Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

378 results about "Rooted tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

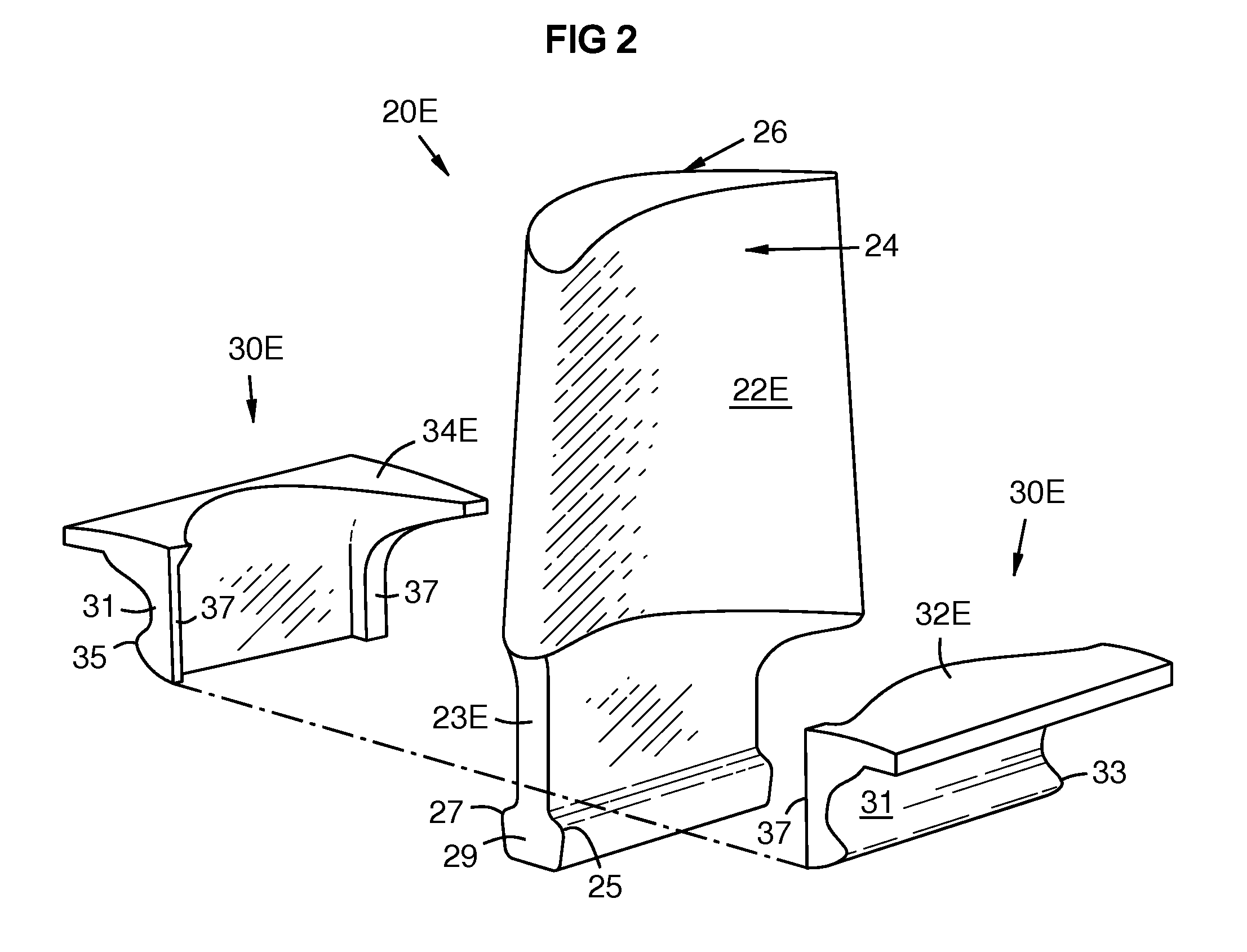

Modular turbine airfoil and platform assembly with independent root teeth

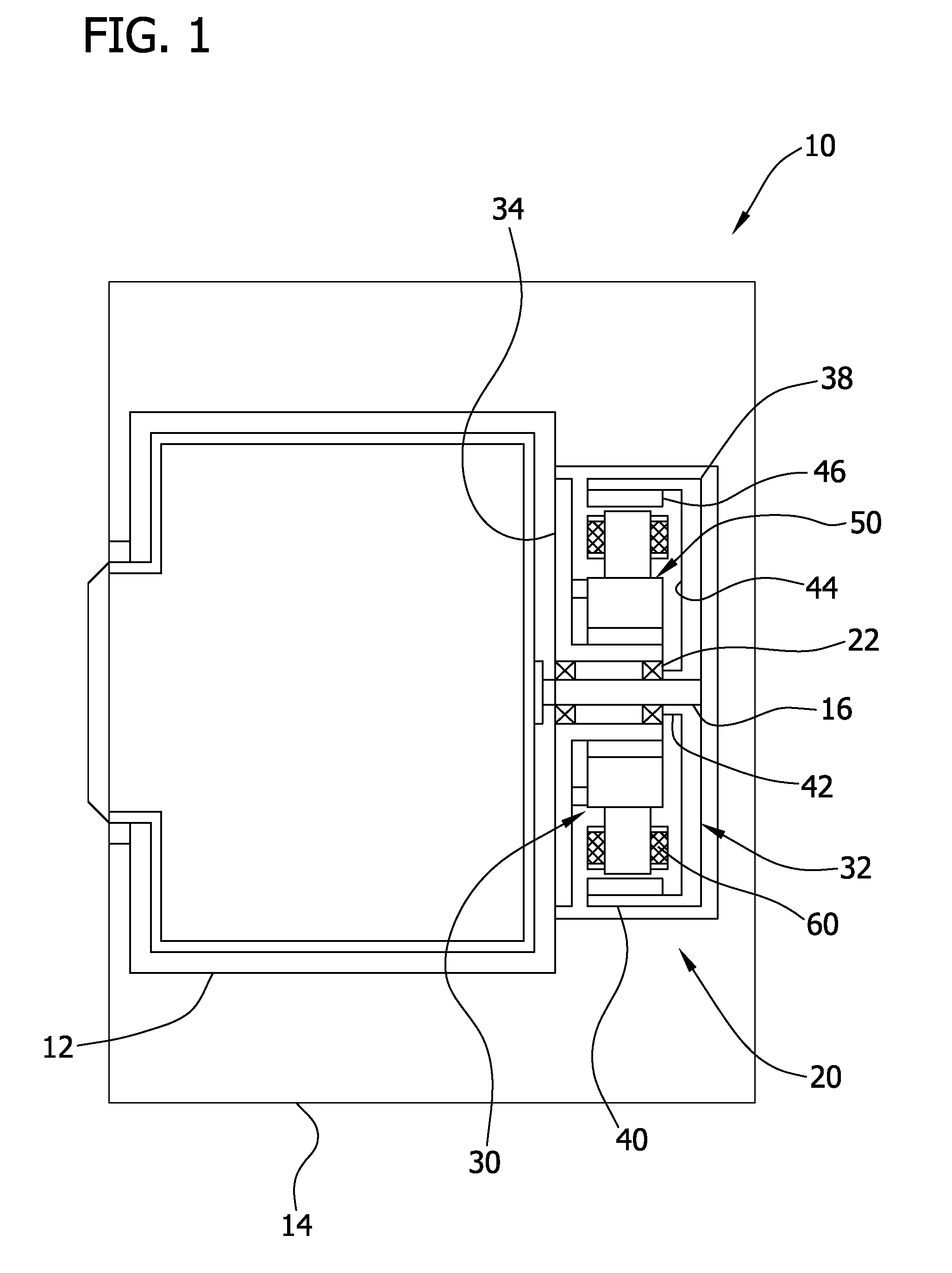

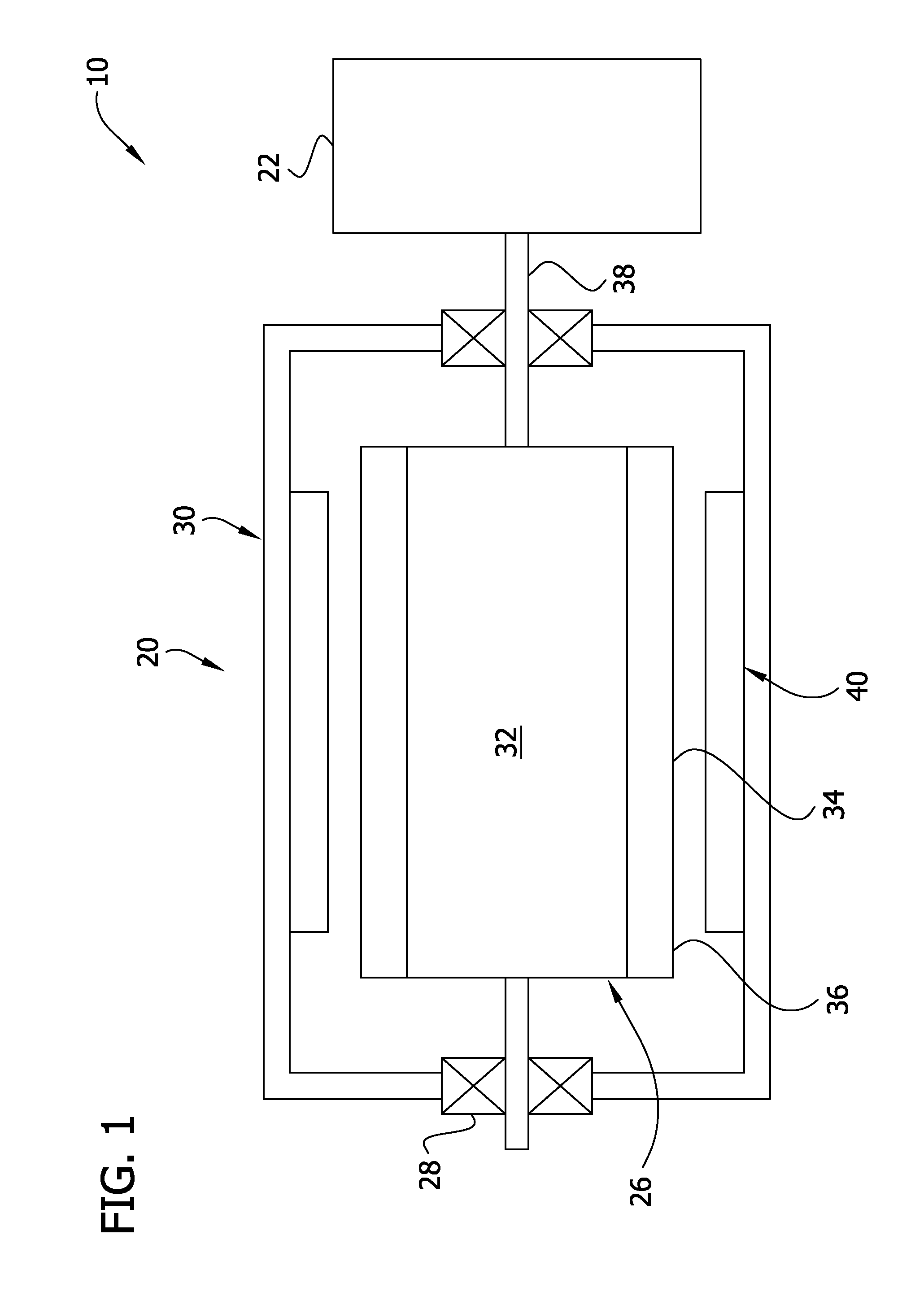

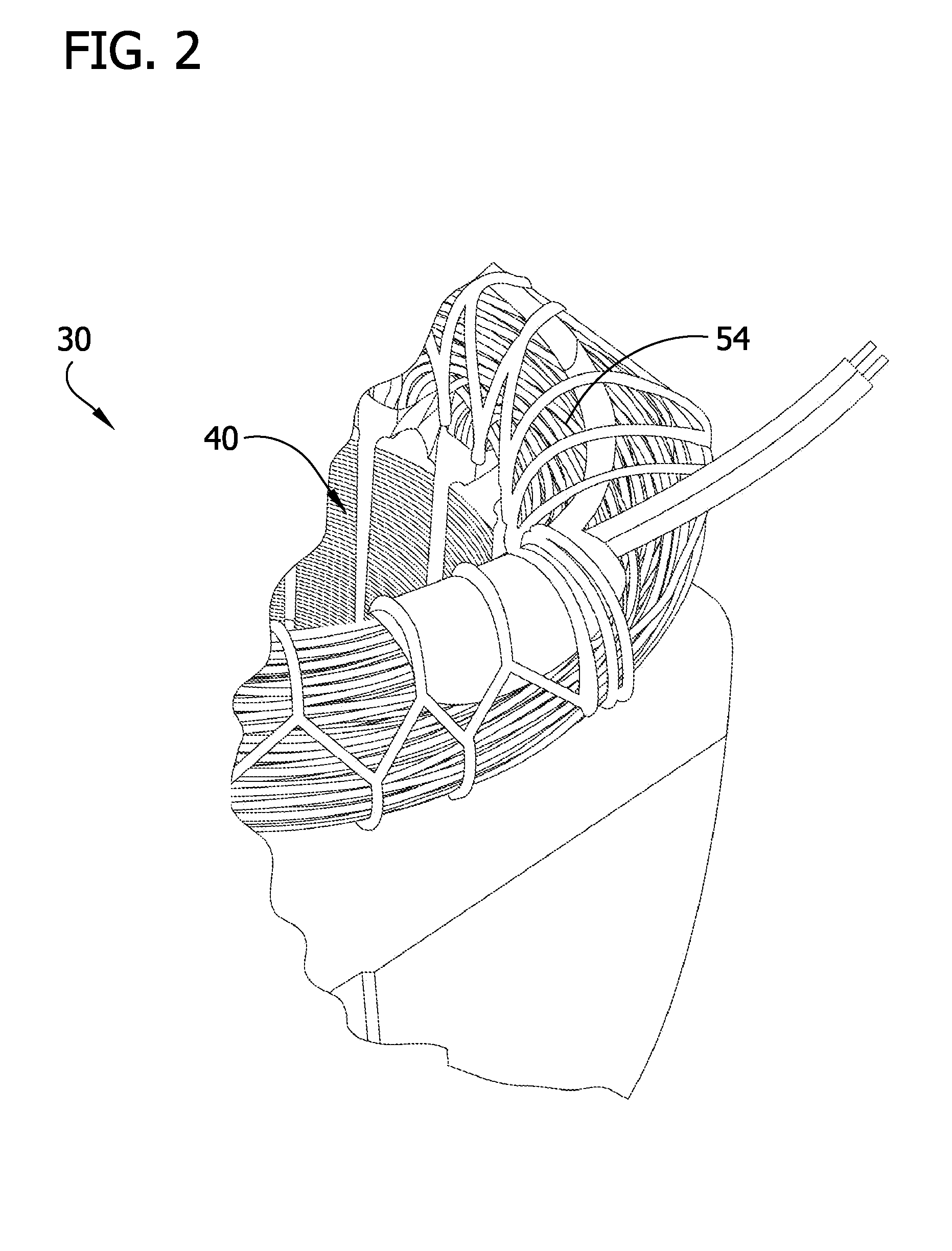

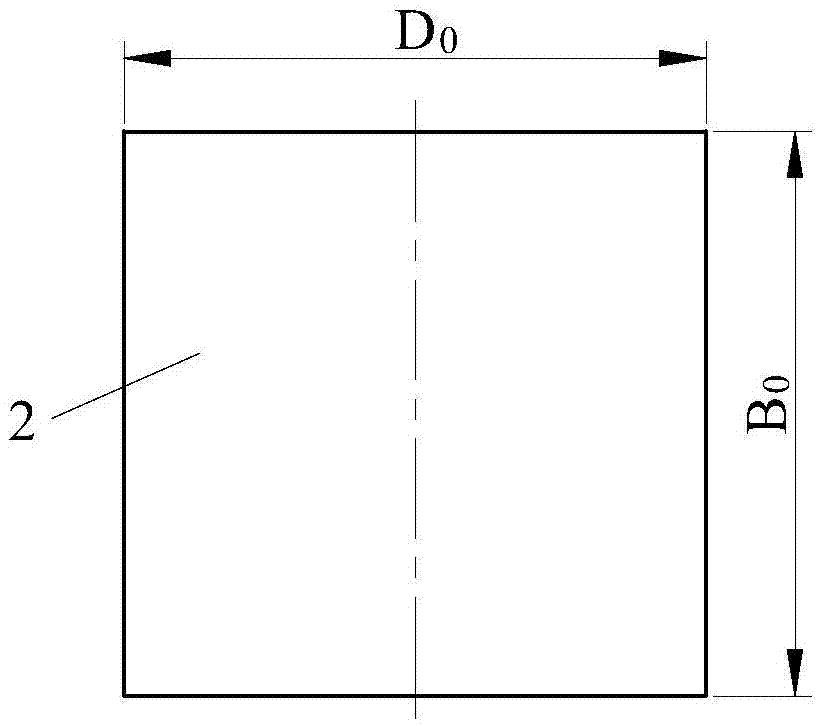

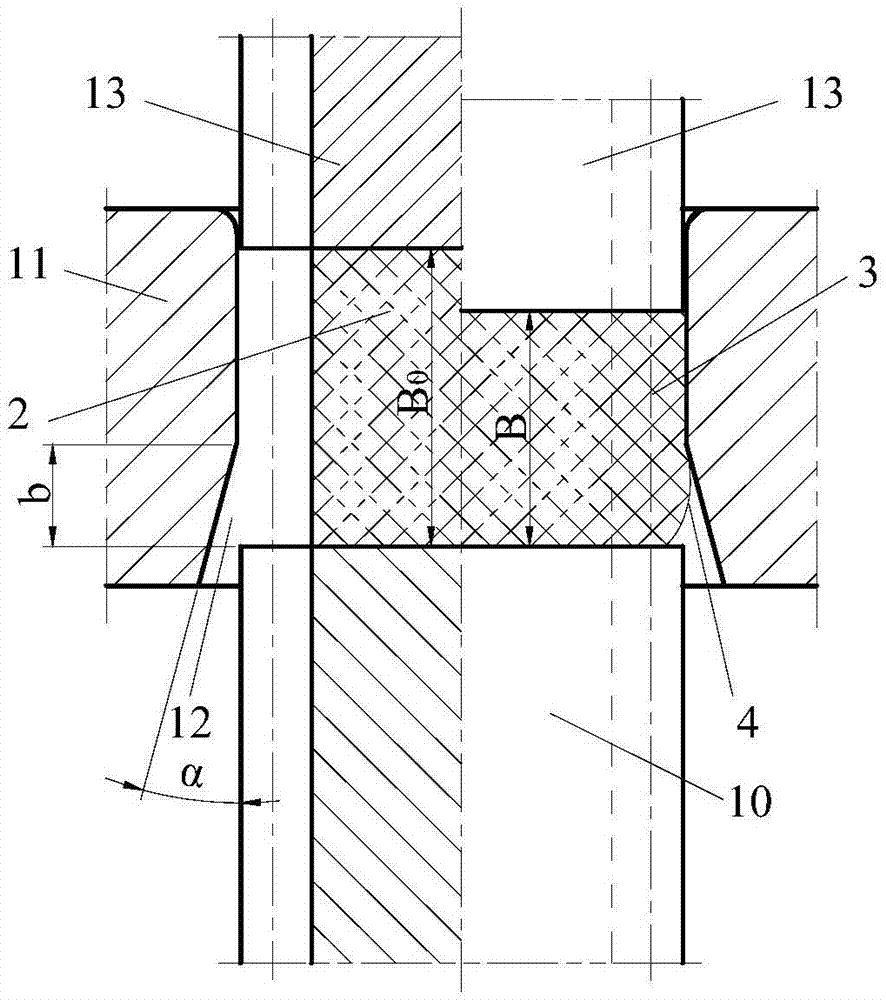

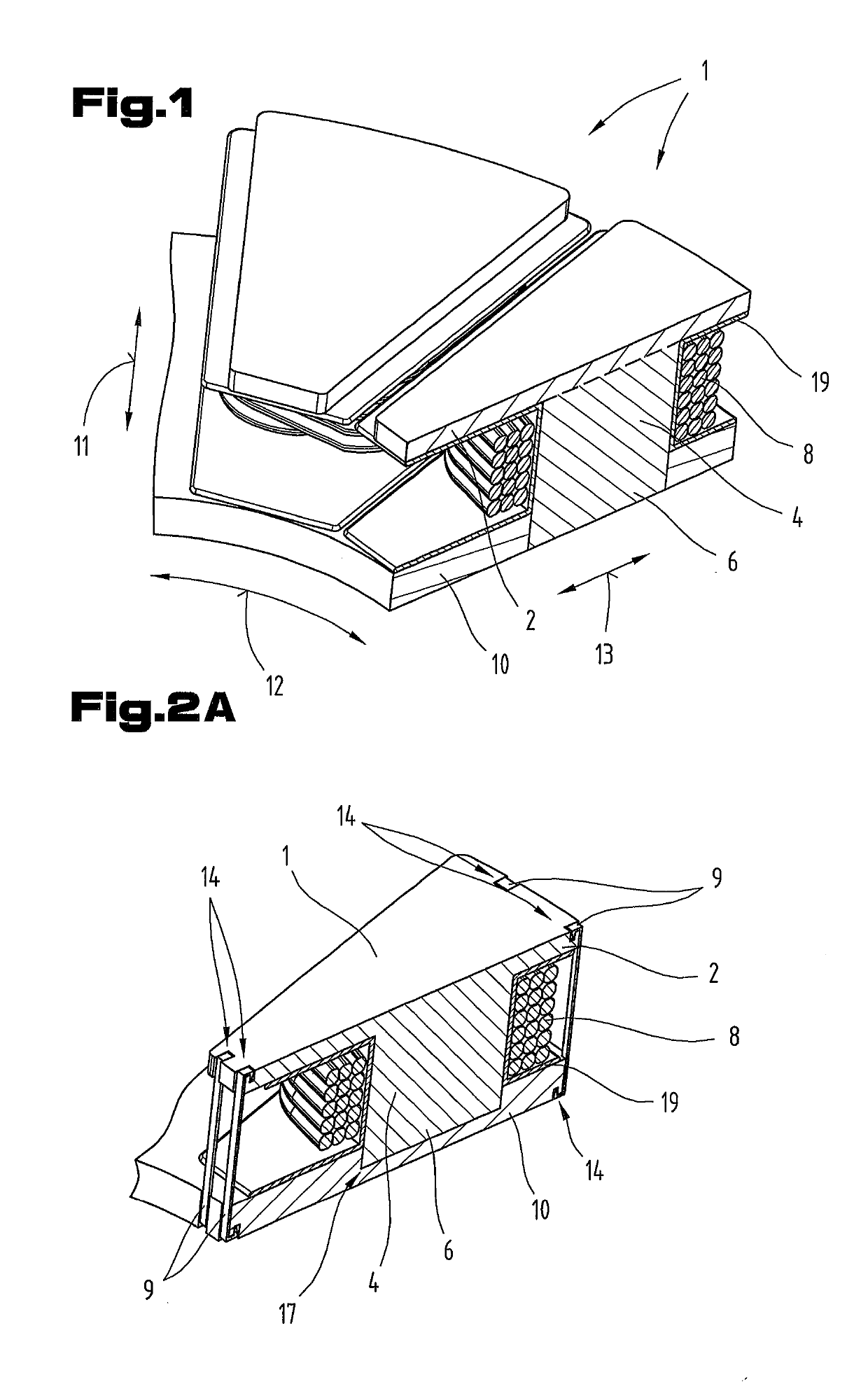

