Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Chemical fibre cloth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

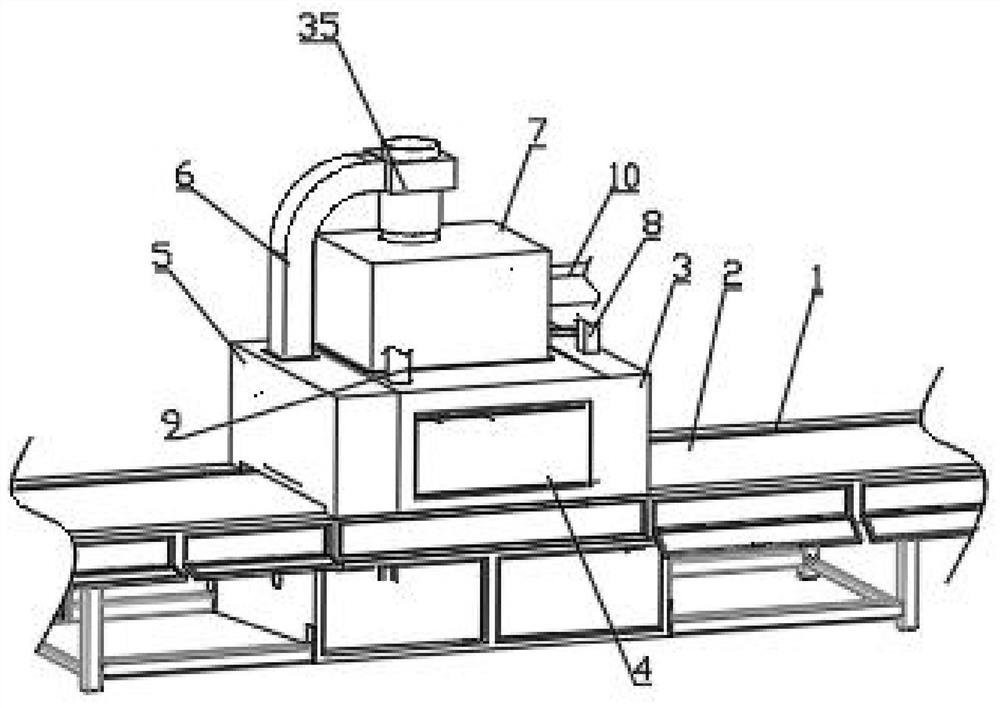

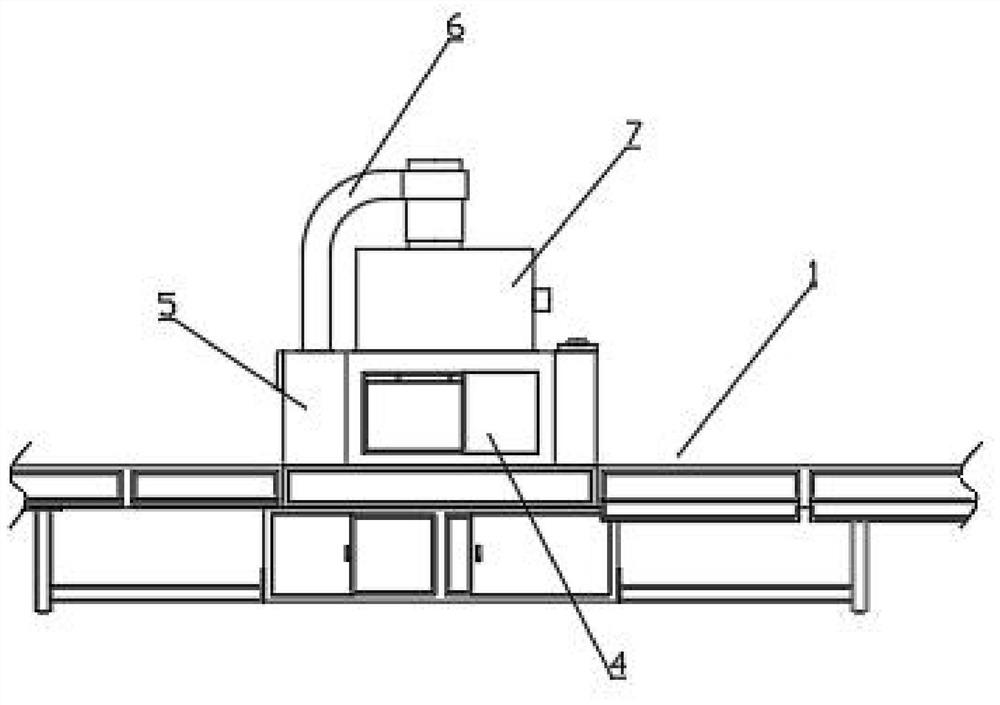

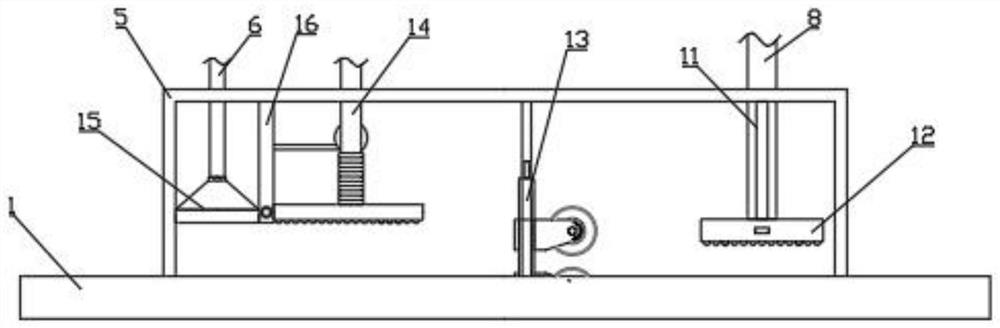

Safe and environment-friendly chemical fabric and production process thereof

InactiveCN111764181AImprove applicabilityImprove drying efficiencyGas treatmentDispersed particle separationProcess engineeringChemical fibre cloth

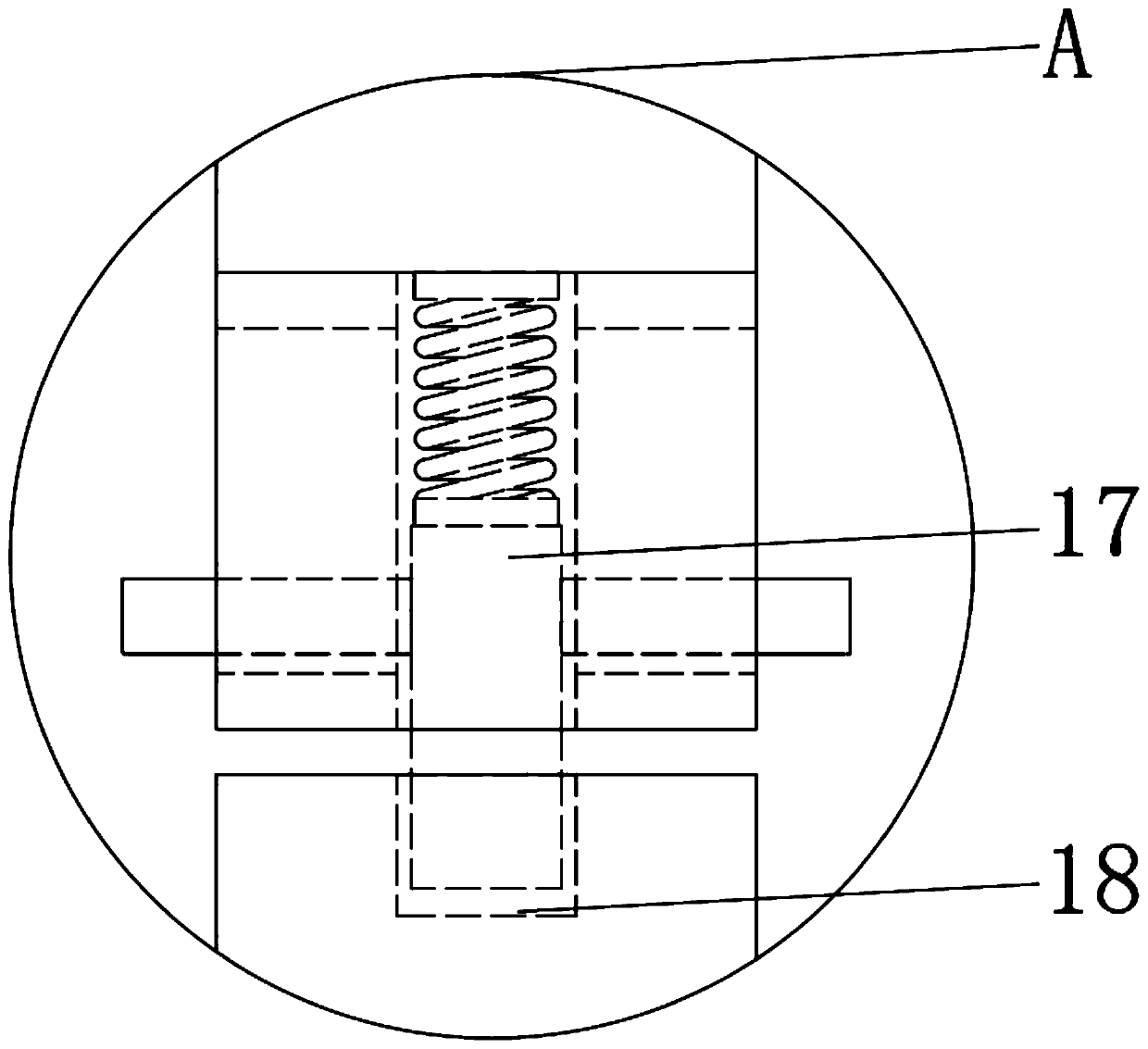

The invention discloses a production process of a safe and environment-friendly chemical fabric. The production process of the chemical fabric includes the following steps of rotating a first screw according to a width of the chemical base layer fabric to drive a piston plate to slide along the inner wall of a flow dividing plate so that a spraying width of the flow dividing plate can be equal tothe width of the chemical base layer fabric; then, rotating a second screw according to a thickness of the chemical base layer fabric to make a sliding installation block to move up and down along a fixed frame so that the distance between a first coating roller and a second coating roller can be adjusted to be matched with the thickness of the chemical base layer fabric; and conveying the chemical base layer fabric along a conveying frame and performing spraying, coating, drying and adsorbing work on the chemical base layer fabric so that the original chemical base layer fabric can form a chemical fabric body. By means of the production process, chemical base layer fabrics of different widths and different thicknesses can be processed, applicability of equipment is greatly improved, spraying, coating, drying and adsorbing are realized, and the chemical fabric is dried on an assembly line.

Owner:安徽东锦环保科技有限公司

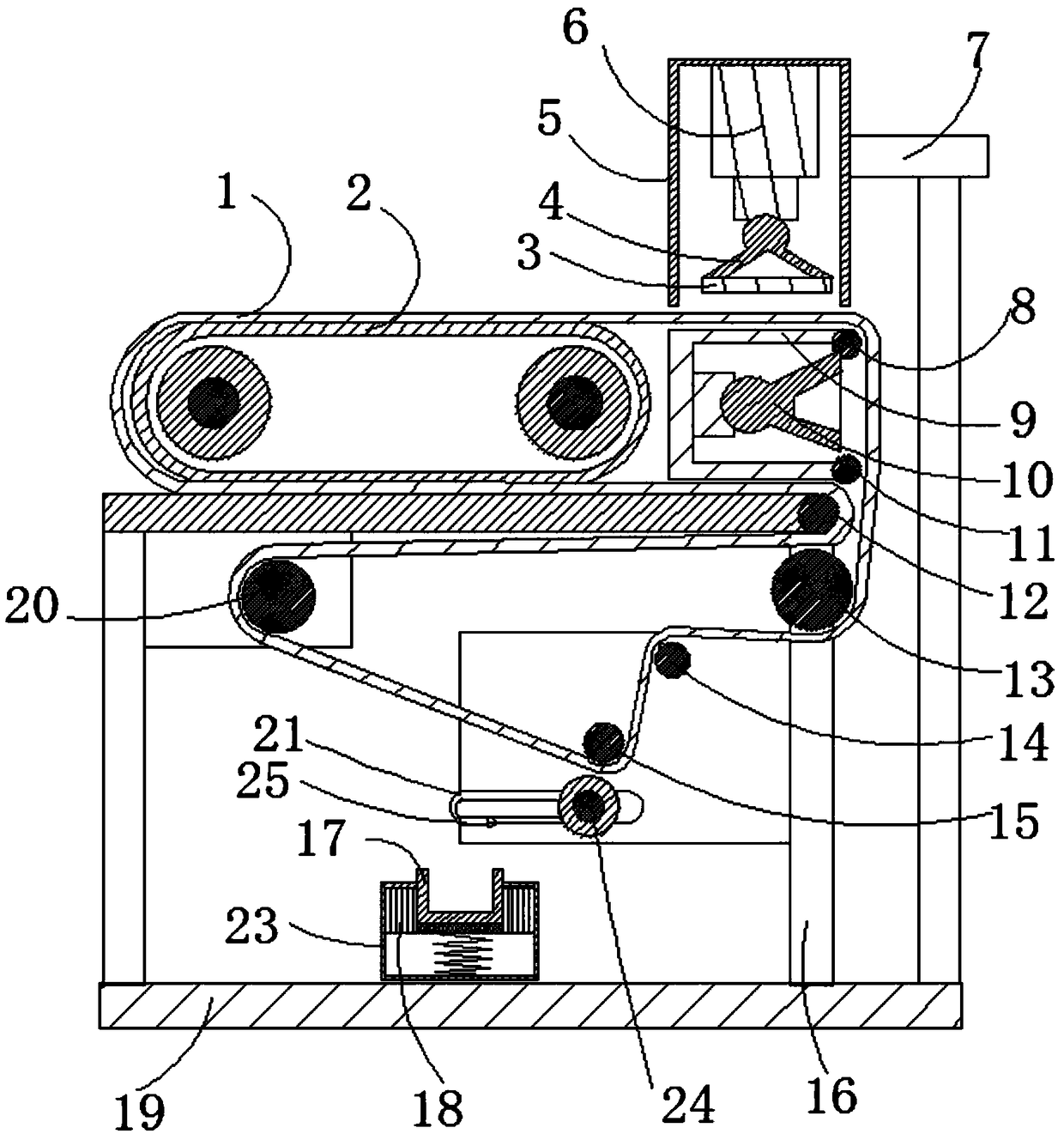

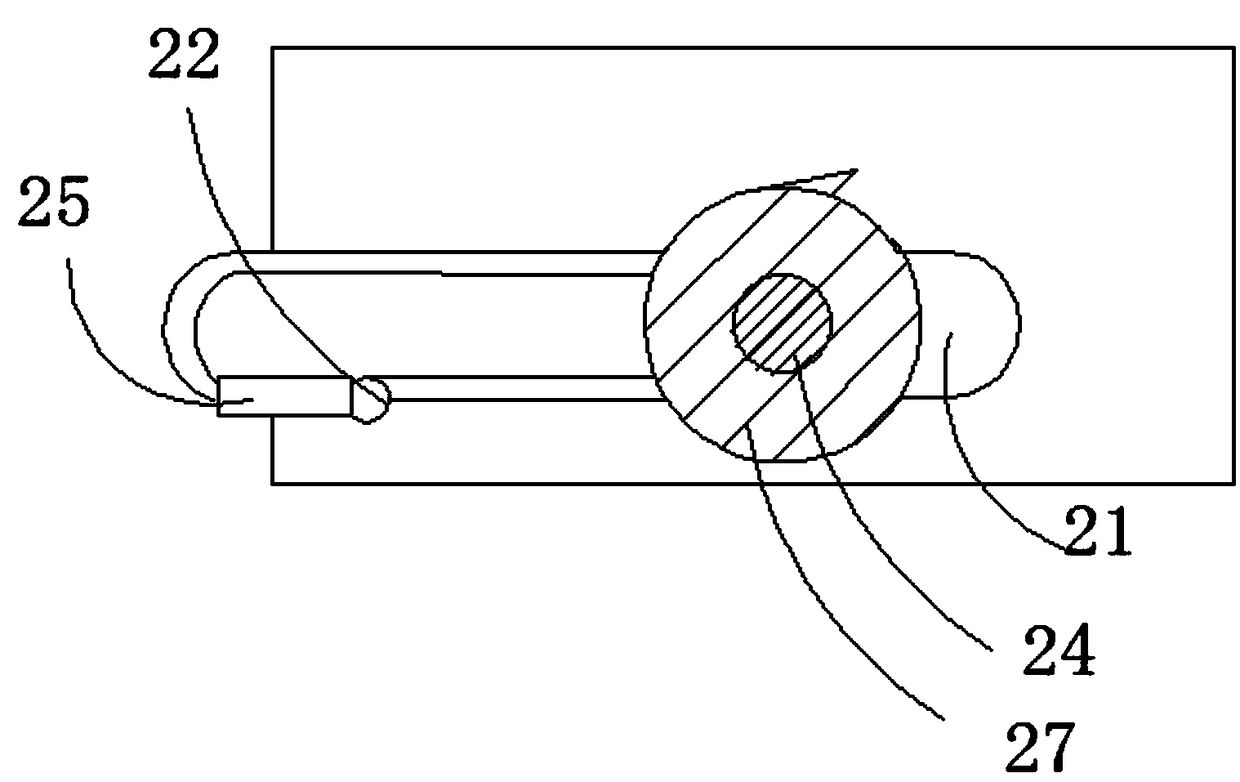

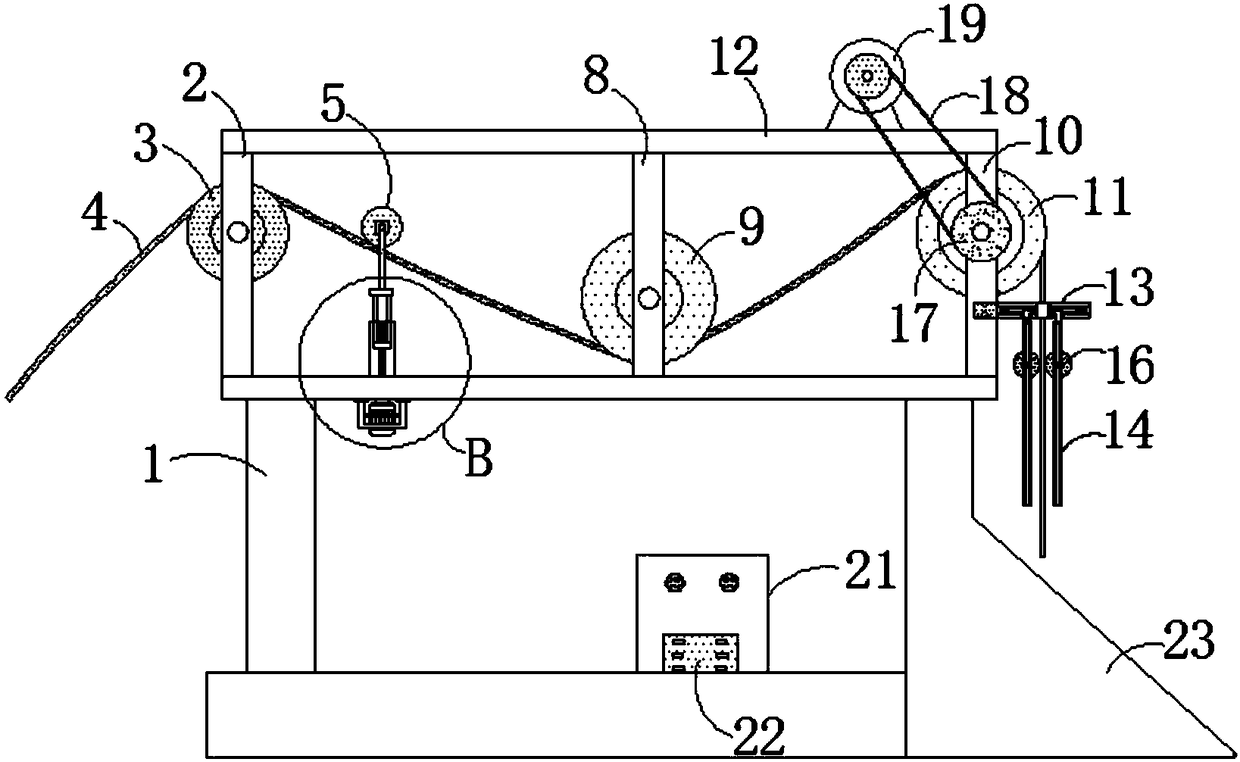

Chemical fabric drying automatic cutting and winding machine

InactiveCN108486853AChange distanceEasy to dryDrying gas arrangementsSevering textilesWinding machineElectrical resistance and conductance

The invention relates to the technical field of textile machinery, in particular to a chemical fabric drying automatic cutting and winding machine. The machine is characterized in that a drying deviceis added, an electric push rod and a resistance wire are added before the winding procedure of winding of the chemical fabric is conducted, and the distance between the drying device and the chemicalfabric can be changed through the height adjustment of the electric push rod; a cutting function is added; cutting chemical fabrics can be conducted through a cutting shaft arranged below a chain, multiple blade fixing holes are formed in the cutting shaft, and therefore the cutting width of the chemical fabrics can be changed by adding or reducing the number of blades according to demands; an automatic power cut-out device is added; a winding shaft is arranged in a moving groove, the winding shaft is located below the chain, so that when the chemical fabric wound on the winding shaft reach acertain thickness, the winding shaft moves in the moving groove, a baffle plate is connected with the moving groove through a hinge, and the winding shaft automatically drops into a material receiving box below when the winding shaft reaches the hinge to cut out a general supply of the machine.

