Warm-keeping and health-care composite fabric and processing technology thereof

A composite fabric and processing technology technology, which is applied in the field of composite fabric processing, can solve the problems of poor thermal insulation performance, insufficient thermal insulation for users, poor thermal insulation, etc., and achieves the effect of improving thermal insulation, thermal insulation and health care composite fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

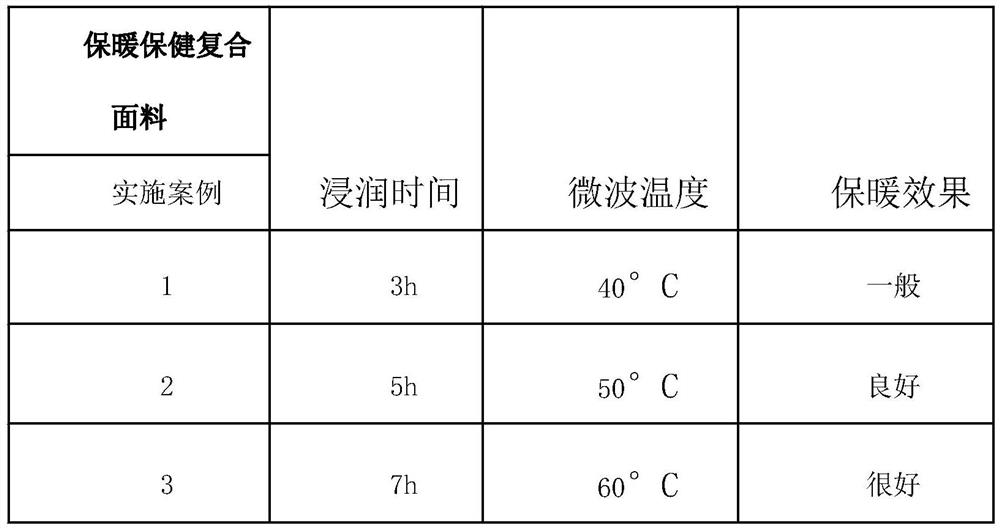

Embodiment 1

[0020] The invention provides a technical solution: a warm-keeping and health-care composite fabric, which is composed of the following raw materials by mass percentage: polyester 33%-35%, composite fiber 30%-40%, spandex 6%-8%, composite fabric 6% -8%, impregnating solution 6%-8%. .

[0021] A processing technology of the above-mentioned warm-keeping and health-care composite fabric, the processing technology comprises the following steps:

[0022] S1: Weaving, the blending of composite fiber and spandex and the blending of polyester filament and spandex alternately arrange the weft yarns, and then adopt the single-sided weaving method, all of which are woven into a flat weave structure, and the spandex is added at the pressing point by using a small pulley , to ensure that the spandex is not exposed under the composite fabric and polyester on the cloth surface;

[0023] S2: dyeing, put the raw materials in S2 on a special dyeing machine for corresponding dyeing, and then c...

Embodiment 2

[0028] The invention provides a technical solution: a warm-keeping and health-care composite fabric, which is composed of the following raw materials by mass percentage: polyester 33%-35%, composite fiber 30%-40%, spandex 6%-8%, composite fabric 6% -8%, impregnating solution 6%-8%. .

[0029] A processing technology of the above-mentioned warm-keeping and health-care composite fabric, the processing technology comprises the following steps:

[0030] S1: Weaving, the blending of composite fiber and spandex and the blending of polyester filament and spandex alternately arrange the weft yarns, and then adopt the single-sided weaving method, all of which are woven into a flat weave structure, and the spandex is added at the pressing point by using a small pulley , to ensure that the spandex is not exposed under the composite fabric and polyester on the cloth surface;

[0031] S2: dyeing, put the raw materials in S2 on a special dyeing machine for corresponding dyeing, and then c...

Embodiment 3

[0036] The invention provides a technical solution: a warm-keeping and health-care composite fabric, which is composed of the following raw materials by mass percentage: polyester 33%-35%, composite fiber 30%-40%, spandex 6%-8%, composite fabric 6% -8%, impregnating solution 6%-8%. .

[0037] A processing technology of the above-mentioned warm-keeping and health-care composite fabric, the processing technology comprises the following steps:

[0038] S1: Weaving, the blending of composite fiber and spandex and the blending of polyester filament and spandex alternately arrange the weft yarns, and then adopt the single-sided weaving method, all of which are woven into a flat weave structure, and the spandex is added at the pressing point by using a small pulley , to ensure that the spandex is not exposed under the composite fabric and polyester on the cloth surface;

[0039] S2: dyeing, put the raw materials in S2 on a special dyeing machine for corresponding dyeing, and then c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com