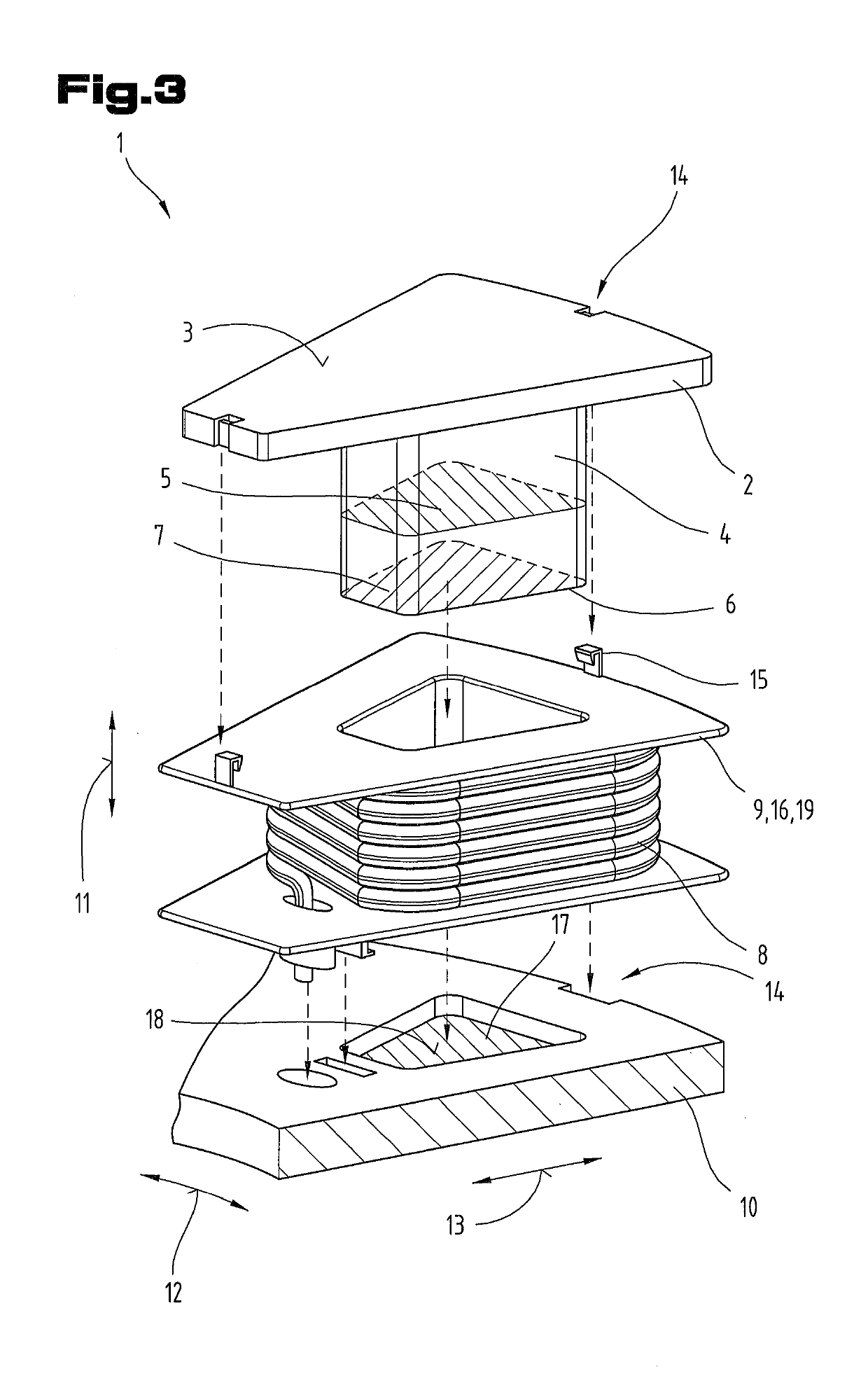

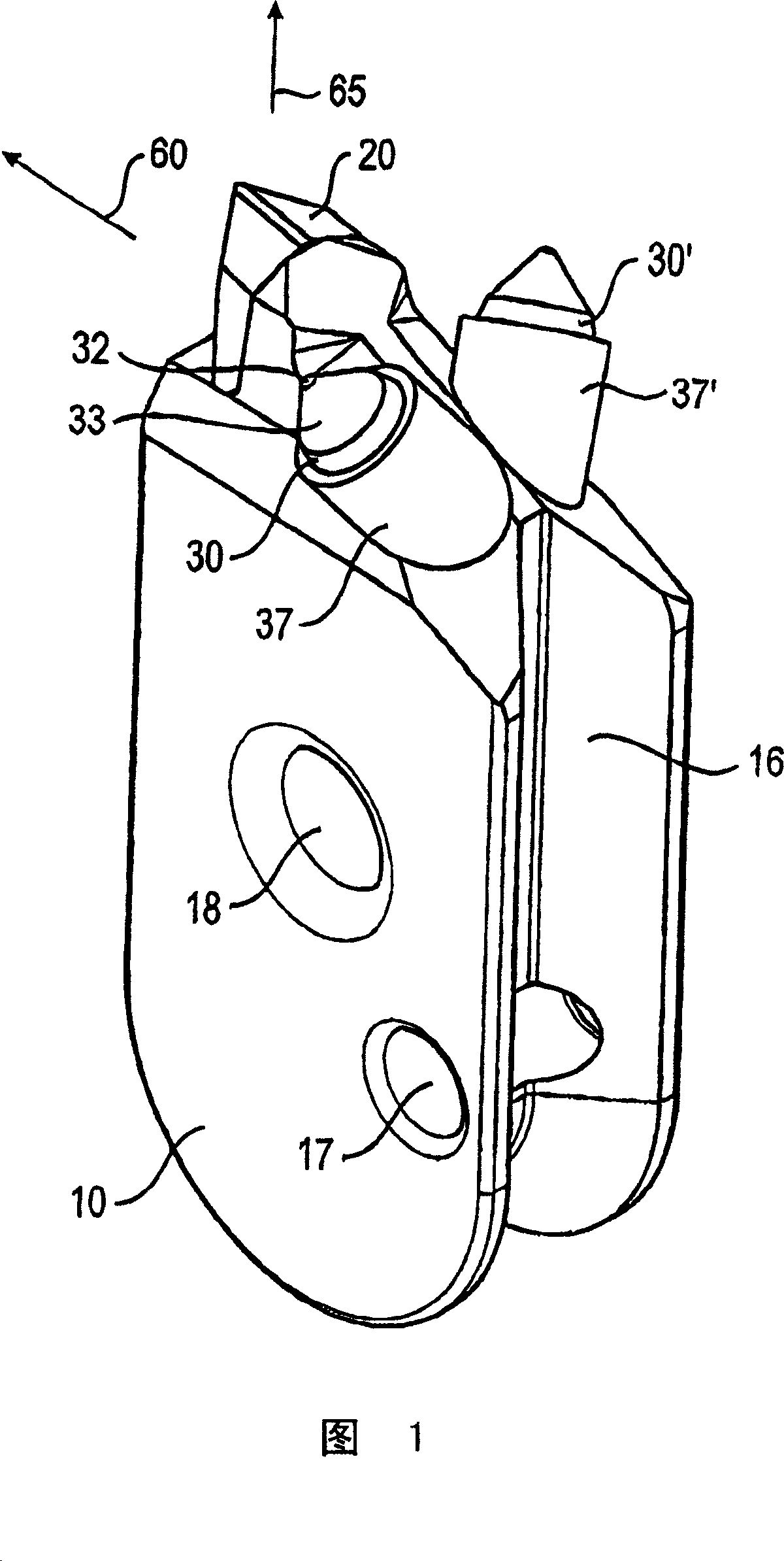

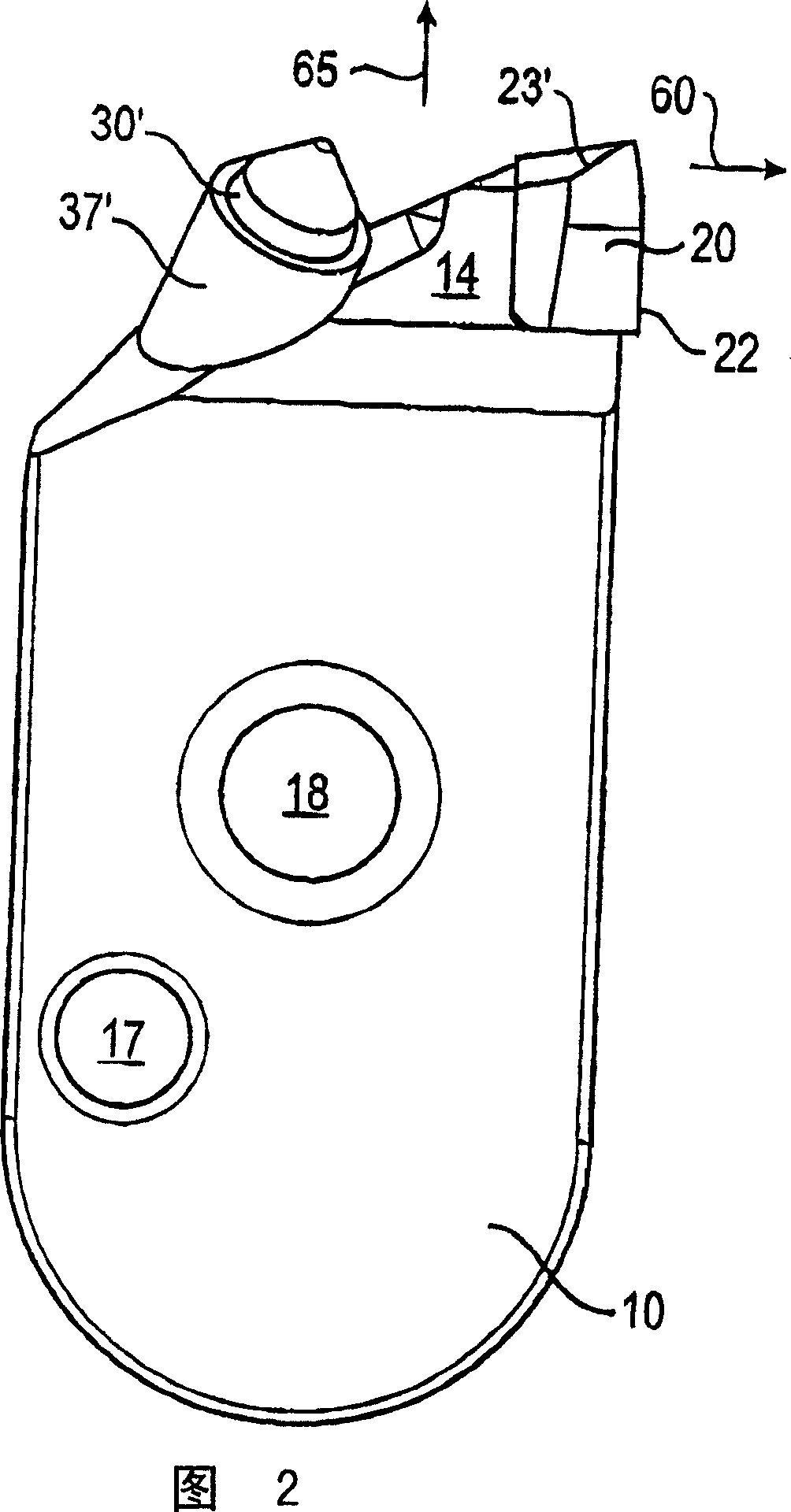

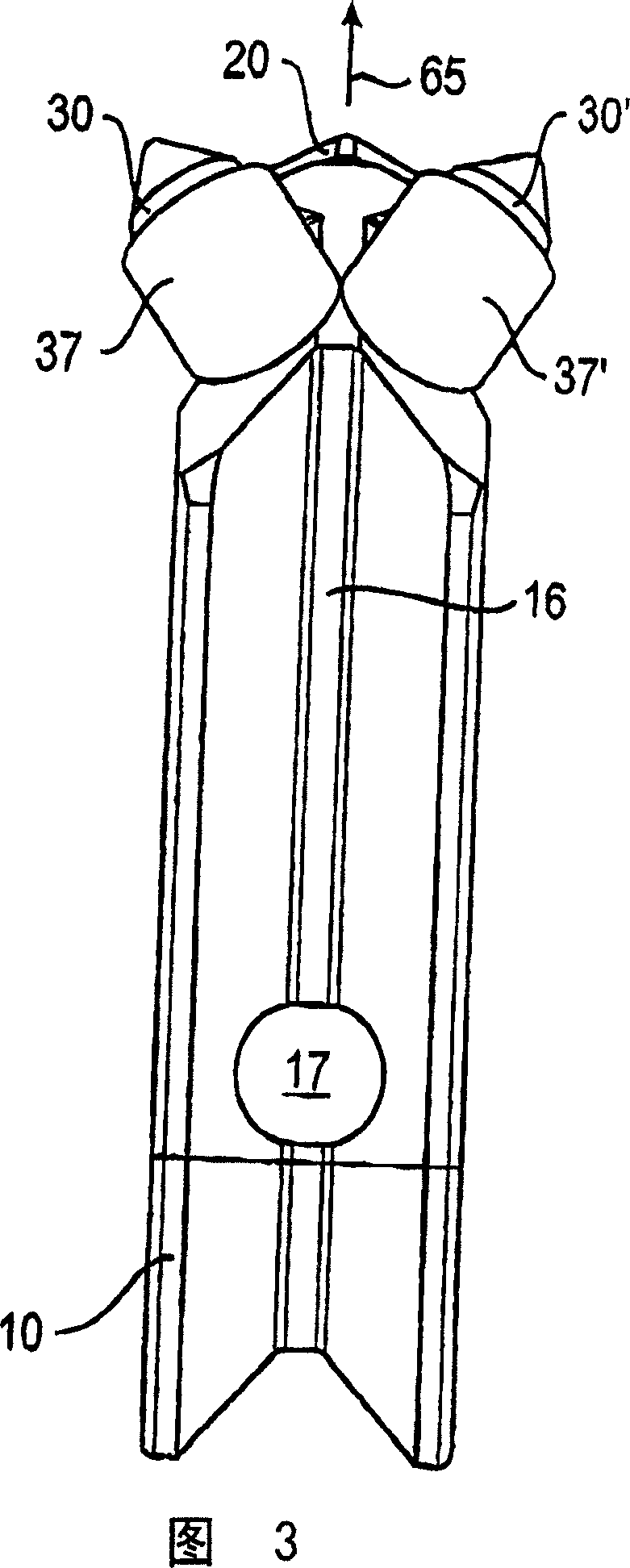

A turbine airfoil (22E-H) extends from a shank (23E-H). A platform (30E-H) brackets or surrounds a first portion of the shank (23E-H). Opposed teeth (33, 35) extend laterally from the platform (30E-H) to engage respective slots (50) in a disk. Opposed teeth (25, 27) extend laterally from a second portion of the shank (29) that extends below the platform (30E-H) to engage other slots (52) in the disk. Thus the platform (30E-H) and the shank (23E-H) independently support their own centrifugal loads via their respective teeth. The platform may be formed in two portions (32E-H, 34E-H), that are bonded to each other at matching end-walls (37) and / or via pins (36G) passing through the shank (23E-H). Coolant channels (41, 43) may pass through the shank beside the pins (36G).

