Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Carbide saw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbide saws are machine tools for cutting. The saw teeth are made of cemented carbide, so that hard materials can be cut.

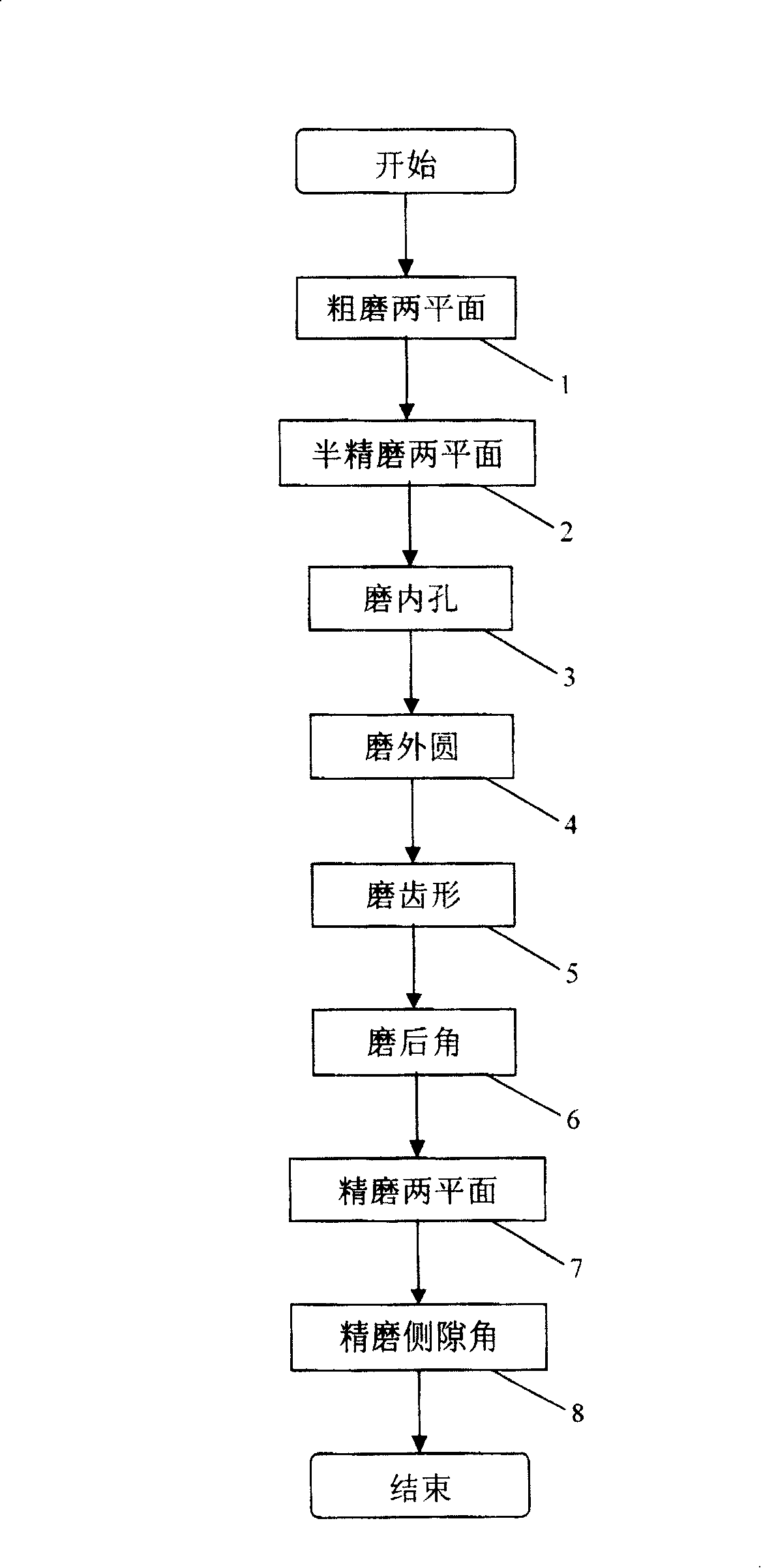

Carbide alloy metal saw production process

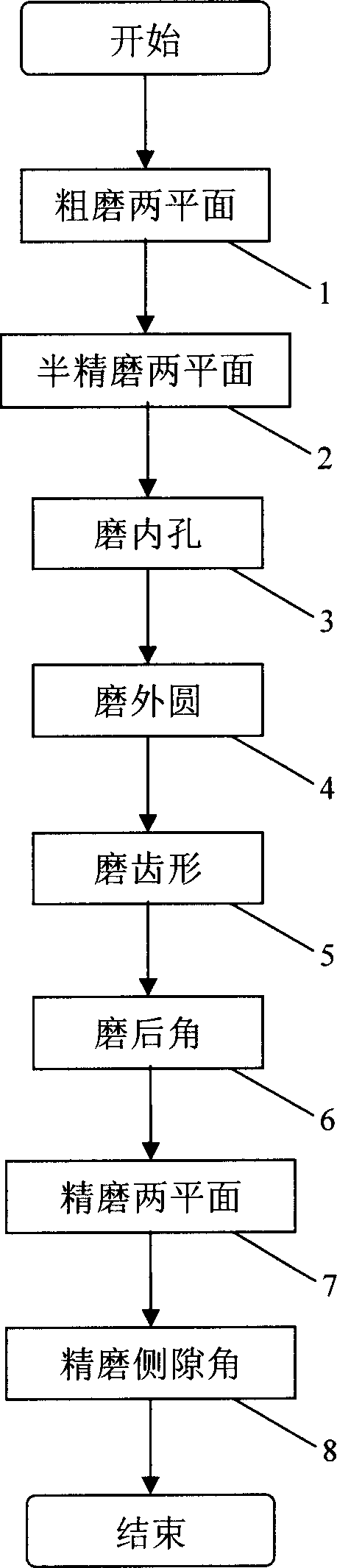

The invention discloses a process for preparing hard alloy saw blade milling cutter, comprising following steps: coarse grinding two surface, semi-correct grinding two surface, grinding internal hole, grinding external circle, grinding gear form, grinding bottom rake and correct grinding two surface and correct grinding side clearance angle. The invention employs several times grinding to prepare ultra-fine particular hard alloy saw blade milling cutter, the thickness of blade milling cutter is very thin, side clearance angle 0degree8'-0degree12'is milled on work piece for further convenience of milling cutter.

Owner:周荣根

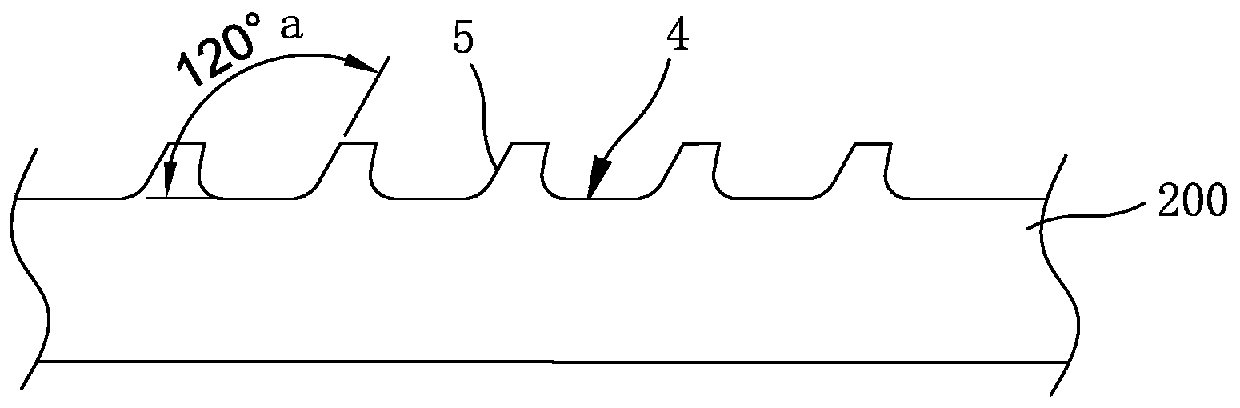

Hard alloy saw web

InactiveCN107282996AHigh strengthHigh hardnessMetal sawing toolsStone-like material working toolsAlloy substrateCarbide saw

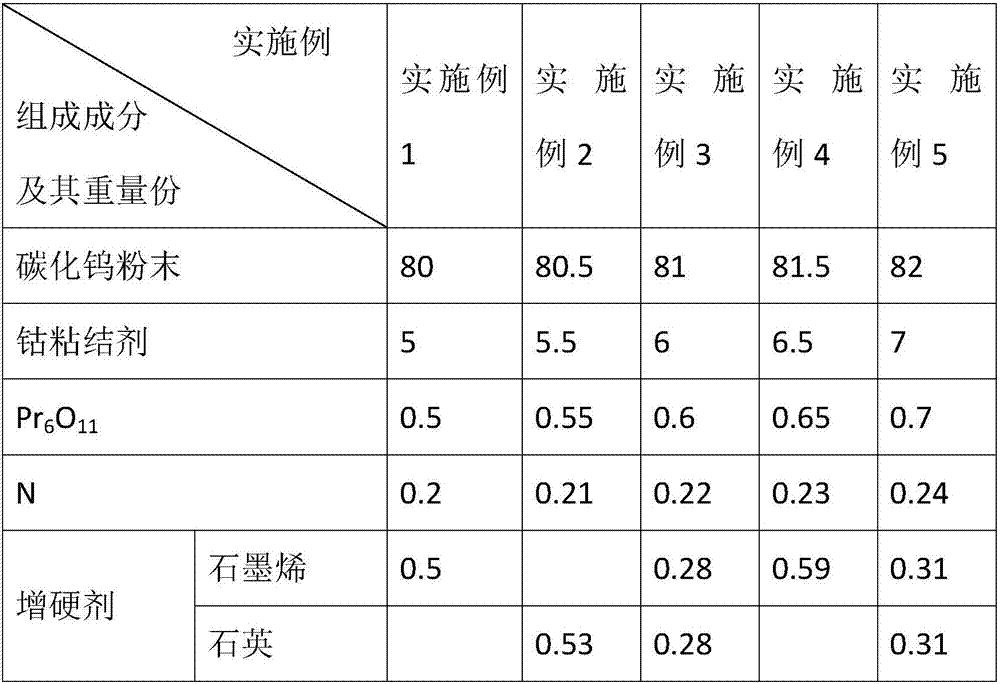

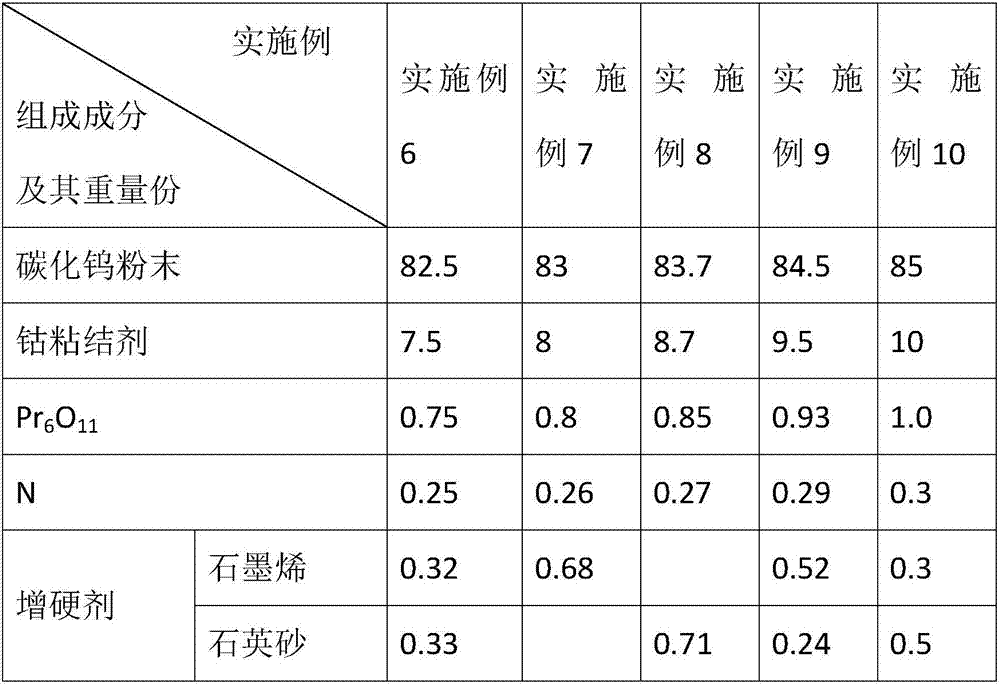

The invention relates to a saw web, in particular to a hard alloy saw web, and belongs to the field of hard alloy materials. The hard alloy saw web is made from a hard alloy material which comprises a hard alloy substrate and a coating arranged on the surface of the hard alloy substrate in a coated mode. The hard alloy substrate comprises the following components of, by weight, 80-85 parts of tungsten carbide powder, 5-10 parts of a cobalt binder, 0.5-1.0 part of Pr6O11, 0.2-0.3 part of nitrogen and 0.5-0.8 part of a hardening agent. The hard alloy with reasonable compatibility is adopted, the Pr6O11, the nitrogen and the hardening agent are added into the hard alloy material, meanwhile, the contents of the components in the hard alloy material are limited, and thus, through the synergistic effect, blending, pressing forming, sintering and coating of all elements and the methods such as hot isostatic pressure and physical vapor deposition, the prepared hard alloy saw web has the advantages of high rigidity, strength and hardness.

Owner:宁波妙力斯五金工具有限公司

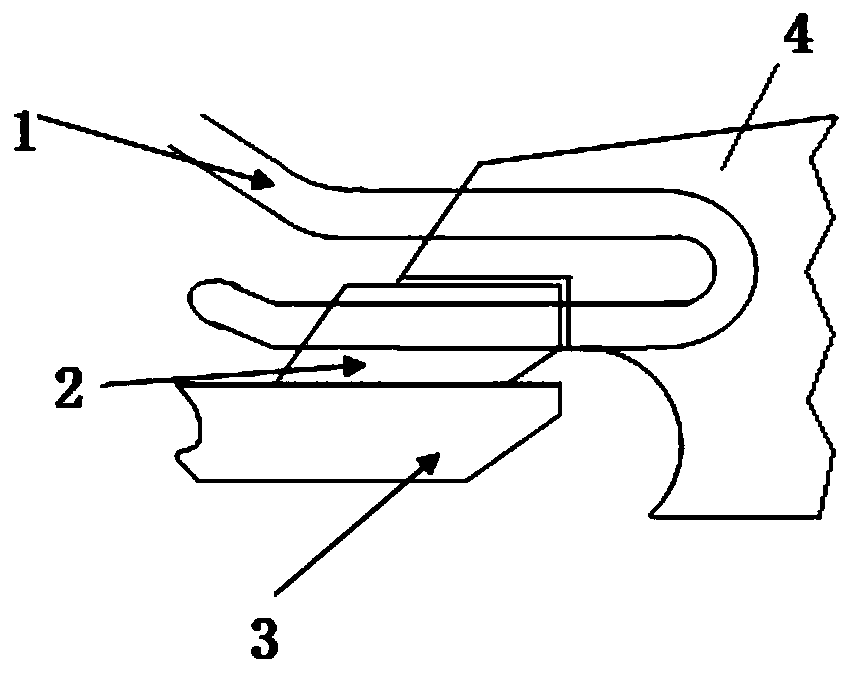

Hard alloy saw chain

ActiveCN103331487AEliminates solder brittlenessAvoid brittle fractureMetal sawing toolsButt weldingCarbide saw

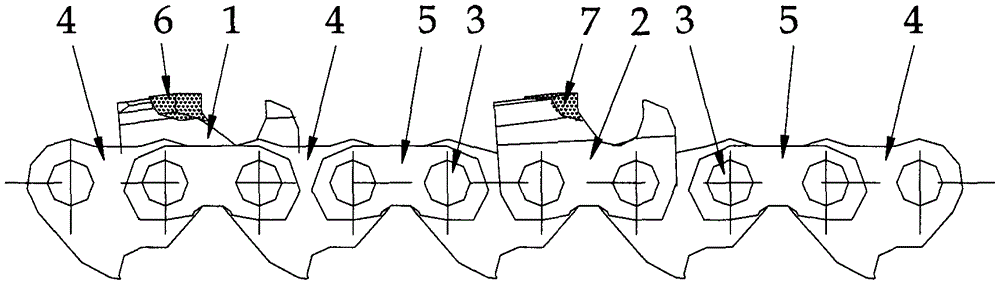

The invention relates to a hard alloy saw chain of a chain saw. The welding face of a hard alloy tooth block and cutting teeth is made to be a cylindrical face, the arc radius of the cylindrical face is 2 to 5mm, and the optimal arc radius is 2.5 to 4mm. The shape of the tooth block is made to be similar to a frustum of a square pyramid, and the height of inner side face of the teeth block is lower than the height of outer side face of the tooth block. The tooth side face of the tooth block concaves inwards and perpendicularly, and a concave angle is 1 degree to 3 degrees. The intersection of the tooth top face of the tooth block and the tooth side face of the tooth block is made to be a circular bead, the tooth tip of the tooth block is made to be a section of arc line, the arc radius of the tooth tip is 0.2 to 0.8mm, and the optimal arc radius of the tooth tip is 0.3 to 0.4mm. According to the hard alloy saw chain, due to the adoption of butt welding, the hard alloy tooth block is welded with the cutting teeth, after the tooth block is welded, local high-temperature tempering is conducted, the joining strength of a welding line is 4 times higher than the jointing strength of brazing, the hard alloy saw chain is very firm, and no teeth drop during saw cutting.

