Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132 results about "Chip formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

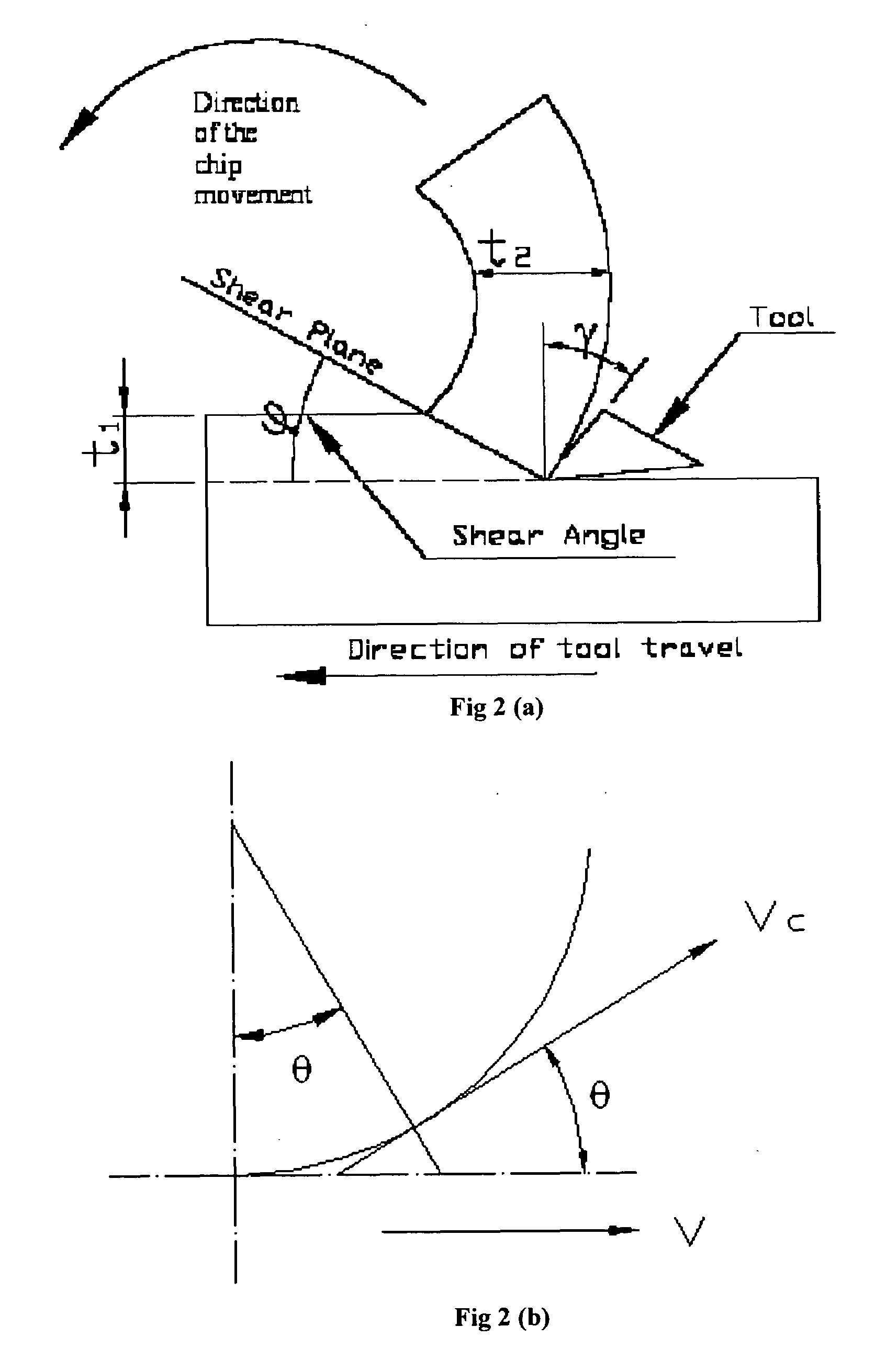

Chip formation is part of the process of cutting materials by mechanical means, using tools such as saws, lathes and milling cutters. An understanding of the theory and engineering of this formation is an important part of the development of such machines and their cutting tools.

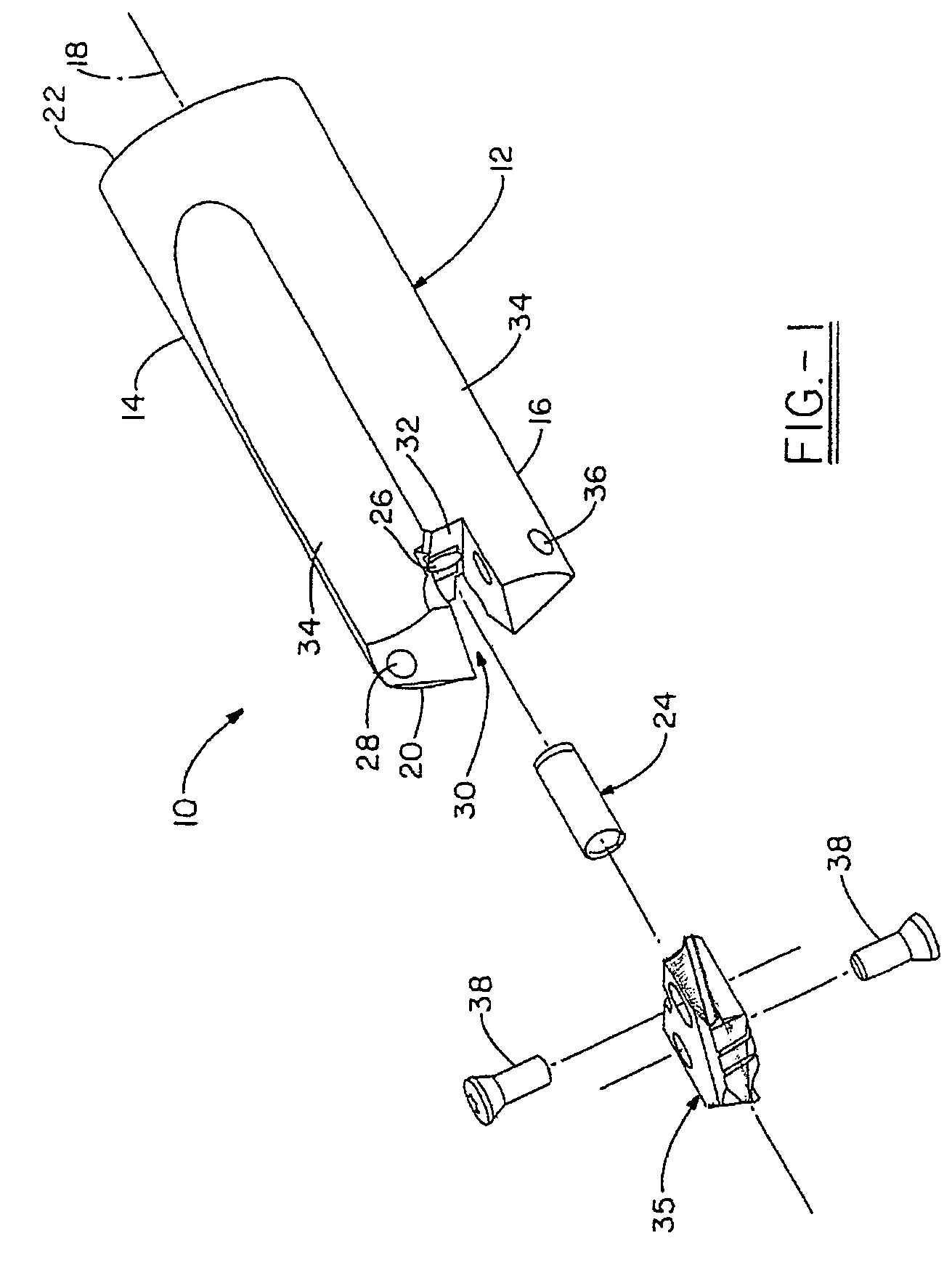

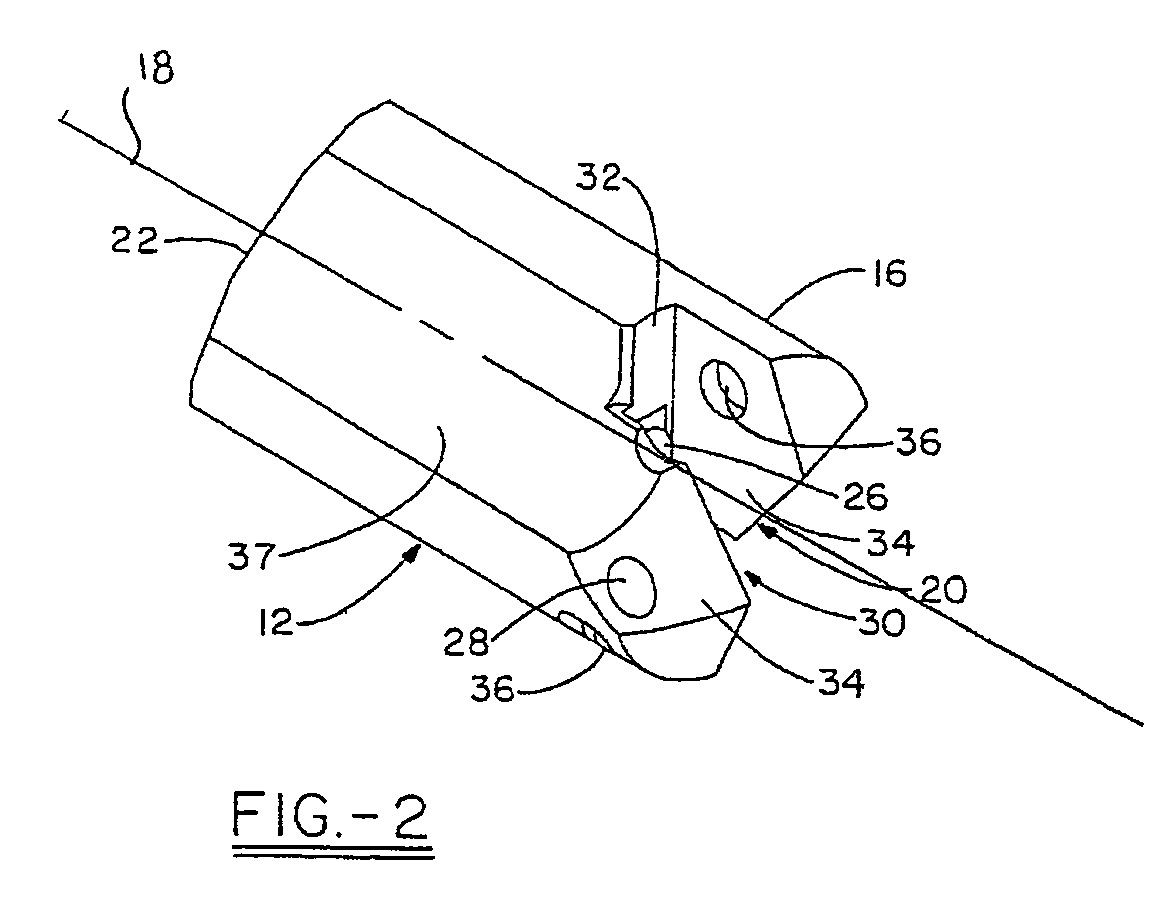

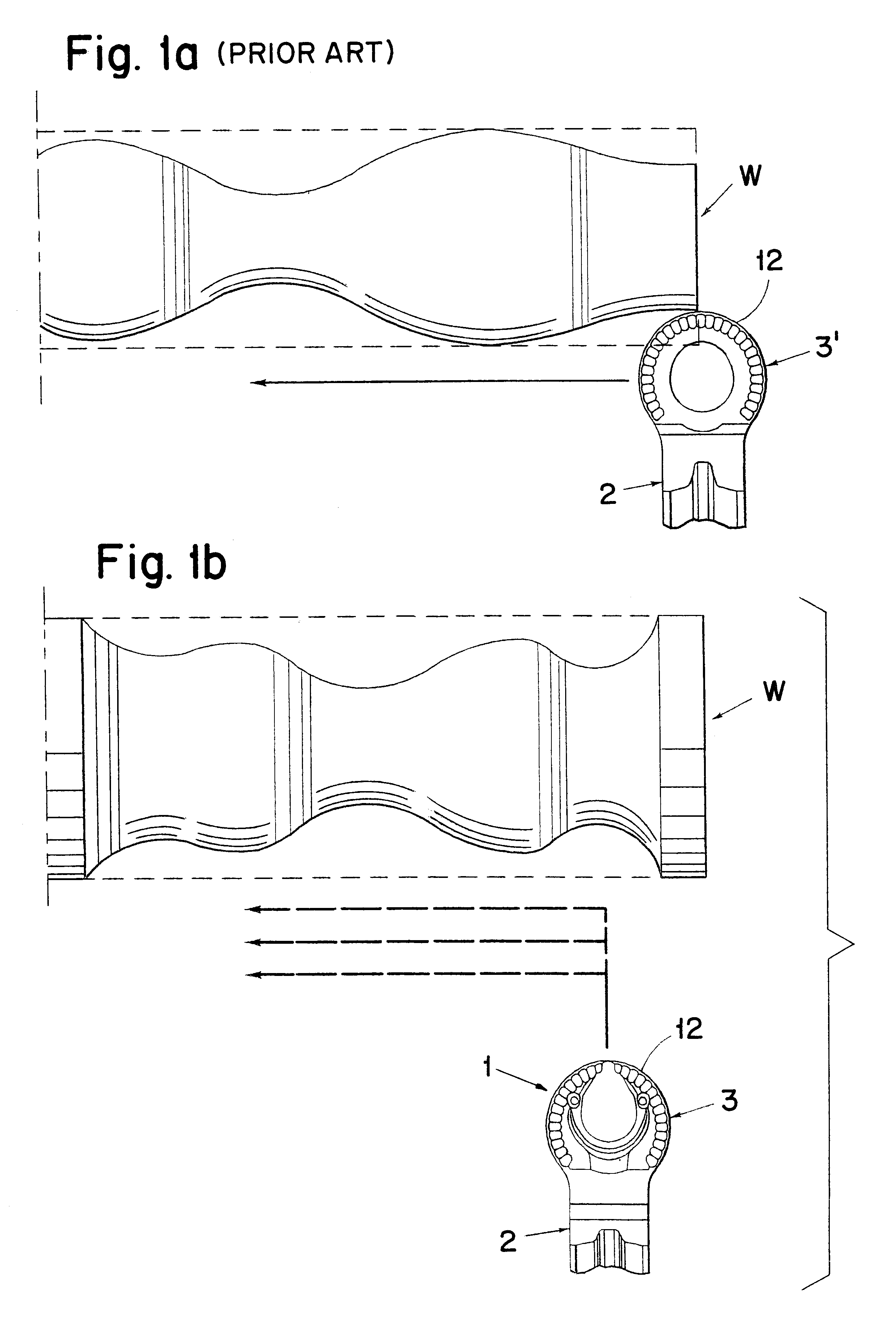

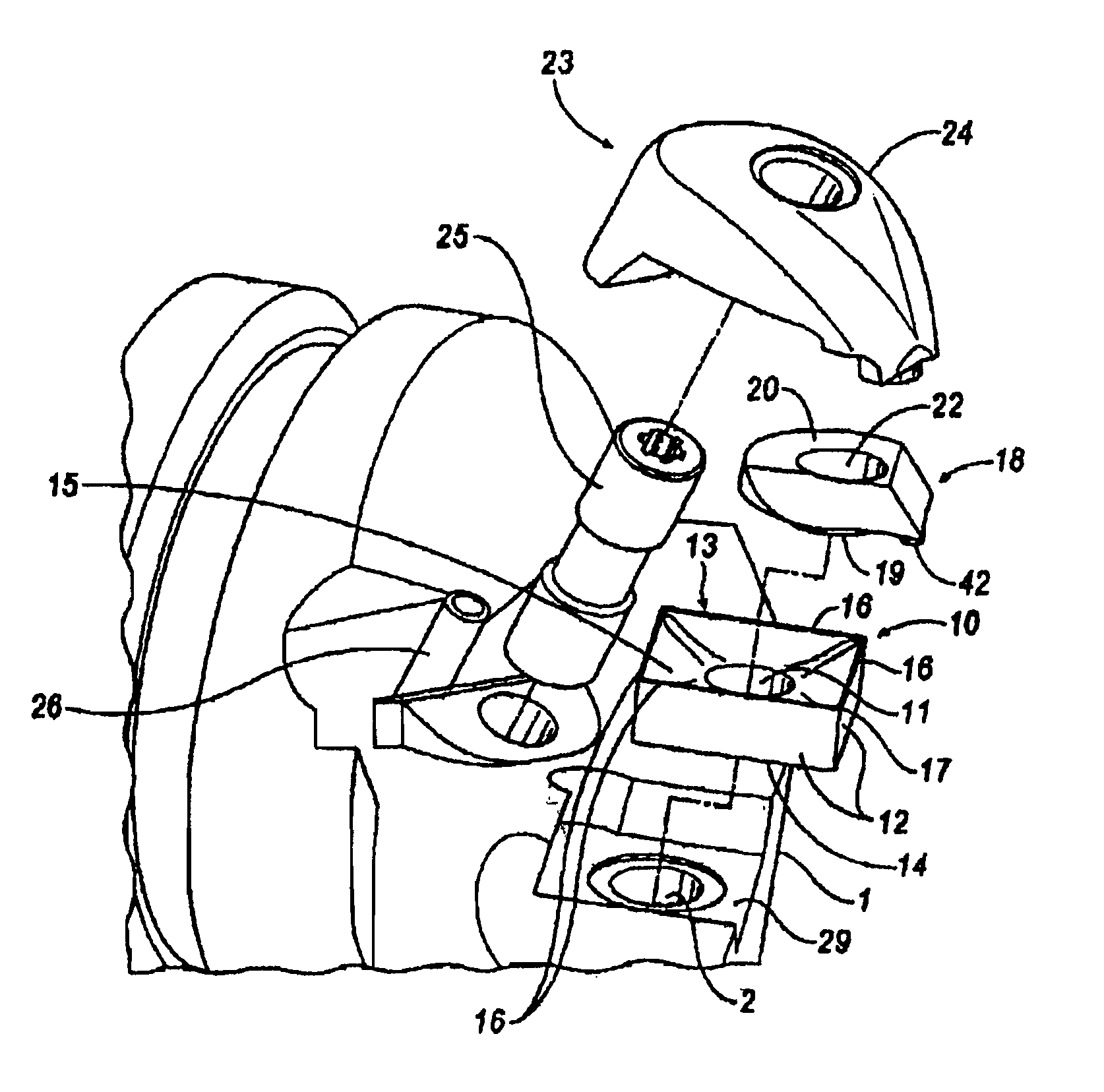

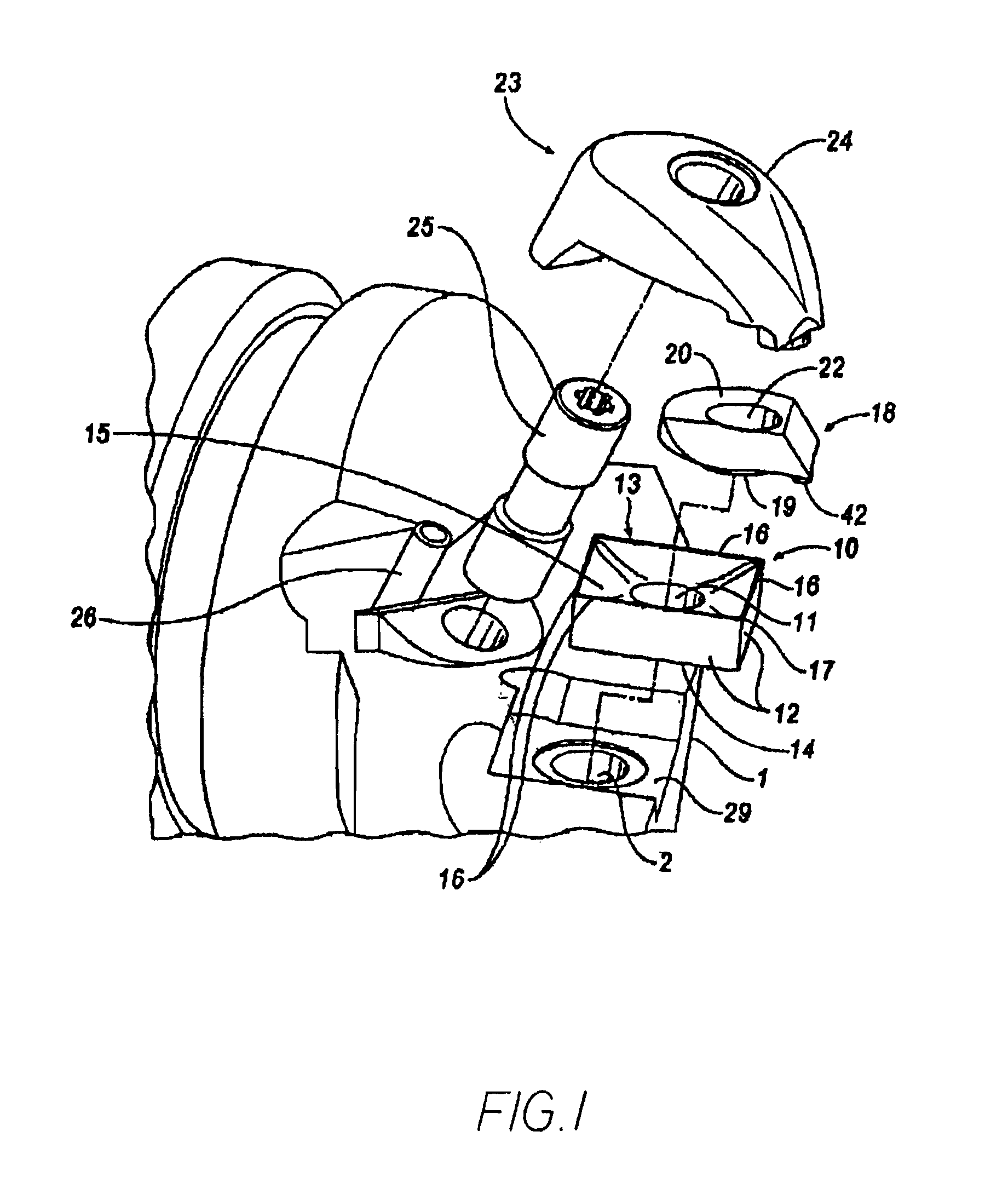

Cutting tool having liquid-spraying nozzles for controlling chip formation

InactiveUS6471448B1Improve chip breaking abilityImprove cooling effectTurning toolsShaping cuttersLiquid jetChip formation

A metal workpiece is cut by rotating the workpiece while pressing the cutting edge of a cutting insert thereagainst for removing a chip from the workpiece. A first liquid jet is directed from a first nozzle toward an upper surface of the cutting insert for creating an hydraulic wedge between the cutting insert and the chip, and a second liquid jet is directed from a second nozzle toward a target point disposed above the upper surface of the cutting insert to engage and deflect the chip upwards and backwards.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Tool for chip removing machining and methods and apparatus for making the tool

InactiveUS6450739B1Drawback can be obviatedDrawbacks of the known technique are eliminatedMetal-working drilling toolsTransportation and packagingWear resistantEngineering

A tool for chip-forming machining is made by passing first and second compounds through first and second coaxial dies, respectively, whereby the first material forms a center core of the tool, and the second material forms an outer rod of the material. The material of the core is tougher and less wear-resistant than the material of the outer rod. The coaxial first and second compounds are passed through a shaping die and then through a flute-forming structure which forms chip flutes in the outer rod.

Owner:SECO TOOLS AB

Cutting insert for cutting and grooving tools

InactiveUSRE37595E1Efficiently manageable safe chipsMore efficientCutting insertsTurning toolsChip formationKnife blades

The present invention relates to a turning insert that comprises a generally rectangularly shaped body having a front end surface with a main cutting edge at the intersection between the front end surface and an upper land area. A chipforming area is provided in the forward portion of the upper surface and is shaped in the form of a number of distinctly provided recesses and ridges in order to promote improved chip control and to obtain narrower chips in grooving operations.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Cutting insert with a wear-resistant coating scheme exhibiting wear indication and method of making the same

ActiveUS8080323B2Improve tool lifeFlat surfacePigmenting treatmentWorkpiecesWear resistantMaterial removal

A coated cutting insert for use in a chip-forming material removal operation wherein the coated cutting insert includes a substrate that has a flank surface and a rake surface and the flank surface intersects the rake surface to form a cutting edge at the intersection. There is a wear-resistant coating scheme that adheres to at least a portion of the substrate. The wear-resistant coating scheme includes one or more coating layers of one or more of alumina, hafnia and zirconia. There is a wear indicating coating that adheres to at least a portion of the wear-resistant coating scheme. The wear indicating coating includes M(OxCyNz) wherein M is selected from the group comprising one or more of the following titanium, hafnium, zirconium, chromium, titanium-aluminum alloy, hafnium-aluminum alloy, zirconium-aluminum alloy, chromium-aluminum alloy, and their alloys, and x>0, y≧0, z≧0 and y+z>0. A method of making a cutting insert with wear indicating coating including the steps of: providing a substrate with an outer alumina coating layer; applying an as-deposited non-wear indicating coating layer to the alumina coating layer; and treating the non-wear indicating coating layer to convert it to a wear indicating coating layer.

