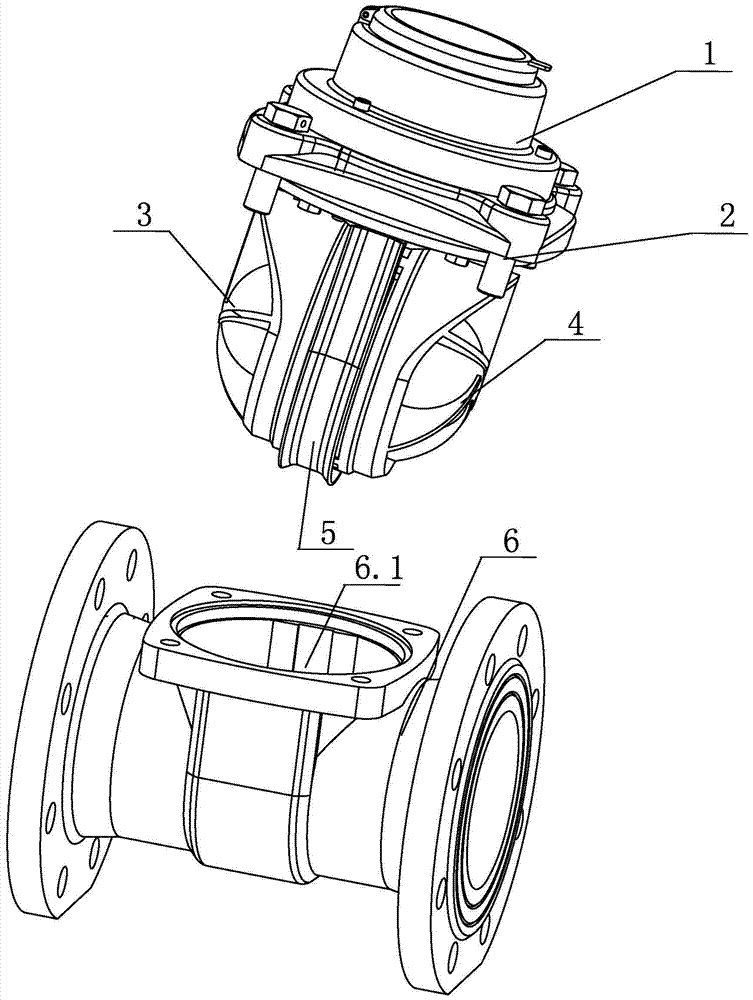

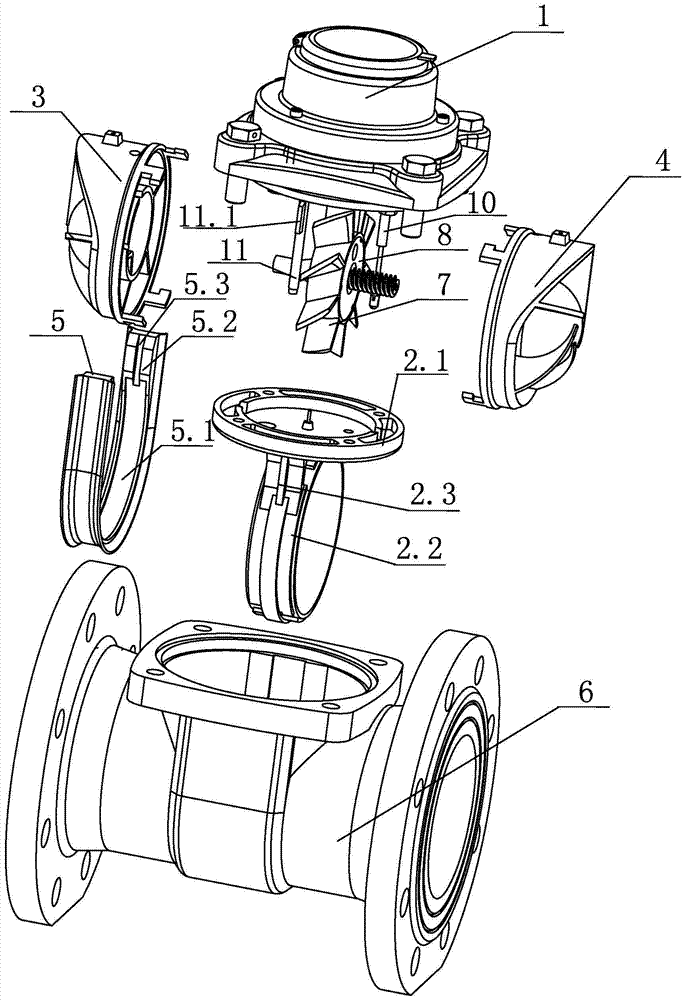

Horizontal screw type water meter

A screw-wing and horizontal technology, applied in the field of horizontal screw-wing water meters, can solve the problems of poor coating, difficulty in breaking through the flow capacity and accuracy of horizontal screw-wing water meters, affecting the flow capacity and accuracy of water meters, and achieving anti-corrosion Good torsional strength and guaranteed balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The second axle 9 is made of the following raw materials: 80 parts of PA12, Al 2 o 3 5 parts, 5 parts of glass fiber, 5 parts of polyetheretherketone, 0.5 parts of coupling agent, 0.8 parts of antioxidant, 1 part of tetraethyl orthosilicate, and 5 parts of carbon black. The coupling agent is silane coupling agent KH550. The antioxidant is one of antioxidant B225 or antioxidant B215.

[0038] The preparation method comprises the following steps:

[0039] 1) After the raw materials are prepared according to the above formula ratio, PA12, Al 2 o 3 Mix glass fiber, polyether ether ketone, and tetraethyl orthosilicate evenly in a high-speed mixer, then add silane coupling agent KH550, and react for 8-10 hours at 45-60°C under the protection of an inert gas;

[0040] 2) Then add antioxidant B225 and carbon black, mix well, and dry the above mixture in an oven at 85-110°C for 1-3h;

[0041] 3) Extrude and granulate the above-mentioned mixture on a twin-screw extruder, a...

Embodiment 2

[0043] The second axle 9 is made of the following raw materials: 85 parts of PA12, Al 2 o 3 6 parts, 10 parts of glass fiber, 8 parts of polyether ether ketone, 0.7 parts of coupling agent, 1.2 parts of antioxidant, 3 parts of tetraethyl orthosilicate, and 9 parts of carbon black.

