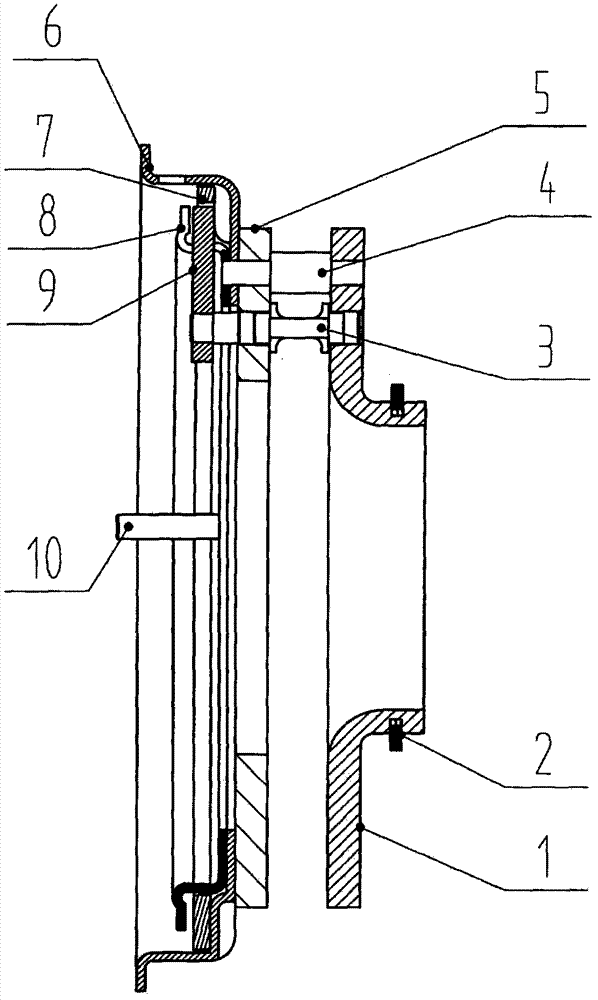

Blade double-supporting variable-section nozzle ring assembly for bi-directional positioning of poking disc

ActiveCN103089344APlay a role in heat insulationPrevent movementMachines/enginesEngine componentsEngineeringDrop out

The invention discloses a poking disc bi-directional positioning blade double-supporting variable-section nozzle ring assembly which enables a poking disc to be reliably positioned in axial and radial directions, protects the a poking disc from deformation and mis-positioning when a load is large at high temperature, and prevents a shift fork from be dropped out of the poking disc due to the deformation or mis-positioning of the poking disc. The nozzle ring assembly is composed of a rear cover 1, a spring piece 2, a blade 3, a spacer sleeve 4, a mounting disc 5, a heat insulation support disc 6, the poking disc 7, a limiting disc 8, the shift fork 9 and a limiting pin 10. The poking disc 7 is placed in a restricted space formed by the heat insulation support disc 6 and the limiting disc 8, and the poking disc 7 is positioned in the axial and radial directions. The heat insulation support disc 6 and the limiting disc 8 are welded to the mounting disc 5 through the spacer sleeve 4, and the shift fork 9 is directly placed in a notch 11 corresponding to the poking disc 7. The head of the blade 3 is inserted into the rear cover and can freely rotate, the tail of the blade 3 is installed in the mounting disc 5 to be welded to the shift fork 9, the limiting pin 10 is directly inserted into the mounting disc 5 to be fixed, and the rear cover 1 is fixed on the mounting disc 5 through the spacer sleeve 4. The rear cover 1, the mounting disc 5 and the blade 3 form a variable-section flow channel. In work, the poking disc 7 is subjected to external force driving. Due to the fact that the poking disc 7 is in sliding fit with the shift fork 9, when the poking disc 7 rotates, the shift fork 9 is driven to rotate, the shift fork 9 drives the blade 3 to rotate, so that a blade angle is changed, the airflow section is adjusted, and an engine can efficiently work at each power section under support of a supercharger.

Owner:PINGXIANG DEBO TECH CO LTD

Straight-through type double-support ultra-fine ring roller grinder

InactiveCN102350394AImprove rotational balanceImprove stabilityGrain treatmentsLow noisePulp and paper industry

The invention discloses a straight-through type double-support ultra-fine ring roller grinder. The ring roller grinder comprises a grinding host, wherein the host shell of the grinding host is arranged on the a grinding host base; a grinding roller and a grinding ring, which are matched with each other, are arranged in the host shell; the grinding roller is arranged on a grinding roller support, and the grinding roller support is arranged on a main shaft; the lower end of the main shaft is in double-support arrangement through upper and lower bearing positions on a grinding host upper cover and the grinding host base; a negative-pressure gas port is formed on the grinding host base; the grinding ring is directly connected with the host shell in a seamless manner; and the gas port is communicated with a grader conveying pipe outside the grinding host. The grinding host is of a structure of feeding from the top and pumping at the bottom, is not restricted by the grading amount of the grader, and prevents discharge from leaking to the outside, so that more materials can be fed under the same using condition, the grinding efficiency is improved, mechanical collision and friction between the grinding roller and the grinding ring are lightened, and the grinding host has low noise.

