Textile waste collector for textile production of chemical fabric

A textile waste and collector technology, applied in sorting and other directions, can solve the problems of not being able to collect waste separately, affecting the centralized treatment and use of waste, etc., to achieve the effect of convenient processing and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

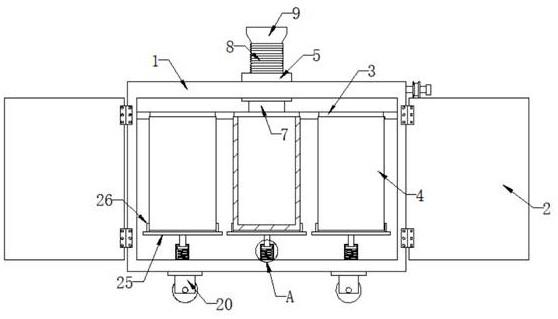

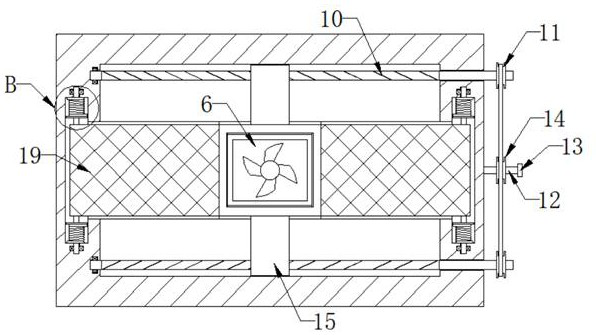

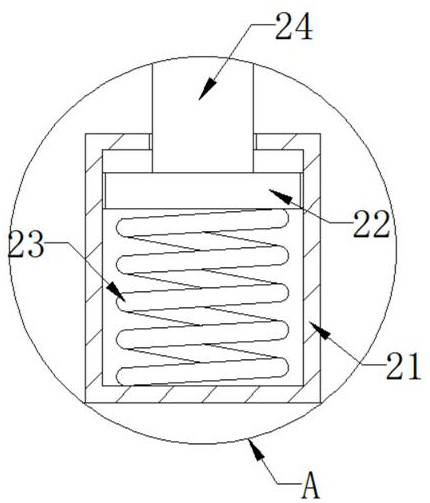

[0020] see Figure 1-4 , the present invention provides a technical solution: a textile waste collector for textile production of chemical fiber cloth, comprising a collection box 1, the front side wall of the collection box 1 is provided with a box door 2 through hinge rotation, and the upper end of the collection box 1 is fixed horizontally A fixed plate 3 is provided, and the side wall of the fixed plate 3 is provided with evenly arranged installation openings, and the inside of the installation opening is fixedly provided with a waste material receiving tube 4, and the upper side wall of the collection box 1 is provided with a strip mouth, and the strip mouth The inside of the mobile shell 5 is slidingly provided with a moving shell 5, the inside of the moving shell 5 is fixedly provided with an exhaust fan 6, the lower side wall of the moving shell 5 is fixedly provided with a feed pipe 7, and the upper side wall of the mobile shell 5 is fixedly provided with a bellows 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com