Textile waste collecting device for textile production of chemical fabric

A technology of textile waste and collection device, which is applied in the direction of combination device, chemical instrument and method, cleaning method using gas flow, etc. problem, to achieve the effect of convenient secondary recycling, easy removal, convenient cleaning and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

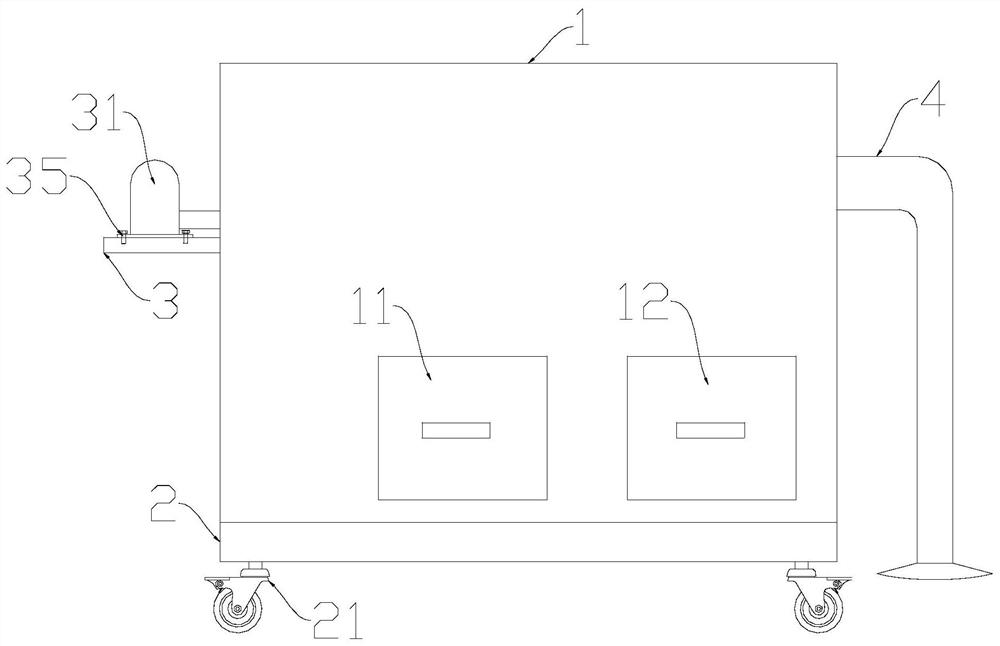

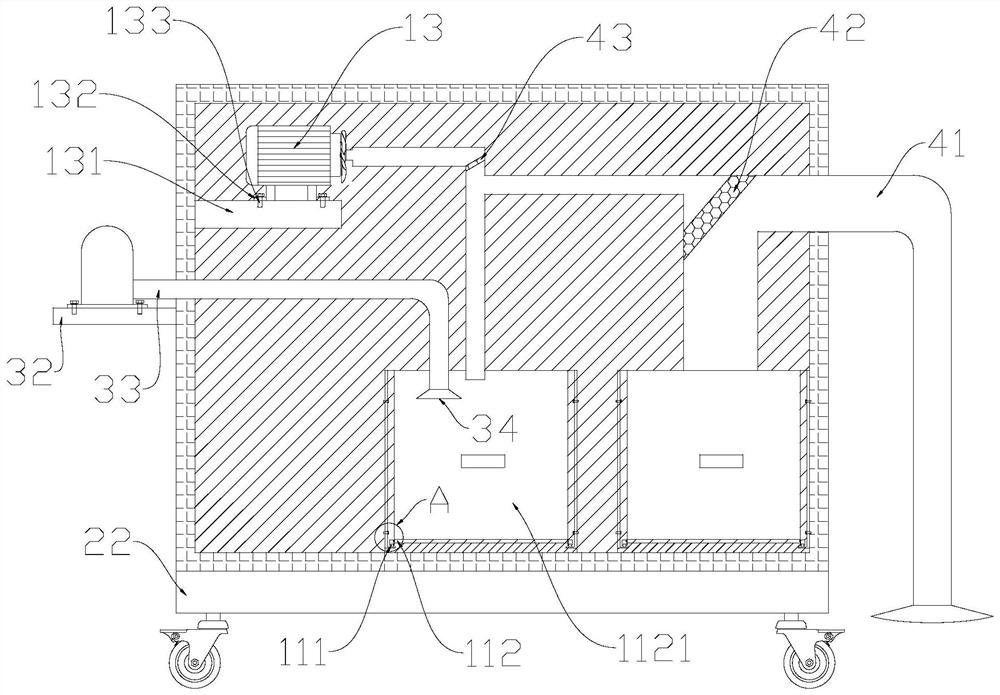

[0025] see Figure 1-3 , in the illustration: this embodiment is a preferred implementation of this technical solution, a textile waste collection device for textile production of chemical fiber cloth, including a housing 1, a moving device 2, a spraying device 3 and a dust collection device 