Owner:缙云县鼎盛工具制造厂(普通合伙)

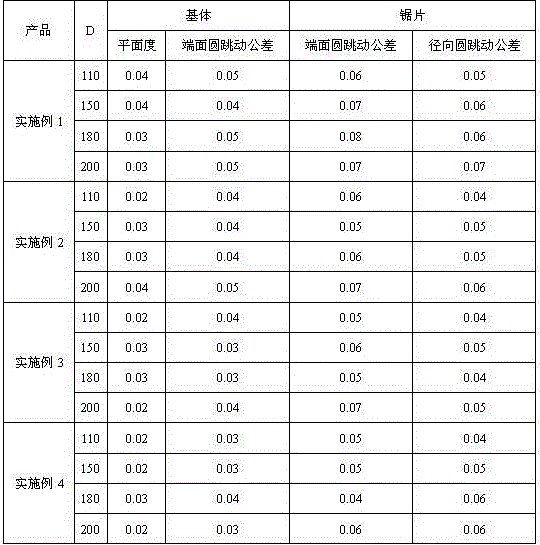

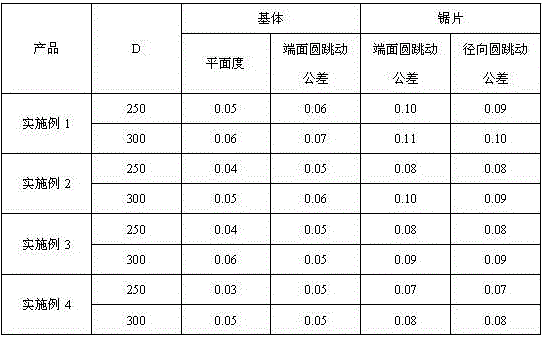

Machining method for hard alloy saw web

InactiveCN105750653AGuaranteed sharpnessReduce collisionMetal sawing tool makingMachining processCarbide saw

The invention relates to a machining method for a hard alloy saw web.The machining method includes the following steps of leveling of a base body of the hard alloy saw web, gear rolling, tool bit welding, sand blasting, gear grinding, polishing, antirust treatment and finished product storage.Gear spacing welding is adopted for the tool bit welding step.An abrasive belt in the polishing step is 180 mesh or 240 mesh, and the relative speed of the base body of the hard alloy saw web and the abrasive belt is 4,000-4,500 r / min.Heating deformation of the base body in the machining process can be effectively controlled, the surface smooth degree is high, and the anti-corrosion effect is good.

Owner:HEBEI JIMEIDA TOOLS CO LTD

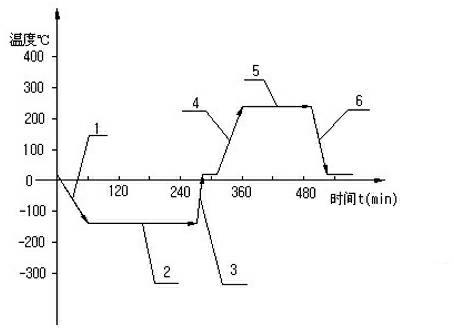

Subzero treatment technology for hard alloy saw blade tool bit

InactiveCN102154540AHigh strengthImprove wear resistanceFurnace typesHeat treatment furnacesTool bitTempering

The invention relates to a production technology for a hard alloy saw blade tool bit, and in particular relates to a subzero treatment technology for a hard alloy saw blade tool bit. The subzero treatment technology comprises the following steps: directly cooling the hard alloy tool bit to be under the subzero state below -120DEG C from the room temperature within 50-70 minutes at the cooling speed of 2-4DEG C / minute; under the subzero state, keeping the temperature for120-600 minutes; taking out the hard alloy tool bit, and cooling the hard alloy tool bit to the room temperature in the air; directly heating to 200-300DEG C for tempering from the room temperature within 50-70 minutes at the warming speed of 2-4DEG C / minute; at the tempering temperature of 200-300DEG C, keeping the temperature for 120-300 minutes; and taking out the hard alloy tool bit and cooling the hard alloy tool bit in the air to the room temperature. According to the subzero treatment technology, the residual austenite amount in the hard alloy is effectively reduced, the possibility of generating residual stress can be lowered, and the intensity, the impact toughness and the abrasive resistance of the hard alloy tool bit can be improved.

Owner:HEBEI SINGSHUO SAW

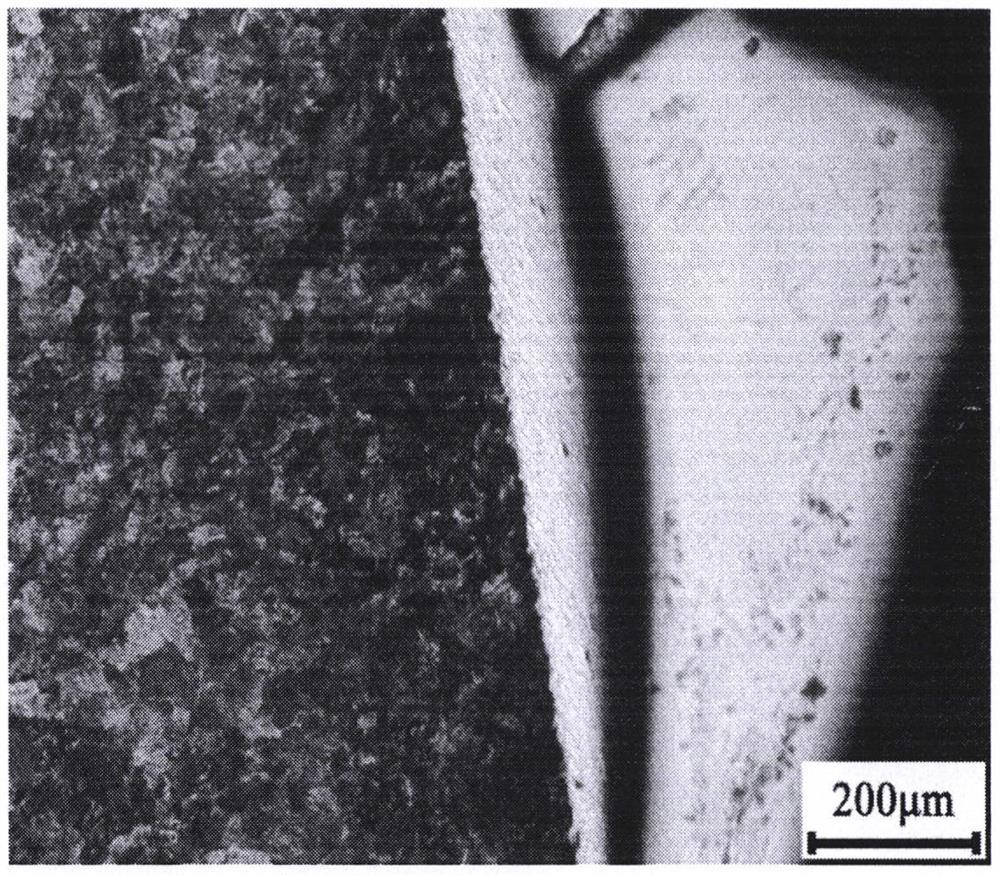

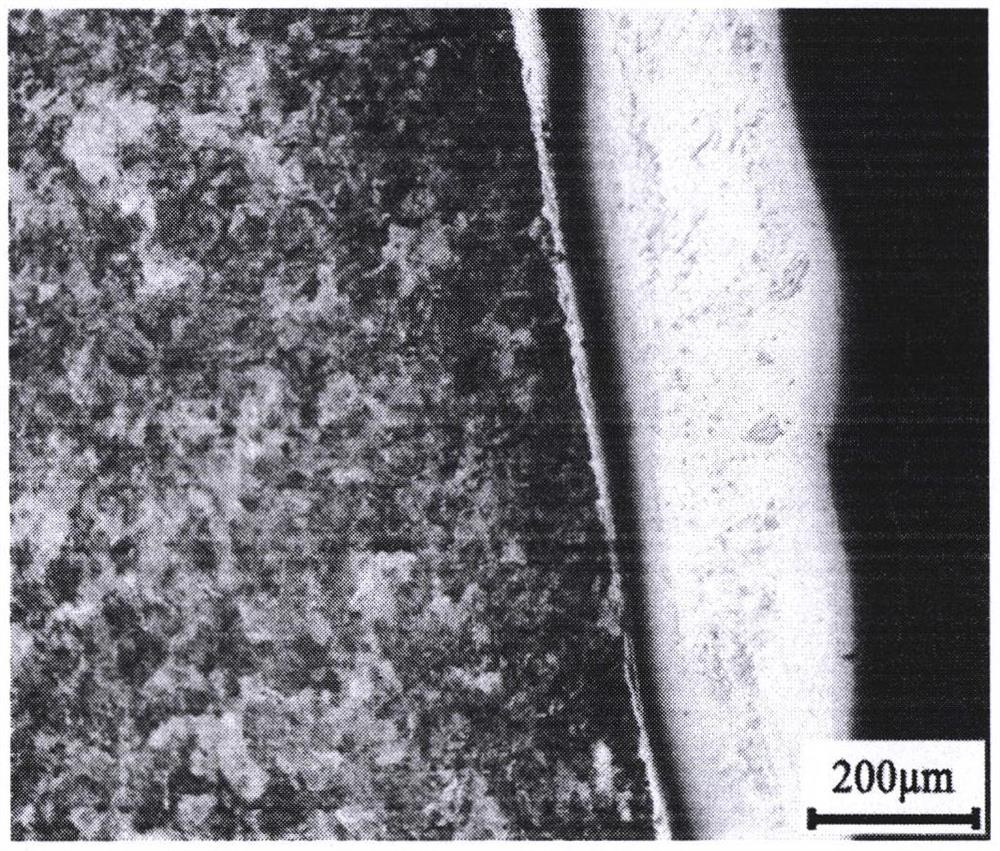

Preparation method of hard alloy saw blade

The invention relates to a preparation method of a hard alloy saw blade, the method mainly comprises the following technological processes: 1. sand blasting processing is carried out to a saw blade basal body before welding, the material of the saw blade basal body is 65Mn steel plate, the thickness is 3 to 5mm, the harness is HRC40-50, and flow marks are cut on the surface of the saw blade basal body by laser; 2. the saw blade basal body is held by an aluminium splint; 3. hard alloy particles are welded at the outer edge of the saw blade basal body, the material of the hard alloy particles is YG8, before being welded, the hard alloy particles are soaked for 3 to 5 minutes and air-dried, and then acryloidcement are uniformly sprayed on the surface of the hard alloy particles, a layer of 200 meshes of red copper powder is uniformly spread on the surface, so as to lead the surface of the hard alloy particles to be adhered with a layer of dried copper powder, the welding flux for welding is compound welding flux according to the proportion that sodium borate : boracic acid is equal to 1 : 1, and flame welding sticks is oxygen-acetylene gas flame, when in welding, the temperature of the oxygen-acetylene gas flame is adjusted to 850 plus or minus 10 DEG C. The preparation method of the hard alloy saw blade can quickly cut various materials.

Owner:JIANGSU FUNLIN SUPER HARD TOOLS

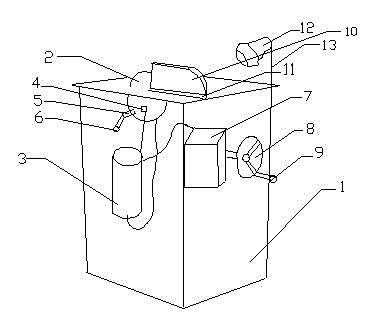

Fine machining treatment process for manufacturing integrated hard alloy saw blade