Owner:长兴超特纺织有限公司

Graphene sterilization cloth and preparation process thereof

InactiveCN111501333AImprove performanceHigh fastnessBiochemical fibre treatmentBiotechnologyChemical fibre cloth

The invention discloses a graphene sterilization cloth and a preparation process thereof. Cotton fabric, knitted fabric, chemical fabric or non-woven fabric is added diluted nano-graphene slurry, andmixtures are dispersed and cured through ultrasonic waves after stirring, and dehydrated and dried to form the graphene sterilization cloth. The graphene sterilization cloth has the beneficial effectsthat sufficient nano-graphene is planted on a textile with a special process more securely, so that the textile is antiviral, antibacterial, antifungal and anti-mould. The preparation process disclosed by the invention is simple, and the prepared graphene cloth is stable in performance, and is antibacterial and washable; viruses, bacteria, fungus and molds on the cloth can be killed efficiently;and the reproduction of the viruses, the bacteria, the fungus and the molds can be suppressed. The prepared graphene cloth further possesses the characteristics of high fastness and breathability.

Owner:诸暨先行机械科技有限公司

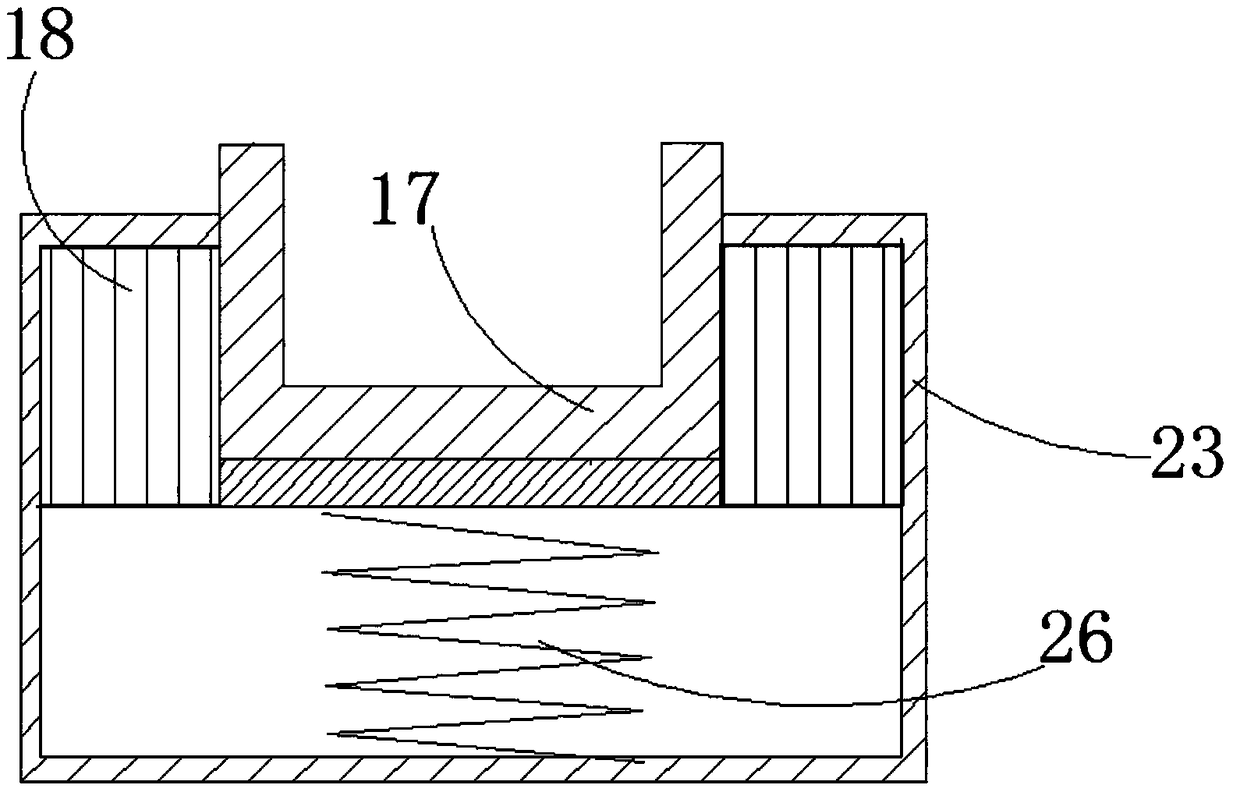

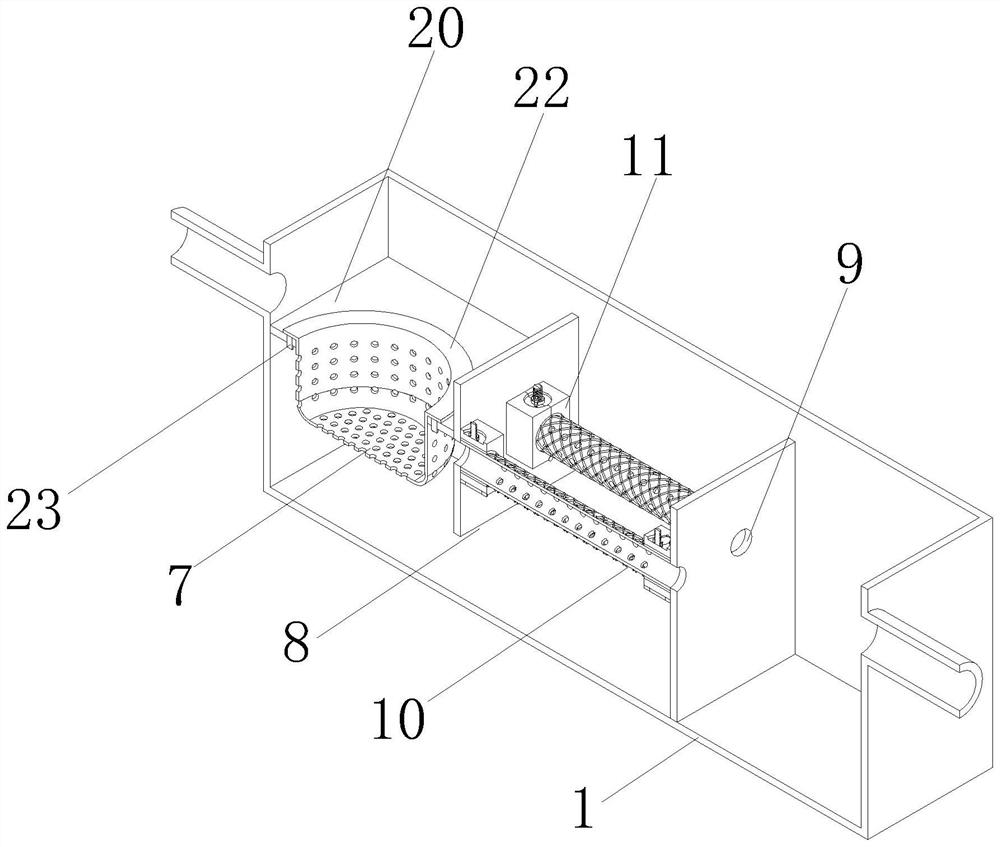

Textile waste collector for textile production of chemical fabric

InactiveCN113083736AEasy to sort and collectEasy to handleSortingWaste collectionEnvironmental engineering

The invention belongs to the technical field of textile waste collection, and particularly relates to a textile waste collector for textile production of chemical fabric. The textile waste collector comprises a collection box, a box door is rotatably arranged on the front side wall of the collection box through a hinge, and a fixing plate is transversely and fixedly arranged at the upper end of the interior of the collection box; mounting openings which are uniformly distributed are formed in the side wall of the fixing plate, a waste containing barrel is fixedly arranged in the mounting openings, a strip-shaped opening is formed in the upper side wall of the collecting box, a movable shell is slidably arranged in the strip-shaped opening, and an air draft fan is fixedly arranged in the movable shell; and a feeding pipe is fixedly arranged on the lower side wall of the movable shell. Textile waste can be conveniently classified, collected and contained according to different colors, the mode that all waste is directly collected and contained together in the past is effectively replaced, and later processing treatment and recycling of the textile waste are more convenient.

Owner:湖北延昌纺织股份有限公司

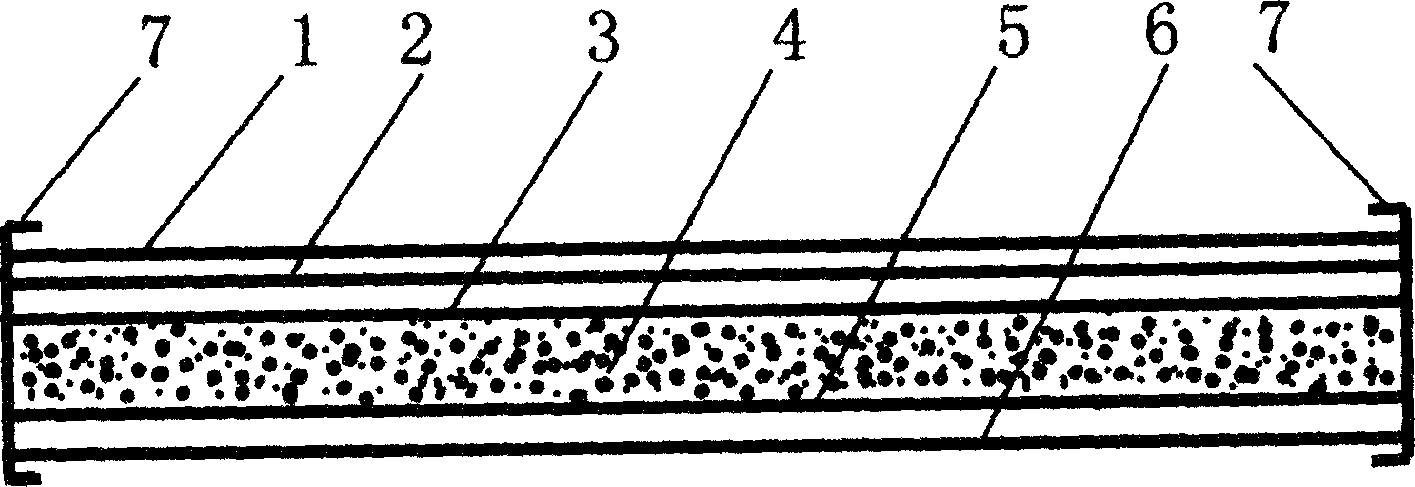

Digital direct-injecting eco-solvent double-sided printing advertisement cloth and preparation process thereof

ActiveCN107447534ALow viscosityLess quantityFireproof paintsClimate change adaptationChemical fibre clothCoating

The invention relates to digital direct-injecting eco-solvent double-sided printing advertisement cloth, which comprises a terylene chemical fabric layer, wherein one side of the terylene chemical fabric layer is provided with a whitening waterproof coating, the surface of the whitening waterproof coating is provided with an antimonous oxide flame-retardant coating, the surface of the antimonous oxide flame-retardant coating is provided with an eco-solvent ink absorbing coating, and the other side of the terylene chemical fabric layer is provided with a dye sublimation ink absorbing coating. The invention further relates to a preparation process of the advertisement cloth. The advertisement cloth provided by the invention has good softness, crease resistance and flame retardant property when being used in practical application; furthermore, one side can be used for printing water-based ink and the other side can be used for printing eco-solvent ink.

Owner:WEIFANG JIACHENG DIGITAL MATERIAL CO LTD

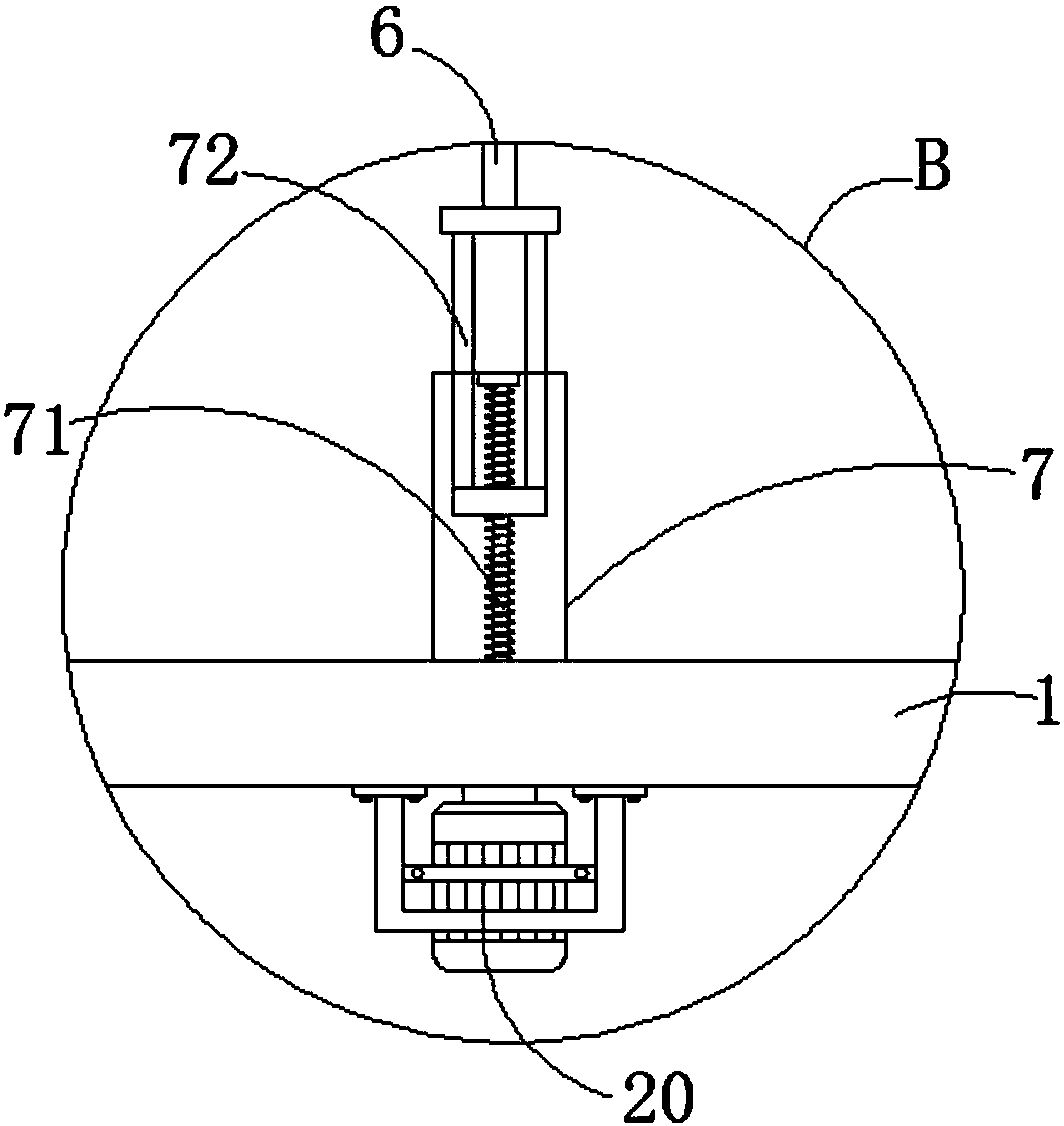

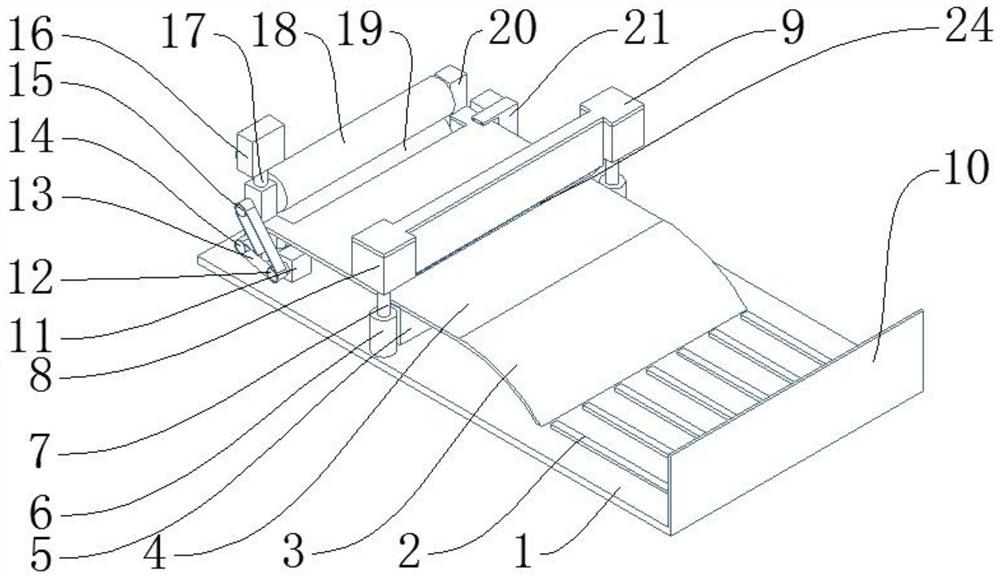

Cloth discharging mechanism of desizing machine for chemical fabric production

The invention discloses a cloth discharging mechanism of a desizing machine for chemical fabric production. The mechanism comprises a mounting rack, wherein a first mounting rod is mounted above the mounting rack, and a first roller is mounted at one side of the first mounting rod; a woven fabric is mounted at one side of the first roller, and a pressing roller is mounted at one side, close to thewoven fabric, of the mounting rack; a connecting rod is mounted below the pressing roller, and a transmission barrel is mounted below the connecting rod; a second mounting rod is mounted at one side,close to the first mounting rod, of the mounting rack, and a second roller is mounted at one side of the second mounting rod. According to the mechanism, a linear motor and a roller are arranged, sothat the flatness of the surface of the woven fabric is ensured, and the woven fabric is conveniently arranged and conveniently processed in later period; the processing time for straightening the woven fabric is saved; the pressing roller and the transmission barrel are arranged, thus the sudden tension change of the woven fabric in long-distance transmission can be effectively relieved; the quality of the woven fabric is ensured; and the woven fabric can be normally discharged.

