Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Chromium trichloride hexahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel-chromium alloy electroplate liquid

The invention relates to nickel-chromium alloy electroplate liquid. A liter of the electroplate liquid comprises from 25g to 35g of nickel sulfate hexahydrate, from 80g to 100g of chromium trichloride hexahydrate, from 30ml to 40ml of formic acid, from 20g to 30g of boric acid, from 1g to 60g of urea, from 30g to 80g of ammonium chloride, from 40g to 60g of potassium chloride, from 30g to 60g of critic acid, from 0.1g to 0.12g of sodium dodecyl sulfate, from 1.5g to 2.5g of saccharin, from 2ml to 4ml of nickel plating brighteners and the balance water. The urea is used as a coordination additive, and the performance of the electroplate liquid is greatly improved, so that behaviors of electrodes, the covering power and the dispersing power of a cathode and the stability, the coating performance and the contamination status of the electroplate liquid are greatly improved.

Owner:LUDONG UNIVERSITY

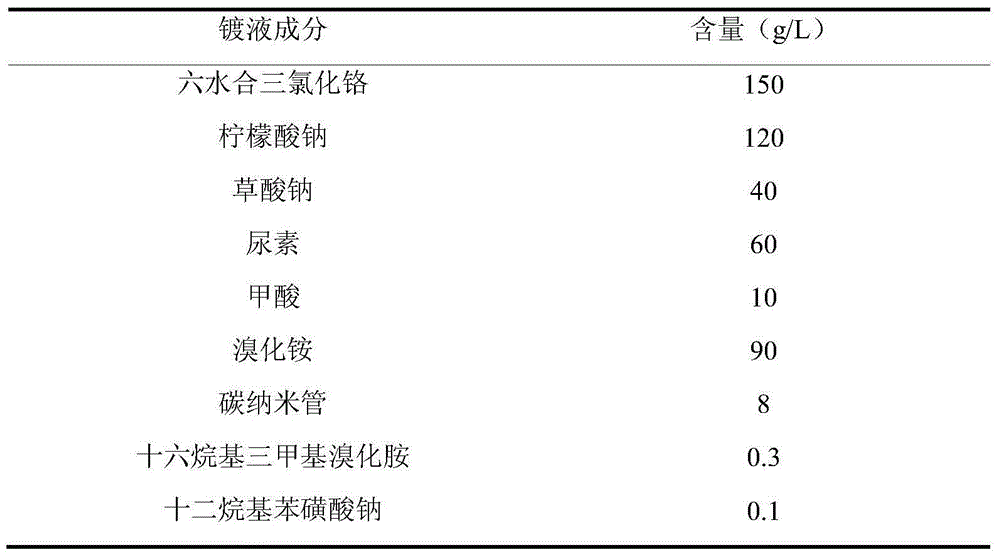

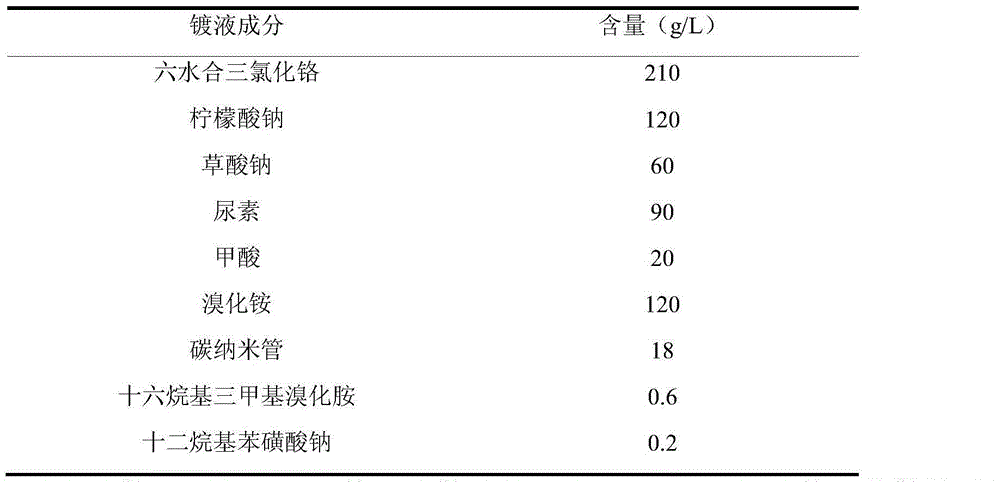

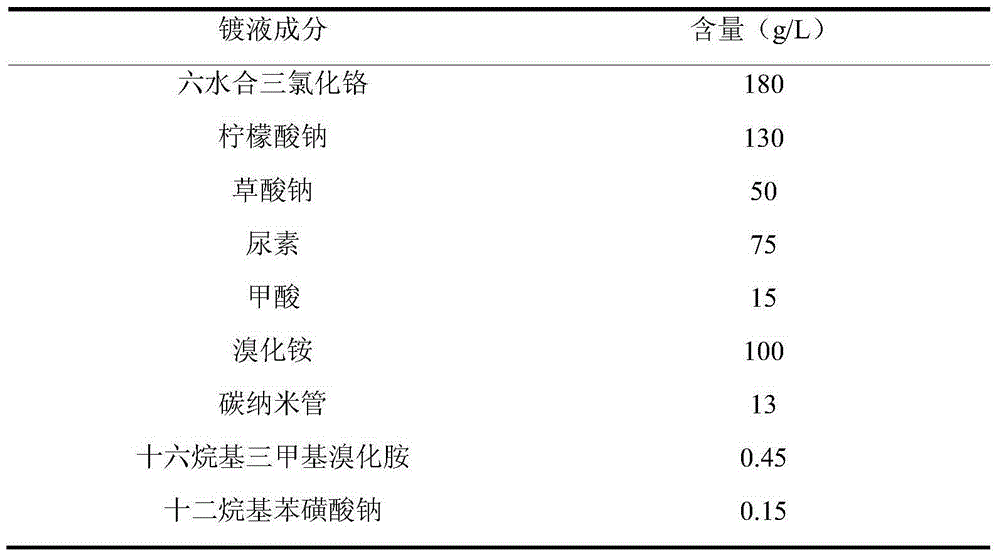

Carbon nanotube composite chromium plating solution and electroplating method

InactiveCN104611735APromote passivationHigh hardnessElectrolytic coatingsCalcium Chloride HexahydrateCarbon nanotube

The invention discloses a carbon nanotube composite chromium plating solution and an electroplating method. The carbon nanotube composite chromium plating solution comprises the following components by content: 150-210g / L chromic chloride hexahydrate, 120-140g / L citrate, 40-60g / L oxalate, 60-90g / L urea, 10-20g / L formic acid, 90-120g / L ammonium bromide, 8-18g / L carbon nanotube, 0.3-0.6g / L fatty alkyl methyl halide salt and 0.1-0.2g / L alkylbenzene sulfonate. The plating solution contains carbon nanotube, due to self rigidity of carbon nanotube, the hardness and wear resistance of a plating layer are increased; on one hand, permeation of a corrosion solution can be prevented by filling the aperture of a plating layer and winding the metal crystal grain surface by carbon nanotube, on the other hand, a minisize primary battery is formed by nano WC and the alloy metal microcrystal, passivation of chromium can be promoted, and corrosion resistance is increased.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

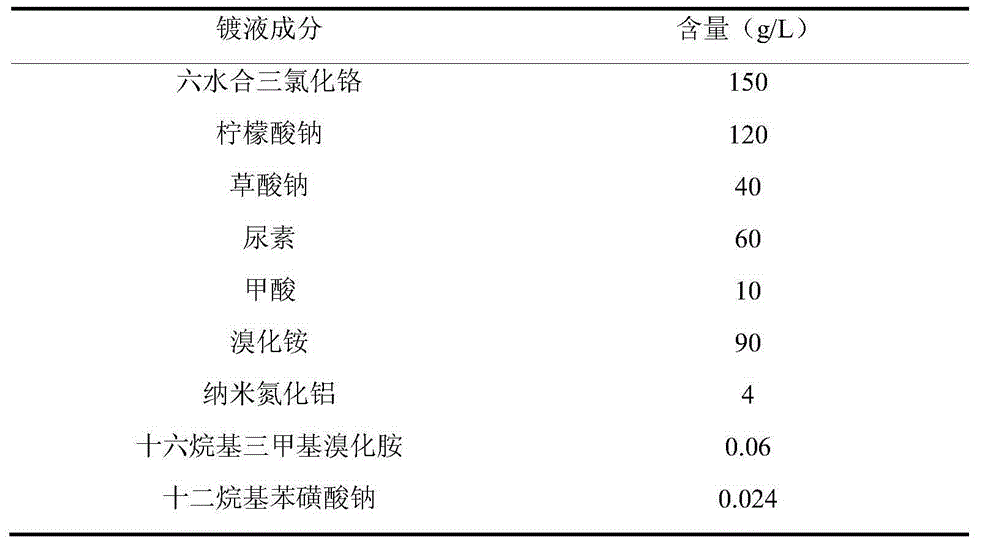

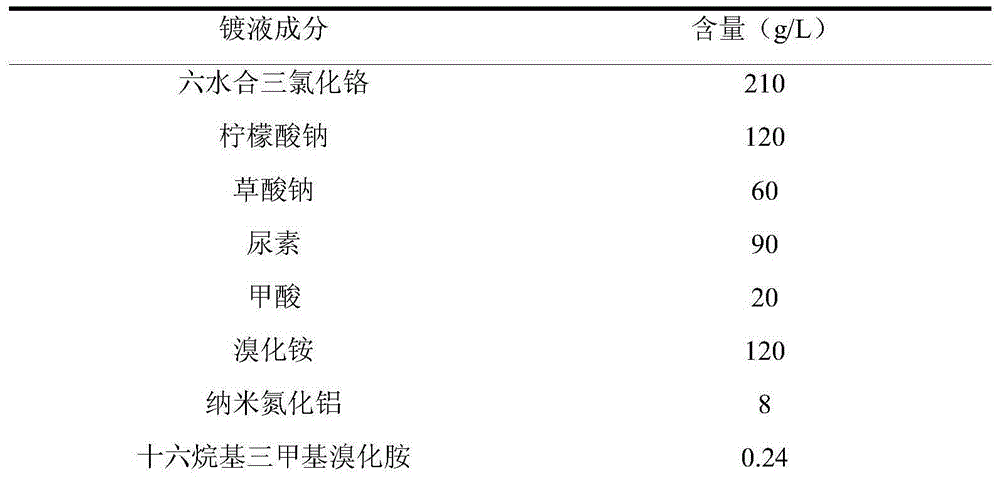

Nano aluminium nitride composite chromium plating solution and electroplating method

InactiveCN104611734AFacilitate depositionPromotes continuous thickeningElectrolytic coatingsCalcium Chloride HexahydrateChromic chloride hexahydrate

The invention discloses a nano aluminium nitride composite chromium plating solution and an electroplating method. The nano aluminium nitride composite chromium plating solution comprises the following components by content: 150-210g / L chromic chloride hexahydrate, 120-140g / L citrate, 40-60g / L oxalate, 60-90g / L urea, 10-20g / L formic acid, 90-120g / L ammonium bromide, 4-8g / L nano aluminium nitride, 0.06-0.24g / L fatty alkyl alkyl methyl halide salt and 0.024-0.06g / L alkylbenzene sulfonate. The plating solution contains nano aluminium nitride, due to self rigidity of nano aluminium nitride, the hardness and wear resistance of a plating layer are increased; on one hand, permeation of a corrosion solution can be prevented by filling the aperture of a plating layer and winding the metal crystal grain surface by nano aluminium nitride, on the other hand, a minisize primary battery is formed by nano aluminium nitride and the chromium metal microcrystal, passivation of chromium can be promoted, and corrosion resistance is increased.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