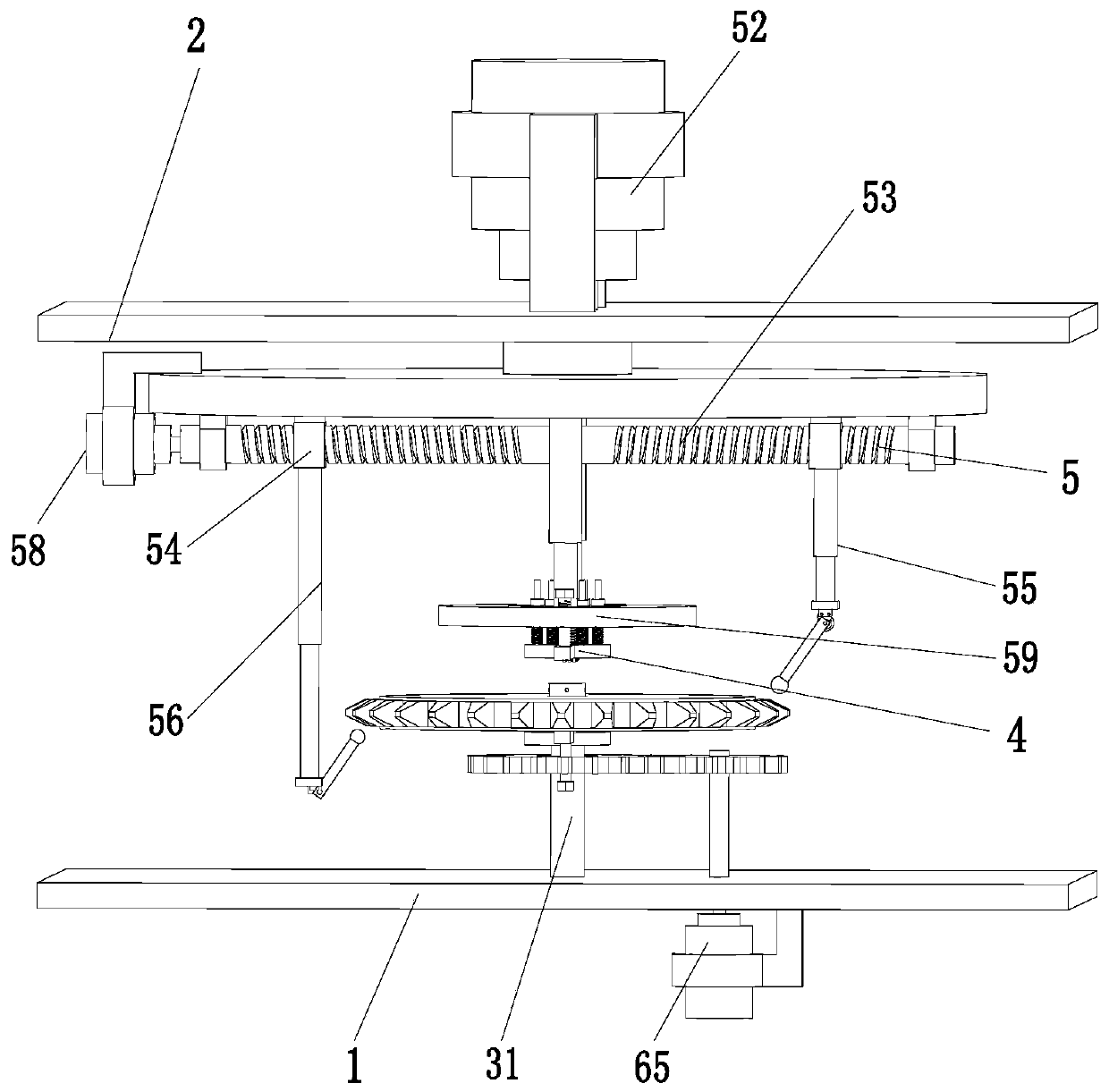

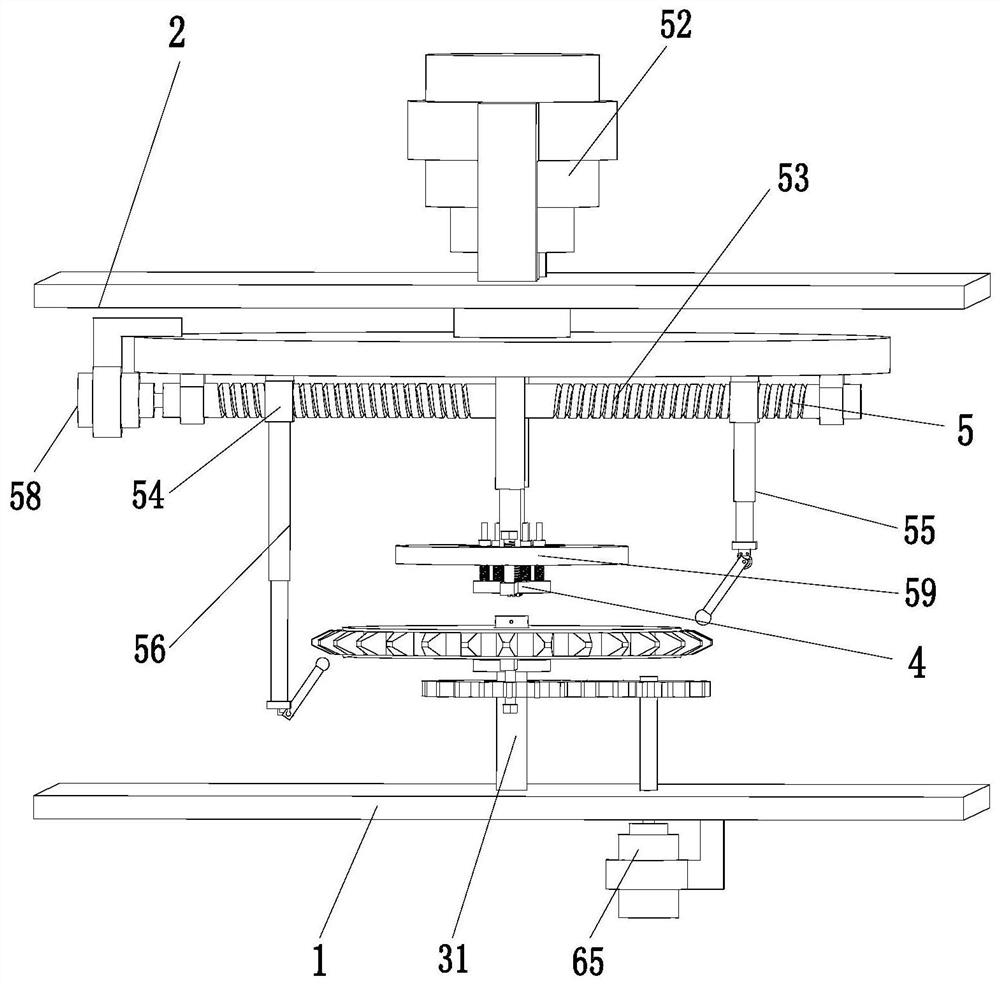

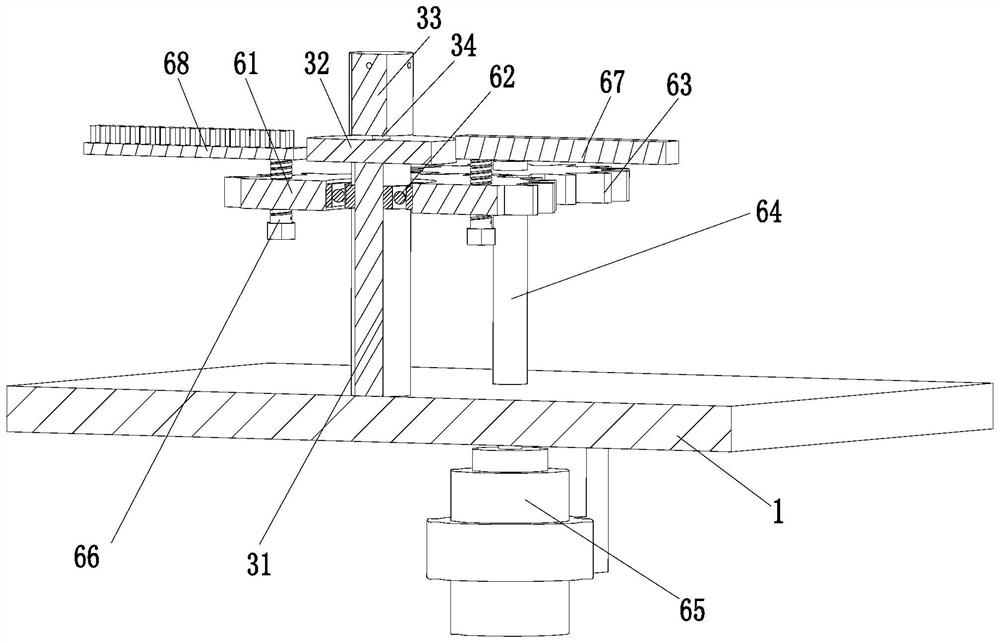

ActiveCN110977031AImprove product qualityAvoid poor cutting effectEdge grinding machinesGrinding drivesCarbide sawElectric machinery

The invention relates to a fine machining treatment process for manufacturing an integrated hard alloy saw blade. The alloy saw blade treatment process adopts an alloy saw blade fine machining treatment device as follows. The alloy saw blade fine machining treatment device comprises a bottom plate, a top plate, a bearing mechanism, a locking mechanism, an upper burr grinding device and a lower burr grinding device; the bearing mechanism comprises a fixed rod, a bearing disc, an inner hole block and a connecting post; the upper burr grinding device comprises a fixed disc, a rotary motor, a bi-directional screw, screw nuts, an upper edge grinding element, a lower edge grinding element, a screw motor and an upper blade surface grinding mechanism; the alloy saw blade treatment process adopts the alloy saw blade fine machining treatment device comprises the following steps of S1, fixing a saw blade; S2, grinding and positioning; and S3, removing burrs. According to the fine machining treatment process for manufacturing the integrated hard alloy saw blade, the problems that the existing saw blade grinding machine can only perform primary single-surface grinding on the saw blade, much room is available for efficiency improvement, and a welding position between a saw body and saw teeth cannot be ground can be solved.

Owner:山东华大金科新材料有限公司

High-hardness and high-strength hard alloy saw blade and processing method thereof

The invention discloses a high-hardness and high-strength hard alloy saw blade and a processing method thereof in the field of alloy processing. The hard alloy saw blade comprises the components of tungsten carbide, cobalt powder, tantalum carbide, chromium carbide and vanadium carbide. The processing method comprises the specific steps of step I, processing of tungsten carbide: carrying out carbonization and reduction on tungsten carbide and an additive at the high temperature; step II, ball milling: carrying out ball milling on tungsten carbide and cobalt powder with cylindrical grinding bodies; step III, addition of a forming agent: adding the PEG forming agent; step IV, introduction of a protective gas: introducing nitrogen or argon as the protective gas; step V, punch forming: carrying out punch forming at 30 to 100 tons of pressure; step VI, sintering: carrying out sintering at the temperature of 1400 to 1450 DEG C and the pressure of 10 MPa; and step VII, surface treatment. The hard alloy saw blade processed through the scheme is good in stability, high in size precision, good in compactness and low in damage rate, hardness and strength of a product are improved, brittleness is reduced, and the hard alloy saw blade is more suitable for cutting high-hardness profiles.

Owner:ZUNYI ZHONGBO CEMENTED CARBIDE

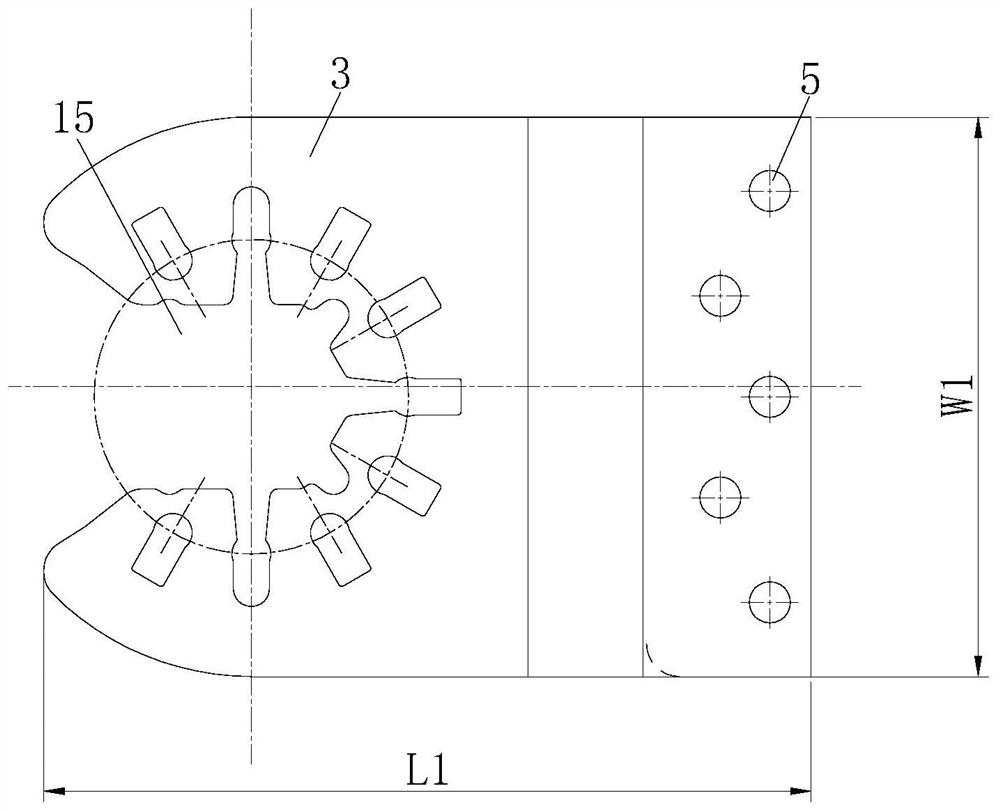

Punching die for producing hard alloy saw-tooth tool bit

The invention relates to a punching die for producing a hard alloy saw-tooth tool bit, comprising a die body, an upper punch seat, a lower punch seat, an upper punch and a lower punch, wherein the upper punch and the lower punch are respectively installed on the upper punch seat and the lower punch seat, an upper fixing sheet and a lower fixing sheet are respectively arranged between the upper punch seat and the upper punch as well as between the lower punch seat and the lower punch; the upper punch is sleeved on the upper fixing sheet; the lower punch is sleeved on the lower fixing sheet; annular pad forks are also sleeved at two sides of the lower punch; the die body is placed on the upper end faces of the annular pad forks; a die cavity is formed by the upper end face of the lower punch and the die body; and the upper punch is correspondingly arranged above the die cavity. Because the annular pad forks, the upper fixing sheet and the lower fixing sheet are arranged, the punching die for producing the hard alloy saw-tooth tool bit has simple structure and is convenient for mounting and dismounting; when the punching die is produced, the damage to the lower punch, caused by stress concentrated on the lower punch, is avoided by means of the annular pad forks through stamping the upper punch and the lower punch in one step, and the stamping is stable, therefore, the production efficiency is greatly improved, the maintenance cost is saved, and the product quality is enhanced.