[0044] The preparation method comprises the following steps:

[0045] 1) After the raw materials are prepared according to the above formula ratio, PA12, Al 2 o 3 , glass fiber, polyether ether ketone, and tetraethyl orthosilicate are mixed uniformly in a high-speed mixer, then add silane coupling agent KH550, and react at 45-60°C for 8-10 hours under the protection of an inert gas;

[0046] 2) Then add antioxidant B215 and carbon black, mix well, and dry the above mixture in an oven at 85-110°C for 1-3h;

[0047] 3) extruding and granulating the above-mentioned mixture on a twin-screw extruder, and processing the obtained pellets into a second axle (9) on an injection machine.

Embodiment 3

[0049] The second axle 9 is made of the following raw materials: 100 parts of PA12, Al 2 o 3 8 parts, 15 parts of glass fiber, 15 parts of polyether ether ketone, 1 part of coupling agent, 1.5 parts of antioxidant, 5 parts of tetraethyl orthosilicate, and 10 parts of carbon black.

[0050] The preparation method comprises the following steps:

[0051] 1) After the raw materials are prepared according to the above formula ratio, PA12, Al 2 o 3 Mix glass fiber, polyether ether ketone, and tetraethyl orthosilicate evenly in a high-speed mixer, then add silane coupling agent KH550, and react for 8-10 hours at 45-60°C under the protection of an inert gas;

[0052] 2) Then add antioxidant B215 and carbon black, mix well, and dry the above mixture in an oven at 85-110°C for 1-3h;

[0053] 3) Extrude and granulate the above-mentioned mixture on a twin-screw extruder, and process the obtained pellets into a second axle (9) on an injection machine.

[0054] After testing, the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com