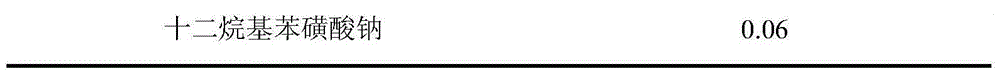

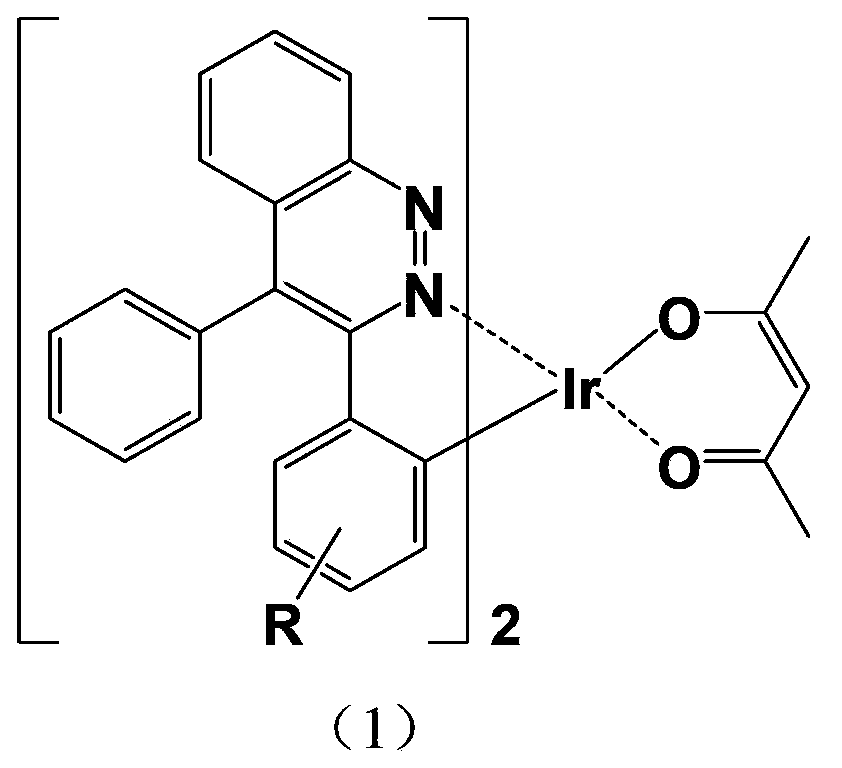

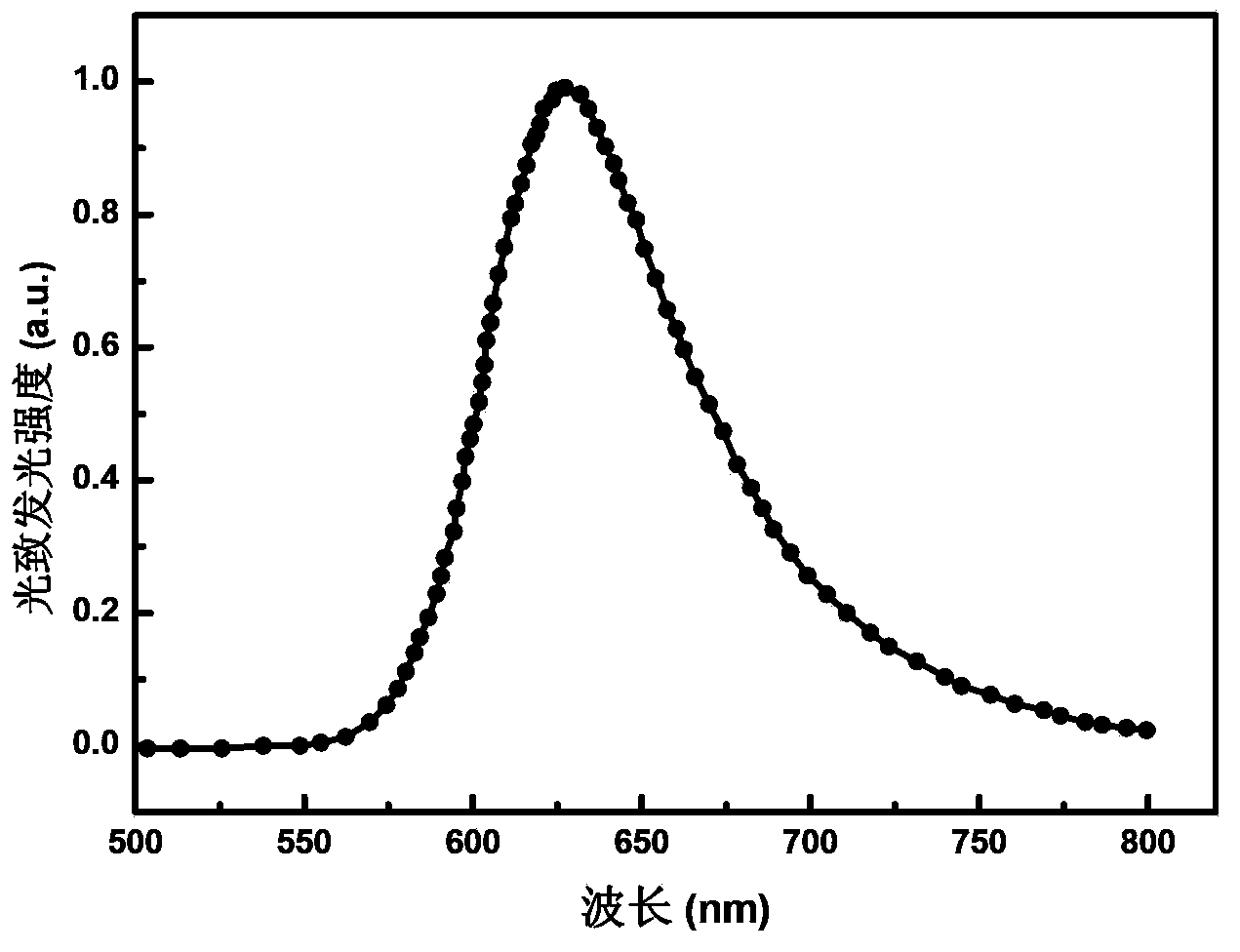

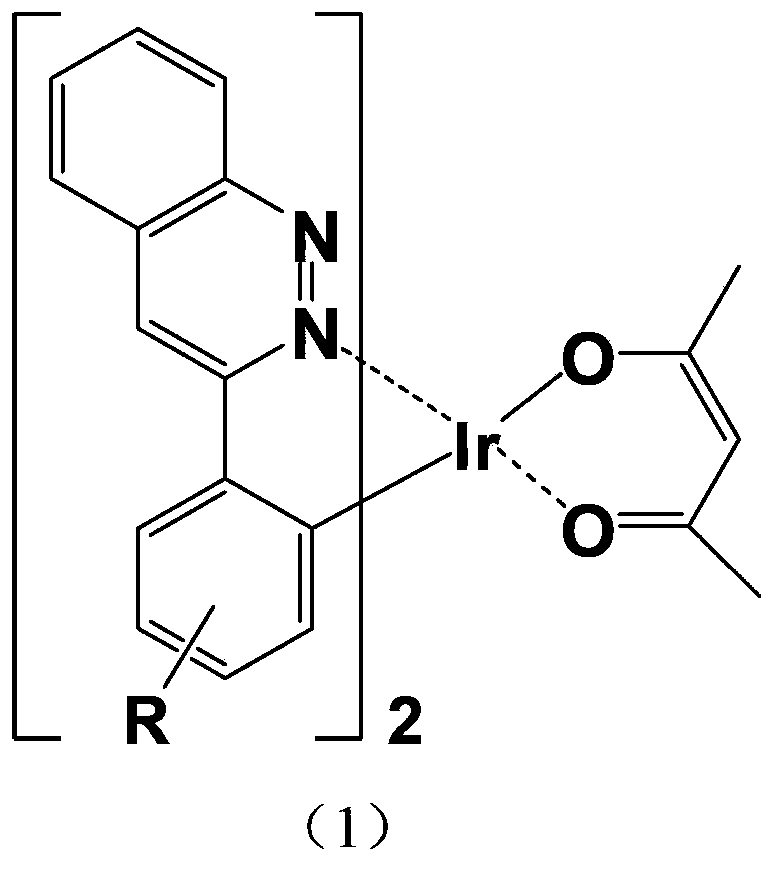

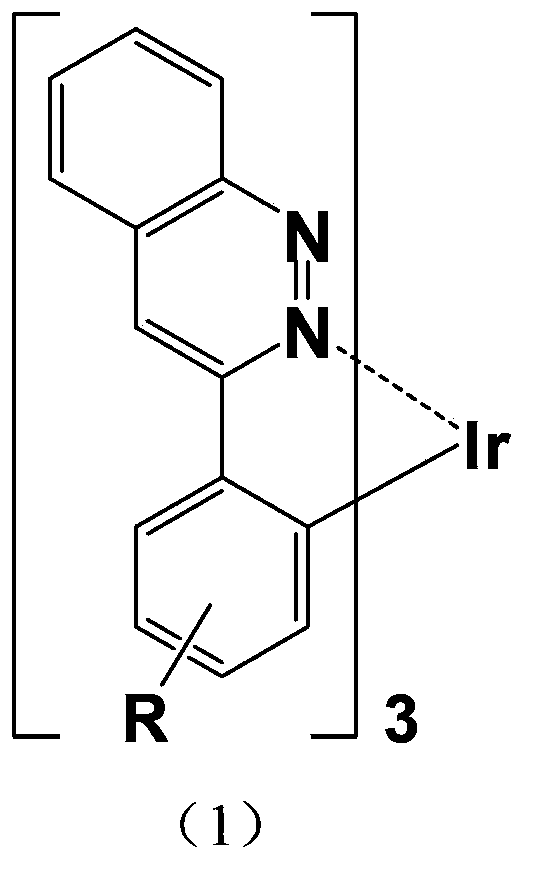

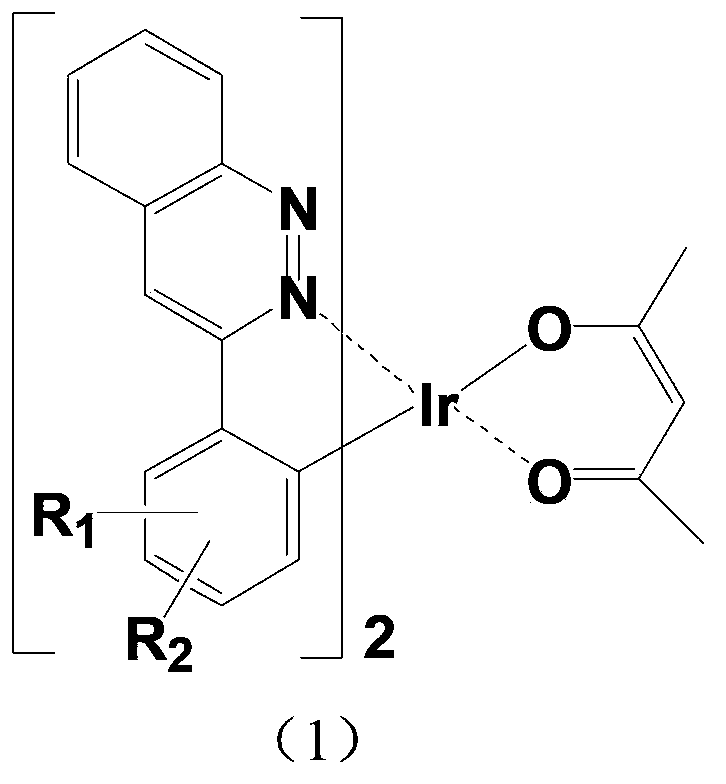

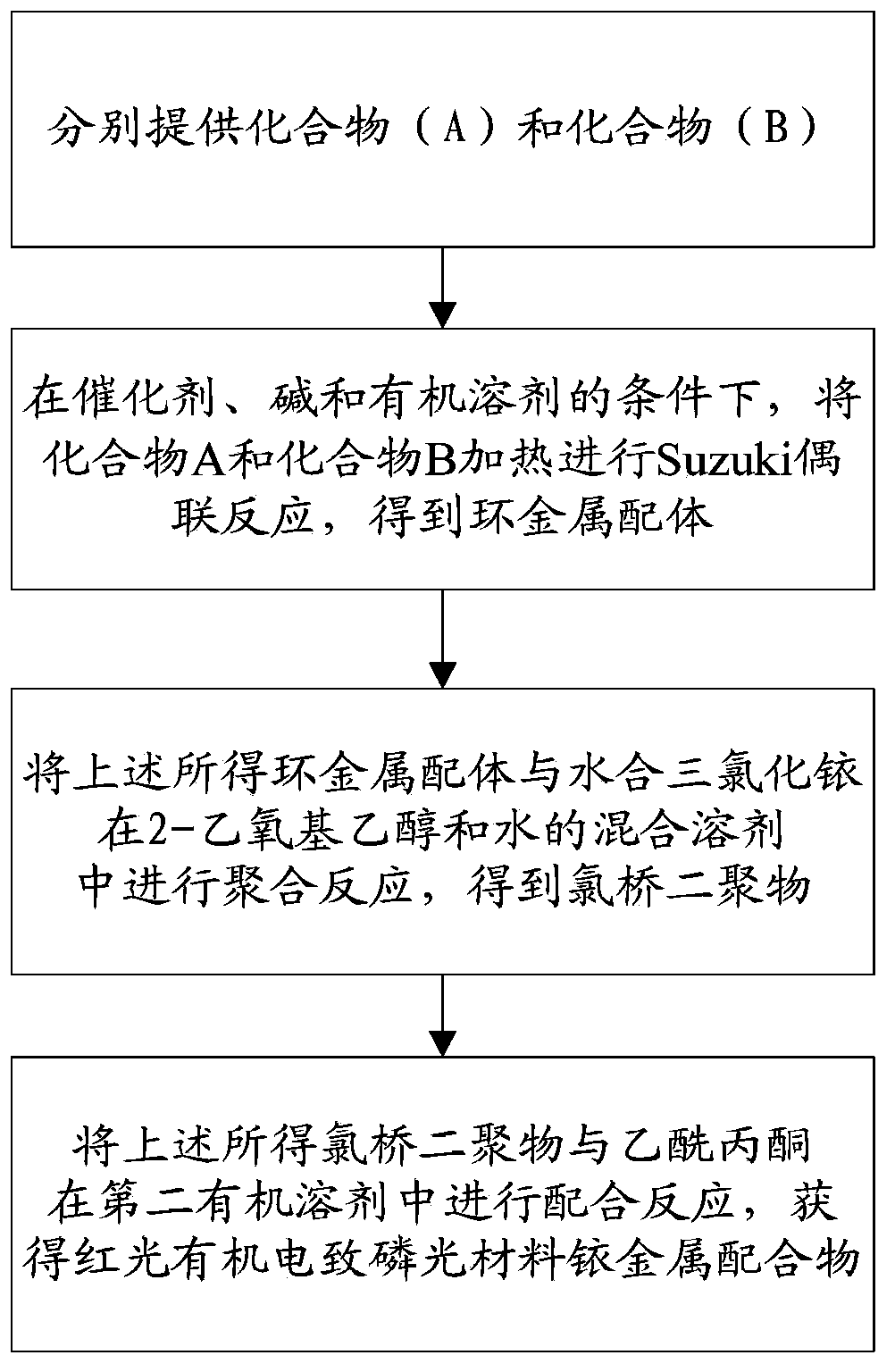

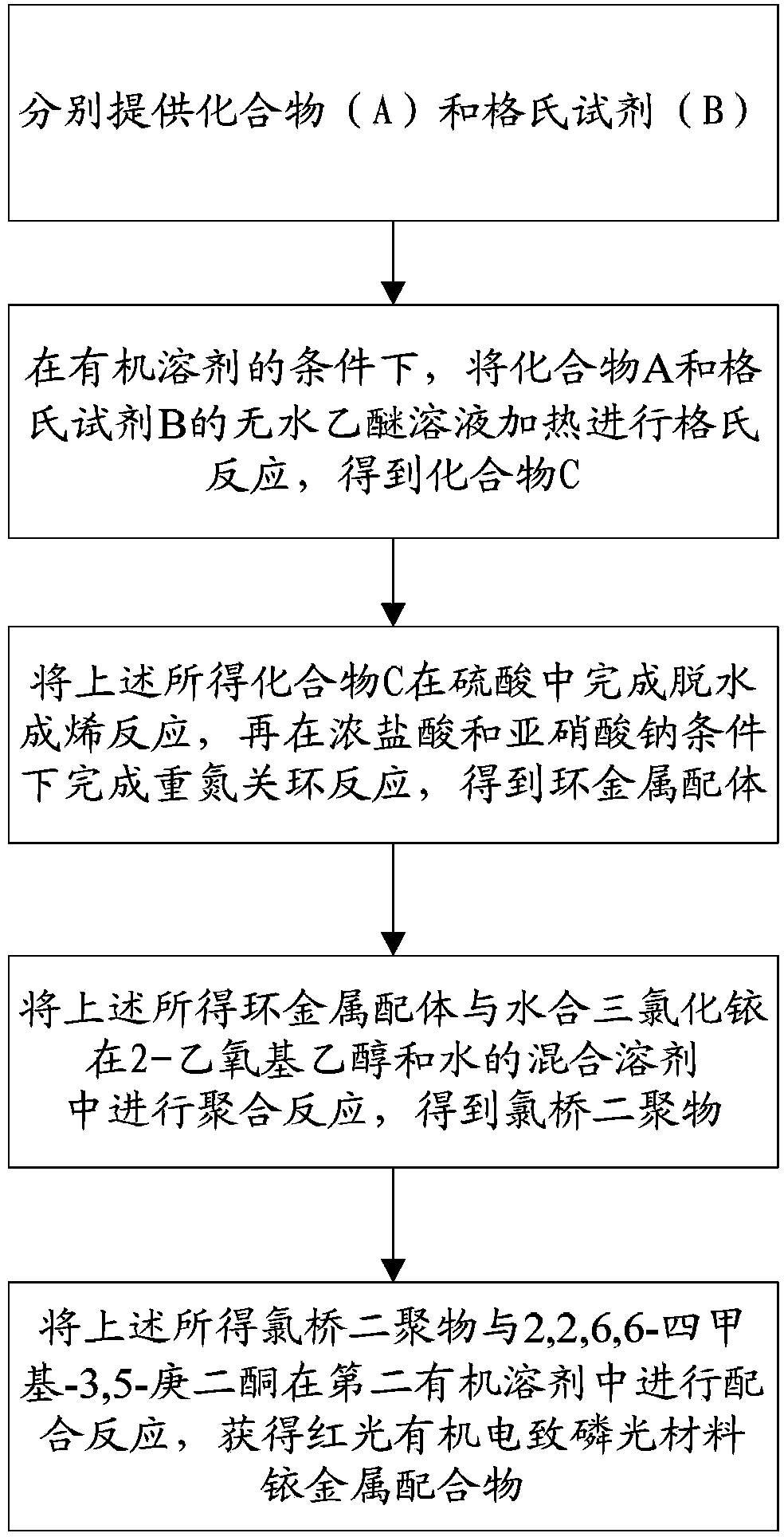