Owner:GUILIN SHENGXING MACHINERY MFG

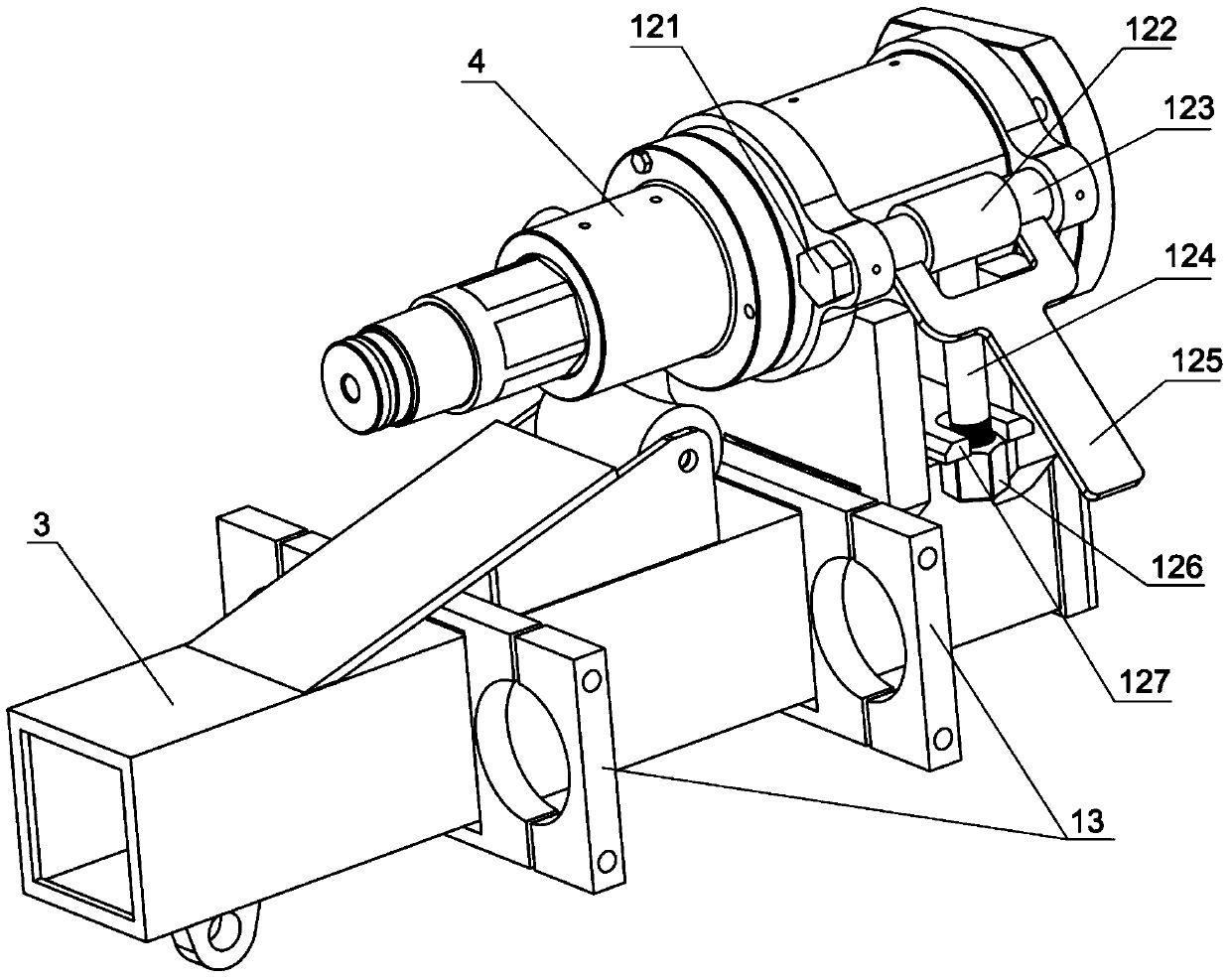

Three-coordinate double-support arm positioner

InactiveCN102700726AMeet precise positioningImprove accuracyAircraft assemblyStress conditionsGrating