Owner:CHANGXING JUFENG SILK WEAVING FACTORY

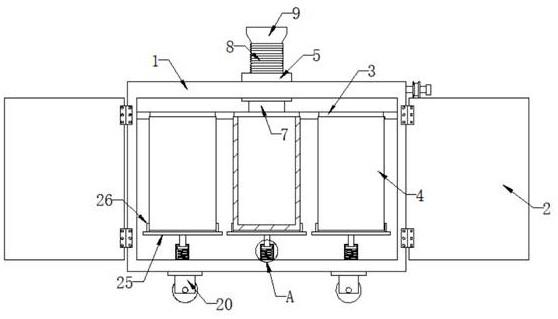

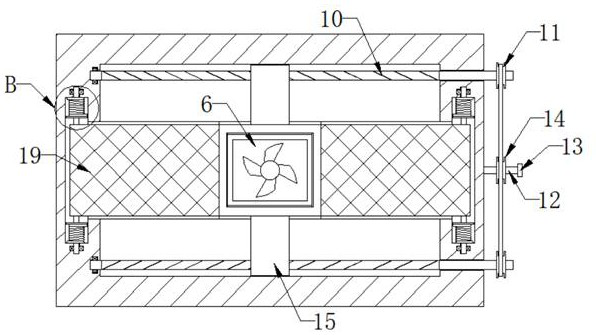

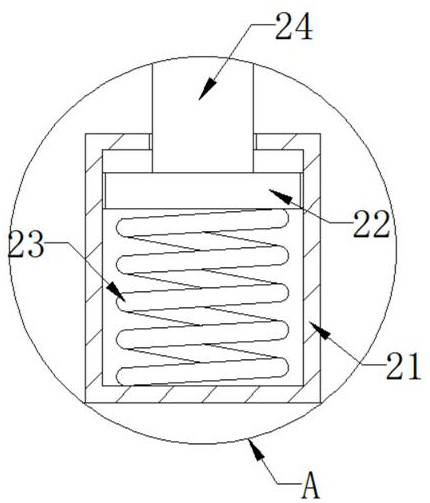

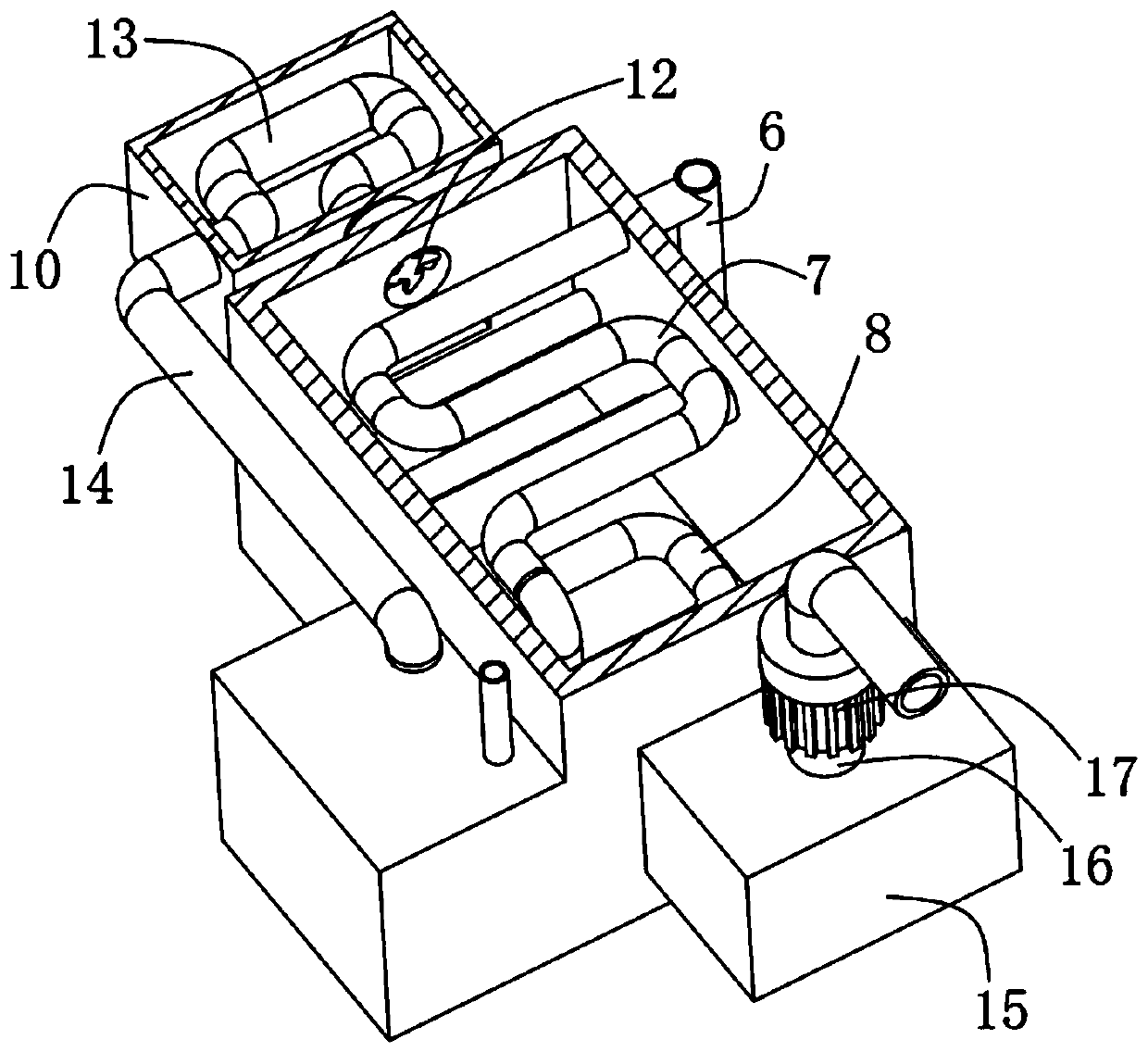

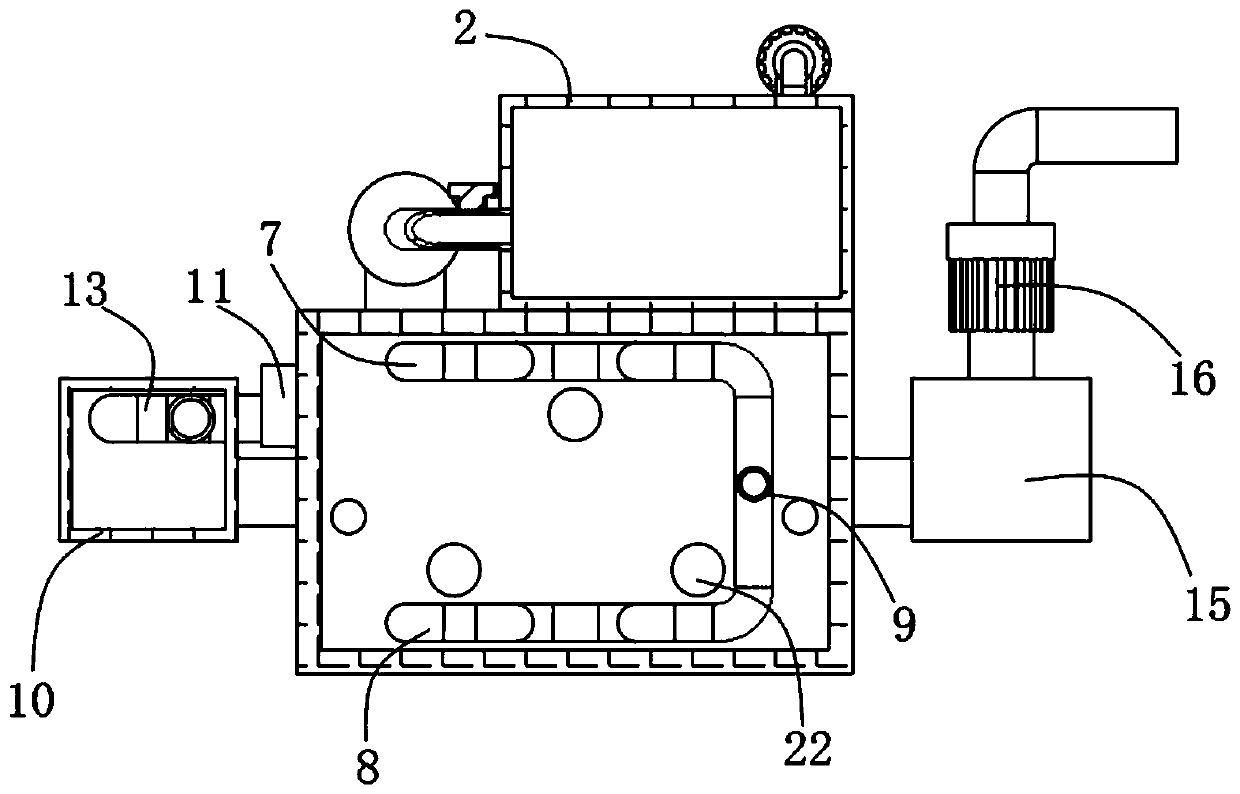

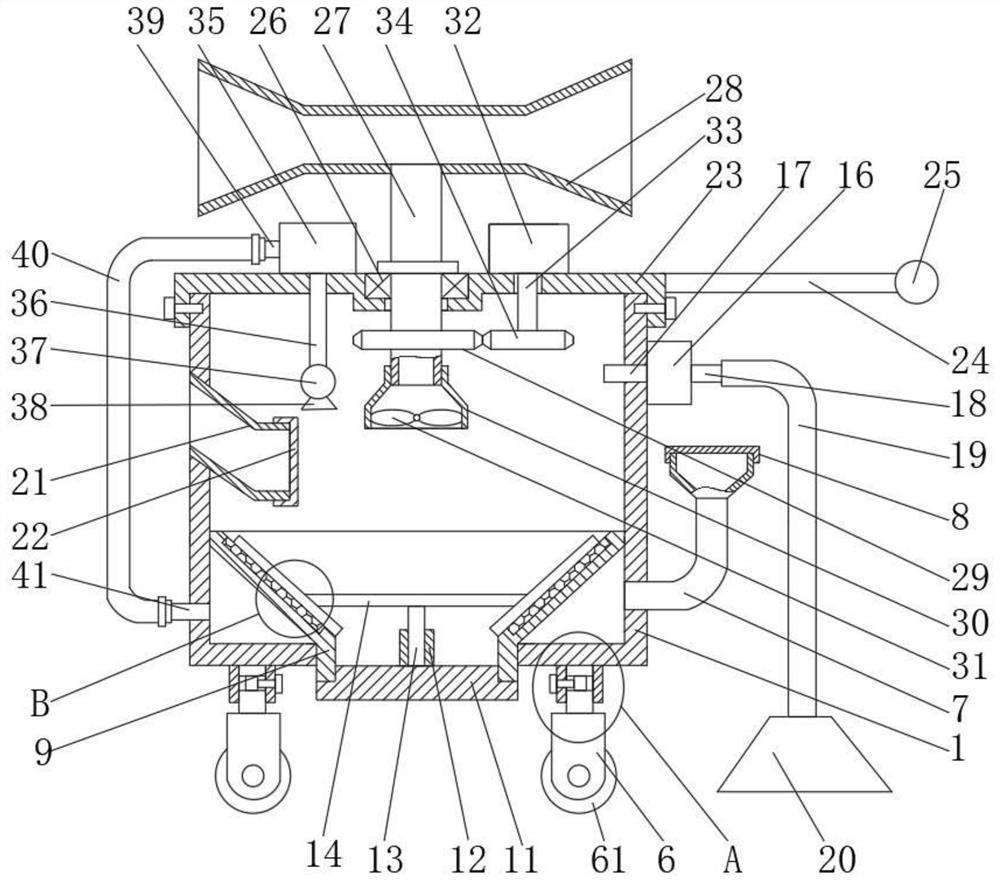

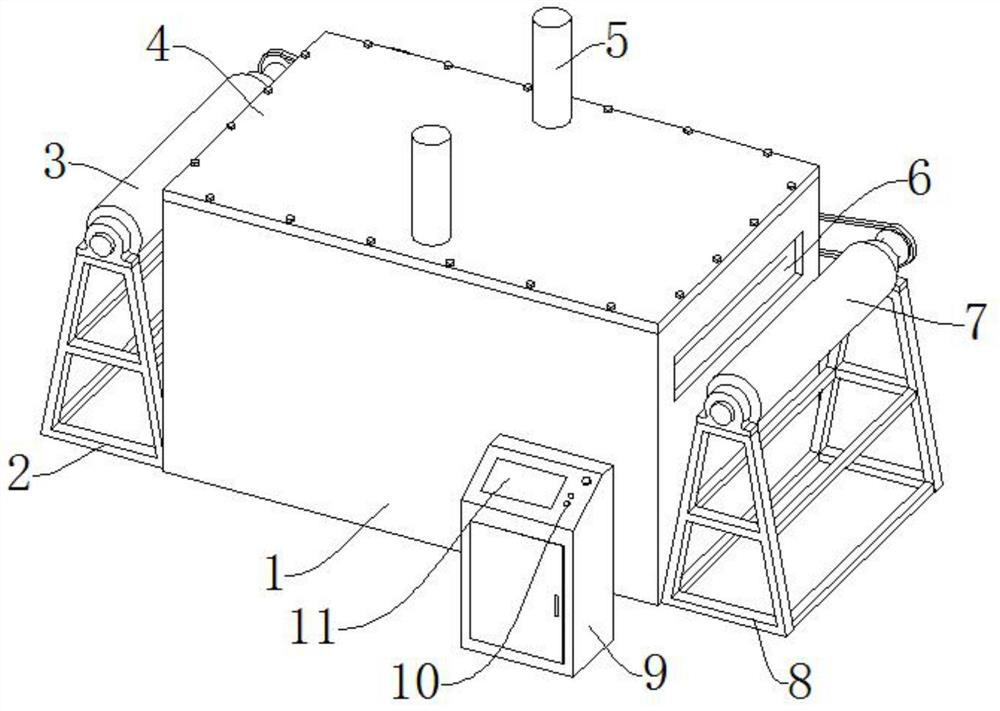

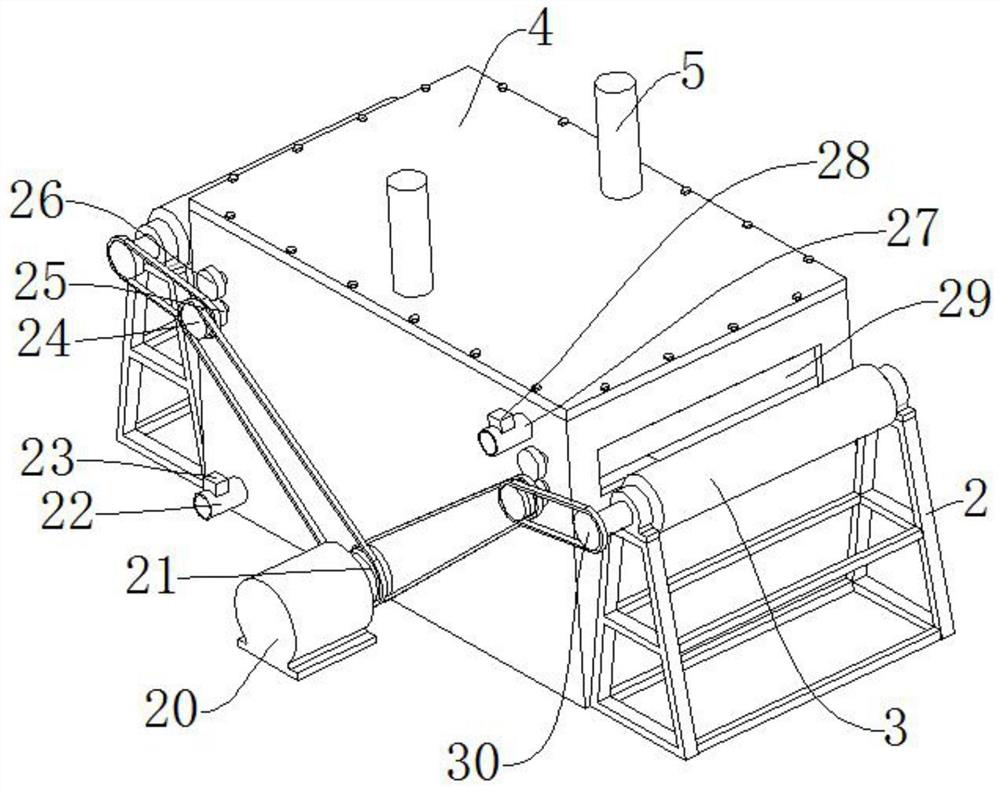

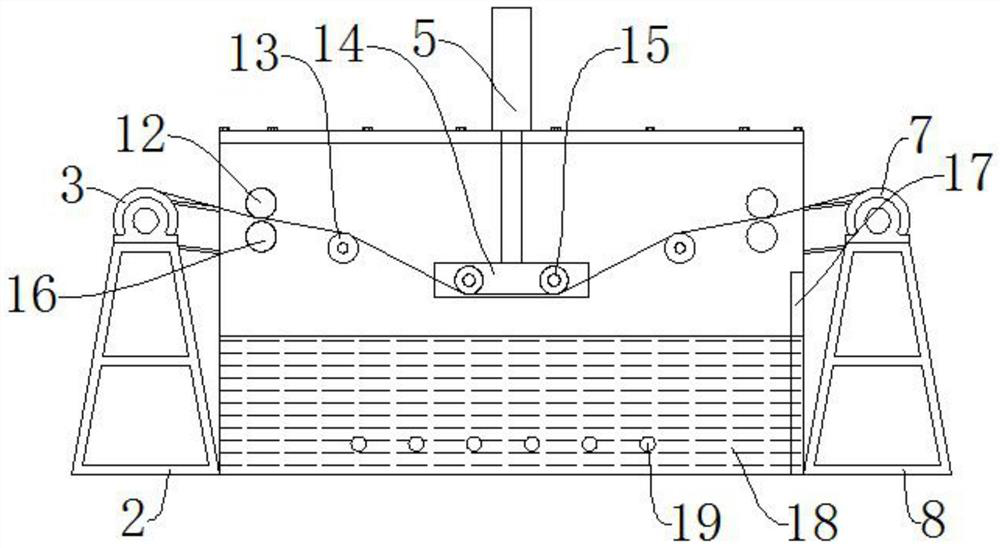

Rapid drying device for pulping machine for chemical fabric processing

InactiveCN110849121AScientific and reasonable structureEasy to useDrying machines with progressive movementsDrying solid materialsThermodynamicsProcess engineering

The invention discloses a rapid drying device for a pulping machine for chemical fabric processing. The rapid drying device comprises a drying box, wherein a water tank is fixedly connected to the side position of the top end of the drying box, a fixed seat is fixedly connected to the position, corresponding to the side of the water tank, of the top end of the drying box, and a steam generator isfixedly connected to the top end of the fixed seat. According to the rapid drying device, the water tank, the fixed seat, the steam generator, a water outlet pipe, an air outlet pipe, an upper heatingpipe, a lower heating pipe and a second exhaust pipe are arranged, the water tank continuously supplies water to the steam generator through the water outlet pipe, water is converted into high-temperature steam through the steam generator and discharged through the air outlet pipe, and heat in the steam is uniformly transferred to the top and the bottom of the inner wall of the drying box throughthe upper heating pipe and the lower heating pipe, so that the internal temperature of the drying box is increased, the moisture inside the drying box is evaporated, and then the drying degree of thechemical distribution cloth is improved; and meanwhile, cooled steam is discharged through a second exhaust pipe, and the drying effect is guaranteed.

Owner:长兴县新盛纺织有限公司

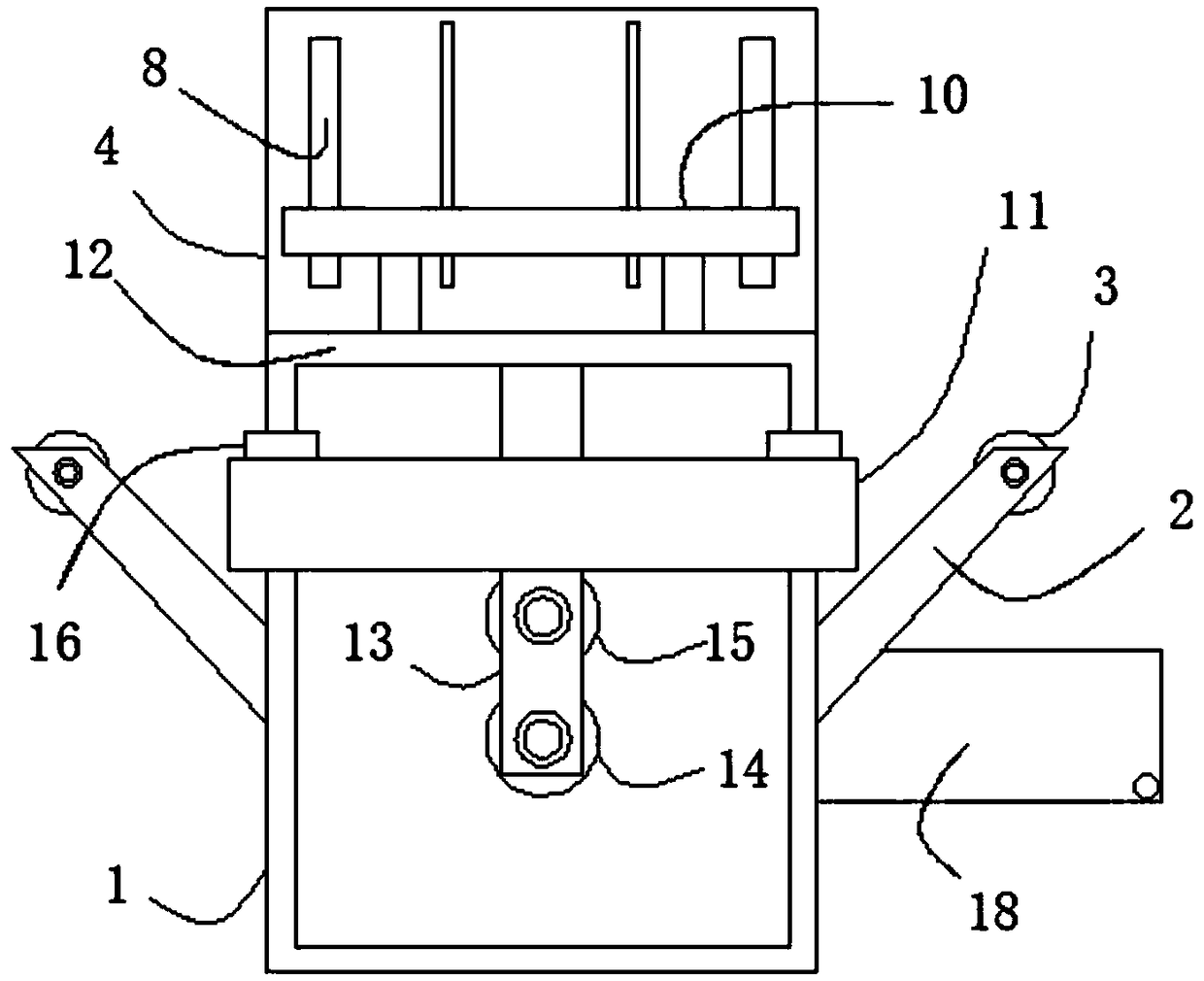

Chemical-fiber-fabric-pattern dyeing device

InactiveCN109385778APrecise positioningMeet the needs of useTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentHydraulic cylinderFiber

The invention belongs to the field of dyeing devices, and discloses a chemical-fiber-fabric-pattern dyeing device. The chemical-fiber-fabric-pattern dyeing device comprises a box, a fixed frame is welded to the top of the box, supporting rods symmetrically arranged are welded to the two sides of the box, guiding rollers are rotationally connected between the two supporting rods located on the sameside, a fixed plate arranged in the vertical direction is welded to the opposite-side of the box, a supporting plate arranged in the horizontal direction is welded to the side, away from the box, ofthe fixed plate, positioning holes symmetrically formed and located on the fixed plate are formed in the upper portion of the supporting plate in the vertical direction, and a hydraulic cylinder is installed at the top of the supporting plate. In the chemical-fiber-fabric-pattern dyeing device, a guide roller inside the box can be mutually matched with a guide roller outside the box, a chemical fiber fabric can be better guided and positioned accordingly, the using requirement is met, a top cover is easily lifted, and the chemical fiber fabric is conveniently inserted between the two guide rollers inside the box, is conveniently positioned, and is conveniently dyed.