Owner:KENNAMETAL INC

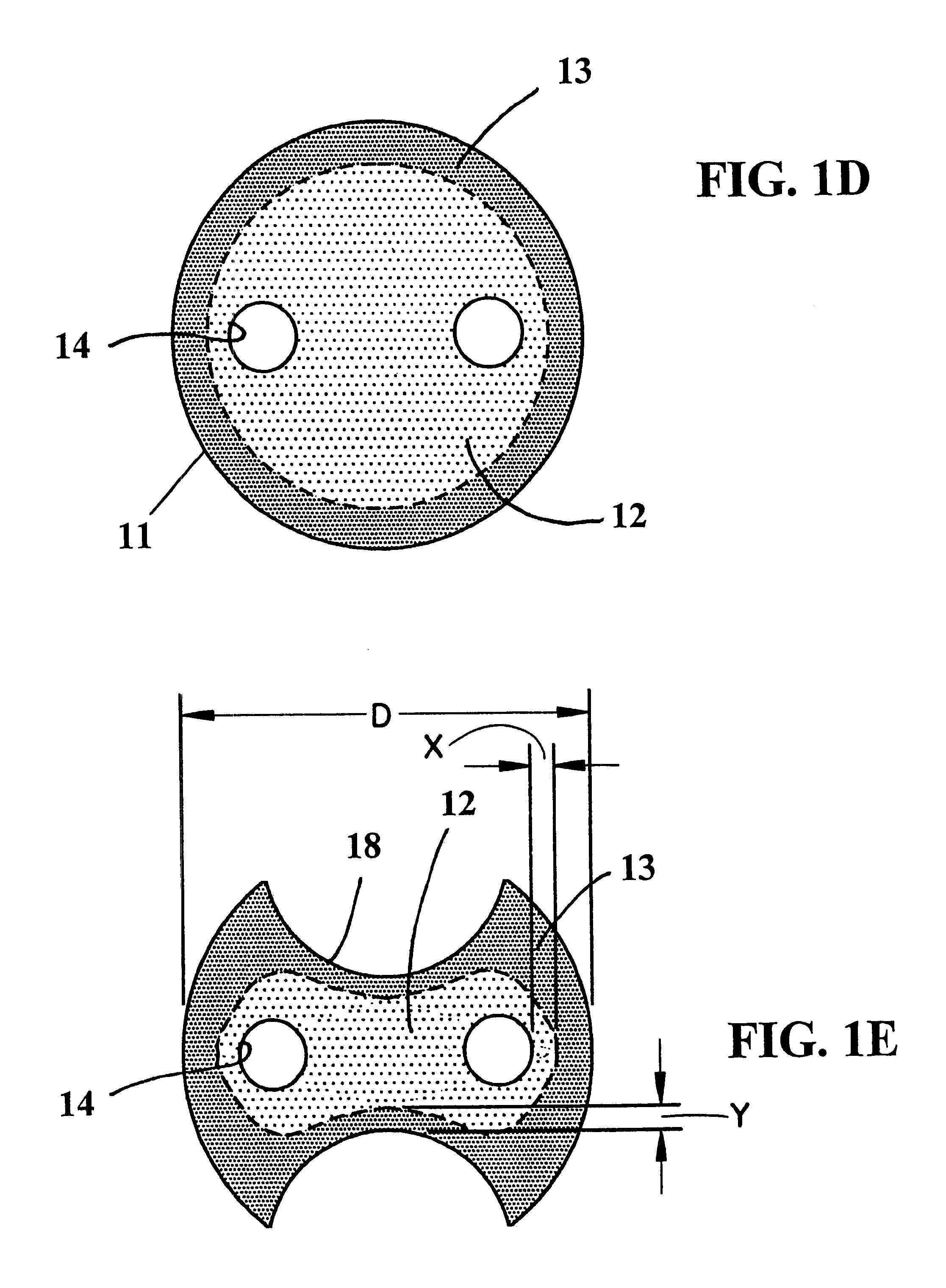

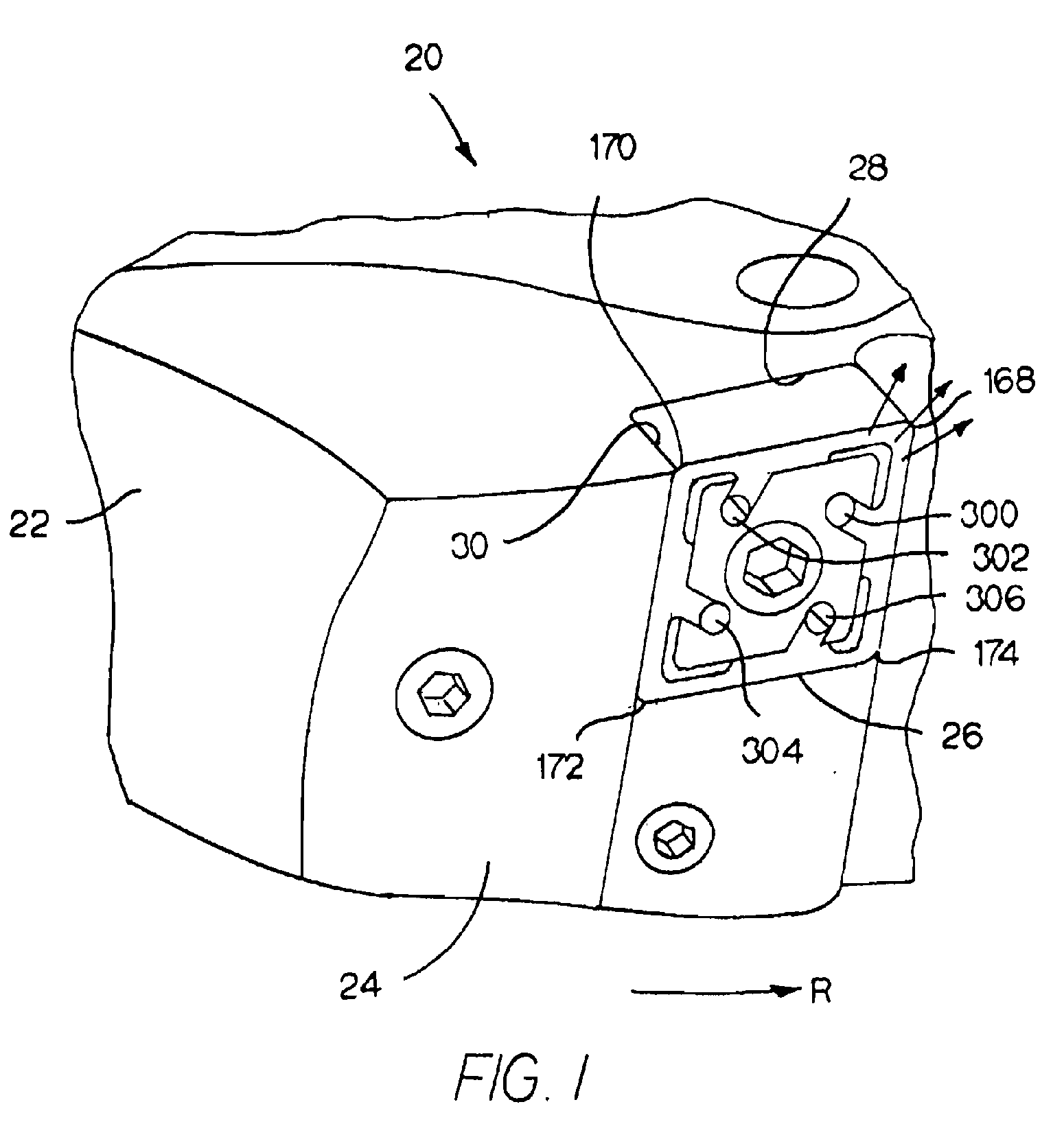

Spade drill insert having curved cutting edges

ActiveUS7018145B2Improved chip formationWood turning toolsTransportation and packagingEngineeringChip formation

Owner:ALLIED MASCH & ENG CORP

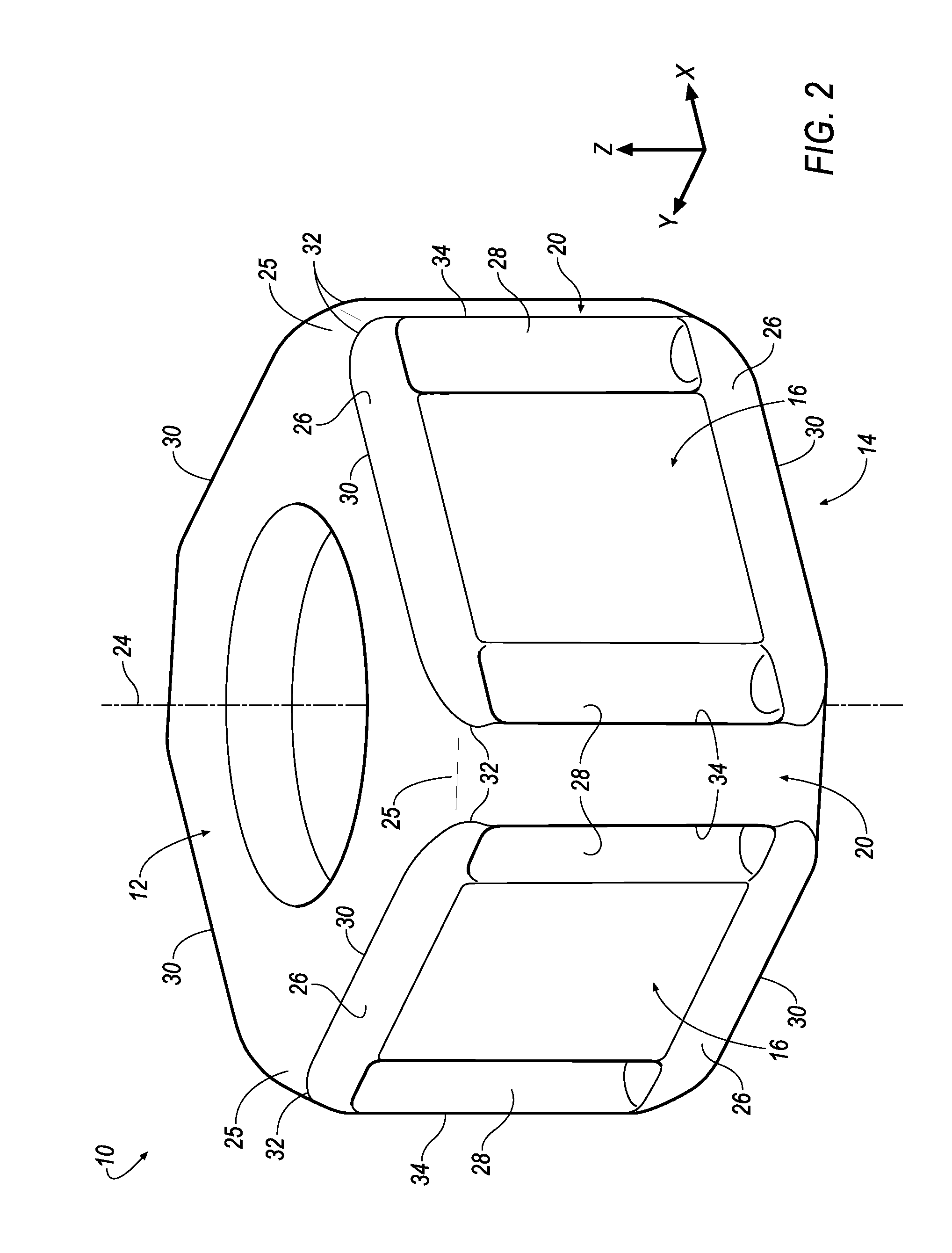

Cutting tool and double-ended cutting insert therefor

A cutting tool for grooving, parting and turning machining operations is capable of grooving to unlimited depths of cut. The cutting tool includes an indexable double-ended cutting insert having a downwardly extending insert clamping portion resiliently clamped in a self-retaining manner in an insert pocket so that chip formation is not hindered during such machining operations.

Owner:ISCAR LTD

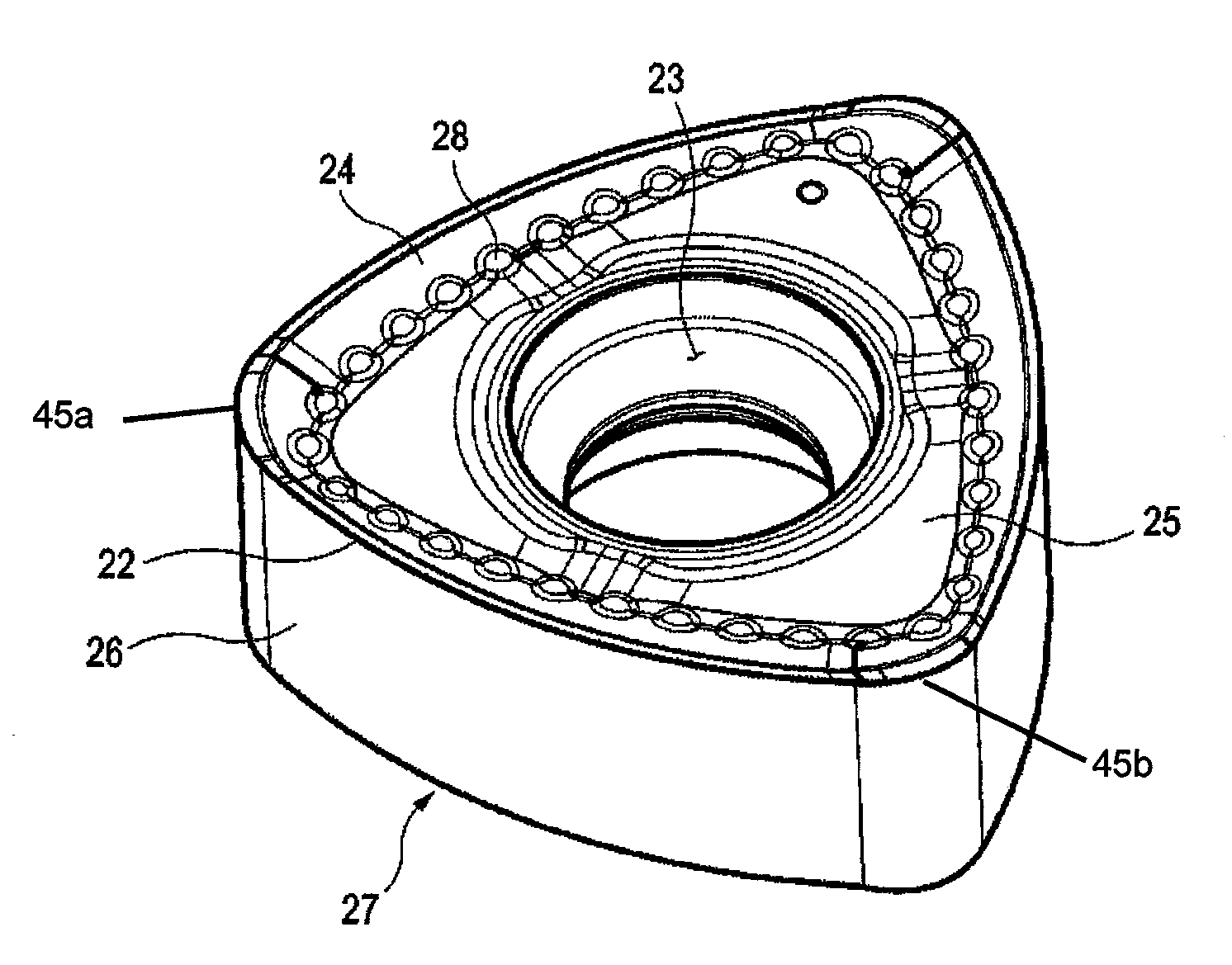

Cutting insert for grooving and profiling

A cutting insert for grooving and parting as well as profiling and longitudinal turning of metallic work-pieces, includes a shaft part and at least one cutting head. There is a front end surface at the front end of the cutting insert, and a rear end surface at the rear end of the cutting insert. The shaft part includes a top side, a bottom side and side surfaces extending between the tope and bottom two sides. The cutting head carries a cutting edge defined by the intersection between a chip surface and a clearance surface. The cutting edge has a circular shape and has mainly a constant curvature between the ends thereof. The chip side of the cutting head is provided with a first chip-forming device placed immediately inside the cutting edge.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

