Low-cost thermal compounding process for aluminum foil chemical fabric

A composite process and low-cost technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of easy blockage of internal pipelines, difficult maintenance, high energy consumption, etc., to avoid excessive downtime, Improved production efficiency and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

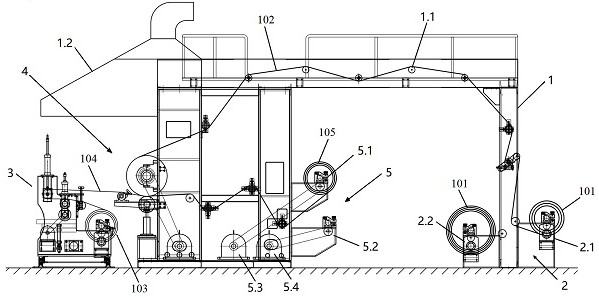

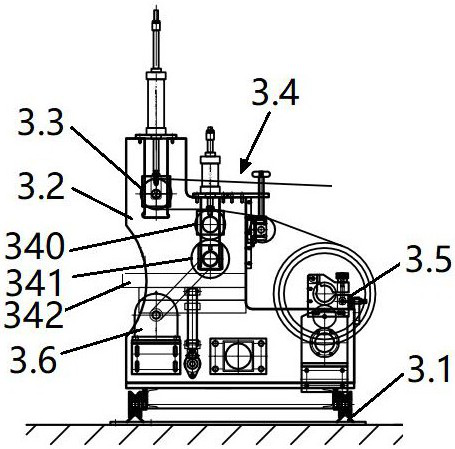

[0034] see Figure 1~5 , the present invention relates to a low-cost aluminum foil chemical fiber thermal cloth composite process, the low-cost aluminum foil chemical fiber thermal cloth composite process is realized based on an aluminum foil chemical fiber thermal cloth composite machine, and the aluminum foil chemical fiber thermal cloth composite machine includes A frame 1 with a plurality of guide rollers 1.1, a track 3.1 set on the left side of the frame 1, a chemical fiber unwinding device 2 set at the right end of the frame 1, two sets of aluminum foil unwinding systems 3 slidingly set on the track 3.1, The thermal lamination system 4 arranged at the left end of the frame 1 and the winding device 5 arranged at the middle of the frame 1;

[0035] The aluminum foil unwinding system 3 includes a base 3.2 slidingly arranged on a track 3.1, an aluminum foil heating roller 3.3, a gluing device 3.4, and an aluminum foil unwinding device 3.5 are sequentially arranged on the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com