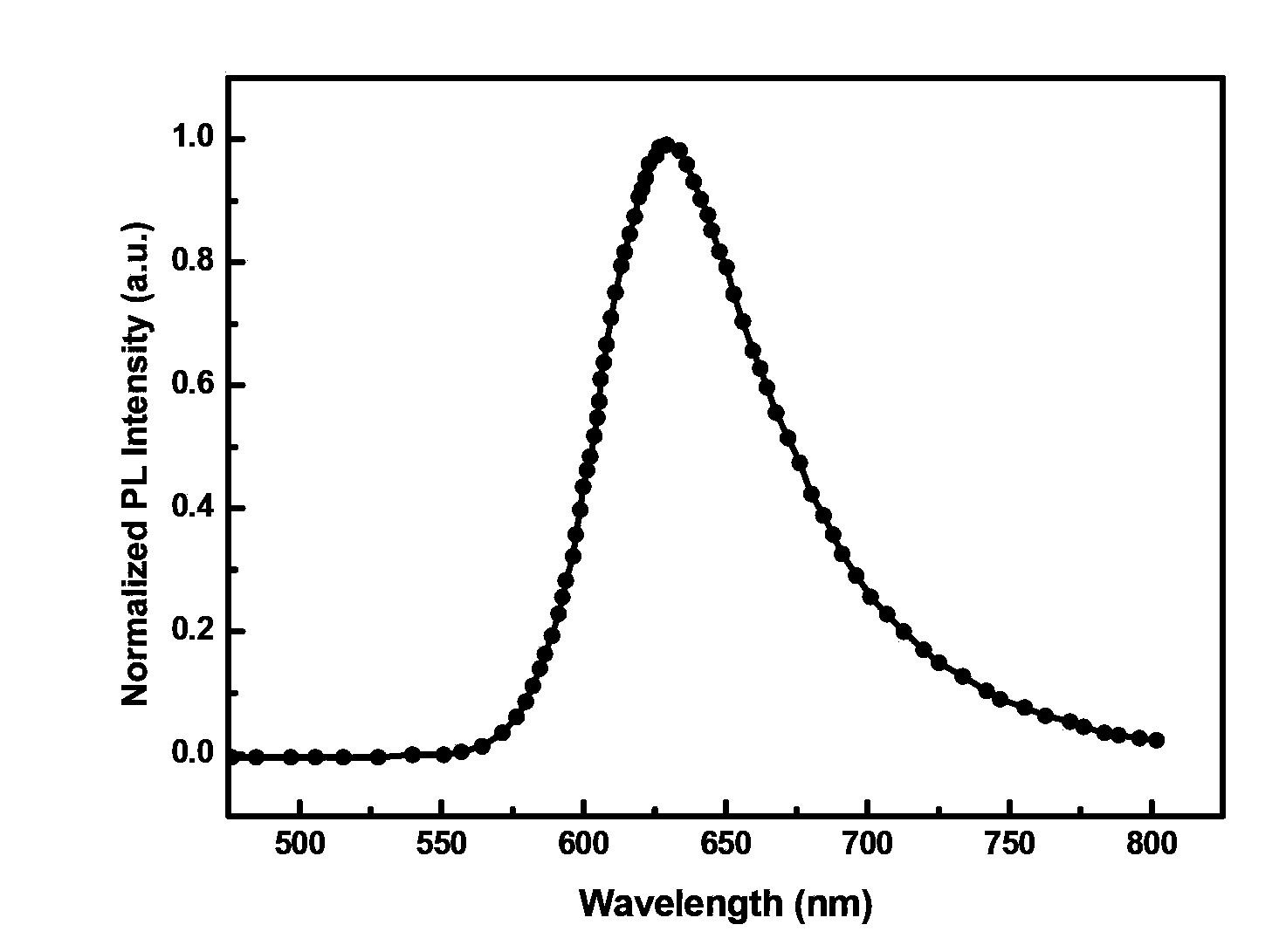

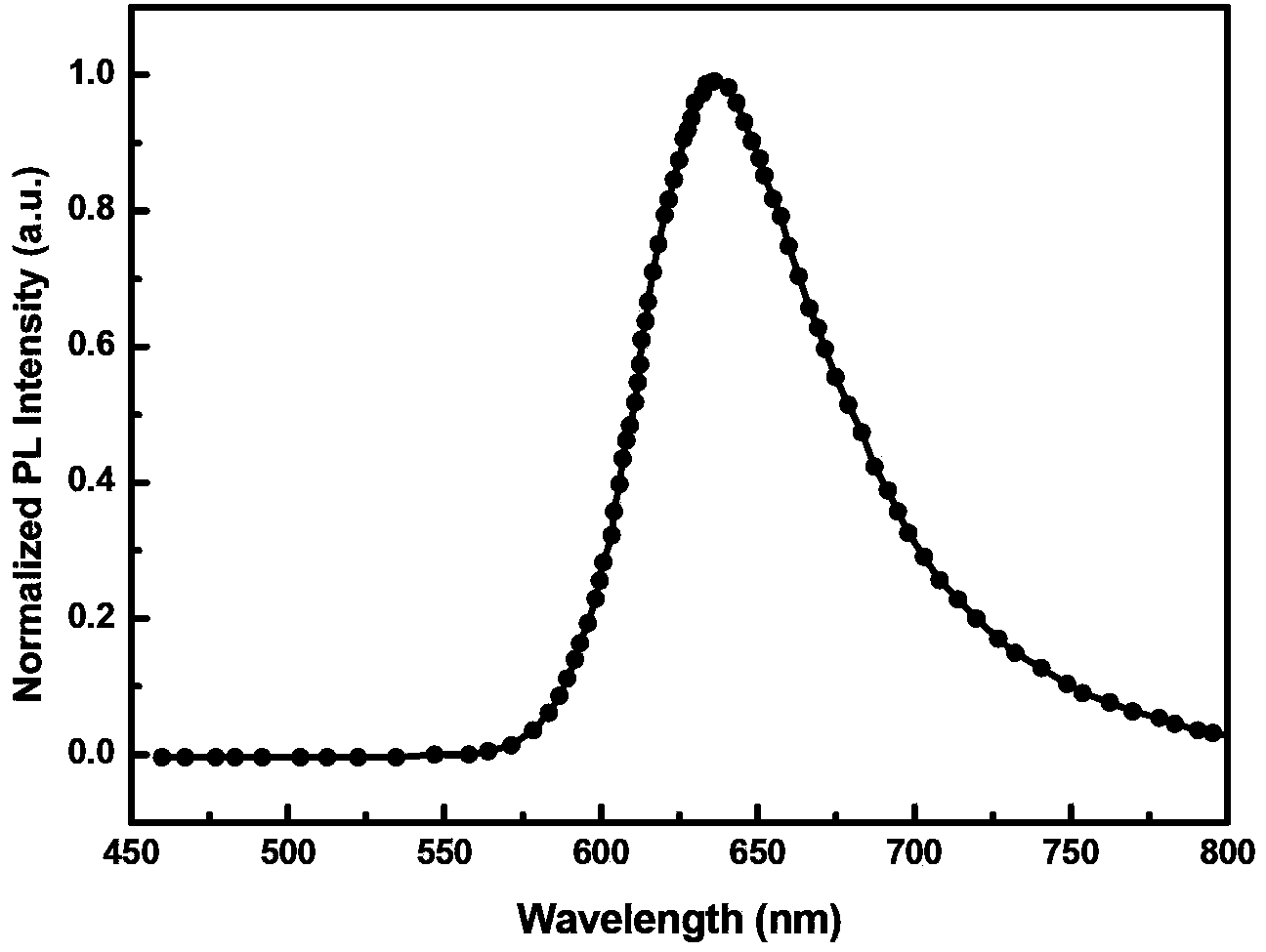

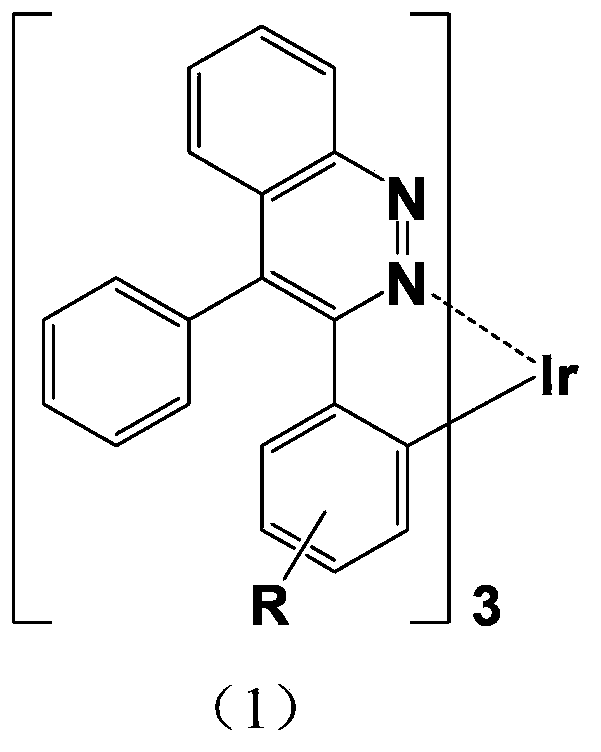

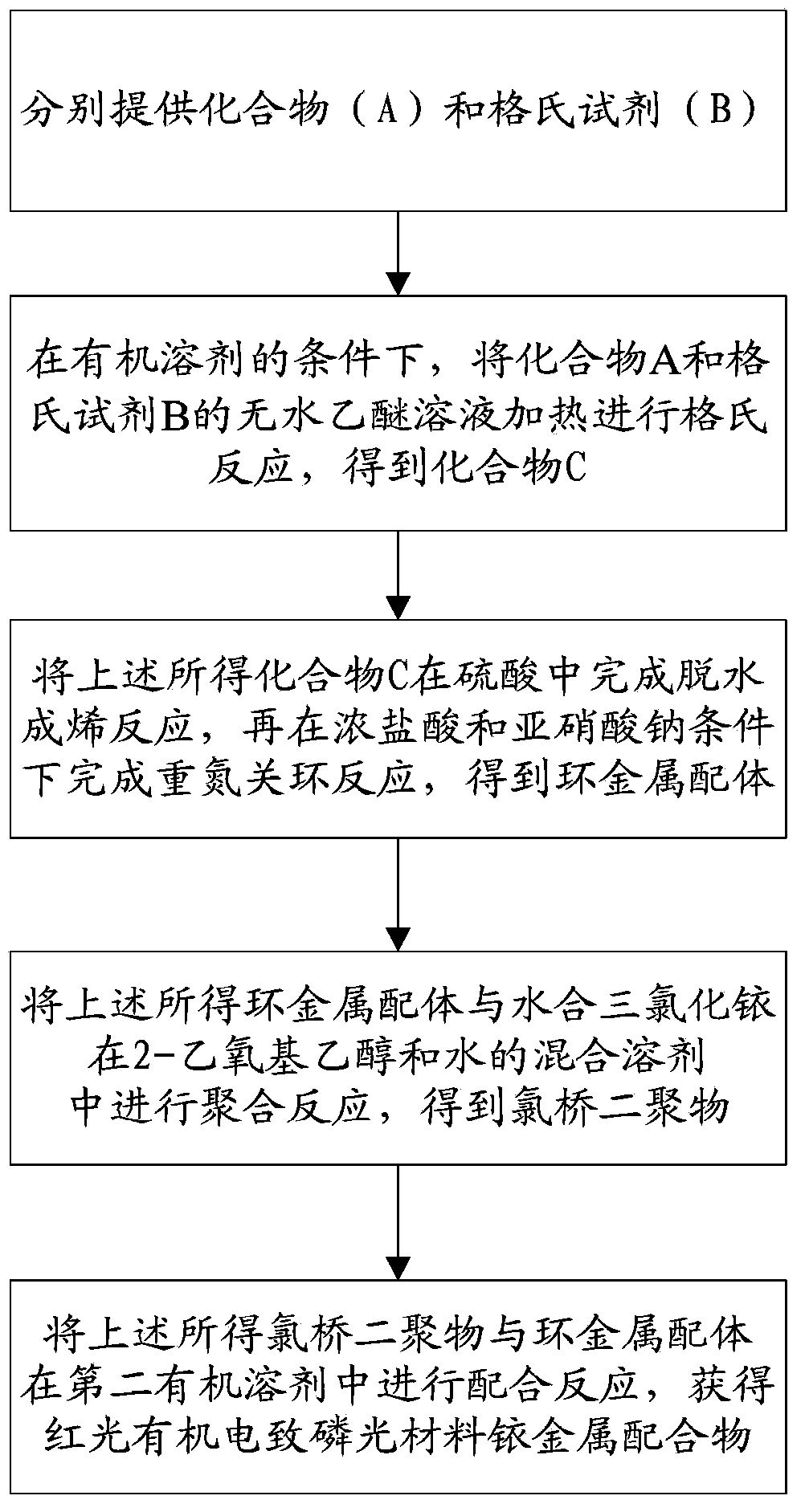

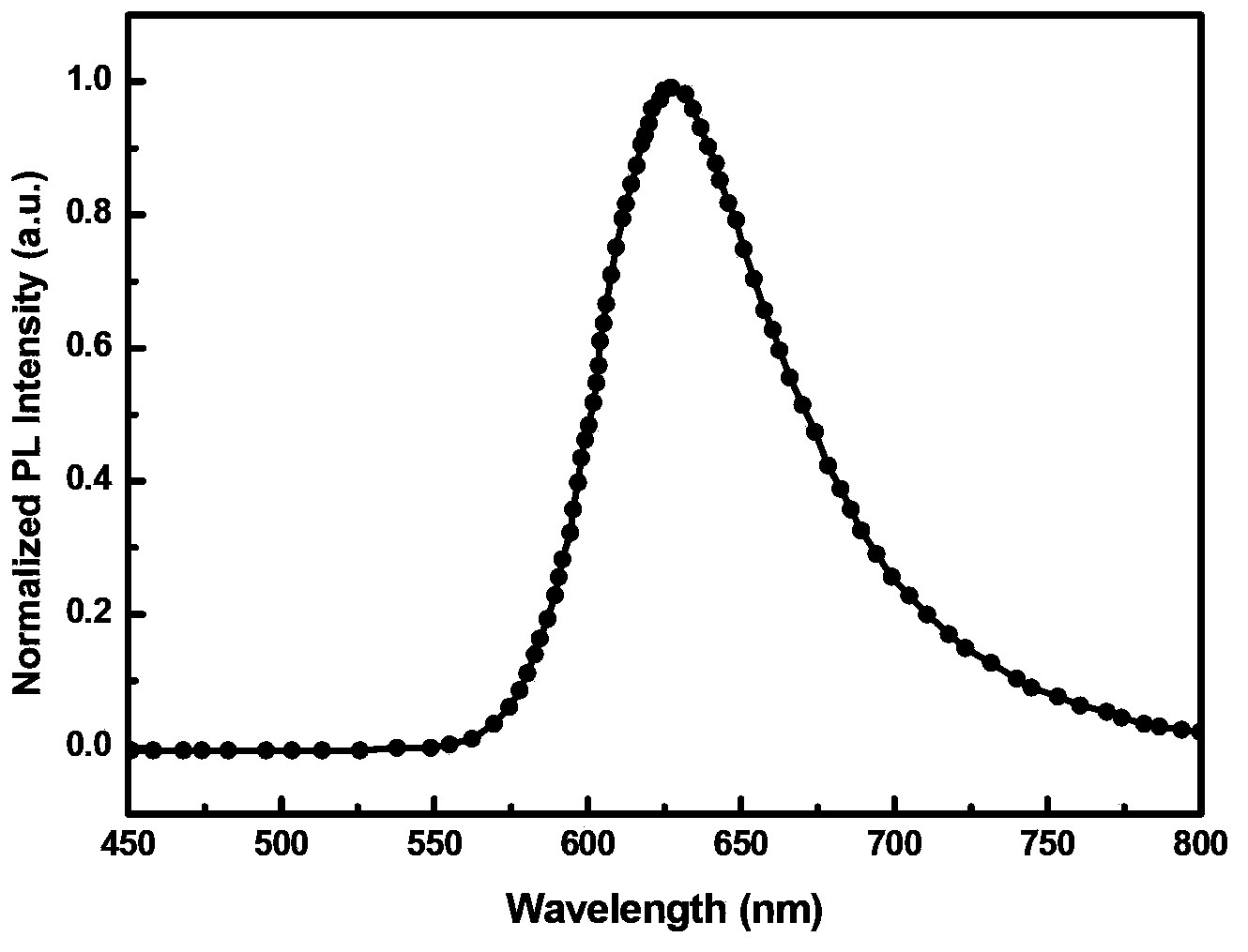

Red organic electrophosphorescent material iridium metal complex, preparation method thereof, and organic electroluminescent device