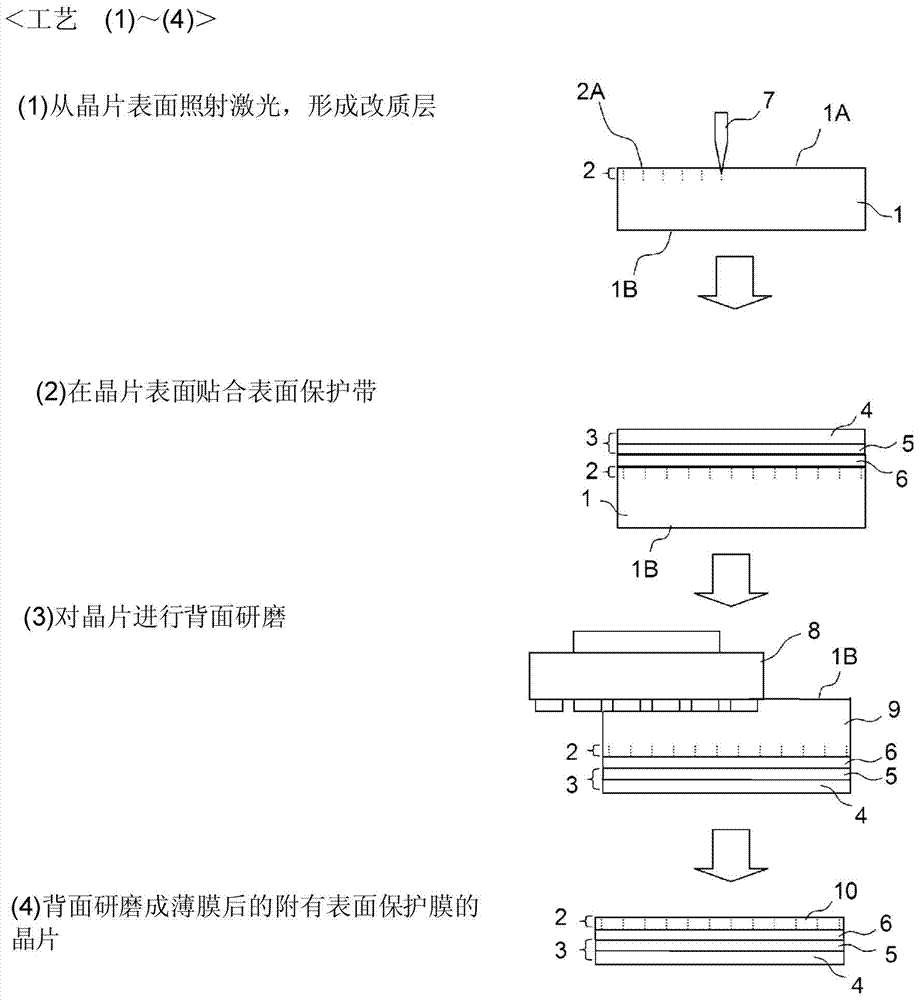

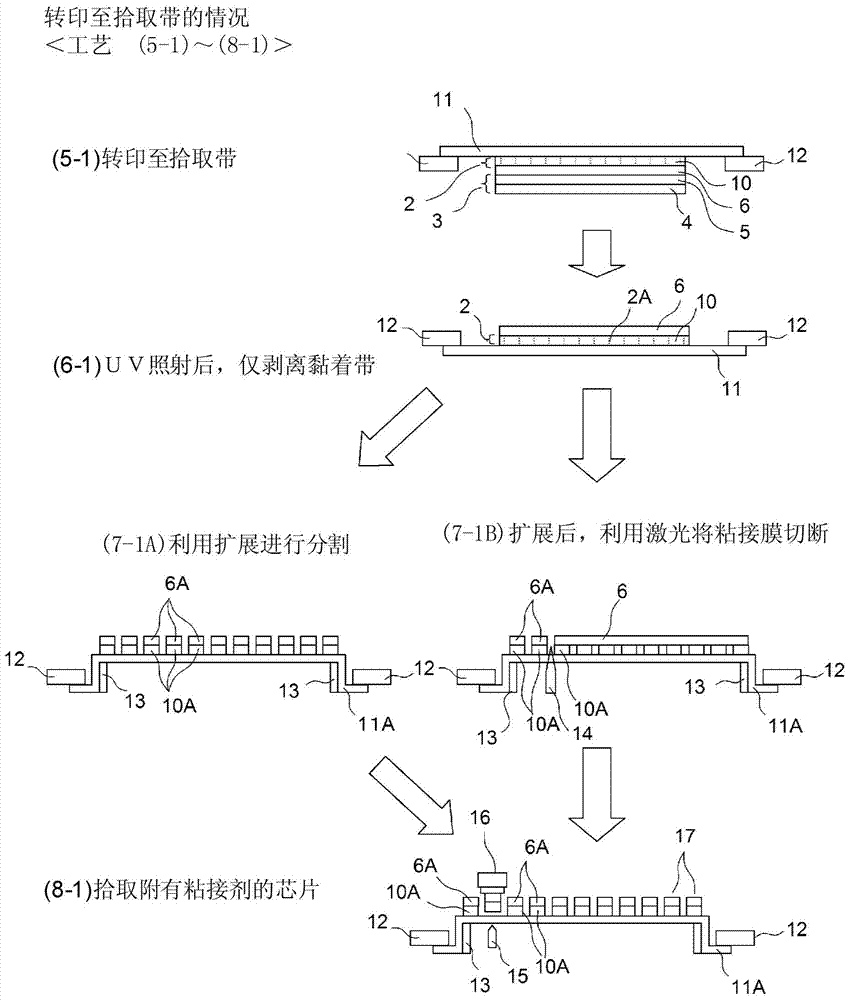

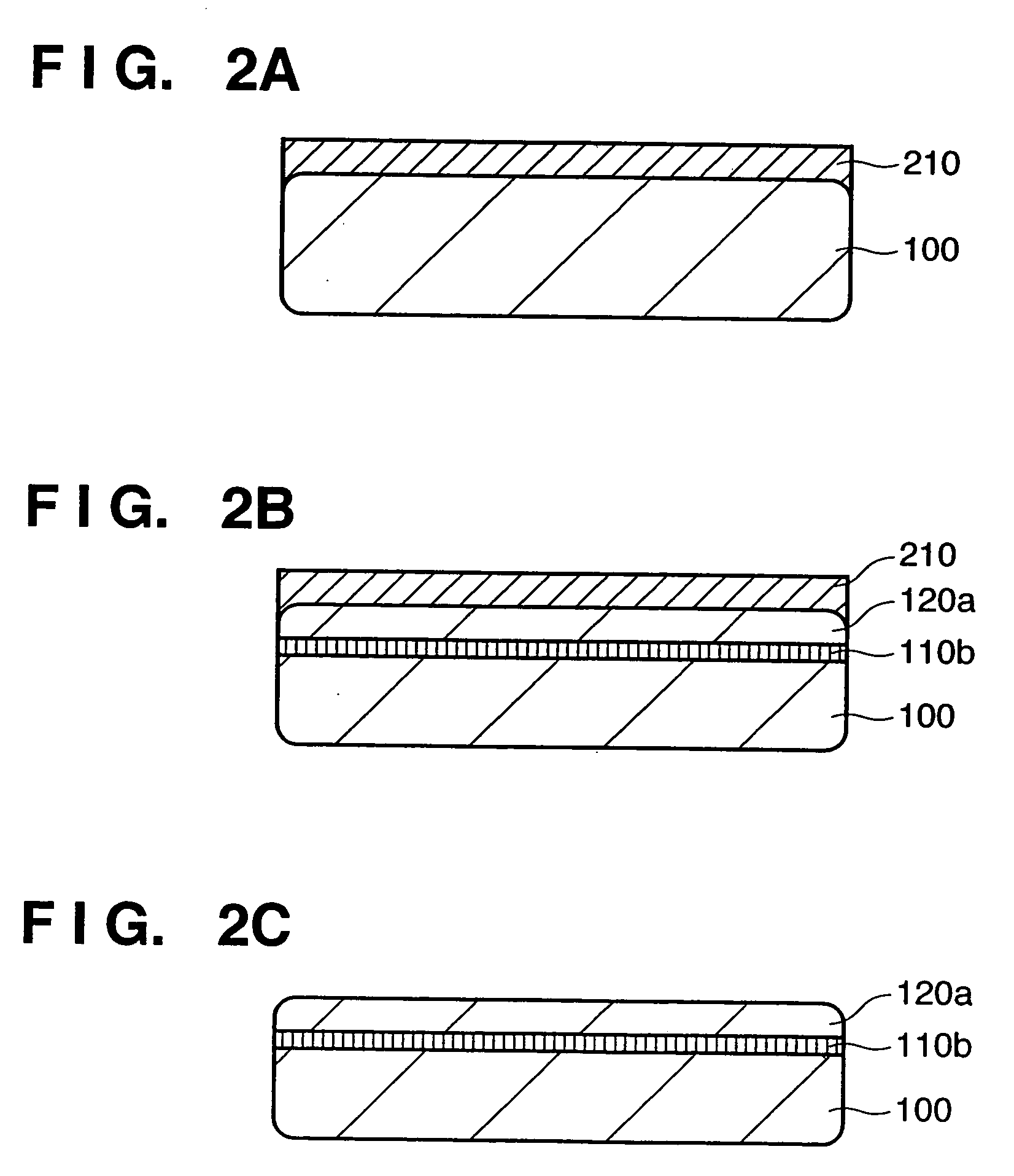

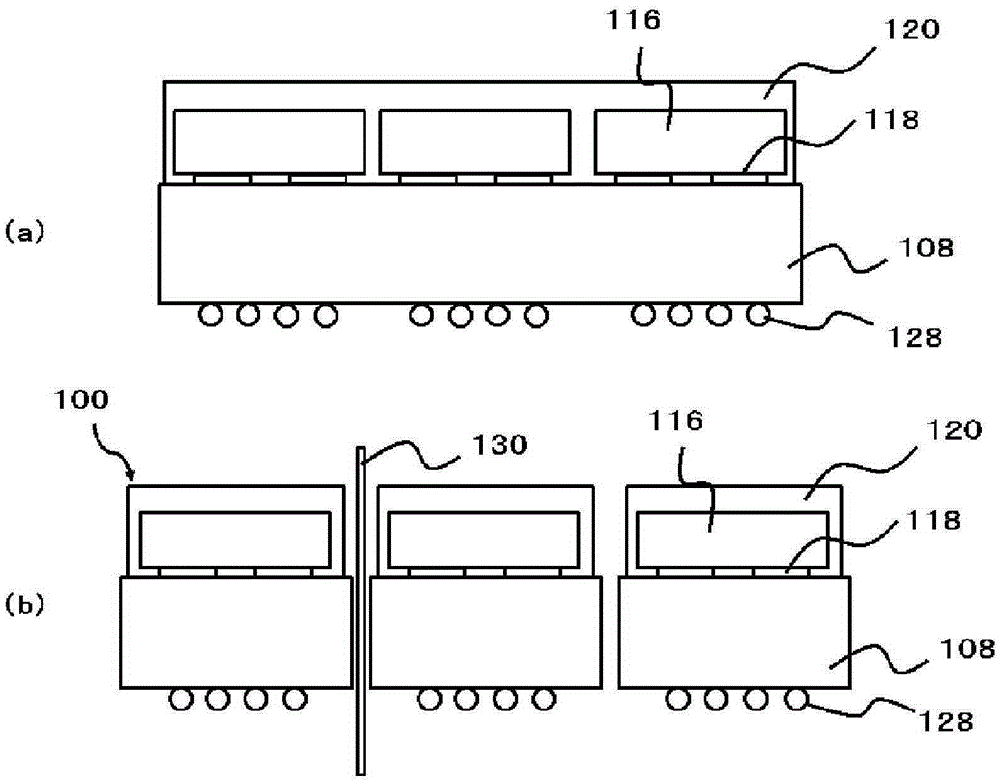

Method for manufacturing semiconductor chips and surface protective tape for thin-film grinding used in same

InactiveCN104781912AHigh precisionThe preparation method is simple and easyFilm/foil adhesivesSolid-state devicesSemiconductor chipEngineering

[Problem] To provide a high precision and simple method for manufacturing semiconductor chips in semiconductor chip manufacturing that carries out back surface grinding of a semiconductor wafer which is used in a flip chip mounting process and has bump electrodes and simultaneously or in a process thereafter carries out chip formation without using underfilling, and also to provide a surface protective tape for thin-film grinding used in that method. [Solution] This manufacturing method for semiconductor chips grinds the back surface of a semiconductor wafer after formation of a modified layer within a wafer with bump electrodes, which has bumps for electrodes, on the semiconductor wafer on which a semiconductor circuit has been formed, and carries out division into individual chips in a batch. This method for manufacturing semiconductor chips has a step for applying surface protective tape for thin-film grinding in which a bonding film is laminated on an adhesive layer in an adhesive tape that has an adhesive layer on a base material film to the side of a semiconductor wafer on which a semiconductor circuit is formed on the bonding film side after formation of the modified layer and before the back surface of the semiconductor wafer is ground, and a step for creating a state in which only the bonding film bonds to the chips when the chips are picked up after back surface grinding of the semiconductor wafer or when transferred to a tape used for pick-up. The surface protective tape for thin-film grinding used therein is also provided.

Owner:FURUKAWA ELECTRIC CO LTD

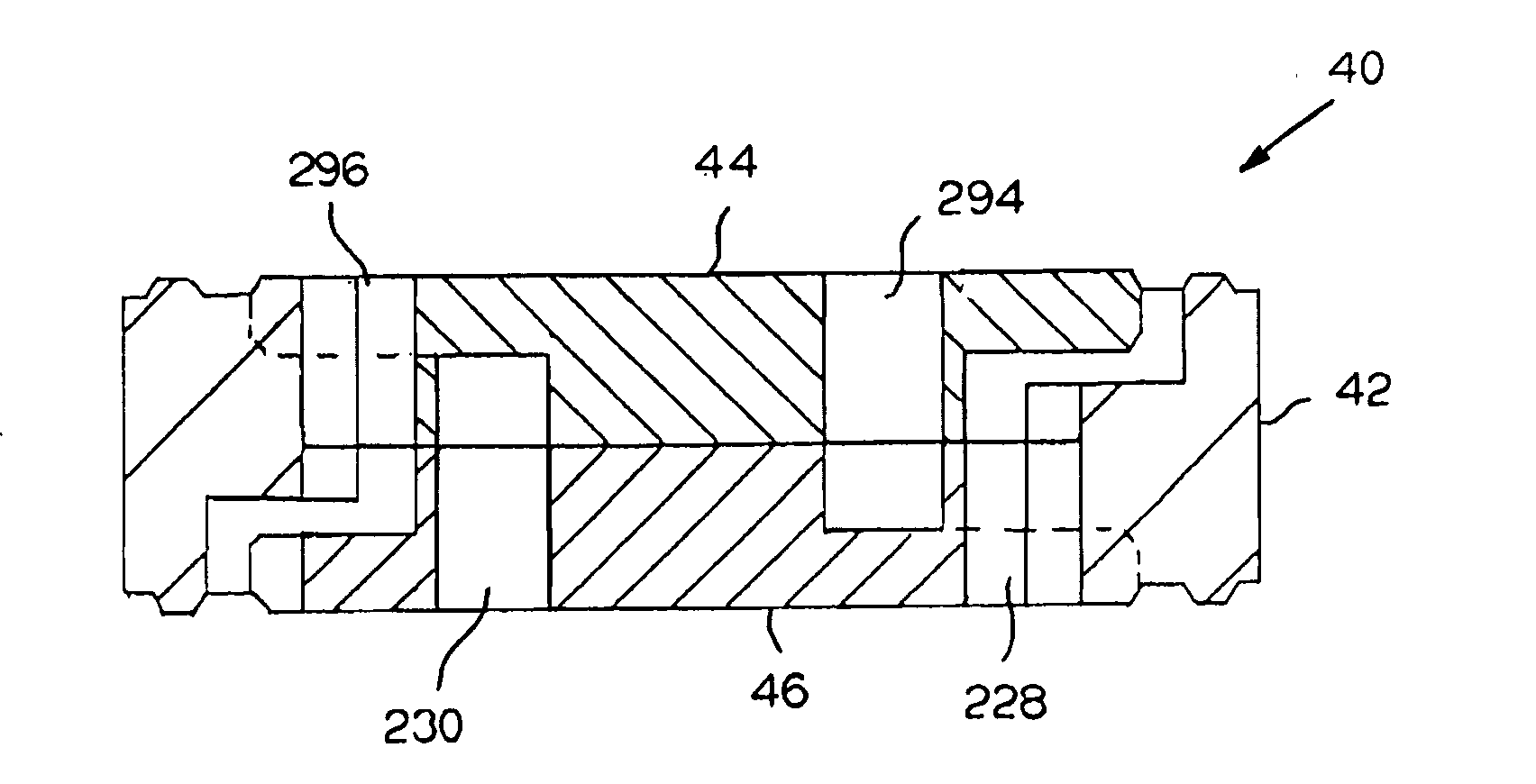

Cutting insert with coolant delivery and method of making the cutting insert

ActiveUS20100172704A1Reduce deliveryReduce negative impactMilling cuttersCutting insertsMaterial removalEngineering

An assembly of components for forming upon consolidation of the components a cutting insert for use in chipforming and material removal from a workpiece wherein the cutting insert receives coolant from a coolant source. The assembly comprises a cavity member that presents opposite first and second rake surfaces and a flank surface. The cavity member further presents a first cutting edge at the juncture of the first rake surface and the flank surface. The cavity member further has a first depression in the first rake surface that is generally adjacent to the first cutting edge. The cavity member has a first cavity channel in communication with the first depression. The assembly also has a first core member that has a first core channel and a first flange wherein when the components are assembled, the first core channel is adjacent to the first cavity channel and the first flange is adjacent to the first depression. The assembly also has a second core member which has a second flange containing a fifth notch and the second core member further containing a fifth notch channel opening into the fifth notch. When the components are assembled, the fifth notch is adjacent to the second rake surface and the fifth notch channel is adjacent to the first cavity channel. Upon consolidation of the components, the cavity member, the first core member and the second core member join together so that the first depression and the first flange define a first fluid spray chamber, and the first cavity channel and the first core channel and the fifth notch channel join together to form a fifth internal fluid passageway, which provides fluid communication from the fifth notch adjacent to the second rake surface to the first fluid spray chamber adjacent to the first rake surface.

Owner:KENNAMETAL INC

Cutting insert for grooving and profiling

A cutting insert for grooving and parting as well as profiling and longitudinal turning of metallic work-pieces, includes a shaft part and at least one cutting head. There is a front end surface at the front end of the cutting insert, and a rear end surface at the rear end of the cutting insert. The shaft part includes a top side, a bottom side and side surfaces extending between the tope and bottom two sides. The cutting head carries a cutting edge defined by the intersection between a chip surface and a clearance surface. The cutting edge has a circular shape and has mainly a constant curvature between the ends thereof. The chip side of the cutting head is provided with a first chip-forming device placed immediately inside the cutting edge.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Cutting insert with coolant delivery and method of making the cutting insert

ActiveUS7955032B2Reduce deliveryReduce negative impactMilling cuttersCutting insertsMaterial removalEngineering

An assembly of components for forming upon consolidation of the components a cutting insert for use in chipforming and material removal from a workpiece wherein the cutting insert receives coolant from a coolant source. The assembly comprises a cavity member that presents opposite first and second rake surfaces and a flank surface. The cavity member further presents a first cutting edge at the juncture of the first rake surface and the flank surface. The cavity member further has a first depression in the first rake surface that is generally adjacent to the first cutting edge. The cavity member has a first cavity channel in communication with the first depression.

Owner:KENNAMETAL INC

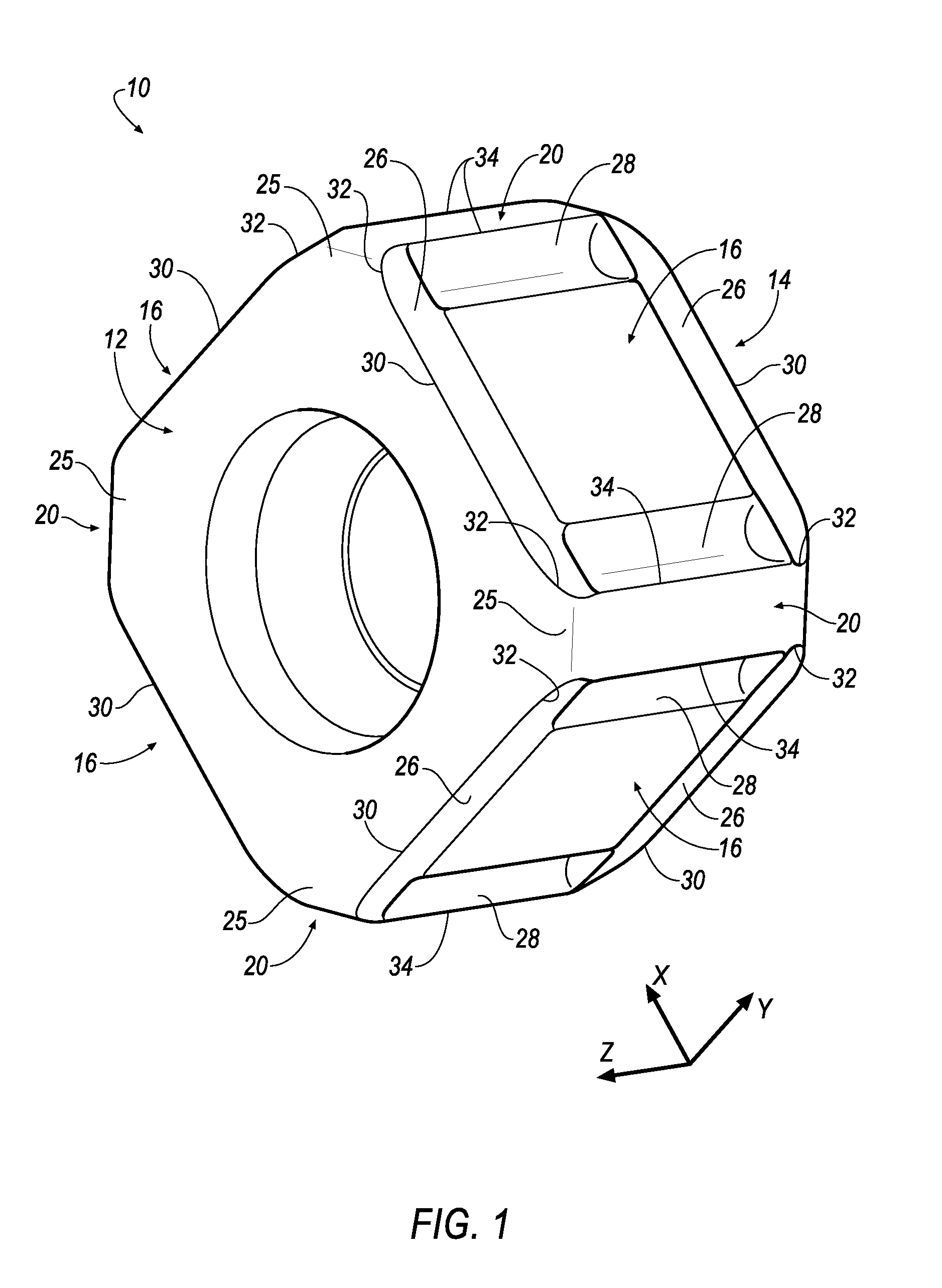

Cutting inserts

A cutting insert for use in a chipforming material removal operation that includes a cutting insert body, which has a seating surface, a flank face, and a corner cutting region at the intersection of a peripheral edge and the flank adjacent corresponding corners thereof. The cutting insert body contains a central aperture. The seating surface contains a coolant delivery trough, which has a radial orientation toward a corresponding corner cutting region. The coolant delivery trough has a radial outward end terminating at the peripheral edge and a radial inward end opening into the central aperture. There are a pair of lateral topographic regions wherein the one lateral topographic region is along one side of the coolant delivery trough and the other lateral topographic region is along other side of the coolant delivery trough.

