Portable power head core drill

A technology of core drilling rig and power head, which is applied in the direction of rotary drilling rig, percussion drilling, rotary drilling, etc. It can solve the problems of low work efficiency, large swing range of drill pipe, and poor rock drillability, etc., and achieves The disassembly and assembly of the power head is convenient, the installation and disassembly are convenient, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

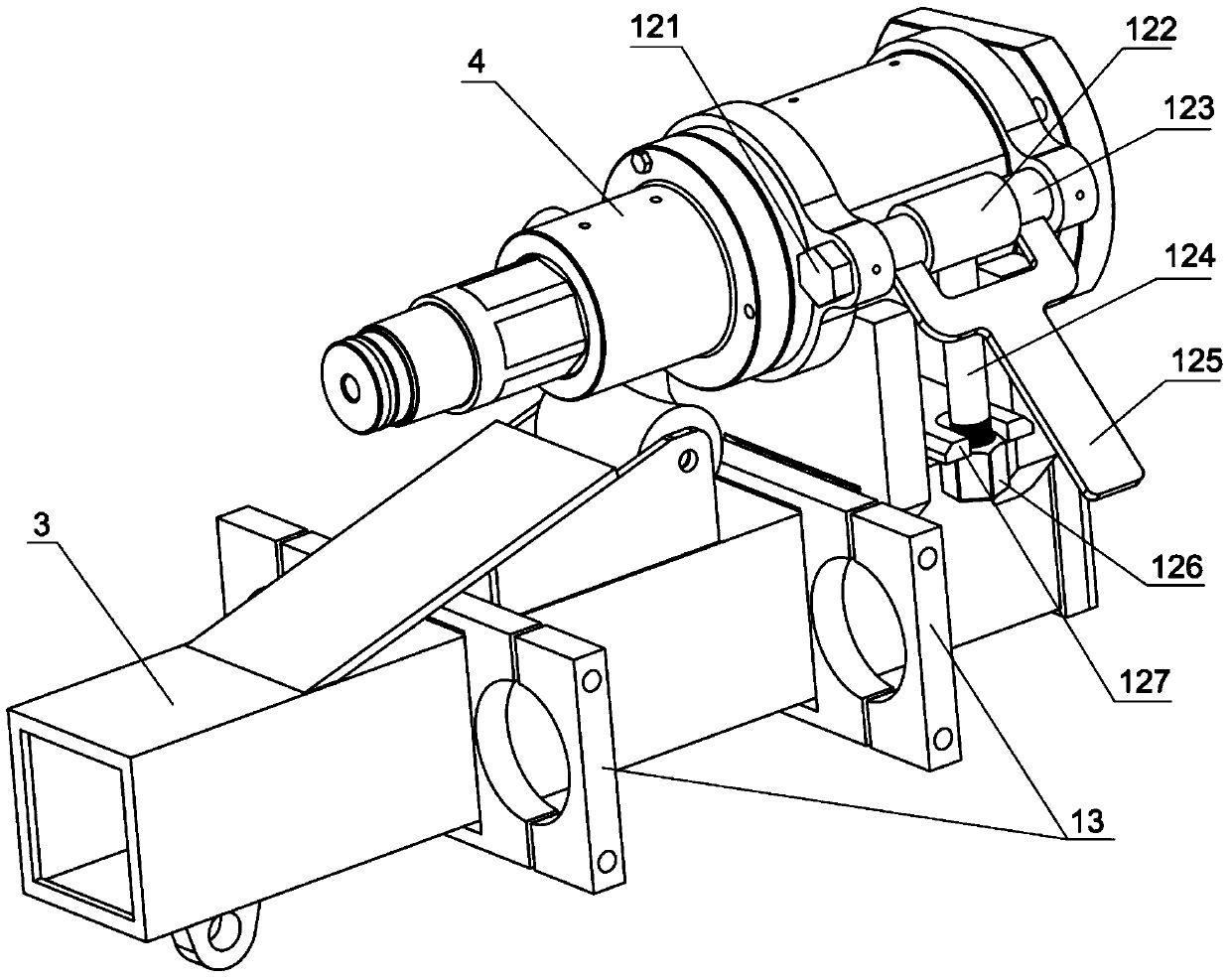

[0036] refer to figure 1 , figure 2 , a portable power head core drilling rig of the present invention, including: double rail base 11, guide rail 5, sliding sleeve 3, power head 4, mast 6, support rod, holder 1 and lifting cylinder 2. A mud pump 9 and a hoist 8 are also arranged on the double-track base 11 . One end of the guide rail 5 is fixedly connected to the rotating shaft 14 , and is connected to the double-rail base 11 through the rotating shaft 14 , and the guide rail 5 can rotate around the rotating shaft 14 . A movable sliding sleeve 3 is set on the guide rail 5, and a power head 4 is installed on the sliding sleeve 3 through a locking device 12. A lifting cylinder 2 is arranged between the sliding sleeve 3 and the rotating shaft 14 to drive the sliding sleeve 3 to slide along the guide rail 5. The mast 6 is fixedly connected with the other end of the guide rail 5 , and the mast 6 has a fixed double support pulley 601 and a movable single support pulley 602 . Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com