Electric valve

An electric valve, valve body technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of shortened thread fit length, large gap between magnet and shell, and reduced output torque, etc., to achieve reduced valve needle swing, The effect of increasing wear resistance and reducing clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

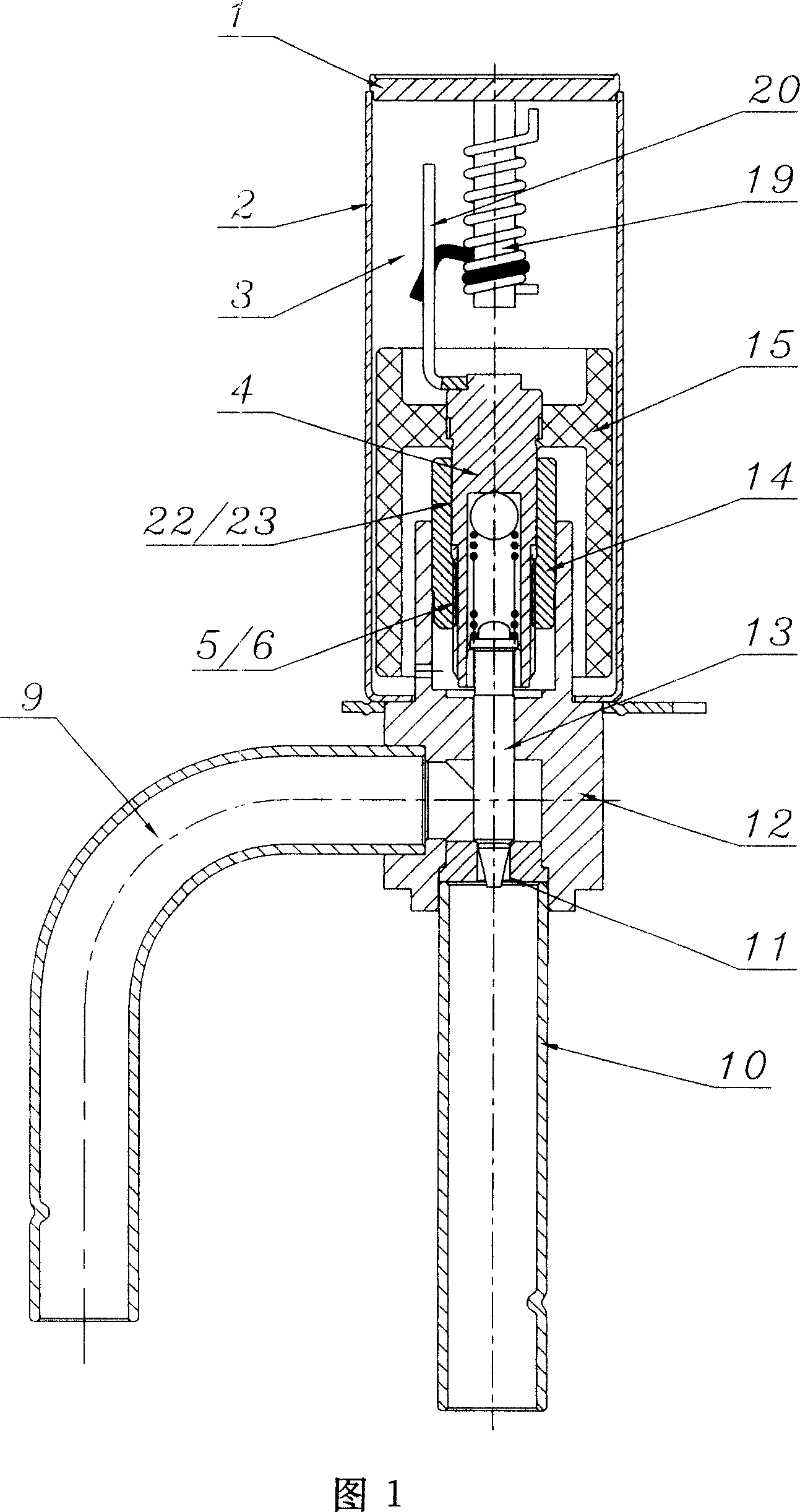

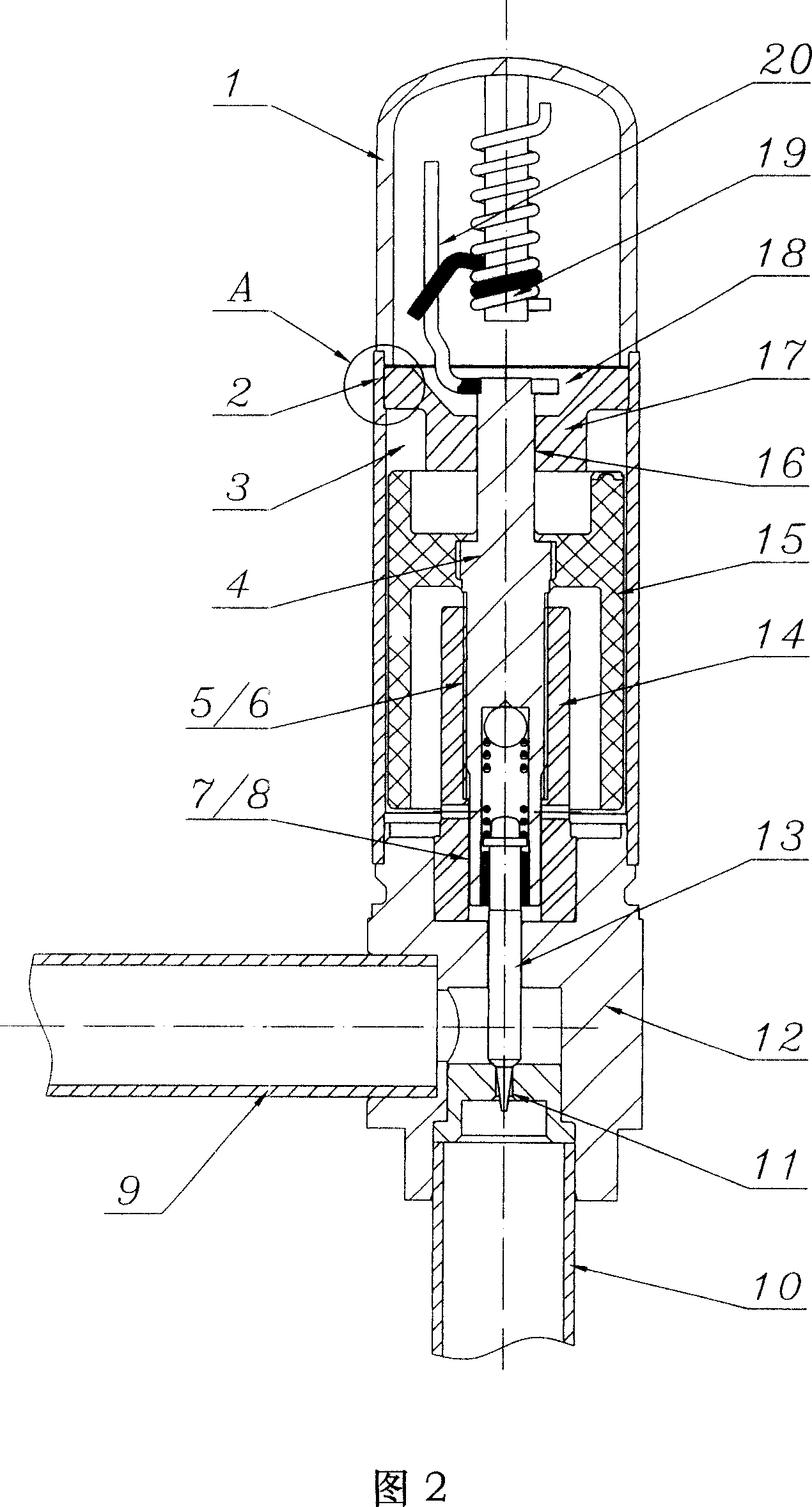

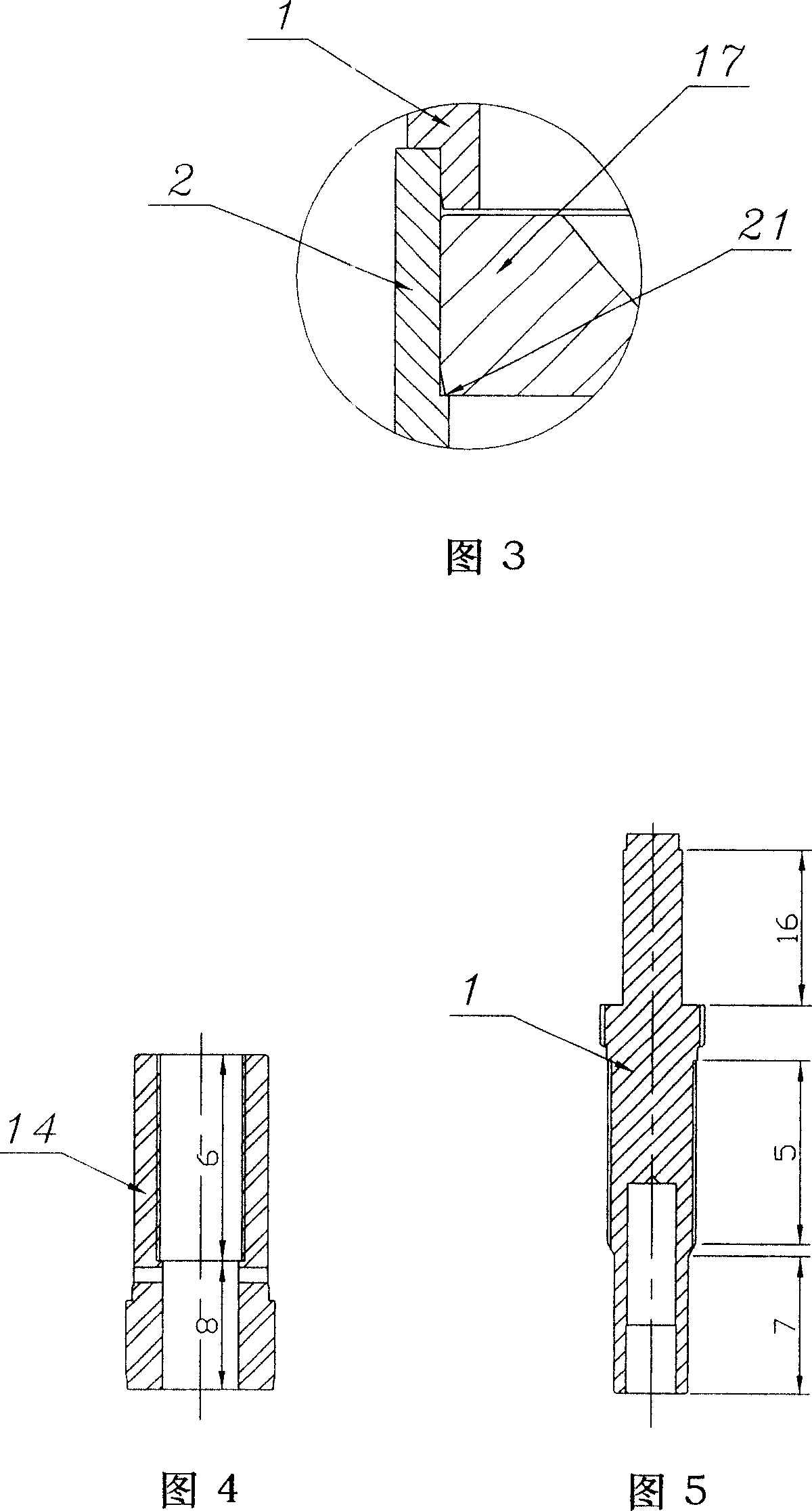

[0021] As for the electric valve shown in Figure 2, there are a metal stopper 19, a stop rod 20, and a magnet 15 in the housing cavity 3, and the screw rod 4 and the magnet 15 are integrally injection-molded, and the two ends of the screw rod 4 (see Figure 5) are respectively The upper guide section 16 and the lower guide section 7 protruding from the end face of the magnet 15 have an external thread section 5 between the two guide sections of the screw rod 4, wherein the upper guide section 16 is located in the center hole of the guide member 17 and is in a clearance fit. The lower guide section 7 is located in the lower guide section 8 of the nut 14 and also has a clearance fit, and the guide piece is mounted on the inner wall of the housing 2 . As a result, the central axis of the magnet 15 coincides with the central axes of the valve body 12 and the housing 2 as much as possible so as to reduce the vibration of the magnet. The external thread section 5 cooperates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com