Owner:KENNAMETAL INC

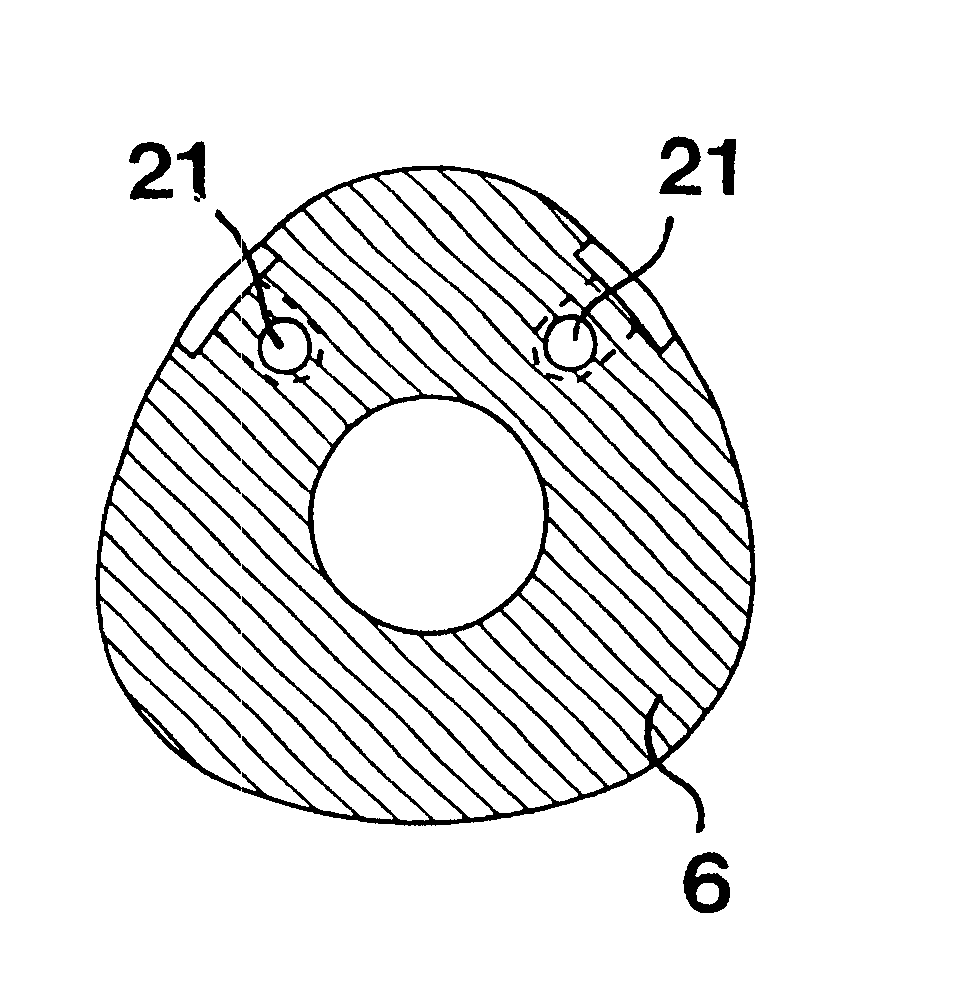

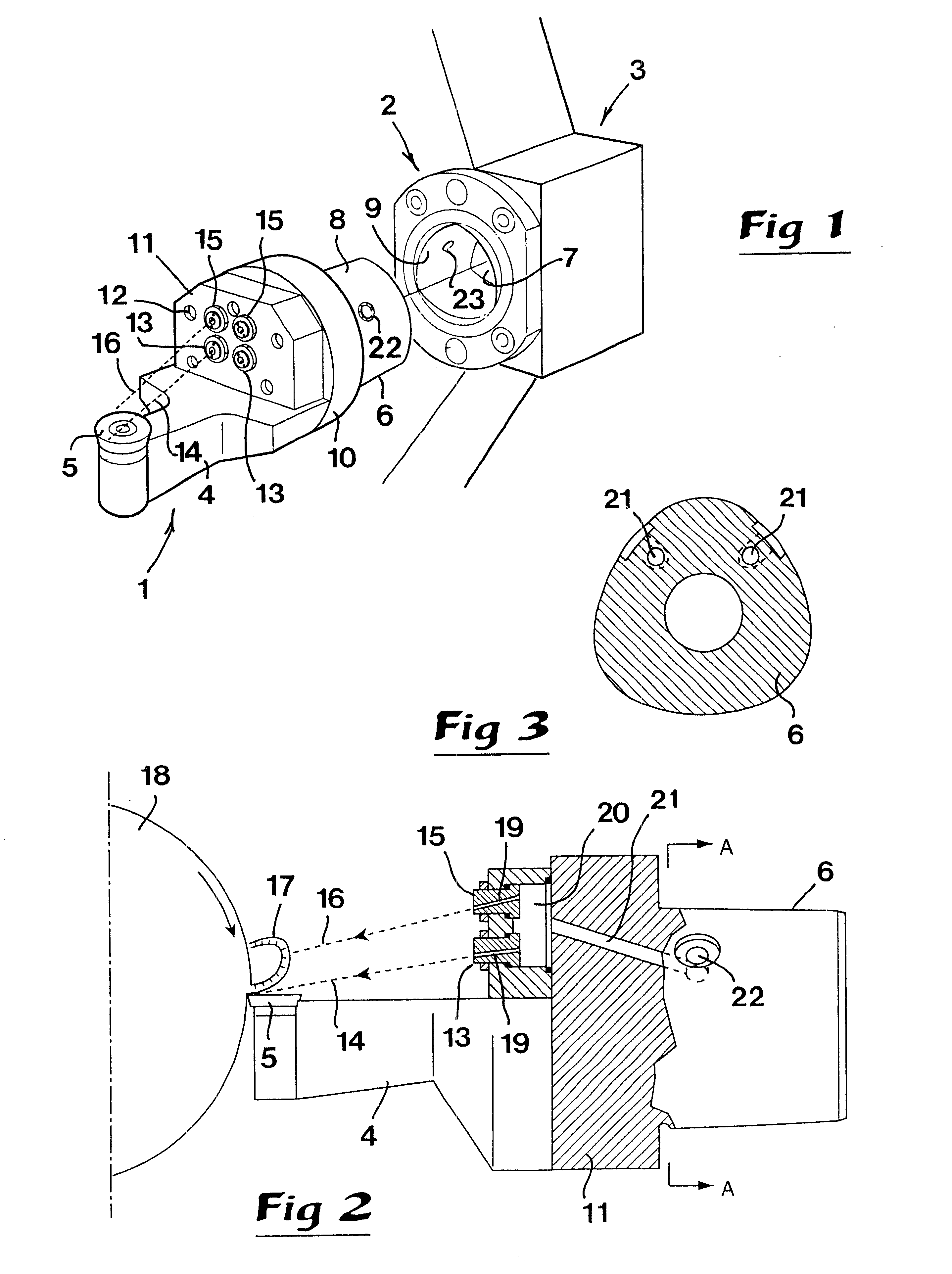

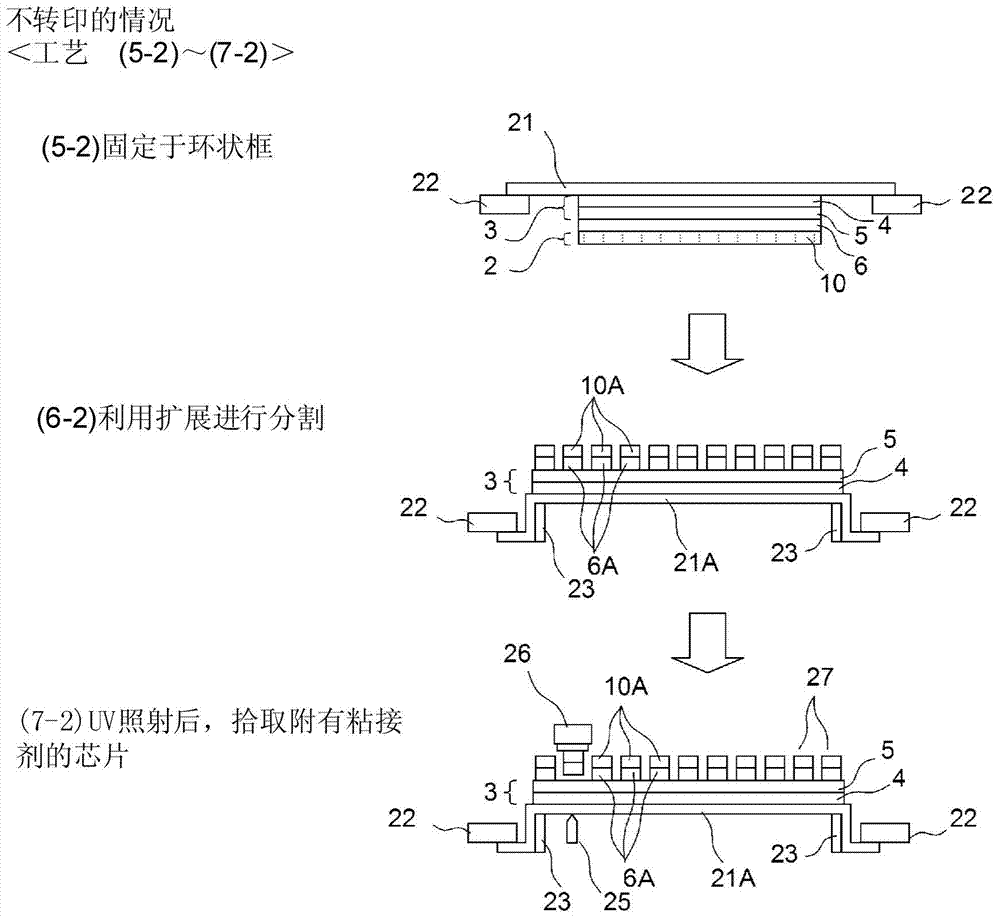

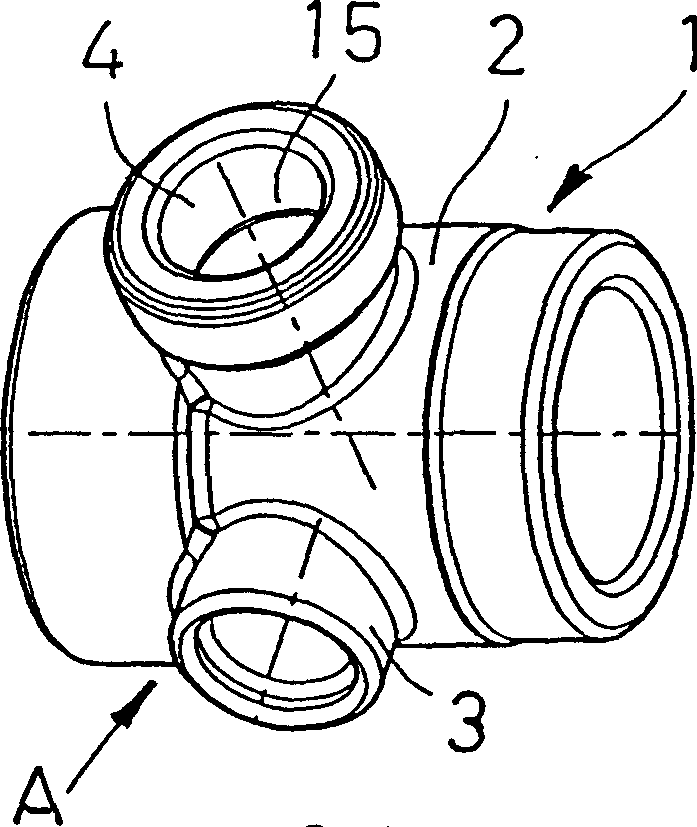

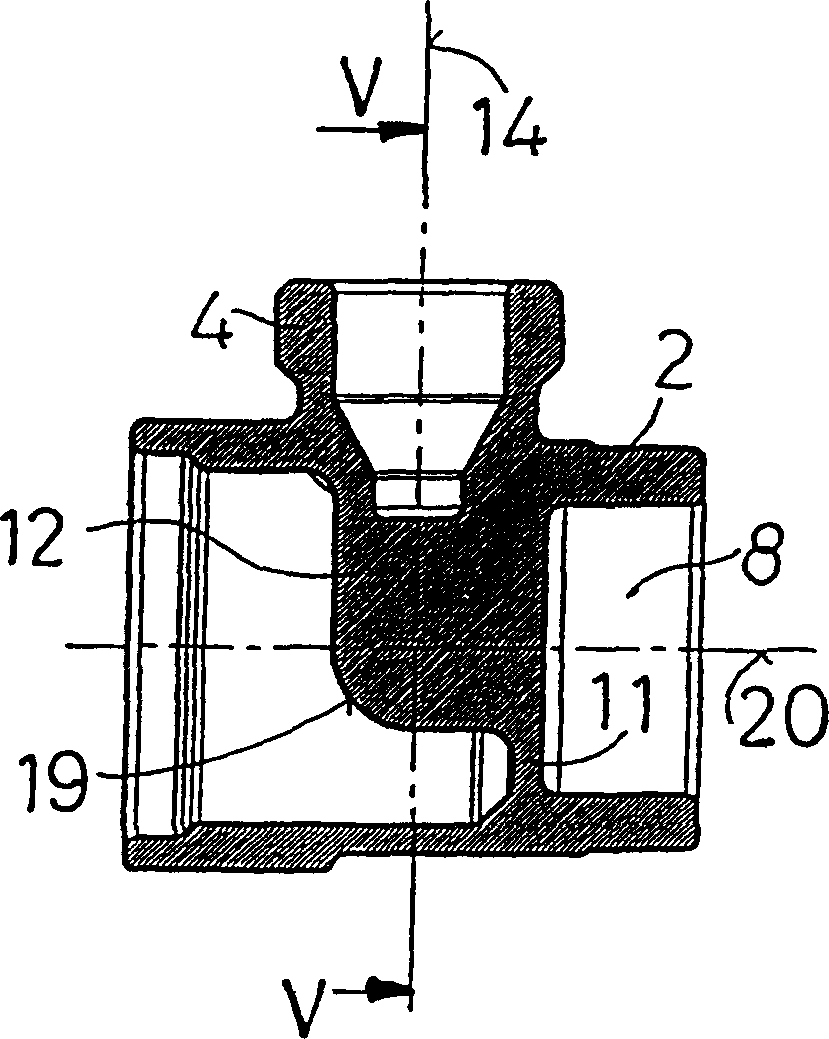

Modular manifold for heating and sanitary systems

Improved modular manifold (40) for heating and sanitary systems, comprising tubular manifold modules (21; 50, 51, 60, 61; 70, 71, 80) having integrally formed End coupling means (22, 23; 53, 54), and or only a tap (4), or a tap (4) and a regulating tap (3) for respectively receiving the pipes and switchgear of the split circuit ( 62). A metal preform (1) is provided for producing said manifold module (21; 50, 51, 60, 61; 70, 71, 80) by hot pressing and chip forming machining steps. Plastic manifold modules (21; 50, 51, 60, 61; 70, 71, 80) may also be injection molded.

Owner:贾科米尼公开有限公司

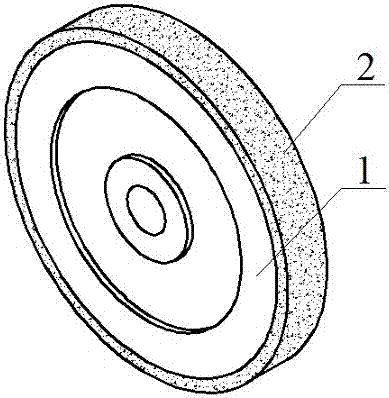

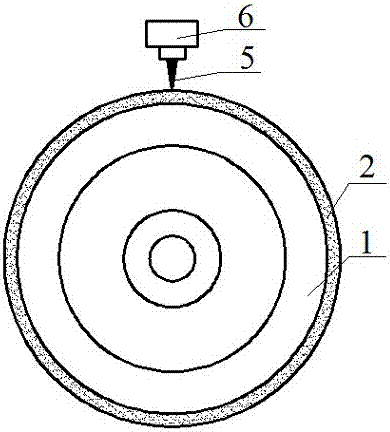

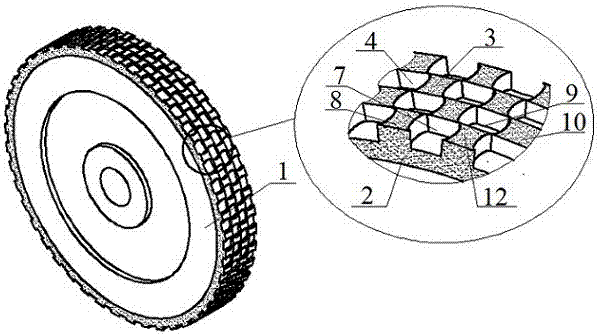

CVD diamond grinding wheel with ordered micro-structured surface and making method thereof

ActiveCN107962510AIncrease the number of effective sharpeningImprove surface qualityBonded abrasive wheelsGrinding devicesMaterial removalGas phase

The invention discloses a CVD diamond grinding wheel with an ordered micro-structured surface and a making method thereof. The grinding wheel is characterized in that a layer of diamond film is deposited on the outer circumferential face of a grinding wheel hub, a large number of staggered in-order micro grinding units are machined on the whole outer circumferential face of the diamond film, and the top ends of the grinding units are in kidney shapes. The making method is characterized in that through the chemical vapor deposition that is CVD, the diamond film is deposited on the outer circumference face of the grinding wheel hub, a pulse laser beam is adopted to machine the large number of micro grooves with the same geometric dimensioning in the outer circumference face of the whole diamond film, and the large number of micro grinding units are formed; the grinding units are arranged in a staggered and in-order manner, the top face of each grinding unit is in a kidney shape, according to the grinding wheel, the effective sharpening number of the grinding wheel during grinding can be improved, the chip formation efficiency and the surface material removal rate are improved, the cutting performance is improved, the surface machining quality and the cutting efficiency can be improved, the holding force of the grinding wheel hub to the grinding units can be increased, and the service life of the grinding wheel can be obviously prolonged.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

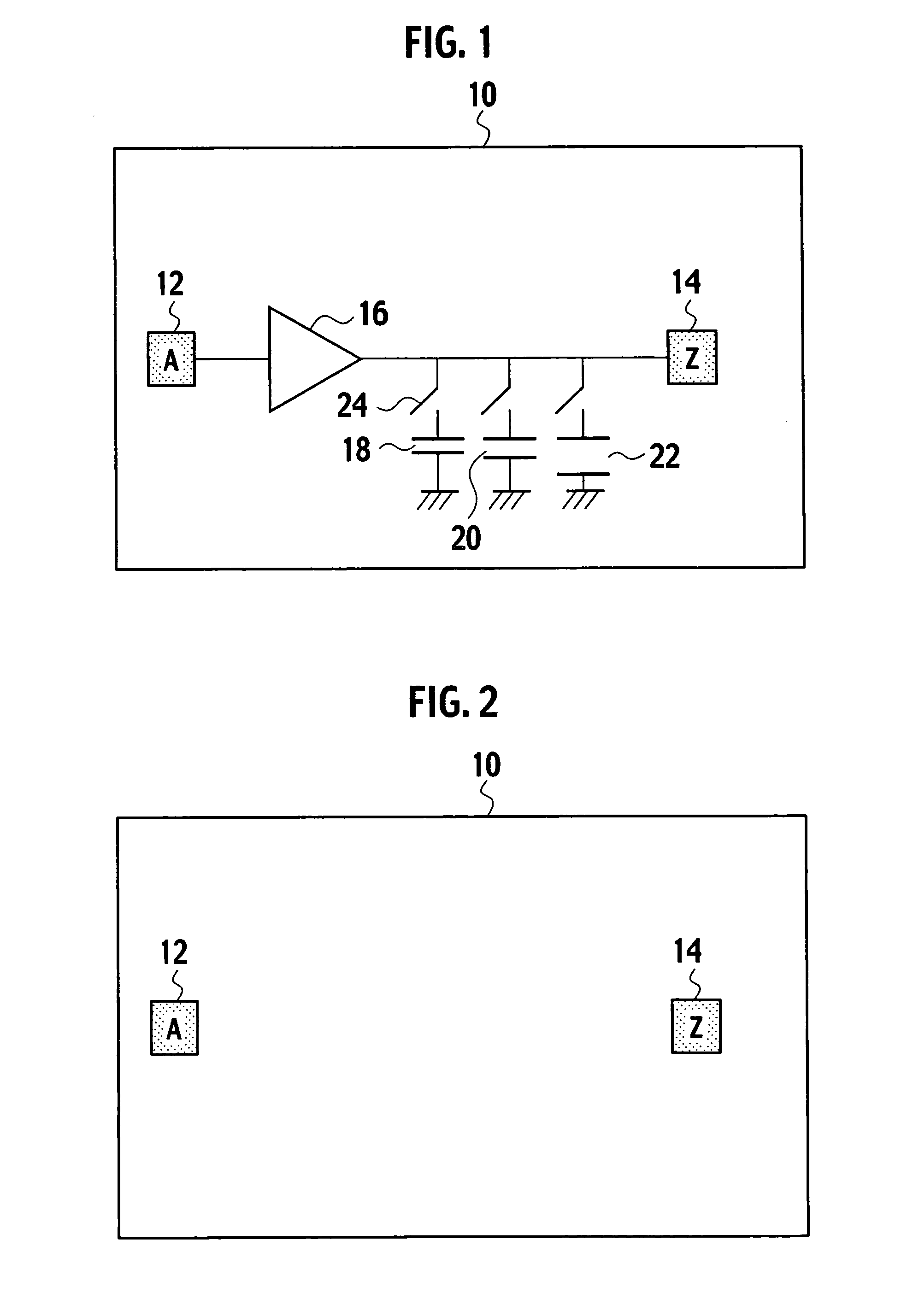

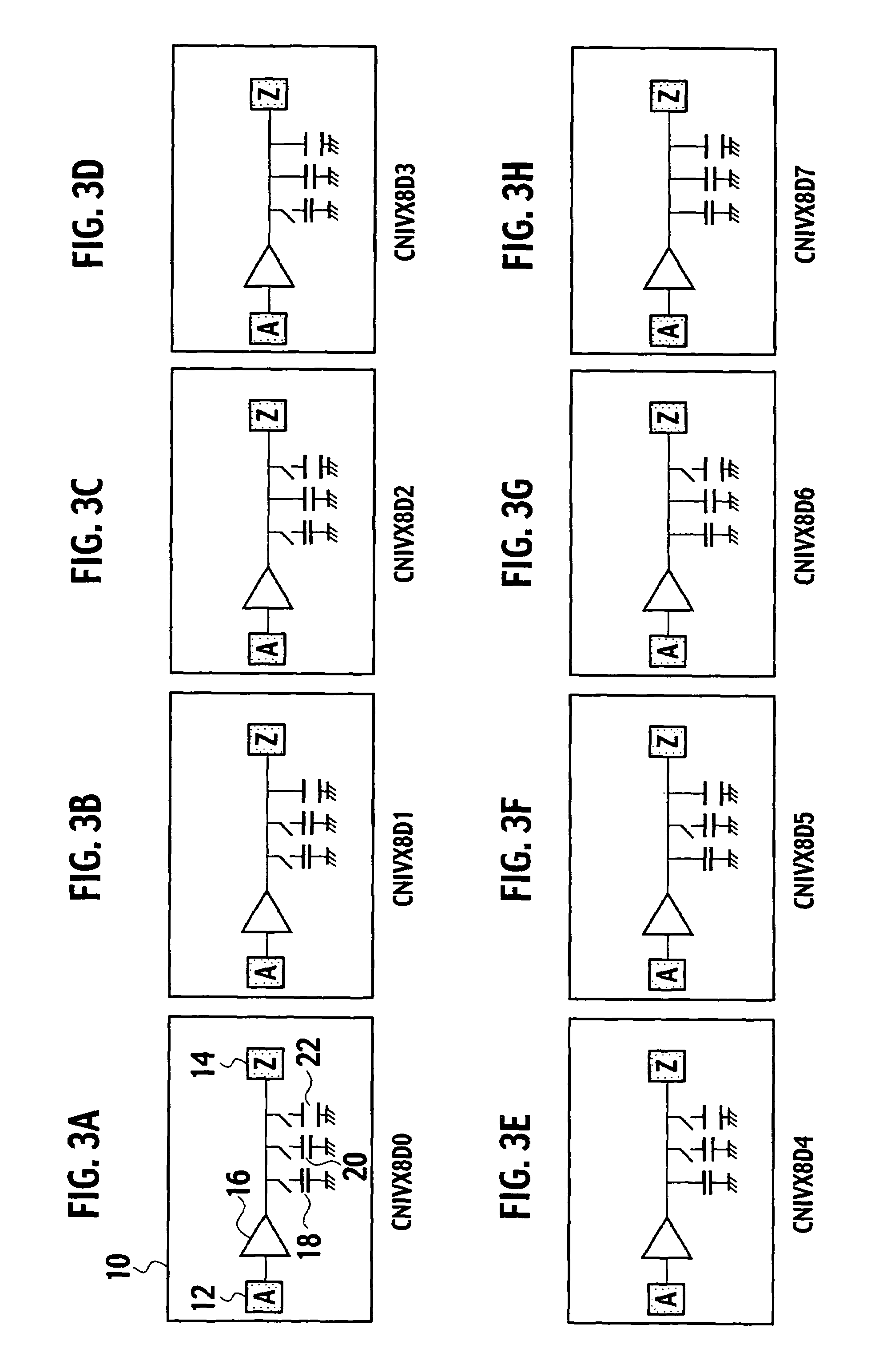

Semiconductor circuit, operating method for the same, and delay time control system circuit

A semiconductor circuit allows a timing adjustment after detailed routing without rearrangement and rerouting, an adjustment of delay variance due to process variation, and a delay adjustment even after chip formation using a primitive cell with a built-in means for adjusting delay time. The circuit connected between an input pad and an output pad, an operating method for the same, and a delay time control system circuit, which externally adjusts delay time of a plurality of control terminal-equipped / variable capacitance embedded buffers configures a semiconductor circuit. The structure includes: a first buffer connected between the input pad and the output pad; and a plurality of capacitances connectable in parallel between a fixed potential and a current flowing path, which is positioned between the first buffer and the output pad, and that controls connection between each of the plurality of capacitances and the output pad.

Owner:KK TOSHIBA

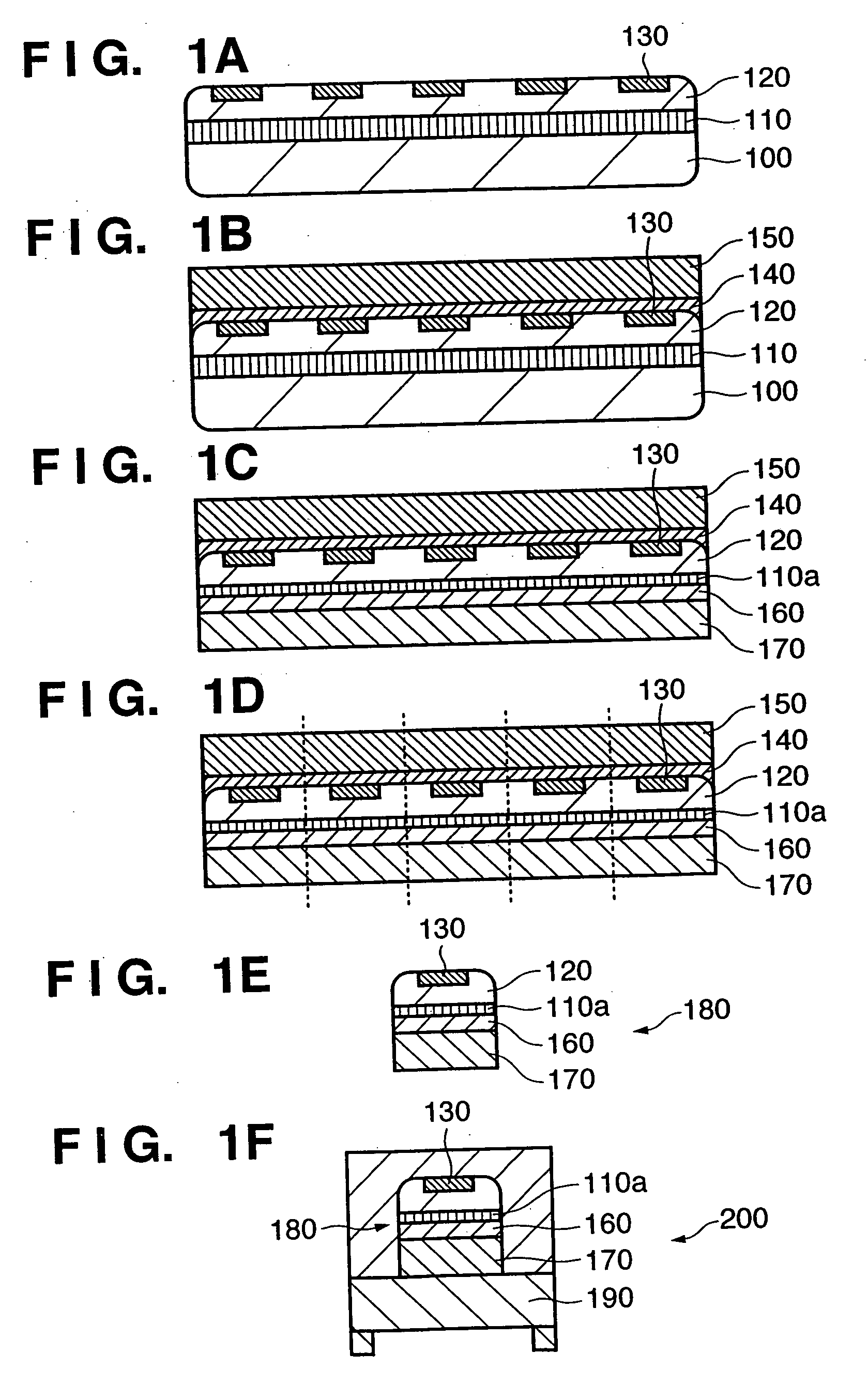

Integrated circuit chip manufacturing method and semiconductor device

ActiveUS20050280119A1Moderate difficultyFacilitate dicingSemiconductor/solid-state device detailsSolid-state devicesEngineeringChip formation

This invention moderates the difficulty in chip formation or packaging which accompanies thinning of a semiconductor region where an integrated circuit is formed. An integrated circuit chip manufacturing method includes a first bonding step of bonding a first support member to a first surface of a semiconductor substrate which has the first surface and a second surface and has a semiconductor region including an integrated circuit on a first surface side thereof, a thinning step of removing a second surface-side portion of the semiconductor substrate bonded to the first support member to leave the semiconductor region, thereby thinning the semiconductor substrate, a second bonding step of bonding a second support member to the second surface side of the thinned semiconductor substrate, and a chip forming step of forming chips by cutting the semiconductor region.

Owner:CANON KK

Semiconductor device manufacturing method, wafer and reticle

InactiveUS20070054199A1Efficient preparationLow costSemiconductor/solid-state device testing/measurementSolid-state devicesDevice materialChip formation

Owner:FUJITSU SEMICON LTD

Double-Sided Cutting Insert and Milling Cutter Mounting The Same

InactiveUS20100028092A1Extend your lifeReduce the differenceMilling cuttersTurning toolsRotational axisMilling cutter

A double-sided milling cutting insert has usable upper and lower faces. The upper face has a polygonal shape with curved edges. The lower face has a rotationally symmetrical relation to the upper face. Flank faces connect edges of the upper face to corresponding edges of the lower face. Upper cutting edges are formed on one of the edges of the upper face. The upper chip-forming portions have rake faces inclined downwardly from the upper cutting edges inwardly of the cutting insert and a plurality of protrusions arranged along inner boundaries of the rake faces for deflecting chips. When the cutting insert is mounted on the cutting tool, a width of the rake face of the upper chip-forming portion adjacent to an edge portion forming a main cutting edge gradually increases in a direction going away from a rotational axis of the cutting tool.

Owner:TAEGUTEC

Cutting insert with finishing and roughing cutting edges

ActiveUS20150071717A1High surface finishTransportation and packagingMilling cuttersMilling cutterEngineering

An indexable cutting insert includes a top surface, a bottom surface and a plurality of side surfaces. Each side surface includes a first pair of chip grooves, and a second pair of chip grooves. A planar corner surface is disposed between each side surface. A corner radius extends between the top and bottom surfaces and the planar corner surface. A plurality of primary wiper cutting edges are formed at an intersection between each of the first pair of chip grooves and the the top and bottom surfaces. A plurality of secondary roughing cutting edges are formed at an intersection between each corner radius and each of the first pair of chip forming grooves. A plurality of wiper cutting edges are formed at an intersection between each planar corner surface and each of the second pair of chip forming grooves. A milling cutter is also disclosed.