The invention discloses a three-coordinate double-support arm positioner. According to the positioner, when an X-axis movement mechanism, a Y-axis movement mechanism and a Z-axis movement mechanism wholly work, different products at any position in a three-dimensional space can be accurately positioned; a double-support arm structural form is adopted, so that accurate positioning in a narrow space can be realized, and two key points of different types can be positioned at the same time; the X-axis movement mechanism and the Z-axis movement mechanism of the positioner are provided with an absolute grating bar respectively, and full closed loop control is realized by the reading feedback of the absolute grating bars; and a displacement sensor and a mechanical sensor are arranged on a positioning part at the tail end of the positioner, and can be used for monitoring the spatial position and stress condition of a positioning point of a part relative to the positioning part and feeding back an error generated during assembly to a control system for error compensation to effectively support and position the part of an airplane and improve the assembly accuracy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

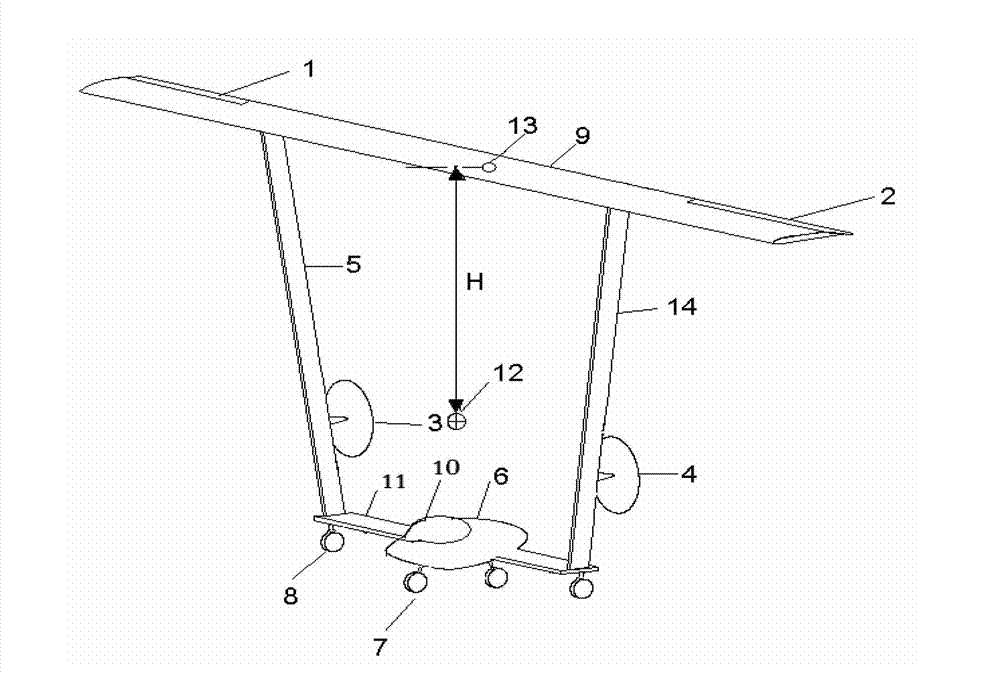

Novel solar airplane

The invention relates to a solar airplane which has a high lift-drag ratio and low energy consumption. In order to improve the lift-drag ratio, positive camber wings (9) with a large lift coefficient are adopted, a gravity center (12) of the positive camber wing is arranged right below a wing focus (13) so as to generate a large lift-drag ratio and a large rising moment, and meanwhile, the whole airplane has static stability; the lift-drag ratio of the airplane can be improved, and the whole airplane has static stability; the areas of the wings (9) are large enough, so more solar cell panels are suitable to be mounted, and enough energy is guaranteed to be stored for flights at night and on cloudy days; and meanwhile, in order to improve the structural strength of the airplane and lighten the structural weight, a structure of double wing surfaces (9) and (11) and double supporting wings (5) and (14) is adopted.

Owner:BEIHANG UNIV

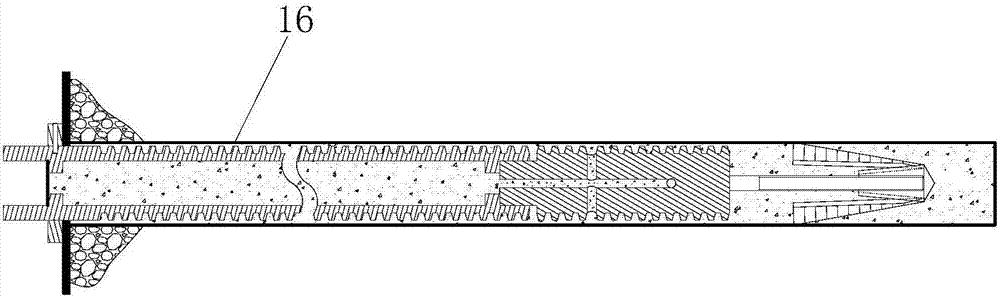

Support method implemented by aid of liquid carbon dioxide blasting, permeability improving and grouting composite anchor rods

