Water-based high moisture permeability, anti-ultraviolet functional coating glue and preparation method

A technology of anti-ultraviolet and coating glue, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of undisclosed technologies, and achieve the effects of low production cost, simple preparation method, and good moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

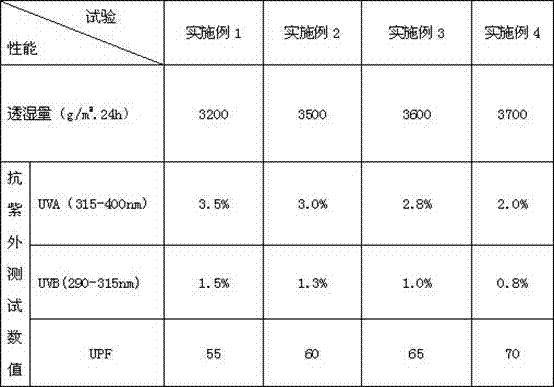

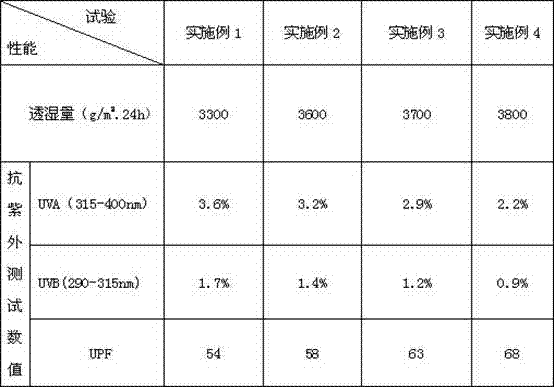

Examples

Embodiment 1

[0034] Polymerization: 90 parts of ethylene glycol polyether with an average molecular weight of 2000, 110 parts of ethylene glycol polyether with an average molecular weight of 1000, 60 parts of toluene diisocyanate, and 60 parts of acetone are added to the reactor and heated to 77-83 °C. React at low temperature for 2 hours, add 8 parts of 1,4-butanediol, react at 77-83°C for 3 hours, add 2.5 parts of nano-titanium dioxide, react at 77-83°C for 1 hour, cool down to 57-63°C Put the material in the emulsification kettle, add 620 parts of deionized water to disperse into polyurethane emulsion;

[0035] Emulsion thickening: Add 2 parts of associative polyurethane leveling rheology agent, stir for 1 hour, filter and discharge to obtain the product.

Embodiment 2

[0037] Polymerization: 95 parts of ethylene glycol polyether with an average molecular weight of 2000, 105 parts of ethylene glycol polyether with an average molecular weight of 1000, 57 parts of toluene diisocyanate, and 62 parts of acetone are added to the reactor and heated to 77-83 °C. React at low temperature for 2.5 hours, add 9 parts of 1,4-butanediol, react at 77-83°C for 3.5 hours, add 3 parts of nano-titanium dioxide, react at 77-83°C for 1.5 hours, cool down to 57-63°C Put the material in the emulsification kettle, add 585 parts of deionized water to disperse into polyurethane emulsion;

[0038] Emulsion thickening: Add 1.6 parts of associative polyurethane leveling rheological agent, stir for 1.5 hours, filter and discharge to obtain the product.

Embodiment 3

[0040] Polymerization reaction: 100 parts of ethylene glycol polyether with an average molecular weight of 2000, 100 parts of ethylene glycol polyether with an average molecular weight of 1000, 59 parts of toluene diisocyanate, and 64 parts of acetone are added to the reactor and heated to 77-83 °C. React at low temperature for 2 hours, add 9.5 parts of 1,4-butanediol, react at 77-83°C for 3 hours, add 3.5 parts of nano-titanium dioxide, react at 77-83°C for 1 hour, cool down to 57-63°C Put the material in the emulsification kettle, add 605 parts of deionized water to disperse into polyurethane emulsion;

[0041] Emulsion thickening: Add 1.8 parts of associative polyurethane leveling rheological agent, stir for 1 hour, filter and discharge to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com