Owner:SIEMENS ENERGY INC

Quenching and tempering method in tooth punching process of gear with medium-hard tooth surface

InactiveCN102501035AHigh hardnessReduce pittingSolid state diffusion coatingFurnace typesHobbingTempering

Owner:NANJING JINXIN TRANSMISSION EQUIP

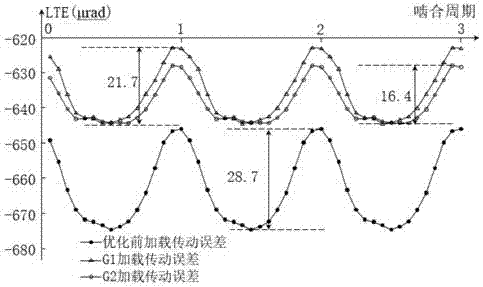

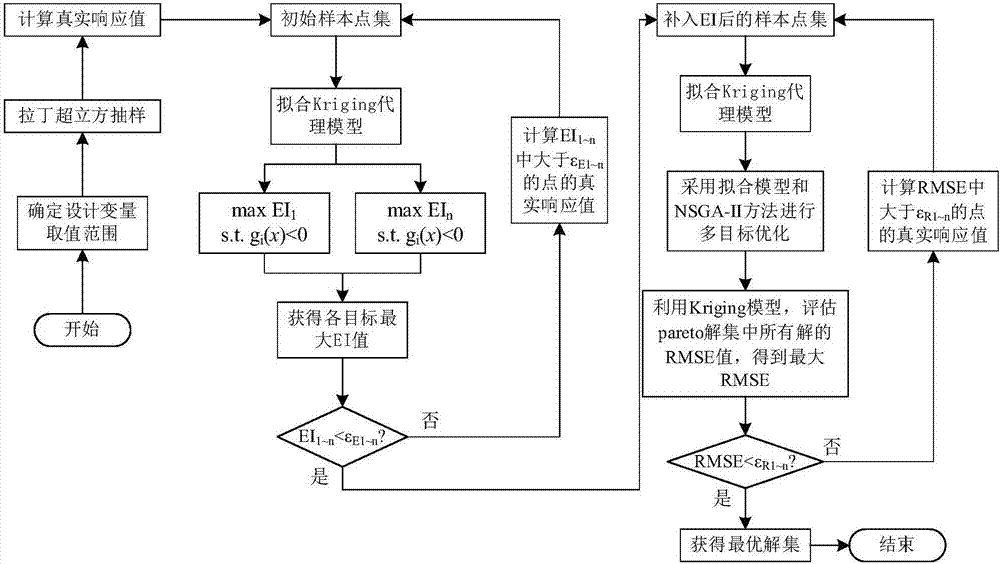

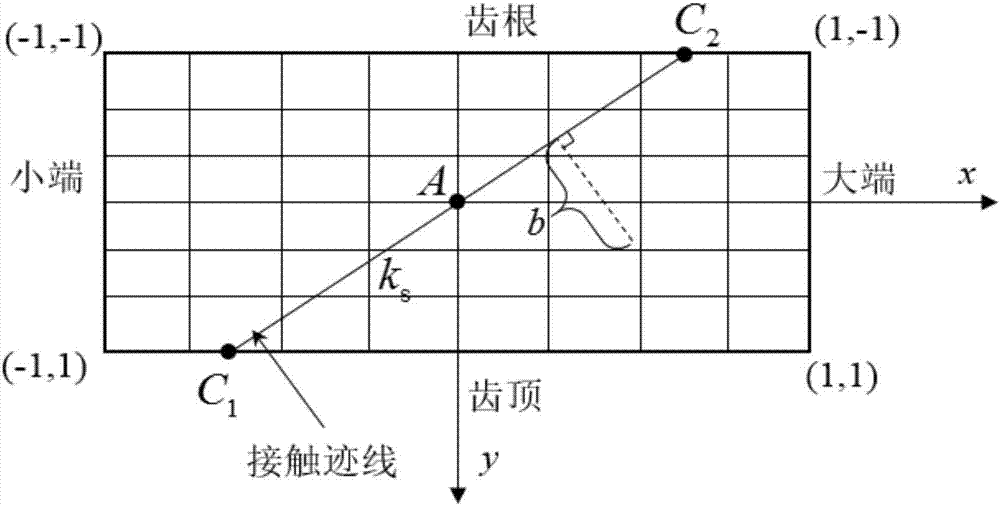

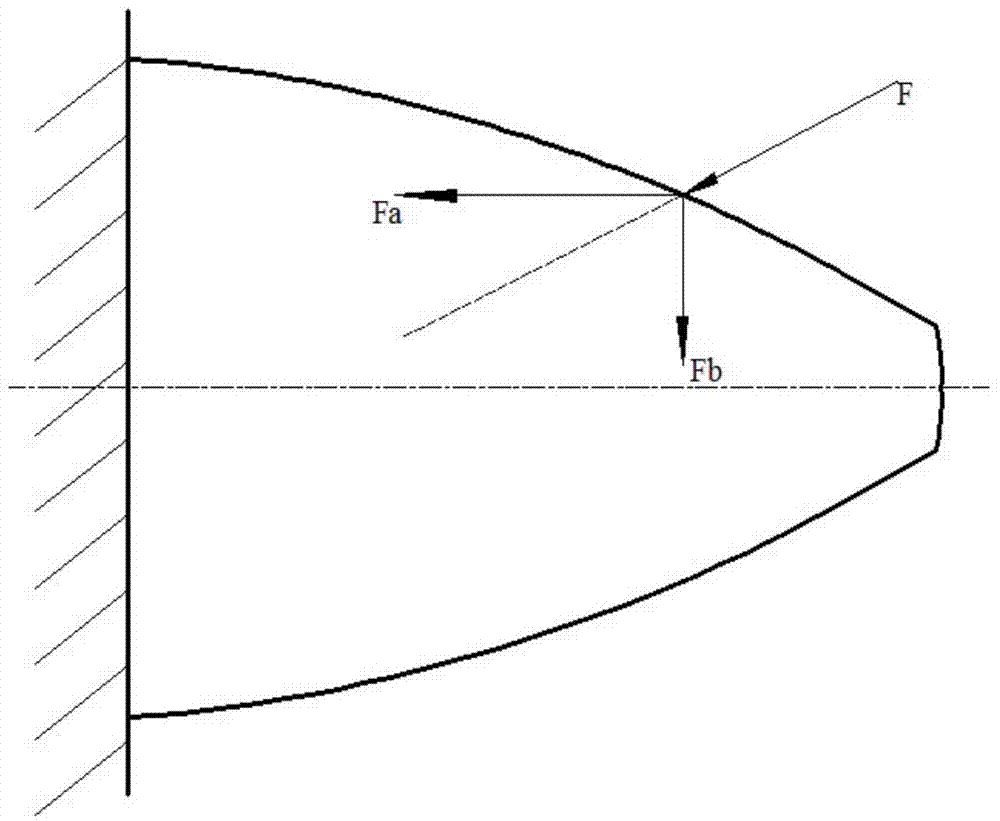

Spiral bevel gear tooth surface loading performance multi-objective optimization method

ActiveCN107577876AImprove loading effectAvoid broken teethSpecial data processing applicationsMathematical modelRooted tooth

The invention relates to a spiral bevel gear tooth surface loading performance multi-objective optimization method. The method is characterized by comprising the following steps that firstly, a mathematical model of a spiral bevel gear tooth surface loading performance multi-objective optimization problem is established, and test design sample points are obtained; secondly, a tooth surface loadingcontact analysis method considering tooth root bending stress is established, tooth surface loading contact analysis is conducted on the test design sample points, target functions corresponding to the test design sample points and response values of the target functions are obtained, and then an initial sample point set including the test design sample points and the corresponding response values is obtained; thirdly, a Kriging proxy model is fitted on the basis of the initial sample point set, the mathematical model of the spiral bevel gear tooth surface loading performance multi-objectiveoptimization problem is solved, and the optimal solution set of the spiral bevel gear tooth surface loading performance multi-objective optimization problem is obtained. The method is high in calculation efficiency, high in calculation accuracy and capable of being widely applied to spiral bevel gear tooth surface loading performance multi-objective optimization.

Owner:TSINGHUA UNIV +1

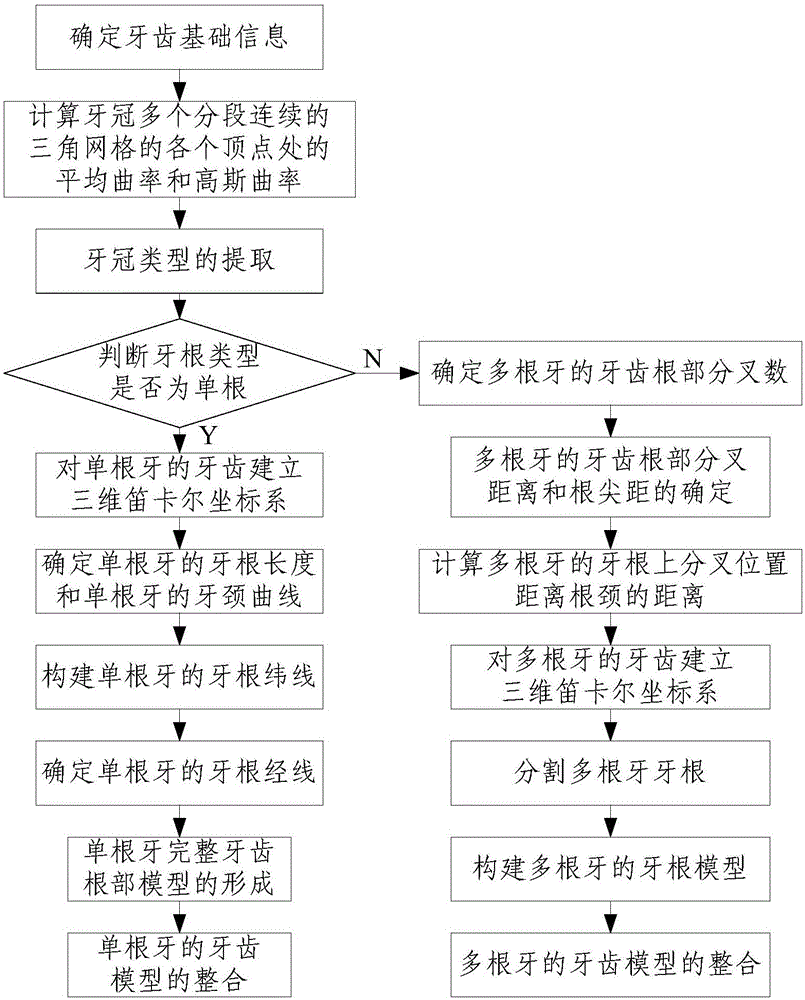

Tooth modeling method based on dental crown and tooth root characteristics

ActiveCN106295170AGet data fastHigh precisionMedical simulationSpecial data processing applicationsRooted toothSingle tooth

The invention discloses a tooth modeling method based on dental crown and tooth root characteristics. The tooth modeling method includes the following steps that 1, tooth basis information is determined; 2, the average curvature and the gaussian curvature at a top point of a triangular mesh are determined; 3, the computational processes of the average curvatures and the gaussian curvatures at all the top points of continuous triangular meshes of multiple segmentations of a dental crown are completed; 4, the type of the dental crown is extracted; 5, whether the tooth type is single or not is judged; 6, a tooth model of the single-root tooth is established; 7, the tooth model of the multi-root tooth is established. According to the tooth modeling method, a dental crown model of a single tooth is obtained through a laser three-dimensional scanner, the dental crown and tooth roots are separated, the type of the tooth is determined according to the characteristics of the dental crown, the corresponding tooth root model is established, and the tooth modeling method is high in accuracy, small in calculation quantity, visible, rapid, effective and low in cost.

