A hard alloy saw chain

A technology of hard alloy and hard alloy teeth, which is applied in the field of chain saws, can solve the problems of easy cracking of welding seams, easy cracking of tooth blocks, difficult sawing resistance, etc., and achieve the effect of eliminating welding brittleness and preventing brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

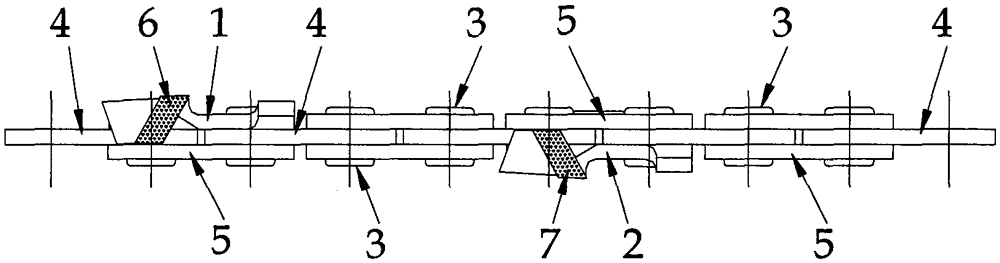

[0022] Figure 1-Figure 4 Among them, the cemented carbide saw chain is composed of a left cutting tooth chain piece 1, a right cutting tooth chain piece 2, a chain shaft 3, a transmission piece 4 and a connecting piece 5. The tooth pitch of the standard tooth pitch cemented carbide saw chain is 4 pitches. The tooth pitch of the closely spaced cemented carbide saw chain is 2 pitches, the left carbide tooth block 6 is welded on the left cutting tooth chain piece 1, and the right cemented carbide tooth piece 7 is welded on the right cutting tooth chain piece 2. The structures and shapes of the left cutter chain piece 1 and the right cutter chain piece 2 are completely symmetrical.

[0023] Figure 5-Figure 14 Among them, both the left cutter chain piece 1 and the right cutter chain piece 2 are composed of cutting teeth 8 , material limiting teeth 9 , connecting parts and two riveting holes 10 . The welding surfaces of the left cemented carbide tooth block 6 and the right cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com