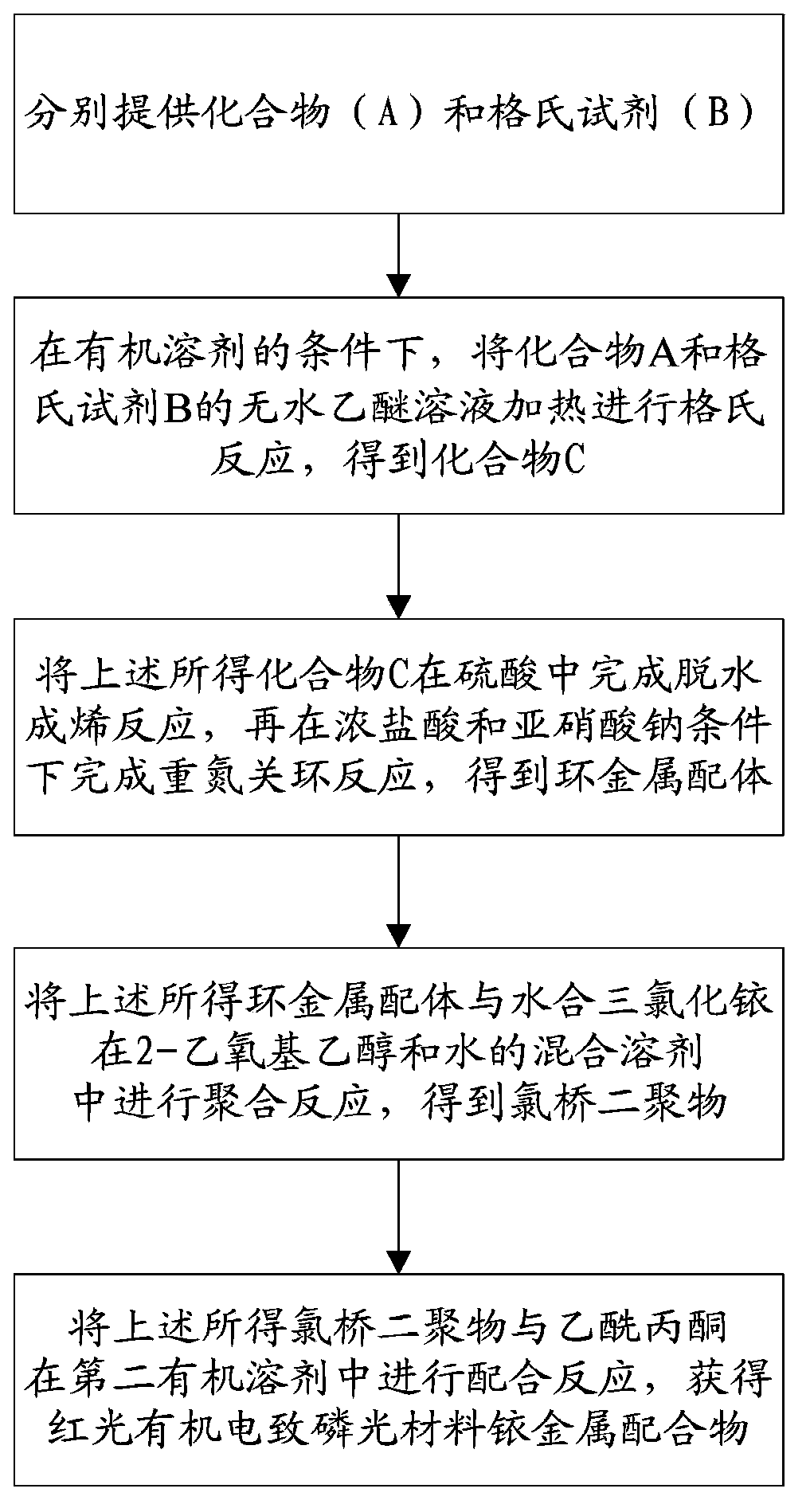

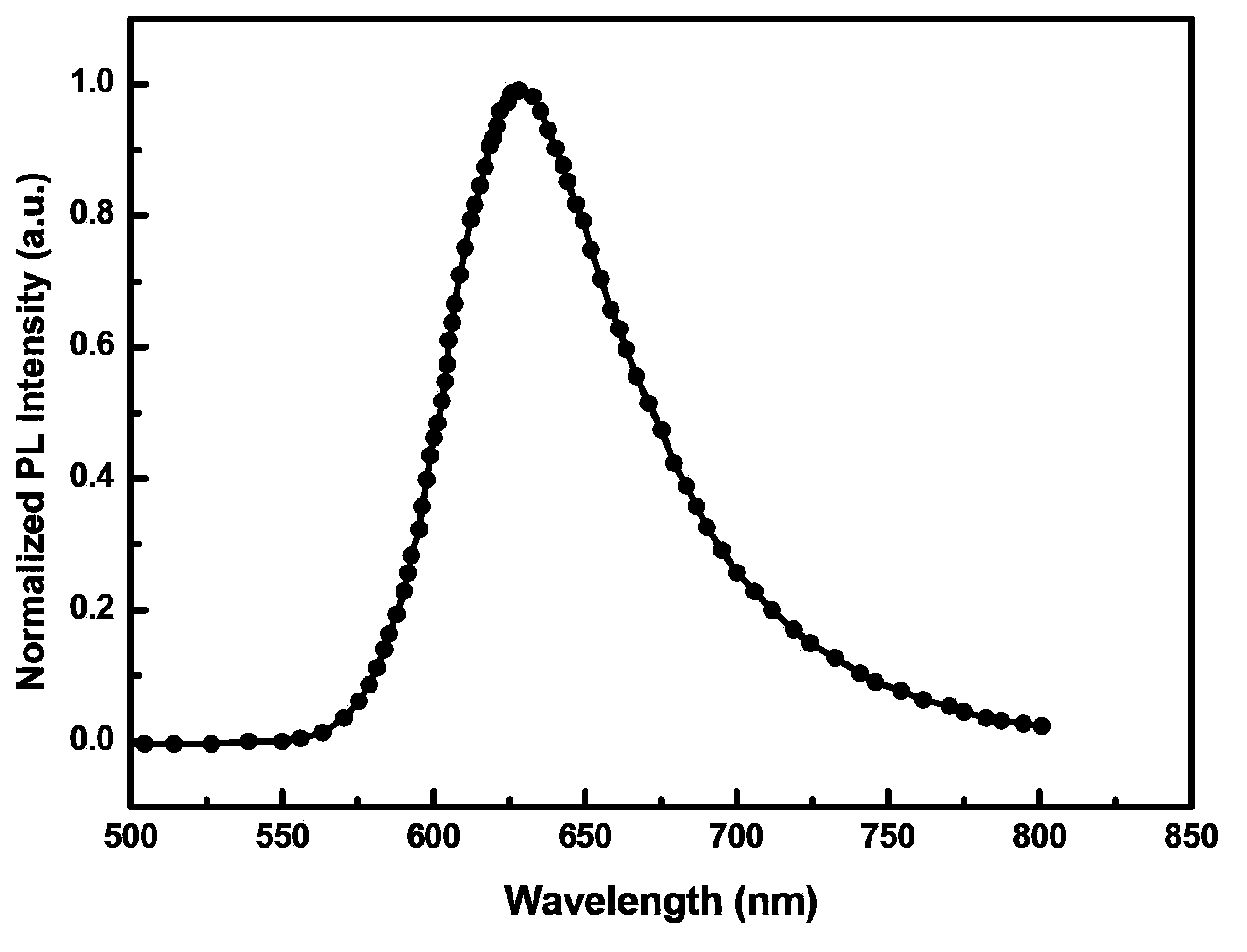

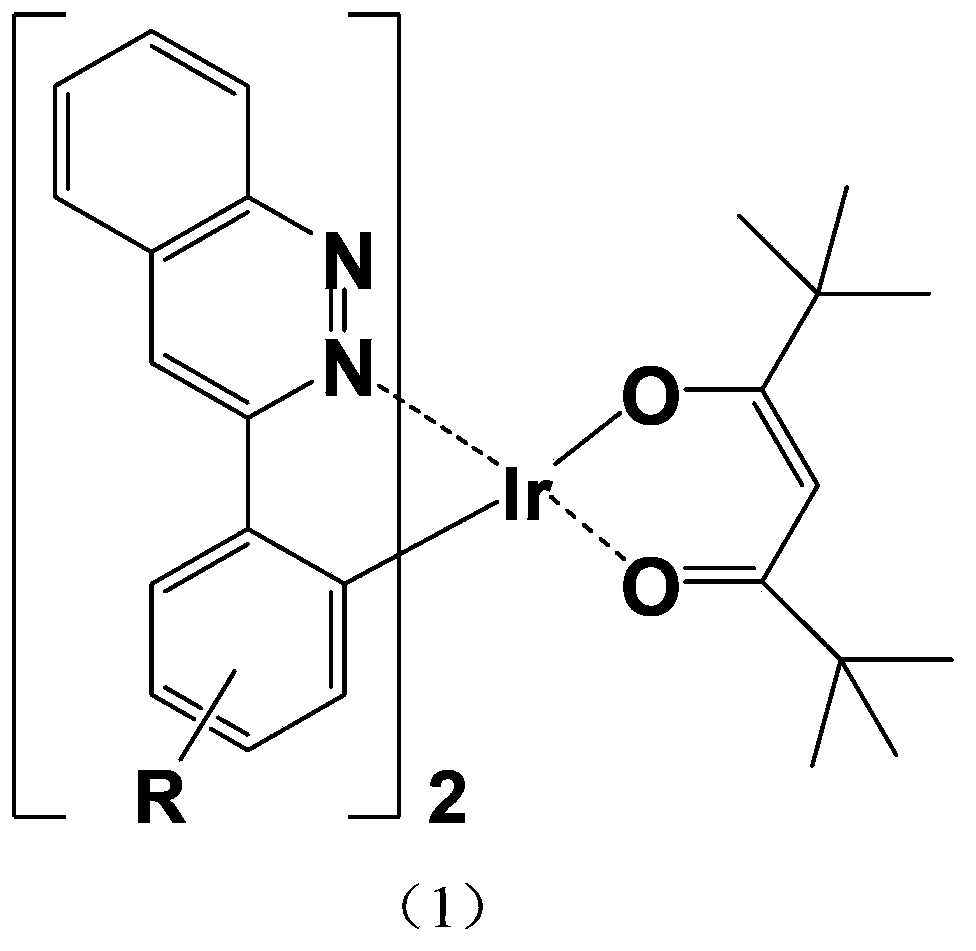

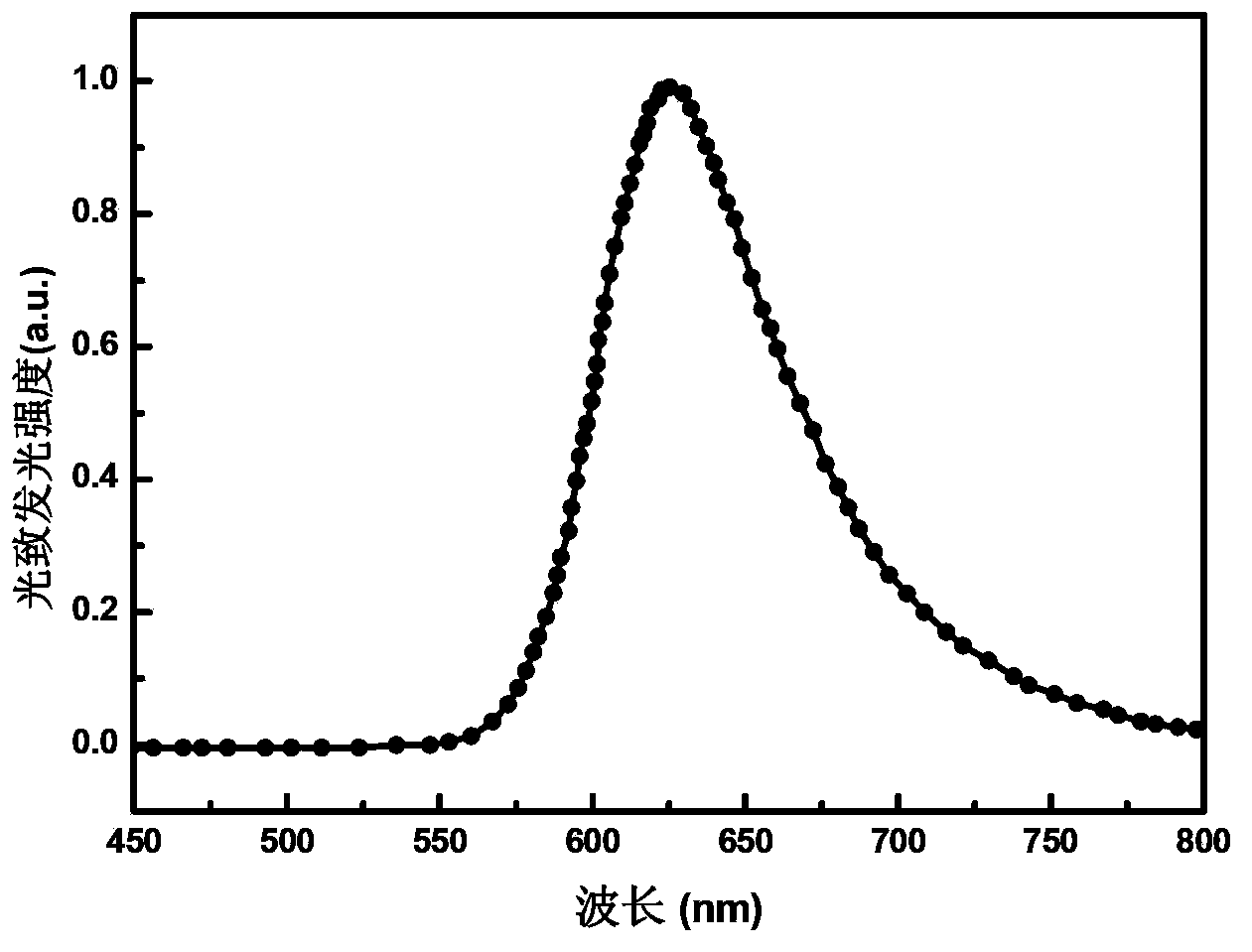

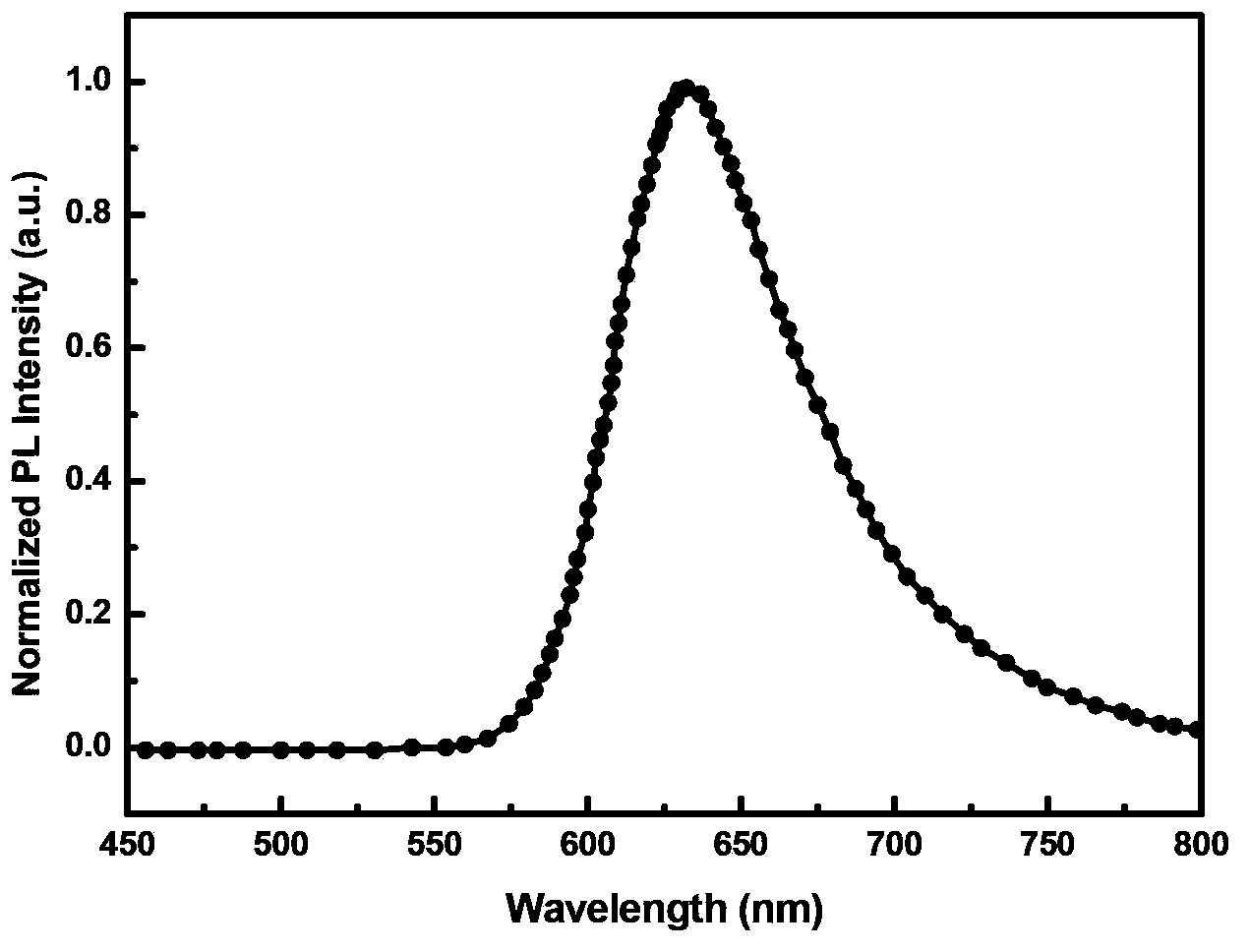

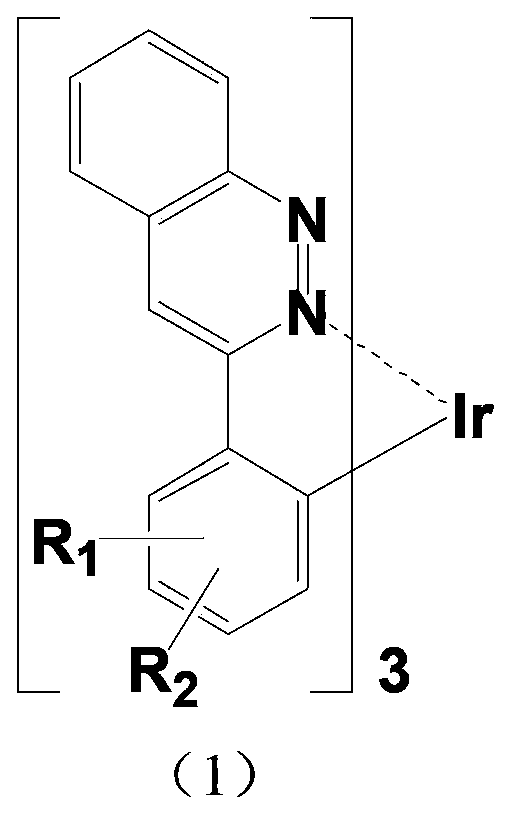

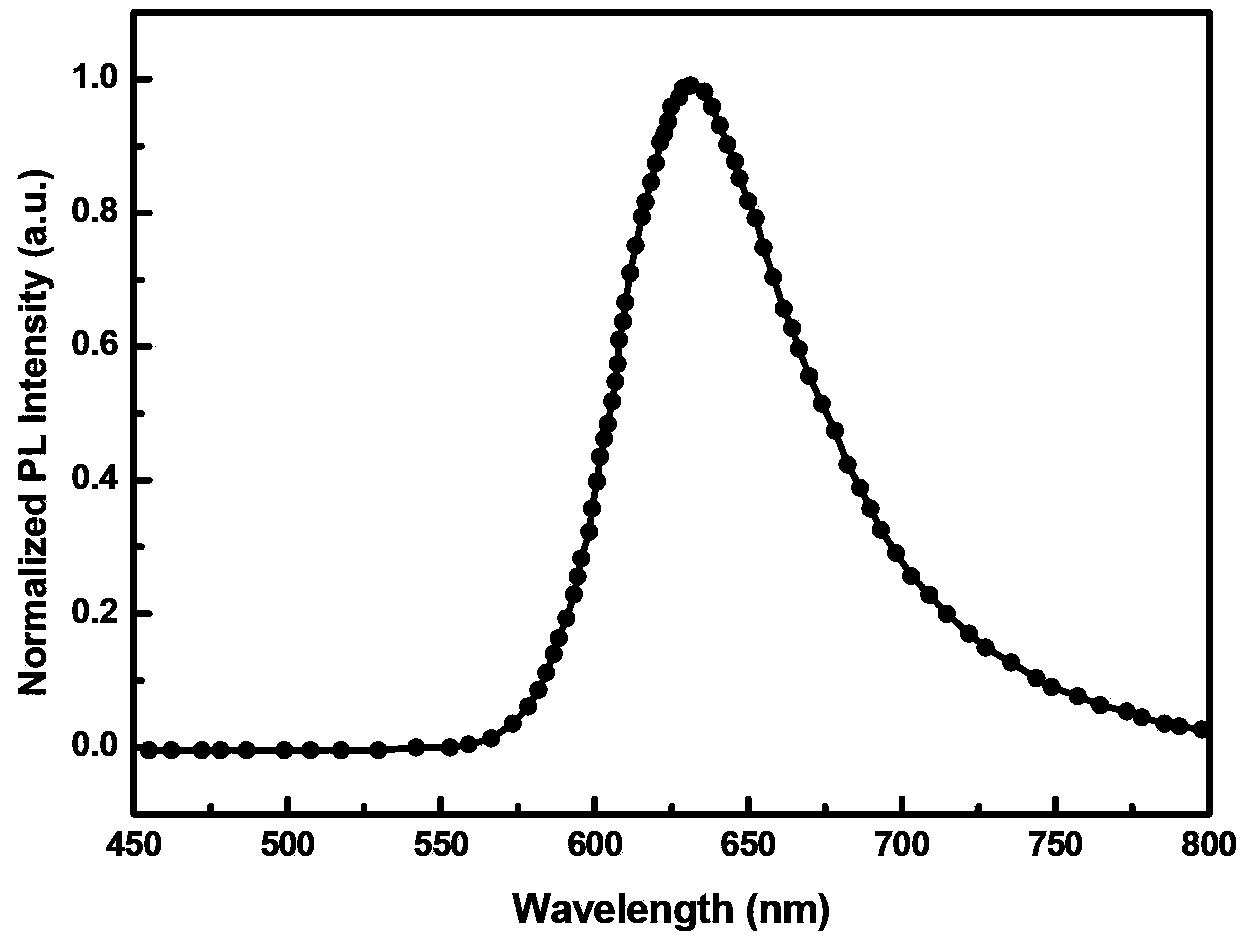

InactiveCN104140441AGood energy transfer efficiencyAppropriate red light emission wavelengthGroup 8/9/10/18 element organic compoundsSolid-state devicesIridiumGrignard reaction

The invention provides a red organic electrophosphorescent material iridium metal complex with the structure represented by formula (1). In the formula (1), R is a hydrogen atom or a C1-C4 straight chain or alkoxy group. The red organic electrophosphorescent material iridium metal complex is prepared through the following steps: carrying out a Grignard reaction on an iridium metal complex to prepare a compound C, carrying out dehydration cyclization on the compound C to obtain a cyclomedtalating ligand, carrying out a polymerization reaction on the cyclomedtalating ligand and chromium trichloride hexahydrate in a 2-ethoxyethanol and water mixed solvent to obtain a chlorendic dimer, and carrying out a complex reaction on the chlorendic dimer and acetylacetone to obtain the red organic electrophosphorescent material iridium metal complex represented by formula (1). The above material has good energy transmission efficiency and appropriate red light emitting wavelength, and can be widely used to make red or white phosphorescent electroluminescent devices in order to reduce the power consumption of the devices, improve the performances of the devices and prolong the life of the devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Red organic electrophosphorescent material iridium metal complex, preparation method thereof, and organic electroluminescent device

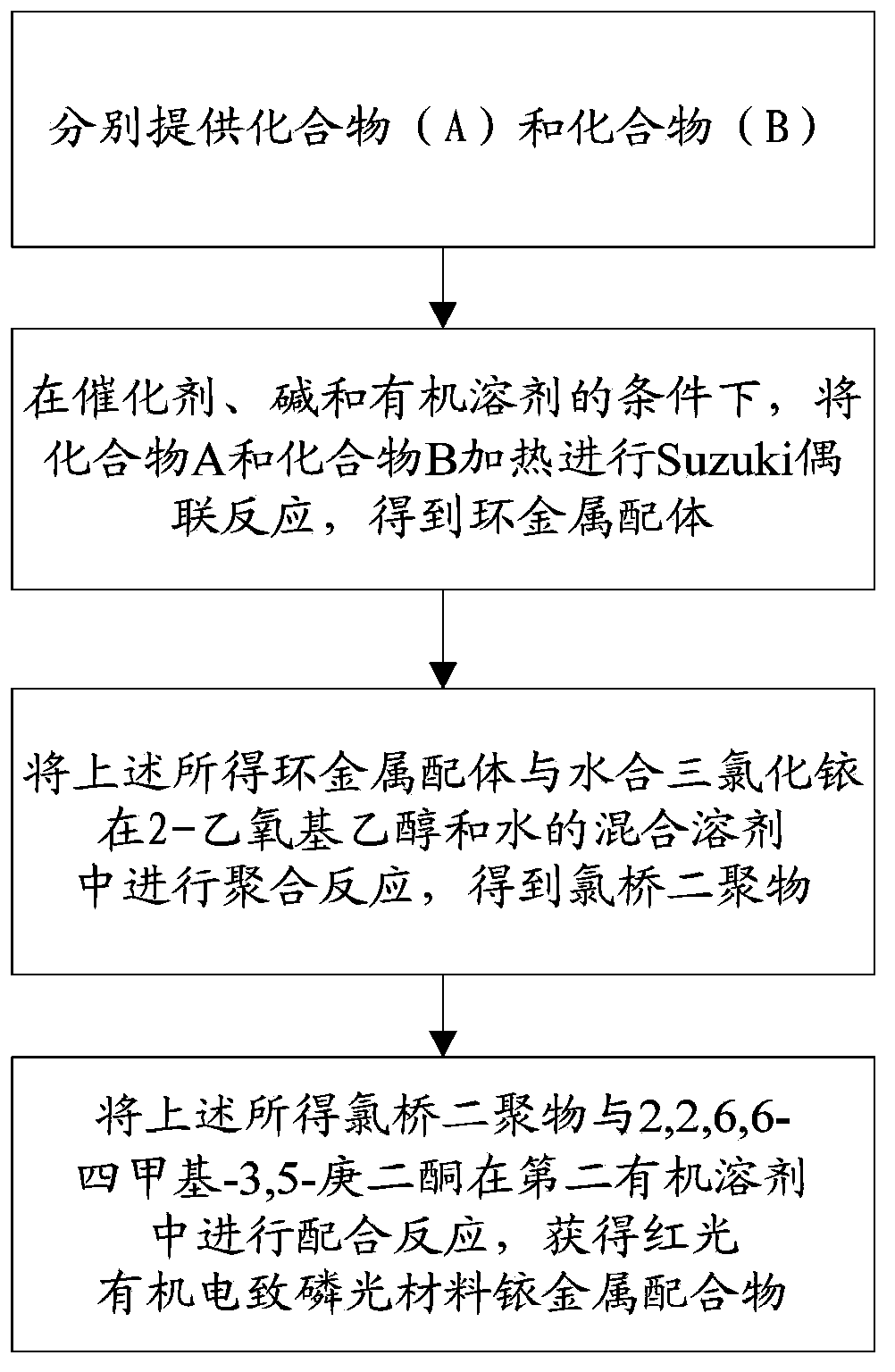

InactiveCN104140446AReduce direct effectReduce self-quenchingGroup 8/9/10/18 element organic compoundsSolid-state devicesIridiumWavelength