Owner:昆山长鹰硬质材料科技股份有限公司

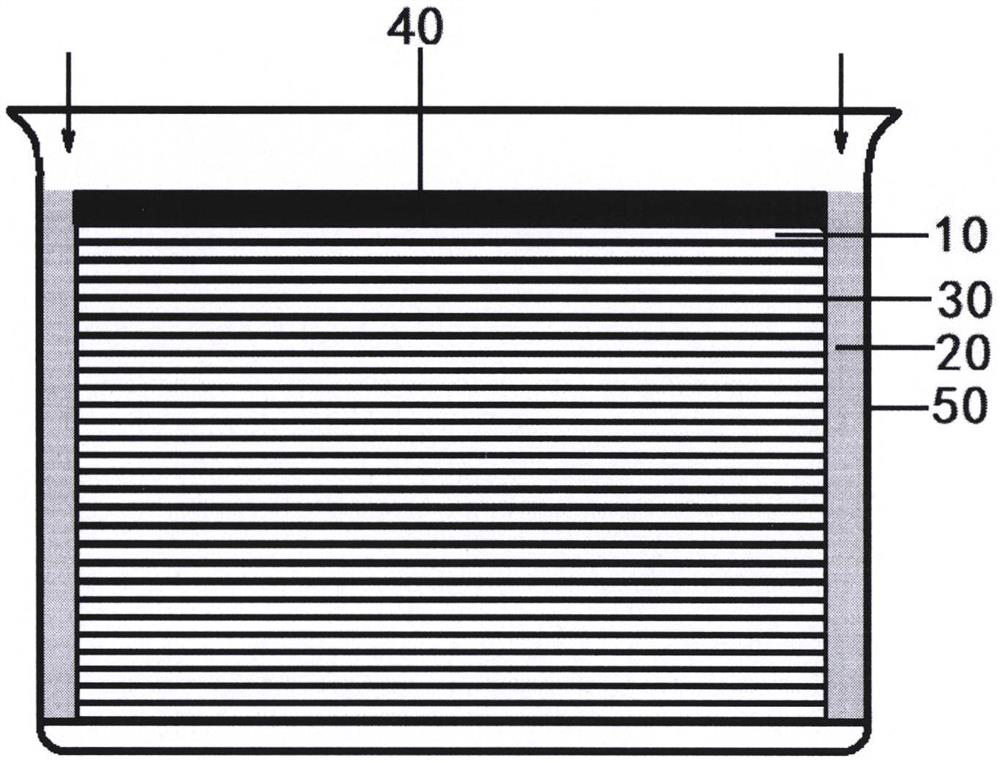

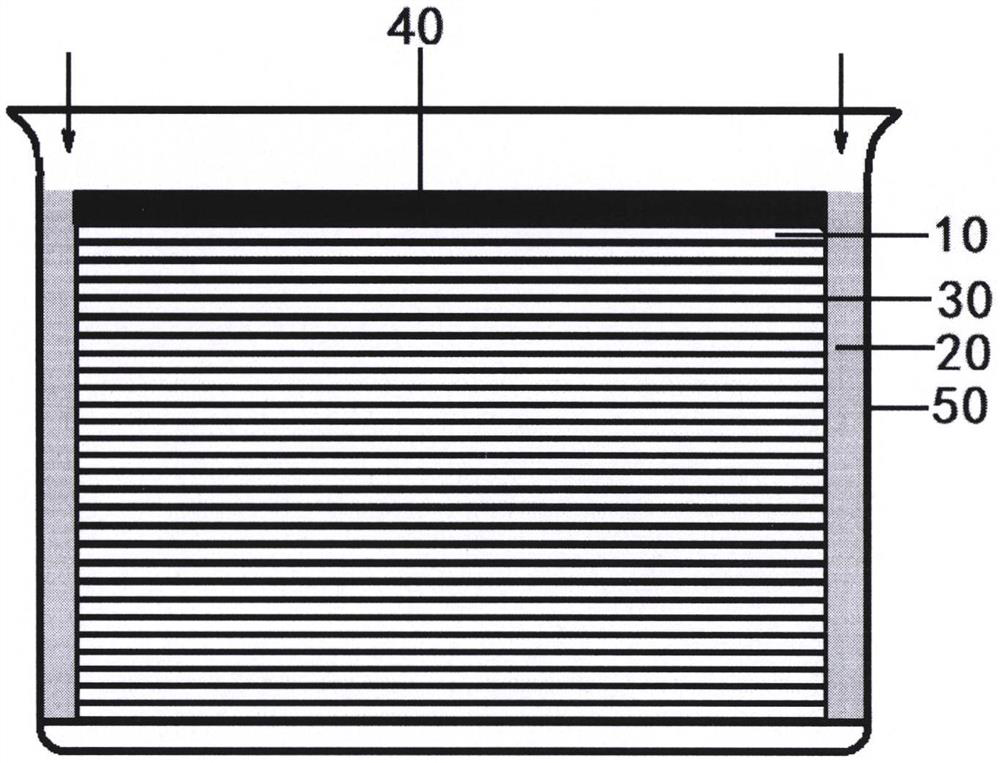

Preparation method of hard alloy saw web

The invention relates to a preparation method of a hard alloy saw web, and belongs to the technical field of hard tools. The preparation method of the hard alloy saw web comprises the following stepsthat (1) a graphite mold is provided, and multiple layers of metal saw web base bodies are stacked in the graphite mold in the height direction; (2) hard alloy particles are pr-arranged in a gap between the edges of the metal saw web base bodies and the inner wall of the graphite mold; and (3) the hard alloy particles are covered with a molten metal bonding agent to form a saw web working layer. According to the preparation method in the embodiment, the technological process is simplified, special sintering powder does not need to be adopted for the metal bonding agent, and therefore the raw material cost can be reduced; and the metallurgical bonding strength between the saw web working layer and the saw web base bodies can be guaranteed through the saw web working layer formed through melting.

Owner:江苏华昌工具制造有限公司

Cutting machine

InactiveCN104625221AEasy to cleanStay safeMetal sawing devicesMaintainance and safety accessoriesManufacturing technologyAlloy

The invention relates to the technical field of machining and manufacturing of iron chromium aluminum alloy, in particular to a cutting machine. The cutting machine comprises a shell, a disc cutter and a motor. The shell is connected with the disc cutter, and the disc cutter is connected with the motor; the shell is connected with the motor, and a double-metal-piece temperature control device is arranged in the disc cutter; the double-metal-piece temperature control device is in series connection with the motor; a protection shell is arranged above the disc cutter, and a sliding groove is formed in the shell; the protection shell is connected with the sliding groove, and the disc cutter is a tungsten-cobalt class hard alloy blade; and the height of the cutting machine ranges from 70 cm to 90 cm. The normal use function of the cutting machine is not affected, and meanwhile, the phenomenon that under the non-attention condition, the disc cutter possibly hurts the human body can be avoided. Operation safety and cleanness are ensured. The tungsten-cobalt class hard alloy blade is used by the cutter disc, and has the good impact resistance, hardness and rigidity. The cutting leveling of a cut object is ensured, and meanwhile the machining period can be greatly shortened.

Owner:DANYANG ZHISHENG ALLOY

Cutting machine

InactiveCN104275523AEasy to cleanStay safeShearing machinesMaintainance and safety accessoriesTemperature controlMetal alloy

The invention relates to the field of metal alloy, in particular to a cutting machine, comprising a shell, a cutting disc and a motor; the shell is connected with the cutting disc connected with the motor; the shell is connected with the motor; a dual metal sheet temperature control device is arranged in the cutting disc and is connected with the motor in series; a protection shell is arranged above the cutting disc; a chute is formed in the shell and is connected with the protection shell; the cutting disc is a tungsten cobalt hard alloy saw blade; the cutting machine is 70-90cm high. The normal functions of the cutting machine are not influenced while the possible harm to a human body caused by the cutting disc under an inattention condition can be avoided, and the operation safety and cleanliness are ensured; the cutting disc uses the tungsten cobalt hard alloy saw blade having good impact resistance, harness and rigidity, and the machining period is greatly shortened while a flat cutting surface of a cut object is ensured.

Owner:中山市鸿程科研技术服务有限公司

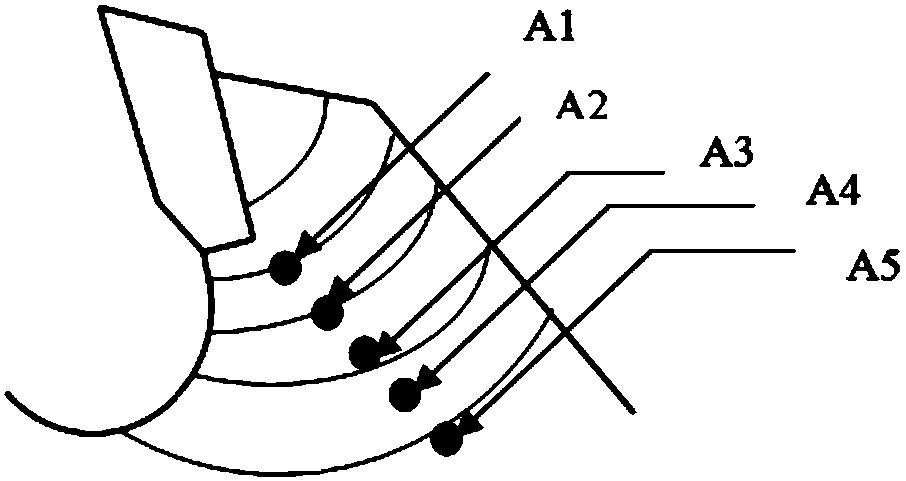

Multi-angle sawtooth cutting device for hard alloy saw blade

InactiveCN112809089AGood processing needsIncrease flexibilityMetal sawing tool makingLarge fixed membersCarbide sawElectric machinery

The invention discloses a multi-angle sawtooth cutting device for a hard alloy saw blade. The multi-angle sawtooth cutting device for the hard alloy saw blade comprises a cutting mechanism and a bearing mechanism; the cutting mechanism is installed on the upper end face of the bearing mechanism, and a limiting sliding barrel correspondingly slides for a corresponding distance in a sliding groove, so that the sawtooth machining angle is changed, and the sawtooth cutting flexibility is improved. According to the device, the other end of a curved bar is arranged in an inner cavity of a second fixing clamping plate and movably connected with the second fixing clamping plate; the top end of a push rod is connected with the inner side of a mounting plate, and the surface of a positioning plate is connected with a gear motor through a bolt, so that when the device cuts sawteeth of the hard alloy saw blade, an air cylinder drives a mounting plate to incline by a certain angle through the push rod so as to drive a cutting assembly to rotate by a certain angle, then sawtooth depth cutting is conducted on the saw blade, meanwhile, the up-down moving distance of the cutting assembly in the vertical direction can be adjusted through a bolt so that the sawtooth machining angle can be changed, and the machining requirement can be met conveniently.