4; The lower end of the housing 1 is provided with a mobile device 2, the mobile device 2 is welded and fixed to the lower surface of the housing 1, and the right outer end of the housing 1 is provided with a spraying device 3, and the spraying device 3 is connected to the housing 1. The right outer end is fixedly connected, the left outer end of the housing 1 is provided with a dust suction device 4, and the dust suction device 4 is fixedly connected to the left outer end of the housing 1;

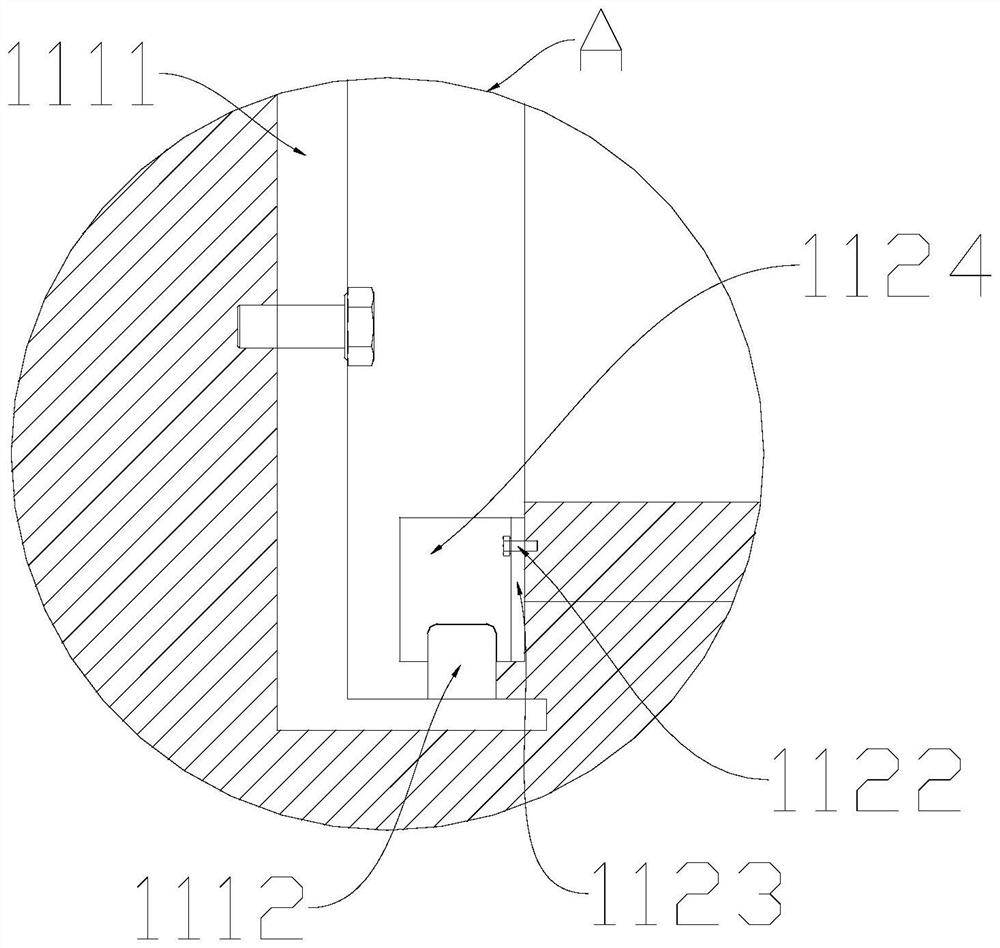

[0026] Such as figure 2 As shown, the housing 1 includes a dust collection device 11, a textile waste collection mechanism 12, and a dust collection motor assembly 13. A dust collection device 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com