Electrodeposition preparation method of stainless steel coating by means of deep-eutectic solvent

A deep eutectic solvent and electrodeposition technology, applied in the field of surface engineering and surface treatment, can solve problems such as low current efficiency and difficulty in achieving clean production, achieve excellent wear resistance and corrosion resistance, and have a bright, smooth and dense surface appearance , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This deep eutectic solvent electrodeposition prepares the method for stainless steel coating, and its specific steps are as follows:

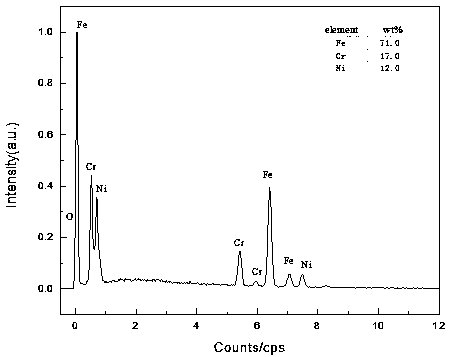

[0019] Step 1. Under an inert gas environment, firstly mix the quaternary ammonium salt and the polyol according to the molar ratio of 1:3 to form a 50mL deep eutectic solvent, and then add hexahydrate di Nickel chloride, chromium trichloride hexahydrate and ferrous chloride tetrahydrate, the prepared deep eutectic solvent electrolyte; wherein the quaternary ammonium salt is choline chloride, the polyhydric alcohol is ethylene glycol; dichloride hexahydrate The molar ratio of nickel chloride, chromium trichloride hexahydrate and ferrous chloride tetrahydrate is 1:6:3;

[0020] Step 2. Use the chromium sheet as the anode, and the pretreated substrate (copper sheet, the pretreatment process is that the substrate is polished with sandpaper, ultrasonically acetone, rinsed with distilled water, and dried with cold air) as the cathode, and ele...

Embodiment 2

[0023] This deep eutectic solvent electrodeposition prepares the method for stainless steel coating, and its specific steps are as follows:

[0024] Step 1. Under an inert gas environment, firstly mix the quaternary ammonium salt and the polyol according to the molar ratio of 1:1 to form a 50mL deep eutectic solvent, and then add hexahydrate di Nickel chloride, chromium trichloride hexahydrate and ferrous chloride tetrahydrate are prepared deep eutectic solvent electrolyte; wherein the quaternary ammonium salt is benzyltriethylammonium chloride, and the polyhydric alcohol is glycerol; The molar ratio of nickel dichloride hexahydrate, chromium trichloride hexahydrate and ferrous chloride tetrahydrate is 1:6:3;

[0025] Step 2. Use graphite as the anode, and the pretreated substrate (low carbon steel, the pretreatment process is that the substrate is polished with sandpaper, ultrasonicated with acetone, rinsed with distilled water, and dried with cold air) as the cathode, and el...

Embodiment 3

[0027] This deep eutectic solvent electrodeposition prepares the method for stainless steel coating, and its specific steps are as follows:

[0028] Step 1. Under an inert gas environment, firstly mix the quaternary ammonium salt and the polyol with a molar ratio of 1:6 to form a 50mL deep eutectic solvent, and then add hexahydrate di Nickel chloride, chromium trichloride hexahydrate and ferrous chloride tetrahydrate are prepared deep eutectic solvent electrolyte; wherein the quaternary ammonium salt is benzyltriethylammonium chloride, and the polyhydric alcohol is glycerol; The molar ratio of nickel dichloride hexahydrate, chromium trichloride hexahydrate and ferrous chloride tetrahydrate is 1:6:3;

[0029] Step 2. Use lead-tin alloy (lead content is 90wt%, and the rest is tin) as the anode, and the pretreated substrate (aluminum sheet, the pretreatment process is that the substrate is polished with sandpaper, acetone is ultrasonicated, and then rinsed with distilled water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com