ActiveCN107100656AGood support effectImprove stabilityBlasting cartridgesAnchoring boltsPre stressLiquid carbon

The invention discloses a support method implemented by the aid of liquid carbon dioxide blasting, permeability improving and grouting composite anchor rods. The support method includes arranging the filled liquid carbon dioxide blasting, permeability improving and grouting composite anchor rods in preliminarily formed drilled holes during operation; turning composite anchor rod main pipes to open expansion shells of anchoring sections at the front ends of the composite anchor rod body pipes to fix the anchor rods; detonating the composite anchor rods, carrying out phase change on liquid carbon dioxide in the body pipes to generate high-pressure gas and ejecting the high-pressure gas from spray holes in the body pipes; increasing the crack density of surrounding rock on the walls of the drilled holes under the impact effects of high-pressure gas jet and expanding the range of the surrounding rock on the walls of the drilled holes under the impact effects of the high-pressure gas jet; utilizing the blasted body pipes as grouting channels and connecting the grouting channels and external grouting pumps with one another to carry out grouting; allowing grout to flow out of the spray holes and filling crack with the grout; sleeving the tail ends of the body pipes with support plates and reinforcement nuts after grouting is completely carried out so as to apply prestress to the anchor rods. The support method has the advantages that the grout diffusion radiuses can be effectively increased by the aid of the support method, anchoring and grouting double-support effects can be realized, working procedures are simple, and the support method is safe and reliable.

Owner:CENT SOUTH UNIV

Centerless grinding machine for conical rollers

ActiveCN103394978ANot easy to wearImprove grinding accuracyGrinding carriagesRevolution surface grinding machinesElectrical controlEngineering

A centerless grinding machine for conical rollers comprises a grinding wheel mechanism, a composite base, a guide plate and guide frame mechanism and a guide wheel mechanism. The grinding wheel mechanism is fixed onto a machine body, the composite base matches with the machine body through a MV guide rail, and the guide plate and guide frame mechanism is arranged on the composite base by a cross roller guide rail through a guide plate and guide frame base. The cross roller guide rail is also adopted on a sliding rail in a grinding wheel dressing part of the grinding wheel mechanism, a grinding wheel spindle adopts a double-support ceramic bearing bush, and the end portion of a grinding wheel dressing pen is provided with a King Kong pen point. The grinding wheel dressing part, the composite base and the guide plate and guide frame base are driven by servo motors, and each servo motor and driving motor are under servo control through a electrical control cabinet. The centerless grinding machine is high in degree of automation, fine in accuracy and consistency of grinding machining, convenient to adjust, mount and maintain, high in grinding efficiency, and lower in equipment failure rate, maintenance load, and maintenance cost.

Owner:临清市宏森轴承有限公司

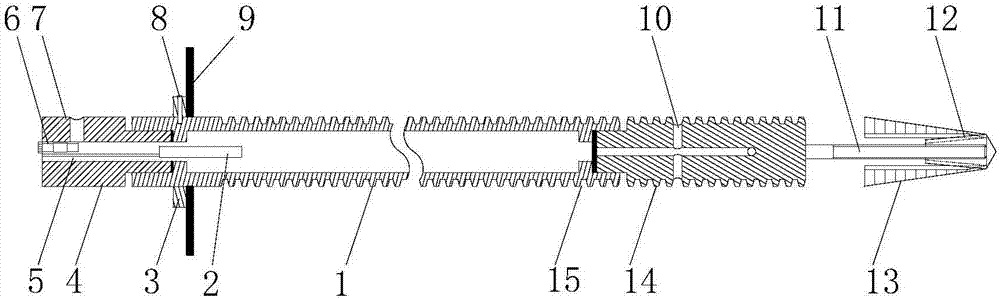

Portable power head core drill

ActiveCN104179451AReduce swingExtended service lifeDrilling rodsConstructionsSingle supportPortable power

The invention discloses a portable power head core drill. The portable power head core drill comprises a double-rail base, a guide rail, a slide bushing, a power head, a mast, supporting rods, a gripper and lift cylinders. The power head is fixedly mounted on the slide bushing through a locking device, and the mast is fixedly connected with the other end of the guide rail and provided with a fixed double-support pulley and a moving single-support pulley; the supporting rods include a main supporting rod and an auxiliary supporting rod, the main supporting rod is connectedly hinged between the end of the guide rail and the double-rail base, and the auxiliary supporting rod is in lap joint between the guide rail and the double-rail base during erection; the gripper comprises a gripper body and a drill stem stabilizing ring, the drill stem stabilizing ring consists of a stabilizing bearing block and a stabilizing bearing ring, the stabilizing bearing block is fixedly connected with one end of the gripper body, the stabilizing bearing ring is mounted in the stabilizing bearing seat, and the inner diameter of the stabilizing bearing ring is 1-2mm larger than the outer diameter of a drill stem. The portable power head core drill is convenient to assemble, disassemble and carry and stable in operation of the drill stem.