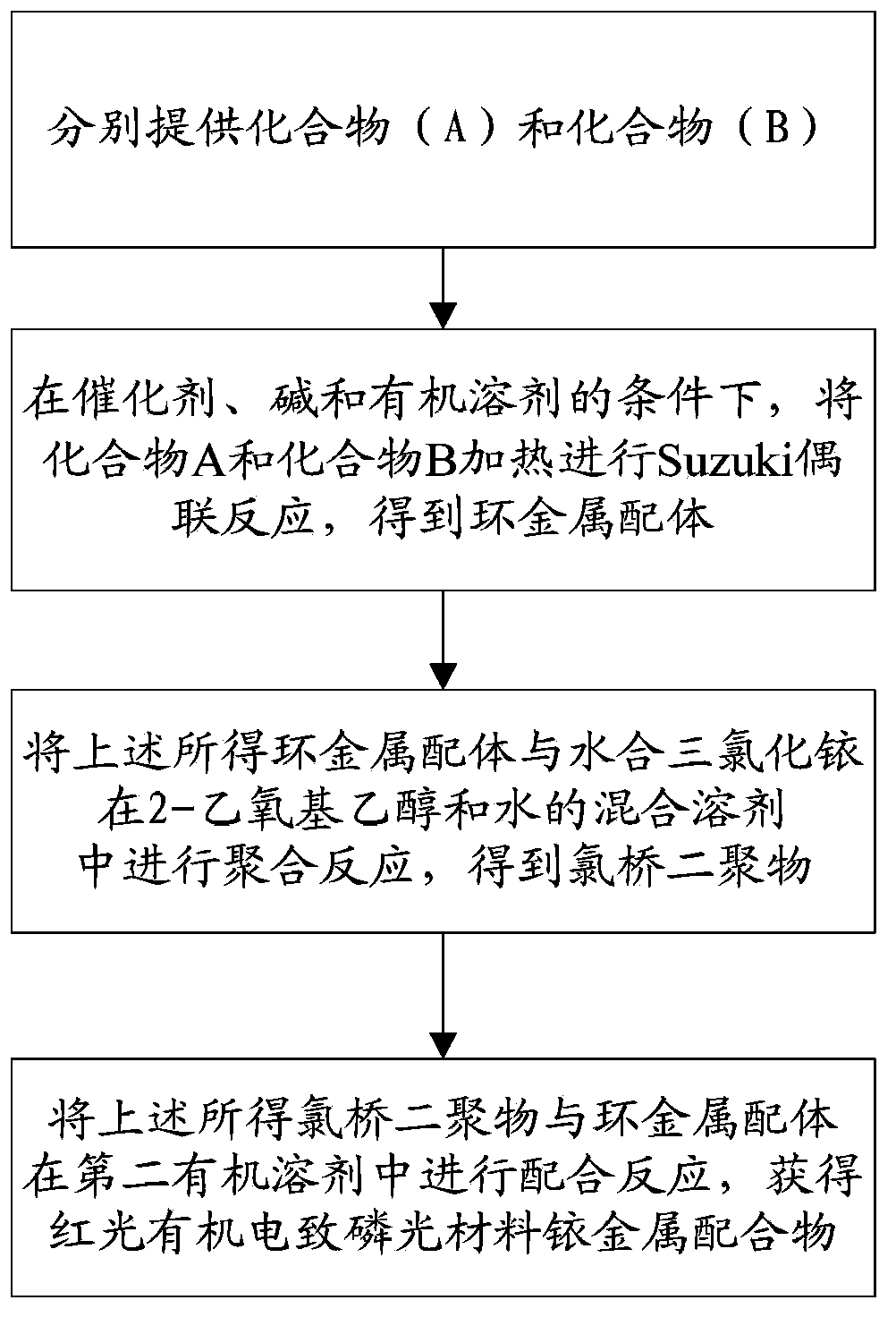

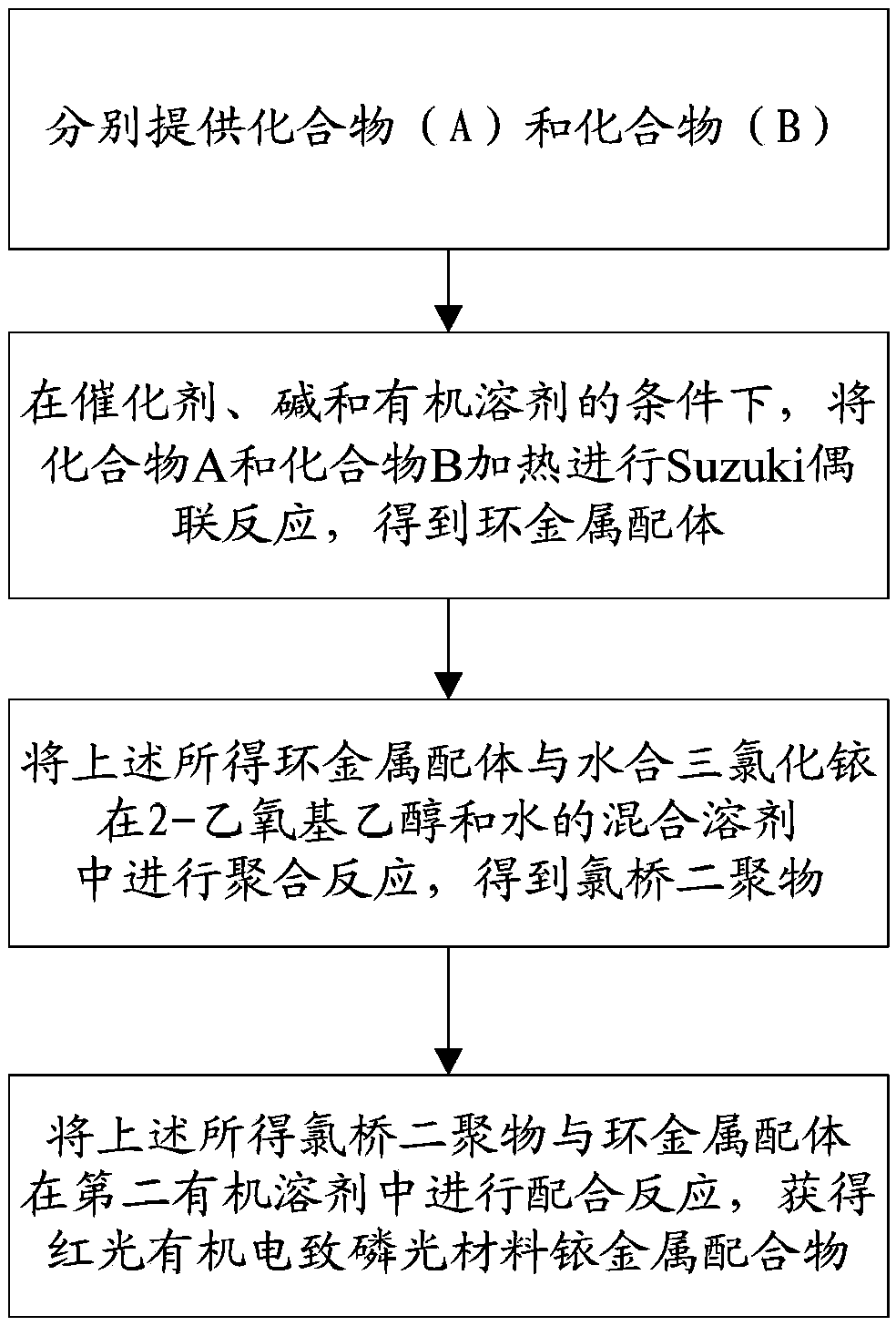

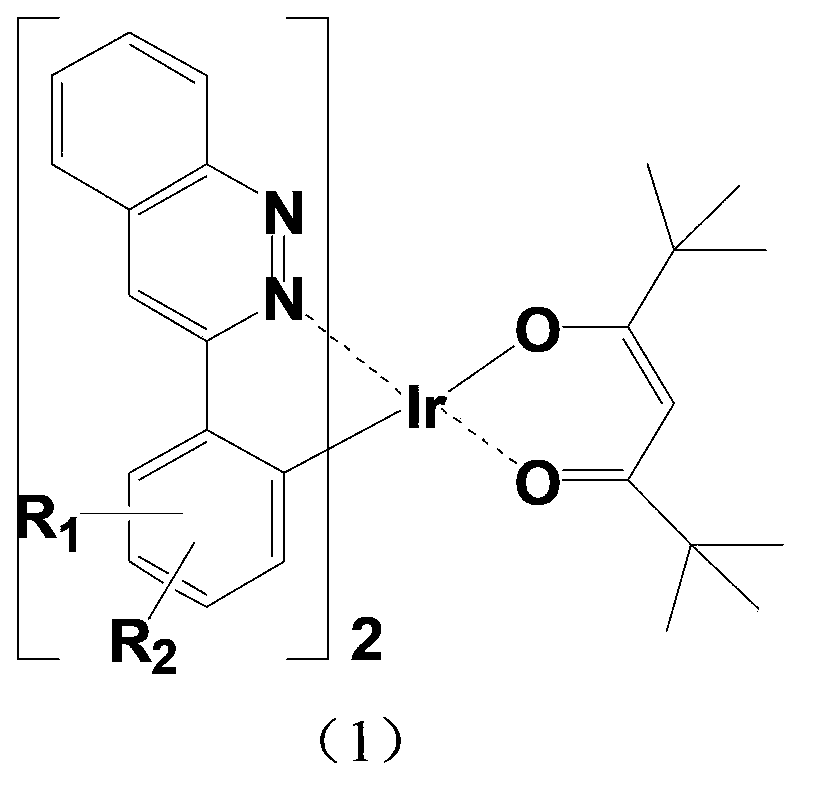

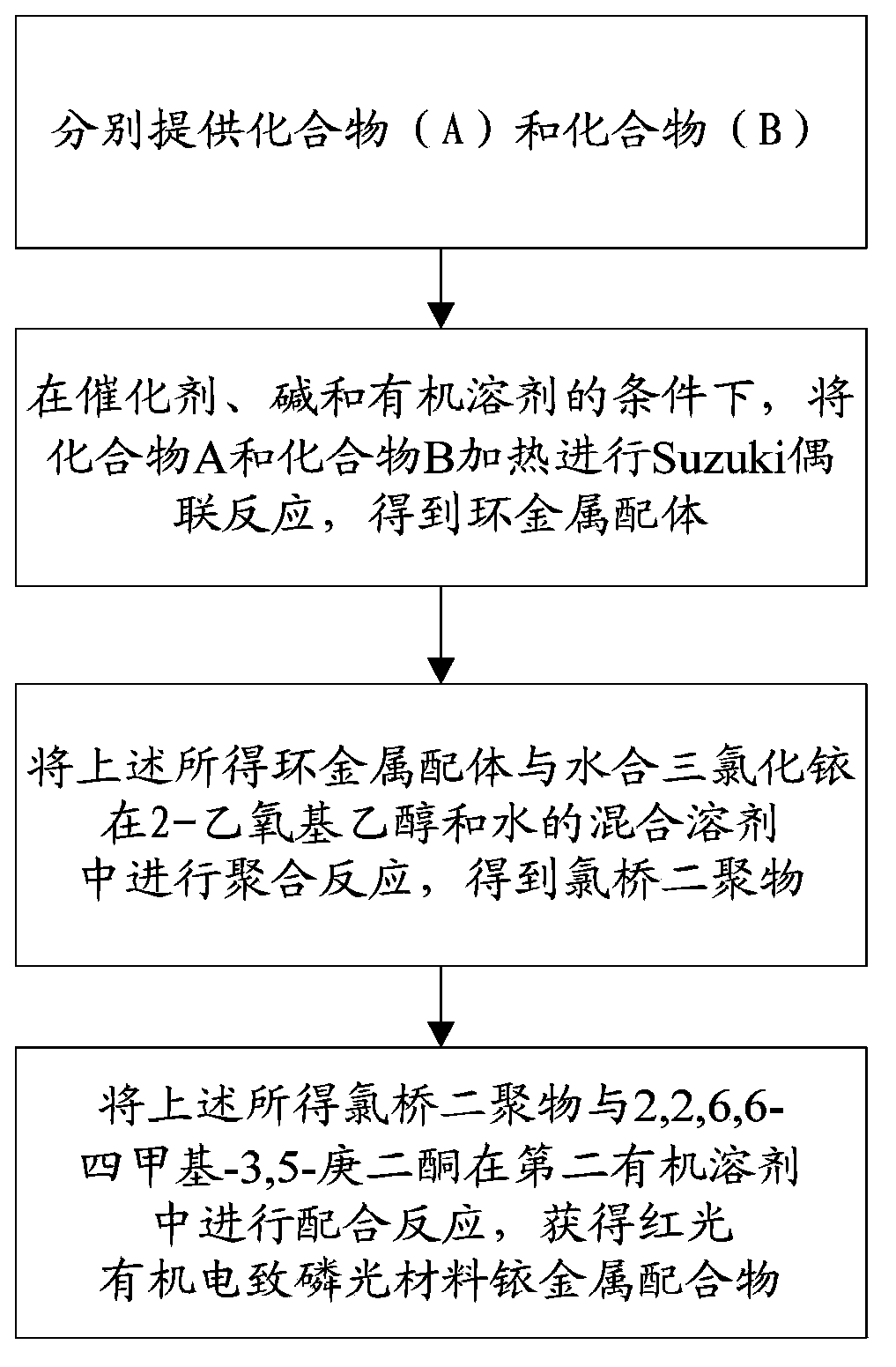

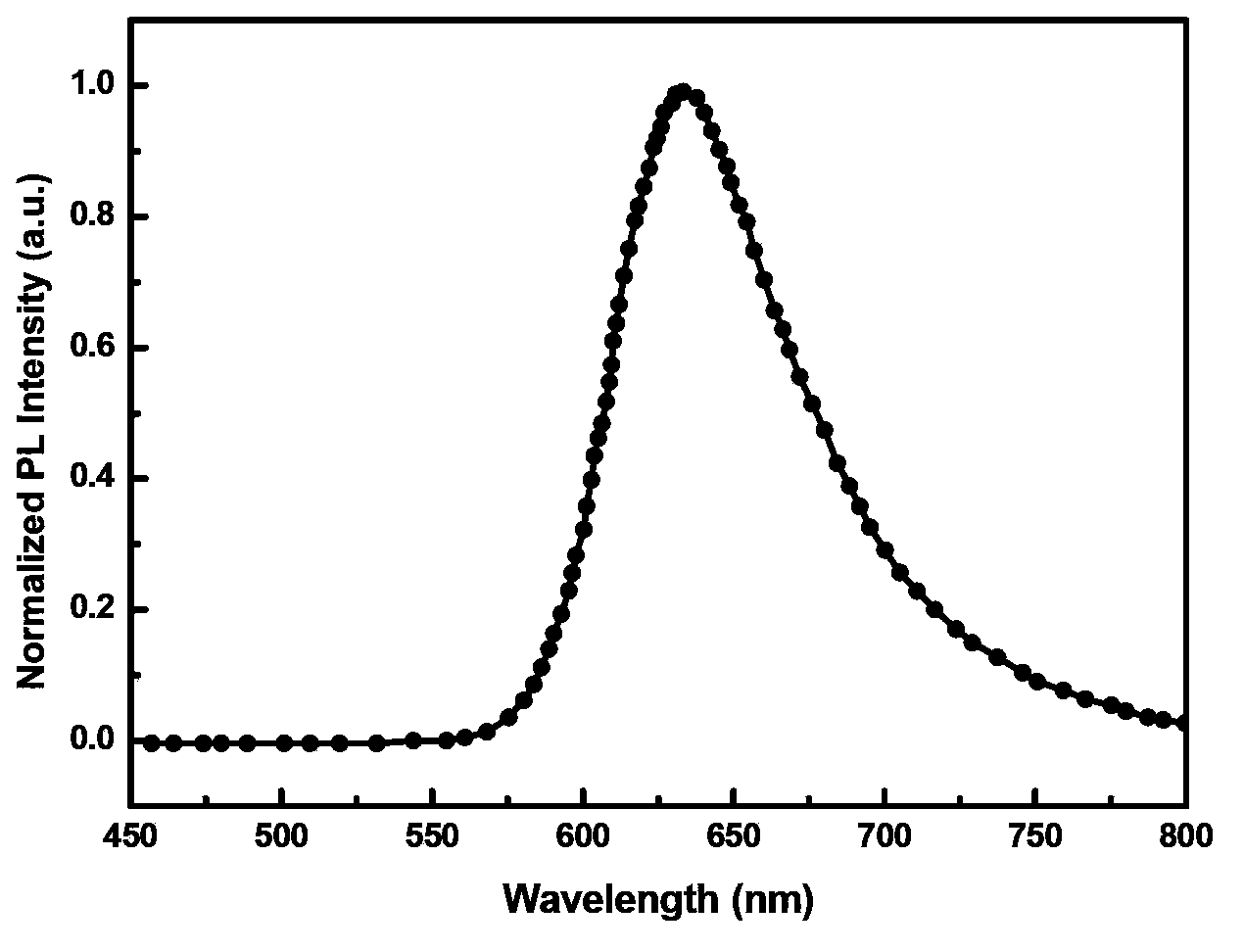

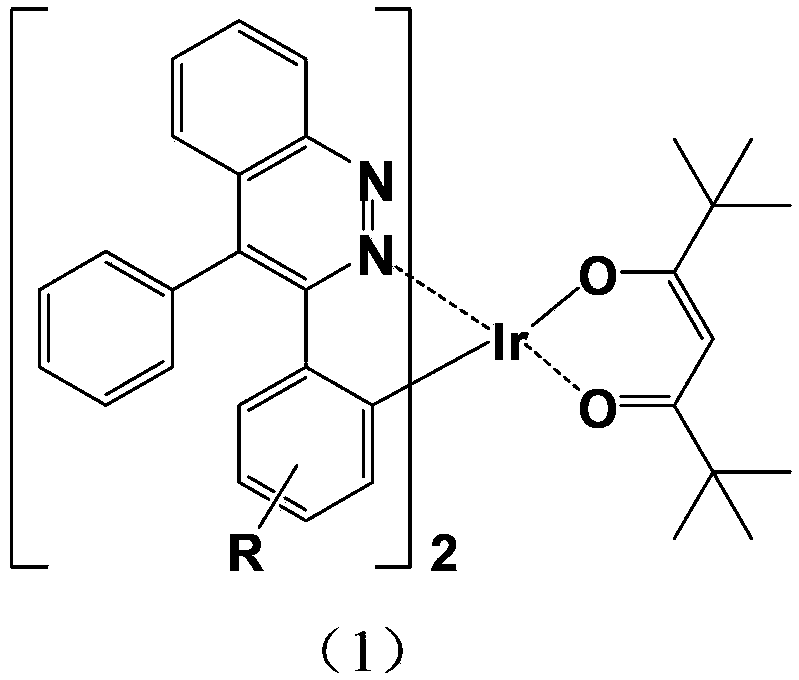

The invention provides a red organic electrophosphorescent material iridium metal complex with the structure represented by formula (1). In the formula (1), R is a hydrogen atom or a C1-C4 straight chain or alkoxy group. The red organic electrophosphorescent material iridium metal complex is prepared through the following steps: carrying out a Suzuki coupling reaction on an iridium metal complex to prepare a cyclomedtalating ligand, carrying out a polymerization reaction on the cyclomedtalating ligand and chromium trichloride hexahydrate in a 2-ethoxyethanol and water mixed solvent to obtain a chlorendic dimer, and carrying out a complex reaction on the chlorendic dimer and an auxiliary ligand 2,2,6,6-tetramethyl-3,5-heptanedione to obtain the red organic electrophosphorescent material iridium metal complex represented by formula (1). The above material has good energy transmission efficiency and appropriate red light emitting wavelength, and can be widely used to make red or white phosphorescent electroluminescent devices in order to reduce the power consumption of the devices, improve the performances of the devices and prolong the life of the devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Red organic electrophosphorescent material iridium metal complex, preparation method thereof, and organic electroluminescent device

InactiveCN104140440AGood energy transfer efficiencyAppropriate red light emission wavelengthGroup 8/9/10/18 element organic compoundsSolid-state devicesIridiumSolvent

The invention provides a red organic electrophosphorescent material iridium metal complex with the structure represented by formula (1). In the formula (1), R is a hydrogen atom or a C1-C4 straight chain or alkoxy group. The red organic electrophosphorescent material iridium metal complex is prepared through the following steps: carrying out a Suzuki coupling reaction on an iridium metal complex to prepare a cyclomedtalating ligand, carrying out a polymerization reaction on the cyclomedtalating ligand and chromium trichloride hexahydrate in a 2-ethoxyethanol and water mixed solvent to obtain a chlorendic dimer, and carrying out a complex reaction on the chlorendic dimer and an auxiliary ligand acetylacetone to obtain the red organic electrophosphorescent material iridium metal complex represented by formula (1). The above material has good energy transmission efficiency and appropriate red light emitting wavelength, and can be widely used to make red or white phosphorescent electroluminescent devices in order to reduce the power consumption of the devices, improve the performances of the devices and prolong the life of the devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