Owner:刘瑞兰

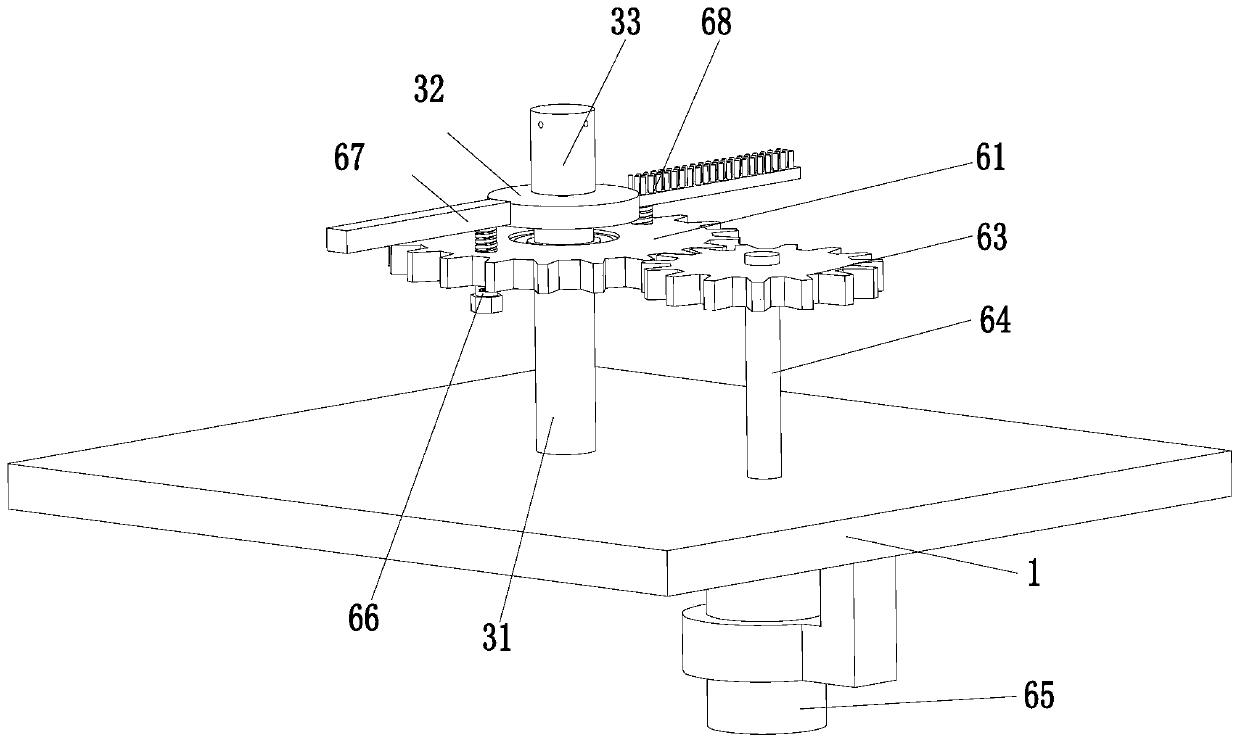

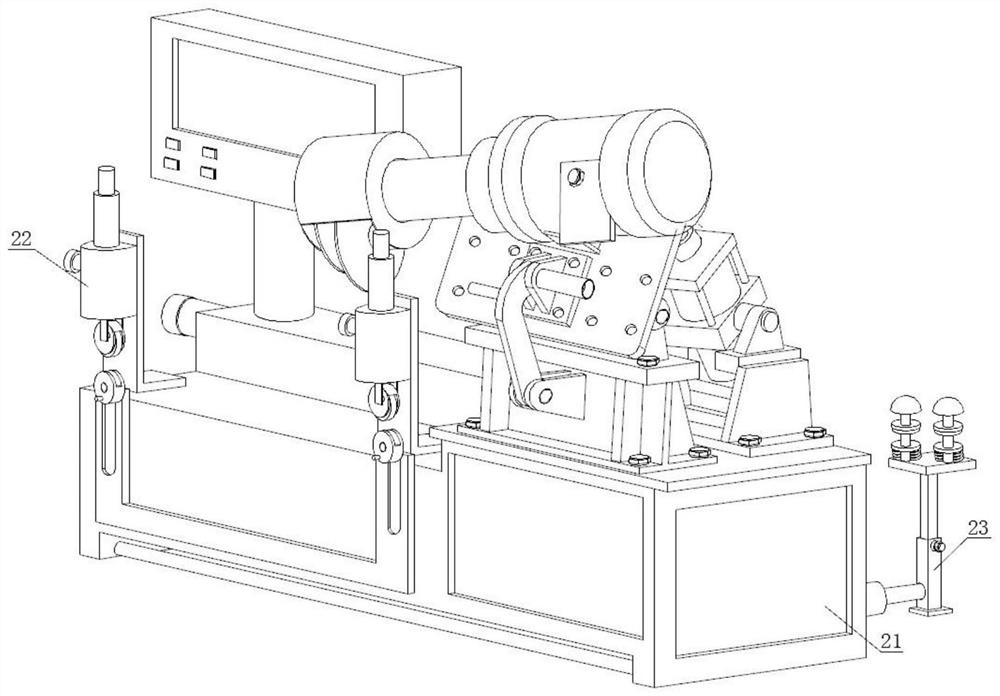

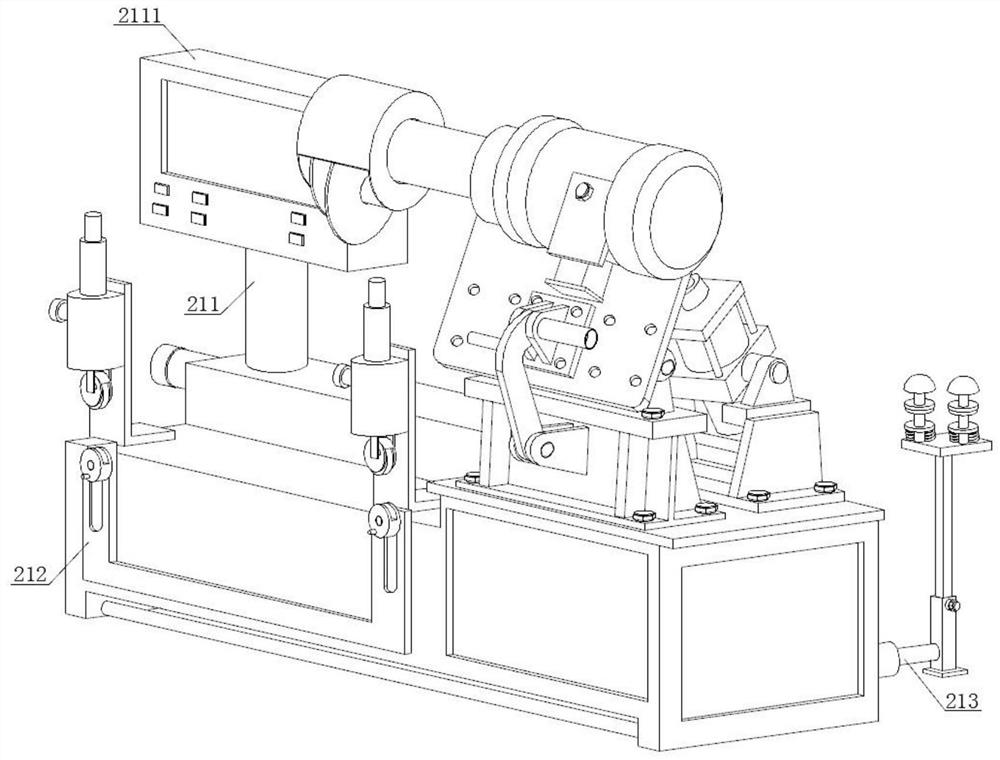

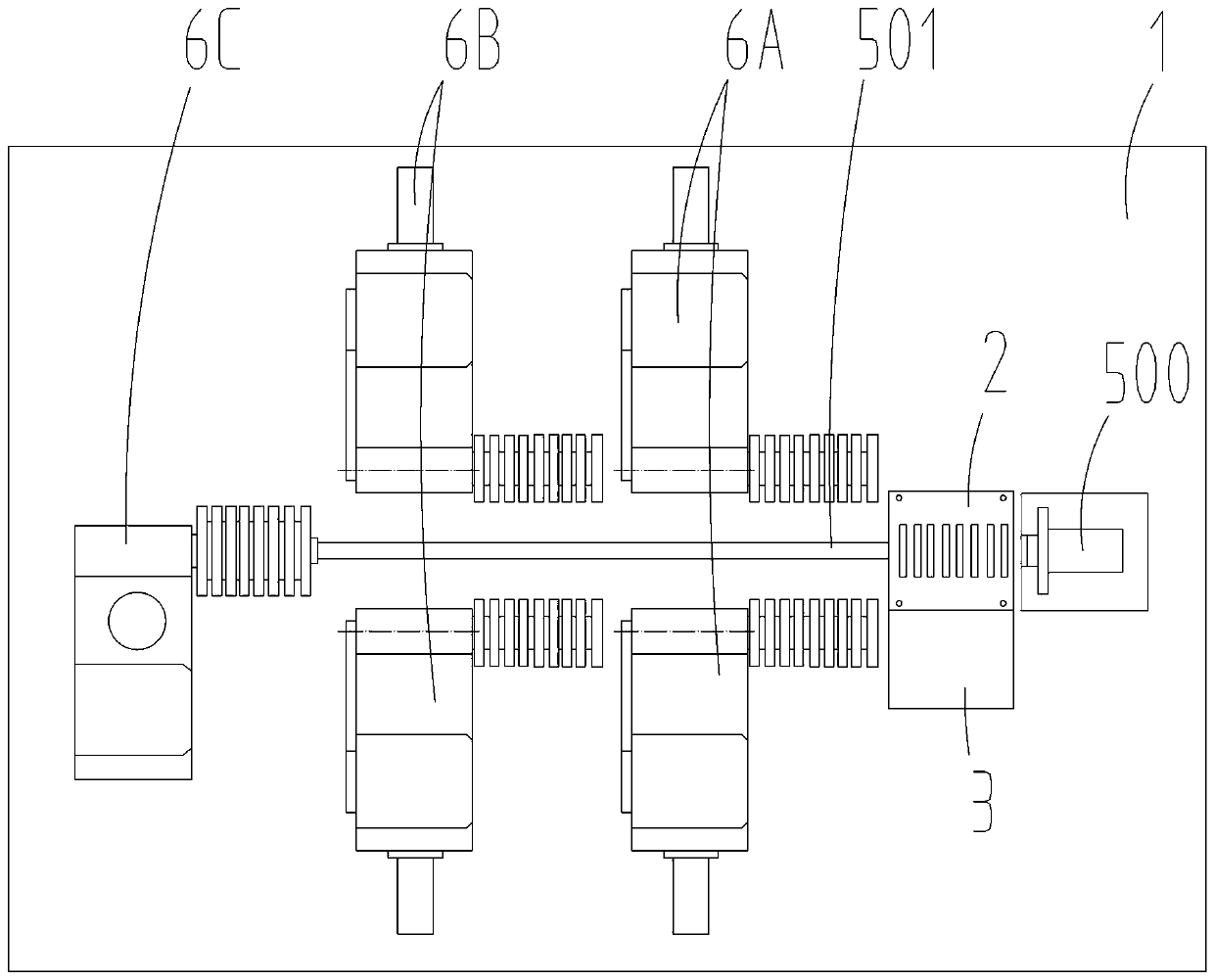

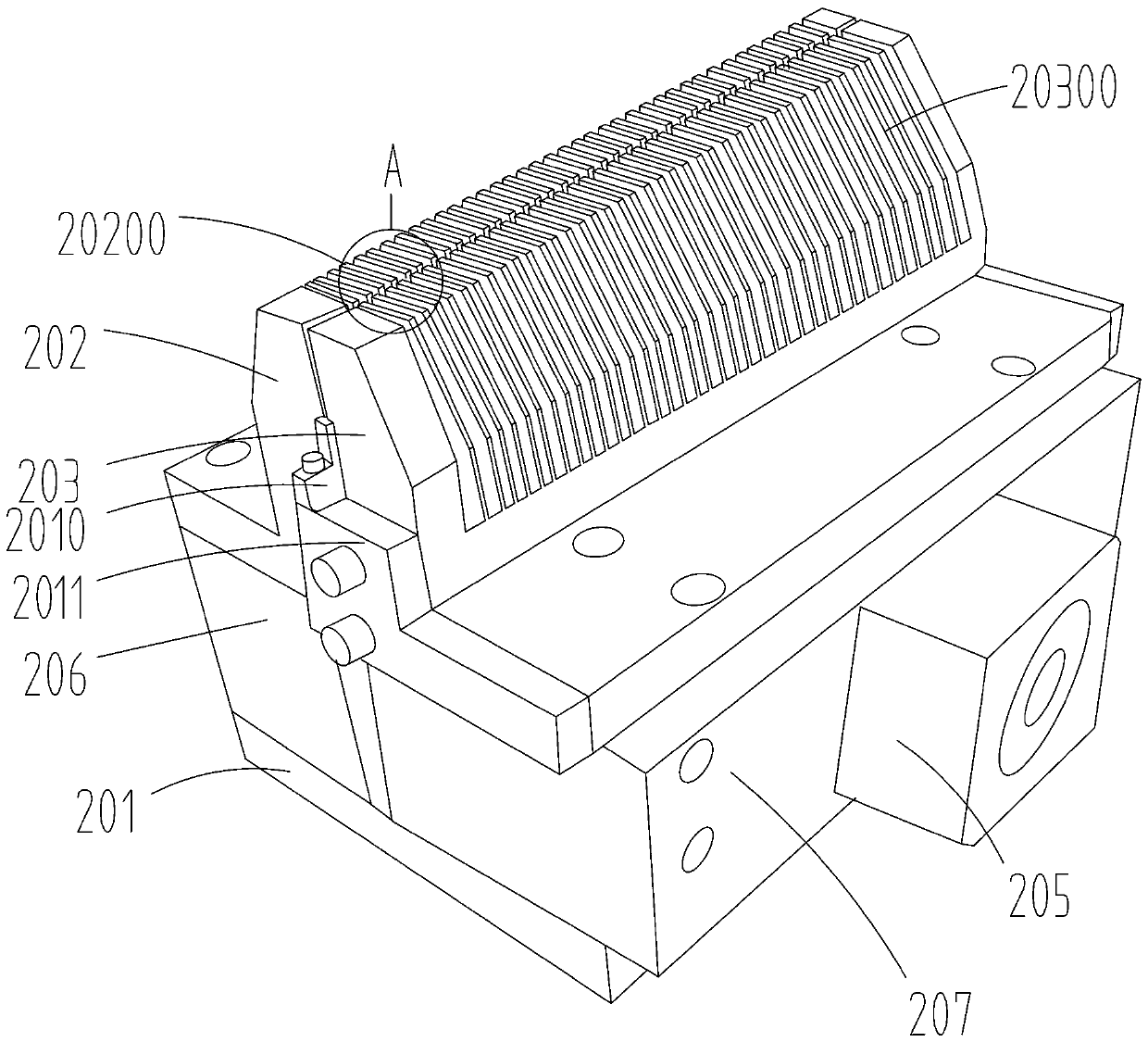

Hard alloy saw blade tooth grinding machine tool

PendingCN110125484AReduce inputIncrease productivityGrinding drivesMetal sawing tool makingCarbide sawEngineering

The invention belongs to the technical field of saw blade machining equipment, and particularly relates to a hard alloy saw blade tooth grinding machine tool. A workbench, at least one grinding device, a clamping device arranged on the workbench and a clamping device drive mechanism capable of driving the clamping device to move towards the grinding device are included. The clamping device comprises a clamping base, a first clamping base fixedly connected to the clamping base, a second clamping base which is in sliding connection to the clamping base, and a clamping drive mechanism driving thesecond clamping base to slide on the clamping base, wherein the first clamping base is fixedly connected with a row of first clamping ribs, the second clamping base is fixedly connected with a row ofsecond clamping ribs corresponding to the first clamping ribs in a one-to-one manner, and in one row of clamping ribs, a through groove is formed between every two adjacent clamping ribs. According to the hard alloy saw blade tooth grinding machine tool, the purpose of multi-tooth two-side-angle grinding through one-time feeding is achieved, the existing traditional technology that only one toothis ground is changed, the production efficiency is greatly improved, the grinding cost is greatly reduced, and the tooth grinding machine tool input amount is greatly reduced.