Owner:KENNAMETAL INC

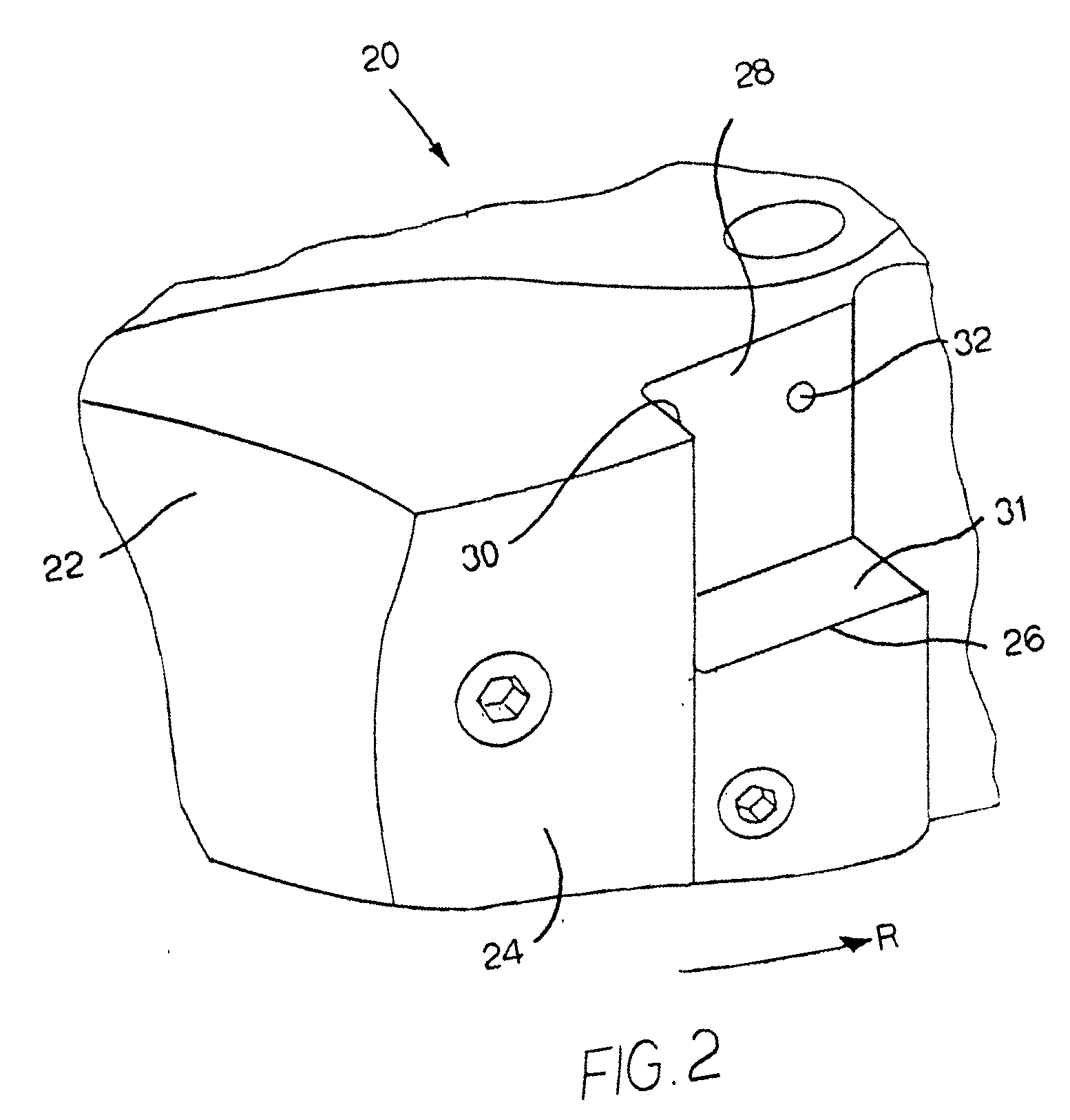

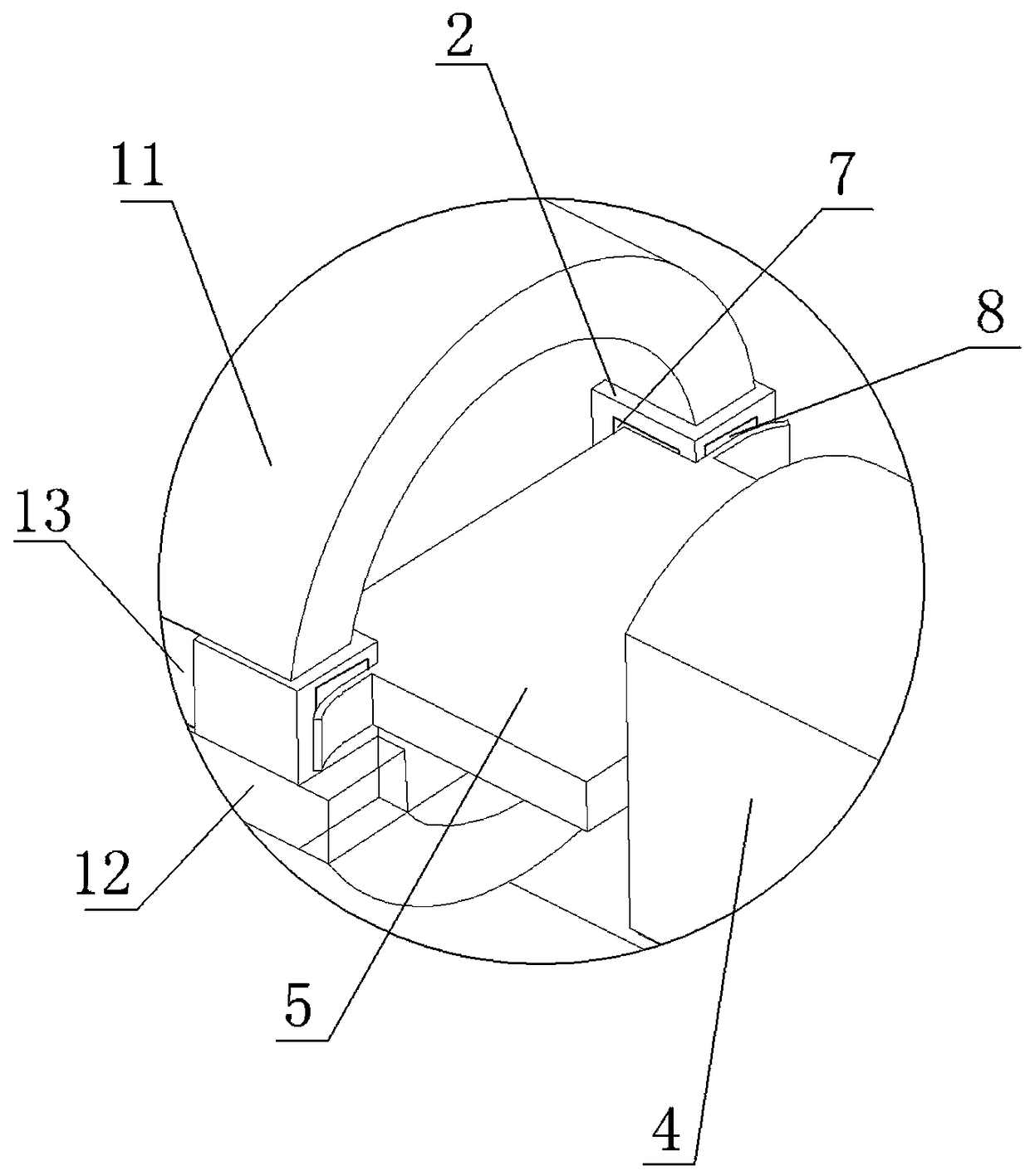

Device and method for monitoring tool state in cutting process and chip formation

ActiveCN108356607ASuppression of low frequency vibrationGuaranteed Acquisition AccuracyMeasurement/indication equipmentsData acquisitionChip formation

The invention discloses a device and a method for monitoring the tool state in a cutting process and chip formation. The device comprises a tool and an AE signal collector which are mounted on a toolholder, a workpiece, a test platform and a data acquisition system, wherein the tool holder includes a main clamp holder, a sub-clamp-holder and a heat-insulating damping pad, the tool and the heat-insulating damping pad are arranged side by side between the main clamp holder and the sub-clamp-holder, the sub-clamp-holder is locked on the main clamp holder in the forward direction through connecting bolts penetrating through the heat-insulating damping pad, the sub-clamp-holder reversely and tightly abuts against the main clamp holder through an adjusting bolt, and the AE signal collector is mounted on the sub-clamp-holder; and a first piezoelectric force transducer is arranged on the flank surface of the tool, a second piezoelectric force transducer is arranged on the rake face of the tool, a surface strain meter is mounted on the main clamp holder, and a high speed CCD camera is mounted above the tool. According to the device and the method for monitoring the tool state in the cutting process and the chip formation, AE signal has high acquisition precision, good independence and high relevance.

Owner:CENT SOUTH UNIV +1

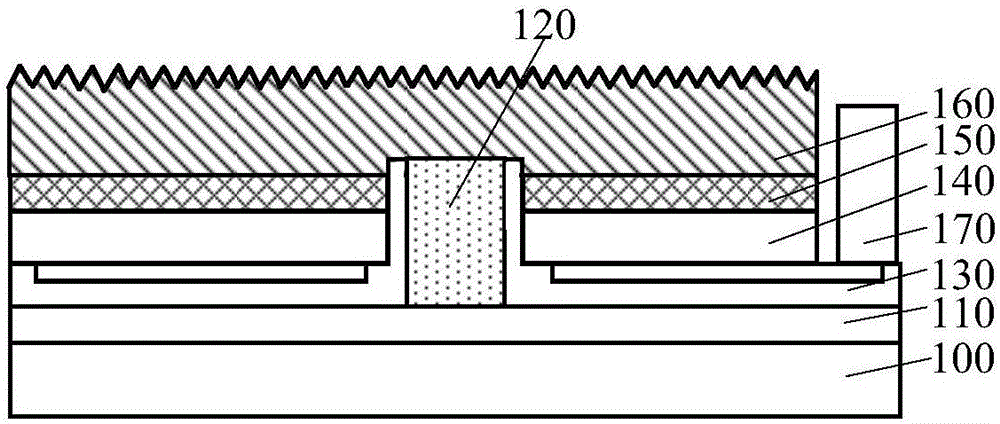

LED chip and formation method thereof

InactiveCN106409997AReduce process complexitySemiconductor devicesInsulation layerElectrical conductor

The present invention provides a LED chip and a formation method thereof. The method comprises: providing a first substrate which is provided with a front end structure consisting of a first semiconductor layer, an active layer and a second semiconductor layer from up to down, wherein the front structure has a zone 1 and a zone 2; forming a groove at the zone 1, wherein the groove penetrates the second semiconductor layer and the active layer; forming a connection conducting layer at the zone 1 around the groove and at the surface of the top of the second semiconductor layer; forming an insulation layer covering the connection conducting layer and the side wall of the groove and exposing the first semiconductor layer at the bottom of the groove and the surface of the top of the second semiconductor layer of the zone 2; performing the bonding processing to allow the insulation layer, the first semiconductor layer at the bottom of the groove and the second semiconductor layer of the zone 2 to combine with a second substrate through a bonding body; removing the first substrate; etching the front end structures of the zone 1 and the part of the zone 2 to respectively correspondingly expose part of the bonding body and the connection conducting layer; and forming an electrode layer at the surfaces of the connection conducting layer and the bonding body. The LED chip formation method can reduce the chip packaging complexity on a LED chip board.

Owner:ENRAYTEK OPTOELECTRONICS

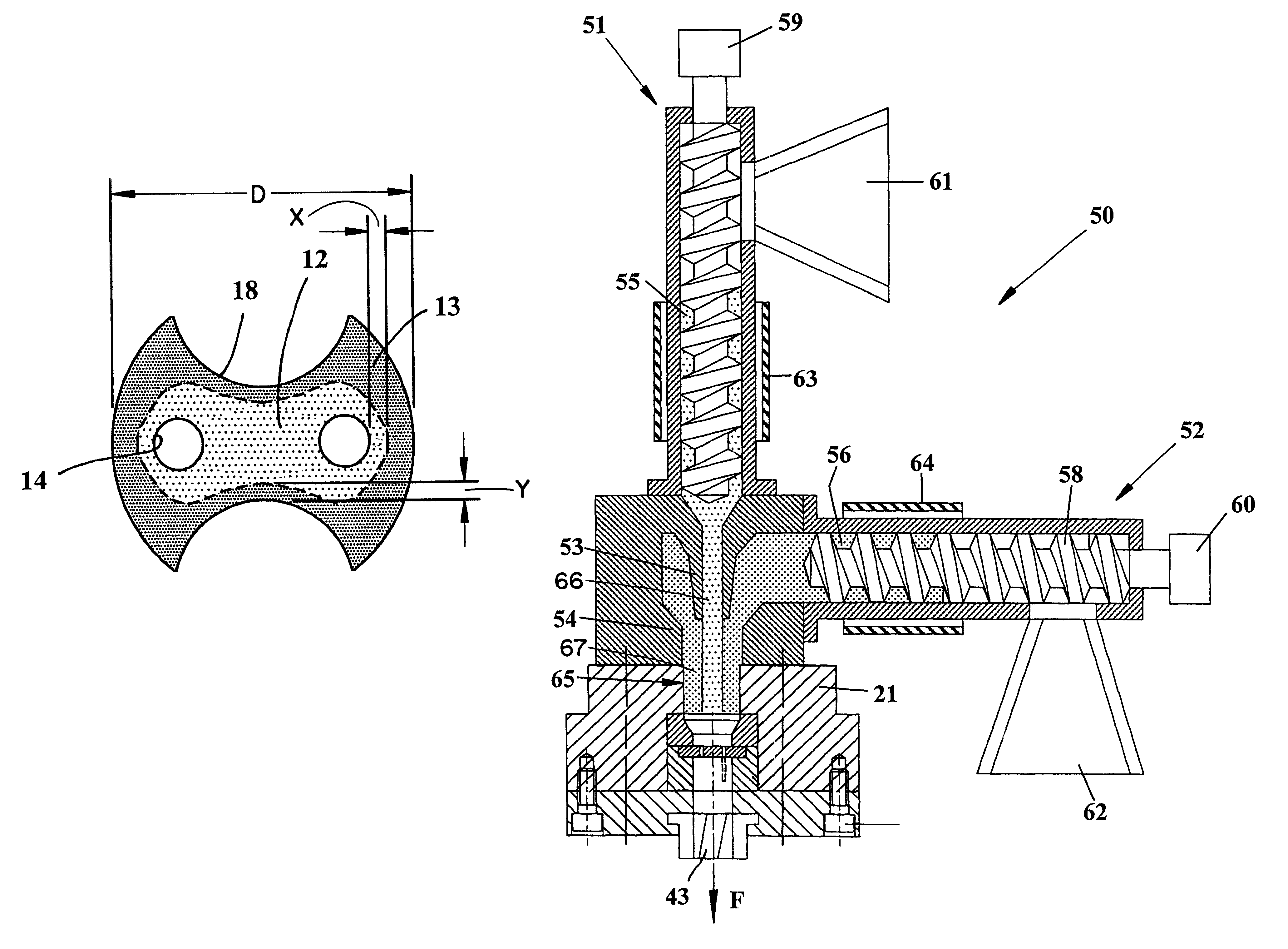

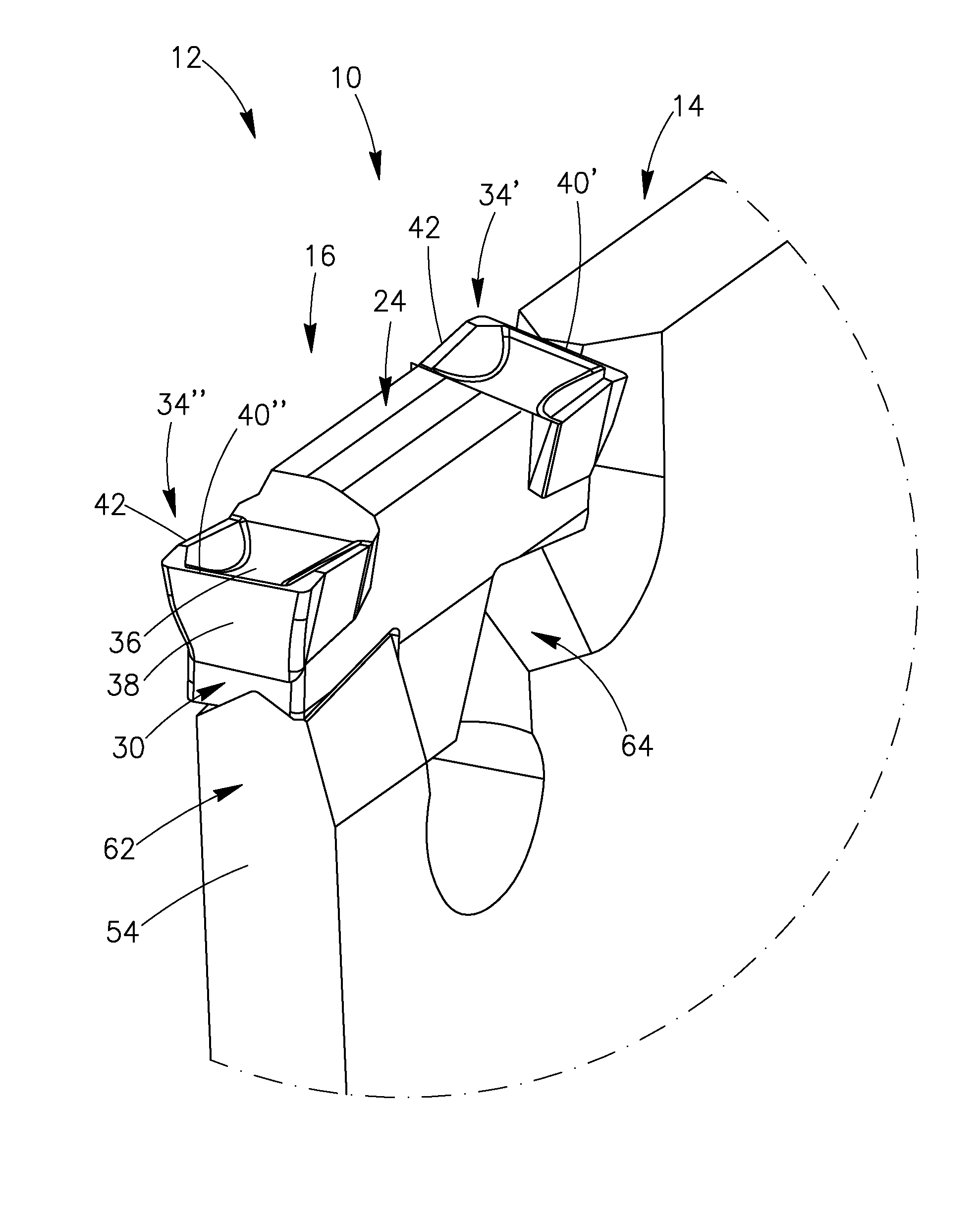

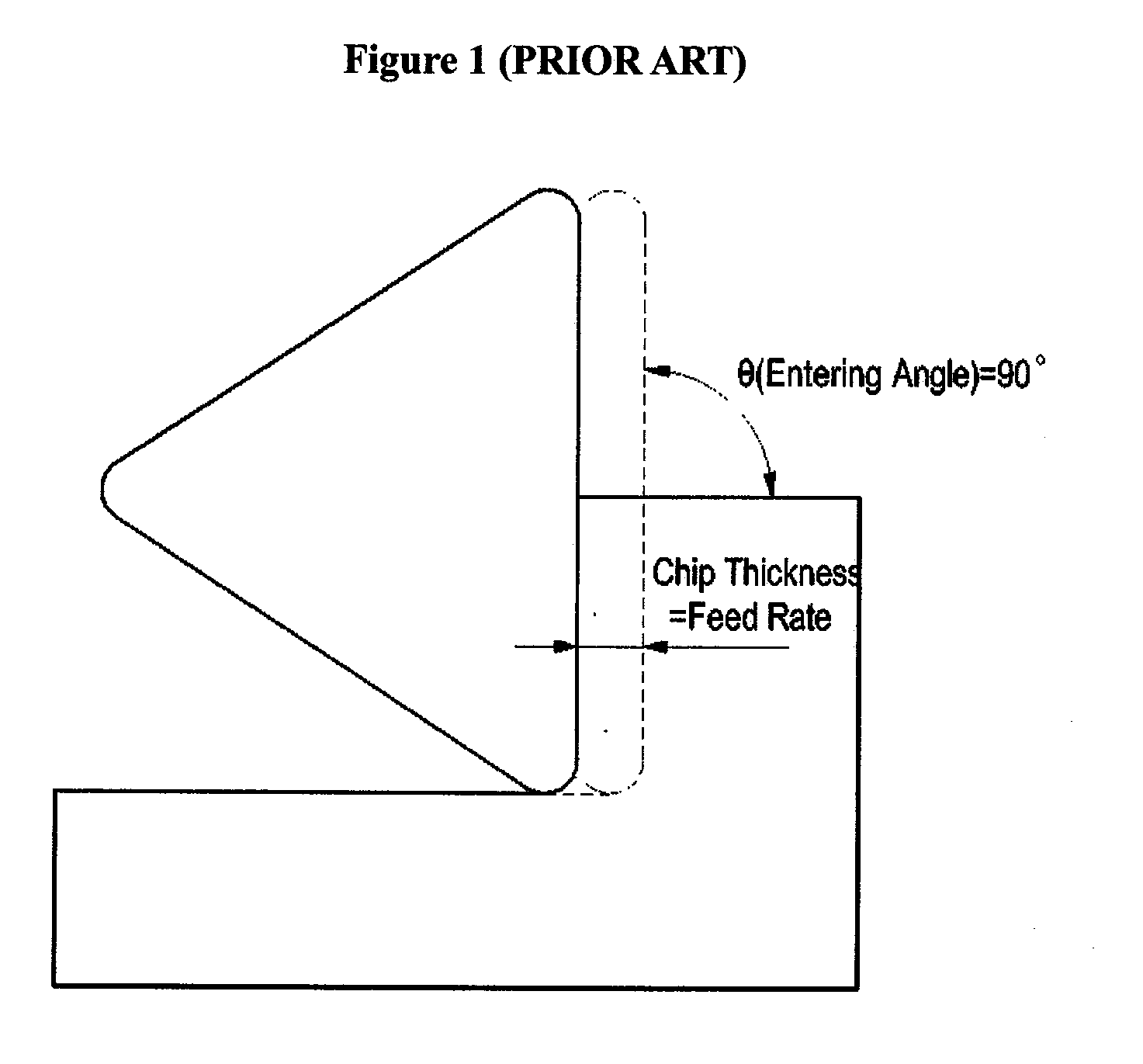

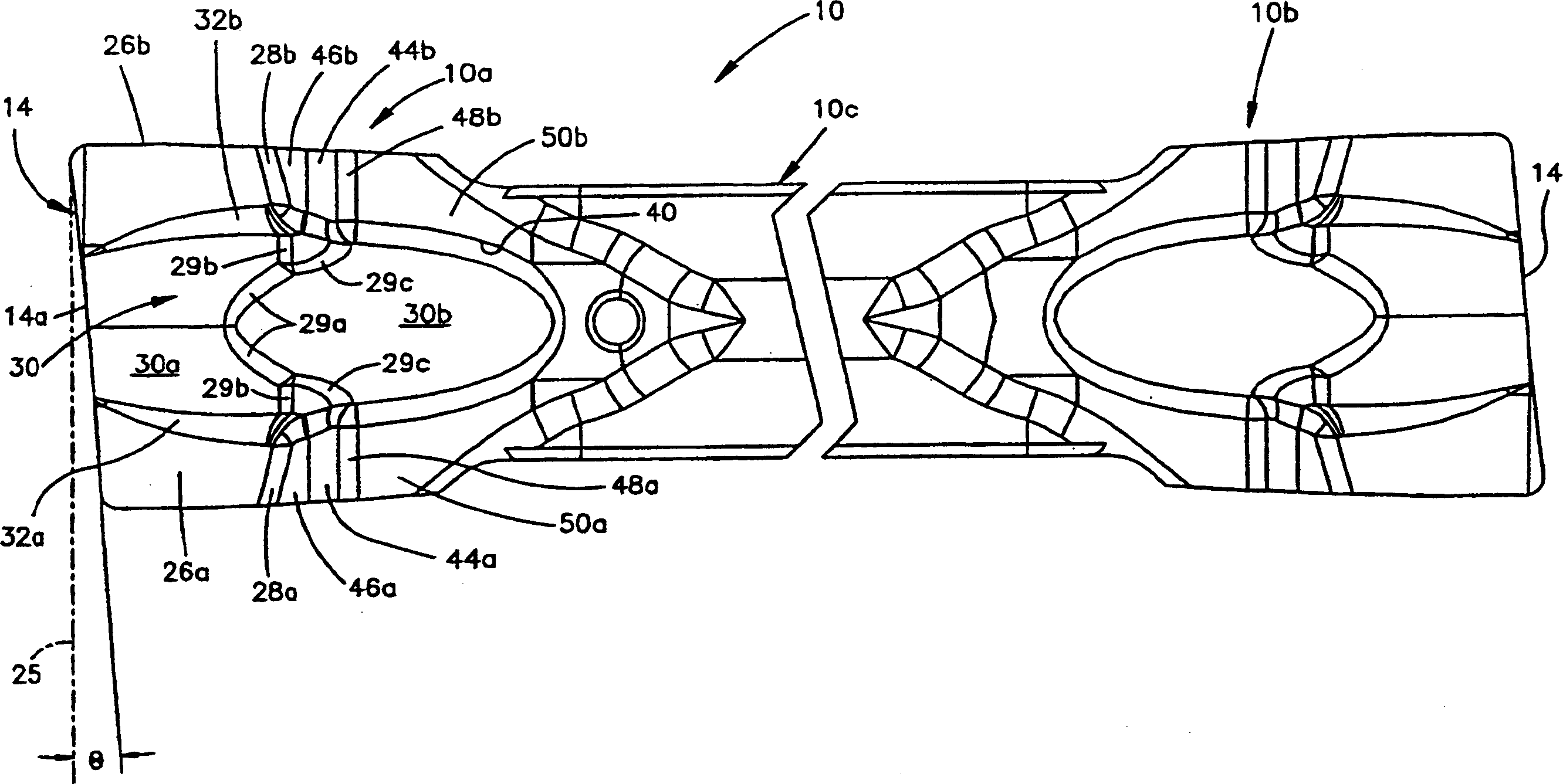

Spade drill insert having curved cutting edges

ActiveUS20050100420A1Improved chip formationWood turning toolsTransportation and packagingChip formationKnife blades

A spade drill insert and drilling tool assembly is provided wherein the spade drill insert body comprises curved cutting edges and a lip groove having a trough substantially parallel to a plane formed through each adjacent curved cutting edge, which provides a significant improvement in chip formation during cutting operations.