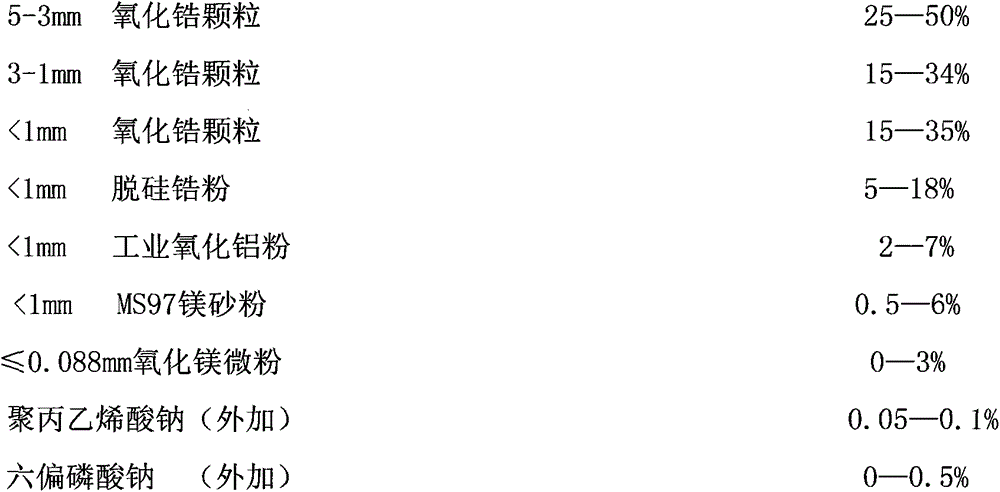

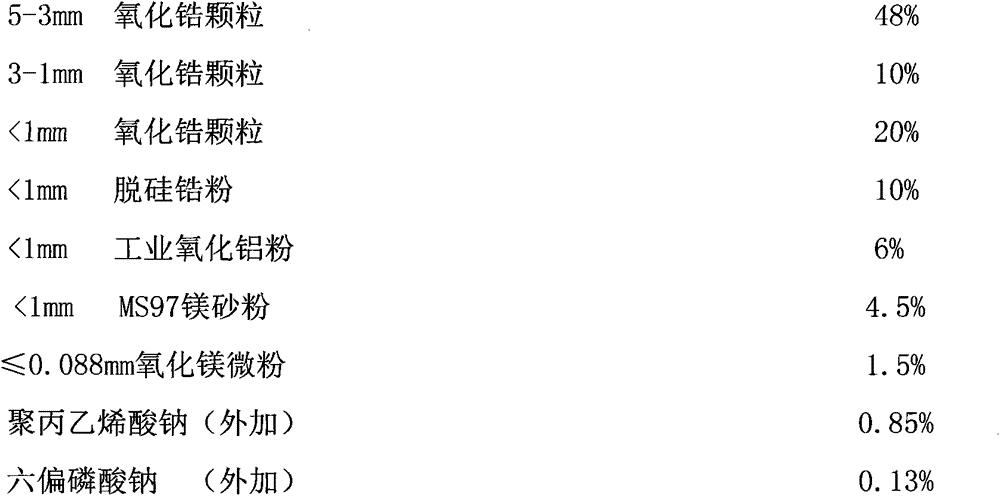

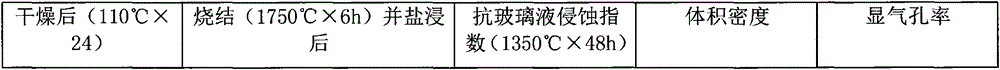

Compact anti-erosion reinforced sintered zirconium oxide big brick and production process thereof

ActiveCN105174975ASolve the problem of high recycling processing costsAchieve reuseBrickThermal insulation

The present invention relates to a compact anti-erosion reinforced sintered zirconium oxide big brick and a production process thereof, wherein the big brick comprises 25-50% of zirconium oxide with a particle size of 5-3 mm, 15-34% of zirconium oxide with a particle size of 3-1 mm, 15-35% of zirconium oxide with a particle size of less than 1 mm, 5-18% of desilication zirconium with a particle size of less than 1 mm, 2-7% of industrial alumina with a particle size of less than 1 mm, 0.5-6% of MS97 magnesia with a particle size of less than 1 mm, 0-3% of magnesium oxide with a particle size of less than or equal to 0.088 mm, 0.05-0.1% of additional sodium ethylene polypropylene, and less than or equal to 0.5% of additional sodium hexametaphosphate. The process comprises casting, sintering and brining, wherein the casting comprises material preparing, material mixing, vibration casting and drying, the drying time is 3-5 h, the sintering temperature is 1600-1650 DEG C, the sintering time is 60-80 h, the thermal insulation time is 4-8 h, and the brining comprises preparing chromic chloride hexahydrate into a 10-30% chromium salt solution, and immersing a brick into the salt solution under a vacuum environment 2-5 times. According to the present invention, the product with the large size and the specific shape can be produced, and the good glass liquid corrosion resistance is provided.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

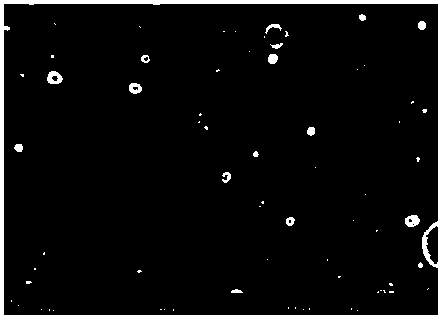

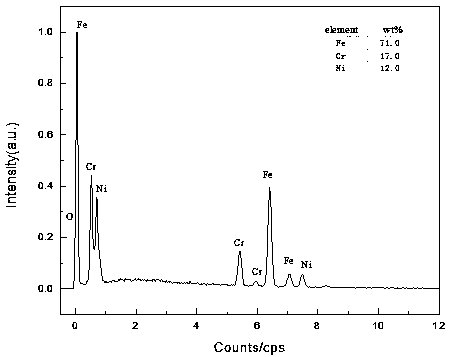

Electrodeposition preparation method of stainless steel coating by means of deep-eutectic solvent

The invention relates to an electrodeposition preparation method of a stainless steel coating by means of a deep-eutectic solvent and belongs to the technical field of surface engineering and surfacetreatment. The method comprises the steps that firstly, under an inert gas environment, quaternary ammonium salt and polyhydric alcohol are uniformly mixed to form the deep-eutectic solvent, then nickel dichloride hexahydrate, chromium trichloride hexahydrate and ferrous dichloride tetrahydrate are added into the deep-eutectic solvent, and deep-eutectic solvent electrolyte is obtained through preparation; and secondly, a chromium sheet or an inert electrode serves as an anode, a pretreated substrate serves as a cathode, under the conditions that the temperature of the deep-eutectic solvent electrolyte is controlled to be 50-80 DEG C, the bath voltage is controlled to be 0.6-1.2 V, and the distance between the anode and the cathode is controlled to be 1 cm, the anode and the cathode are subjected to electrodeposition for 30-90 min in the prepared deep-eutectic solvent electrolyte, the cathode substrate subjected to electrodeposition is flushed through acetone and distilled water and then dried, and then the coating containing the component of 304 or 316 stainless steel is obtained on the cathode substrate. The method aims at solving the problems that the existing stainless steel electroplating industry is low in current efficiency, and clean production is difficult to achieve.

Owner:KUNMING UNIV OF SCI & TECH

Red organic electrophosphorescent material iridium metal complex, preparation method thereof, and organic electroluminescent device

InactiveCN104140447AGood energy transfer efficiencyAppropriate red light emission wavelengthGroup 8/9/10/18 element organic compoundsSolid-state devicesSolventCoordination complex

The invention provides a red organic electrophosphorescent material iridium metal complex with the structure represented by formula (1). In the formula (1), R is a hydrogen atom or a C1-C4 straight chain or alkoxy group. The red organic electrophosphorescent material iridium metal complex is prepared through the following steps: carrying out a Suzuki coupling reaction on an iridium metal complex to prepare a cyclomedtalating ligand, carrying out a polymerization reaction on the cyclomedtalating ligand and chromium trichloride hexahydrate in a 2-ethoxyethanol and water mixed solvent to obtain a chlorendic dimer, and carrying out a complex reaction on the chlorendic dimer and the cyclomedtalating ligand to obtain the red organic electrophosphorescent material iridium metal complex represented by formula (1). The above material has good energy transmission efficiency and appropriate red light emitting wavelength, and can be widely used to make red or white phosphorescent electroluminescent devices in order to reduce the power consumption of the devices, improve the performances of the devices and prolong the life of the devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

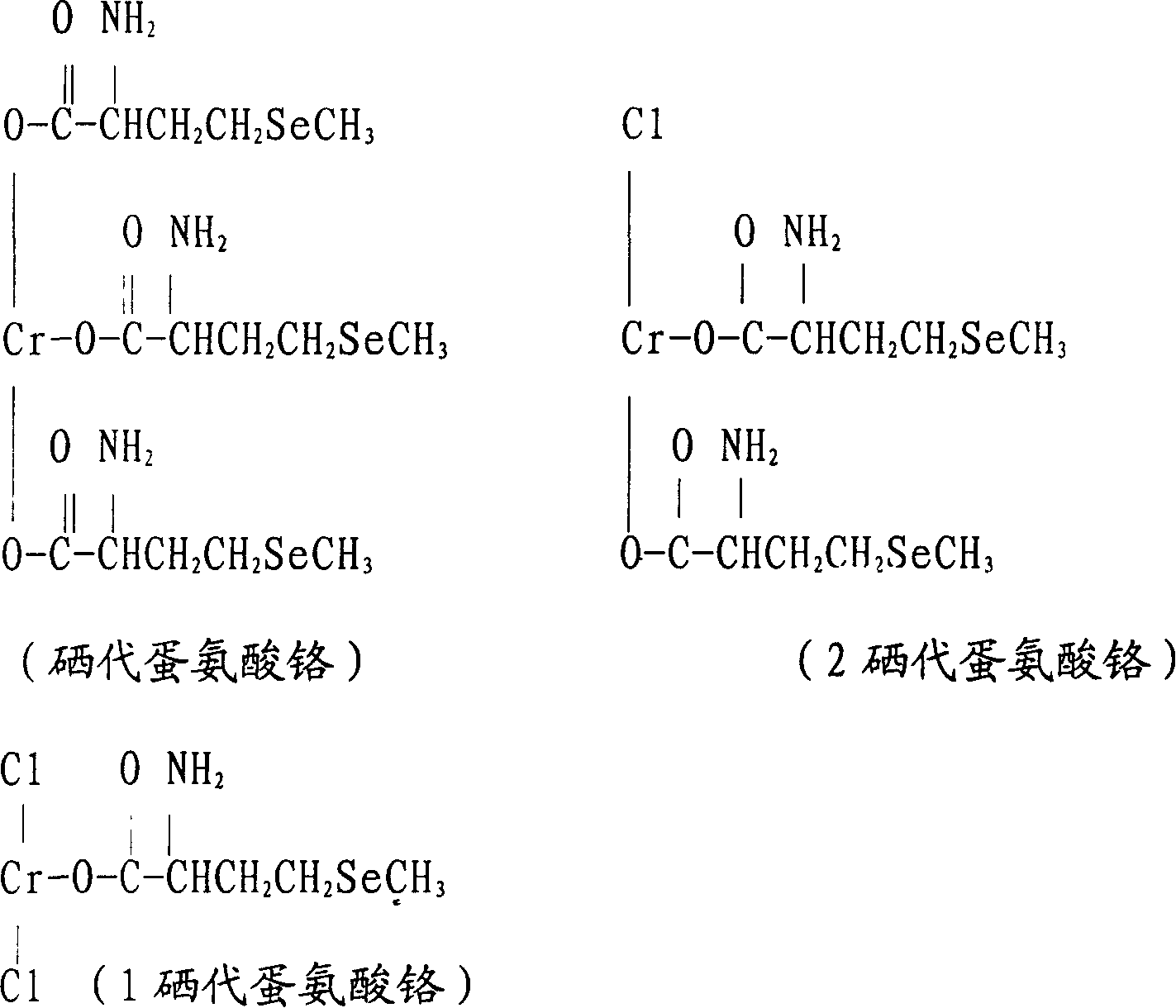

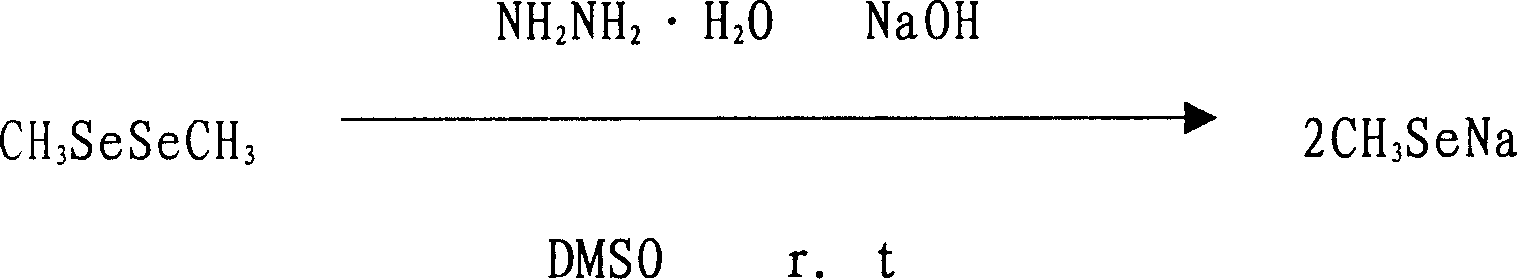

Hydantion method compolete preparation of chromium selenomethionine compounds (III) and its uses

The invention relates to a integrated method for preparing seleno chromium methionine (III) through hrdantoin and its application. The intermediate seleno acimetion with multiple biological activity and usage can be prepared with said method. The Cr3+ in chromium trichloride hexahydrate can produce three modifications of different construction with one to three acid molecules, which are named as I-seleno chromium methionine, II-seleno chromium methionine and seleno chromium methionine (containing three acid molecules). The difference in performance and effect of three modifications is favorable for controlling content and proportion of selenium and chromium in compound. The compound can be widely used in medicine, health care product, feed addictive and cosmetics, especially used to produce capsule, tablet and oral liquid prevent and treating diabetes.

Owner:董国臣

Trivalent chromium plating solution and electroplating method

The invention provides trivalent chromium plating solution and a plating method. The plating solution consists of compositions according to the following mass ratio: the ratio of C5H14ClNO to chromium (III) chloride hexahydrate equals to between 1 to 0.95 and 5.73. The method comprises the following steps: cathode which is subjected to grinding, polishing, soaking, cleaning and drying is inserted into plating solution with the temperature of between 40 and 80 DEG C; applying current with current density of between 0.0005 and 0.005 ampere / centimeter<2> to the plating solution; plating the cathode for 1 to 8 hours; taking out the cathode, and removing the plating solution by cleaning solution to obtain the trivalent chromium plated product. The plating solution uses the C5H14ClNO and the chromium(III) chloride hexahydrate as raw materials, has the advantages of low toxicity, environmental protection, good thermal and chemical stability, high conductivity, simple synthesis, convenient use, reduction of hydrogen evolution compared with the prior aqueous solution chromium plating, and the improvement on current efficiency.

Owner:KUNMING UNIV OF SCI & TECH

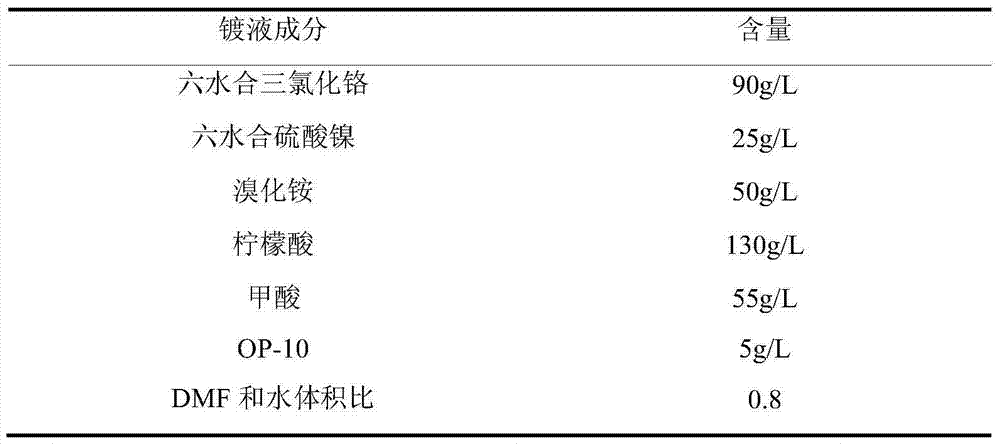

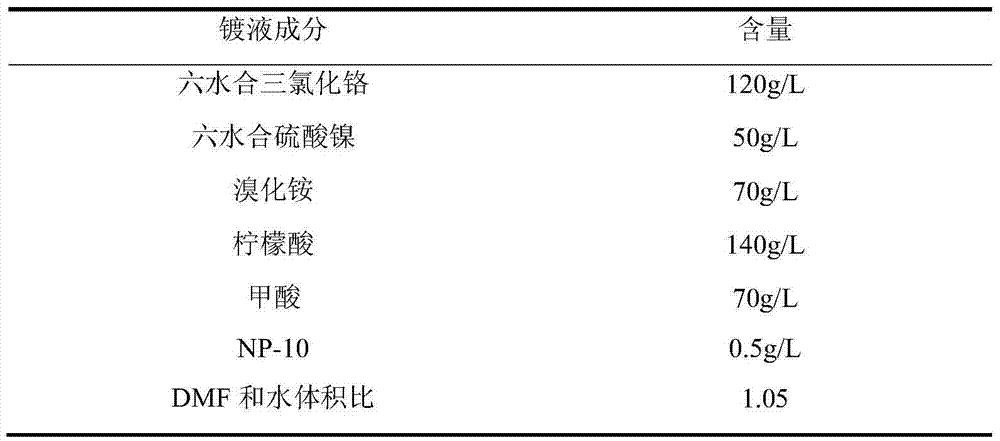

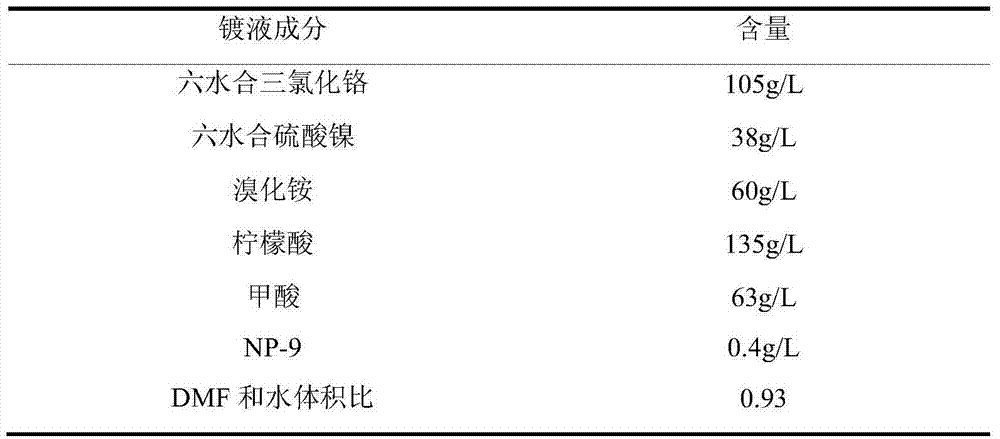

Chromium-nickel alloy electroplating solution and electroplating method

The invention discloses a chromium-nickel alloy electroplating solution and an electroplating method. The chromium-nickel alloy electroplating solution includes: 90-120g / L chromium chloride hexahydrate, 25-50g / L nickel sulfate hexahydrate, 50-70g / L ammonium bromide, 130-140g / L citric acid, 55-70g / L formic acid, 0.3-0.5g / L an emulsifier and the balance a solvent. The solvent is a mixed solution of DMF and water in a volume ratio of (0.8-1.05):1. The chromium-nickel alloy electroplating solution provided by the invention adopts the mixed solution of DMF and water as the solvent of the electroplating solution, citric acid and formic acid are taken as the compound complexing agent, citric acid and formic acid are selected as the buffering agent to replace boric acid, thus simplifying the formula, enhancing the hardness and corrosion resistance of the coating, and improving the dispersion ability and deep plating ability of the electroplating solution.

Owner:WUXI HUAYE IRON & STEEL

Method for preparing color hollow glass bead insulation coating through using chemical coating technology

InactiveCN107903694AExcellent reflectanceImprove the problem of unsatisfactory dispersion performanceReflecting/signal paintsLight reflectionChromium trichloride hexahydrate

The invention discloses a method for preparing a color hollow glass bead insulation coating through using a chemical coating technology. A chromium trichloride hexahydrate solution is hydrolyzed to generate a chromic oxide crystal, and the chromic oxide crystal precipitates and coats the surface of a hollow glass bead. The concentration of the chromium trichloride hexahydrate solution is reasonably controlled in the hydrolysis process to make the hollow glass bead uniformly coated with a chromic oxide film, so the dispersibility is obviously improved, the color hollow glass bead has a good heat conduction coefficient; and the greenness of the chromic oxide is introduced, so the color hollow glass bead has a high reflectivity on lights in 500-550 nm and 780-2300 nm wavebands, and remarkablyimproves the light reflection effect. The method improves the problem of unsatisfactory dispersibility of the hollow glass bead in an aqueous coating, introduces the color to the hollow glass bead, makes the hollow glass bead have the ability to become a colorizing functional pigment filler, and provides a new preparation technology for the preparation of a color composite exterior wall heat insulation coating.

