Carbide alloy metal saw production process

A saw blade milling cutter and cemented carbide technology, which is applied in milling cutters, metal processing equipment, milling machine equipment, etc., can solve the problem of no saw blade milling cutter production method, etc., and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

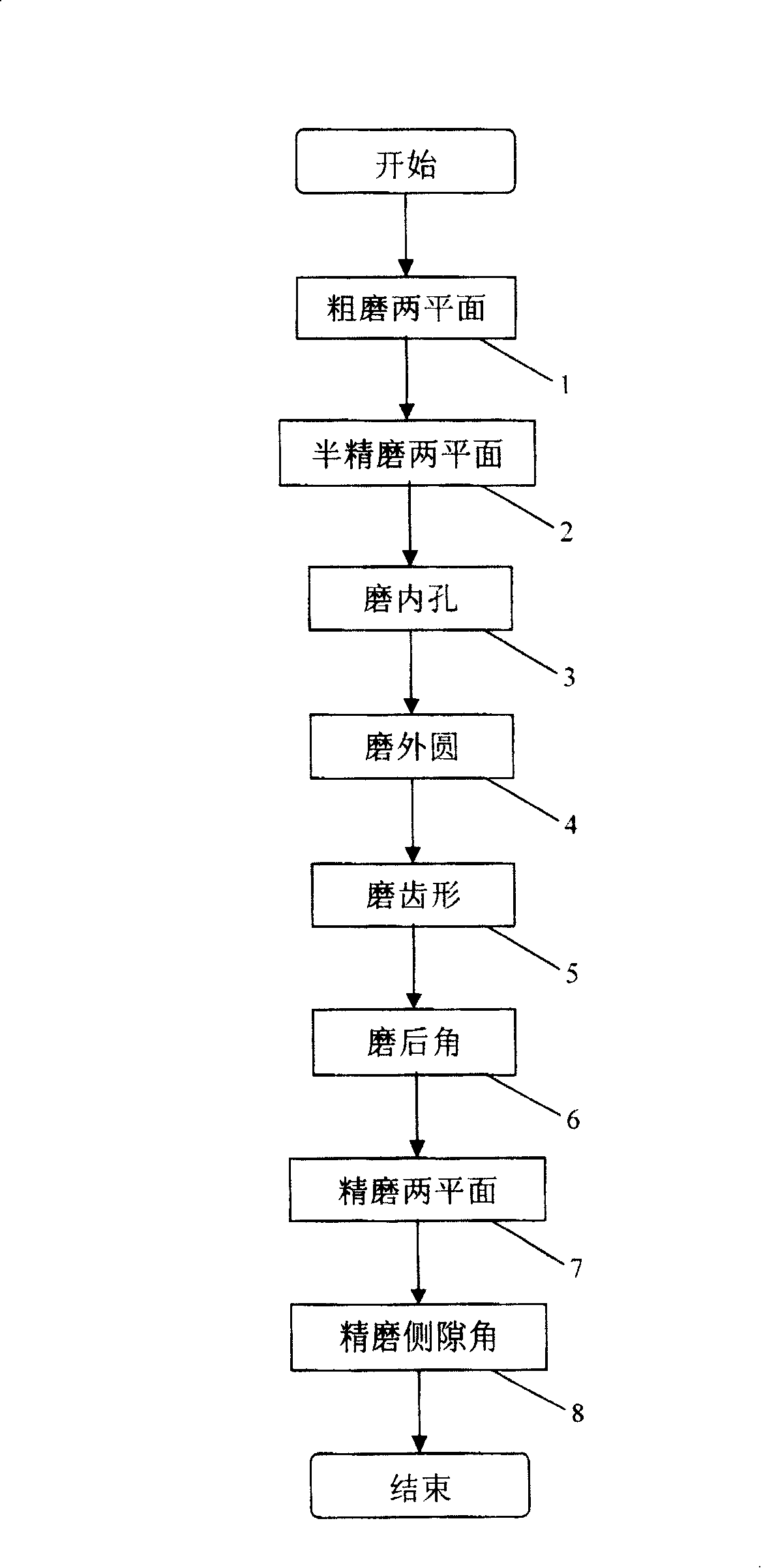

[0022] figure 1 It is a flowchart of the manufacturing process of the cemented carbide saw blade milling cutter of the present invention. Include the following steps in turn:

[0023] Rough grinding of two planes 1: Use a universal tool grinder and a bowl-shaped grinding wheel with a grain size of about 120 to roughly grind the two planes of the workpiece, and grind the thickness of the workpiece to 0.40mm-0.42mm; the thickness of the workpiece is preferably ground to 0.42mm; requirements The runout at the outer edges of the two planes is not more than 0.01mm, and the moving speed of the workpiece is between 10-12m / min.

[0024] Semi-finishing two planes 2: using a cylindrical grinder and a parallel grinding wheel with a grain size of about 100 to semi-finish the two planes of the workpiece, and grind the thickness of the workpiece to 0.26mm-0.28mm; the thickness of the workpiece is preferably ground to 0.28mm; It is required that the runout at the outer edges of the two pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com