Owner:浙江盛邦化纤有限公司

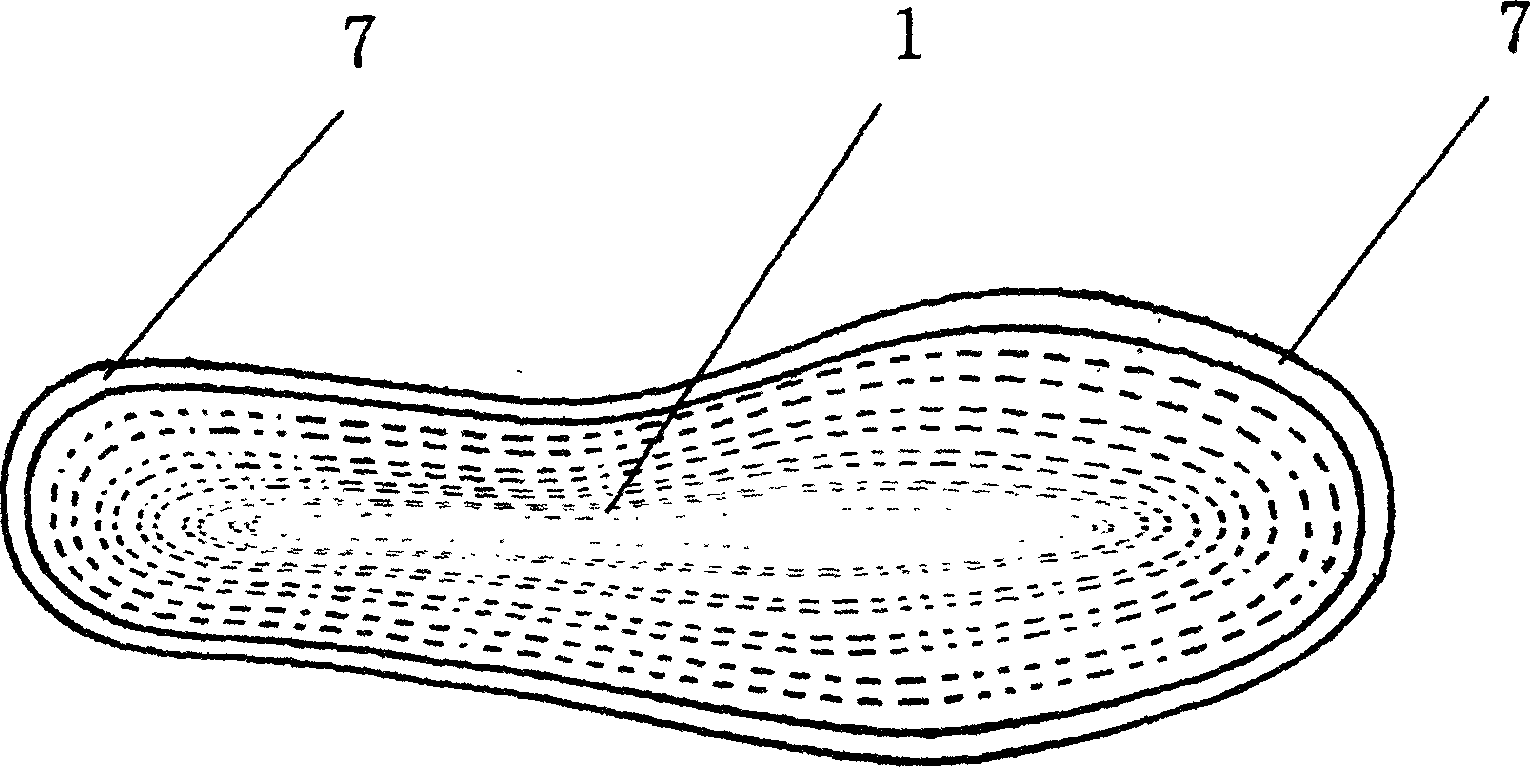

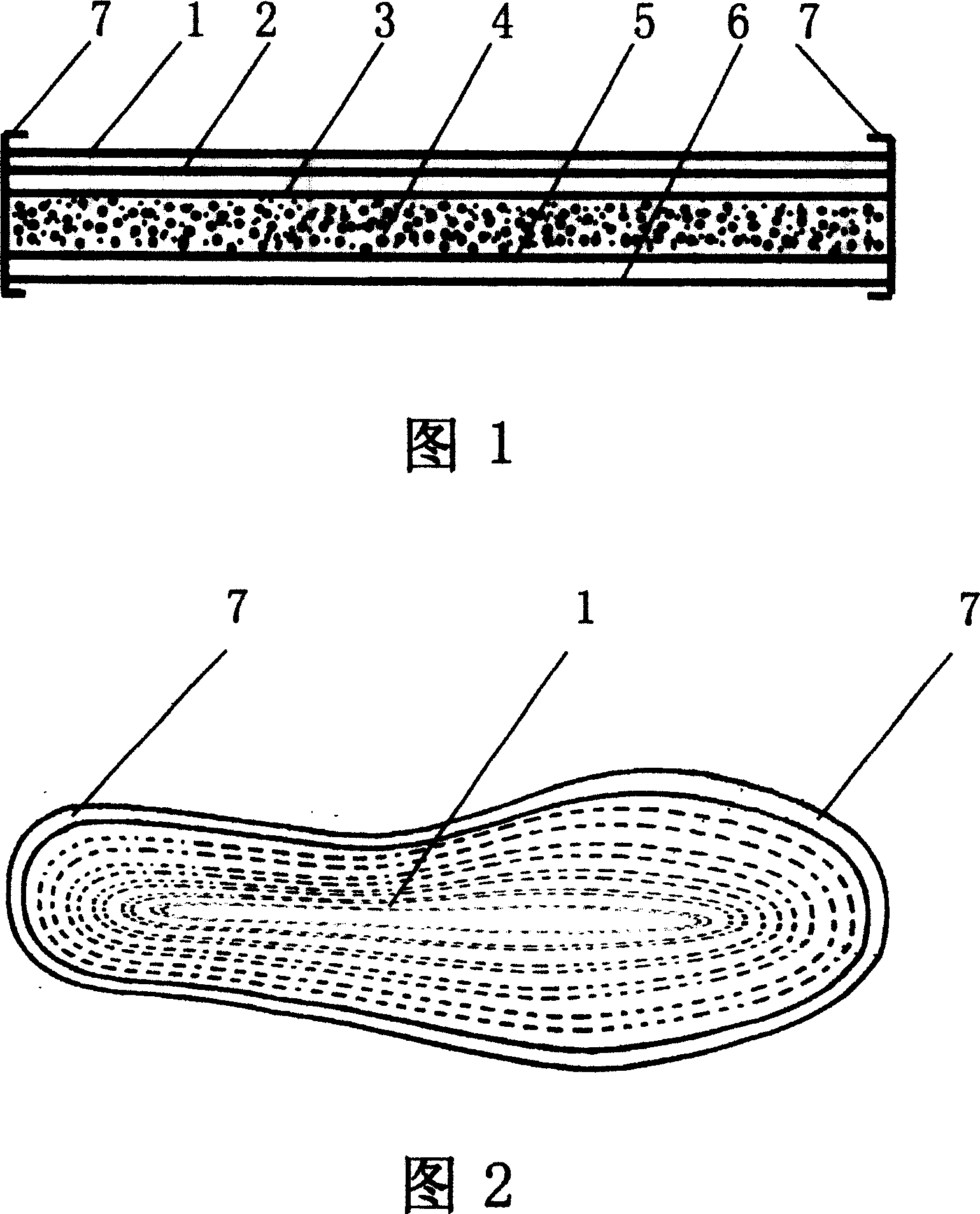

Shoe pads of odor treatment and sucking sweat, and preparation method

InactiveCN1600193ASimple production processObvious deodorant and sweat absorption effectInsolesChemical fibre clothEnvironmental engineering

Owner:许庆华

Textile thread dividing device for chemical fiber cloth

The invention provides a textile thread dividing device for chemical fiber cloth, and belongs to the field of chemical fiber cloth processing. The device comprises brackets, wherein the tops of the brackets are fixedly provided with a second-level frame, a fixing plate is fixedly arranged between the two brackets, one side of the fixing plate is fixedly provided with a baffle, the upper surface ofthe baffle is fixedly provided with a limiting rod, the upper side of the limiting rod is provided with a first fixing frame, the inner portion of the first fixing frame is provided with a first transmission wheel, the upper side of the first fixing frame is provided with a second fixing frame, the inner portion of the second fixing frame is provided with a second transmission wheel, the two sides of the bottom of the second-level frame are fixedly provided with thread subdivision wheels, a thread guide roller is hinged between the two thread subdivision wheels, the top of the thread guide roller is welded with equidistantly distributed thread guide discs, and the other side of the fixing plate is fixedly provided with a first-level frame. Woven threads can be arranged and divided througha thread dividing groove and a thread arrangement shaft, and through the design, multiple threads can be simultaneously woven, thereby greatly improving the weaving efficiency.

Owner:徐州宁和布业有限公司

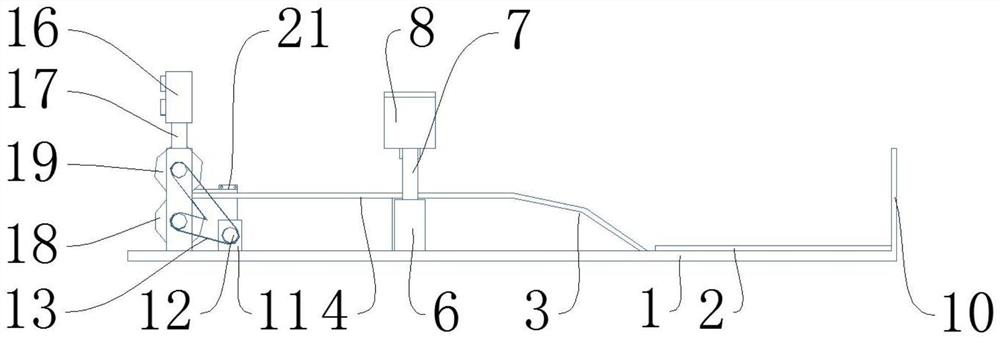

Hot cutting device for chemical fabric production and using method thereof

InactiveCN112064330AReduce labor intensityIncrease productivitySevering textilesHydraulic cylinderEngineering

The invention discloses a hot cutting device for chemical fabric production and a using method thereof. The hot cutting device comprises a bottom plate and a cutting module, a baffle is arranged on the upper part of the bottom plate, an anti-skid mark is arranged on one side of the baffle, a sliding way is arranged on one side of the anti-skid mark, a conveying plate is arranged on one side of thesliding way, a displacement sensor is arranged on the rear part of the conveying plate, supporting legs are arranged on the lower part of the conveying plate, hydraulic cylinders are arranged on thefront sides of the supporting legs, telescopic rods are arranged on the upper parts of the hydraulic cylinders, a cutting module is arranged on the upper parts of the telescopic rods, the cutting module comprises heaters, a heating pipe is arranged between the heaters, and a hot cutting tool is arranged on the lower part of the cutting module. Through the arrangement of the displacement sensor, semi-automation can be completed, and a worker only needs to load chemical fabric into a roller shaft; through the arrangement of the anti-skid mark and the sliding way, the cut chemical fabric can be collected, the production efficiency is improved, and the labor intensity of the worker is reduced; and an electric heater and the hot cutting tool are used, so unlike laser cutting, energy loss is small, and the quotation is low.

Owner:长兴布布高纺织有限公司

Environment-friendly cotton cloth plate for construction and decoration and preparation method thereof

InactiveCN101871252AEliminate pollutionEliminate dependenciesCovering/liningsSolid waste managementCotton clothEmulsion

The invention relates to an environment-friendly cotton cloth plate for construction and decoration and a preparation method thereof and the cotton cloth plate is used for the decoration of buildings, reduces the discrepancy between the use of organic decoration materials and the forest resource starvation and natural environment disruption, and lowers the adverse effects of the discarded and waste clothes of human to the environment. The cotton cloth plate comprises the waste clothing scraps of cotton cloth or chemical fabric cloth, emulsion adhesive, oxidized starch and melamine. The preparation method comprises the following steps: removing other sundries from the waste clothes raw material, processing to scraps; adding raw materials in a stirrer according to designated percentages to stir evenly; placing the mixture in the moulds of the required product, flattening, heating, pressurizing, maintaining the pressure; and demoulding and drying to obtain the product of the invention. The positive effects of the environment-friendly cotton cloth plate of the invention are as follows: the cotton cloth plate is used to replace wood-based panels, thus eliminating the pollution of waste clothes to the environment, facilitating the preservation of the forest and improving the natural environment. The quality of the obtained product is better than that of the density board and the laminated wood board.

Owner:李春光

Environment-friendly cotton cloth plate for construction and decoration and preparation method thereof

InactiveCN101871252BImprove impact resistanceImprove bending resistanceCovering/liningsSolid waste managementAdhesiveCotton cloth

The invention relates to an environment-friendly cotton cloth plate for construction and decoration and a preparation method thereof and the cotton cloth plate is used for the decoration of buildings, reduces the discrepancy between the use of organic decoration materials and the forest resource starvation and natural environment disruption, and lowers the adverse effects of the discarded and waste clothes of human to the environment. The cotton cloth plate comprises the waste clothing scraps of cotton cloth or chemical fabric cloth, emulsion adhesive, oxidized starch and melamine. The preparation method comprises the following steps: removing other sundries from the waste clothes raw material, processing to scraps; adding raw materials in a stirrer according to designated percentages to stir evenly; placing the mixture in the moulds of the required product, flattening, heating, pressurizing, maintaining the pressure; and demoulding and drying to obtain the product of the invention. The positive effects of the environment-friendly cotton cloth plate of the invention are as follows: the cotton cloth plate is used to replace wood-based panels, thus eliminating the pollution of waste clothes to the environment, facilitating the preservation of the forest and improving the natural environment. The quality of the obtained product is better than that of the density board and the laminated wood board.

Owner:李春光

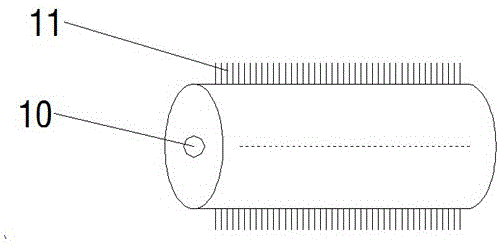

Chemical fabric ventilation device

InactiveCN106078907AHigh degree of automationSave manpower and material resourcesDrying gas arrangementsMetal working apparatusAgricultural engineeringChemical fibre cloth

The invention discloses a chemical fabric ventilation device. The chemical fabric ventilation device comprises a base, a control panel, a cloth storage roller, a drying heating sprayer, fixed rolling shafts, a ventilation roll shaft, a dust suction ventilator, a cloth accommodation roller, a driving motor, a support shaft, ventilation needles, electric heating wires and air openings, wherein the control panel is arranged on the upper side of the base; the cloth storage roller is arranged on the upper side of the control panel; the drying heating sprayer is arranged on the right and lower side of the cloth storage roller; the fixed rolling shafts are arranged on the right side of the drying heating sprayer; the ventilation roll shaft is arranged on the right side of the fixed rolling shafts; the dust suction ventilator is arranged on the upper side of the ventilation roll shaft; the cloth accommodation roller is arranged on the right and lower side of the dust suction ventilator; the driving motor is arranged on the lower side of the cloth accommodation roller; the support shaft is arranged on the center of the ventilation roll shaft; and the ventilation needles are arranged on the outer wall of the ventilation roll shaft. According to the chemical fabric ventilation device, the ventilation roll shaft is arranged, so that the automation degree is high; a great amount of manpower and material resource is saved; and the ventilation effect is good.

Owner:长兴县鑫盛轻纺有限公司

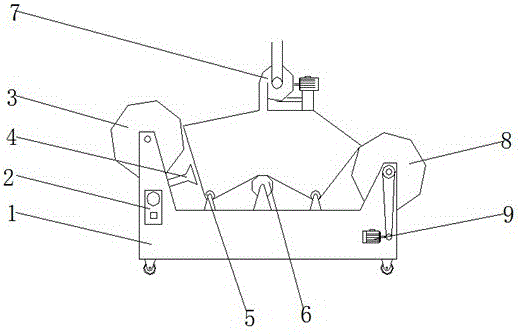

Arrangement device for anti-bacterial and moisture-proof chenille sofa fabric and chemical fabric weaving

InactiveCN110834978AEasy to openEasy to closeMechanical cleaningPressure cleaningWinding machineStructural engineering

The invention discloses an arrangement device for anti-bacterial and moisture-proof chenille sofa fabric and chemical fabric weaving. The arrangement device comprises a base, a box body, a top plate and vertical plates, wherein the box body is fixedly mounted at the top surface of the base, the top plate is fixedly mounted on the top surface of the box body, one vertical plate is fixedly mounted at one end of the top surface of the top plate, a first reel is rotatably mounted at the middle of one vertical plate, a telescopic column is fixedly mounted at the middle of the top surface of the topplate, a clamping plate is rotatably mounted at one side of the top end of the telescopic column, a suction opening is formed in one side of the interior of the clamping plate, the suction opening isconnected with one end of a filter cylinder through a transmission pipe, one vertical plate is fixedly mounted at the other end of the top surface of the top plate, a second reel is rotatably mountedat the middle of one vertical plate, and one end of the second reel is rotatably connected with a motor. According to the arrangement device, one device is arranged on a fabric winding machine, wherein the device can brush away and suck in dust or other impurities on the surface of current fabric, so that the effect of multiple functions and improving the practicability are achieved, the reels are changed into rotary clamping-in type fixation, and feeding and discharging are facilitated.

Owner:海宁德逸纺织有限公司

Shoe pads of odor treatment and sucking sweat, and preparation method

InactiveCN100364469CSimple production processObvious deodorant and sweat absorption effectInsolesChemical fibre clothEnvironmental engineering

Owner:许庆华

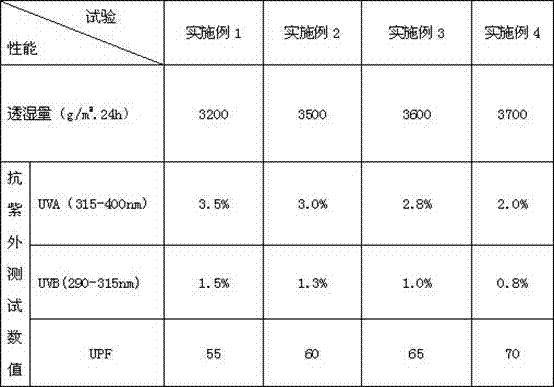

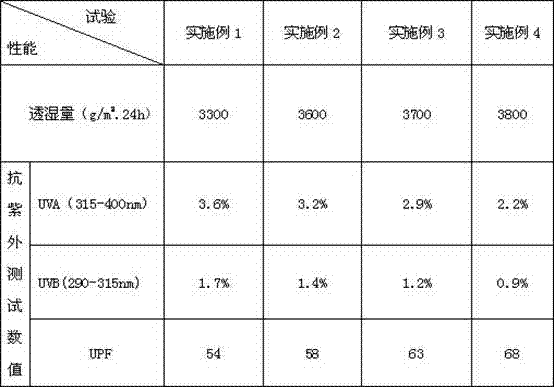

Water-based high moisture permeability, anti-ultraviolet functional coating glue and preparation method

The invention discloses waterborne high-moisture-permeability anti-ultraviolet functional coating glue which is prepared in the mode that 90-110 parts of ethylene glycol polyether with the average molecular weight being 2000, 90-110 parts of ethylene glycol polyether with the average molecular weight being 1000, 55-60 parts of toluene diisocynate, 60-65 parts of acetone, 8-10 parts of 1,4-butanediol and 2.5-4 parts of nano titanium dioxide are polymerized, and the materials are dispersed in 580-620 parts of deionized water and thickened through 1.5-2 parts of associative polyurethane flatting and rheological agents. The moisture-permeable anti-ultraviolet functional coating glue is particularly suitable for 15-20D fine-denier nylon chemical fabric, and is soft in using hand feel and good in fastness.

Owner:LIAONING FIXED STAR FINE CHEM

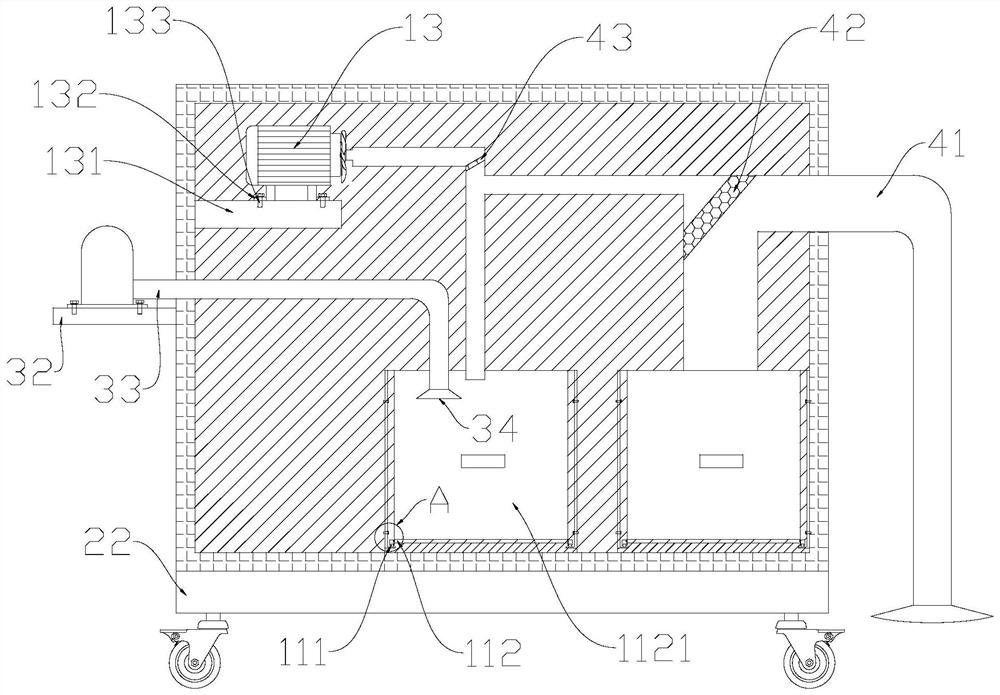

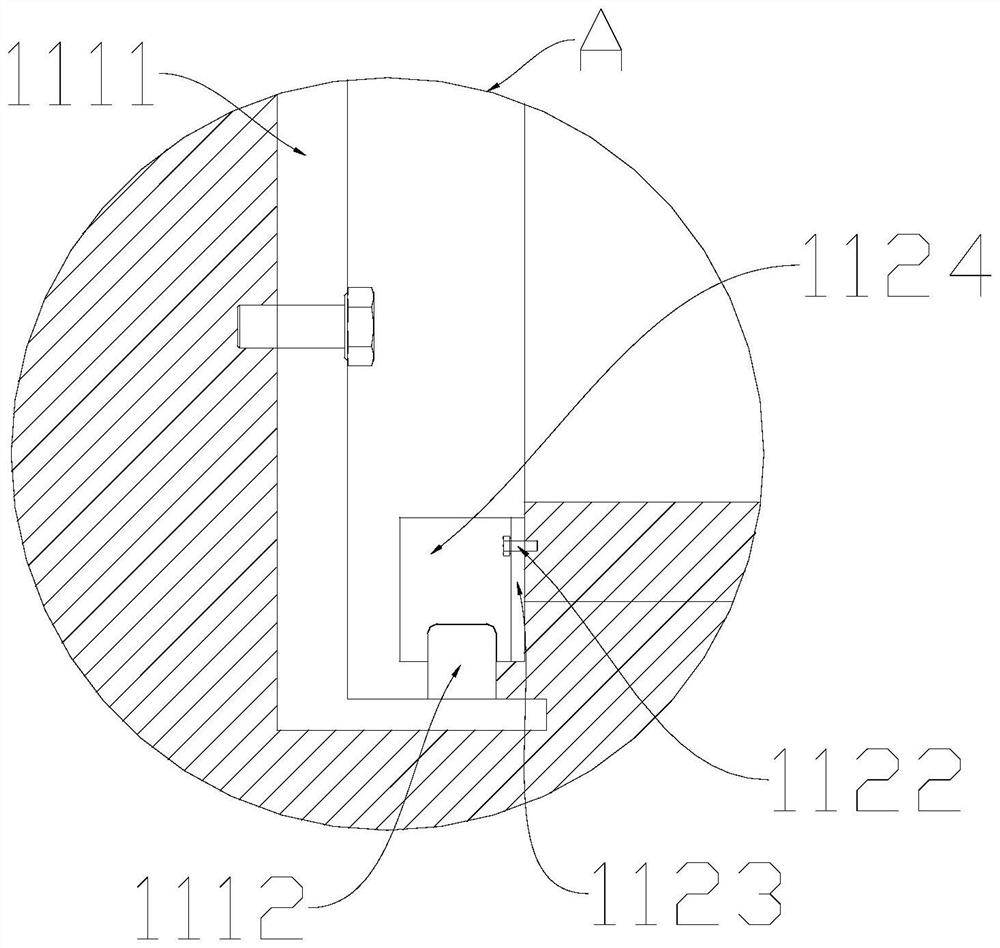

Printing and dyeing device applied to production of chemical fabric and using method of printing and dyeing device

InactiveCN112111879ASame speedImprove printing and dyeing effectTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsTorque motorChemical fibre cloth

The invention discloses a printing and dyeing device applied to production of chemical fabric and a using method of the printing and dyeing device. The printing and dyeing device comprises a supporting mechanism, a winding mechanism, a drying mechanism and a controller, and further comprises a printing and dyeing mechanism, wherein the printing and dyeing mechanism comprises a dye box, a feeding pipe, a straight-through pipe, a dye cylinder, discharging pipes, pressure switches, printing and dyeing heads, a winding drum, a servo motor, the chemical fabric and a workbench; the dye box is connected onto a fixing plate through screws, the feeding pipe is connected to the front of the dye box through screws, the straight-through pipe is connected to the end of the feeding pipe through a bearing, the straight-through pipe penetrates through the fixing plate and is connected to the fixing plate through a bearing, the dye cylinder is welded to the end of the straight-through pipe, and the discharging pipes are welded around the dye cylinder. The arrangement of a scraper and a tension spring is beneficial to spreading of the chemical fabric and tensioning of the chemical fabric; the discharging pipes, the pressure switches and the printing and dyeing heads can be used for printing and dyeing the chemical fabric with different widths; the arrangement of a torque motor ensures that the linear speed of a collected chemical fabric roll is the same as that of the winding drum, and the printing and dyeing effect is improved.

