Straight-through type double-support ultra-fine ring roller grinder

A double-support, ring roller milling technology, applied in grain processing, etc., can solve the problems of large mechanical loss, low grinding efficiency, and large vibration of the milling host, so as to reduce mechanical collision and wear, improve grinding efficiency, and improve overall rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

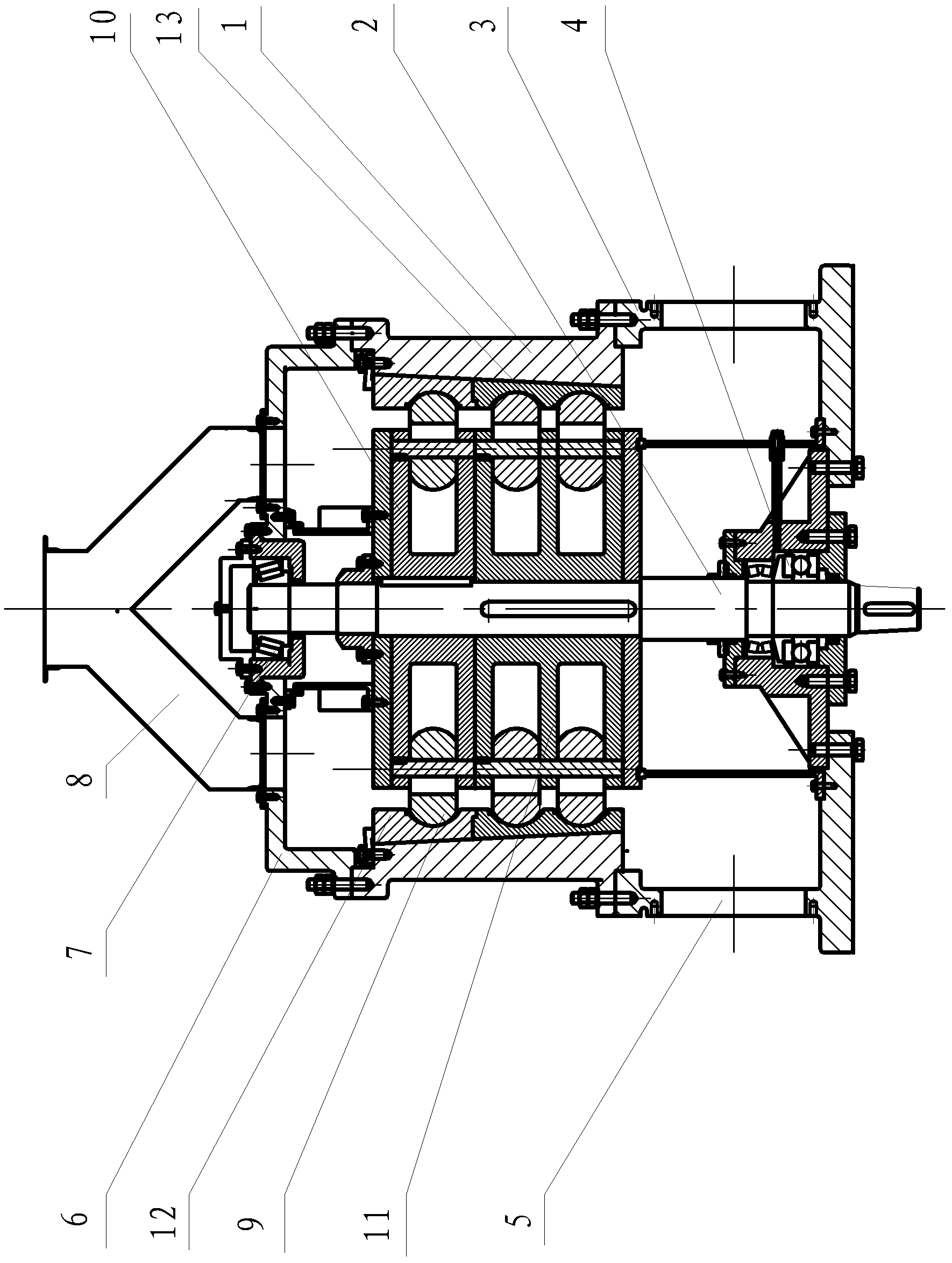

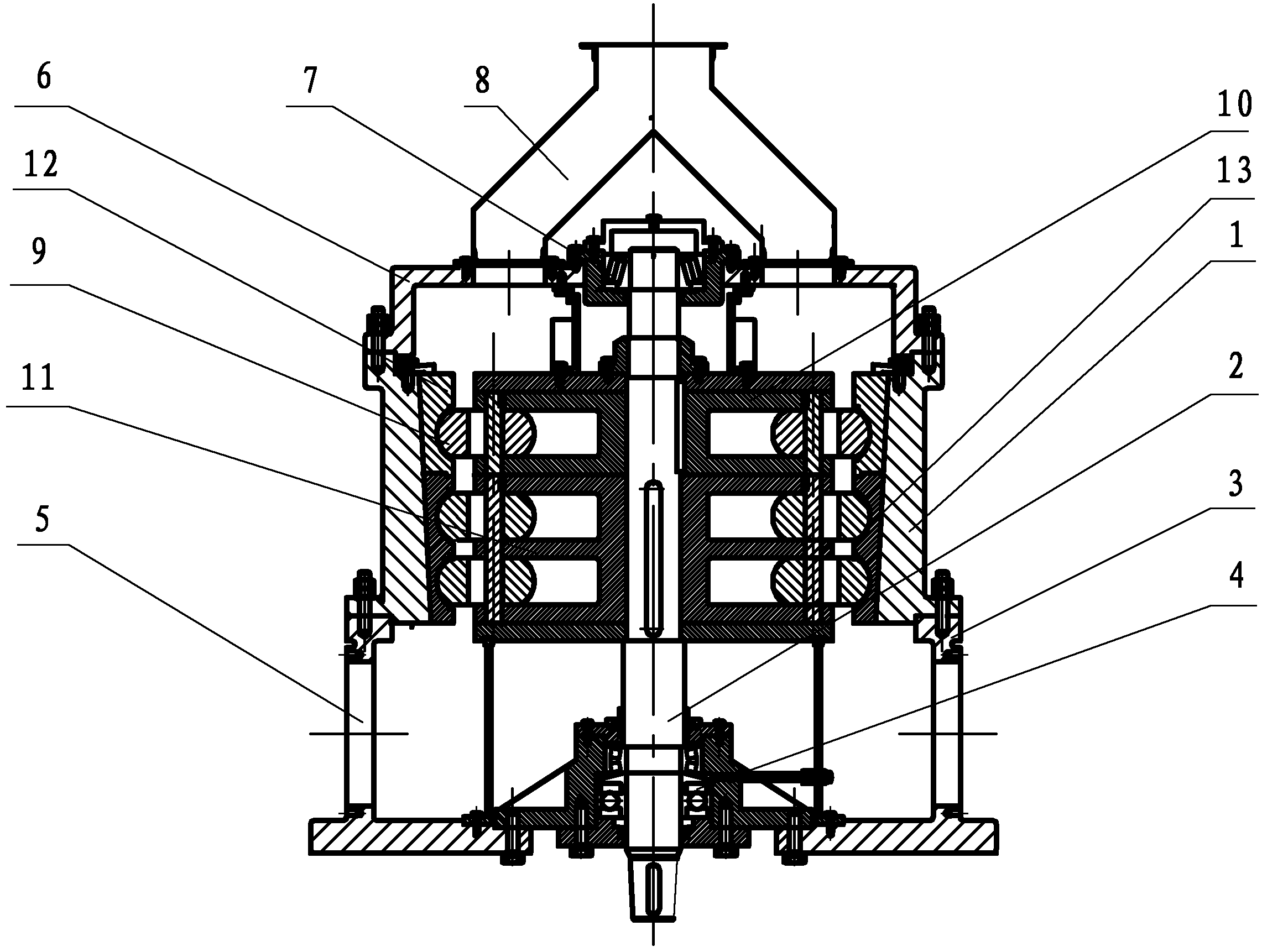

[0021] The milling machine of the direct-flow ultra-fine ring roller mill of the present invention comprises a main machine shell 1, a main machine upper cover 6, a main machine base 3, a main shaft 2, a grinding roller 9 and a grinding ring, and the upper and lower openings of the main machine shell 1 pass through flanges. Connect and install with the host upper cover 6 and the host base 3 respectively, the main shaft 2 is vertically placed on the central axis of the main machine casing 1, the upper and lower ends of the main shaft 2 are respectively supported and installed by the upper and lower bearing positions 7, 4, and the upper , the lower bearing positions 7, 4 are respectively arranged in the center of the main machine cover 6 and the main machine base 3, the grinding roller 9 is installed on the grinding roller frame, and the grinding roller fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com