Owner:四川诺克钻探机械有限公司

Electromagnetism-static pressure double supporting transverse bearing

ActiveCN107165937AImprove carrying capacityIncrease stiffnessBearingsSupporting systemHydrostatic pressure

Provided is an electromagnetism-static pressure double suspension supporting transverse bearing. A hydrostatic pressure supporting system of the electromagnetism-static pressure double suspension supporting transverse bearing comprises a rotor shaft, a bearing base, a bearing upper cover and a stator. The stator is arranged in the bearing upper cover and the bearing base, and the outer circumferential surface of the stator corresponds to the bearing upper cover and the bearing base. Eight poles which are evenly distributed in the radial direction are arranged on the circumference surface in the stator. The length of the circumference direction cambered surface of the centripetal free end surface of each pole is larger than the length of the cambered surface of the other section of the pole, and the space between the centripetal free end surfaces of every two adjacent poles is larger than or equal to the thickness of enameled wire rings. A static pressure supporting cavity is arranged on the centripetal free end surface of each pole. A radial oil inlet hole A is formed in the end surface of the middle of each groove. A radial oil returning hole A is formed in the base body between every two poles. The centripetal free end surfaces of the eight poles are connected with the rotor shaft through concentrating flux sleeves. Each pole of the stator is sleeved with one enameled wire ring. The eight poles are distributed by adopting an NSSNNSSN way. According to the electromagnetism-static pressure double suspension supporting transverse bearing, the bearing capacity and the rigidity of the bearing can be improved substantially, and the adjusting capacity and the precision of the bearing system can be improved.