Owner:浙江长兴天盛化纤有限公司

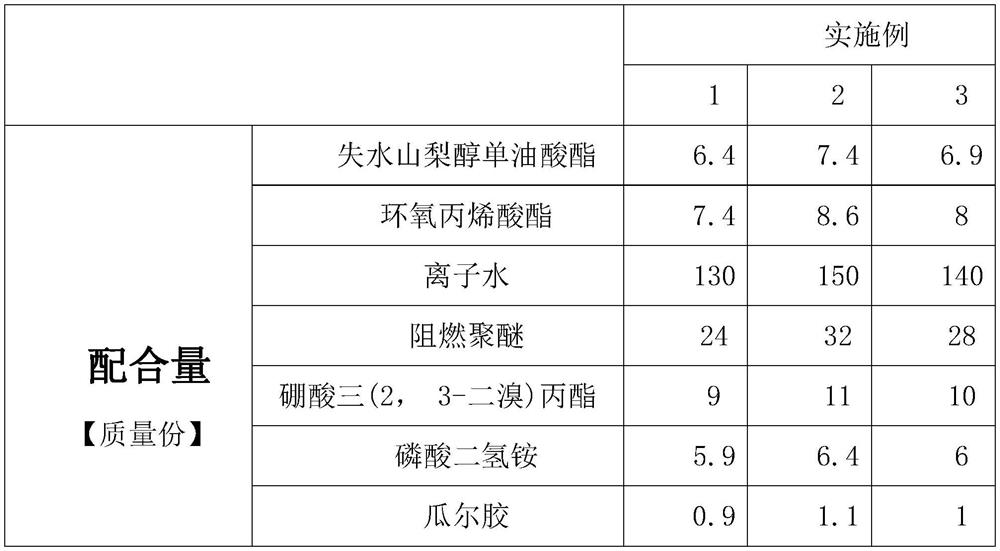

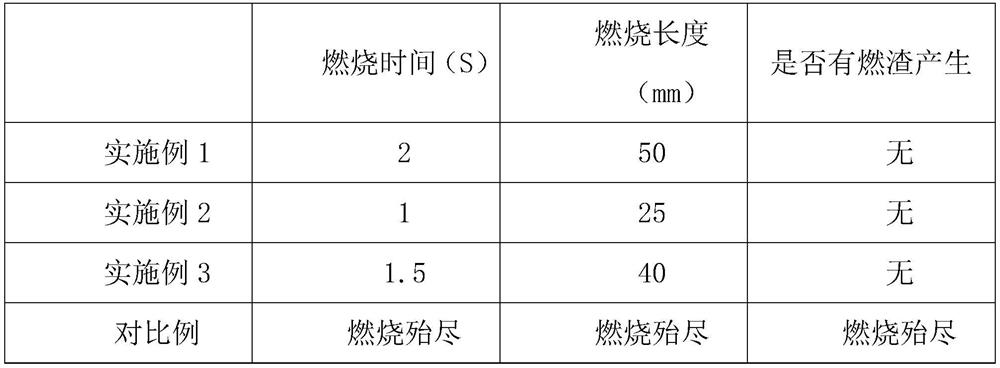

Flame-retardant process for chemical fabric

PendingCN114351461AImprove flame retardant performanceDoes not affect the quality of useFibre treatmentHeating/cooling textile fabricsPolymer scienceEngineering

The invention discloses a chemical fabric flame-retardant process, which belongs to the technical field of chemical fabric processing, and specifically comprises the following process steps: S1, chemical fabric pretreatment; s2, preparing a flame-retardant finishing agent; s3, padding the chemical fabric; s4, drying the padding cloth; s5, reshaping the gray fabric; and S6, rolling and packaging. According to the method, the chemical fabric subjected to setting treatment is soaked in the flame-retardant finishing liquid, and then the flame retardant is deposited and cross-linked on the fabric through the processing technologies of pre-drying, baking, re-setting and the like, so that the flame-retardant property of the chemical fabric is integrally improved, and meanwhile, the use quality and the service life of the chemical fabric are not influenced.

Owner:吴国娟

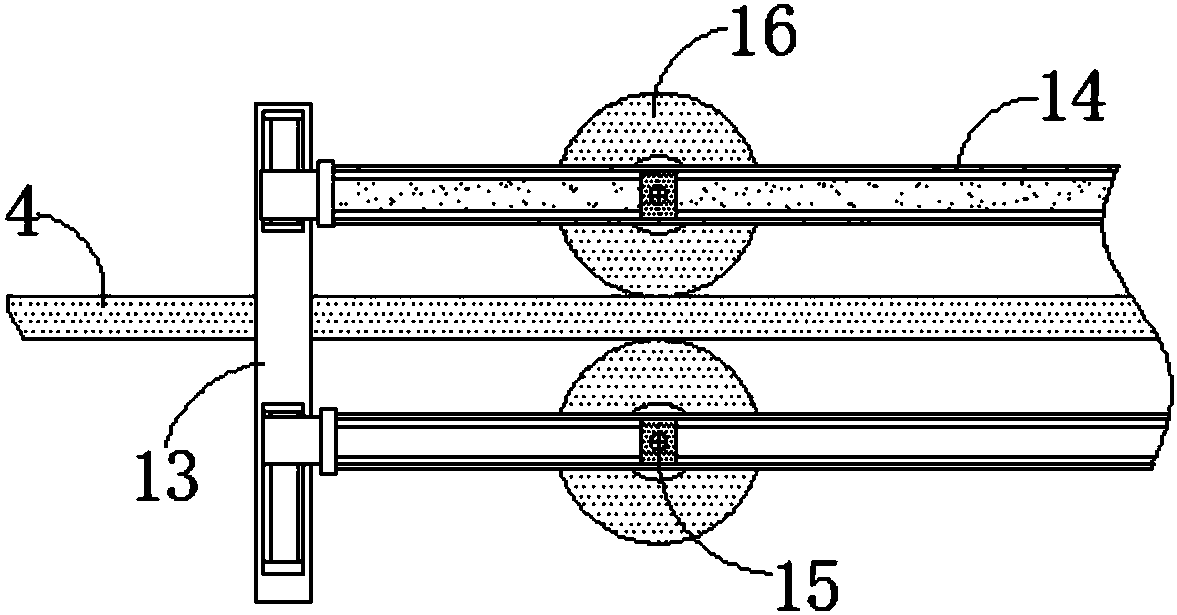

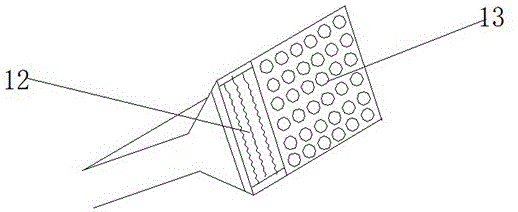

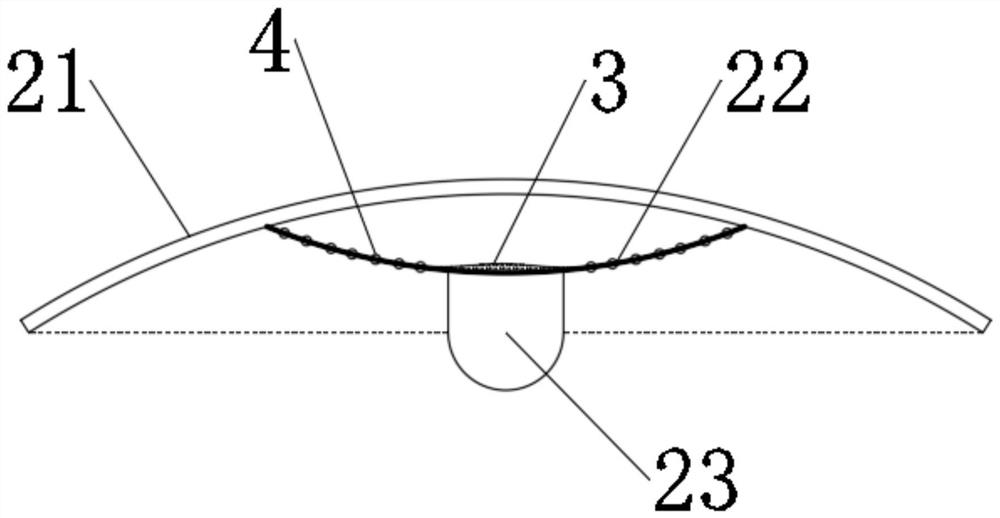

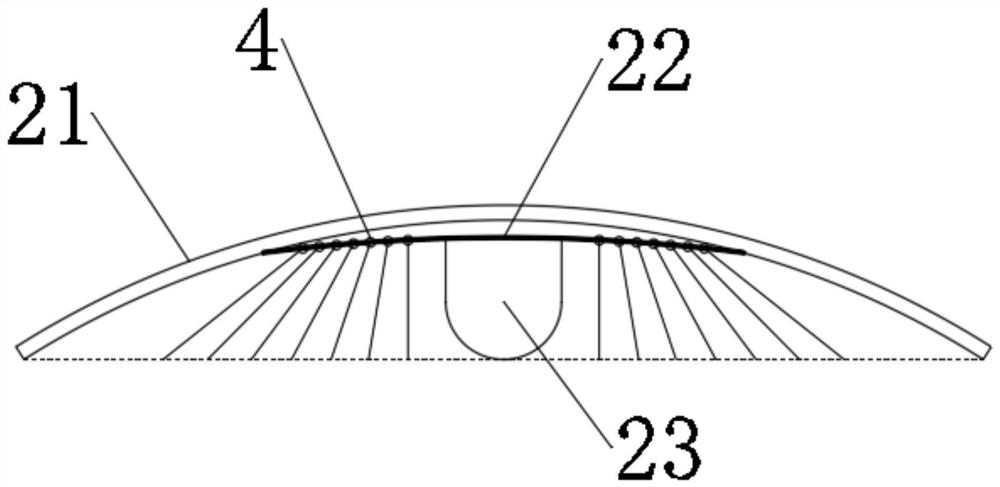

Chemical fabric cover plate type flame-retardant layer coating process

The invention discloses a chemical fabric cover plate type flame-retardant layer coating process, and belongs to the technical field of chemical fabrics. According to the chemical fabric cover sheet type flame-retardant layer coating process provided by the invention, after flame-retardant glue is sprayed on the surface of chemical fabric, by utilizing the attraction effect of a magnetic field on permeation-assisting cover plates, the permeation-assisting cover plates are forced to cover and extrude the flame-retardant glue on the surface of the chemical fabric, the internal deformation action is triggered, the permeation-assisting cover plates are continuously attracted by the magnetic field after the whole is broken up into parts, and more detailed multi-point extrusion is carried out on the flame-retardant glue, so that the chemical fabric is forced to have a good stretching effect locally, pores of the chemical fabric are increased, permeation of the flame-retardant glue into the chemical fabric is accelerated under the extrusion actions of the permeation-assisting cover sheets, and compared with the self-permeation action of the flame-retardant glue, a more excellent coating effect can be achieved through obvious external force intervention in the chemical fabric cover plate type flame-retardant layer coating process; and the permeation effect is locally concentrated and then integrally covered in a multi-covering mode, so that the coating quality of the flame-retardant glue is remarkably improved.

Owner:FUZHOU CHUNHUI CLOTHING CO LTD

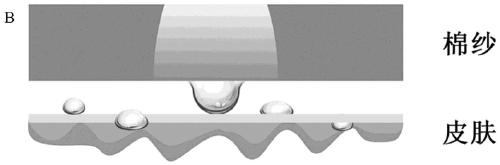

Penetrating type sweat guide and quick-drying composite fabric and preparation method thereof

ActiveCN111206326ASolve the problem of \"not absorbing sweat\"Solve the two problems of \"slow drying\" of cotton fabricsWeft knittingFilament/thread formingFiberEngineering

The present invention provides a penetrating type sweat guide and quick-drying composite fabric, which is woven by an inner layer and an outer layer; and the inner layer is made of bionic skin-core structure fibers and the outer layer is made of hydrophilic fibers. The invention creates a novel moisture-absorbing and sweat-releasing mode, wherein the wetted radius of the inner layer is small and the sweat absorbed and retained by the inner layer is less, so that a purpose of enabling the inner layer to be dry and comfortable is achieved; the sweat of the outer layer is diffused and evaporatedat a larger area, and the sweat can be naturally dried fast. The functions of the inner layer and the outer layer are separated, the inner layer is used for guiding the sweat and the outer layer is used for diffusing and evaporating. The sweat in the inner layer is like a stalk of a mushroom and can penetrate through the inner layer at a small area; a mushroom-like umbrella part at the outer layercan be diffused and evaporated at a large area, so that the problems that the chemical fabric does not absorb the sweat, and the inner layer absorbs more sweat and is dry slowly, cold and damp are solved. Meanwhile, due to the fact that the sweat of the outer layer is not in contact with the skin, so that the body-adhered or cold and damp discomfort cannot be generated.

Owner:广东彩艳股份有限公司

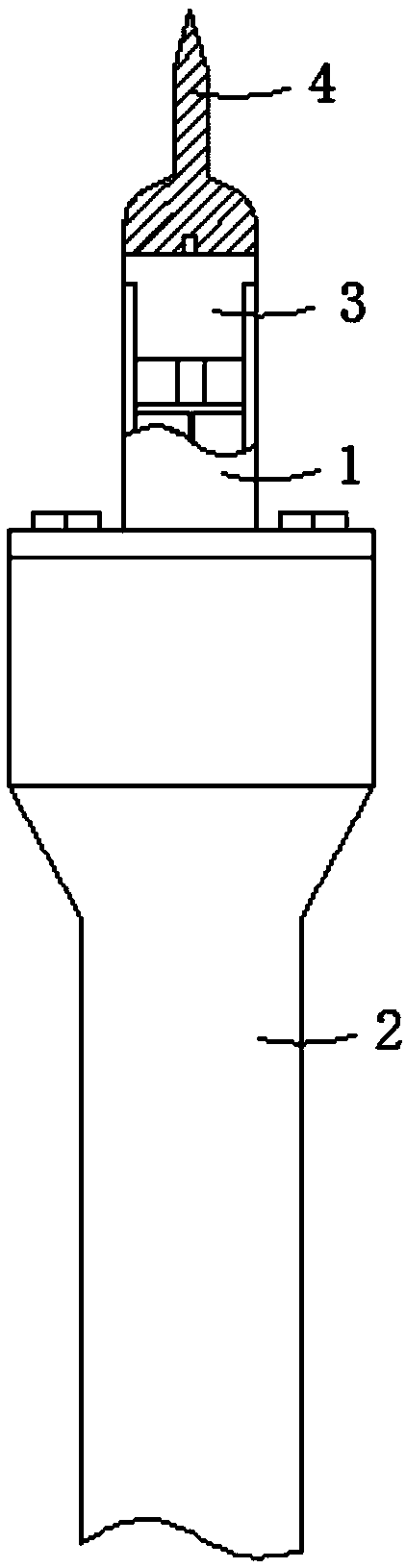

Chemical fibre cloth cutter

InactiveCN108642850AIncrease temperatureGuaranteed temperatureSevering textilesChemical fibre clothEngineering

The invention discloses a chemical fiber cloth cutter, which comprises a connecting element, one end of the connecting element is fixedly connected with a handle through bolts, one end of the connecting element, far away from the handle, is connected with a cutter head through an outer heat insulation sleeve, a mounting plate is welded inside the connecting element, one side of the mounting plateis welded with an inner heat insulation sleeve, the inner part of the inner heat insulation sleeve is internally provided with a connecting switch and a heating element, the heating element is locatedat one side of the connecting switch, and one end of the heating element, away from the connecting switch, is engaged with the inside of the cutter head, and a plurality of cooling holes are arrangedat the position of the outer wall of the connecting element located at the mounting plate, away from the side of the inner insulating sleeve. According to the invention, the connecting switch and theheating element are arranged, during the initial heating process, the connecting switch is in an ON state, the conductive column inside the connecting switch is in full contact with the conductive contact on the heating element, and the heating wires inside the heating element is in a heating state so that the heating element is in a rapid heating state.