Owner:北京赢冠口腔医疗科技股份有限公司

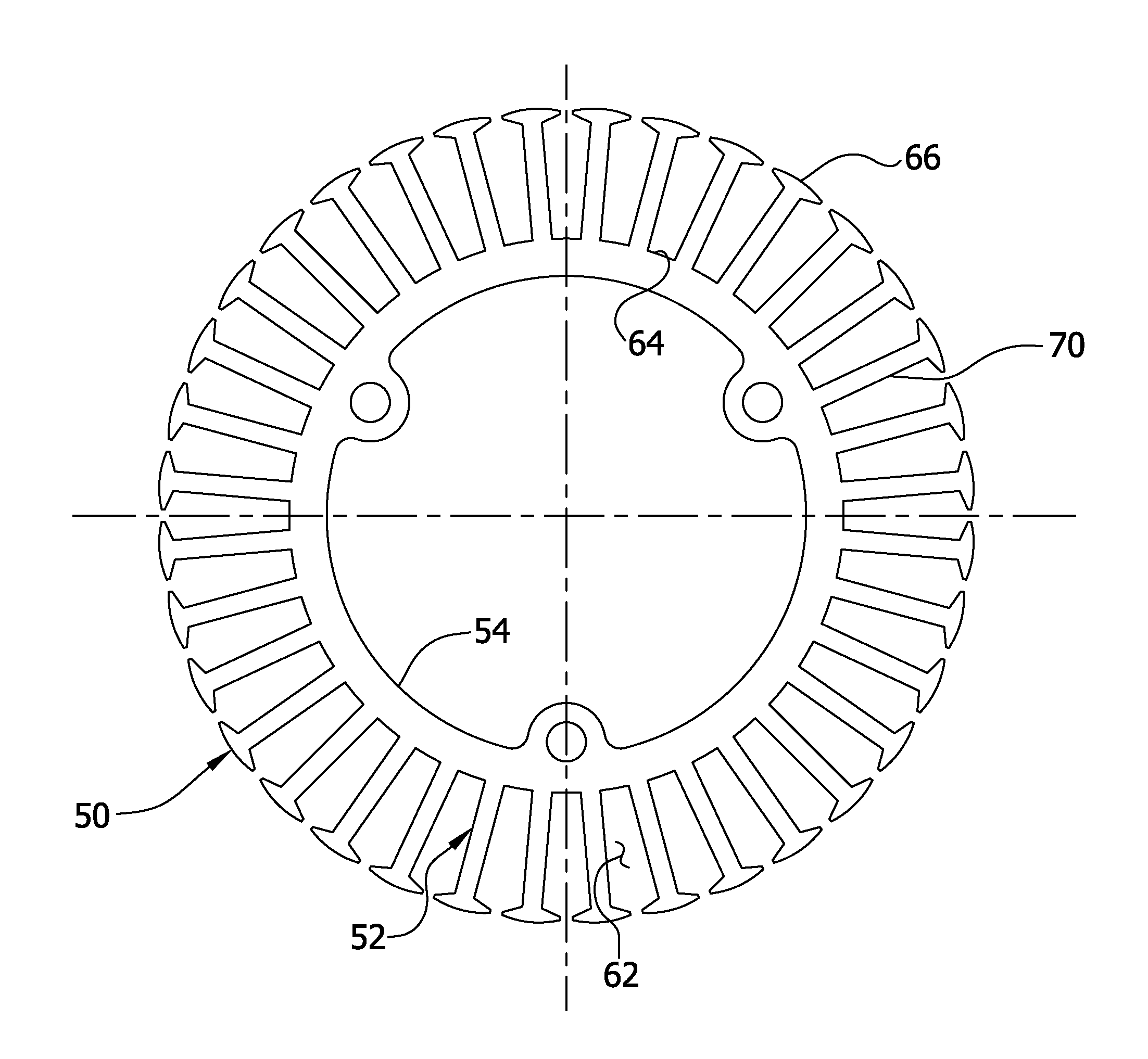

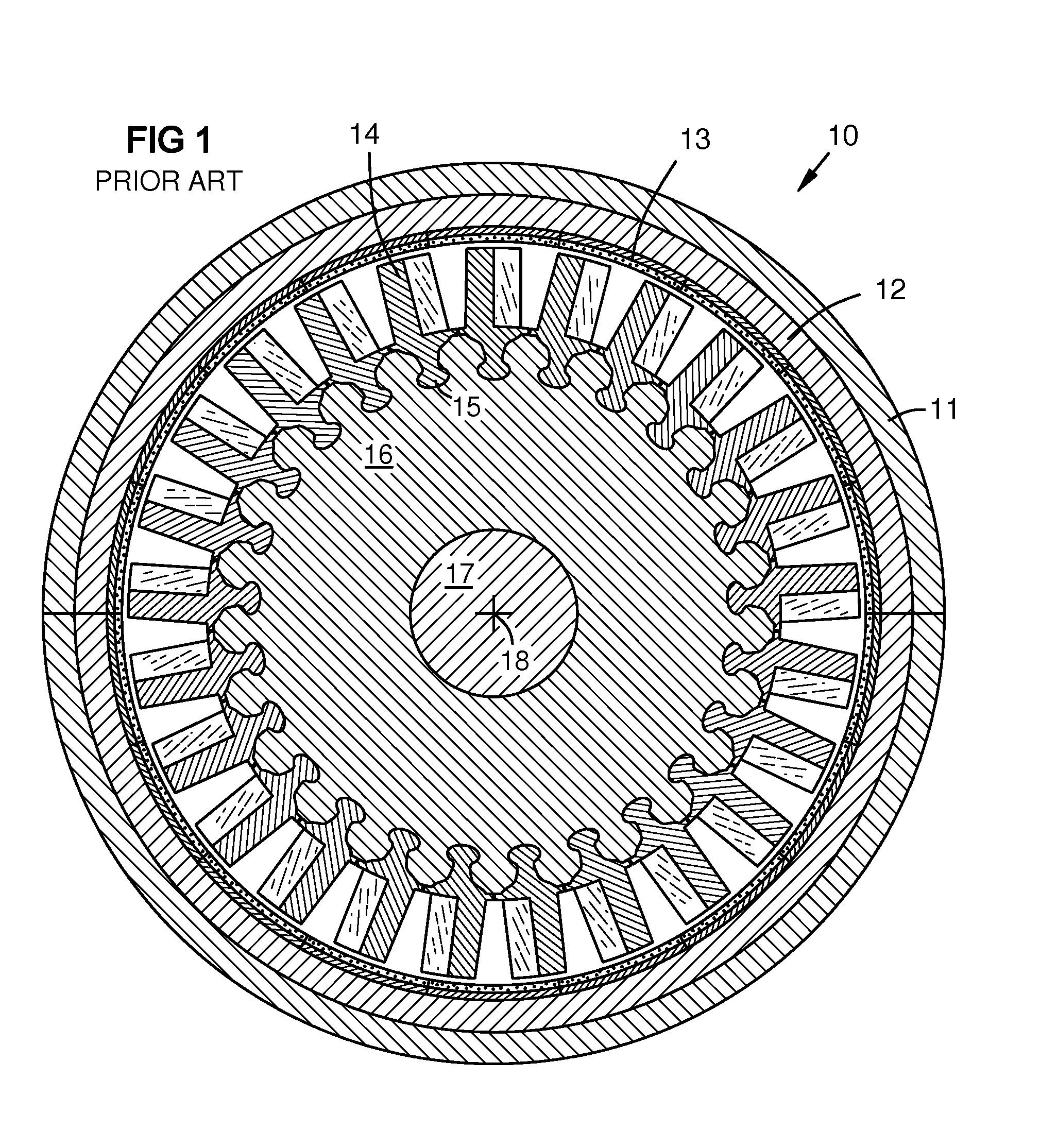

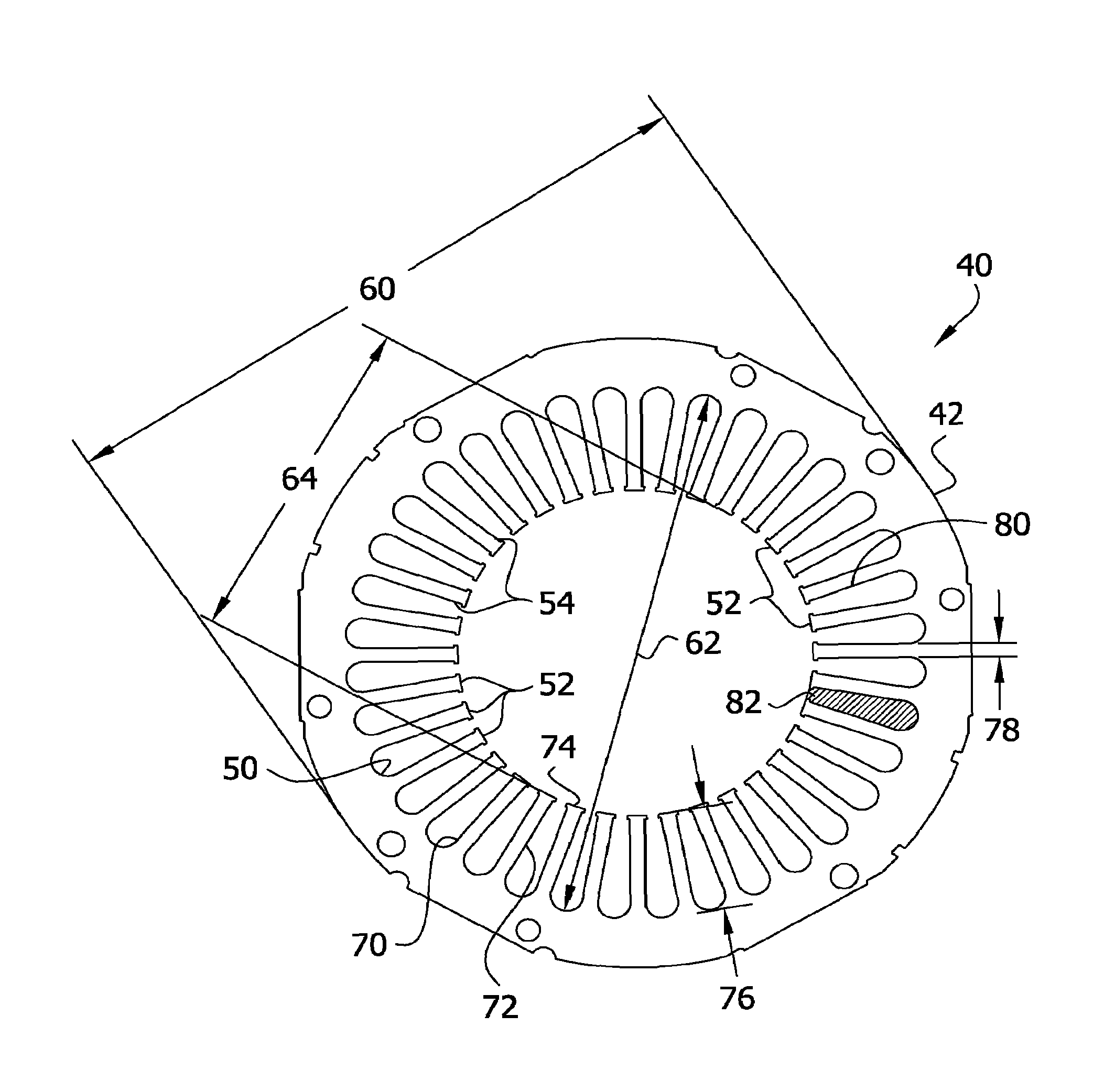

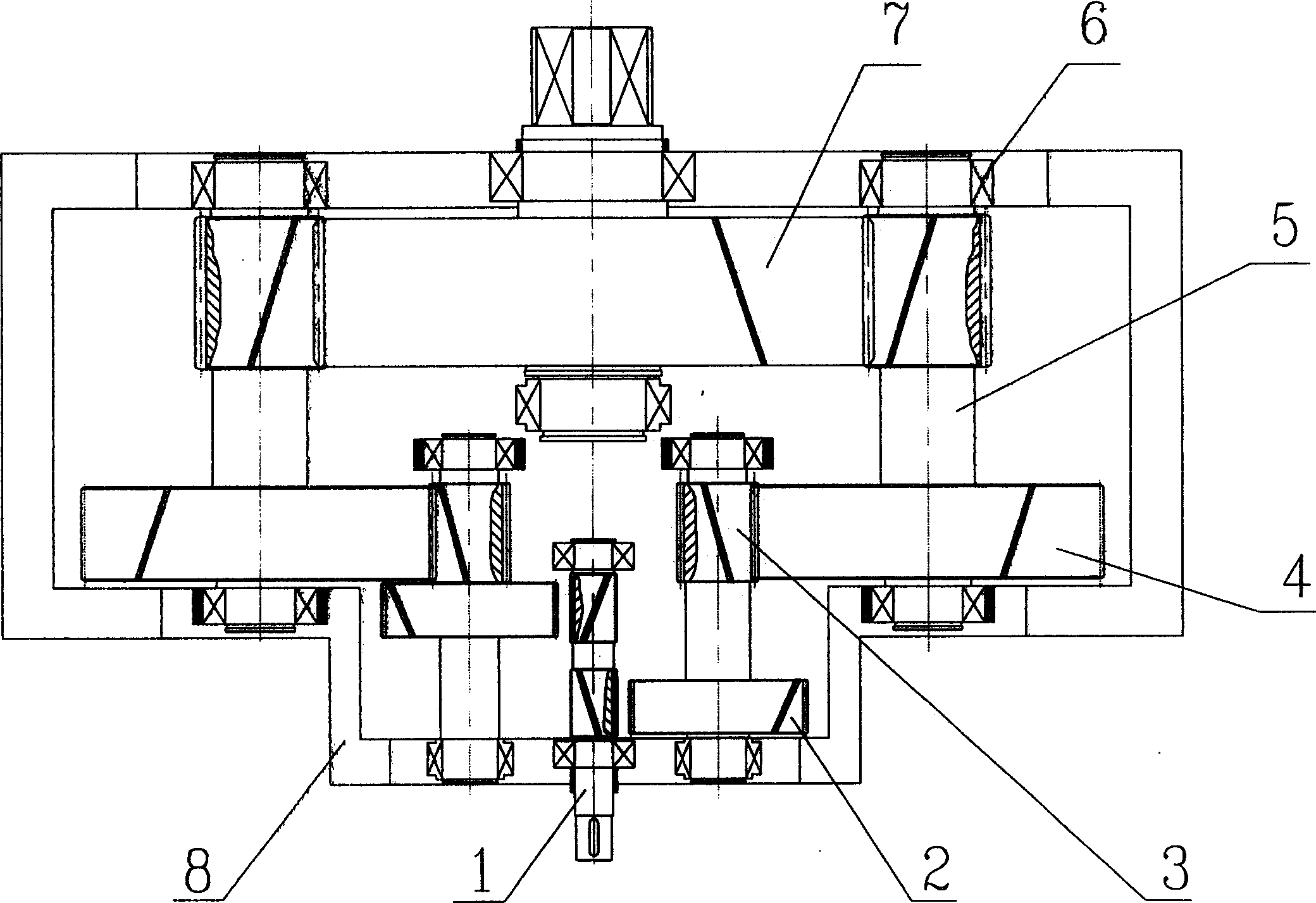

Electric machine

ActiveUS7777386B2Magnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsElectric machineRooted tooth

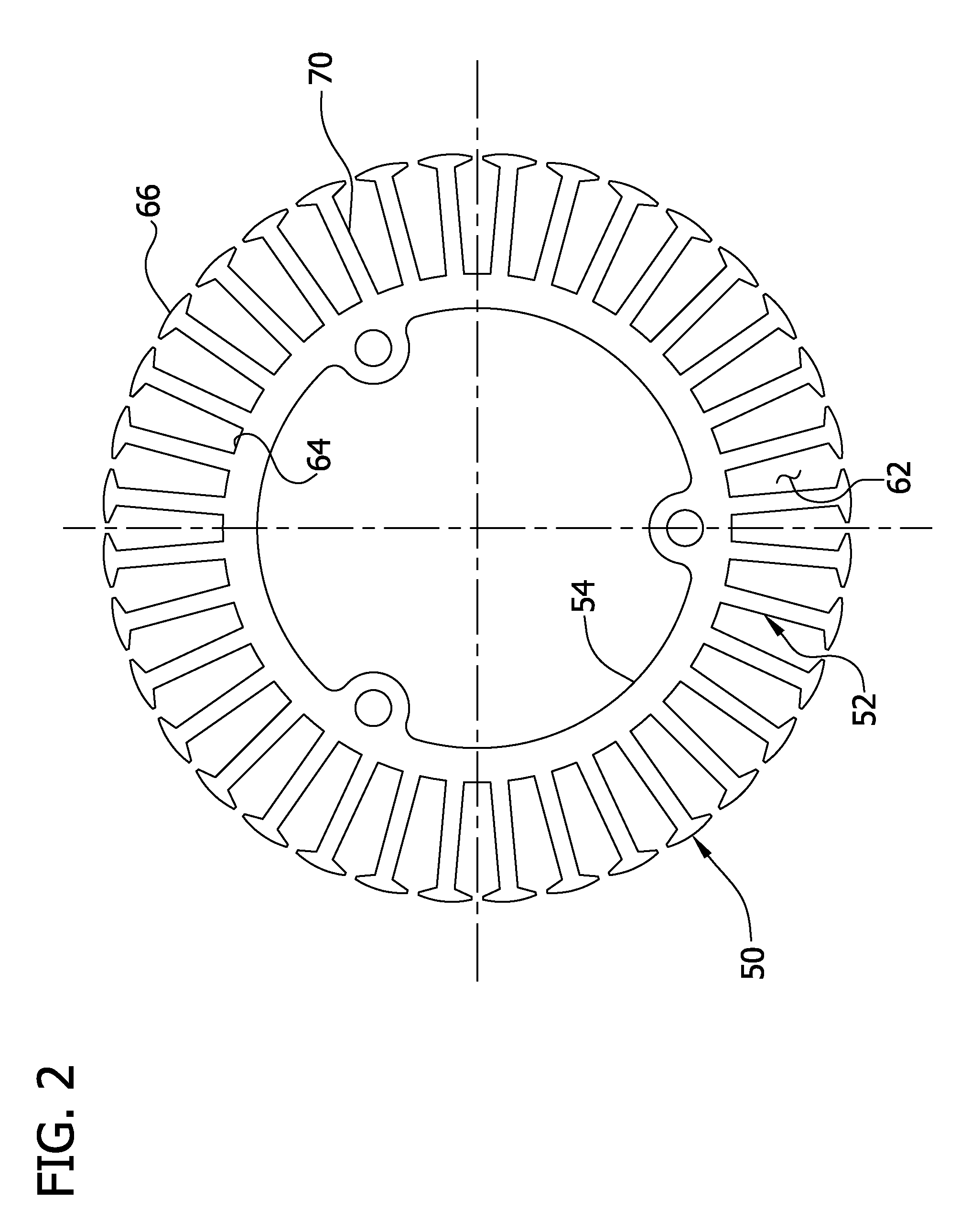

A stator assembly adapted for use in an external rotor electric motor. The assembly includes a stator core having a hub, a plurality of teeth extending radially outward from the hub, a root tooth diameter and an outer diameter. Each tooth has a root, a neck extending from the root and a head opposite the root. The neck has a maximum width. Each adjacent pair of teeth has a pitch measured at the roots of the corresponding teeth. The assembly includes a winding wrapped around each tooth of at least three teeth of the stator core. A ratio of the root tooth diameter of the stator core to the outer diameter of the stator core is less than about 0.75. A ratio of the maximum tooth neck width to the tooth pitch measured at the root of the teeth is greater than about 0.36.

Owner:NIDEC MOTOR CORP

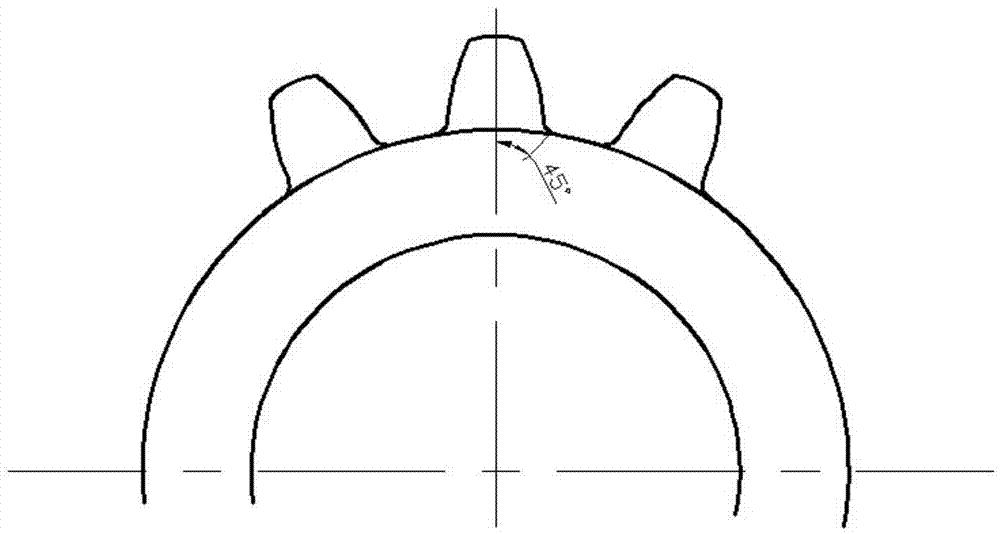

Design for three-circular-arc tooth profiles of continuous conjugate cup-shaped or silk-hat-shaped harmonic gear

ActiveCN107191570AImprove carrying capacityHigh transmission precisionSustainable transportationGearingGear wheelRooted tooth

