Method for manufacturing steel ingots through ultra-supercritical steam turbine blade steel electro-slag remelting

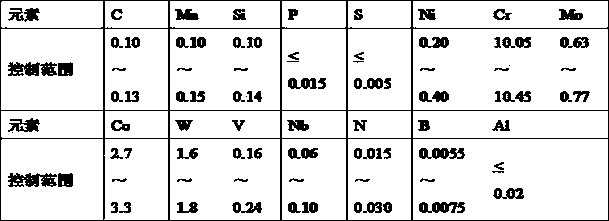

A technology for steam turbine blades and electroslag remelting steel, which is applied to the manufacture of ultra-supercritical steam turbine blade steel electroslag remelting ingots, the manufacture of low Al steel ingots, and the field of high purity and low Si, and can solve the problem of the bottom end of electroslag ingots The difference in oxygen content and purity at the filling end, the large amount of element burning loss, and the lack of uniform chemical composition, oxygen content, and purity of electroslag ingots have achieved the effect of uniform purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] 1. Steelmaking process

[0083] ①Electric furnace process

[0084] The total furnace capacity is 31.83t, and the ingredients are high-quality steel scrap and pig iron; the alloy materials are low-chromium, metal chromium, nickel plate, tungsten iron, cobalt plate, molybdenum iron, vanadium iron, niobium iron, boron iron and Benxi Iron and steel return materials. Tapping control: C: 0.06%, P: 0.004%, tapping temperature 1684°C;

[0085] ②LF process

[0086] Use aluminum particles and carbon powder for diffusion deoxidation and maintain the atmosphere, the amount of aluminum powder is 35kg, CaC 2 The amount of powder is 75kg, added in two batches, the white slag time is guaranteed to be 40min, the tapping temperature is 1660°C, and S: 0.007%.

[0087] ③VOD / VHD furnace

[0088] After the molten steel is scraped to clean the initial slag, it is put into the VOD tank. Along with the slag material (lime, fluorite), add 49kg of deoxidizer Al powder, 15 kg of Ca-Si ...

Embodiment 2

[0098] 1. Steelmaking process

[0099] ①Electric furnace process

[0100] The total furnace capacity is 31.90t, and the ingredients are high-quality steel scrap and pig iron; the alloy materials are low-chromium, metal chromium, nickel plate, tungsten iron, cobalt plate, molybdenum iron, vanadium iron, niobium iron, boron iron and Benxi Iron and steel return materials. Tapping control: C: 0.07%, P: 0.005%, tapping temperature 1655°C;

[0101] ②LF process

[0102] Use aluminum particles and carbon powder for diffusion deoxidation and maintain the atmosphere, the amount of aluminum powder is 41kg, CaC 2 The amount of powder is 80kg, added in two batches, the white slag time is guaranteed to be 40min, the tapping temperature is 1670°C, and S: 0.006%.

[0103] ③VOD / VHD furnace

[0104] After the molten steel is scraped to clean the initial slag, it is put into the VOD tank. Along with the slag (lime, fluorite), add 35kg of deoxidizer Al powder, 20kg of Ca-Si bl...

Embodiment 3

[0114] 1. Steelmaking process

[0115] ①Electric furnace process

[0116] The total furnace capacity is 31.88t, and the ingredients are high-quality scrap steel and pig iron; the alloy materials are low-chromium, metal chromium, nickel plate, tungsten iron, cobalt plate, molybdenum iron, vanadium iron, niobium iron, boron iron and Benxi Iron and steel return materials. Tapping control: C: 0.06%, P: 0.005%, tapping temperature 1680°C;

[0117] ②LF process

[0118] Use aluminum particles and carbon powder for diffusion deoxidation and maintain the atmosphere, the amount of aluminum powder is 40kg, CaC 2 The amount of powder is 70kg, added in two batches, the white slag time is guaranteed to be 35min, the tapping temperature is 1680°C, and S: 0.005%.

[0119] ③VOD / VHD furnace

[0120] After the molten steel is scraped to clean the initial slag, it is put into the VOD tank. Along with the slag material (lime, fluorite), add 35kg of deoxidizer Al powder, 30kg of C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com