Owner:YANSHAN UNIV

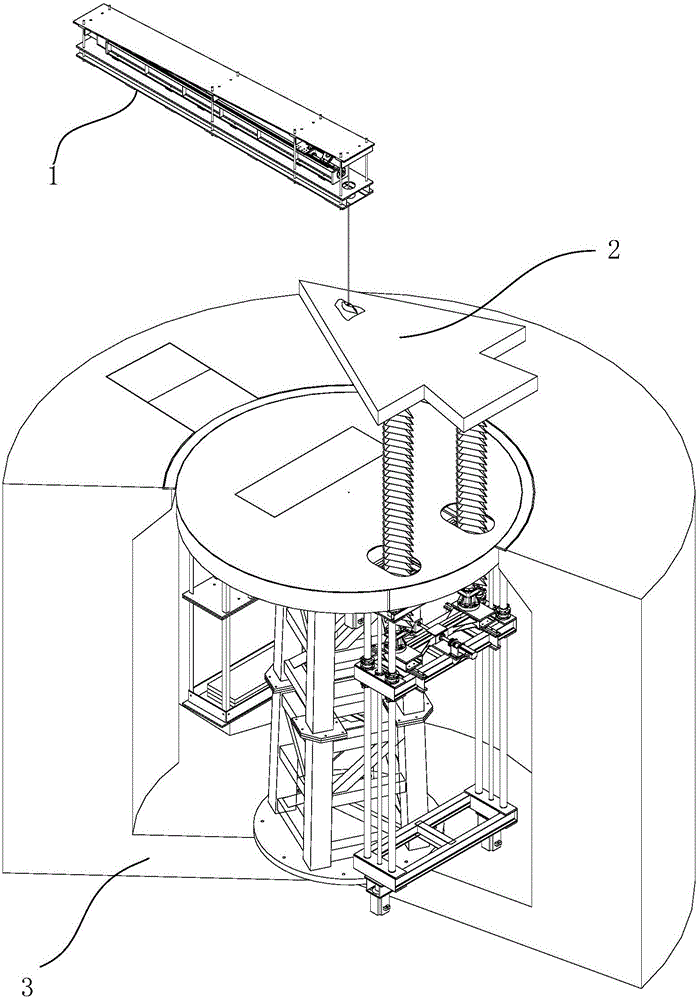

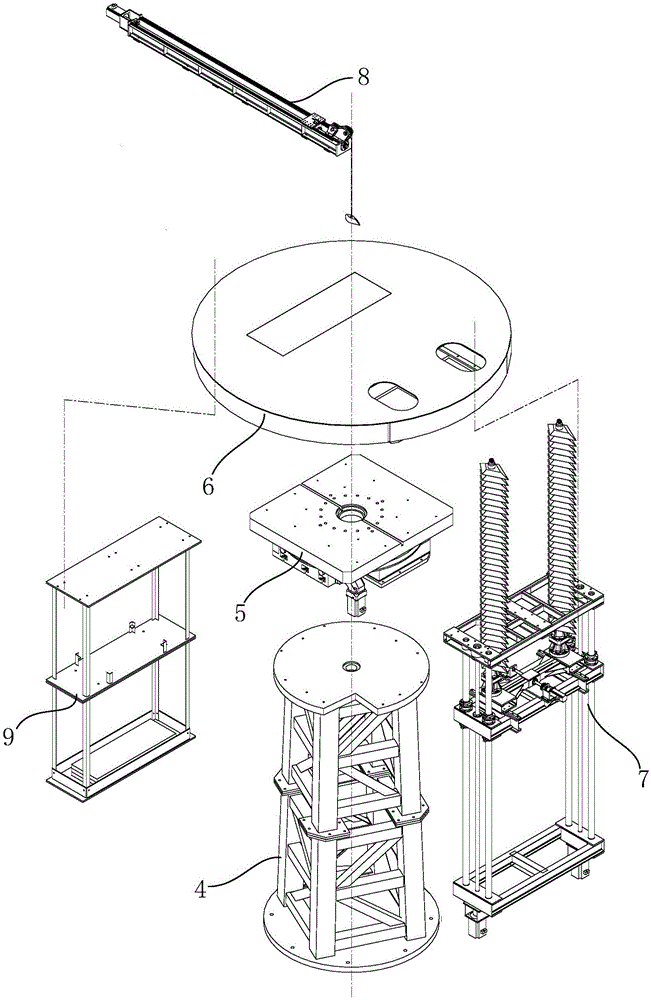

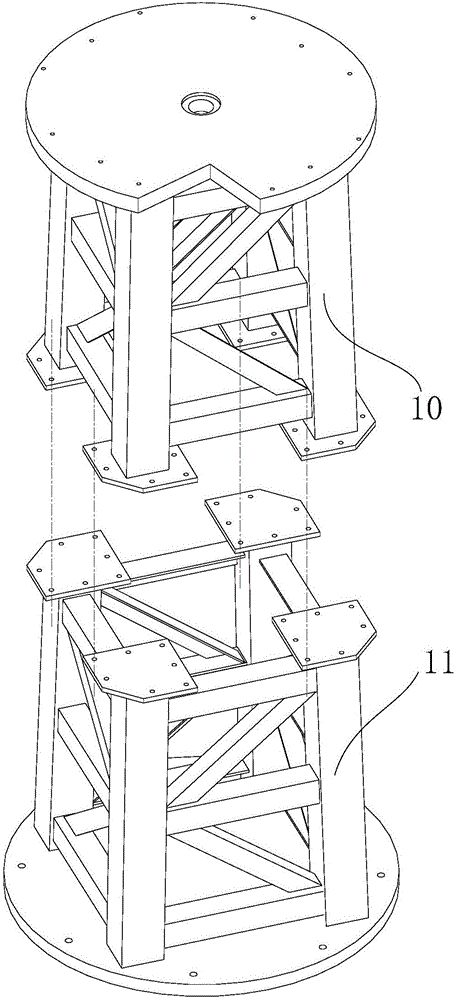

Double-supporting one-hanging object supporting rotary table for RCS measurement

ActiveCN106338719AReliable liftingSmooth liftWave based measurement systemsNumerical controlEngineering

Provided is a double-supporting one-hanging object supporting rotary table for RCS measurement. The object supporting rotary table is composed of a central tower, a precise numerical control rotary table, a rotating table, a support unit, a counterweight body and a drawing unit. The central tower is mounted in an installing ground pit of the object supporting rotary table, the precise numerical control rotary table is mounted on the central tower, the rotating table is mounted on a rectangular workbench of the precise numerical control rotary table, the numerical control rotary table drives the rotating table to rotate for 360 degrees, the support unit and the counterweight body are mounted under the rotating table symmetrically, and can rotate together with the rotating table, and the drawing unit is mounted on a drawing unit installation platform. Original supporting and hanging points in an object to be measured are utilized, the original structure of the object to be measured needs not to be changed, the object can be lifted to a measuring position safely, reliably and stably, dismounting is convenient, and the efficiency is high; and a support rod is arranged under the object and supports the object, a drawing rope is hung on the object, and key test parts of the object is almost not shielded in the RCS measuring process.