Owner:ALLIED MASCH & ENG CORP

Virtual manufacturing of transmission elements

A software structure which when adapted in an apparatus is capable of virtual manufacturing of transmission elements for example gear means with chip formation, the software structure comprising a start module for loading the source file in a main editor-file that contains the computer program, an input module for providing input parameters that are essential for the configuration of a product and a cutting tool, a product design module for evolving the parameters for the manufacturing of the product; and a virtual manufacturing module having at least three sub-modules one each for tool generation, visualisation of machining operation, and disassembly of the product from the machine bed.

Owner:IONSENSE +1

Cutting inserts

A cutting insert for use in a chipforming material removal operation that includes a cutting insert body, which has a seating surface, a flank face, and a corner cutting region at the intersection of a peripheral edge and the flank adjacent corresponding corners thereof. The cutting insert body contains a central aperture. The seating surface contains a coolant delivery trough, which has a radial orientation toward a corresponding corner cutting region. The coolant delivery trough has a radial outward end terminating at the peripheral edge and a radial inward end opening into the central aperture. There are a pair of lateral topographic regions wherein the one lateral topographic region is along one side of the coolant delivery trough and the other lateral topographic region is along other side of the coolant delivery trough.

Owner:KENNAMETAL INC

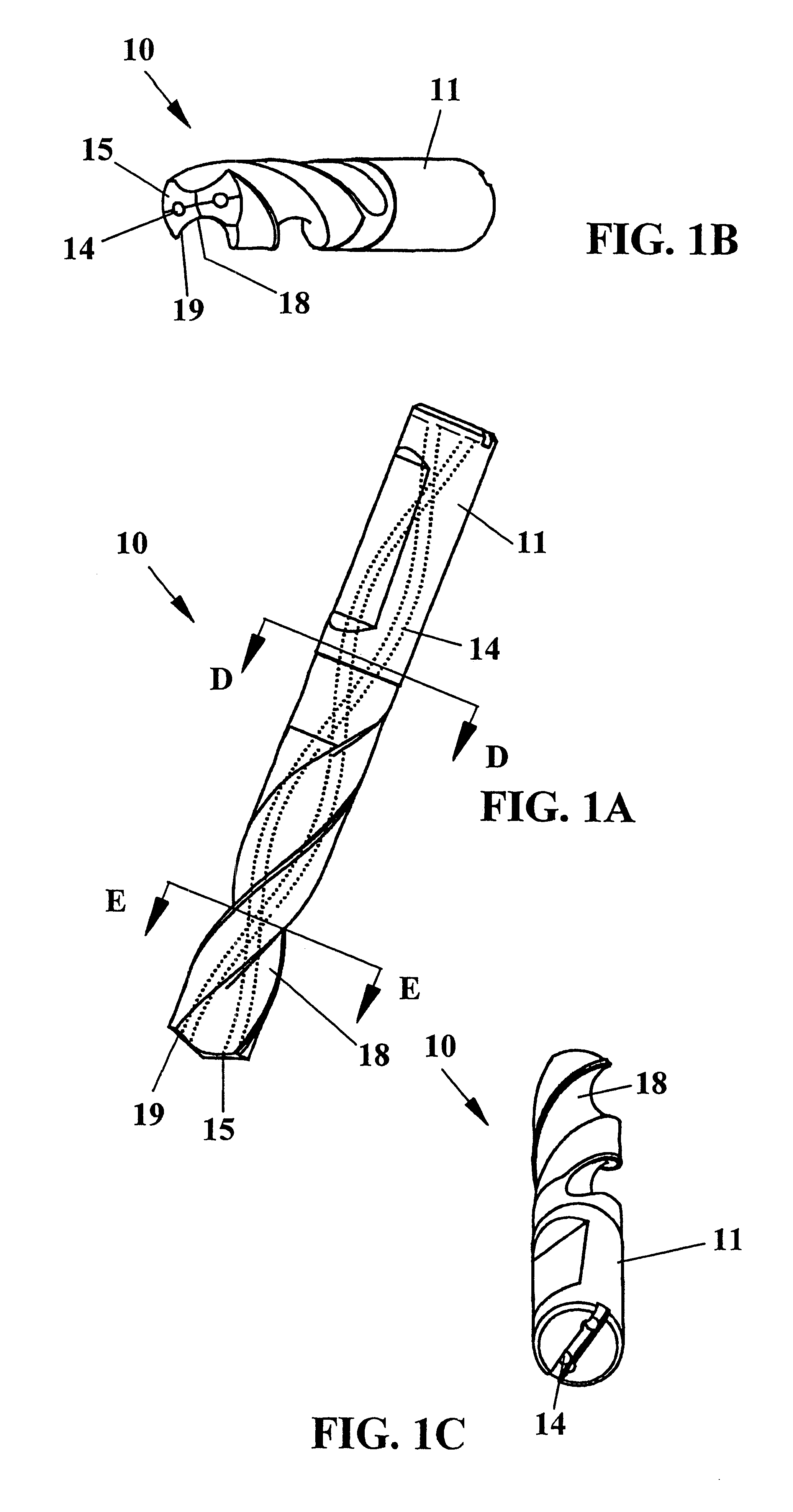

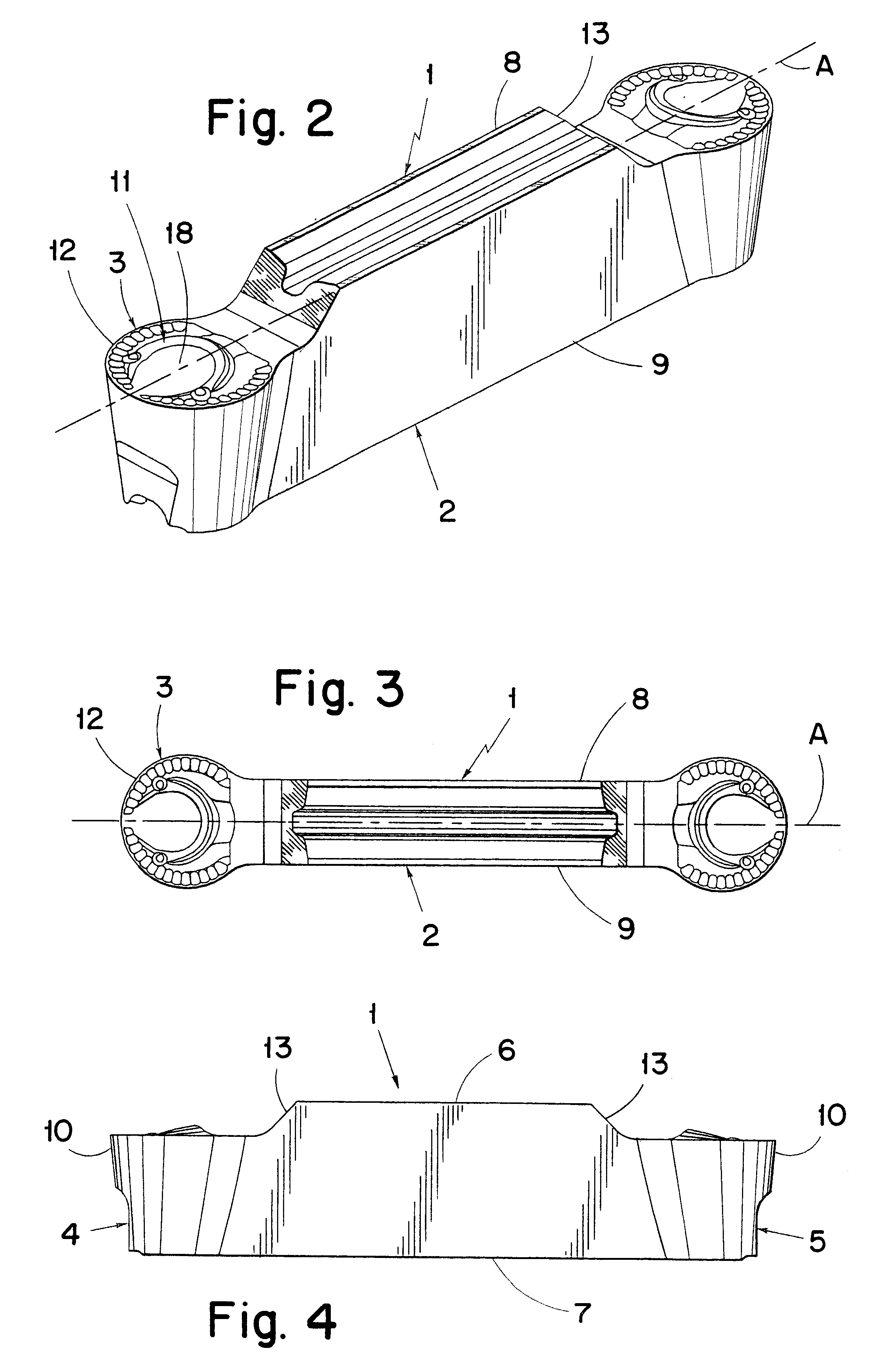

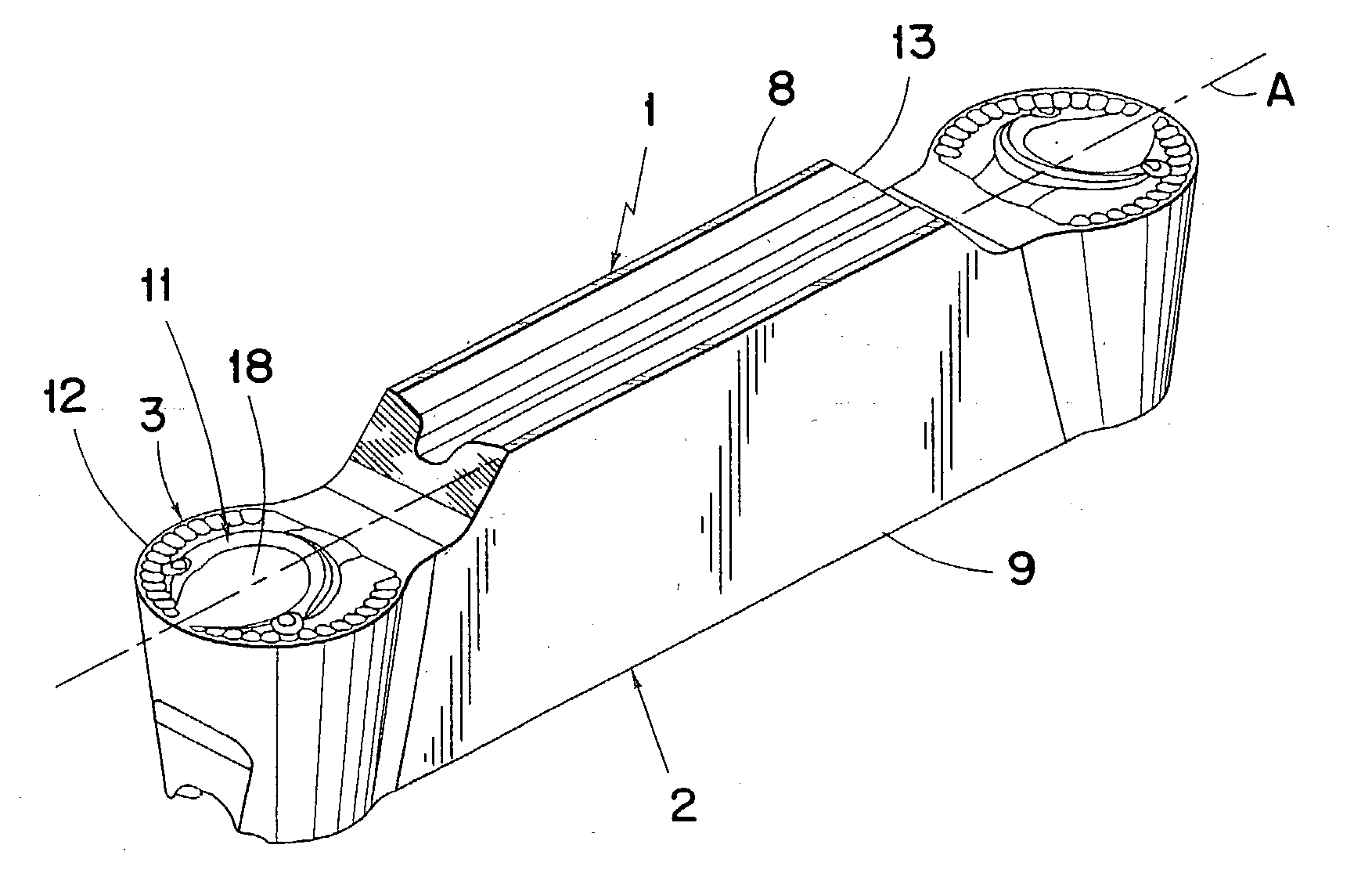

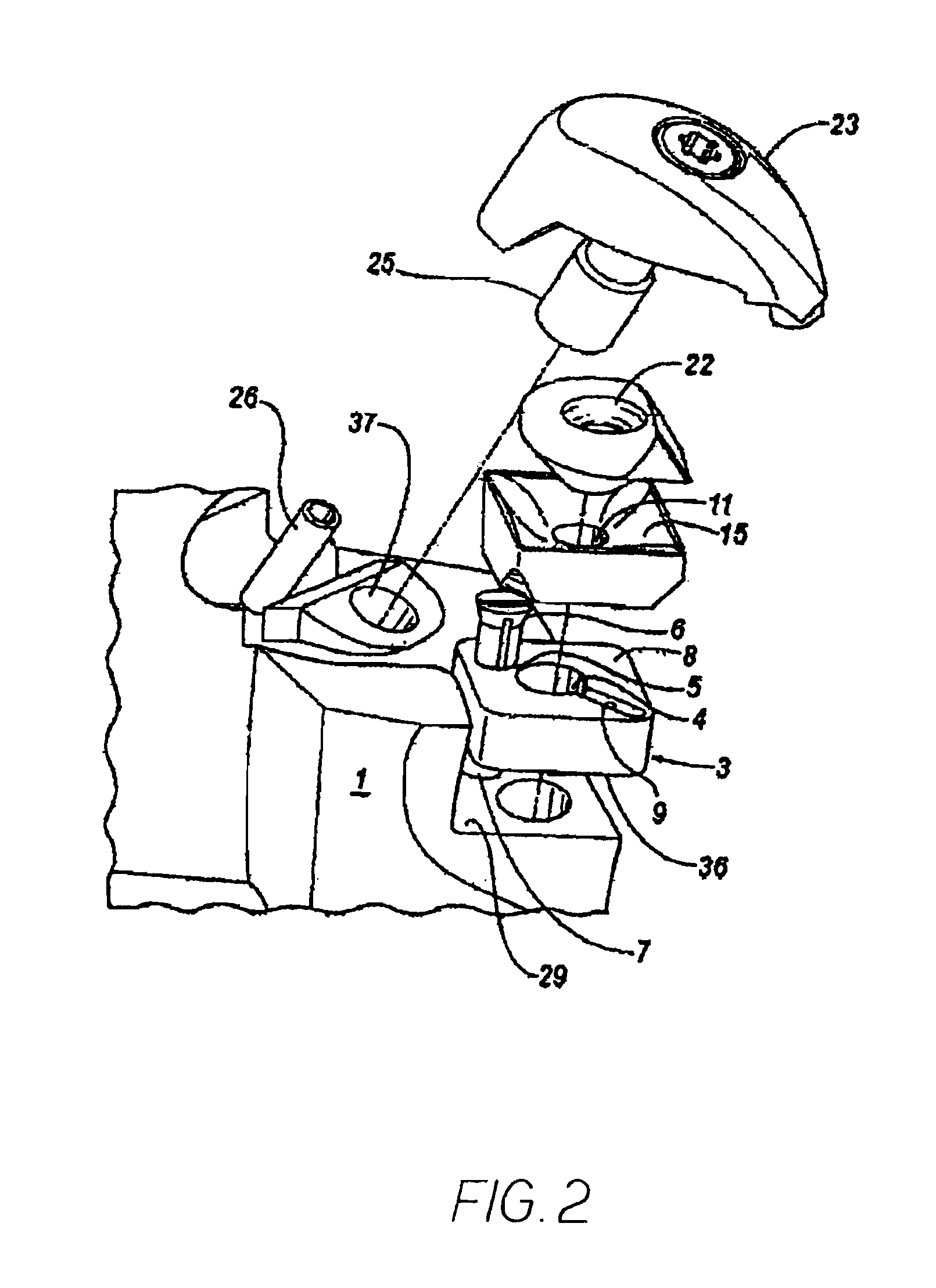

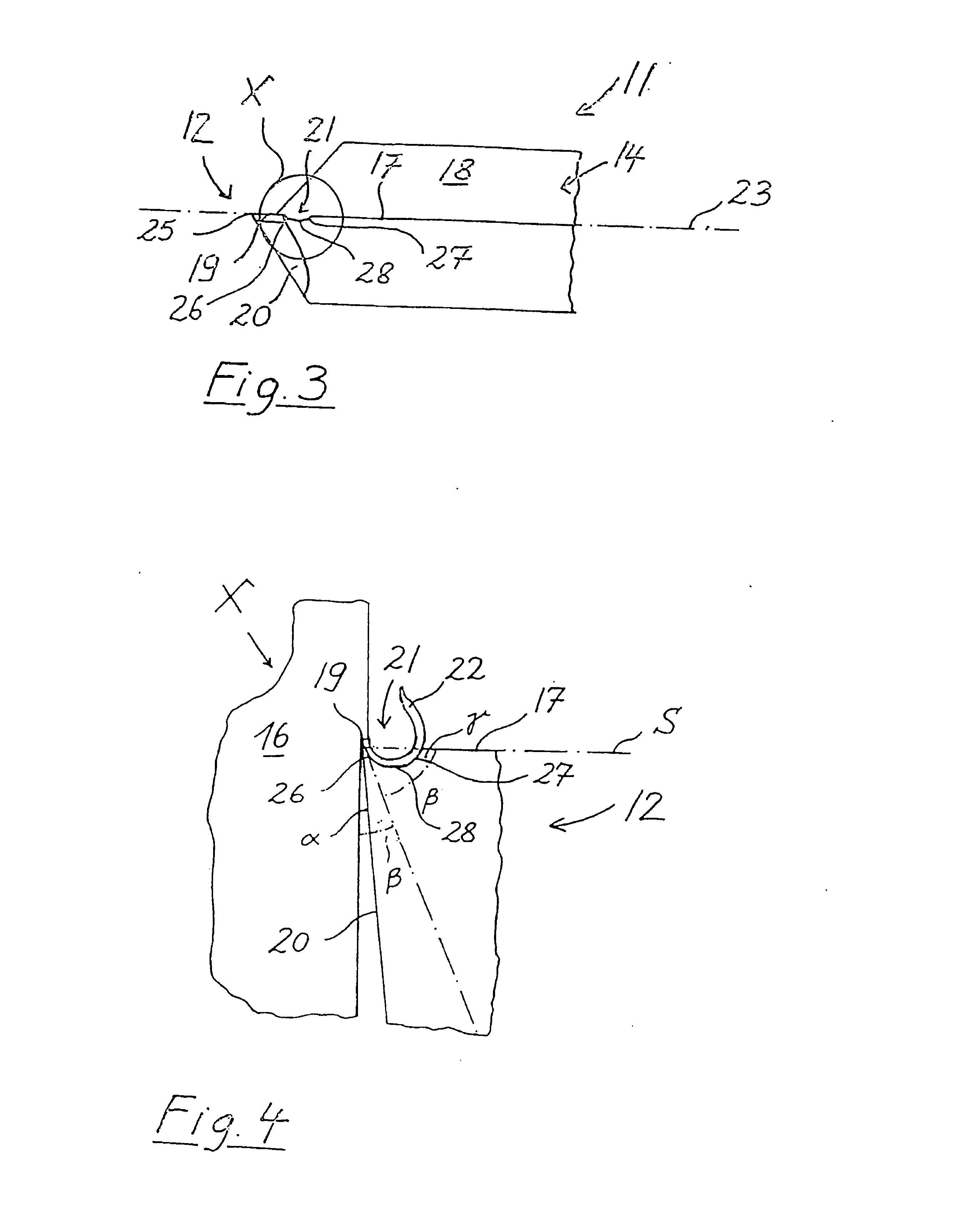

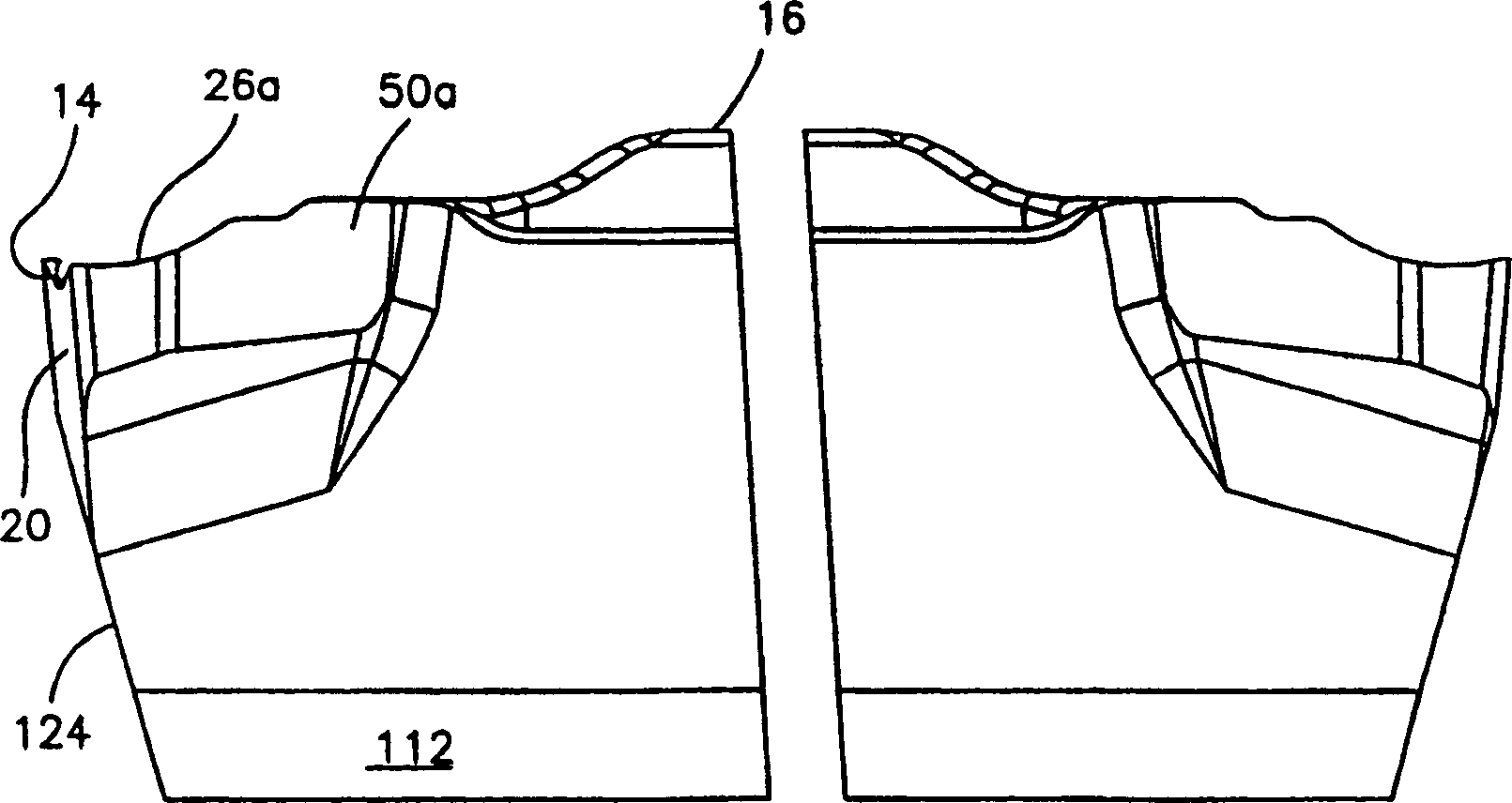

Single-lip drill and method for the production thereof

ActiveUS20070041801A1Low viscosityReliable removalThread cutting toolsWood turning toolsEngineeringChip formation

Disclosed is a single-lip drill comprising a drill head (11) that is provided with a blade (12) which is embodied on said drill head. The blade encompasses a cutting edge (19) for machining a workpiece (16) in a cutting manner. At least one chip-forming device (21) which shapes chips (22) cut by the cutting edge is associated with the cutting edge. The chip-forming device is provided with a positive cutting angle (gamma) such that the mechanical and thermal stress can be reduced in the area of the blade (12). In addition, the chip-forming device can comprise a functional coating (29a, 29b) which is made especially of hard material and is applied after providing the drill with the exterior shape thereof.