Owner:温州贵能工具有限公司

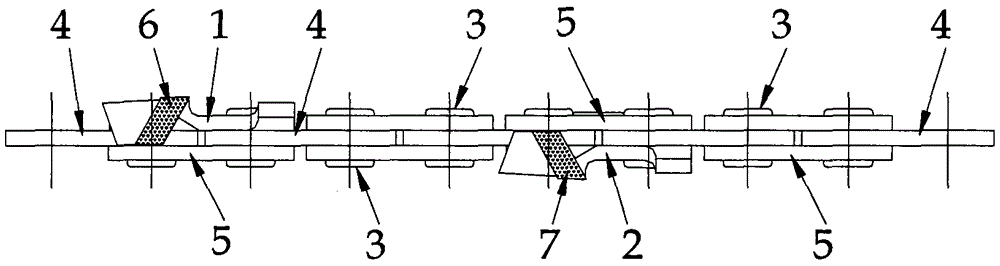

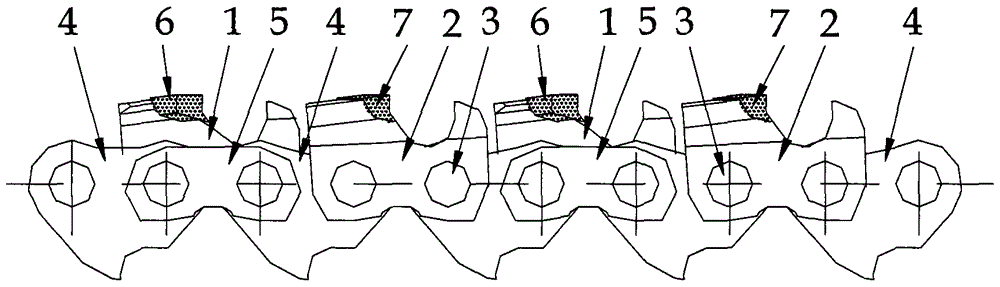

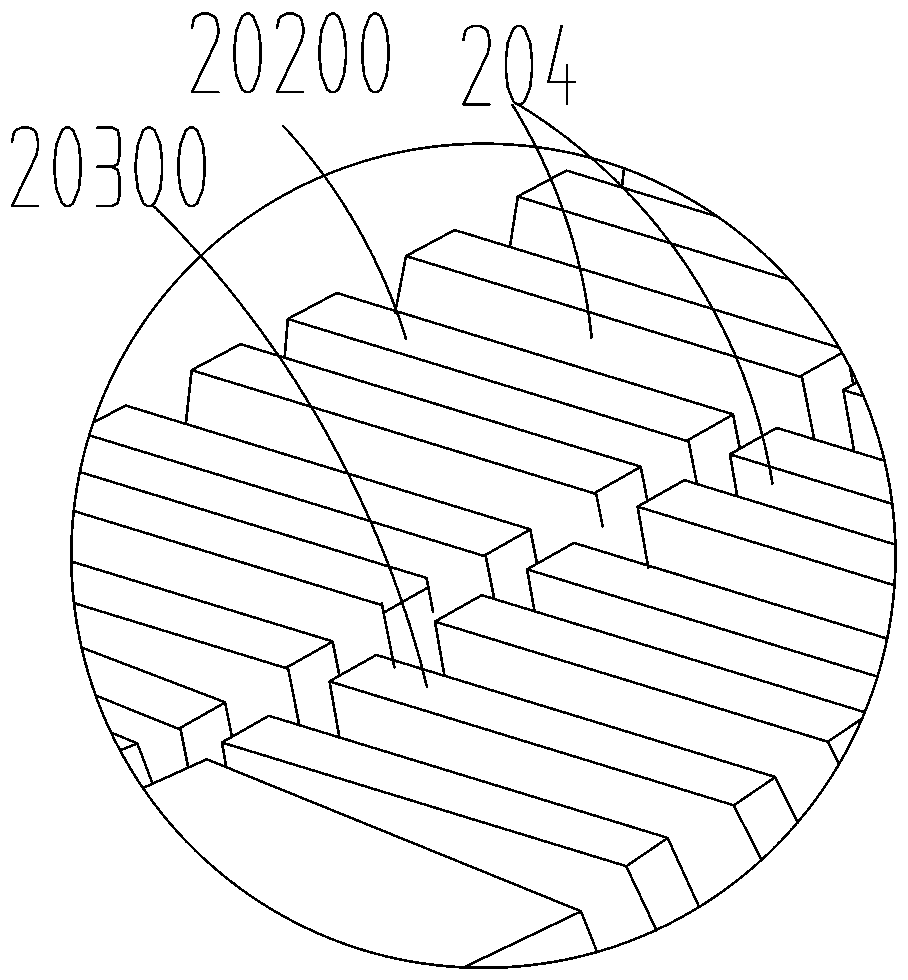

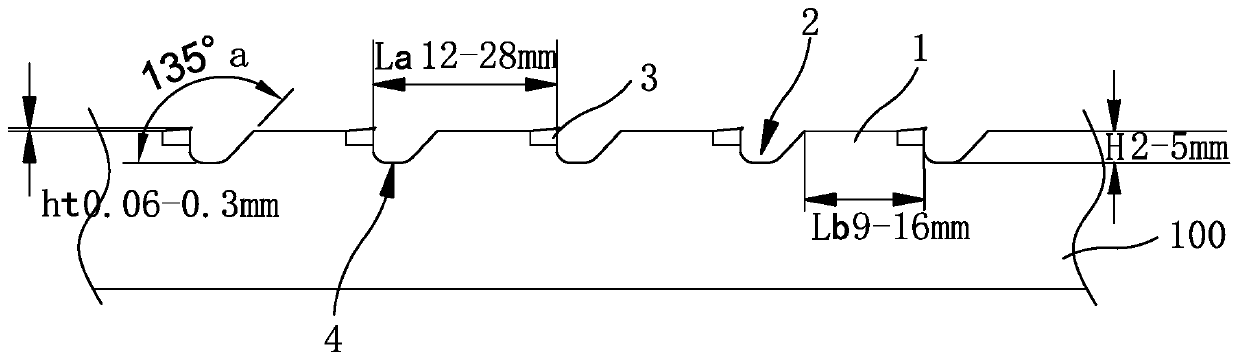

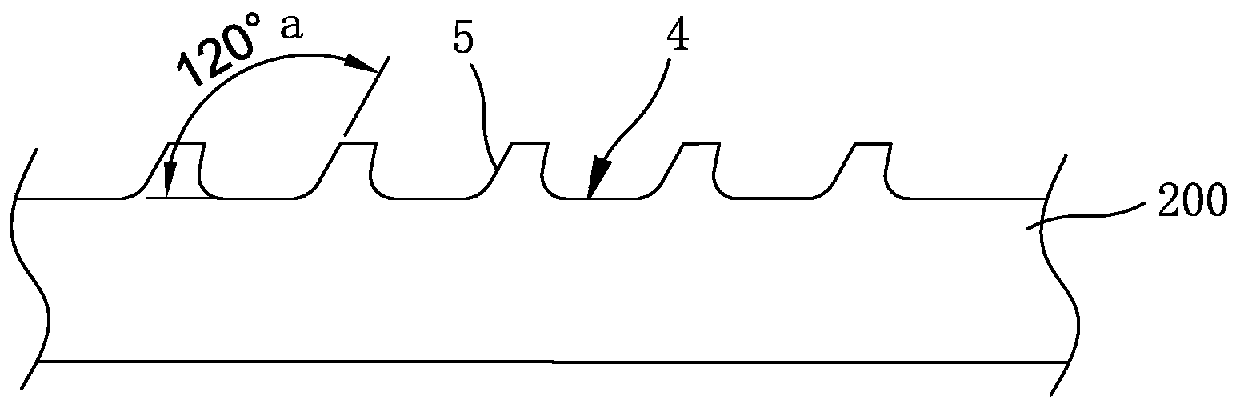

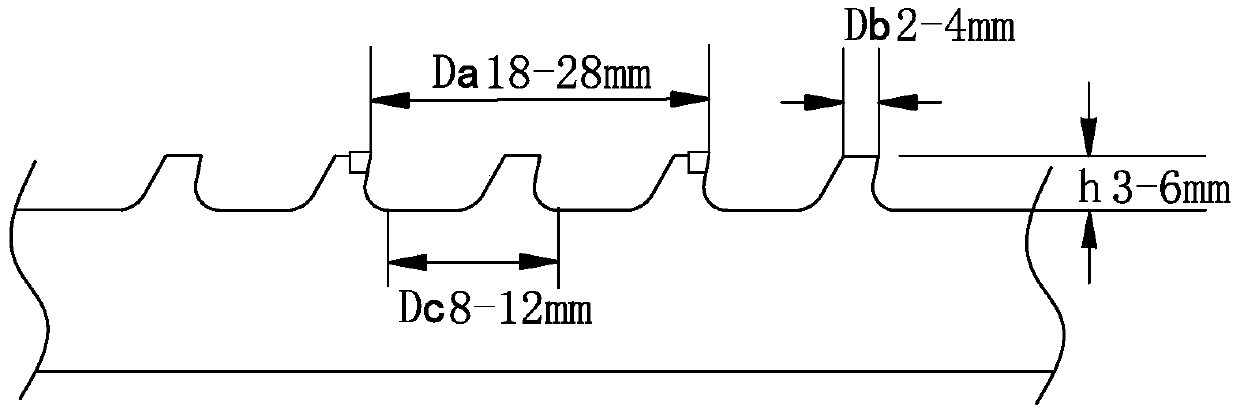

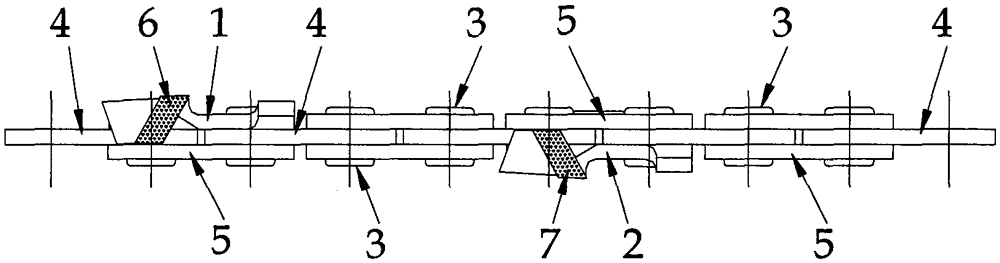

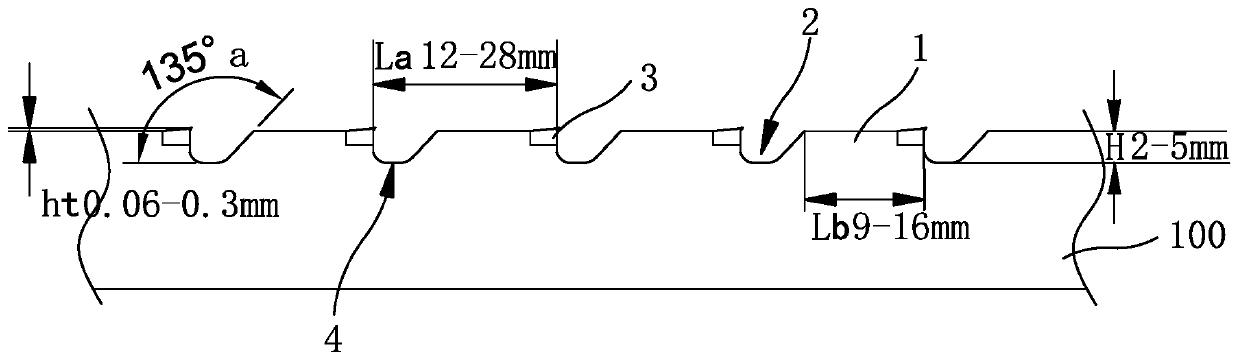

Impact-resistant interval hard alloy saw and manufacturing method thereof

ActiveCN110744139AReasonable structural designReduce manufacturing costMetal sawing tool makingMetal sawing toolsRooted toothCarbide saw

The invention relates to an impact-resistant interval hard alloy saw and a manufacturing method thereof. The saw is designed to solve the technical problems that according to existing similar products, blades are prone to being broken, the firmness is poor, production and machining are inconvenient and the scrap rate is too low. A body of the hard alloy saw is a spring steel sheet, tooth tips arearranged at the tip ends of sawteeth of the spring steel sheet, and the teeth are made of hard alloy. The saw is characterized in that the tooth tips are square hard alloy welding blocks with the length of 1-3 mm; each tooth tip is provided with a two-section integrated rear angle which warps upwards and outwards and a rake angle located at the tip of the rear angle, wherein the length of the rakeangle is 0.12-0.3 mm, and the bevel edges on the two sides of the rake angle also warp to be higher than side faces on the two sides; and the height difference between the tip ends of the rake anglesand the top plane of the sawteeth is 0.06-0.3 mm, the distance between the top plane and tooth roots of the sawteeth is 2-6 mm, the tip ends of the tooth tips of the spring steel sheet are at the same height, and the included angle e between the lower portions and the vertical line of the tooth roots of the sawteeth at a saw groove is 10-20 degrees.

Owner:孙禹平

A kind of preparation method of cemented carbide saw blade

The invention relates to a method for preparing a cemented carbide saw blade, which belongs to the technical field of hard tools. The preparation method of cemented carbide saw blade of the present invention comprises the following steps: (1) graphite mold is provided, and multi-layer metal saw blade substrate is stacked along height direction in graphite mold; Carbide particles are preset in the gap between the inner walls of the mold; (3) The cemented carbide particles are covered with molten metal binder to form a saw blade working layer. The preparation method of this embodiment simplifies the process flow, and the metal bond does not need to use special sintered powder, which is beneficial to reduce the cost of raw materials; the saw blade working layer formed by melting can ensure the metallurgical bond strength between the saw blade matrix.

Owner:江苏华昌工具制造有限公司

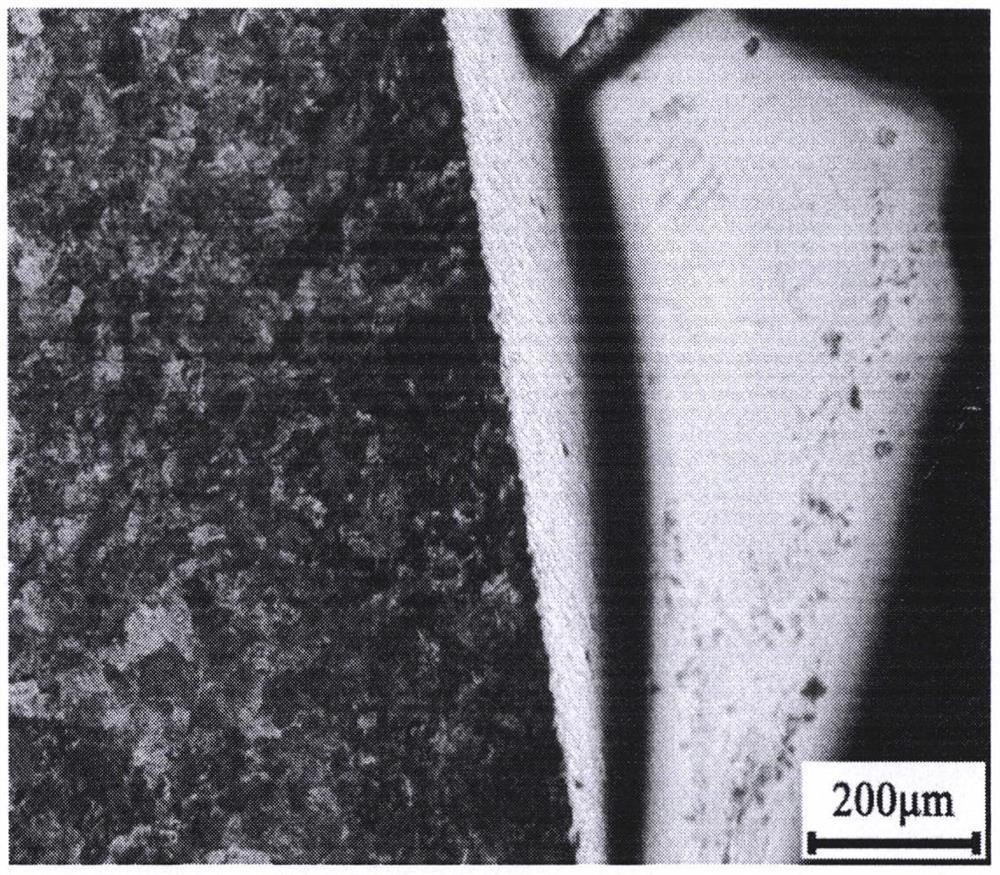

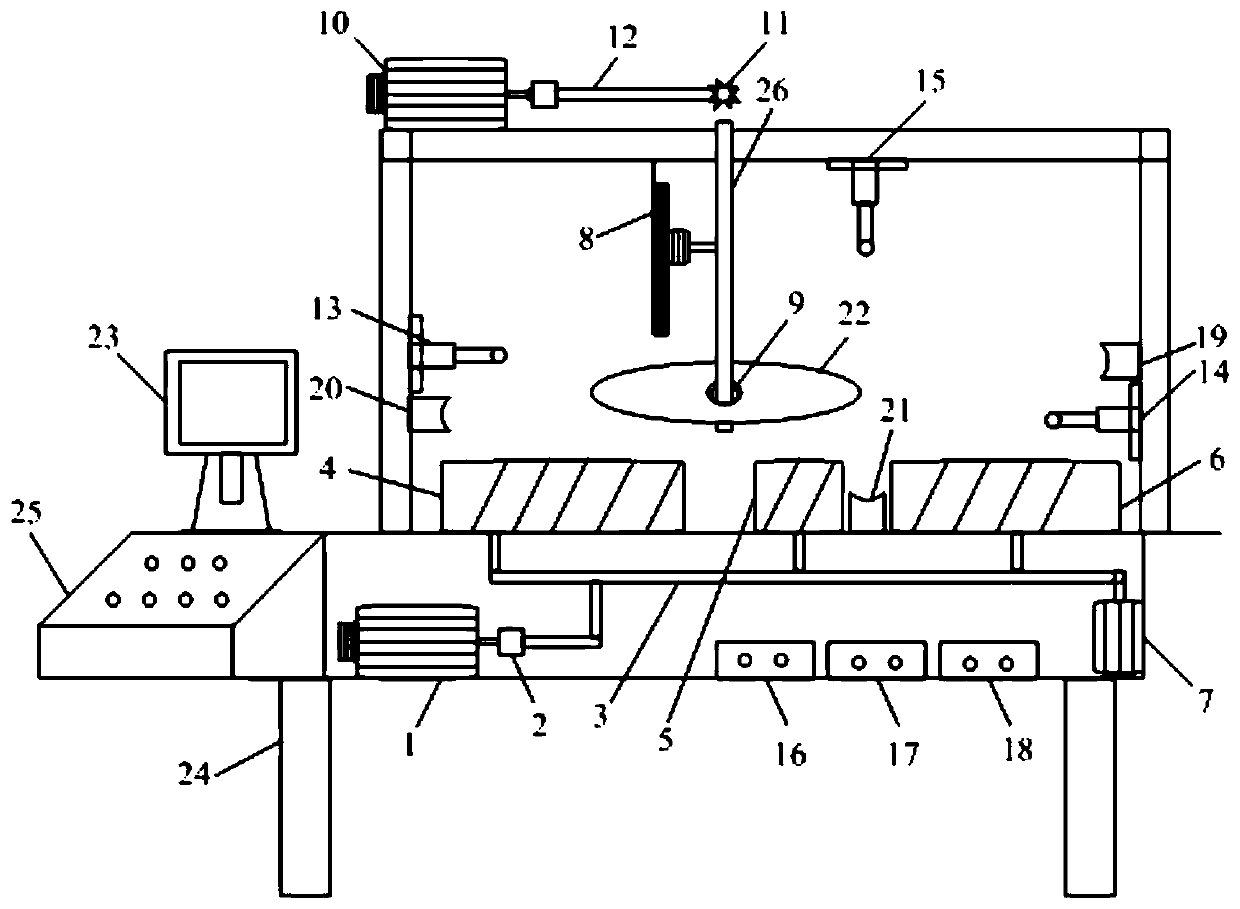

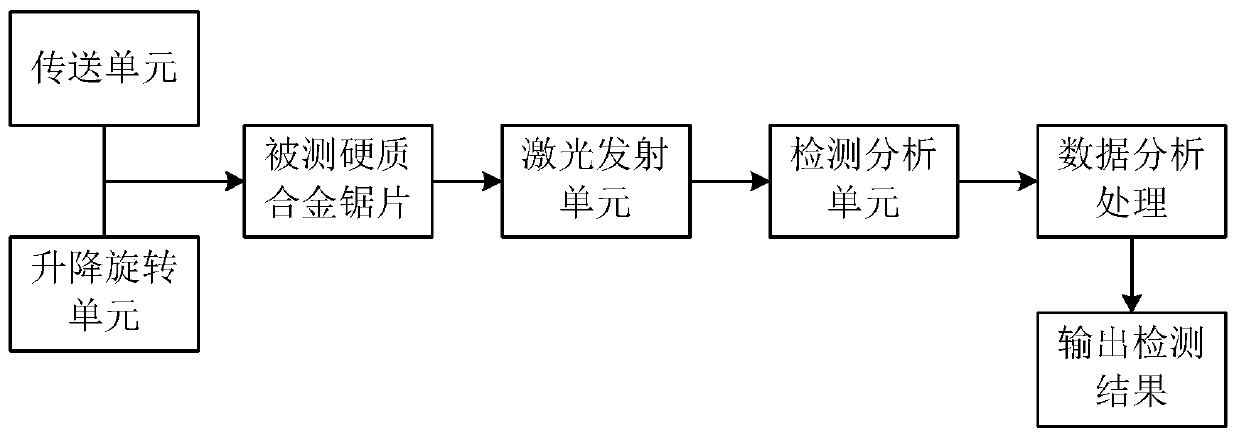

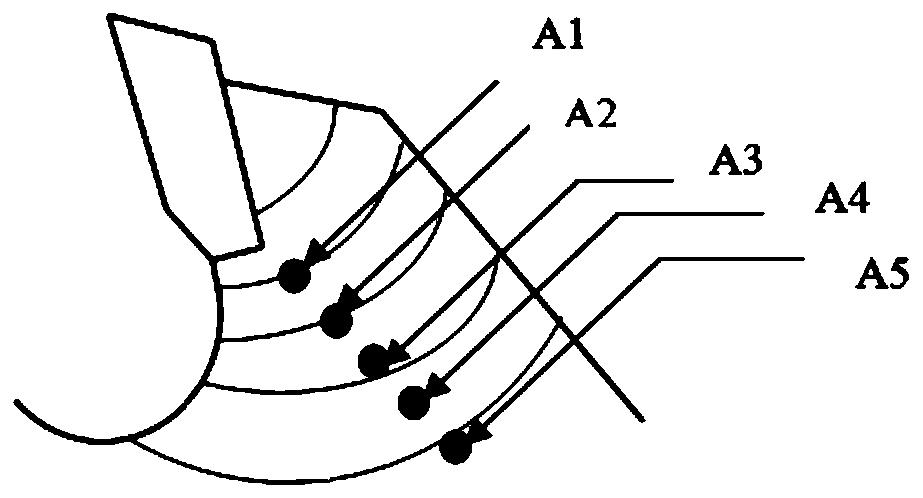

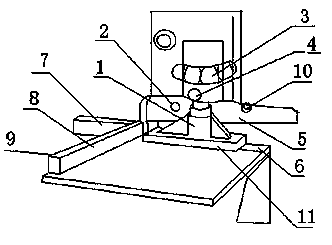

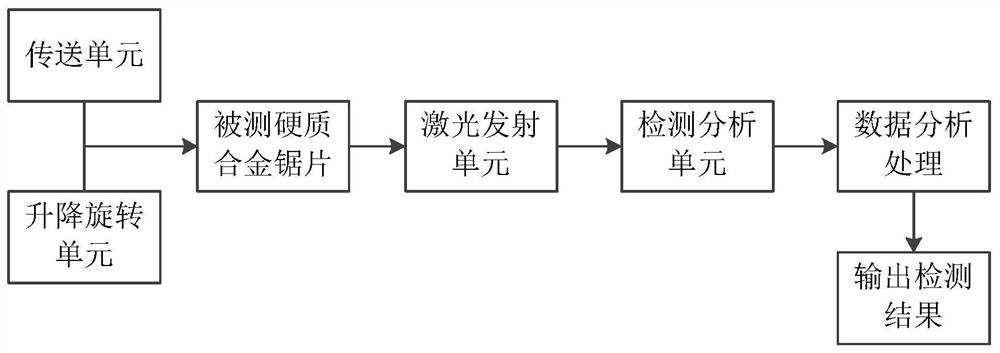

Welding angle detection device for hard alloy saw blade tool bit

ActiveCN109884071AQuality improvementRealize online detectionOptically investigating flaws/contaminationCarbide sawAlloy