Owner:安徽铭能保温科技有限公司

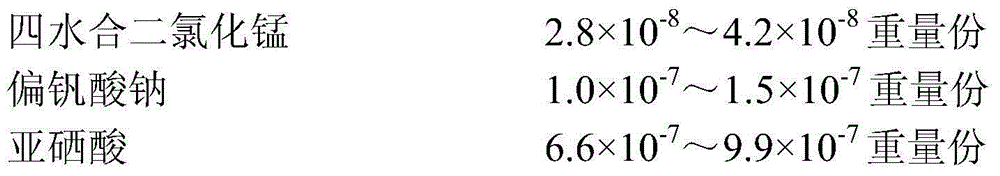

An animal cell culture medium, a preparing method thereof and applications of the culture medium

InactiveCN106032526AThe composition is simple and clearEasy to getVertebrate cellsArtificial cell constructsLithium chlorideCell culture media

An animal cell culture medium, a preparing method thereof and applications of the culture medium are provided. The culture medium comprises 150-230 parts by weight of amino acids or salts thereof, 180-280 parts by weight of carbohydrates, 160-260 parts by weight of inorganic salts, 1-2 parts by weight of vitamins and 0.002-0.003 part by weight of trace elements. The trace elements comprise manganese chloride tetrahydrate, sodium metavanadate, selenious acid, germanium dioxide, potassium bromide, chromium chloride hexahydrate, ammonium metavanadate, rubidium chloride, cadmium chloride, cobalt chloride hexahydrate, barium acetate, zirconyl chloride octahydrate, sodium fluoride, ammonium molybdate tetrahydrate, copper chloride dihydrate, lithium chloride and aluminium chloride hexahydrate. The culture medium is simple and definite in components, convenient to prepare and use, stable in quality, and low in batch differences, and can be particularly used for culturing a plurality of animal cells. Cell growth states are good and stable.

Owner:中生天信和(无锡)生物科技有限公司

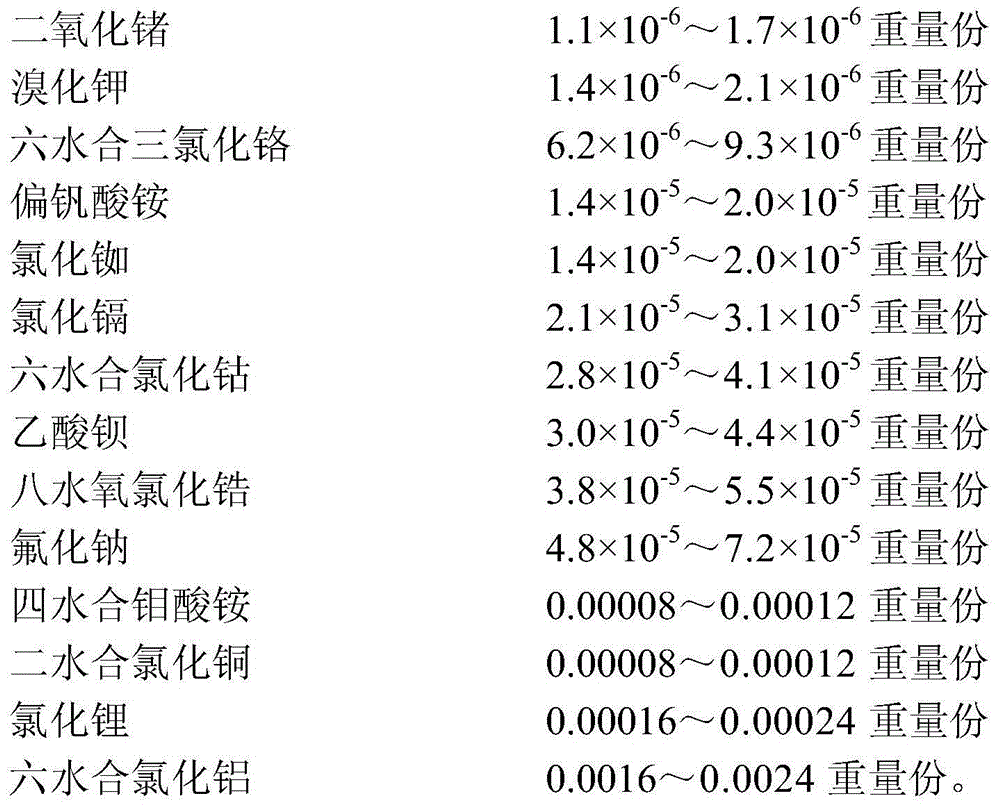

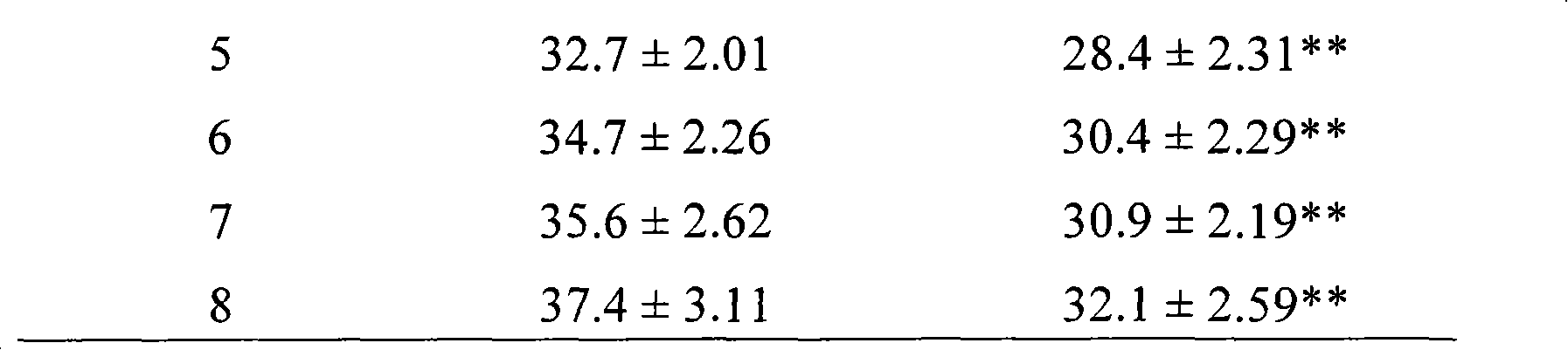

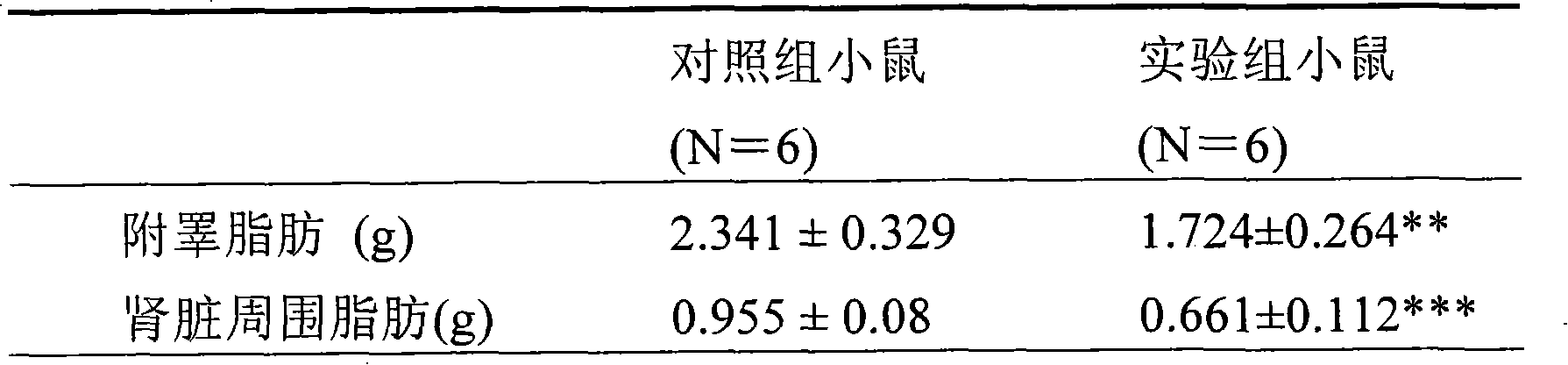

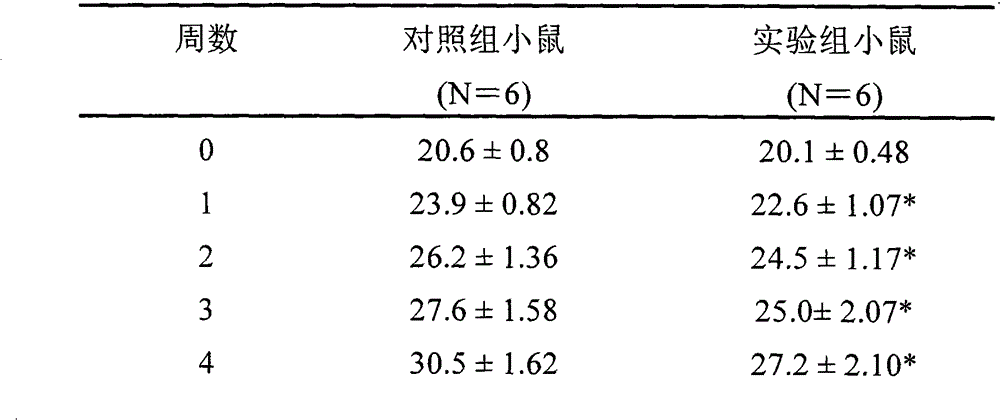

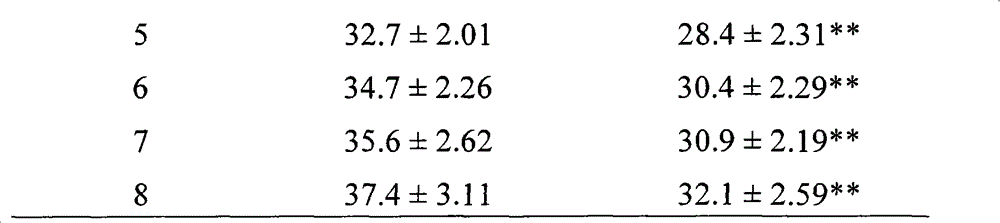

Component for reducing body fat formation and application thereof

ActiveCN101632832AImprove hyperleptinemiaReduce storageMilk preparationHeavy metal active ingredientsChromium CompoundsChromium trichloride hexahydrate

The invention relates to a component for reducing body fat formation and application thereof. The component comprises lactoferrin and a trivalent chromium compound, wherein the trivalent chromium compound is selected from a group consisting of free chromium trichloride hexahydrate, chromium trichloride, chromium acetate, chromium sulphate, chromium picolinate, chromium nicotinate, chromium glucose tolerance factor, chromium yeast, other inorganic trivalent chromiums, other organic trivalent chromiums as well as compositions of the compounds. The component of the invention can be transferred into muscular tissues by glucoses in helper cells to be used and can reduce the transformation of the glucoses into fats for storage, thereby realizing the control of weight.

Owner:MAXLUCK BIOTECH CORP

Decorative chromium plating process for imitating stainless steel color

The invention relates to the technical field of chromium plating processing, and particularly discloses a stainless steel color-imitating decorative chromium plating process which comprises the following steps: S1, shielding parts except a to-be-chromium-plated area of an electroplated part, and carrying out wax removal, oil removal and water washing on the to-be-chromium-plated area of the electroplated part; s2, the electroplated part is put into a trivalent chromium electroplating solution to be electroplated; and S3, washing and drying the electroplated part, and then carrying out heat treatment to obtain a product, the trivalent chromium electroplating solution takes water as a solvent, and the trivalent chromium electroplating solution comprises the following solutes in terms of solute: chromium trichloride hexahydrate, an amphoteric pyridinium salt ligand, ethylenediaminetetraacetic acid, malic acid, conducting salt, a buffering agent, a wetting agent, N, N-dimethylformamide, diphenylcarbazide and ferric trichloride. A product obtained through the decorative chromium plating process is free of rime fog, yellowing and dark fringes in appearance, high in chromium electrodeposition rate, high in chromium layer thickness and high in chromium layer hardness, and the market requirement is met.

Owner:厦门市金宝源实业有限公司

Red organic electrophosphorescent material iridium metal complex, preparation method thereof, and organic electroluminescent device

InactiveCN104140443AGood energy transfer efficiencyAppropriate red light emission wavelengthGroup 8/9/10/18 element organic compoundsSolid-state devicesIridiumSolvent

The invention provides a red organic electrophosphorescent material iridium metal complex with the structure represented by formula (1). In the formula (1), each of R1 and R2 is a methyl group. The red organic electrophosphorescent material iridium metal complex is prepared through the following steps: carrying out a Suzuki coupling reaction on an iridium metal complex to prepare a cyclomedtalating ligand, carrying out a polymerization reaction on the cyclomedtalating ligand and chromium trichloride hexahydrate in a 2-ethoxyethanol and water mixed solvent to obtain a chlorendic dimer, and carrying out a complex reaction on the chlorendic dimer and an auxiliary ligand acetylacetone to obtain the red organic electrophosphorescent material iridium metal complex represented by formula (1). The above material has good energy transmission efficiency and appropriate red light emitting wavelength, and can be widely used to make red or white phosphorescent electroluminescent devices in order to reduce the power consumption of the devices, improve the performances of the devices and prolong the life of the devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Red organic electrophosphorescent material iridium metal complex, preparation method thereof, and organic electroluminescent device

InactiveCN104140807AGood energy transfer efficiencyAppropriate red light emission wavelengthGroup 8/9/10/18 element organic compoundsSolid-state devicesIridiumSolvent

The invention provides a red organic electrophosphorescent material iridium metal complex with the structure represented by formula (1). In the formula (1), each of R1 and R2 is a methyl group. The red organic electrophosphorescent material iridium metal complex is prepared through the following steps: carrying out a Suzuki coupling reaction on an iridium metal complex to prepare a cyclomedtalating ligand, carrying out a polymerization reaction on the cyclomedtalating ligand and chromium trichloride hexahydrate in a 2-ethoxyethanol and water mixed solvent to obtain a chlorendic dimer, and carrying out a complex reaction on the chlorendic dimer and the cyclomedtalating ligand to obtain the red organic electrophosphorescent material iridium metal complex represented by formula (1). The above material has good energy transmission efficiency and appropriate red light emitting wavelength, and can be widely used to make red or white phosphorescent electroluminescent devices in order to reduce the power consumption of the devices, improve the performances of the devices and prolong the life of the devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Red organic electrophosphorescent material iridium metal complex, preparation method thereof, and organic electroluminescent device

InactiveCN104140439AReduce direct effectReduce self-quenchingGroup 8/9/10/18 element organic compoundsSolid-state devicesIridiumSolvent

The invention provides a red organic electrophosphorescent material iridium metal complex with the structure represented by formula (1). In the formula (1), each of R1 and R2 is a methyl group. The red organic electrophosphorescent material iridium metal complex is prepared through the following steps: carrying out a Suzuki coupling reaction on an iridium metal complex to prepare a cyclomedtalating ligand, carrying out a polymerization reaction on the cyclomedtalating ligand and chromium trichloride hexahydrate in a 2-ethoxyethanol and water mixed solvent to obtain a chlorendic dimer, and carrying out a complex reaction on the chlorendic dimer and an auxiliary ligand 2,2,6,6-tetramethyl-3,5-heptanedione to obtain the red organic electrophosphorescent material iridium metal complex represented by formula (1). The above material has good energy transmission efficiency and appropriate red light emitting wavelength, and can be widely used to make red or white phosphorescent electroluminescent devices in order to reduce the power consumption of the devices, improve the performances of the devices and prolong the life of the devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Preparation process of green pigment capable of reflecting infrared rays and heat-insulating paint

ActiveCN104910673BImprove performanceAdequate responsePolyester coatingsPigment physical treatmentInfraredThermal insulation

The invention discloses a preparation method of a green pigment capable of reflecting infrared ray, and a thermal-insulation paint. According to the preparation method, chromium chloride hexahydrate, and aluminium sulfate octadecahydrate are dissolved in water, and then are uniformly mixed with titanium dioxide and molybdenum trioxide; ammonium hydroxide is added dropwise into an obtained mixture; an obtained mixed material is subjected to ultrasonic wave treatment and stirring dispersion so as to obtain a mixed colloidal coprecipitation containing a composite doping component; the mixed colloidal coprecipitation containing the composite doping component is subjected to precipitation grinding, is subjected to sintering for 2 to 3h at 1000 to 1050 DEG C, is cooled, and then is delivered into a ball mill so as to obtain a powder via grinding. The green pigment possesses excellent infrared reflection performance, and can be added into paint so as to prepare thermal insulation coating products.