Owner:BEIHANG UNIV

Self-centering synchronously clamped silicon rod butting machine

InactiveCN102248609AHigh dimensional accuracyImprove shape and position accuracyFine working devicesElectric machineryEngineering

The invention discloses a self-centering synchronously clamped silicon rod butting machine. The silicon rod butting machine comprises a feeding slipway seat, a feed motor, a feed slipway, a longitudinal feeding slipway, a longitudinal feeding motor, a jacking device, a self-centering double-supporting positioning clamping device, a vertical rack with a saw side, a saw blade, a hydraulic station and an electric control tank, wherein the self-centering double-supporting positioning clamping device can be used for self-centering, positioning and clamping a silicon rod to be cut so that axial lines of all silicon rods to be cut are on the same axial line, and two end faces of each silicon rod to be cut are vertical to the axial line; the jacking device can guarantee that the silicon rods to be cut are reliably clamped in a jacking state so that the silicon rods to be cut are always in an accurate positioned and clamped state in the processing procedure; since the silicon rod section is positioned and clamped in two steps, the silicon rods are not only free from sticking, but also free from a plurality of times of positioning and clamping in the whole cutting processing procedure; four sides of the silicon rods can be cut by only clamping once, the processed size precision and shape precision is higher than those of the prior art, and the processing efficiency can be improved by 25-30%.

Owner:CHANGZHOU TIANZE PV EQUIP MFG

Front pipe variable-angle shopping buddy bicycle

InactiveCN101870317ASimple conversion methodThe conversion method is convenientConvertible cyclesFoldable cyclesShopping basketVehicle frame

The invention provides a front pipe variable-angle shopping buddy bicycle, comprising a front frame pipe, a frame vertical pipe, a small frame telescopic main pipe, a large frame telescopic main pipe, a middle frame joint, a handlebar, a front fork, a hanger, a double support, a saddle, a saddle pipe, a front wheel, a back wheel, a shopping basket and the like, wherein, a hinge is arranged between the front frame pipe and the small frame telescopic main pipe and is fixed by a set fixed ring; a rack is arranged at the lower part of the small frame telescopic main pipe; a mandril is positioned at the upper part of the large frame telescopic main pipe, a gear wheel is arranged in the lower part of the large frame telescopic main pipe and a handle is arranged on the gear wheel; the rack is meshed with the gear wheel; two universal wheels are positioned on one end of the double support and form a shopping travelling system with the front wheel together; the front fork is provided with a location hole, and a location rod corresponding to the location hole is arranged on the middle frame joint; and the location hole coincides with the location rod so that the front wheel can rotate but not swing. The front pipe variable-angle shopping buddy bicycle has the advantages of multiple purposes and practicability, being a bicycle as well as a shopping trolley and simple, rapid and convenient conversion from the bicycle to the shopping trolley.