Owner:长兴明远布艺科技有限公司

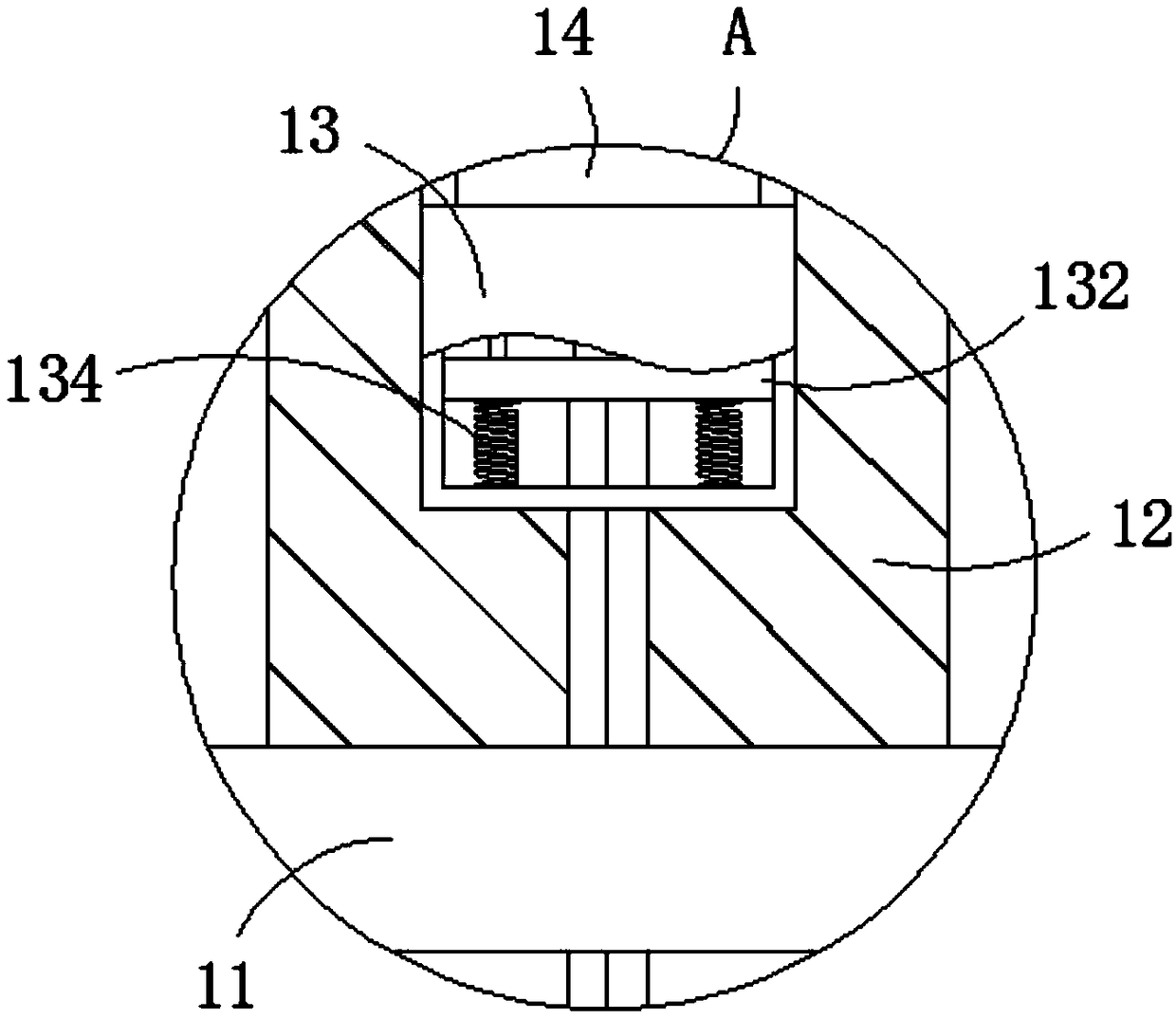

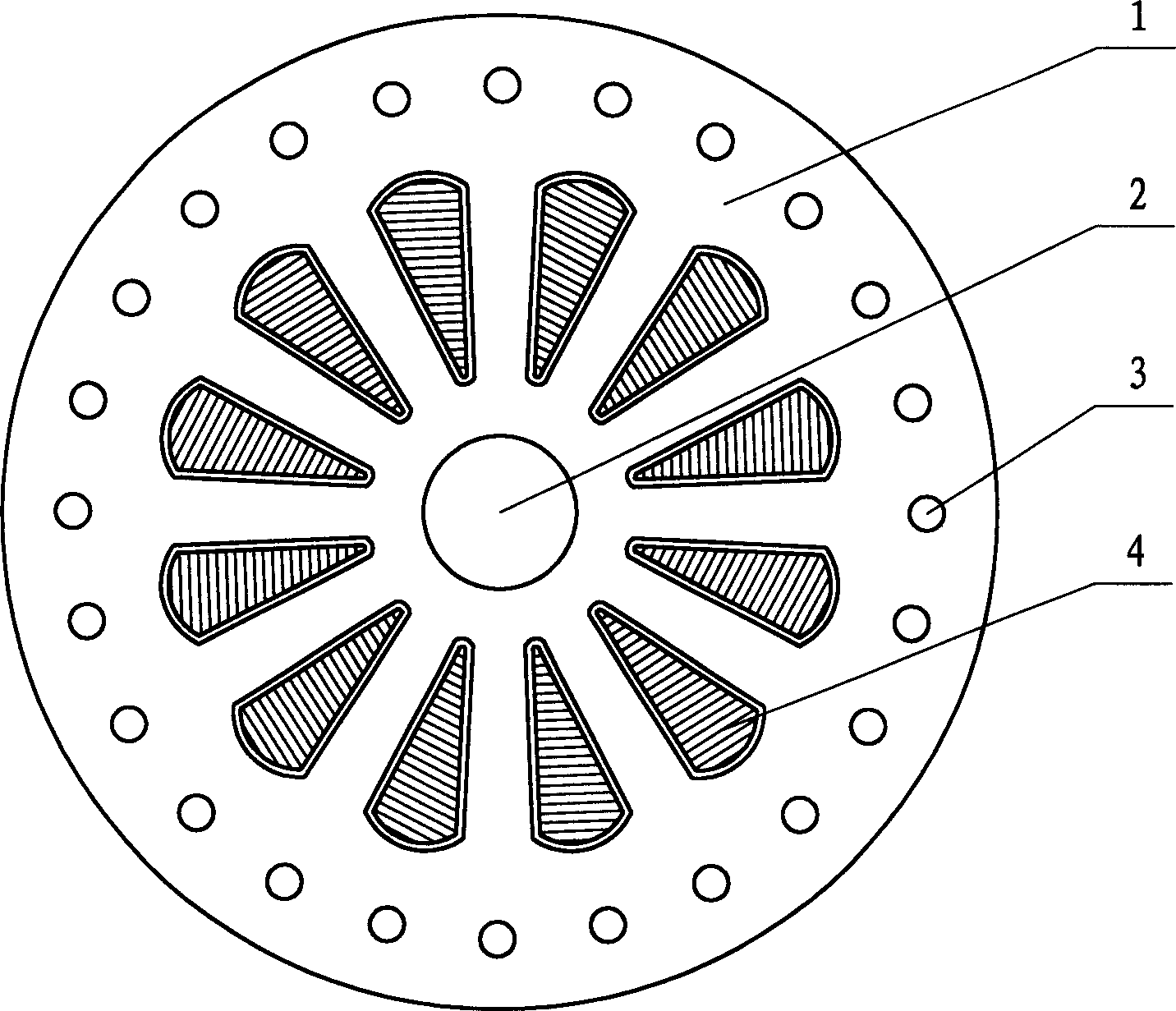

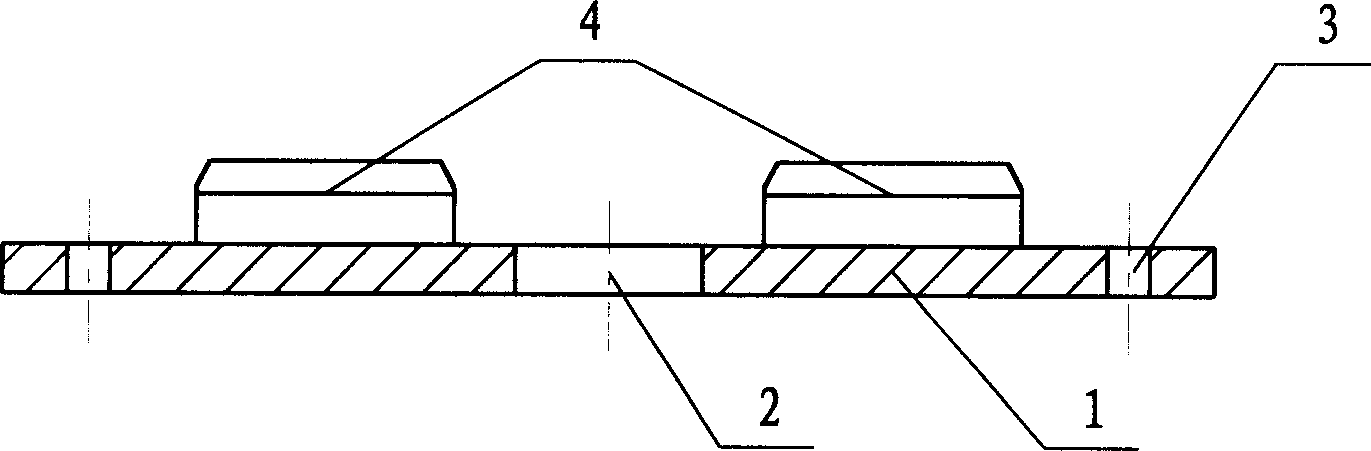

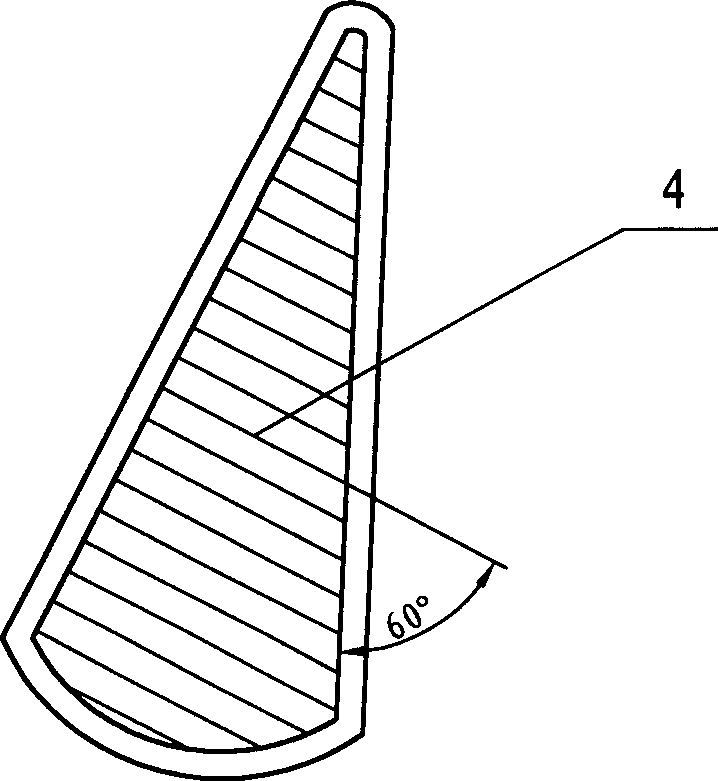

Polishing cerium oxide disk and its making method

InactiveCN1115230CLow costExtend your lifeEdge grinding machinesOptical surface grinding machinesFiberChemical fibre cloth

A polishing cerium oxide disk is composed of circular substrate disk, central hole, holes on edge and abrasing head, and is prepared from chemical fibre cloth through immersing in resin, adhering squeezing and shaping. Its advantages include long service life, high tear strength, and shear strength, high firmness of abrasing head, and low cost.

Owner:北京中电光明抛磨技术发展中心 +1

Waste collecting device for chemical fabric

PendingCN113441507AEnhanced function of waste suctionSmooth rotationCombination devicesDirt cleaningSuction forceAir pump

The invention belongs to the field of textile production, and particularly relates to a waste collecting device for chemical fabric. The device comprises a box body, a supporting hopper is fixedly connected in the box body, a filter screen is adhered to the supporting hopper, the lower end of the supporting hopper is in threaded connection with a bottom cover, the upper end of the bottom cover is fixedly connected with a connecting sleeve, a square rod is connected into the connecting sleeve in a sliding mode, a supporting rod is fixedly connected to the upper end of the square rod, shifting pieces are fixedly connected to the two ends of the supporting rod, the shifting pieces make contact with the filter screen, an air pump is fixedly installed on the outer side of the box body, and an air outlet is formed in one side of the air pump. Waste on the ground can be sucked and collected by designing the air pump, a suction pipe and a suction cover on the box body, a vertical pipe and a waste suction pipe driven by a motor are designed on a box cover, and a rotating cover and fan blades are designed at the bottom of the vertical pipe, so that suction force can be generated, the waste suspended in the air can be sucked and collected, and the waste suction function is enhanced.

Owner:孟丹

Textile waste collecting device for textile production of chemical fabric

PendingCN112893317AEasy to take outEasy to cleanCombination devicesGas current separationElectric machineryEnvironmental engineering

Owner:莫晨良

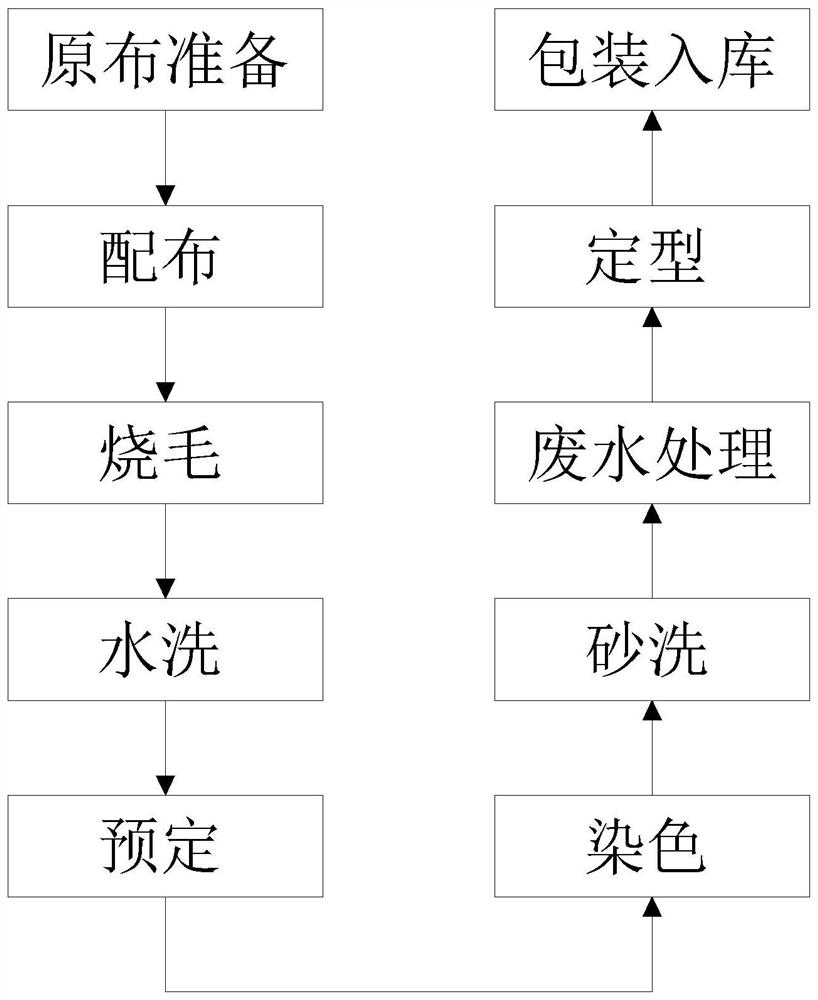

Dyeing process of chemical fabric

PendingCN114753081ARemove creasesEliminate wrinklesSingeingHeating/cooling textile fabricsProcess engineeringChemical fibre cloth

The invention discloses a chemical fabric dyeing process, which relates to fabric dyeing and comprises the following steps of raw fabric preparation, fabric preparation, singeing, water washing, presetting, dyeing, sand washing, wastewater treatment, sizing, packaging and warehousing. The device has the beneficial effects that equipment and manpower are orderly combined, the automation degree is high, the process continuity is good, the production efficiency is high, short hair on the surface of the gray fabric can be removed, creases and wrinkles on the gray fabric can be eliminated, the surface of the gray fabric is neat and flat, and therefore the subsequent dyeing quality of the gray fabric is effectively guaranteed, and the production efficiency is improved. Various impurities on the grey cloth can be removed, the drapability of the grey cloth is improved, the texture of the grey cloth is enhanced, and therefore the quality of the grey cloth is improved, wastewater can be discharged after being treated in a centralized mode, and environmental pollution can be effectively avoided.

Owner:SHAOXING JINMU PRINTING & DYEING

Printing and dyeing device for chemical fabric processing and using method thereof

InactiveCN112064249APass through at a constant speedAvoid squeezingTextile treatment containersTextile treatment machine arrangementsChemical fibre clothMechanical engineering

The invention discloses a printing and dyeing device for chemical fabric processing and a using method thereof. The printing and dyeing device comprises a dye box, a raw material roller and a materialreceiving roller, a first support is arranged on one side of the dye box, the raw material roller is connected with the first support, a second support is arranged on the other side of the dye box, the material receiving roller is connected with the second support, and third chain wheels are mounted at the rear ends of the raw material roller and the material receiving roller. Through the arrangement that a servo motor drives a first chain wheel to rotate, the first chain wheel transmits power to a second chain wheel to drive a second feeding roller to rotate, a first feeding roller rotates under meshing of a first gear and a second gear, chemical fabric is subjected to moving force before and after printing and dyeing, and meanwhile the second chain wheel drives the third chain wheel torotate so the raw material roller and the material receiving roller rotate synchronously; and the rotating speeds of the first feeding roller, the second feeding roller, the raw material roller and the material receiving roller are equal, so that the chemical fabric stably passes through dye at a constant speed, the chemical fabric is prevented from being extruded or stretched, and the printing and dyeing efficiency and quality are improved.

Owner:长兴布布高纺织有限公司

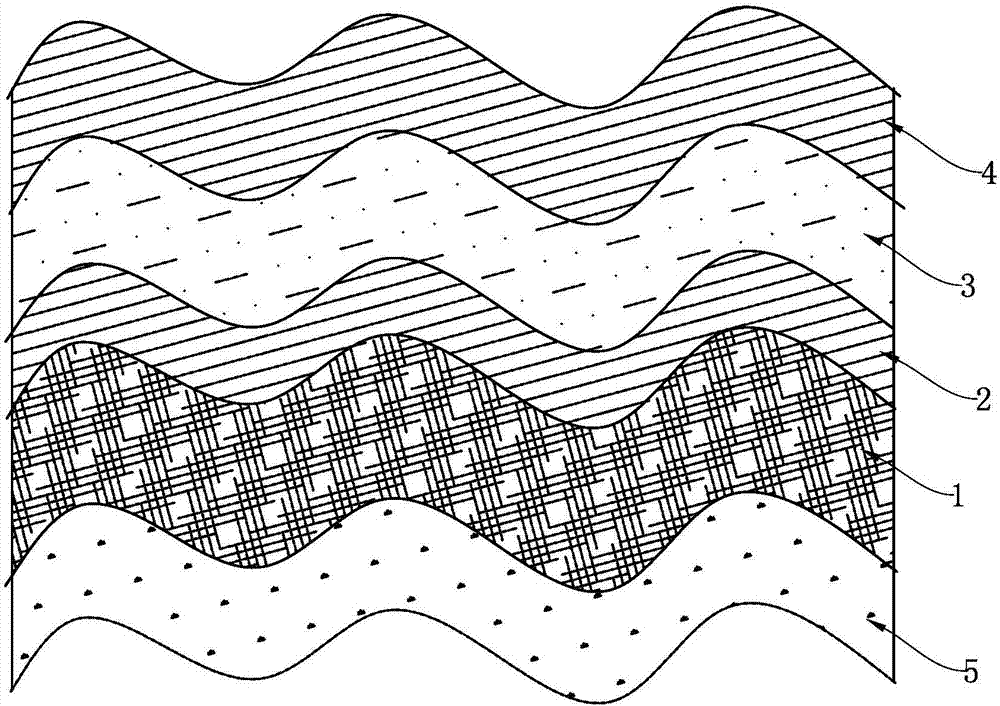

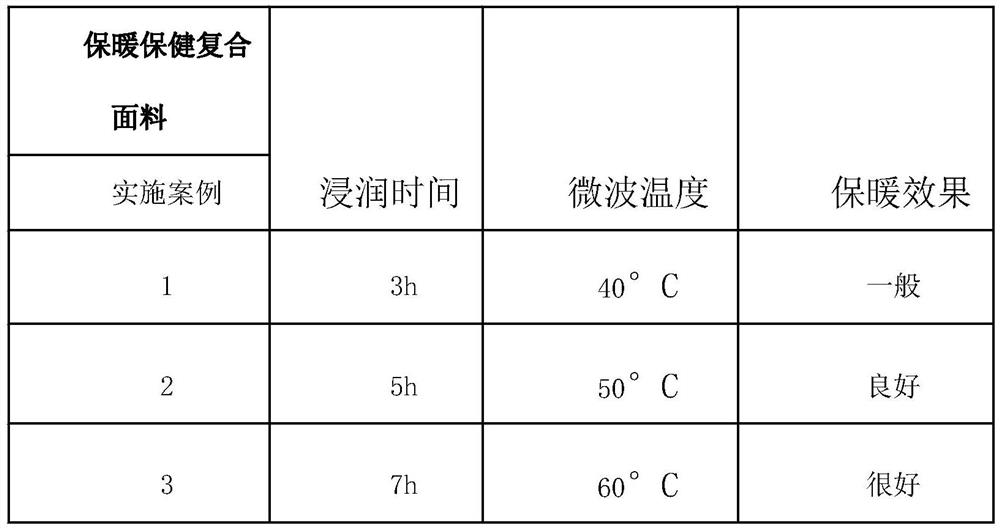

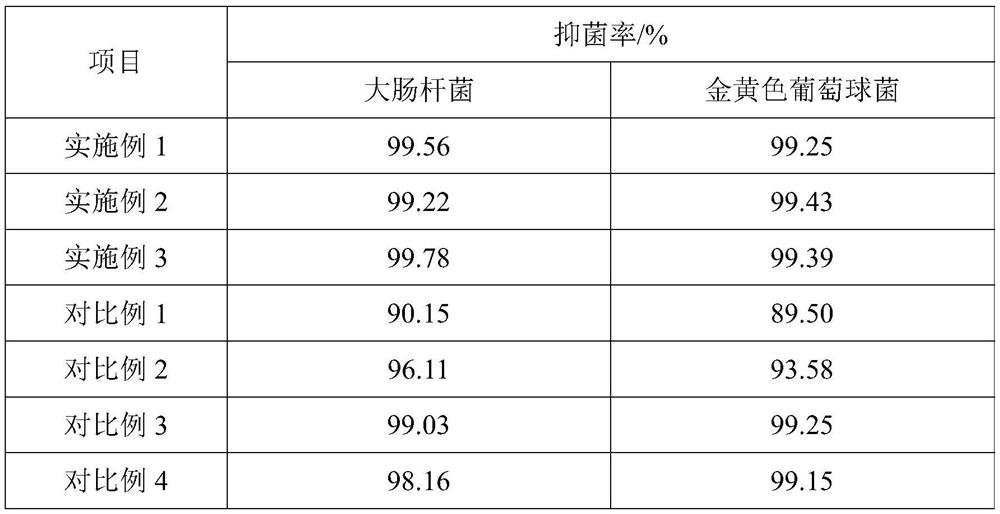

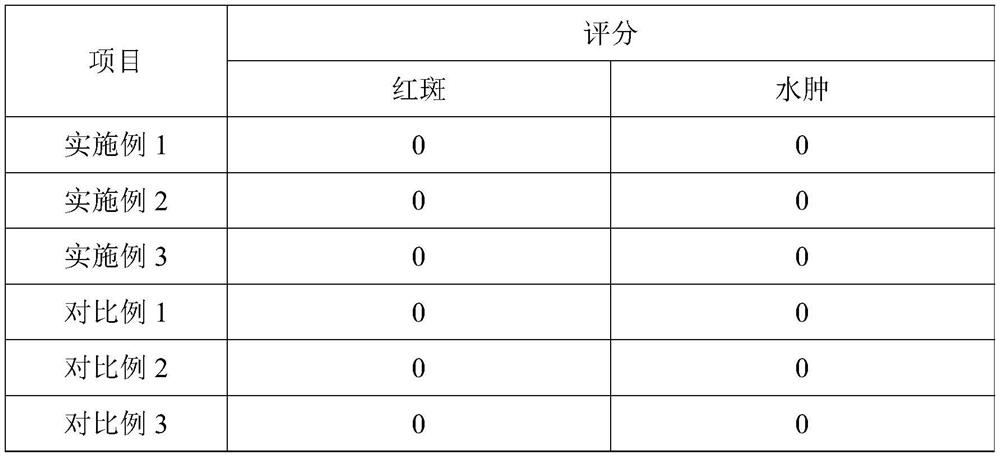

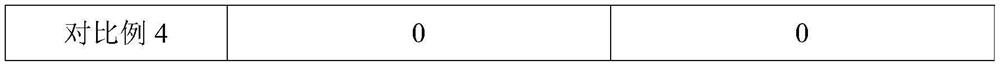

Warm-keeping and health-care composite fabric and processing technology thereof

PendingCN114148055AImprove insulation effectLamination ancillary operationsWeft knittingPolyesterChemical fibre cloth

The invention discloses a warm-keeping and health-care composite fabric, stone-like paint of the warm-keeping and health-care composite fabric is prepared from, by mass, 33%-35% of polyester, 30%-40% of composite fibers, 6%-8% of spandex, 6%-8% of composite fabric and 6%-8% of steeping liquor, and the processing technology comprises the following steps of weaving, dyeing, steeping liquor preparation and warm-keeping fabric and gel layer preparation. Microwave drying; according to the processing technology, raw materials specified by the national standard are adopted, the prepared warm-keeping and health-care composite fabric is greatly improved, a heat preservation fabric and a gel layer are added to the composite fabric, a heat preservation material is formed by sewing two layers of honeycomb plastic films with the thickness being 2 mm, two layers of non-woven fabric and chemical fabric, and the heat preservation performance of the composite fabric can be greatly improved.