The invention discloses a welding angle detection device for a hard alloy saw blade tool bit, belongs to the field of hard alloy saw blade detection, and aims to solve the problem in the prior art that detection efficiency is low since an artificial sampling inspection way is usually adopted for detecting the hard alloy saw blade. The device comprises a supporting rack, a tested hard alloy saw blade and a control unit, wherein the supporting rack is provided with a lifting and rotation unit and a laser detection unit, wherein the laser detection unit comprises a plurality of laser components;the laser components independently detect the upper surface, the lower surface and the outer side edge of the tested hard alloy saw blade; the lifting and rotation unit sends the tested hard alloy sawblade to a detection station; and the laser detection unit sends a detection signal to the control unit. By use of the device, tool bit welding angle detection can be efficiently and accurately realized, and powerful technical support is provided for the welding quality and the service life of the hard alloy saw blade.

Owner:HARBIN UNIV OF SCI & TECH

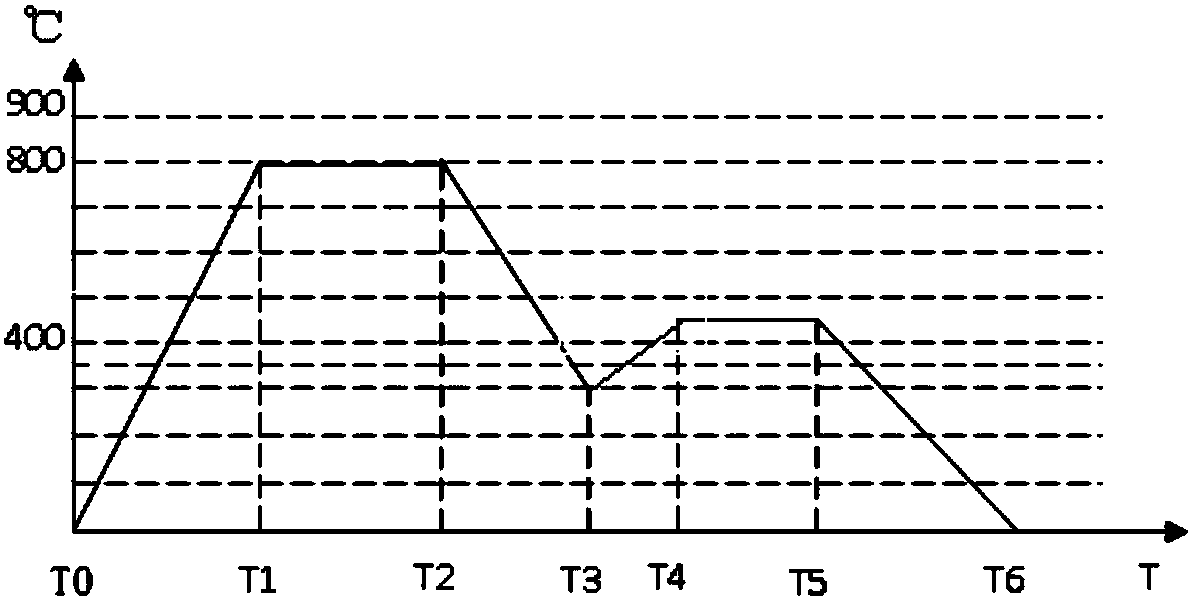

Hard alloy saw blade and welding method thereof

ActiveCN107838494ASolve the problem of stress crackingMetal sawing tool makingSoldering apparatusCarbide sawAlloy

The invention discloses a hard alloy saw blade and a welding method thereof. The method comprises the following steps: (S1) a hard alloy tool bit, a saw blade basal body, a welding wire and a flux areheated after placement; (S2) under 760-840 DEG C temperature environment, the molten welding wire is paved in a gap between the hard alloy tool bit and the saw blade basal body by using a wetting effect of the flux; (S3) a primary welding body is obtained by cooling; and when the temperature of the primary welding body is lower than 350 DEG C, the primary welding body is primarily tempered; and (S4) the primary welding body is secondarily tempered within 1-3 hours after primary tempering to obtain the hard alloy saw blade; the secondary tempering is performed in a closed container; and the temperatures in all space positions in the container are kept consistent. The tooth base rupture problem during cutting and the stress crack problem between adjacent saw teeth are solved.

Owner:ZHONGSHAN KINGWAVE SAW BLADE MFG LTD

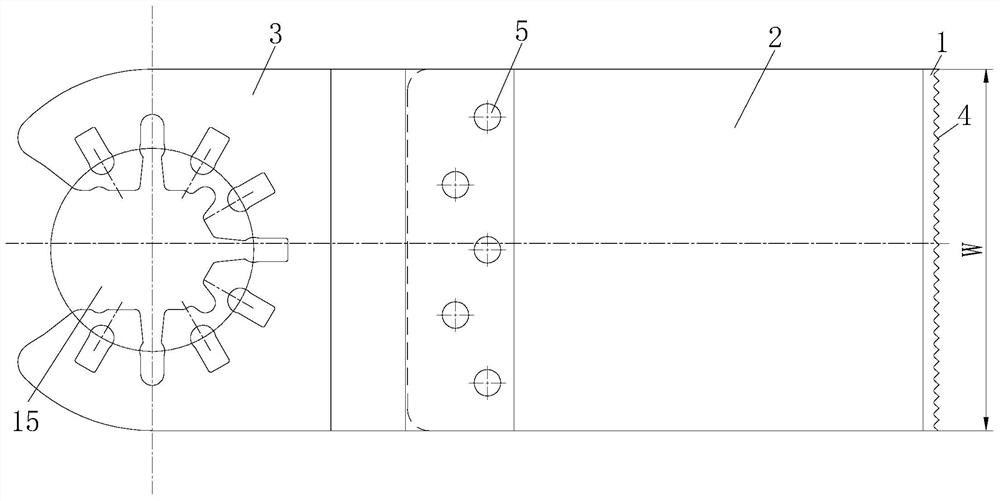

Hard alloy saw blade and machining process thereof

ActiveCN112276234AReduce pollutionWeld firmlyMetal sawing tool makingMetal sawing toolsHand heldMetal machining

The invention relates to a hard alloy saw blade and a machining process thereof, belongs to the technical field of metal machining tool manufacturing, and is suitable for being used in cooperation with a handheld tool. The hard alloy saw blade comprises a hard alloy strip, a saw blade main body and a mounting handle part; and the hard alloy saw blade is structurally characterized by further comprising saw teeth and welding points, the welding points are arranged on the mounting handle part, the welding points are connected with the saw blade main body, and the saw blade main body and the mounting handle part are of an integrated structure; and the hard alloy strip is connected with the saw blade main body, the hard alloy strip and the saw blade main body are of an integrated structure, thehard alloy strip is located at the side portion of the saw blade main body, the saw teeth are arranged on the hard alloy strip, and a connector is arranged at the mounting handle portion. According to the hard alloy saw blade, welding filler is not needed when the hard alloy strip and the saw blade main body are welded, and the hard alloy saw blade has the advantages of being firm in welding, convenient to machine, capable of reducing production and manufacturing cost, long in service life, wide in application range, high in cost performance, small in environmental pollution and the like.

Owner:HAILIAN SAW BLADE TECH CO LTD

A high-hardness and high-strength cemented carbide saw blade and its processing method