The invention provides a cup-shaped or silk-hat-shaped harmonic gear with three-circular-arc tooth profiles in consideration of the axial taper deformation of a flexible gear body. The cup-shaped or silk-hat-shaped harmonic gear is composed of a rigid gear body, the flexible gear body and a wave generator; the flexible gear body is a straight-tooth cylindrical external gear body with the three-circular-arc tooth profile; and the rigid gear body is a straight-tooth cylindrical inner gear body with the three-circular-arc tooth profile. The invention further provides a design method for the tooth profiles of the cup-shaped or silk-hat-shaped harmonic gear with the three-circular-arc tooth profiles. According to the design method, parameters of the three-circular-arc tooth profile of the flexible gear body are selected according to the design criterion that the envelope existence interval is the largest on a design section; the circular-arc tooth profiles of a tooth root and a tooth top of the rigid gear body adopt outer envelope fitting calculation of the movement tracks of the tooth profile of the flexible gear body on the front cross section and the rear cross section of a gear ring of the flexible gear body; and a middle section adopts circular-arc fitting so as to improve the fitting flexibility of the tooth profiles. Compared with a harmonic gear with double-circular-arc tooth profiles, the harmonic gear with the three-circular-arc tooth profiles has a wider envelope existence interval, a wider conjugate meshing tooth surface and a more uniform backlash, and therefore the bearing capacity and the transmission precision of the harmonic gear can be improved.