Owner:FUJIAN JINJIANG HUAYU WEAVING

Outdoor washing-free bath wiping wet tissue and preparation method thereof

PendingCN113730284AReach the smellEliminate odorCosmetic preparationsToilet preparationsGlycerolIsononyl Isononanoate

The invention discloses outdoor washing-free bath wiping wet tissue. The wet tissue comprises a wet tissue carrier and soaking liquid, wherein the wet tissue carrier comprises a chemical fabric layer which is coated with antibacterial microcapsules and a non-woven fabric layer; and the soaking liquid is prepared from butanediol, glycerol, isononyl isononanoate, cetearyl glucoside, betaine, capryloyl glycine, shale oil sodium sulfonate, octyl polymethylsiloxane, isohexadecane, a skin conditioner, an aromatic, a sun-screening agent, a pH regulator and water. According to the outdoor washing-free bath wiping wet tissue and the preparation method thereof, an antibacterial material is attached into the chemical fabric layer in a microcapsule mode, then, a moisturizing component and a deodorizing component are attached to the non-woven fabric layer in a wetting mode, the antibacterial material is released through friction in a using process, a scrubbed place is subjected to sterilization and bacteriostasis, and part of the antibacterial material, the aromatic and the skin conditioner are attached to a skin through the action of the soaking liquid, so that the multiple effects of moisturizing the skin, protecting the skin, resisting bacteria, removing body peculiar smell and the like are achieved. The invention further discloses a preparation method of the wet tissue.