Owner:TBT TIEFBOHRTECHN

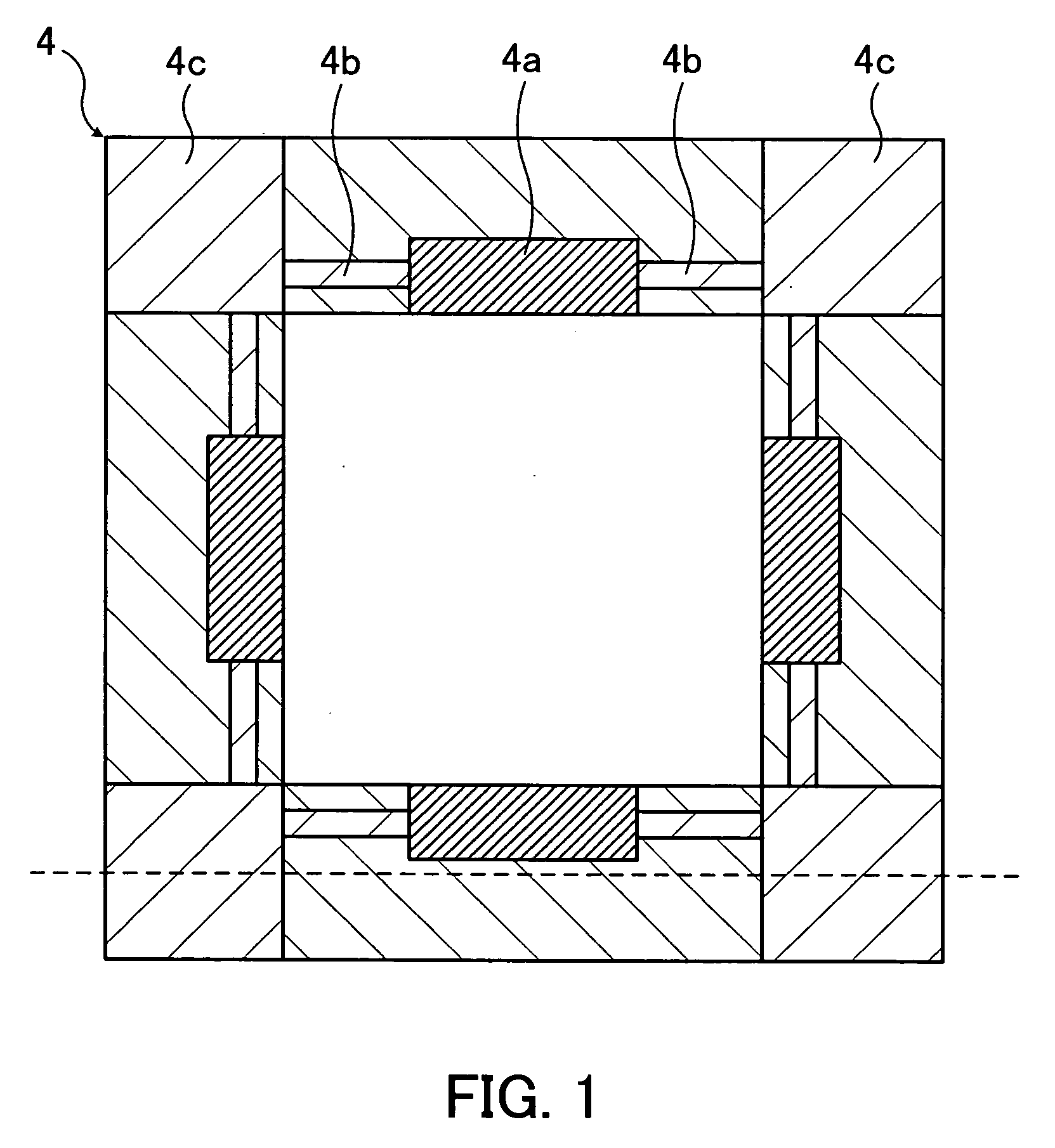

Method of generating ejection pattern data, and head motion pattern data; apparatus for generating ejection pattern data; apparatus for ejecting functional liquid droplet; drawing system; method of manufacturing organic el device, electron emitting device, pdp device, electrophoresis display device, color filter, and organic el; and method of forming spacer, metal wiring, lens, resist, and light diffuser

InactiveUS6863370B2Promote generationThe process is convenient and fastGas discharge electrodesSolid-state devicesHead movementsElectrophoresis

A method of generating ejection pattern data for a plurality of nozzles for use in selectively ejecting functional liquid droplets from the nozzles is to draw on ore more one chip-forming area on a workpiece. The method includes a pixel-setting step of setting pixel information concerning an array of pixels in the chip-forming areas, a chip-setting step of setting chip information concerning an array of the chip-forming areas on the workpiece, a nozzle-setting step of setting nozzle information concerning an array of the nozzles, and a data-generating step of generating the ejection pattern data for the nozzles from the pixel information, the chip information, and the nozzle information, based on a positional relationship between the workpiece and the functional liquid droplet ejection head. The ejection pattern data are easily and quickly generated for the nozzles arranged in an array in the plurality of functional liquid droplet ejection heads.

Owner:KATEEVA

Process for producing semiconductor devices, and semiconductor device

InactiveCN105377980AImprove heat resistanceExcellent resistance to temperature cyclingEpoxySemiconductor chip

A process for semiconductor device production which comprises: a preparation step in which a substrate for element mounting (108) equipped with a plurality of package areas (114) separated by dicing regions (112) is prepared; a mounting step in which semiconductor chips (116) are mounted respectively on the package areas (114) of the substrate for element mounting (108); a molding step in which the semiconductor chips (116) are simultaneously encapsulated by molding with an encapsulating epoxy resin composition; and a chip formation step in which the resultant structure is diced along the dicing regions (112) to separate the individual encapsulated semiconductor chips (116). The encapsulating epoxy resin composition comprises (A) an epoxy resin, (B) a hardener, (C) a silicone resin, (D) an inorganic filler, and (E) a hardening accelerator, wherein the silicone resin (C) is a branched silicone resin that is a methylphenyl-type thermoplastic silicone resin and has repeating structural units represented by general formulae (a), (b), (c), and (d). (In the formulae, symbol * indicates a bond with the Si atom contained in a repeating structural unit of another or the same kind; and R1a, R1b, R1c, and R1d are each a methyl or phenyl group and may be the same as or different from one another. The content of Si-bonded phenyl groups is 50 mass% or higher of the molecule, and the content of Si-bonded OH groups is less than 0.5 mass% of the molecule.) The formulae is shown in the specification.