Owner:TIANJIN POLYTECHNIC UNIV

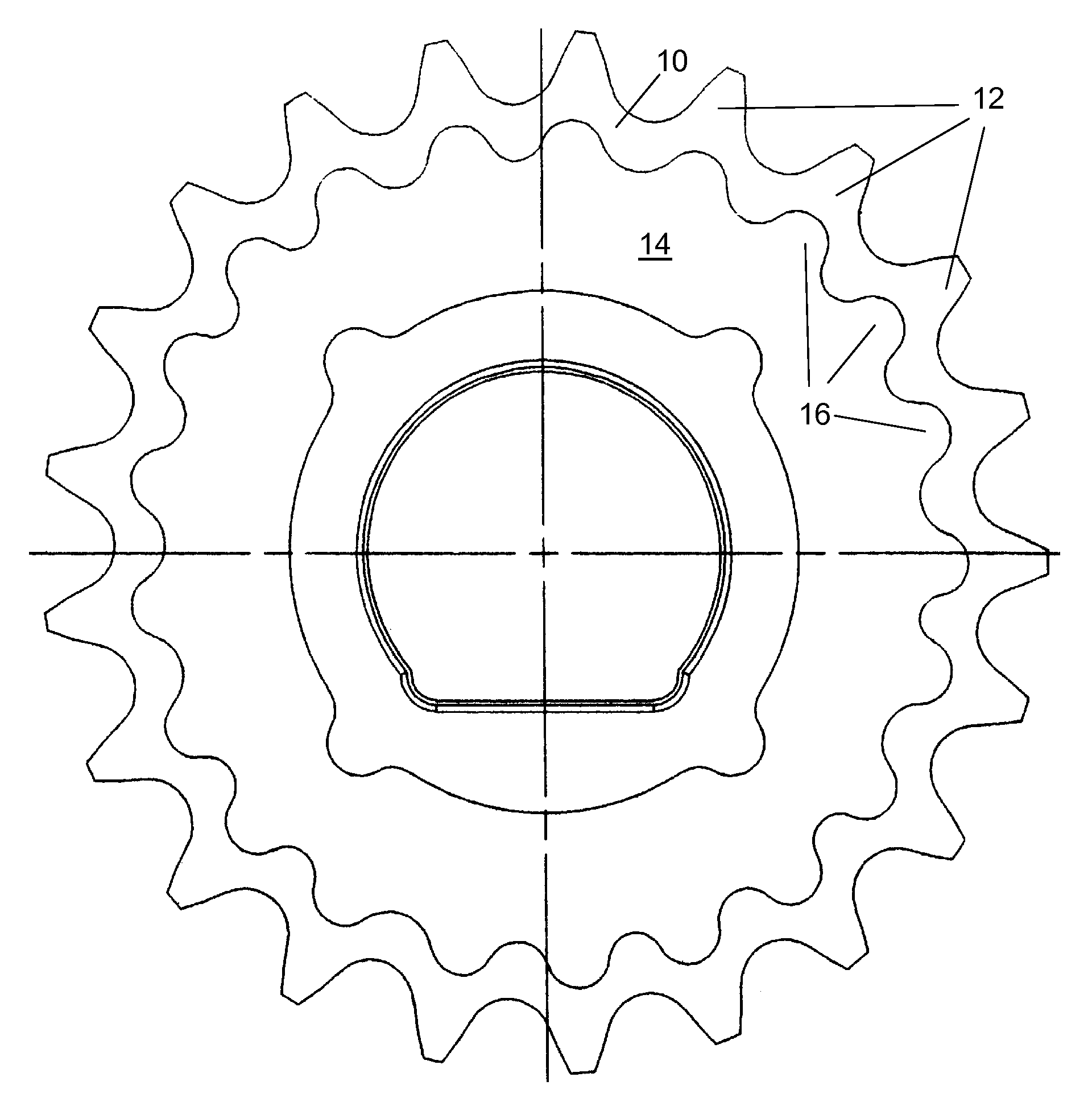

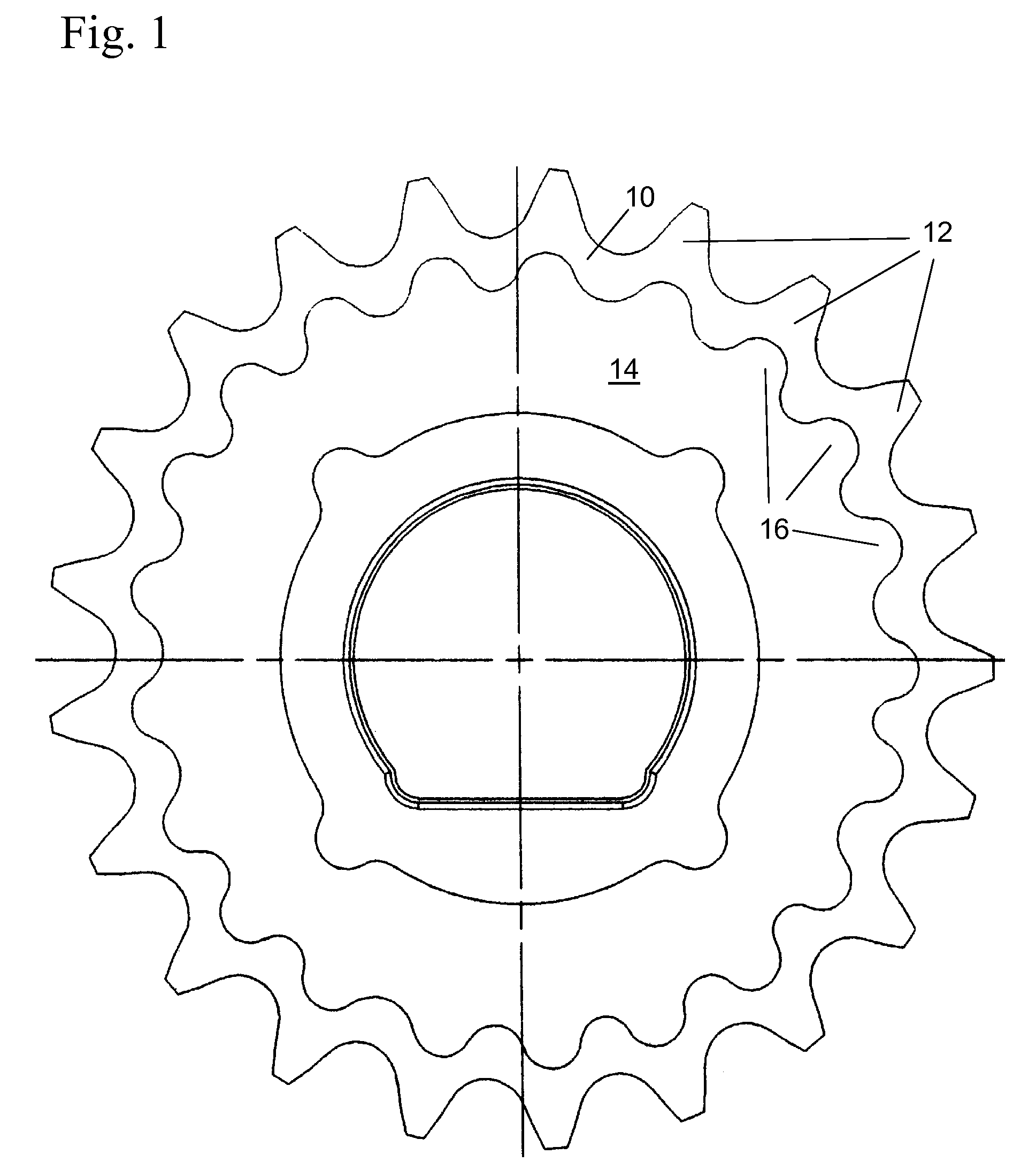

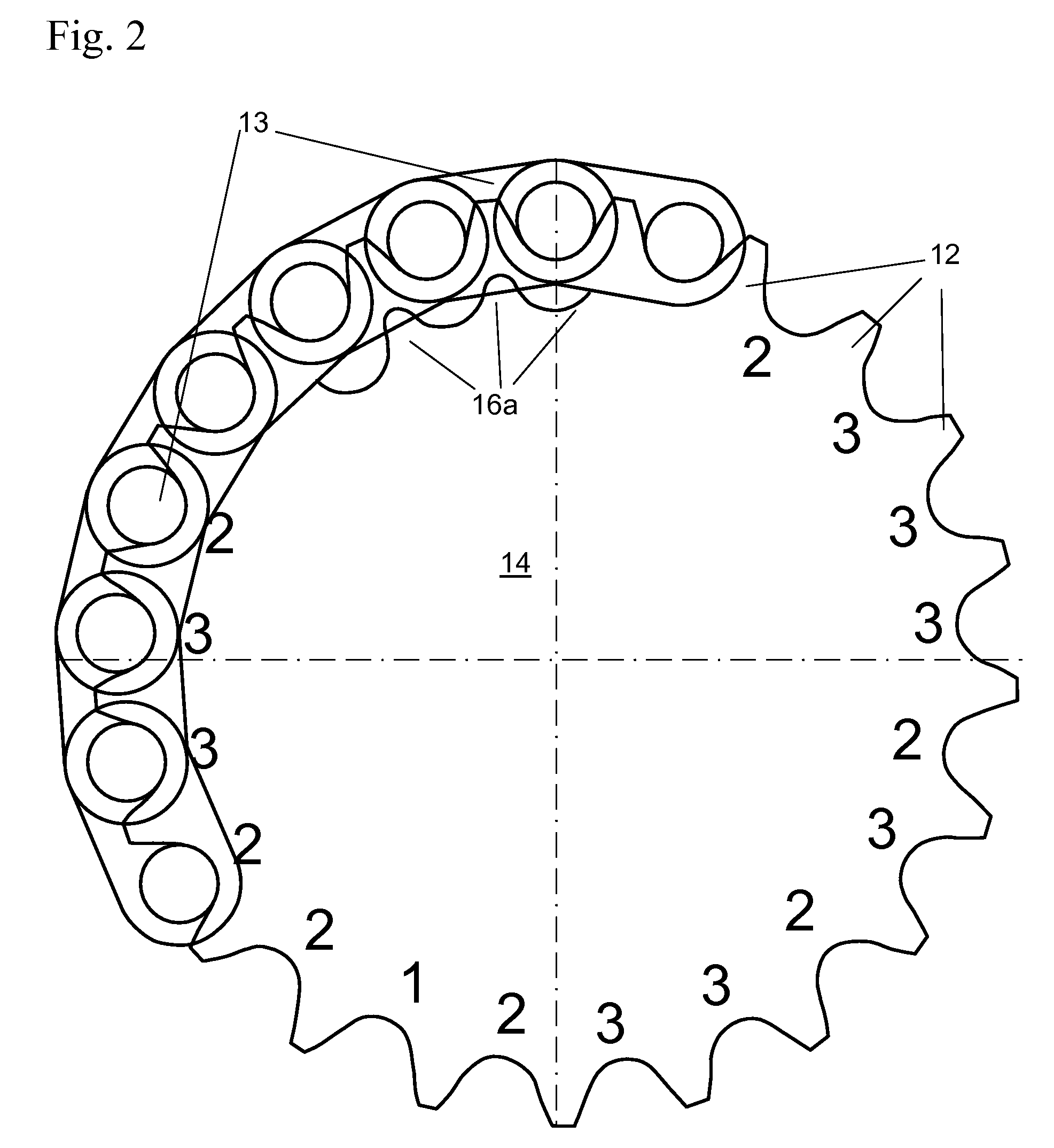

Random elastomer cushion rings for a chain sprocket

ActiveUS20090118047A1Minimize negative impactReduces chain rollerRotating vibration suppressionGearingCushioningElastomer

A sprocket includes a plurality of teeth spaced about its periphery, roots located between pairs of adjacent teeth, and a cushion ring contacted by a chain engaging the sprocket teeth. The roots have root radii defined as the distance between the center of sprocket and the point along the root closest to the sprocket center in the radial direction. In some embodiments, the roots have three distinct radii. The cushioning material of the cushion ring receives the impact while engaging the chain. In some embodiments, the cushion ring has a contour substantially following the contours of the sprocket teeth geometry. In some embodiments, the cushion ring has a randomized contour to provide predetermined cushioning that varies from tooth to tooth around the sprocket.

Owner:BORGWARNER INC

Modular turbine airfoil and platform assembly with independent root teeth

Owner:SIEMENS ENERGY INC

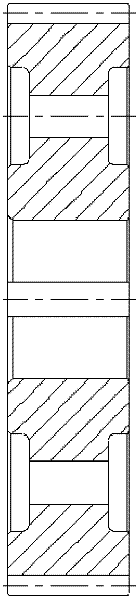

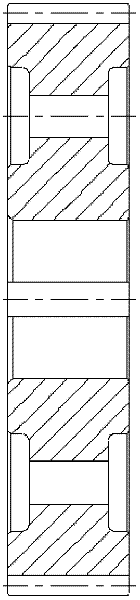

Electric machine

ActiveUS20100026135A1Magnetic circuit stationary partsWindings conductor materialRooted toothElectric machine

A stator assembly adapted for use in an electric motor. The assembly includes a stator core having an annular rim and a plurality of teeth extending radially inward from the rim. The stator core has an outer diameter, a root tooth diameter and an inner diameter. Each tooth has a root, a neck extending inward from the root, a head opposite the root, and a length measured from its root to its head. The neck has a width. Each adjacent pair of teeth define a slot having an area. The assembly also includes a winding having aluminum and / or copper wrapped around at least three teeth of the stator core. The stator core and winding have four, six or eight magnetic dipoles. The stator core outer diameter is in a range from about 5.1 inches to about 5.9 inches. The stator core inner diameter is less than about 3.0 inches.

