Method for manufacturing semiconductor chips and surface protective tape for thin-film grinding used in same

A manufacturing method and semiconductor technology, which can be used in the manufacture of semiconductor/solid-state devices, semiconductor devices, film/sheet adhesives, etc. The effect of precision and simple manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

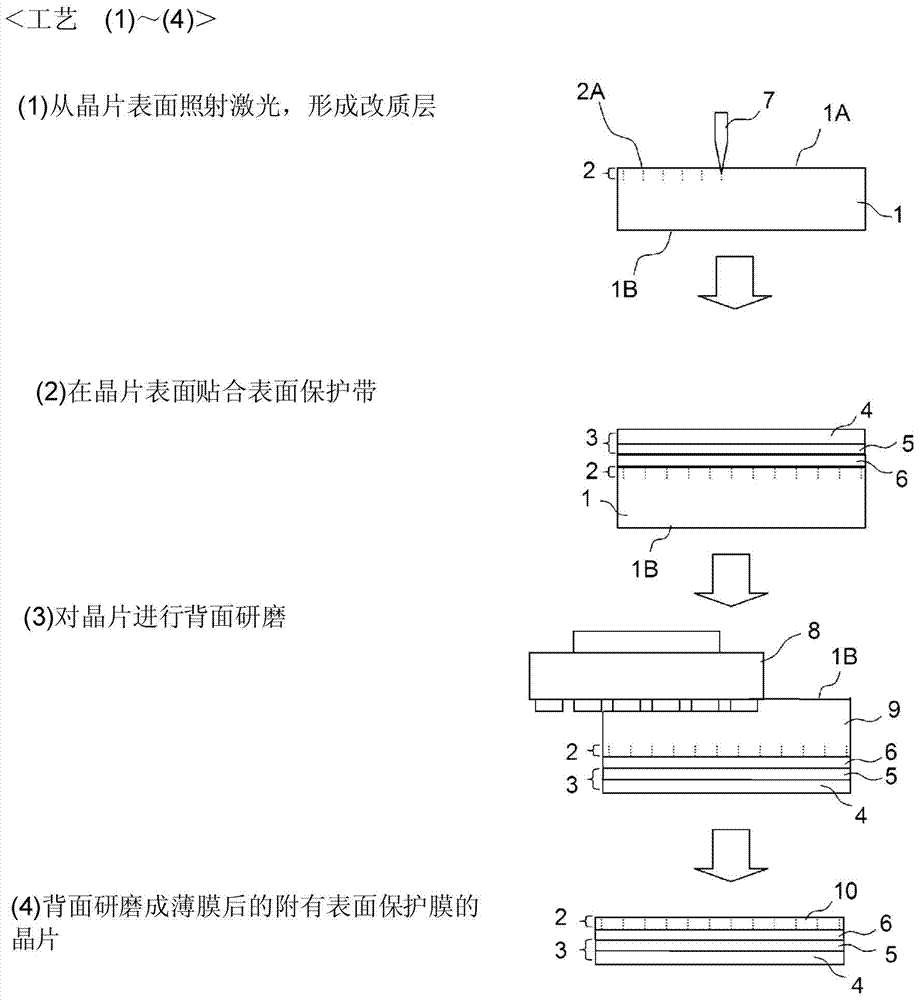

Embodiment 1

[0251] (I) Fabrication of Surface Protection Tape for Thin Film Polishing

[0252] An ultraviolet curable (meth)acrylic adhesive layer is provided on a substrate film made of ethylene-acrylic acid copolymer with a thickness of 100 μm, and a (meth)acrylic copolymer containing epoxy resin is placed on the adhesive layer. An adhesive layer composed of a substance was used to produce the surface protection tape for film polishing of the present invention.