Owner:SUMITOMO BAKELITE CO LTD

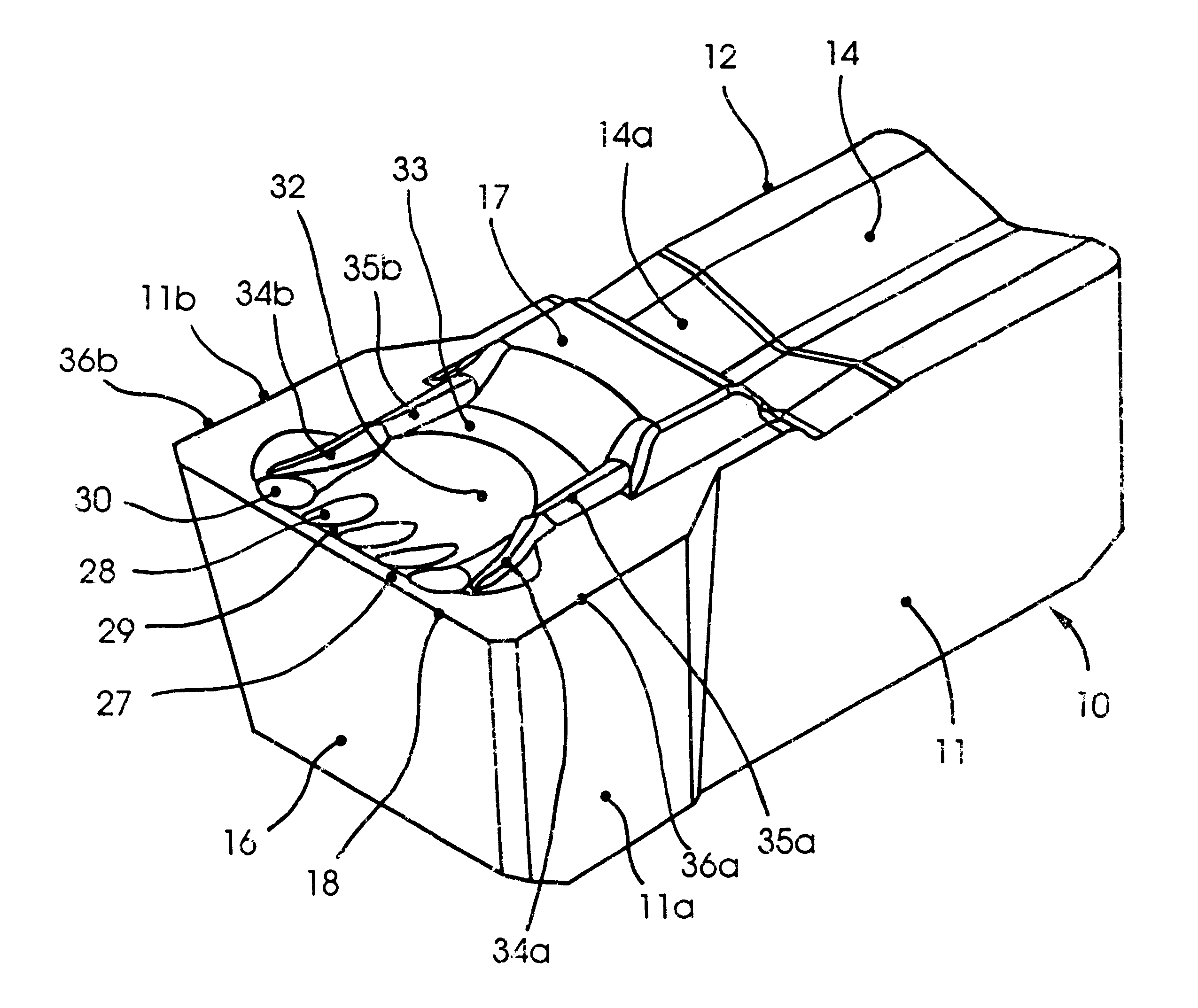

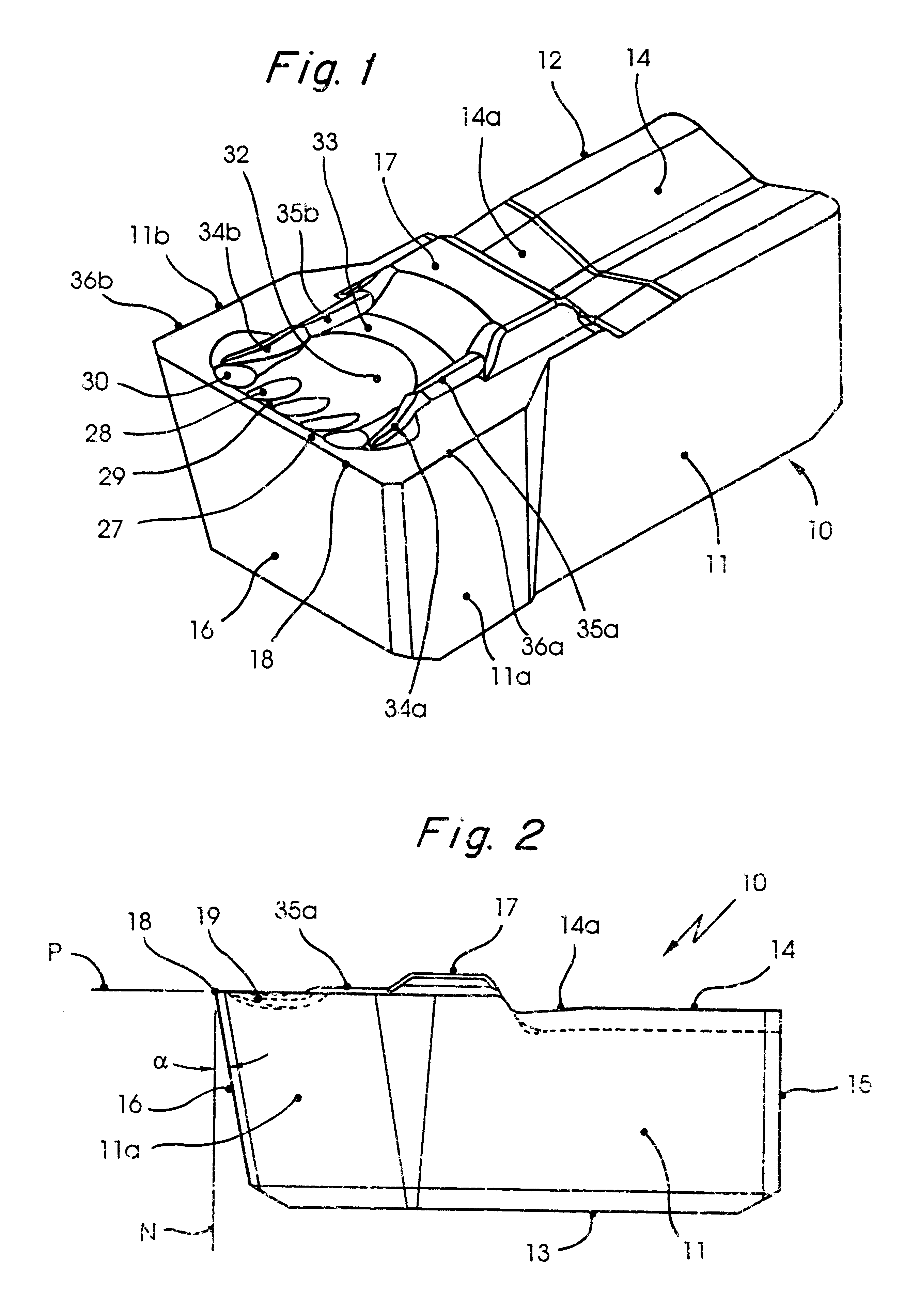

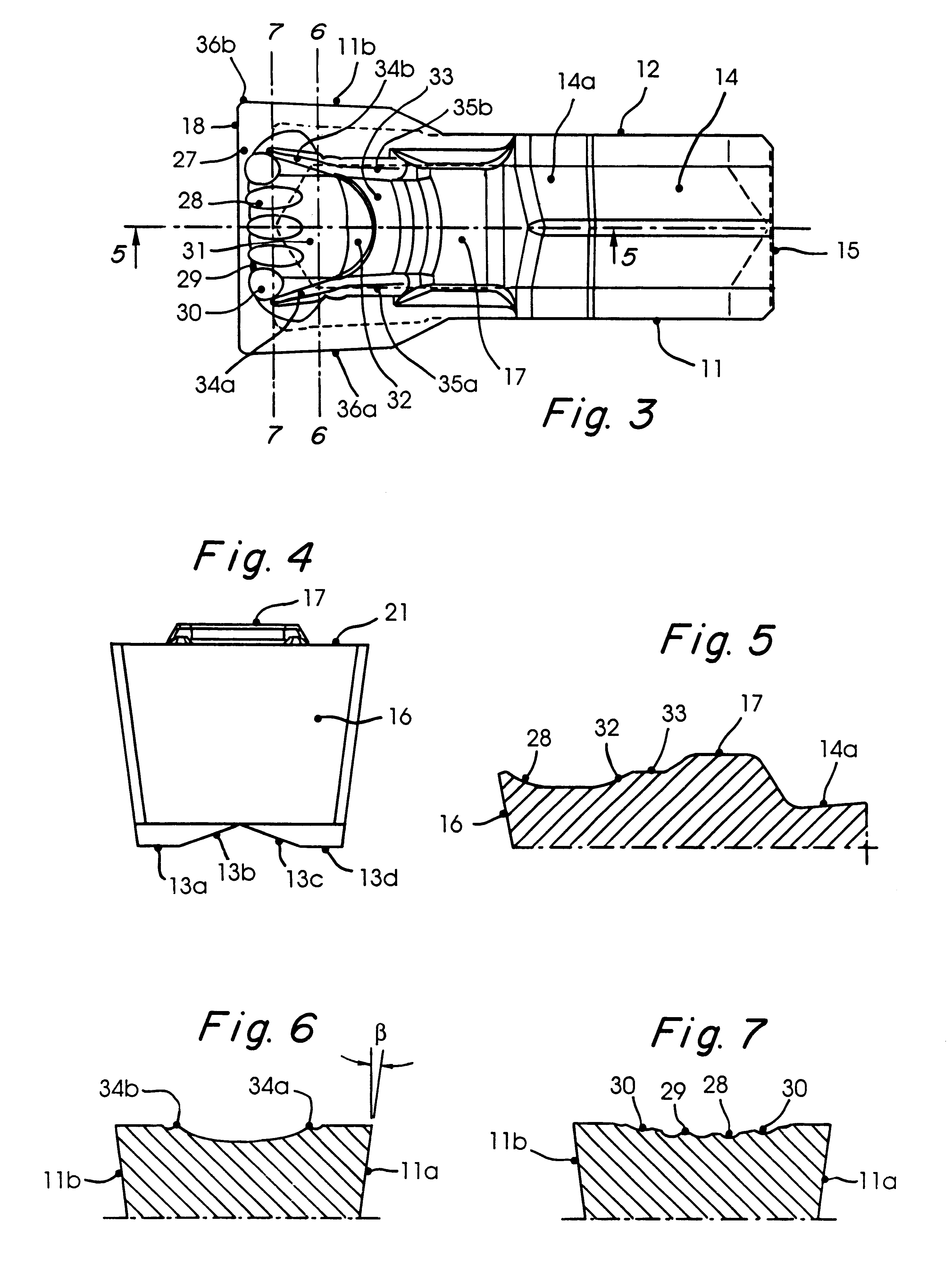

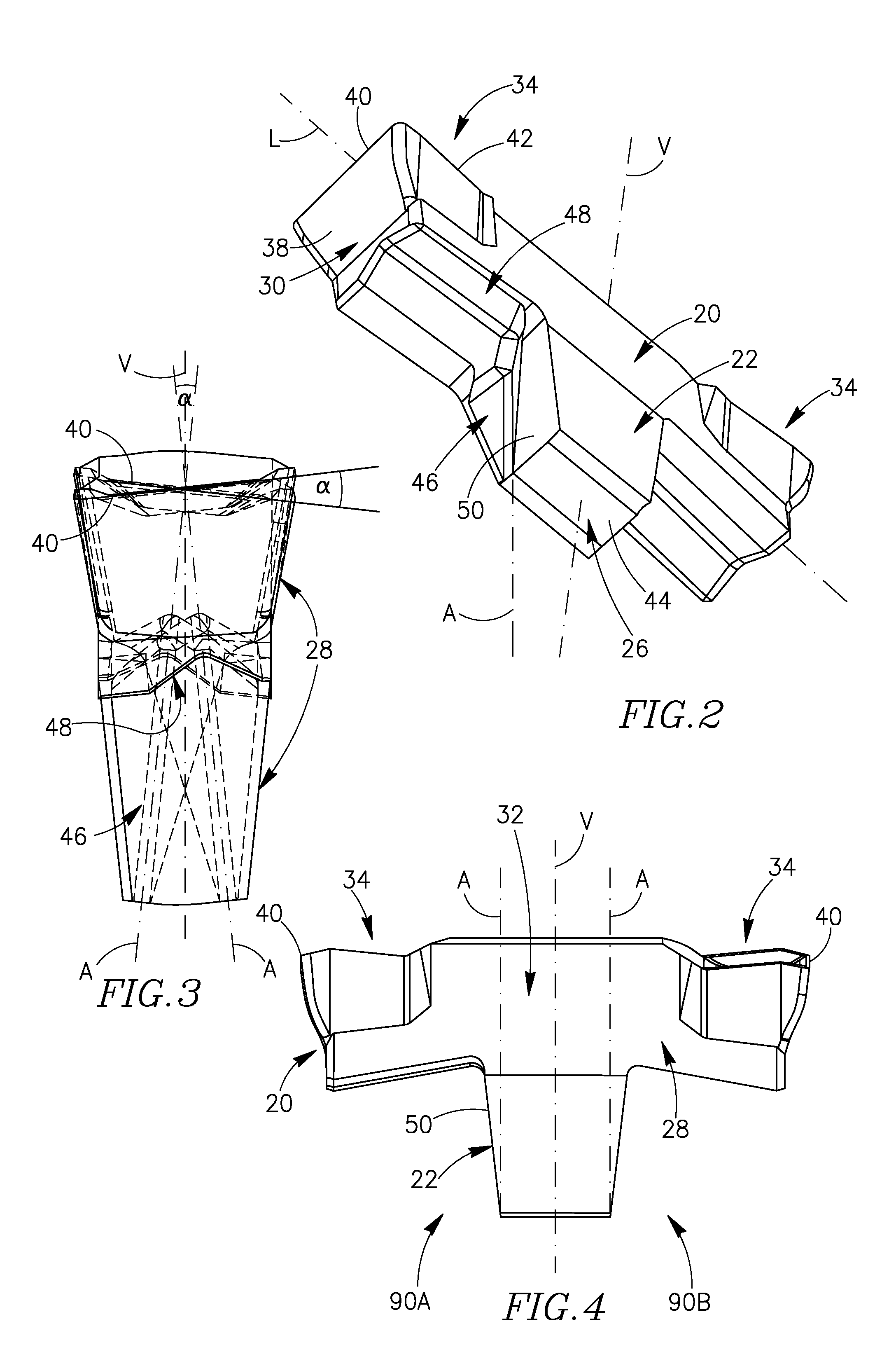

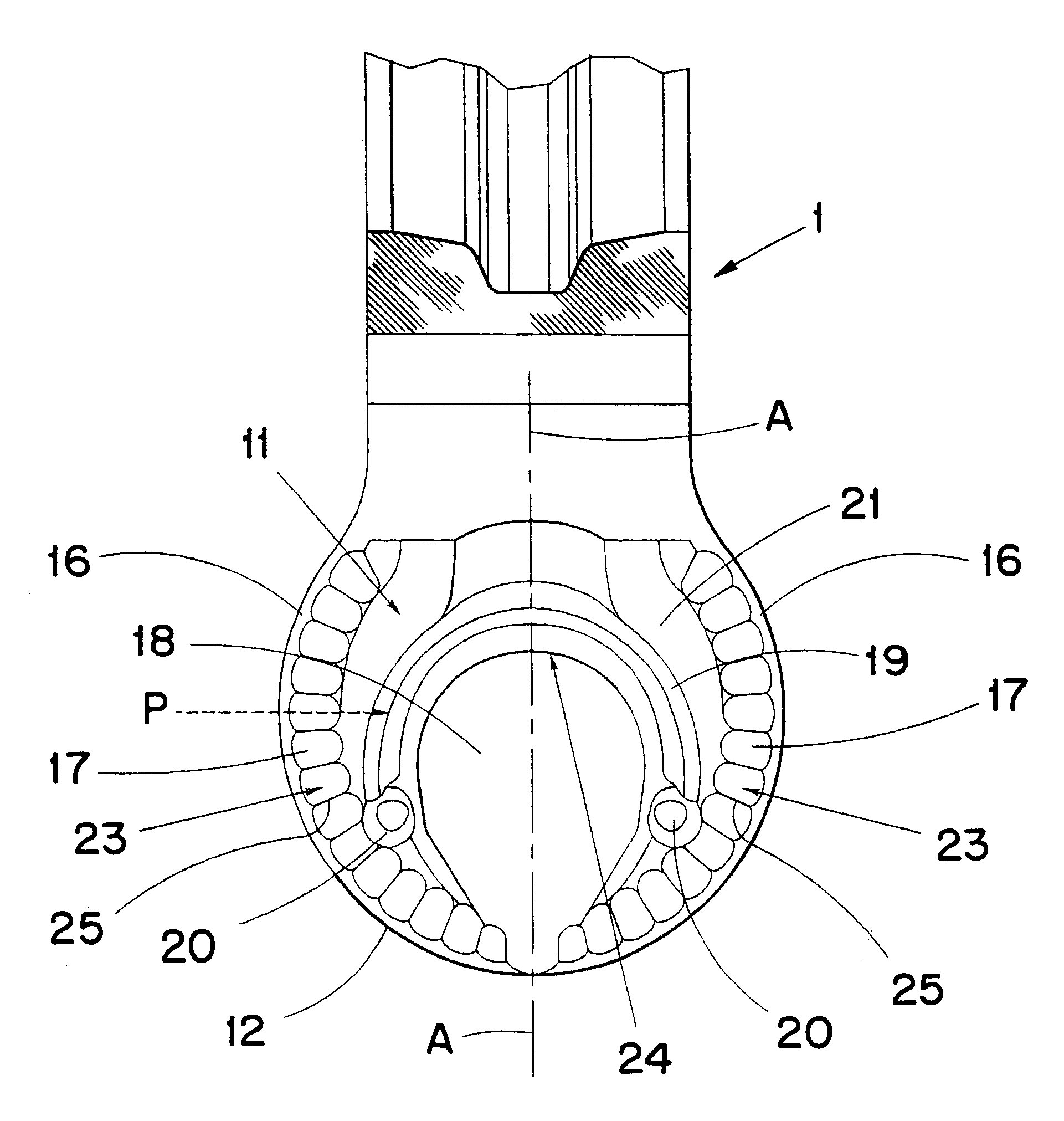

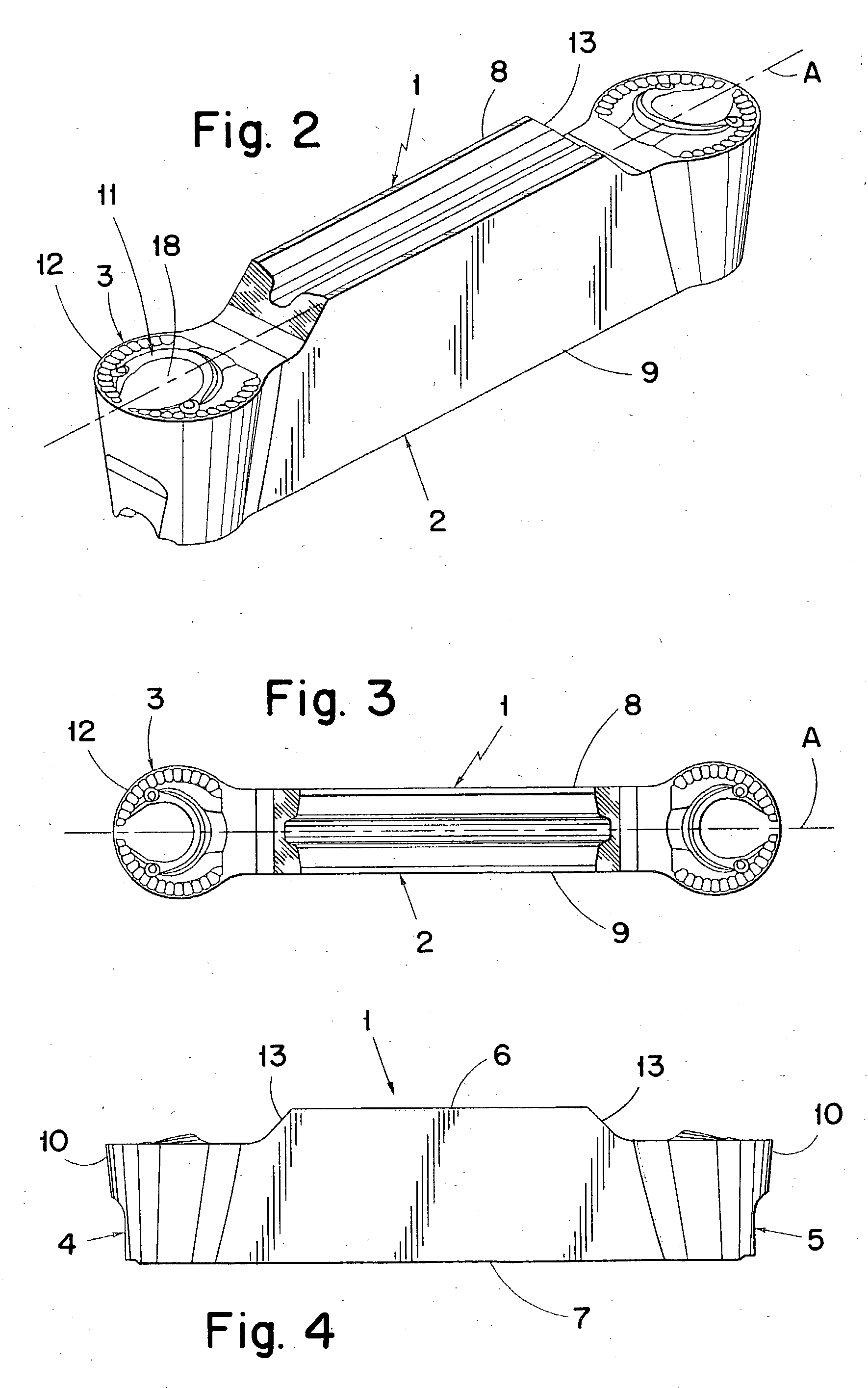

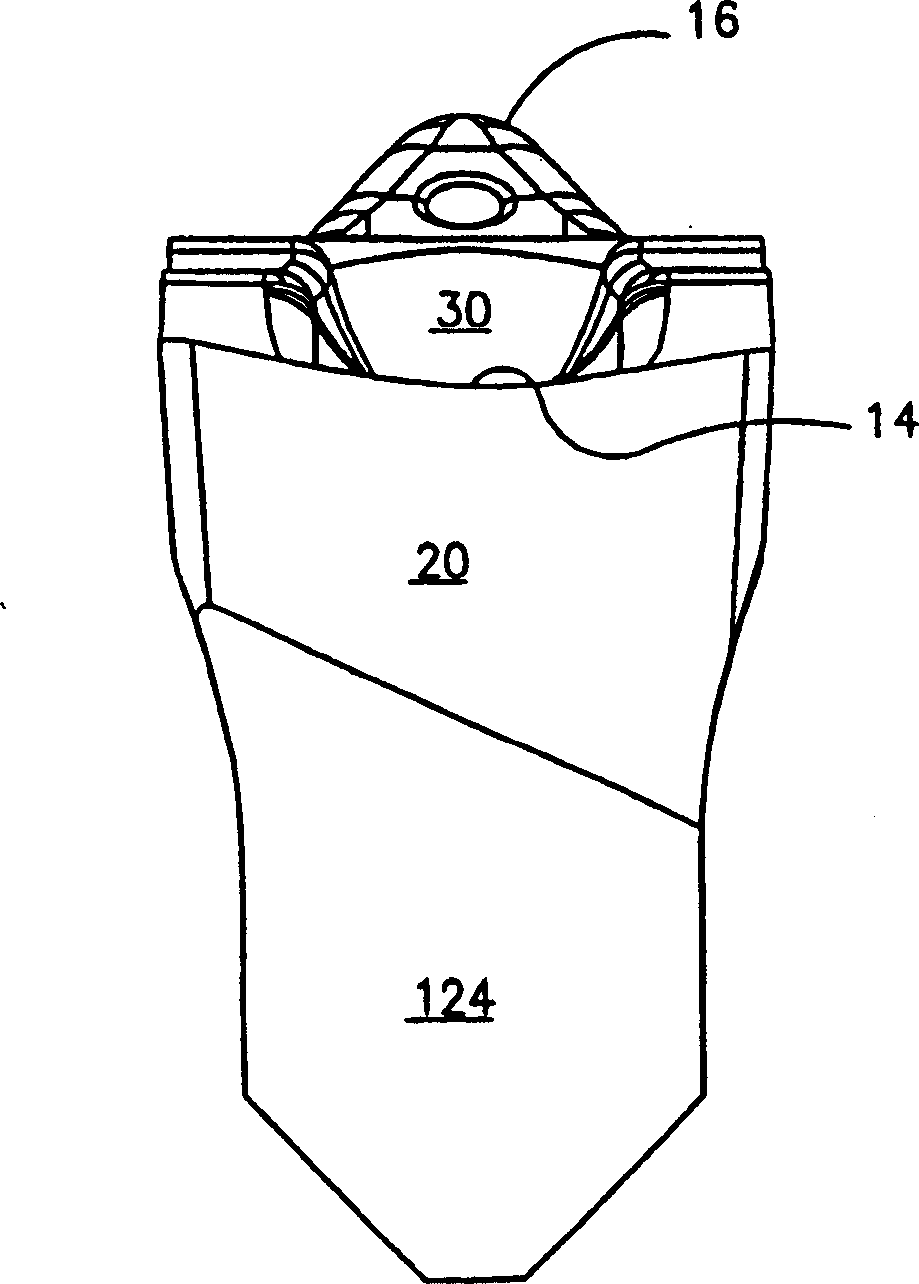

Tool holder and metal cutting insert with chip breaking surfaces

A metal cutting insert having a pair of cutting portions disposed on both sides of a shank, each cutting portion having a front clearance surface with a cutting edge formed on its upper edge. A pair of spaced apart chip breaking surfaces originate at or near the cutting edge and extend therefrom. A pair of second chip breaking surfaces are located downstream of the first chip breaking surfaces and are interconnected with the associated first chip breaking surfaces by transition surfaces. A central channel is located between the chip breaking faces and includes an entry portion beginning at or near the cutting edge. When the chip is cut from the rotating workpiece, the first chip breaking surface forms the initial curl of the chip, while the groove can promote the hardening of the middle part of the chip. The second chip breaking surface further curls the chip to reduce the curl diameter of the chip. A toolholder for securely mounting a metal cutting insert includes a base and a clamping arm forming with the base a clearance for receiving one of the cutting portions of the cutting insert. The toolholder includes first and second planar abutment surfaces. One of the abutment surfaces is for face-to-face engagement with a locating surface formed by a cutting portion of a cutting edge having a lead angle of non-zero degrees; The positioning faces are engaged face-to-face.

Owner:KENNAMETAL INC

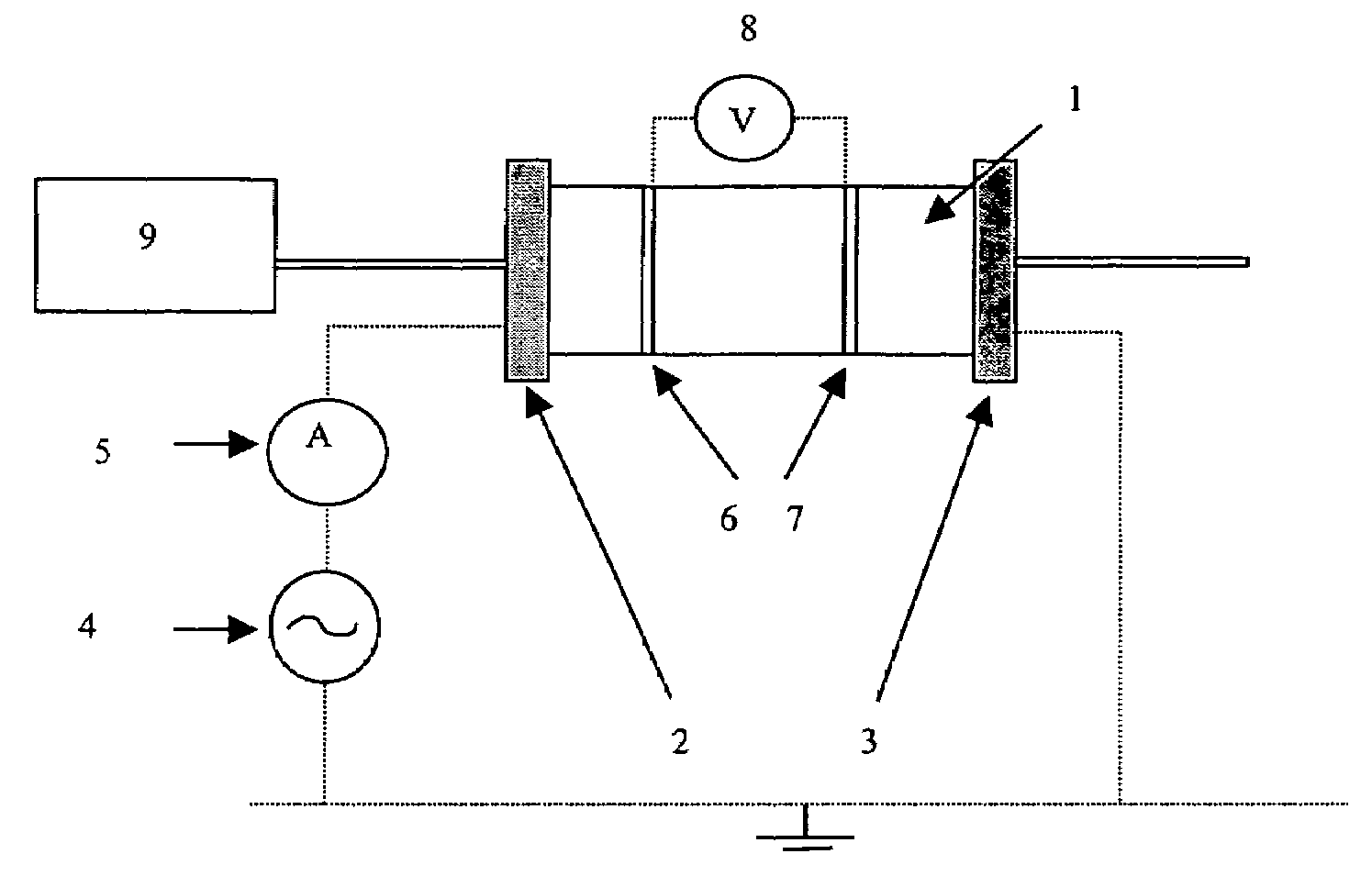

Method for determining of the formation factor for a subterranean deposit from measurements on drilling waste removed therefrom

Method and device for determining the formation factor of underground zones from drill cuttings. The device comprises a cell (1) associated with a device for measuring the electrical conductivity of the cell with the content thereof. The cell containing the drill cuttings is filled with a first electrolyte solution (A) of known conductivity (σA). After saturation of the drill cuttings by first solution (A), the global electrical conductivity (σ*A) of the cell with the content thereof is determined. After discharging first solution (A), the cell containing the drill cuttings is filled with a second electrolyte solution (B) of known conductivity (σB), and the global electrical conductivity (σ*B) of the cell containing the second solution and the cuttings saturated with the first solution is determined. The cuttings formation factor (FF) is deduced therefrom by combination of the measurements.

Owner:INST FR DU PETROLE

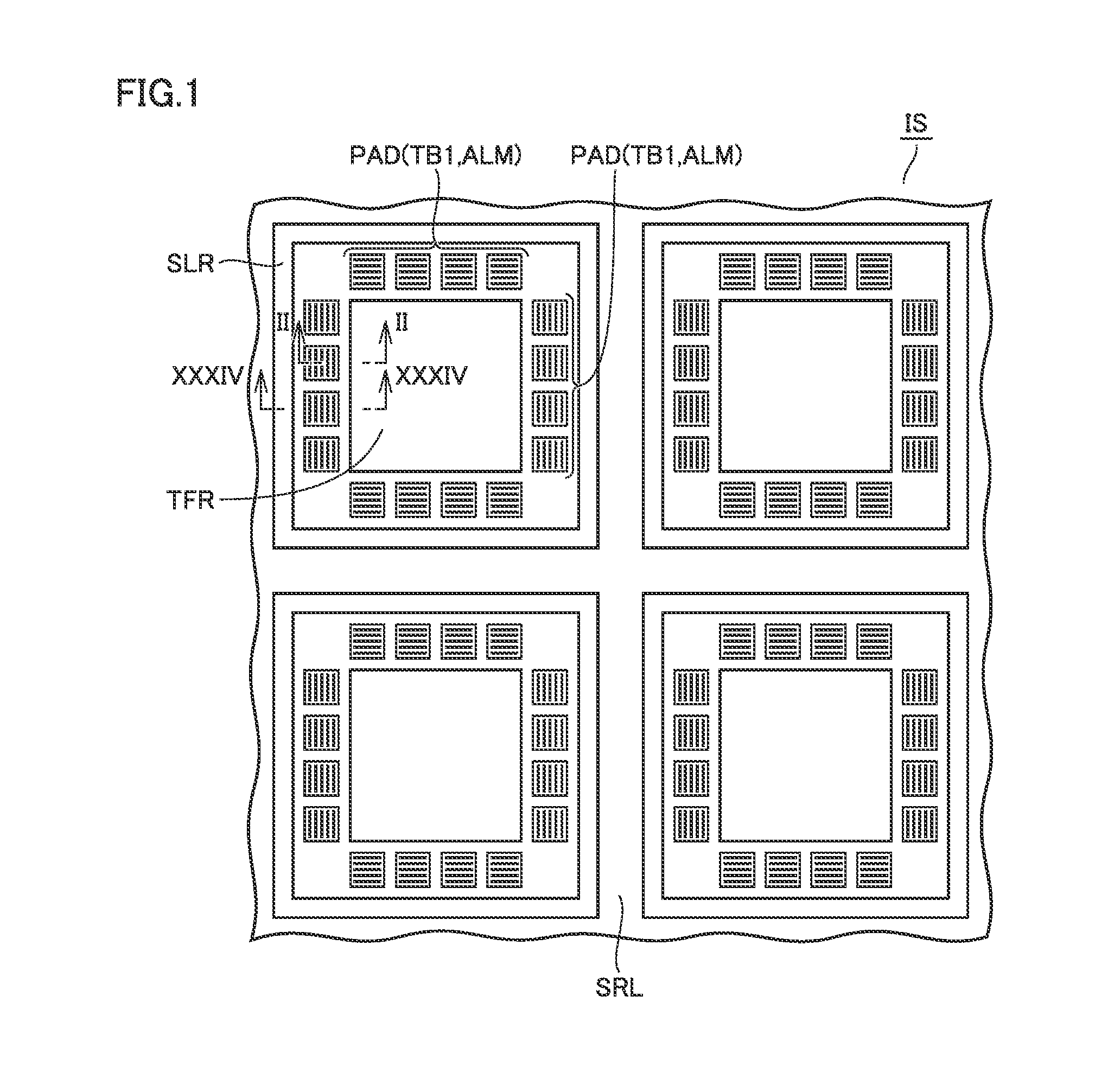

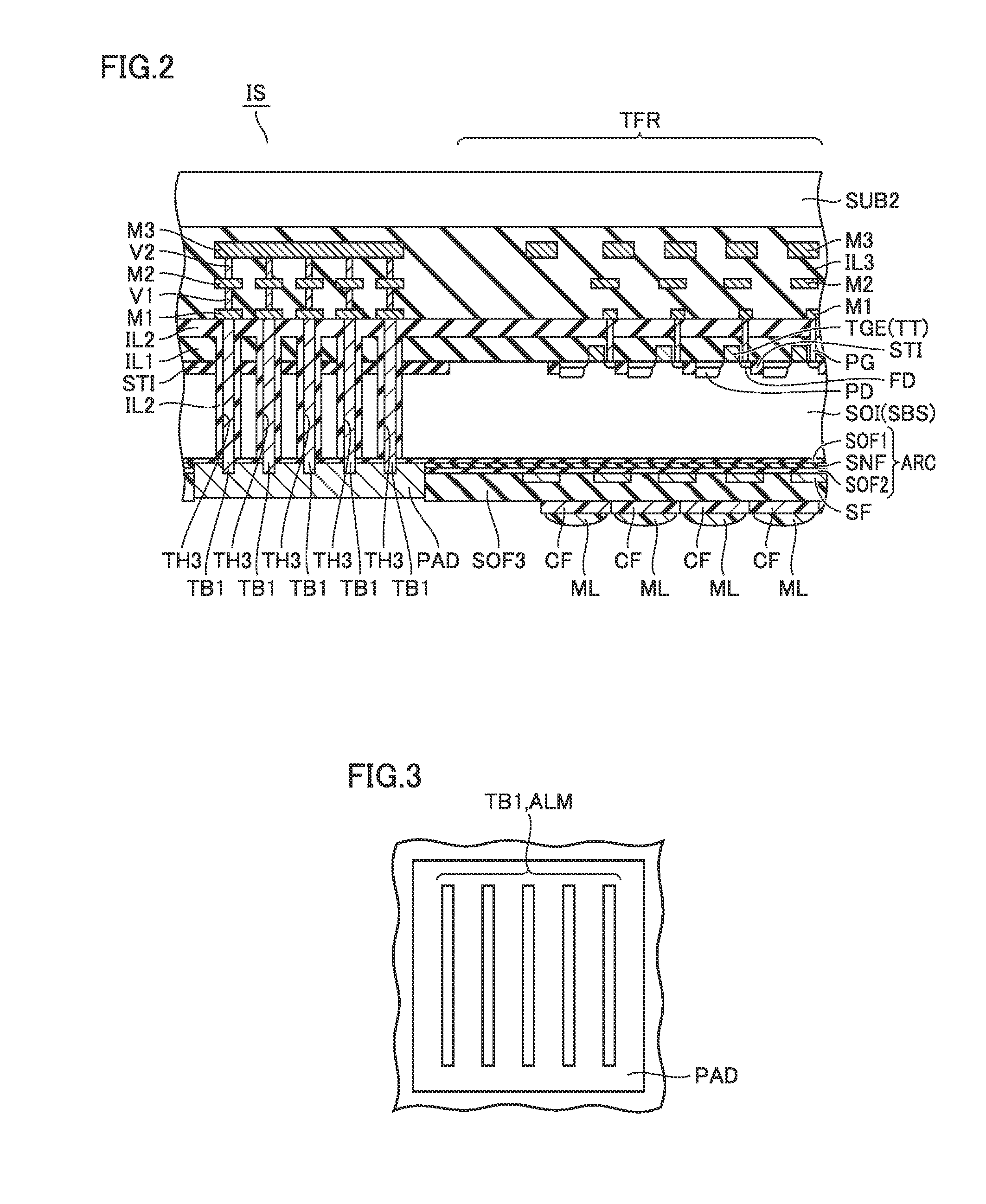

Imaging device and method of manufacturing the same

ActiveUS20160172405A1High mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesInterconnectionChip formation

A groove-type through hole passing through a silicon layer and a first interlayer insulating film is formed in a region around a chip formation region including a photodiode. In the groove-type through hole, a wall-like wall-type conductive pass-through portion corresponding to the groove-type through hole is formed. An electrode pad is in contact with the wall-type conductive pass-through portion. The electrode pad is electrically connected to a first interconnection through the wall-type conductive pass-through portion.

Owner:RENESAS ELECTRONICS CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com