Owner:YANGZHOUSRKLE INDAL

Red organic electrophosphorescent material iridium metal complex, preparation method thereof, and organic electroluminescent device

InactiveCN104140442AGood energy transfer efficiencyAppropriate red light emission wavelengthGroup 8/9/10/18 element organic compoundsSolid-state devicesIridiumGrignard reaction

The invention provides a red organic electrophosphorescent material iridium metal complex with the structure represented by formula (1). In the formula (1), R is a hydrogen atom or a C1-C4 straight chain or alkoxy group. The red organic electrophosphorescent material iridium metal complex is prepared through the following steps: carrying out a Grignard reaction on an iridium metal complex to prepare a compound C, carrying out dehydration cyclization on the compound C to obtain a cyclomedtalating ligand, carrying out a polymerization reaction on the cyclomedtalating ligand and chromium trichloride hexahydrate in a 2-ethoxyethanol and water mixed solvent to obtain a chlorendic dimer, and carrying out a complex reaction on the chlorendic dimer and an auxiliary ligand 2,2,6,6-tetramethyl-3,5-heptanedione to obtain the red organic electrophosphorescent material iridium metal complex represented by formula (1). The above material has good energy transmission efficiency and appropriate red light emitting wavelength, and can be widely used to make red or white phosphorescent electroluminescent devices in order to reduce the power consumption of the devices, improve the performances of the devices and prolong the life of the devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Red organic electrophosphorescent material iridium metal complex, preparation method thereof, and organic electroluminescent device

InactiveCN104140444AGood energy transfer efficiencyAppropriate red light emission wavelengthGroup 8/9/10/18 element organic compoundsSolid-state devicesIridiumGrignard reaction

The invention provides a red organic electrophosphorescent material iridium metal complex with the structure represented by formula (1). In the formula (1), each of R1 and R2 is a methyl group. The red organic electrophosphorescent material iridium metal complex is prepared through the following steps: carrying out a Grignard reaction on an iridium metal complex to prepare a compound C, carrying out dehydration cyclization on the compound C to obtain a cyclomedtalating ligand, carrying out a polymerization reaction on the cyclomedtalating ligand and chromium trichloride hexahydrate in a 2-ethoxyethanol and water mixed solvent to obtain a chlorendic dimer, and carrying out a complex reaction on the chlorendic dimer and 2,2,6,6-tetramethyl-3,5-heptanedione to obtain the red organic electrophosphorescent material iridium metal complex represented by formula (1). The above material has good energy transmission efficiency and appropriate red light emitting wavelength, and can be widely used to make red or white phosphorescent electroluminescent devices in order to reduce the power consumption of the devices, improve the performances of the devices and prolong the life of the devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Red organic electrophosphorescent material iridium metal complex, preparation method thereof, and organic electroluminescent device

InactiveCN104140448AGood energy transfer efficiencyAppropriate red light emission wavelengthGroup 8/9/10/18 element organic compoundsSolid-state devicesIridiumGrignard reaction

The invention provides a red organic electrophosphorescent material iridium metal complex with the structure represented by formula (1). In the formula (1), R is a hydrogen atom or a C1-C4 straight chain or alkoxy group. The red organic electrophosphorescent material iridium metal complex is prepared through the following steps: carrying out a Grignard reaction on an iridium metal complex to prepare a compound C, carrying out dehydration cyclization on the compound C to obtain a cyclomedtalating ligand, carrying out a polymerization reaction on the cyclomedtalating ligand and chromium trichloride hexahydrate in a 2-ethoxyethanol and water mixed solvent to obtain a chlorendic dimer, and carrying out a complex reaction on the chlorendic dimer and the cyclomedtalating ligand to obtain the red organic electrophosphorescent material iridium metal complex represented by formula (1). The above material has good energy transmission efficiency and appropriate red light emitting wavelength, and can be widely used to make red or white phosphorescent electroluminescent devices in order to reduce the power consumption of the devices, improve the performances of the devices and prolong the life of the devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

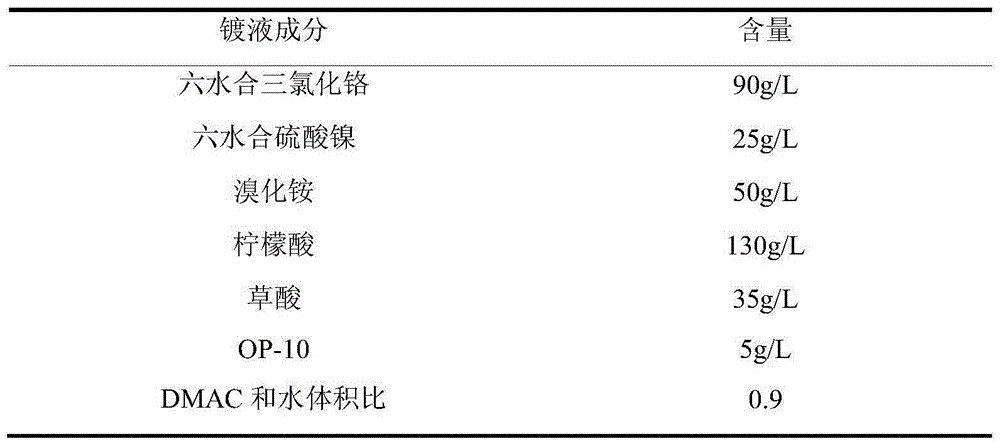

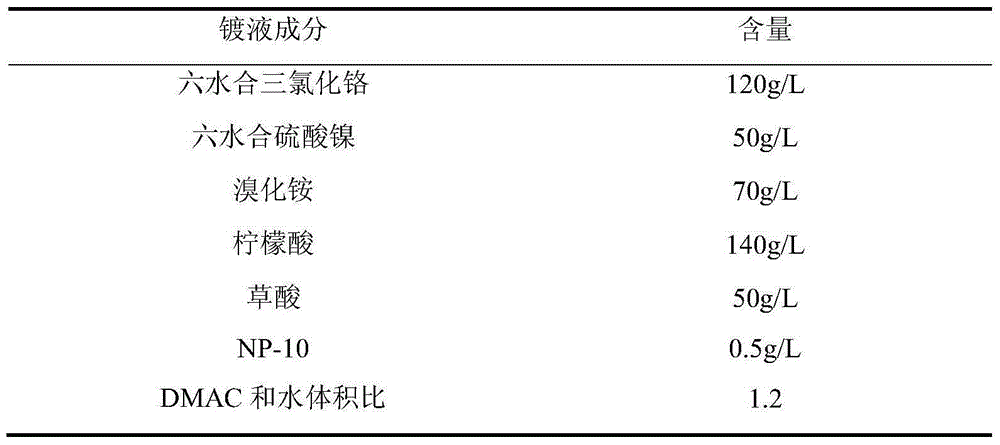

Cr-Ni alloy electroplating liquid and electroplating method

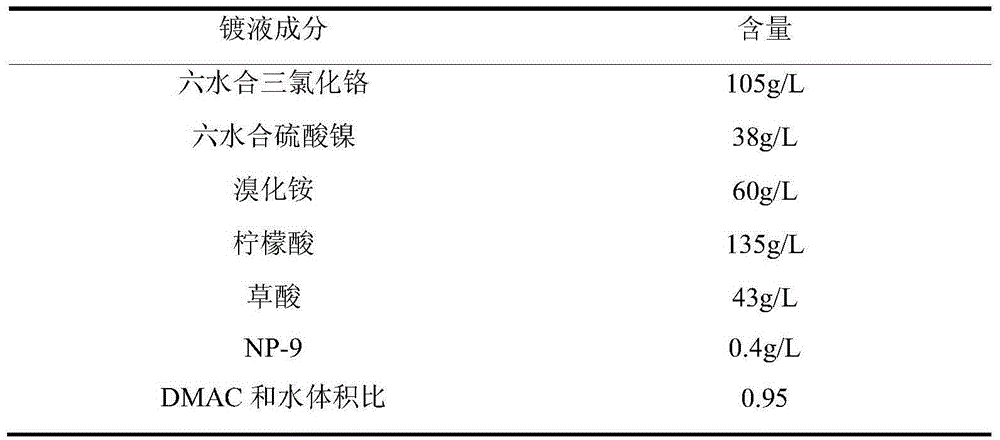

The invention discloses a Cr-Ni alloy electroplating liquid and an electroplating method. The Cr-Ni alloy electroplating liquid includes chromium chloride hexahydrate with the content of 90-120 g / L, nickel sulfate hexahydrate with the content of 25-50 g / L, ammonium bromide with the content of 50-70 g / L, citric acid with the content of 130-140 g / L, oxalic acid with the content of 35-50 g / L, an emulgator with the content of 0.3-0.5 g / L and the balance of solvent, wherein the solvent is a mixed liquid consisting of DMAC and water with the volume ratio of (0.9-1.2):1. According to the Cr-Ni alloy electroplating liquid provided by the invention, the mixed liquid consisting of DMAC and water is used as the solvent of the electroplating liquid, and citric acid and oxalic acid are used as a compound coordination agent, and are also used as a buffer agent for substituting boric acid, so that the formula is simplified, hardness and corrosion resistance of the coating are improved, and the scattering performance and deep plating performance of the electroplating liquid are improved.

Owner:WUXI QINGYANG MACHINERY MFG

Nickel-chromium alloy electroplate liquid

The invention relates to nickel-chromium alloy electroplate liquid. A liter of the electroplate liquid comprises from 25g to 35g of nickel sulfate hexahydrate, from 80g to 100g of chromium trichloride hexahydrate, from 30ml to 40ml of formic acid, from 20g to 30g of boric acid, from 1g to 60g of urea, from 30g to 80g of ammonium chloride, from 40g to 60g of potassium chloride, from 30g to 60g of critic acid, from 0.1g to 0.12g of sodium dodecyl sulfate, from 1.5g to 2.5g of saccharin, from 2ml to 4ml of nickel plating brighteners and the balance water. The urea is used as a coordination additive, and the performance of the electroplate liquid is greatly improved, so that behaviors of electrodes, the covering power and the dispersing power of a cathode and the stability, the coating performance and the contamination status of the electroplate liquid are greatly improved.

Owner:LUDONG UNIVERSITY

Preparation method of green pigment capable of reflecting infrared ray, and thermal-insulation paint

ActiveCN104910673AImprove performanceAdequate responsePolyester coatingsPigment physical treatmentInfraredThermal insulation

The invention discloses a preparation method of a green pigment capable of reflecting infrared ray, and a thermal-insulation paint. According to the preparation method, chromium chloride hexahydrate, and aluminium sulfate octadecahydrate are dissolved in water, and then are uniformly mixed with titanium dioxide and molybdenum trioxide; ammonium hydroxide is added dropwise into an obtained mixture; an obtained mixed material is subjected to ultrasonic wave treatment and stirring dispersion so as to obtain a mixed colloidal coprecipitation containing a composite doping component; the mixed colloidal coprecipitation containing the composite doping component is subjected to precipitation grinding, is subjected to sintering for 2 to 3h at 1000 to 1050 DEG C, is cooled, and then is delivered into a ball mill so as to obtain a powder via grinding. The green pigment possesses excellent infrared reflection performance, and can be added into paint so as to prepare thermal insulation coating products.

Owner:YANGZHOUSRKLE INDAL

Preparation method of green pigment capable of reflecting infrared rays, and thermal insulation paint

InactiveCN107541137AImprove performanceAdequate responsePolyester coatingsReflecting/signal paintsInfraredCalcium Chloride Hexahydrate

The invention discloses a preparation method of a green pigment capable of reflecting infrared rays and a heat-insulating paint. Dissolve hexahydrate chromium trichloride and octadecahydrate aluminum sulfate in water, mix them with titanium dioxide and molybdenum trioxide, and then add ammonia water dropwise , under the ultrasonic wave and stirring dispersion, a mixed colloid co-precipitation containing composite doping components is generated; after the precipitate is ground, it is fired at 1000-1050°C for 2-3 hours, and after it is cooled, it is put into a ball mill. It is ground into a powder. The invention makes the prepared green pigment have good infrared reflection performance, and can be used to add the green pigment to the paint to make heat-insulating paint products.

Owner:天津市东塔涂料有限公司

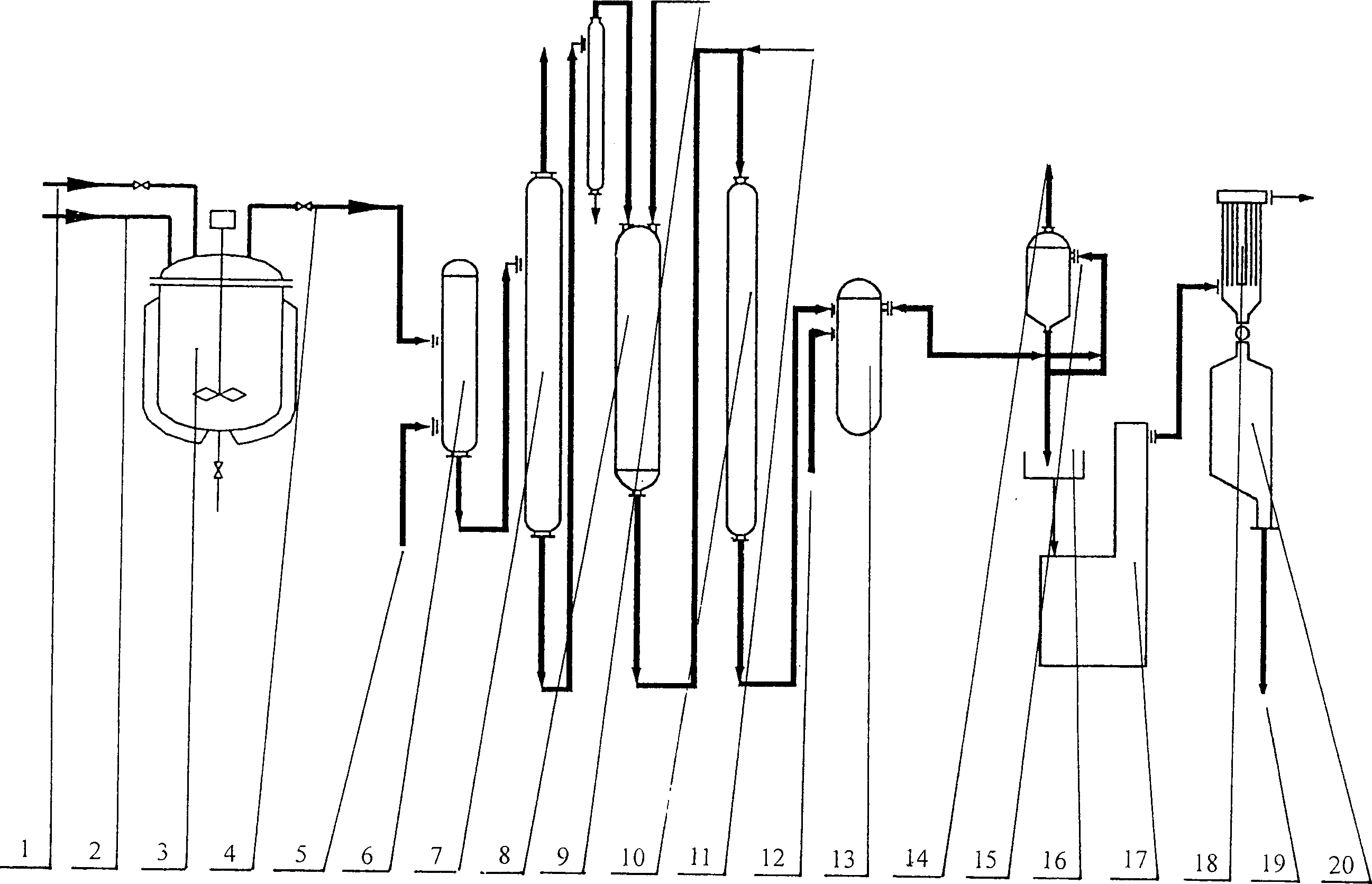

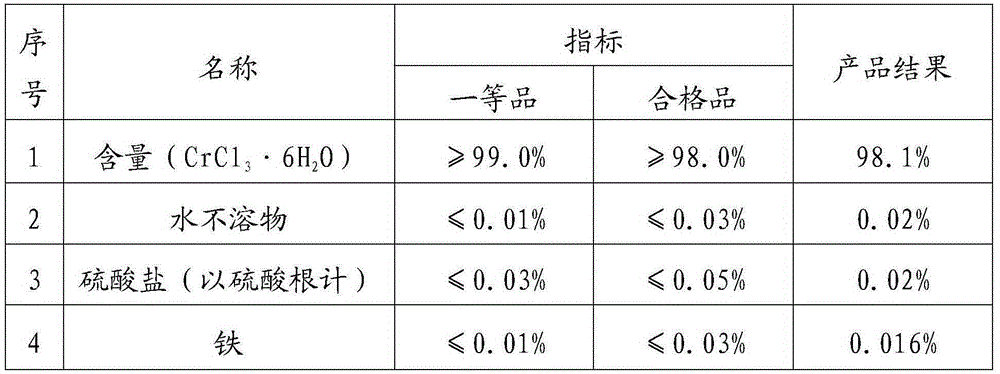

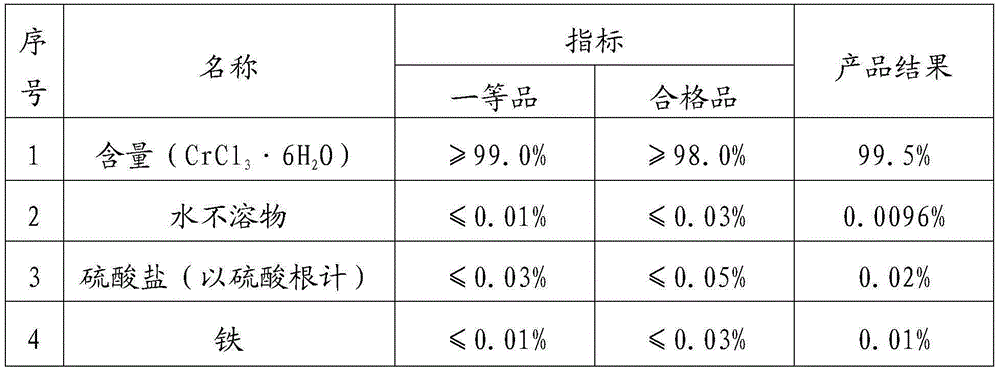

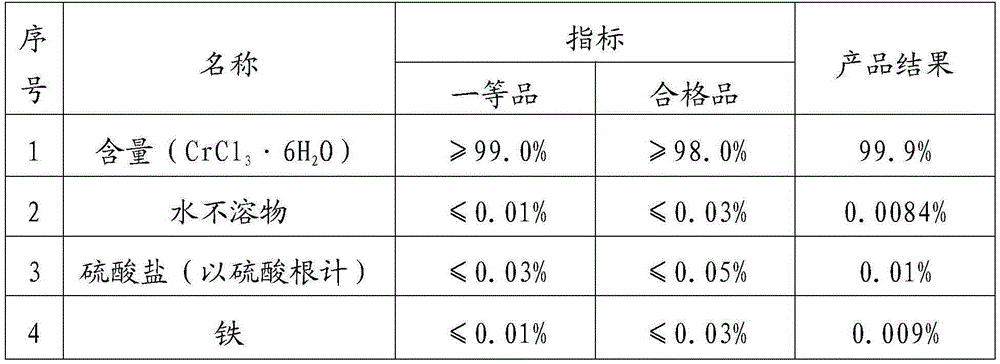

A kind of method for preparing chromium trichloride hexahydrate with sodium chromate

ActiveCN104192906BIncrease contentMeet the requirements of qualified productsChromium halidesCalcium Chloride HexahydrateEvaporation

The invention discloses a method for preparing chromium trichloride hexahydrate by utilizing sodium chromate. The method for preparing chromium trichloride hexahydrate by utilizing sodium chromate comprises the following steps: putting a sodium chromate aqueous solution and a reducing agent in a reaction vessel, controlling temperature to be 115-125 DEG C and slowly dropwise adding hydrochloric acid while stirring; after hydrochloric acid is added, firstly controlling temperature of a reaction solution to be 110-140 DEG C, carrying out reaction on sodium chromate, the reducing agent and hydrochloric acid for a first preset time period while stirring, then controlling the temperature of the reaction solution to be 80-100 DEG C, and curing the reaction solution reacted for the first time period for a second time period while stirring; adding the cured reaction solution into an alkali solution, regulating pH value of the reaction solution to be 6.5-7.5, then filtering to obtain an intermediate product, washing the intermediate product, then adding hydrochloric acid, and carrying out reaction; sequentially carrying out evaporation and concentration, crystallization at room temperature and crystal centrifugal drying on the reaction solution obtained in step three, so that chromium trichloride hexahydrate is obtained. The method for preparing chromium trichloride hexahydrate by utilizing sodium chromate is simple in technology and low in raw material cost and can replace a production method of chromium trichloride hexahydrate by virtue of chromic anhydride.

Owner:SICHUAN YINHE CHEM

Component for preventing and controlling heart diseases

InactiveCN1899606APrevention and control of heart diseasePrevention and Control of DeteriorationHeavy metal active ingredientsMilk preparationDiseaseChromium Compounds

The present invention relates to a kind of composition for preventing and treating heart diseases, and the composition includes lactoferritin and trivalent chromium compound, which is at least one selected from chromium trichloride hexahydrate, chromium trichloride, chromium acetate, chromium sulfate, chromium pyridyl formate, chromium nicotinate and other organic and inorganic trivalent chromium compound. The present invention also relates to the method of preventing and treating heart diseases with the composition.

Owner:MAXLUCK BIOTECH CORP

Component for reducing body fat formation and application thereof

ActiveCN101632832BImprove hyperleptinemiaReduce storageHeavy metal active ingredientsMilk preparationChromium CompoundsSulphate Ion

The invention relates to a component for reducing body fat formation and application thereof. The component comprises lactoferrin and a trivalent chromium compound, wherein the trivalent chromium compound is selected from a group consisting of free chromium trichloride hexahydrate, chromium trichloride, chromium acetate, chromium sulphate, chromium picolinate, chromium nicotinate, chromium glucose tolerance factor, chromium yeast, other inorganic trivalent chromiums, other organic trivalent chromiums as well as compositions of the compounds. The component of the invention can be transferred into muscular tissues by glucoses in helper cells to be used and can reduce the transformation of the glucoses into fats for storage, thereby realizing the control of weight.

Owner:MAXLUCK BIOTECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com