Owner:ZUNYI ZHONGBO CEMENTED CARBIDE

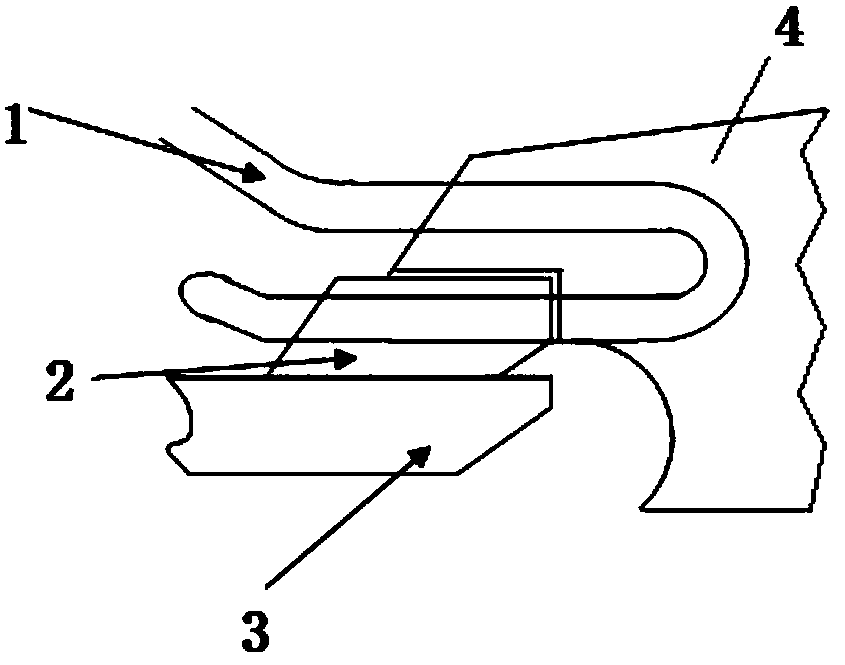

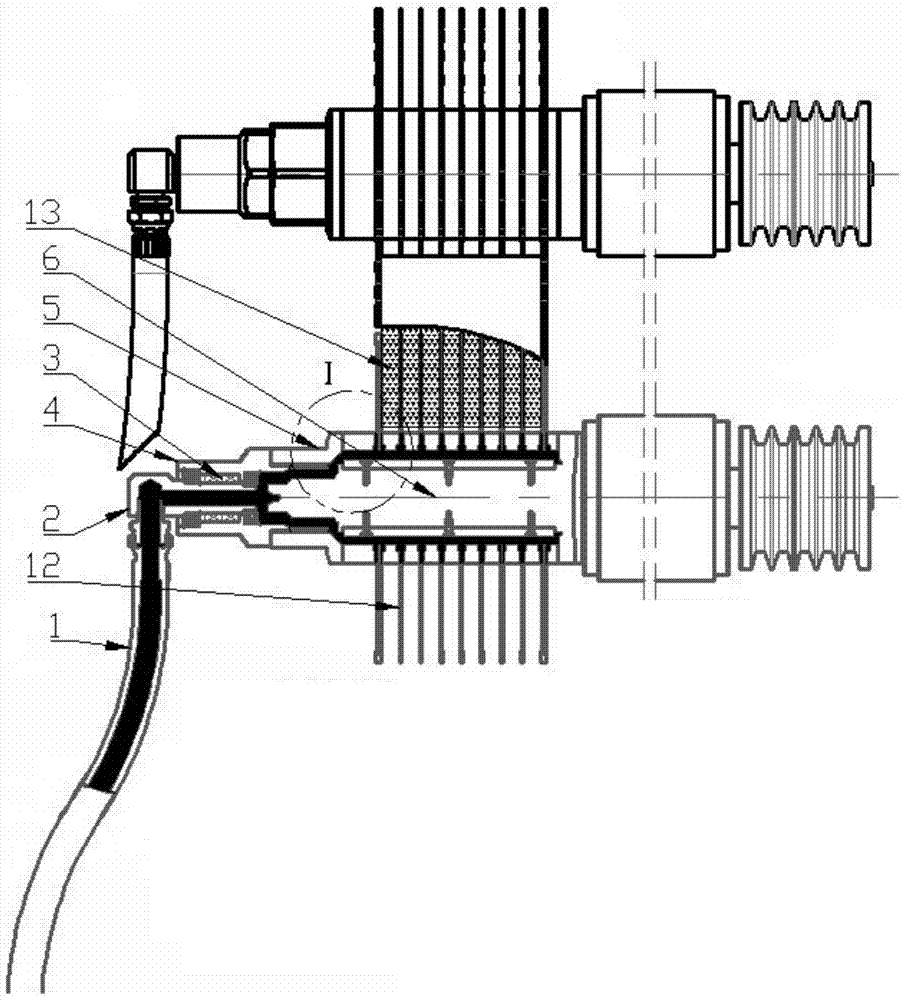

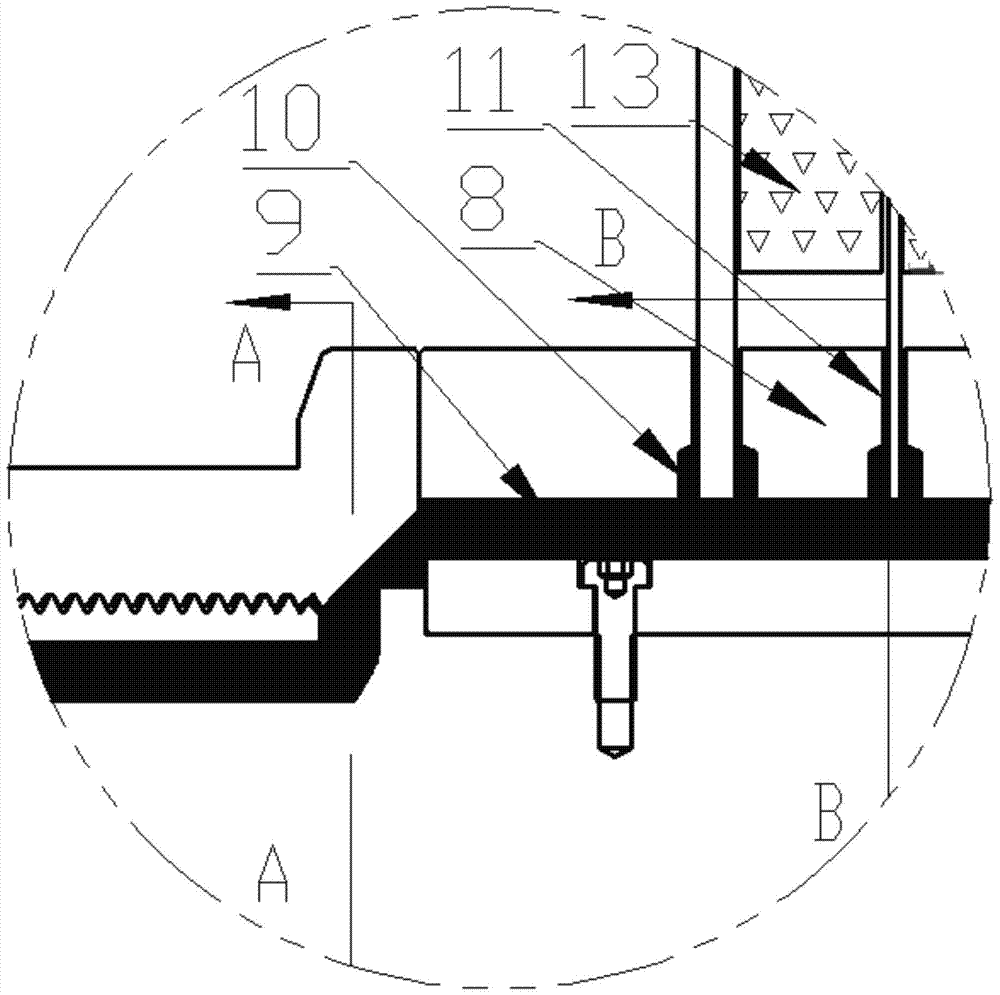

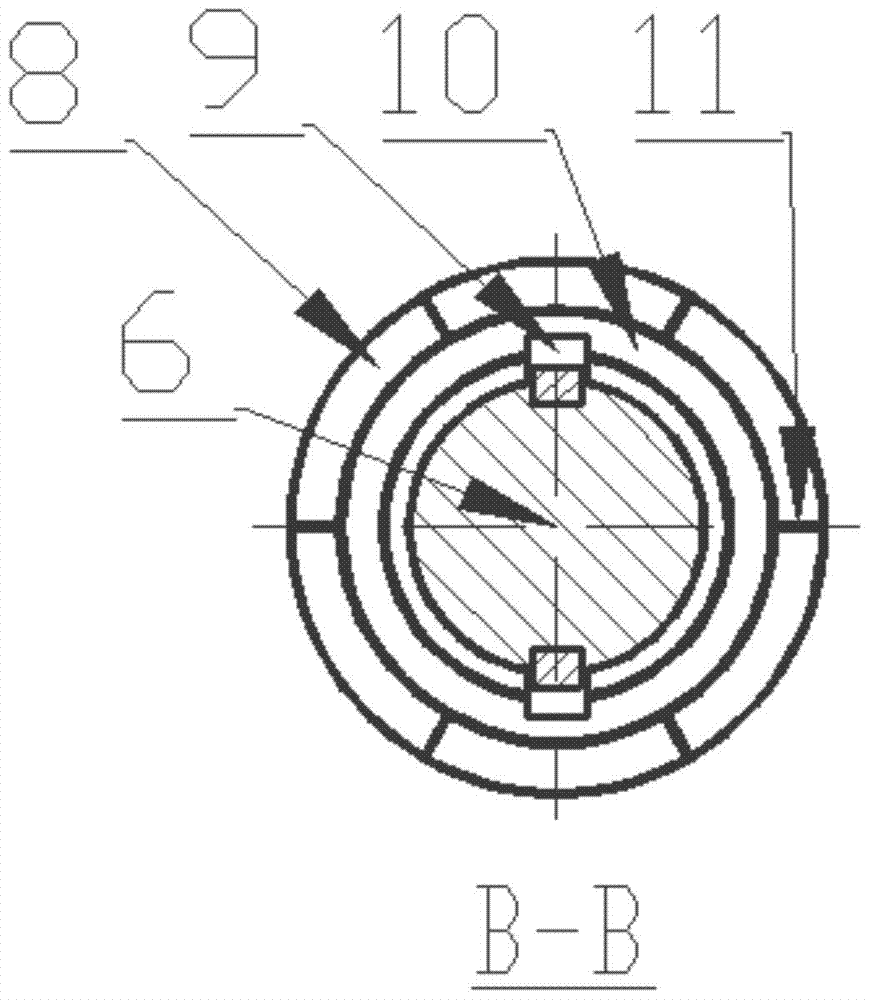

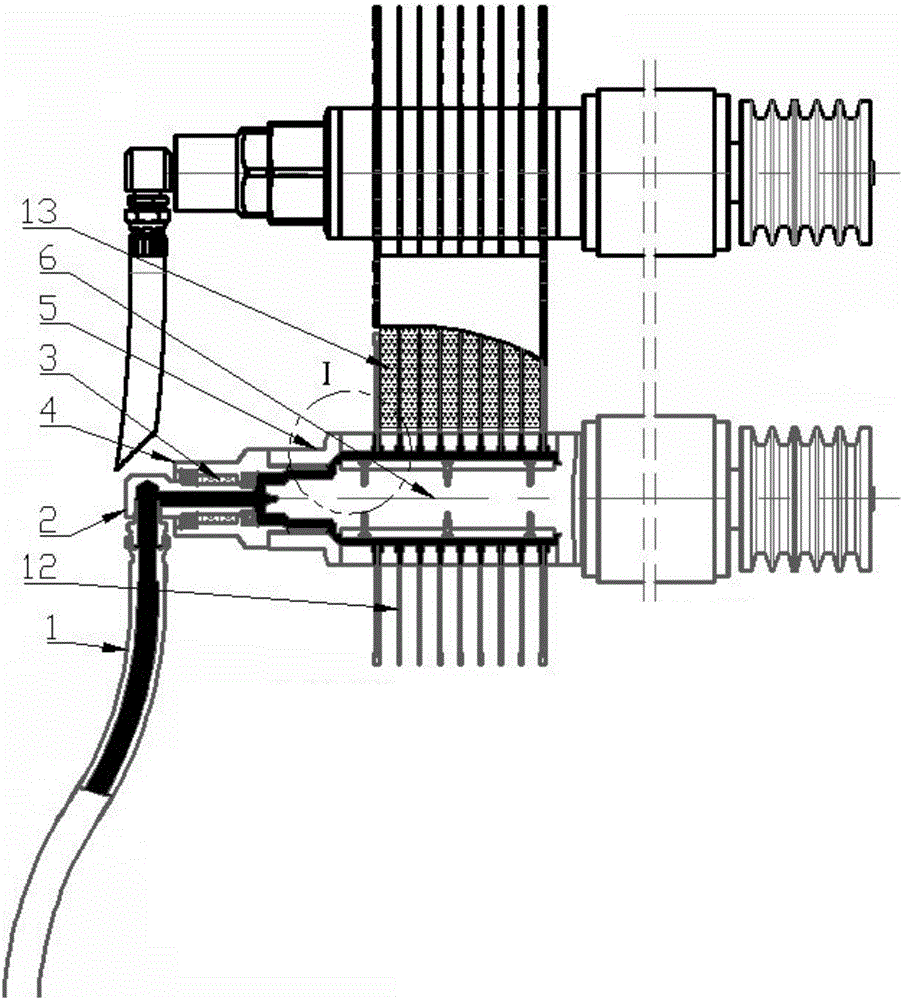

An air cooling device for cooling the circular saw blade

ActiveCN105150284BTo achieve the purpose of coolingReduce loss rateCircular sawsCarbide sawCircular saw

The invention relates to an air-cooling device for cooling circular saw blades, which comprises a compressed air delivery pipe, a saw blade shaft, a rotary joint and several pieces of circular saw blades, and the rotary joint includes a stationary shaft of the rotary joint and a sealing system of the rotary joint And the swivel joint swivel sleeve, wherein: the compressed air delivery pipe is connected to the stationary shaft of the swivel joint, and the swivel joint swivel sleeve is connected to the outer end of the saw blade shaft through the saw blade lock nut, so as to realize the connection between the swivel joint and the saw blade shaft. Through the air-cooling device of the present invention, the compressed refrigerated gas is sprayed out through the compressed air injection groove and then goes along the base of the circular saw blade until the hard alloy saw blade is finally absorbed by the dust collection system together with the sawdust. Part of the compressed and frozen air is sprayed into the saw kerf between the heavy bamboo (wood) glulam and the circular saw blade, thereby blowing away the dust sandwiched between and reducing the friction between the substrate of the circular saw blade and the heavy bamboo (wood) glulam , so as to achieve the purpose of cooling the circular saw blade, and also ensure the drying effect in the seam.

Owner:皇庭雅居家具海安有限公司

Noise-proof cemented carbide saw blade

The invention relates to a noise-proof cemented carbide saw blade, which comprises a saw blade body, a cemented carbide cutter head and a noise reduction device. The saw blade body is circular, and a through hole for fixing the saw blade body is provided at the center of the circle. , The saw teeth are evenly distributed on the peripheral edge of the saw blade body, and the saw teeth are inlaid with hard alloy cutter heads, and the noise reduction device is evenly distributed on the saw blade body. The invention has the advantages of simple and reasonable structure, convenient production and processing, good noise reduction and heat dissipation effects, high cutting precision, long service life and the like.

Owner:苏阳

A finishing process for the manufacture of solid carbide saw blades

ActiveCN110977031BImprove product qualityAvoid poor cutting effectEdge grinding machinesGrinding drivesCarbide sawElectric machinery

The invention relates to a fine machining treatment process for manufacturing an integrated hard alloy saw blade. The alloy saw blade treatment process adopts an alloy saw blade fine machining treatment device as follows. The alloy saw blade fine machining treatment device comprises a bottom plate, a top plate, a bearing mechanism, a locking mechanism, an upper burr grinding device and a lower burr grinding device; the bearing mechanism comprises a fixed rod, a bearing disc, an inner hole block and a connecting post; the upper burr grinding device comprises a fixed disc, a rotary motor, a bi-directional screw, screw nuts, an upper edge grinding element, a lower edge grinding element, a screw motor and an upper blade surface grinding mechanism; the alloy saw blade treatment process adopts the alloy saw blade fine machining treatment device comprises the following steps of S1, fixing a saw blade; S2, grinding and positioning; and S3, removing burrs. According to the fine machining treatment process for manufacturing the integrated hard alloy saw blade, the problems that the existing saw blade grinding machine can only perform primary single-surface grinding on the saw blade, much room is available for efficiency improvement, and a welding position between a saw body and saw teeth cannot be ground can be solved.

Owner:山东华大金科新材料有限公司

A hard alloy saw chain

ActiveCN103331487BEliminates solder brittlenessAvoid brittle fractureMetal sawing toolsButt weldingCarbide saw

The invention relates to a hard alloy saw chain of a chain saw. The welding face of a hard alloy tooth block and cutting teeth is made to be a cylindrical face, the arc radius of the cylindrical face is 2 to 5mm, and the optimal arc radius is 2.5 to 4mm. The shape of the tooth block is made to be similar to a frustum of a square pyramid, and the height of inner side face of the teeth block is lower than the height of outer side face of the tooth block. The tooth side face of the tooth block concaves inwards and perpendicularly, and a concave angle is 1 degree to 3 degrees. The intersection of the tooth top face of the tooth block and the tooth side face of the tooth block is made to be a circular bead, the tooth tip of the tooth block is made to be a section of arc line, the arc radius of the tooth tip is 0.2 to 0.8mm, and the optimal arc radius of the tooth tip is 0.3 to 0.4mm. According to the hard alloy saw chain, due to the adoption of butt welding, the hard alloy tooth block is welded with the cutting teeth, after the tooth block is welded, local high-temperature tempering is conducted, the joining strength of a welding line is 4 times higher than the jointing strength of brazing, the hard alloy saw chain is very firm, and no teeth drop during saw cutting.

Owner:缙云县鼎盛工具制造厂(普通合伙)

Impact-resistant spacer carbide saw and method of manufacture

ActiveCN110744139BReasonable structural designReduce manufacturing costMetal sawing tool makingMetal sawing toolsRooted toothCarbide saw

Owner:孙禹平

Air cooling device used for circular saw blade cooling treatment

ActiveCN105150284ATo achieve the purpose of coolingReduce loss rateCircular sawsCarbide sawCircular saw

The invention relates to an air cooling device used for circular saw blade cooling treatment. The air cooling device comprises a compressed air delivery pipe, a saw blade shaft, a rotation connector and a plurality of pieces of circular saw blades. The rotation connector comprises a rotation connector stationary shaft, a rotation connector sealing system and a rotation connector rotation sleeve. The compressed air delivery pipe is connected in the rotation connector stationary shaft, and the rotation connector rotation sleeve is connected with the outer end of the saw blade shaft through a saw blade lock nut to achieve the connection of the rotation connector and the saw blade shaft. According to the air cooling device, compressed-frozen air goes along the base bodies of the circular saw blades after being sprayed out through a compressed air spraying trough until the compressed-frozen air reaches a hard alloy saw edge and is absorbed by a dust collection system along with saw dust finally. At the same time, part of the compressed-frozen air is further sprayed into saw gaps between heavy bamboo (wood) laminated material and the circular saw blades, so that dust clamped between the heavy bamboo (wood) laminated material and the circular saw blades is blown away, friction between the base bodies of the circular saw blades and the heavy bamboo (wood) laminated material is lowered; therefore, the purpose of cooling the circular saw blades is achieved, and the drying effect in the saw gaps is also ensured.

Owner:皇庭雅居家具海安有限公司

A kind of cemented carbide saw blade and its welding method

ActiveCN107838494BSolve the problem of stress crackingMetal sawing tool makingSoldering apparatusTool bitTempering

The invention discloses a cemented carbide saw blade and a welding method thereof. The method includes: S1, heating the placed cemented carbide cutting head, saw blade base, welding wire and flux; S2, heating at 760°C- Under the temperature environment of 840 °C, the molten welding wire is spread in the gap between the cemented carbide cutter head and the saw blade base by the wetting effect of the flux; S3, cooling to obtain a preliminary welded body, when the temperature of the preliminary welded body is low At 350 ° C, the preliminary welded body is tempered for the first time; S4, within 1 to 3 hours after the first tempering, the preliminary welded body is tempered for the second time to obtain a cemented carbide saw blade; The secondary tempering needs to be performed in a closed container and the temperature of each space in the container should be kept consistent. The present invention solves the problem of tooth base fracture during cutting and the problem of stress cracks between adjacent teeth.

Owner:ZHONGSHAN KINGWAVE SAW BLADE MFG LTD

Full-automatic edge grinder for hard alloy saw blades

InactiveCN103447619ASimple structureIncrease stiffnessSawing tools dressing arrangementsAlloyEngineering

A full-automatic edge grinder for hard alloy saw blades consists of a motor, a flywheel, a pinion, a gearwheel, clutch, a bent axle, a sliding block and an electromagnet, and is characterized in that a spindle of the motor is connected with the flywheel through a transmission belt; the other end of a transmission shaft on the flywheel is connected with the pinion; the flywheel is meshed with the gearwheel; the electromagnet controls the clutch, so that the bent axle and the gearwheel move synchronously; and the bent axle drives bars on the sliding block to move transversely, so that the bars are automatically ground. The full-automatic edge grinder which is connected with a machine tool in parallel has the advantages of simple structure, high rigidity, high speed, high positional accuracy and the like. The full-automatic edge grinder is mainly researched by people in the direction of developing flexible and novel production equipment; and the full-automatic edge grinder can be connected with a numerically-controlled edge grinding machine tool in parallel to form a novel parallel machine tool, the working space and the flexibility of the machine are increased, and the function diversification and the manufacture flexibility of the machine tool are realized.

Owner:孙莲英

A device for detecting welding angle of carbide saw blade head

ActiveCN109884071BQuality improvementRealize online detectionOptically investigating flaws/contaminationTool bitCarbide saw

The utility model relates to a detection device for the welding angle of a carbide saw blade head, which belongs to the detection field of a carbide saw blade. In order to solve the problem of low detection efficiency in the prior art, the detection of cemented carbide saw blades usually adopts manual random inspection; The frame is equipped with a lifting and rotating unit and a laser detection unit. The laser detection unit includes several laser components. The saw blade is sent to the detection station, and the laser detection unit sends the detection signal to the control unit; the invention realizes efficient and accurate end-to-end welding angle detection, and provides strong technical support for the welding quality and service life of the cemented carbide saw blade .

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com