Owner:纳奇科化妆品有限公司

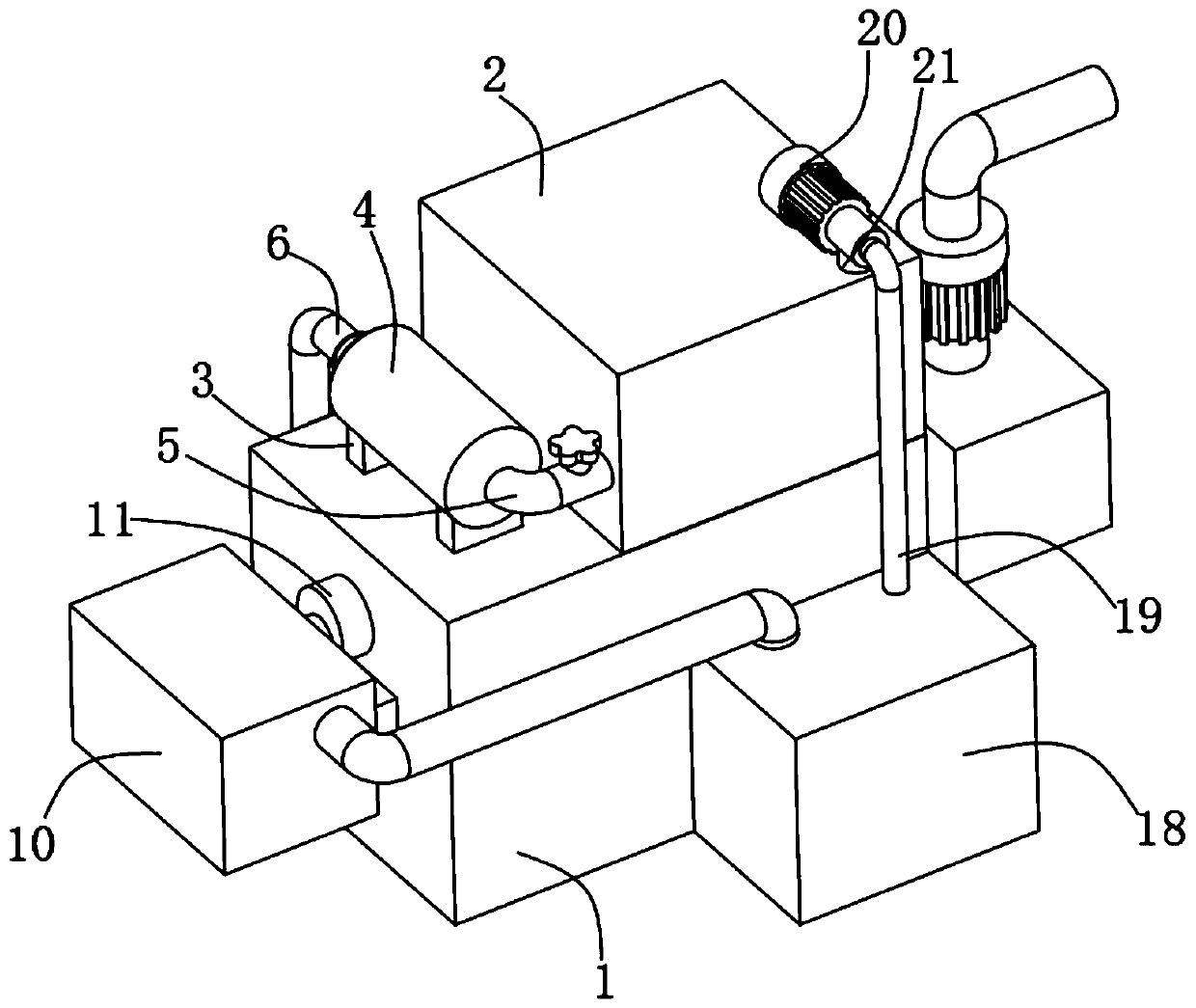

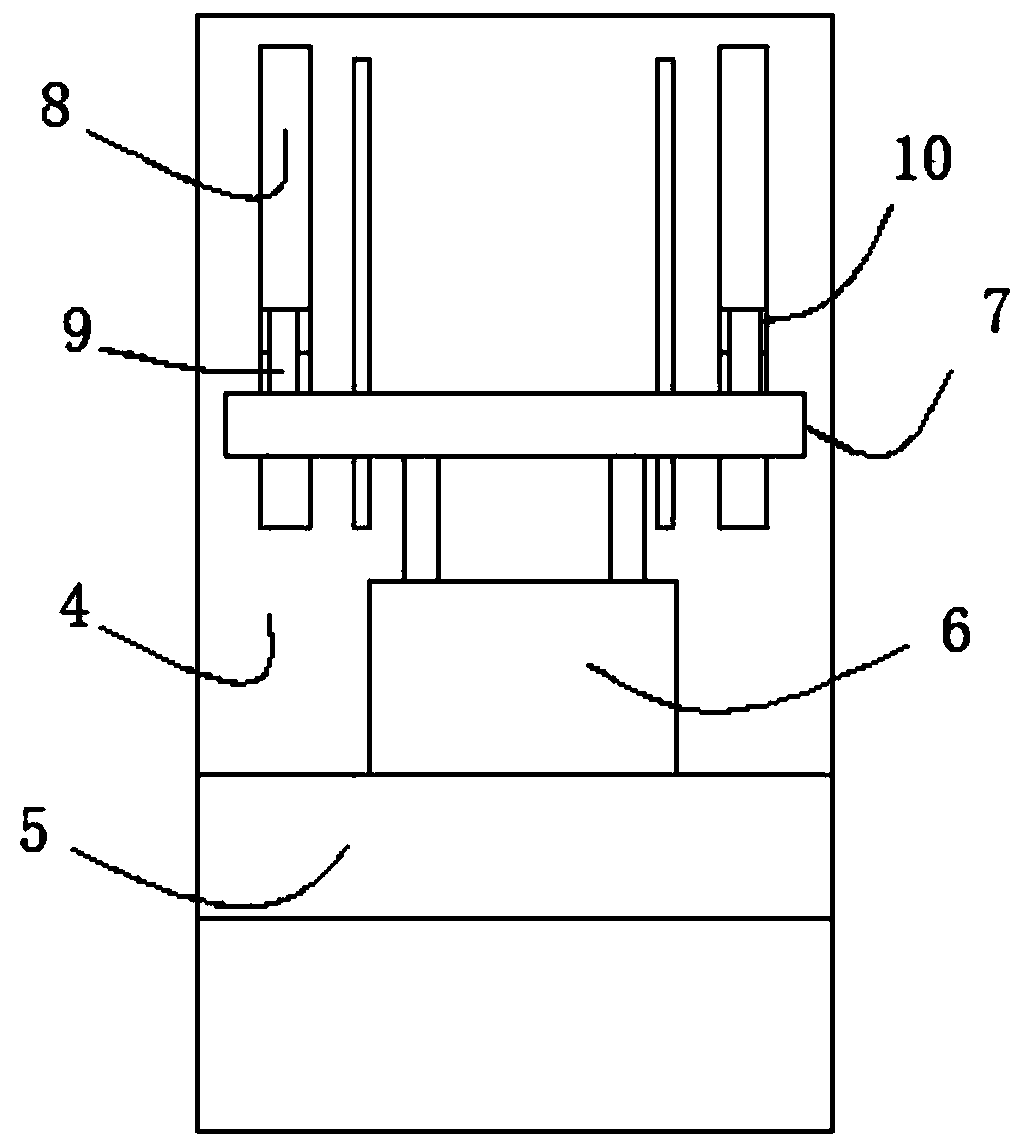

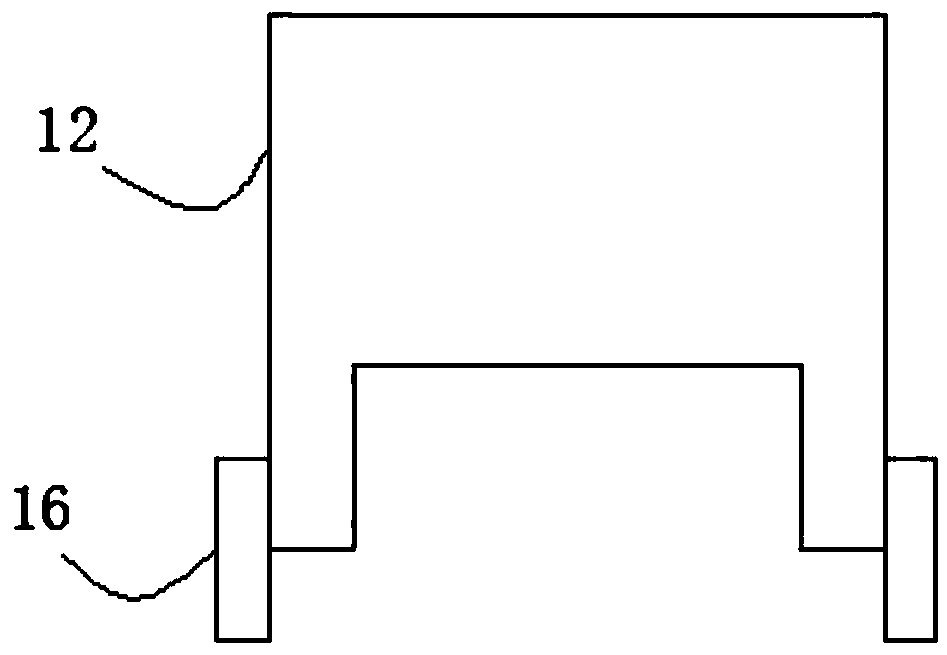

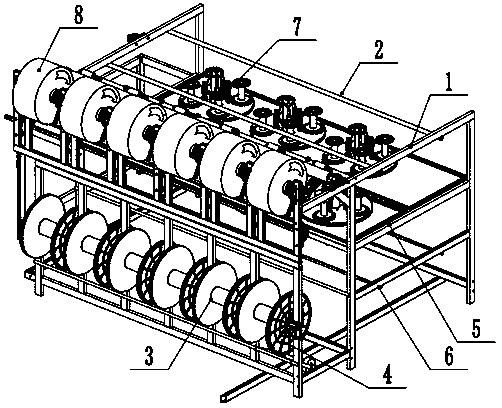

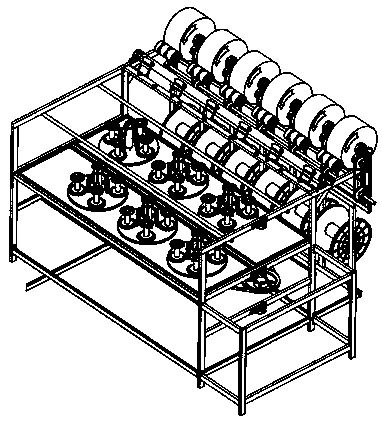

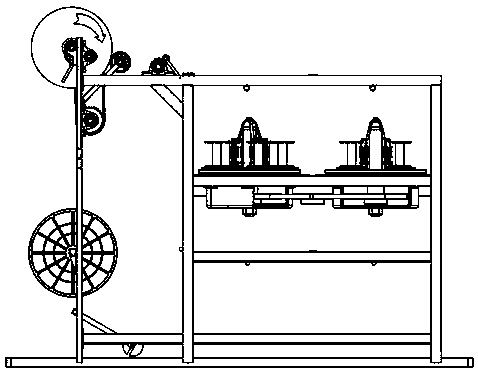

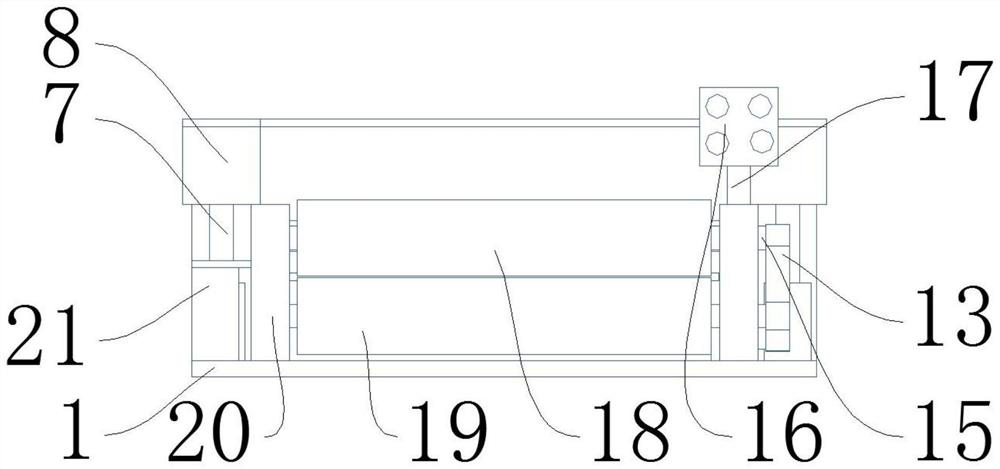

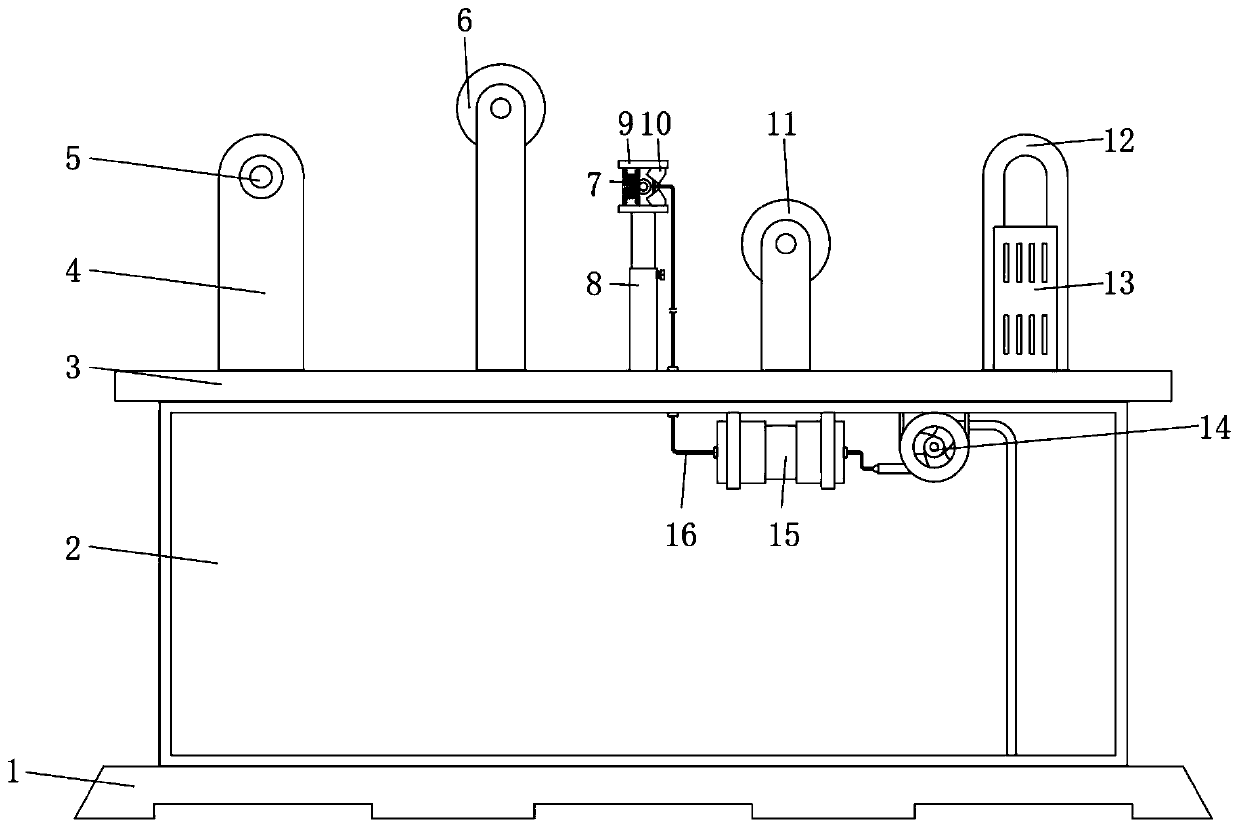

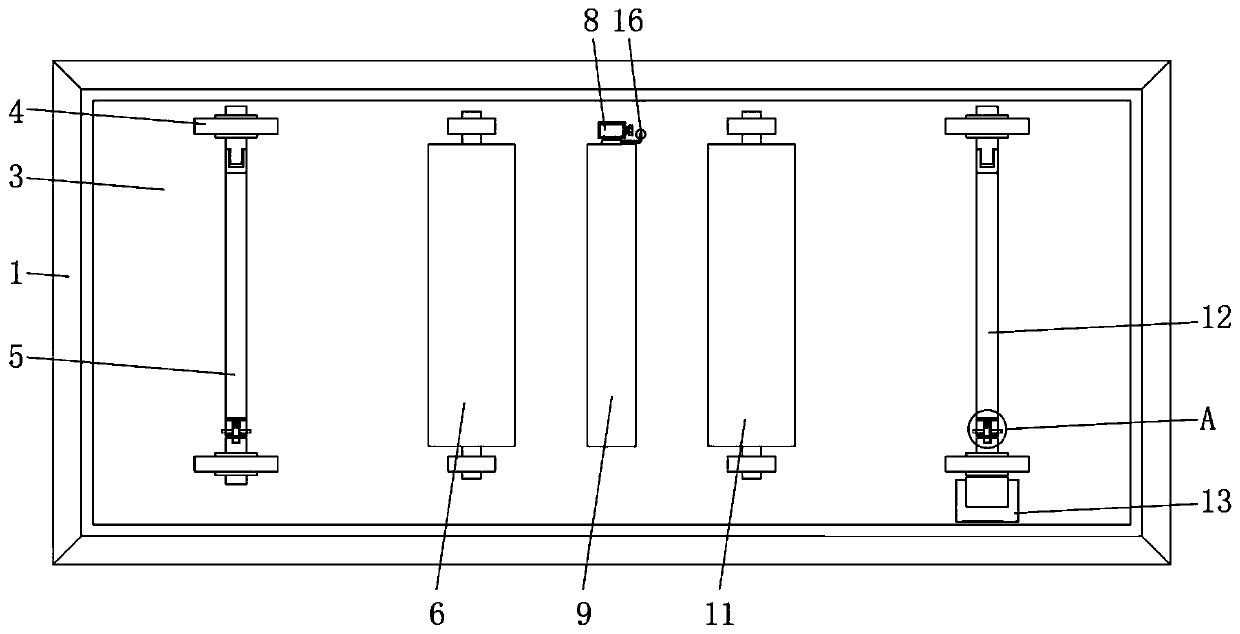

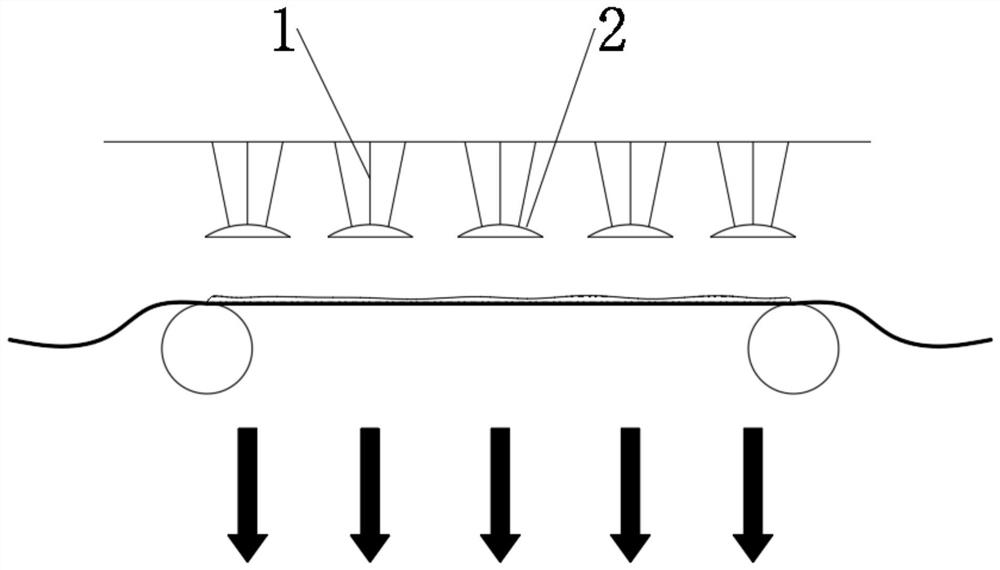

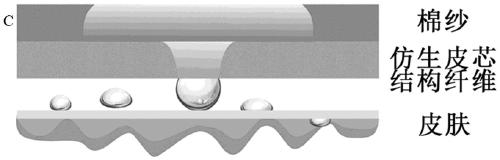

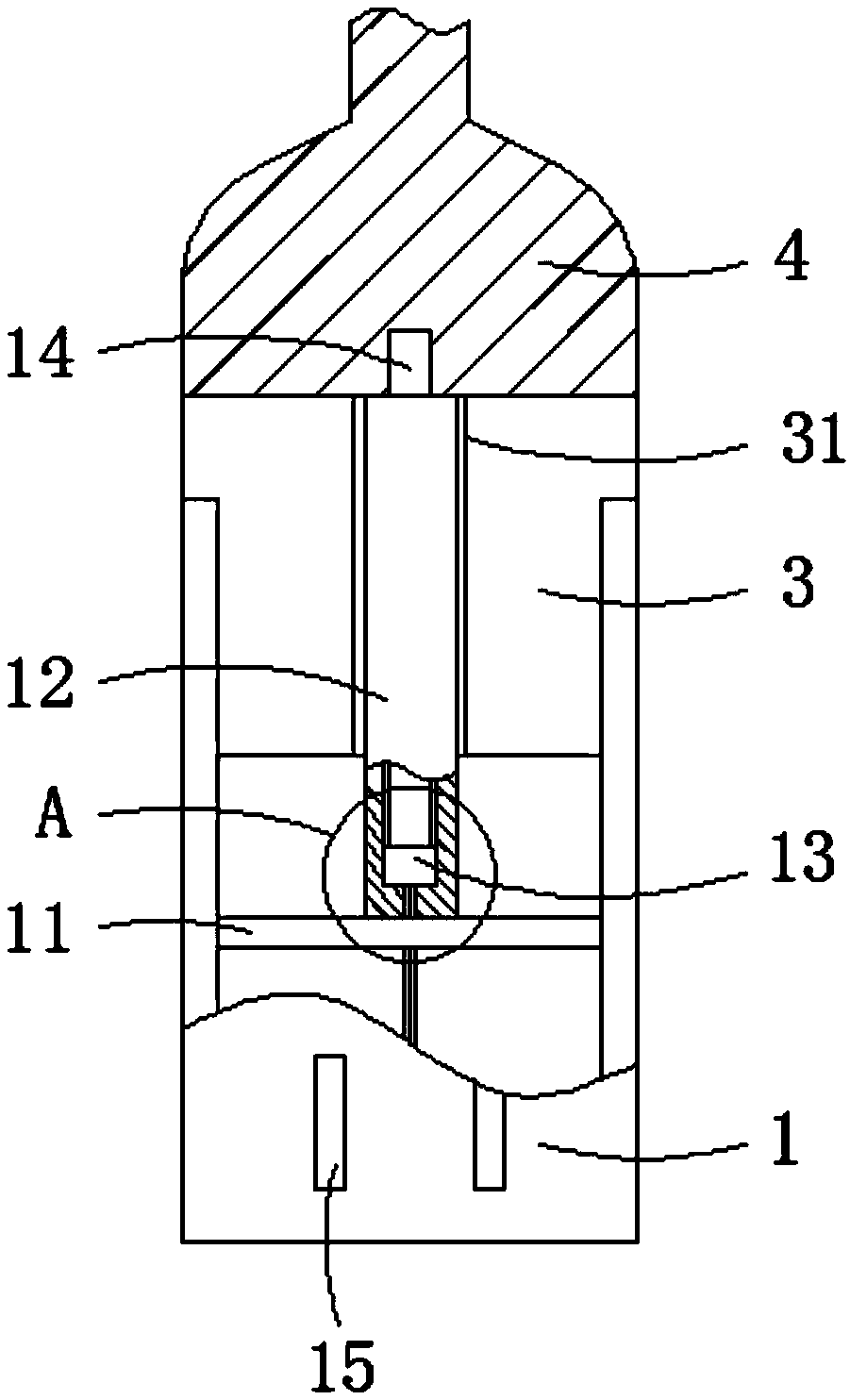

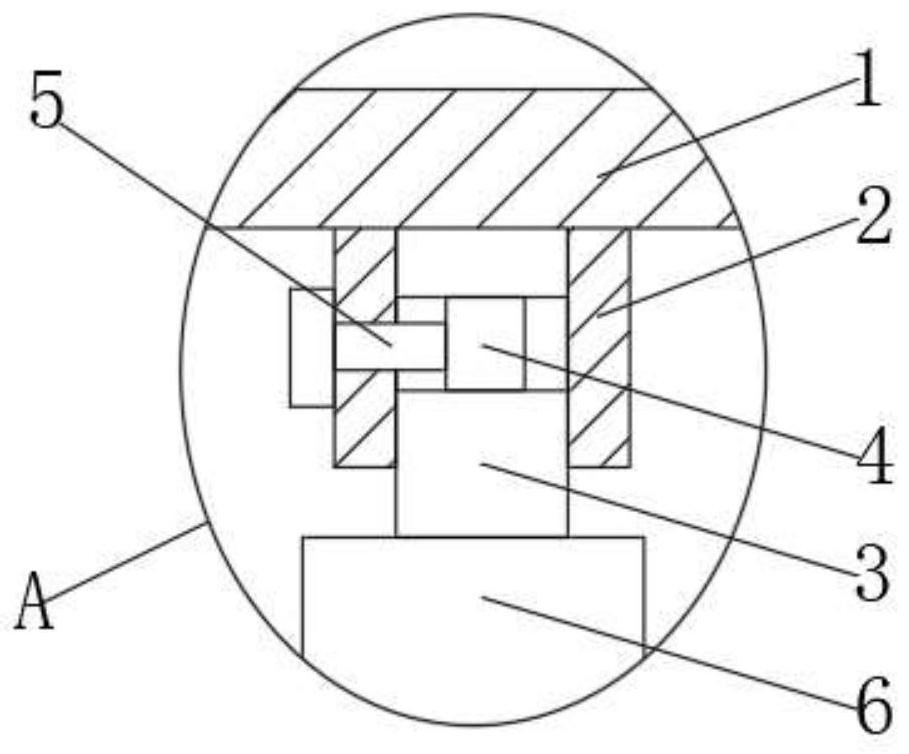

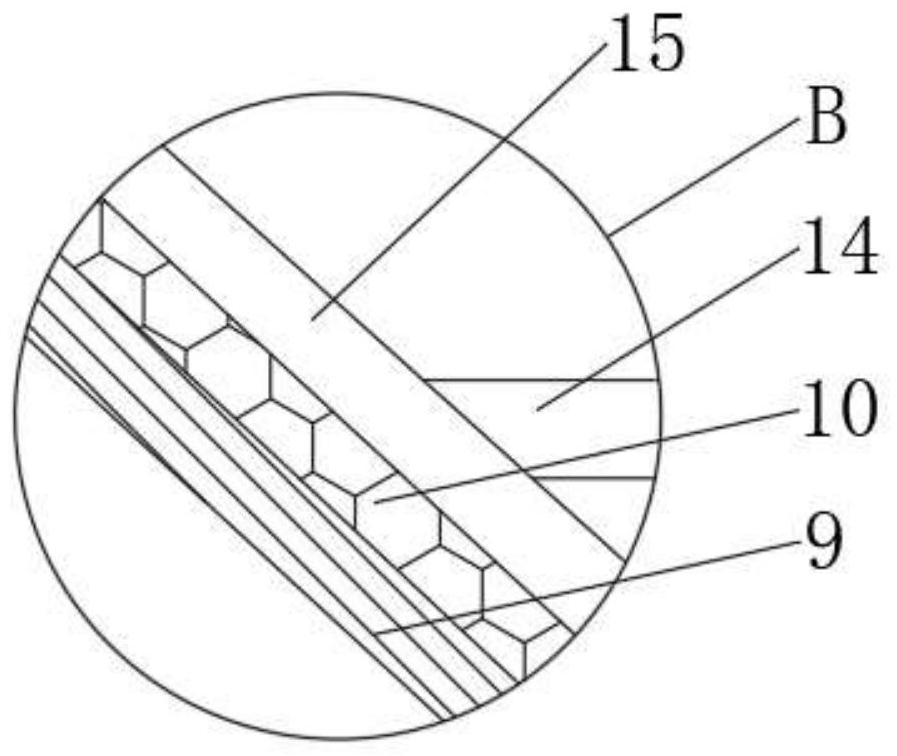

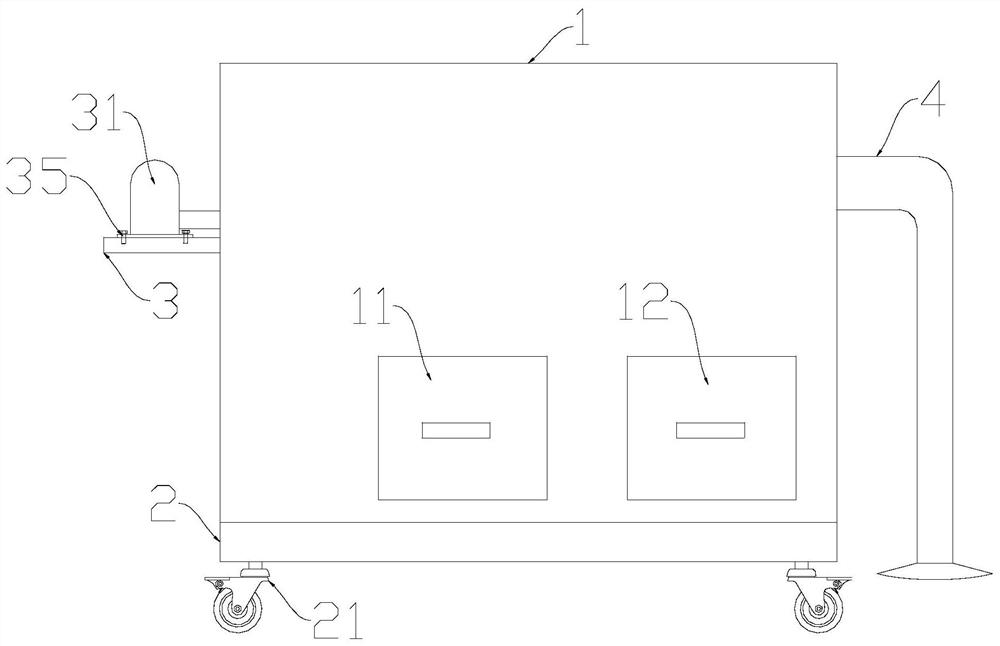

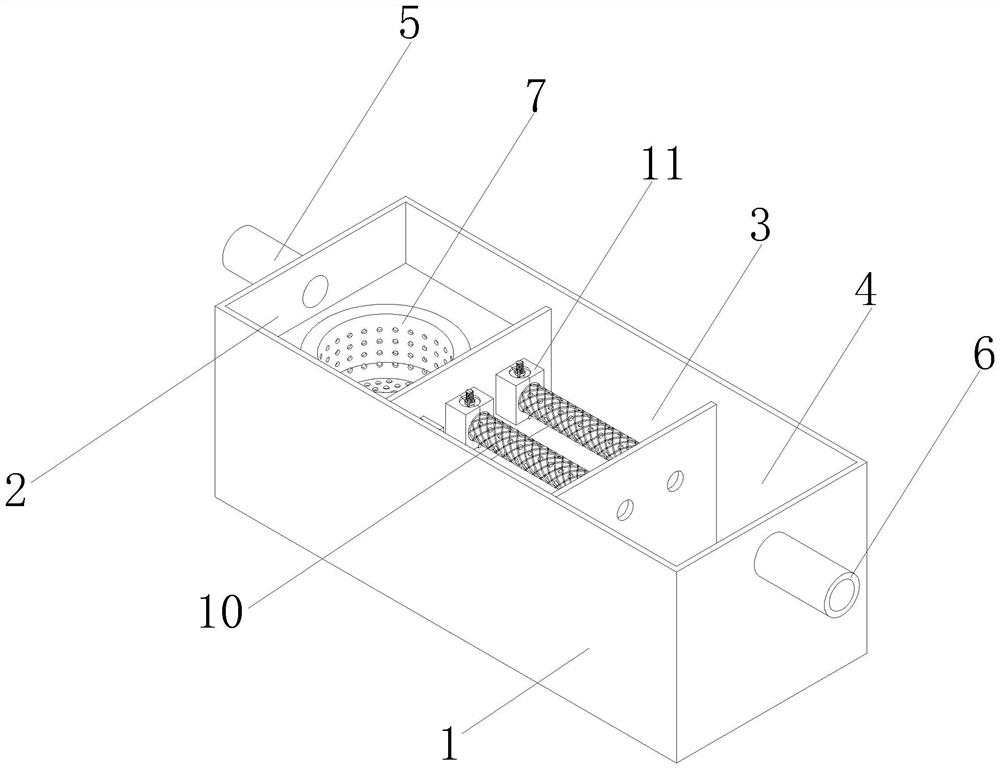

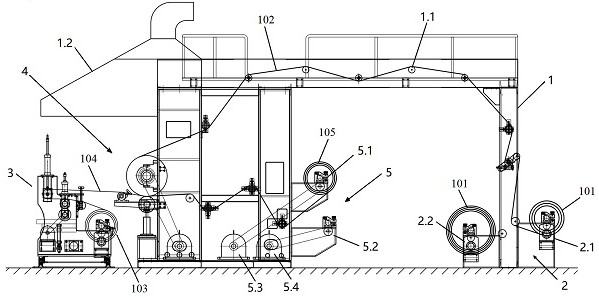

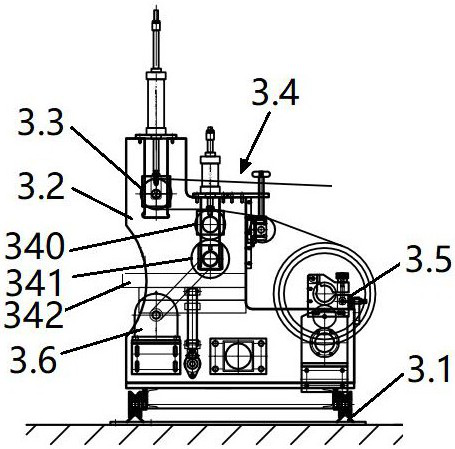

Low-cost thermal compounding process for aluminum foil chemical fabric

PendingCN113246582AAvoid cloggingAvoid uniformityLamination ancillary operationsLaminationChemical fibre clothAluminum foil

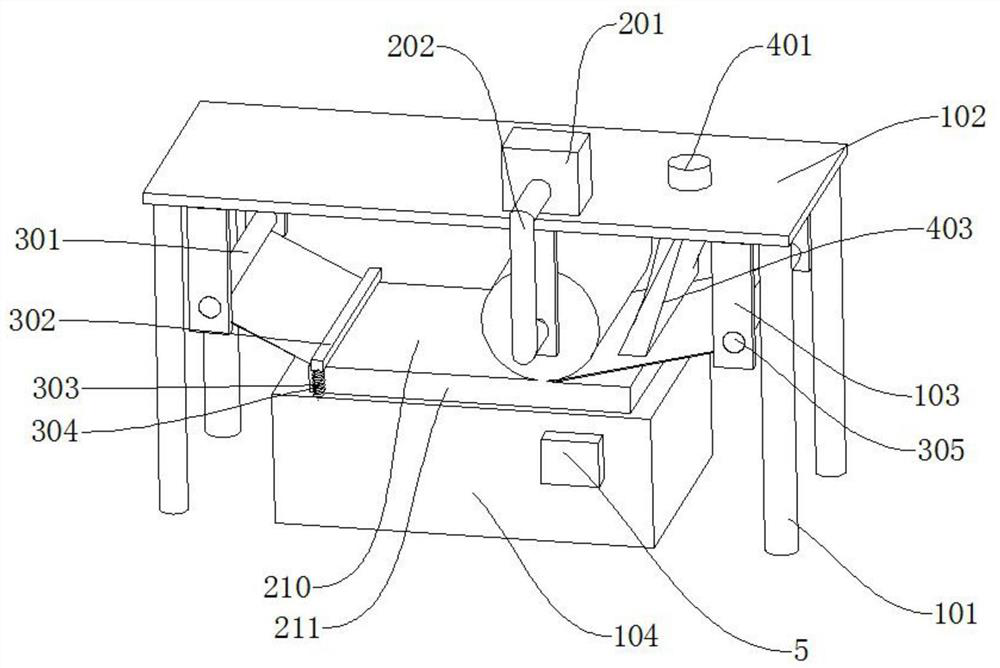

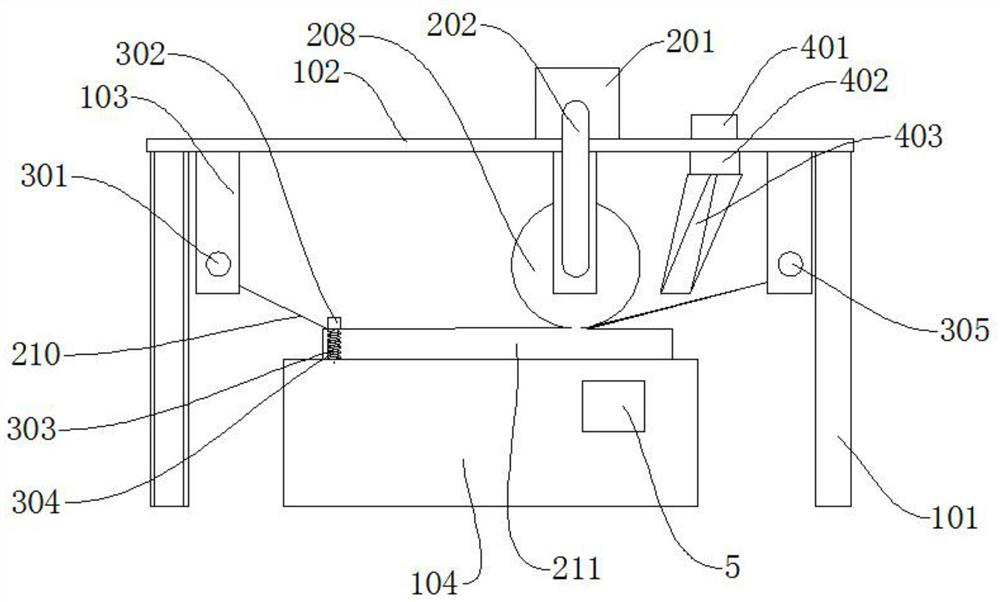

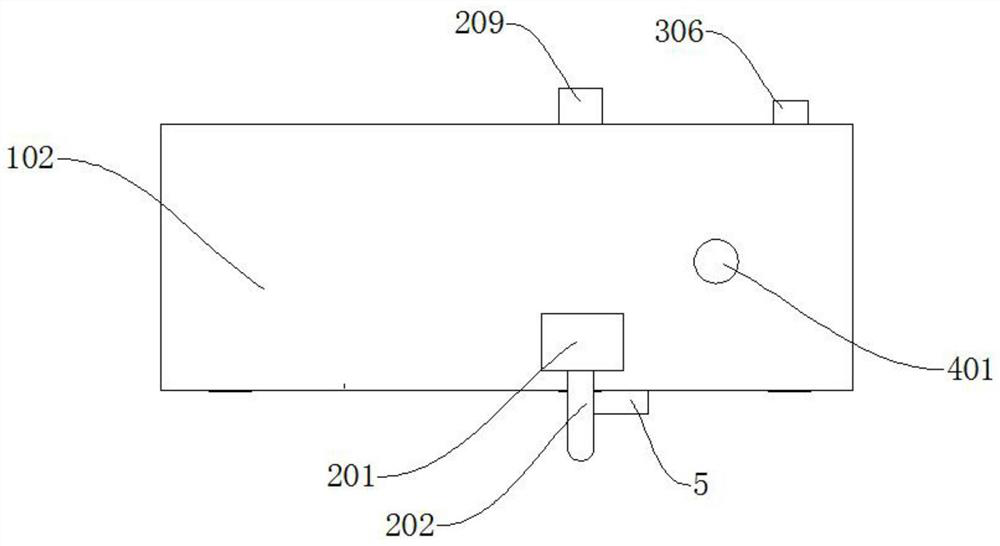

The invention relates to a low-cost thermal compounding process for an aluminum foil chemical fabric. The process is realized on the basis of a thermal compounding machine for an aluminum foil chemical fabric. The thermal compounding machine for the aluminum foil chemical fabric comprises a rack (1) provided with a plurality of guide rollers (1.1), a rail (3.1) arranged on the left side of the rack (1), a chemical fabric unwinding device (2) arranged at the right end of the rack (1), two sets of aluminum foil unwinding systems (3) arranged on the rail (3.1) in a sliding mode, a thermal compounding system (4) arranged at the left end of the rack (1) and a winding device (5) arranged at the middle part of the rack (1). The process comprises the steps of unwinding, gluing, heating, pressing and winding. The low-cost thermal compounding process for the aluminum foil chemical fabric is good in dewaxing and dewatering effect, good in finished product pressing quality, low in failure rate and high in production efficiency, and the used equipment is easy to maintain.

Owner:JIANGNAN LIGHT IND MACHINERY FACTORY JIANGYIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com