Owner:詹富生

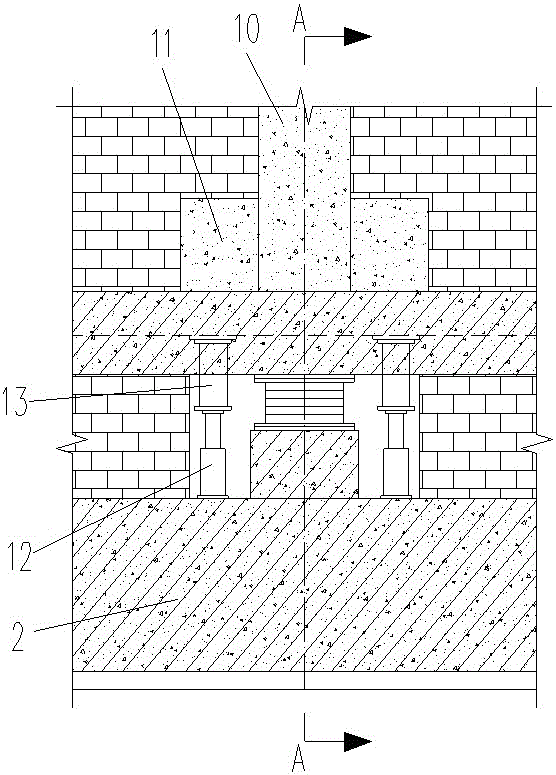

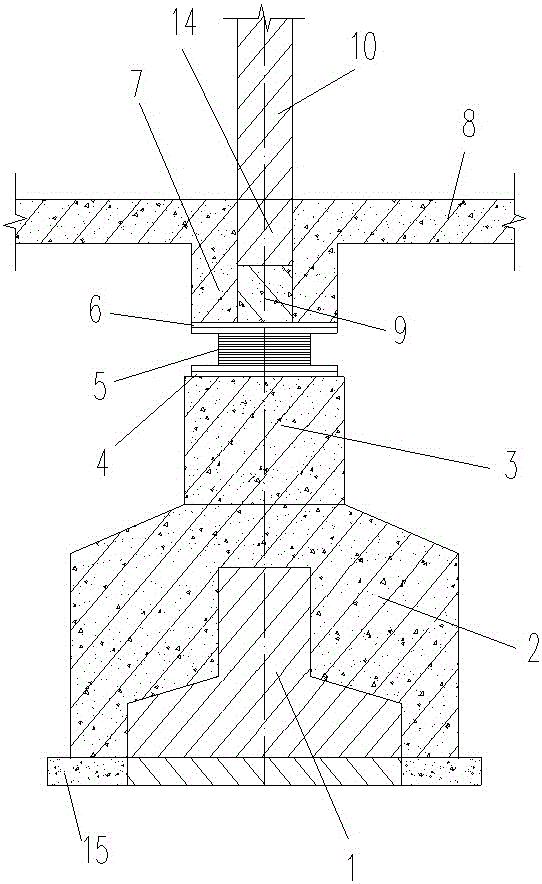

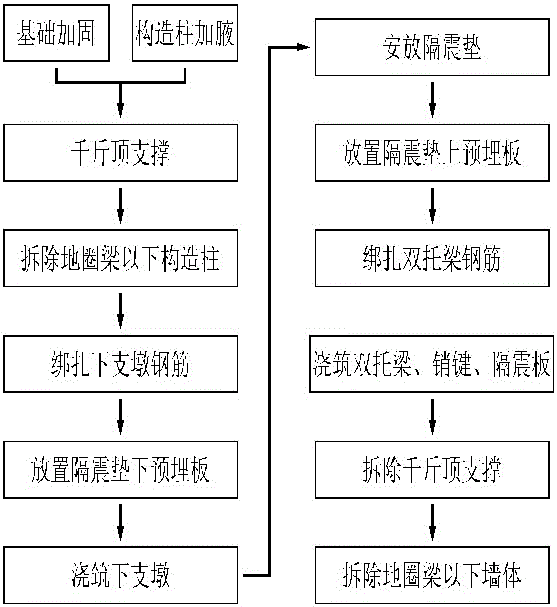

Underpinning and reinforcing structure for seismic isolation bearing of existing brick-concrete structure and construction method for underpinning and reinforcing structure

The invention discloses an underpinning and reinforcing structure for a seismic isolation bearing of an existing brick-concrete structure. The underpinning and reinforcing structure comprises an enlarged foundation arranged on the original foundation, a lower supporting pier arranged on the upper part of the enlarged foundation, a seismic isolation pad lower embedded board arranged on the upper part of the lower supporting pier, a seismic isolation pad arranged on the upper part of the seismic isolation pad lower embedded board, a seismic isolation pad upper embedded board arranged on the upper part of the seismic isolation pad, double supporting beams arranged on the upper part of the seismic isolation pad upper embedded board and a seismic isolation board arranged on the upper parts of the double supporting beams; pin keys are further arranged inside the double supporting beams; and the double supporting beams, the pin keys and the seismic isolation board are of an integrated type poured and molded structure. The invention further provides a construction method for the underpinning and reinforcing structure for the seismic isolation bearing of the existing brick-concrete structure. In this way, the underpinning and reinforcing structure is stable in structure, is high in safety, and has relatively good seismic resistance; besides, the mounting and constructing are relatively convenient, and the efficiency is high.

Owner:JIANGSU DINGDA BUILDING NEW TECH +1

Freewheeling clutch dynamic friction torque tester

ActiveCN101144743ASimple structureFriendly interfaceMachine gearing/transmission testingWork measurementFriction torqueBand shape

The invention discloses a dynamic frictional force torque test set of a free wheeling clutch, and the dynamic frictional force torque test set comprises a controlling system, a testing system, and a testing device; wherein, a computer of the controlling system controls a motor of a drive mechanism through a sensor and a velometer; the motor is connected with a drive axle through a synchronous belt, the drive axle is connected with a chief axle through a clutch, the output end of the chief axle is connected with a fixed tray, an inner sleeve and an outer sleeve are arranged between the fixed tray and a relative supporting tray, and the supporting tray is fixed by a double supporting block; the tested piece is arranged between the inner sleeve and the outer sleeve and is used for three testing states: an inner frictional force torque test, an outer frictional force torque test, and a banding frictional force torque test. The complete machine has simple structure, friendly interface, and convenient operation; the invention can set the parameters such as the testing rotating speed, the sampling time, and the sampling frequency; the testing data is correct and reliable, and the testing precision is high; after being analyzed and processed by a computer software, therefore, not only the test result can be displayed in dynamic state and in visible state, but also the relative data can be analyzed and collated, and the finished testing result can be stochastically displayed, output, and archived.

Owner:LUOYANG BEARING RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com