Manufacturing process of high-performance nano-material ceramic thin-film device

A technology of nano-materials and ceramic films, applied in the field of nano-ceramic materials, can solve the problems of easy brittle cracking, poor film toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

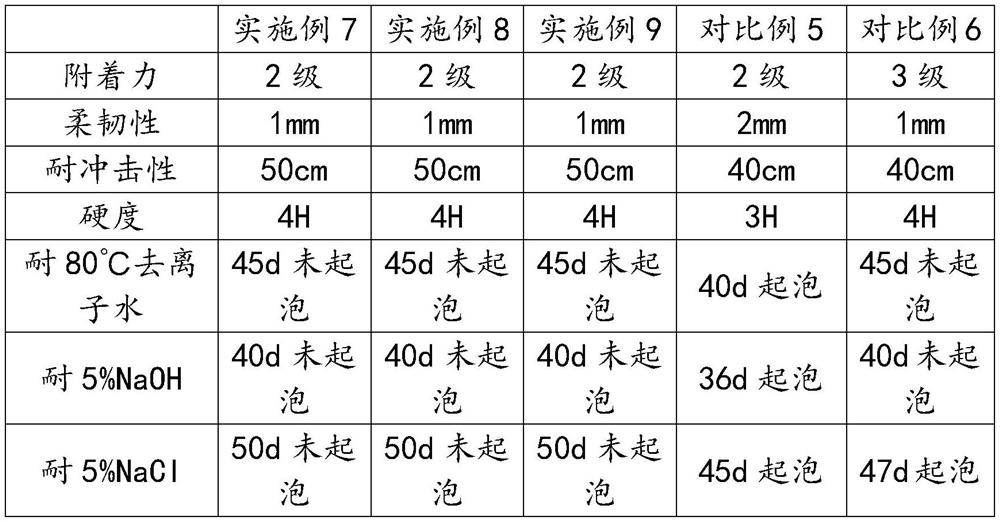

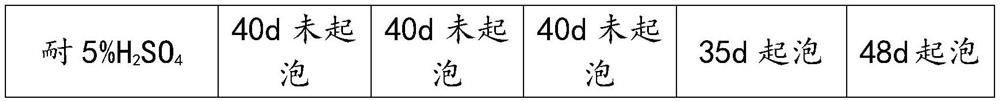

Examples

Embodiment 1

[0035] Preparation of hydrogen-containing POSS:

[0036] A1. Mix 100mL isopropanol, 0.12mol phenyltrimethoxysilane, 2mg deionized water and 0.1mol flake sodium hydroxide, stir well, heat the reaction system to 73°C with an oil bath, and reflux under nitrogen atmosphere After reacting for 5 hours, then stirring and reacting at room temperature for 48 hours, the obtained mixed solution was subjected to rotary evaporation to remove isopropanol, and vacuum dried at 60°C for 18 hours to obtain octaphenyl polysilsesquioxane sodium salt;

[0037]A2. Add 0.1mol octaphenyl polysilsesquioxane sodium salt into a three-necked flask, under nitrogen protection, add 150mL anhydrous tetrahydrofuran, stir well, add 0.21mol triethylamine, react in ice bath at 0°C for 1h, use Slowly add 70 mL of tetrahydrofuran solution containing 0.25 mol of methyldichlorosilane into the constant pressure funnel dropwise at a rate of 2 drops / second, react for 6 hours, then raise the temperature to room temperat...

Embodiment 2

[0039] Functional additives are made by:

[0040] S1. Add 1 mol of carborane and 100 mL of anhydrous tetrahydrofuran into the three-necked flask, blow in nitrogen to drive away the air in the three-necked flask, and add 2.1 mol of n-butyllithium dropwise with a constant pressure dropping funnel at 0°C in a nitrogen atmosphere. Hexane solution, ensure that the temperature of the reaction system remains at 0±1°C during the dropping process, and the dropping rate is 1 drop / second. After the dropping is complete, slowly warm up to room temperature, continue to stir for 2 hours, and then add 80mL of 2.1mol benzyl Trimethylammonium hydroxide methanol solution, stirred at -0.07MPa, 40°C for 30min to remove residual water and methanol in the system, and then dropwise added 2.1mol 1,3-bis(3-amino Anhydrous tetrahydrofuran solution of propyl)-1,1,3,3-tetramethyldisiloxane, the dropping rate is 1 drop / second, after the drop is complete, slowly raise the temperature and reflux for 12 hour...

Embodiment 3

[0044] Functional additives are made by:

[0045] S1. Add 1 mol of carborane and 100 mL of anhydrous tetrahydrofuran into the three-necked flask, blow in nitrogen to drive away the air in the three-necked flask, and add 2.3 mol of n-butyllithium dropwise with a constant pressure dropping funnel at 0°C in a nitrogen atmosphere. Hexane solution, ensure that the temperature of the reaction system remains at 0±1°C during the dropping process, and the dropping rate is 1 drop / second. After the dropping is complete, slowly warm up to room temperature, continue to stir for 2 hours, and then add 2.3mol benzyl Trimethylammonium hydroxide methanol solution, stirred at -0.07MPa, 40°C for 30min, remove residual water and methanol in the system, then add 90mL solution containing 2.3mol 1,3-bis(3- Aminopropyl)-1,1,3,3-tetramethyldisiloxane in anhydrous tetrahydrofuran solution, the dropping rate is 2 drops / second, after the drop is complete, slowly heat up and reflux for 12 hours, after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com