[0253] (1) Manufacturing method of adhesive tape

[0254] Blend 78 mol% of 2-ethylhexyl acrylate, 21 mol% of 2-hydroxyethyl acrylate, and 1 mol% of methacrylic acid, and copolymerize them in an ethyl acetate solution to obtain a copolymer solution with a weight average molecular weight of 700,000 . With respect to 100 parts by mass of the copolymer, 5.0 parts by mass of 2-methacryloyloxyethyl isocyanate (trade name, Karenz MOI manufactured by Showa Denko Co., Ltd.) was mixed in the solution, and they were mixed in the solutio...

Embodiment 2

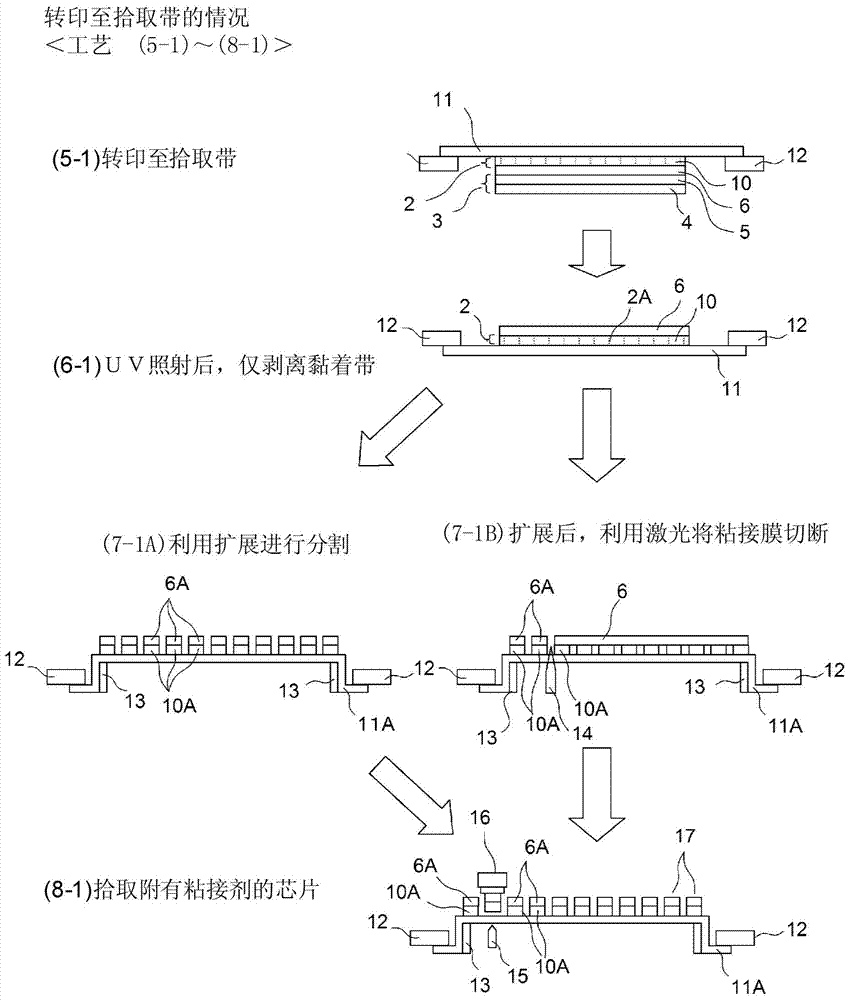

[0276] Using the surface protection tape for film polishing made in Example 1, the process of (6) in Example 1 is changed to the process of the following (6-1) to (6-2), and in addition, A semiconductor chip was produced in the same manner as in Example 1.

[0277] (6-1) The pick-up tape (11) was expanded under conditions of a speed of 1 mm / sec and an expansion amount of 8 mm so as to divide only the semiconductor wafer.

[0278] (6-2) After the above expansion, the adhesive film (adhesive layer) (6) is cut with a laser ( 14 ). { figure 2 Process shown in (7-1B)}

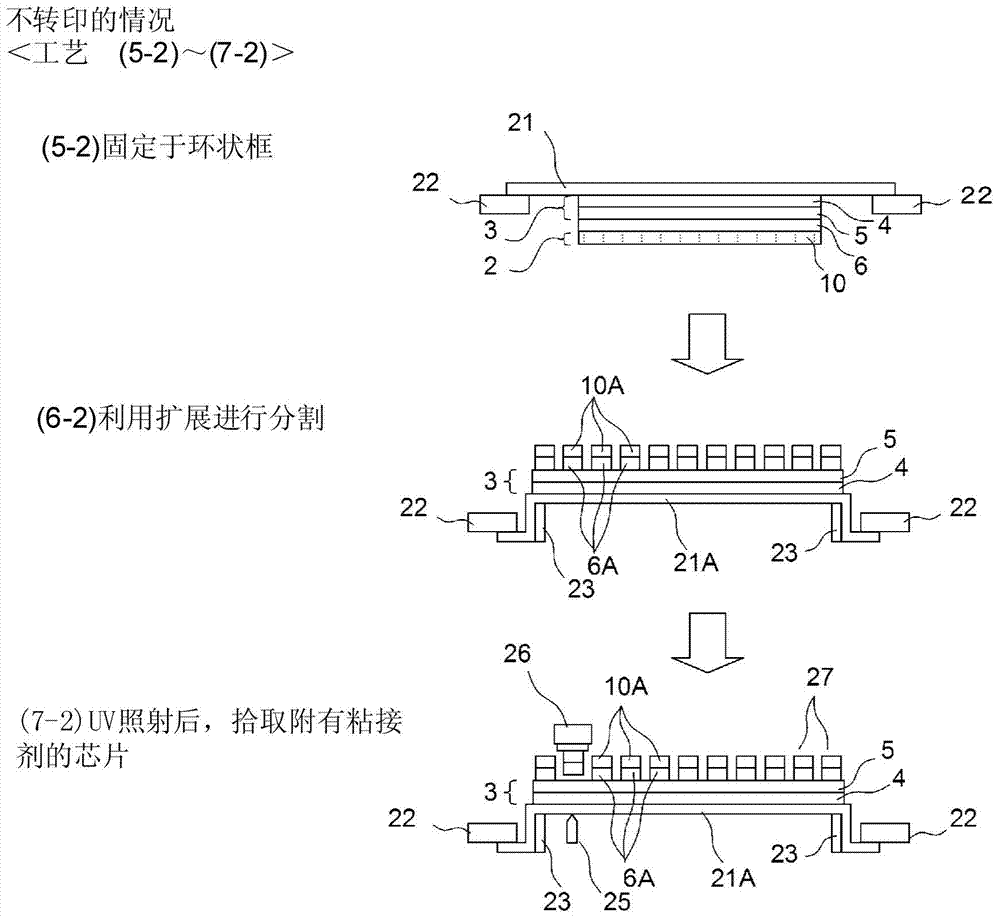

Embodiment 3

[0280] by figure 1 and image 3 The process of making semiconductor chips.

[0281] Use the surface protection tape for film polishing that is made in embodiment 1, after carrying out the process of (1)~(3) in embodiment 1, carry out following process (4A)~(6A) instead of (4)~( 7), Manufacturing semiconductor chips.

[0282] (4A) Attach the same expansion tape (11) (fixation tape (21)) as in Example 1 to the base film (4) side of the film polishing surface protection tape, and fix it to the ring frame (22) . The expanding tape (11) (fixing tape (21)) has an adhesive layer made of an ultraviolet-curable acrylic copolymer on a base film made of vinyl ionomer resin.

[0283] (5A) Expand the above-mentioned fixing tape (21) at a speed of 1 mm / sec and an expansion amount of 20 mm, and divide the adhesive film (adhesive layer) (6) from the semiconductor wafer on the adhesive film (3). .

[0284] (6A) The divided semiconductor wafer (10A) becomes each chip (27) with an adhesive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com