Owner:NIDEC MOTOR CORP

Litchi picking flexible combing-shearing mechanism and rolling combing-shearing device

InactiveCN103262711AImprove accuracy and effectivenessReduce stickingPicking devicesEngineeringMechanical engineering

The invention discloses a litchi picking flexible combing-shearing mechanism and a rolling combing-shearing device. The flexible combing-shearing mechanism comprises a tooth-shaped plate, branch separating components, a sorting component and cutting components, wherein the branching components comprise a plurality of tapered rubber blocks, all the tapered rubber blocks are arranged at the tail ends of all teeth on the tooth-shaped plate respectively, a sorting component is arranged in the middle of a tooth gap between any two adjacent teeth on the tooth-shaped plate, and a cutting component is arranged at a tooth root position of any two adjacent teeth on the tooth-shaped plate. The rolling combing-shearing device is provided with the litchi picking flexible combing-shearing mechanism. According to the litchi picking flexible combing-shearing mechanism and the rolling combing-shearing device, braches with fruits and branches without fruits of litchis can be separated, and effective shear can only be carried out on the branches with the fruits.

Owner:SOUTH CHINA AGRI UNIV

Time-varying characteristic quantitative calculation method for meshing stiffness of gear with minor defect

InactiveCN103577687AReduce complexityReduce the amount of calculationSpecial data processing applicationsRooted toothGear wheel

The invention relates to a quantitative calculation method for the meshing stiffness of a gear with a minor defect. In order to describe the influence of a typical gear fault on the time-varying stiffness characteristic, a meshing stiffness energy method calculation model is firstly introduced, wherein five kinds of elastic strain energy, which refers to bending, shearing, radial compression, contact and base deformation, are respectively considered, and five corresponding stiffnesses are further formed. The quantitative calculation method is based on the energy method, the influences of case crush, tooth root crack and tooth breakage on the stiffness distribution are discussed one after another. Aiming at spalling defects, the influences of spalling length (in the meshing direction) and spalling width (in the tooth width direction) on a stiffness distribution curve is researched, and the quantitative relationship between the spalling size and the stiffnesses degradation is obtained. In the aspect of flexural fatigue crack, the change rule of the stiffness curve along with the crack depth, and the quantitative relationship between the stiffness curve and the crack depth are discussed. In the aspect of broken gear tooth, the influence of missing of a single tooth on the stiffness distribution is discussed. By adopting the quantitative calculation method, the actual meshing situation can be really reflected, the complexity and computation in the process of solving can be lowered.

Owner:BEIJING UNIV OF TECH

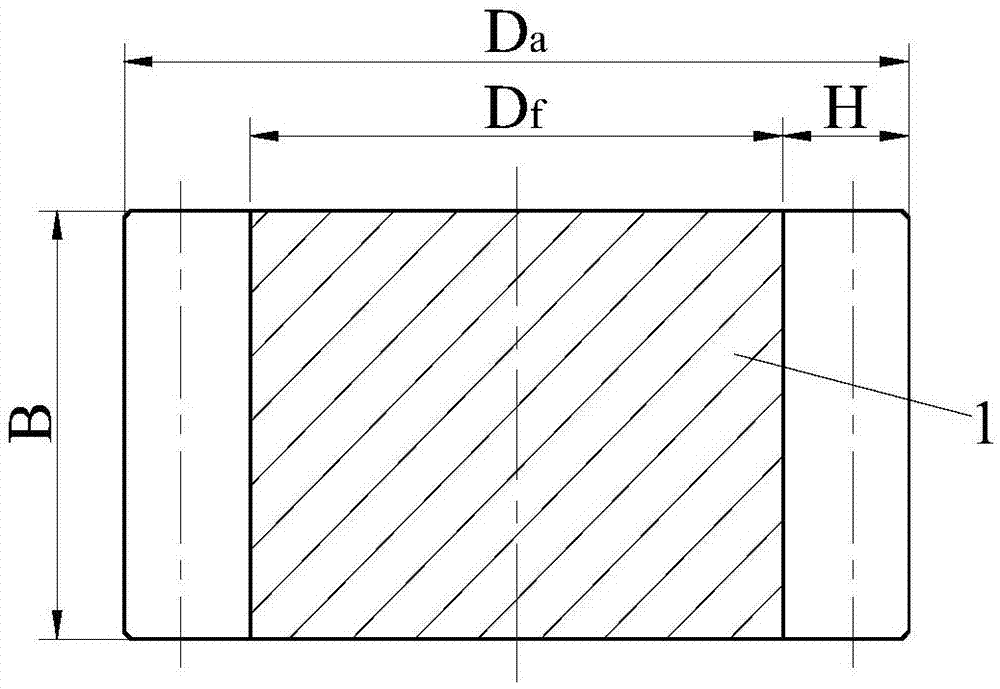

Processing method of involute of gear with large module and a few teeth

Owner:重庆市华丰动力配件有限公司

Involute gear with concave and convex ring surfaces and method for designing and machining involute gear

ActiveCN102588558AThe process is simple and convenientSimple processPortable liftingGear teethInvolute gearEngineering

The invention relates to a gear and a method for designing and machining the same. The gear is particularly characterized in that each of tooth crest curved surfaces and tooth root curved surfaces is a part of a convex ring surface or a concave ring surface, each of the tooth crest curved surfaces and the tooth root curved surfaces of the involute gear with the concave and convex ring surfaces is a part of a ring surface, an arc circularly rotates around an axis of the gear to form the ring surface, a tooth profile curve of the end section of each gear tooth is an involute, and the teeth are synchronously distributed around a center point of the tooth width. By the aid of the gear, three gear transmission forms can be realized, the gear not only can be used for driving of parallel axes, but also can be used for driving of intersecting axes with small axial intersect angles, high axis deflection installation errors are permitted when the gear is used for driving of parallel axes, the axial intersect angles are allowed to dynamically change when the gear is used for driving of intersecting axes, transmission ratio can keep constant when the gear is used for driving of parallel axes and driving of intersecting axes, and the gear teeth are not interfered with each other. By the aid of the method for designing the gear, the involute gear with the ring surfaces is divided into a plurality of tiny tapered involute gears, geometric parameter design of the involute gear with the ring surfaces is carried out, and a process of the method is carried out simply, conveniently and feasibly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

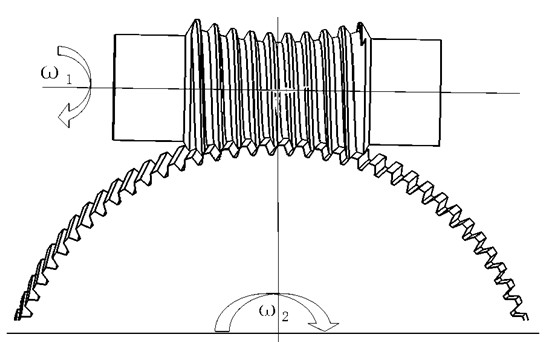

Five-axis side milling method for planar double-enveloping worm

The invention relates to a five-axis side milling method for a planar double-enveloping worm, which includes the processing steps of selecting a side milling cutter, determining side milling process parameters, roughing the bottom surface of a worm tooth root by means of five-axis linkage, roughing tooth surfaces on two sides of the worm by means of side milling, performing quenching heat treatment, finishing the bottom surface of the tooth root by means of five-axis linkage and finishing the tooth surfaces on the two sides of the worm by means of five-axis linkage side milling. The five-axis side milling method is characterized in that a side milling tool path is completely generated according to a tooth surface meshing contact line of the worm, a roughing side milling tool path is generated by offsetting the contact line along the normal direction of the tooth surfaces by the distance of roughing allowance, and a finishing side milling tool path is generated by completely overlapping a tool side blade with the tooth surface contact line. The five-axis side milling method effectively solves the problem of uneven roughing allowance of the planar double-enveloping worm, and finishing efficiency and tooth surface processing accuracy are improved.

Owner:SHANGHAI JIAO TONG UNIV

Micro-alloy weldable cast steel tooth stand and preparation method thereof

This invention discloses a kind of microalloy welded cast-steel tooth holder, of which characteristic lies at its chemical composition: C 0.15-0.25wt%,Si 0.3-1.0wt%,Mn 0.6-1.4wt%,Cr 0.4-1.0wt%,B 0.0005-0.007wt%, Al 0.01-0.1wt%,Ce 0-0.045wt%,La 0-0.035wt%,Ti 0-0.1wt%,P<=0.03wt%,S<= 0.03wt%, and the other is iron and inevitable impurity. By double treating, the tooth holder is of moderate intensity and rigidity, high dynamic ductility, good welding performance, is especially suitable for producing tooth holder or root of tooth of digging machine bucket.

Owner:NINGBO ZHEDONG PRECISION CASTING

Electric machine

ActiveUS7709992B2Magnetic circuit rotating partsMagnetic circuit stationary partsElectric machineRooted tooth

A stator assembly adapted for use in an electric motor. The assembly includes a stator core having an annular rim and a plurality of teeth extending radially inward from the rim. The stator core has an outer diameter, a root tooth diameter and an inner diameter. Each tooth has a root, a neck extending inward from the root, a head opposite the root, and a length measured from its root to its head. The neck has a width. Each adjacent pair of teeth define a slot having an area. The assembly also includes a winding having aluminum and / or copper wrapped around at least three teeth of the stator core. The stator core and winding have four, six or eight magnetic dipoles. The stator core outer diameter is in a range from about 5.1 inches to about 5.9 inches. The stator core inner diameter is less than about 3.0 inches.

Owner:NIDEC MOTOR CORP

Pulling-rope positioning and control method, device and system

ActiveCN102995673AImprove test accuracyReduce mistakesMechanical machines/dredgersTangential pointExcavator

The invention relates to the technical field of earthmoving machines and discloses a pulling-rope positioning and control method, device and system applied to excavating-force test of an excavator. The method comprises the following steps of: obtaining position information of a movable arm, a bucket rod and a shoveling bucket according to a detected result of a sensor; and determining the excavating track according to the position information; determining that a tooth root of the shoveling bucket is used as a tangential point according to the excavating track and a pulling rope arranged along the tangential direction of the excavating track is fixed on the anchoring position on an anchor frame. Compared with the prior art, the technical scheme of the invention has the advantages that the errors caused by artificial visual inspection or manual measurement are greatly reduced, the anchoring position of the pulling rope on the anchor frame is more accurate and the testing accuracy of the excavating force test is greatly increased.

Owner:ZOOMLION HEAVY IND CO LTD

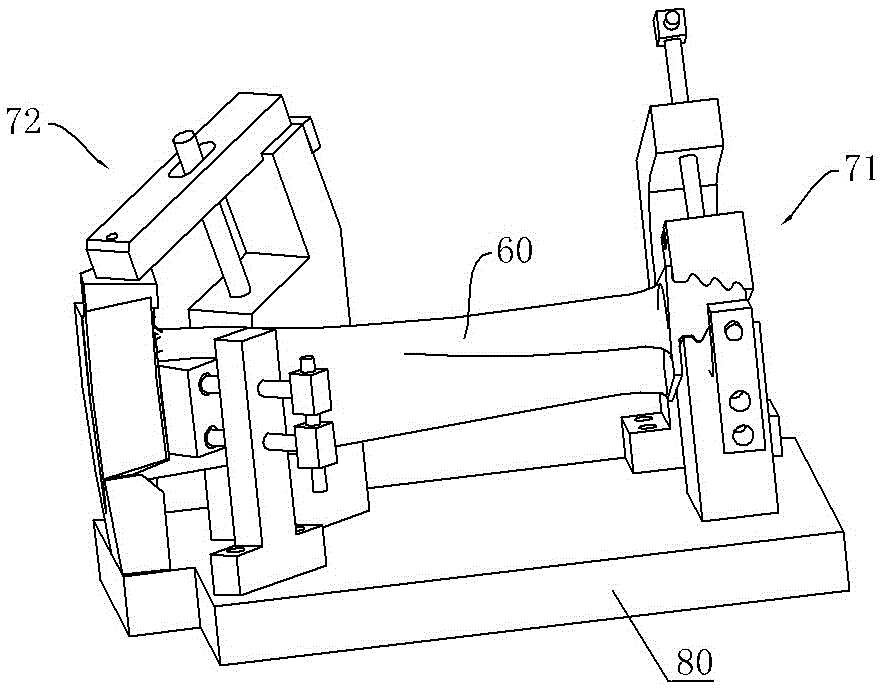

Universal clamp device for total-length finish milling of turbine blades

ActiveCN106514356AImprove versatilityImprove general performancePositioning apparatusMetal-working holdersRooted toothSteam turbine blade

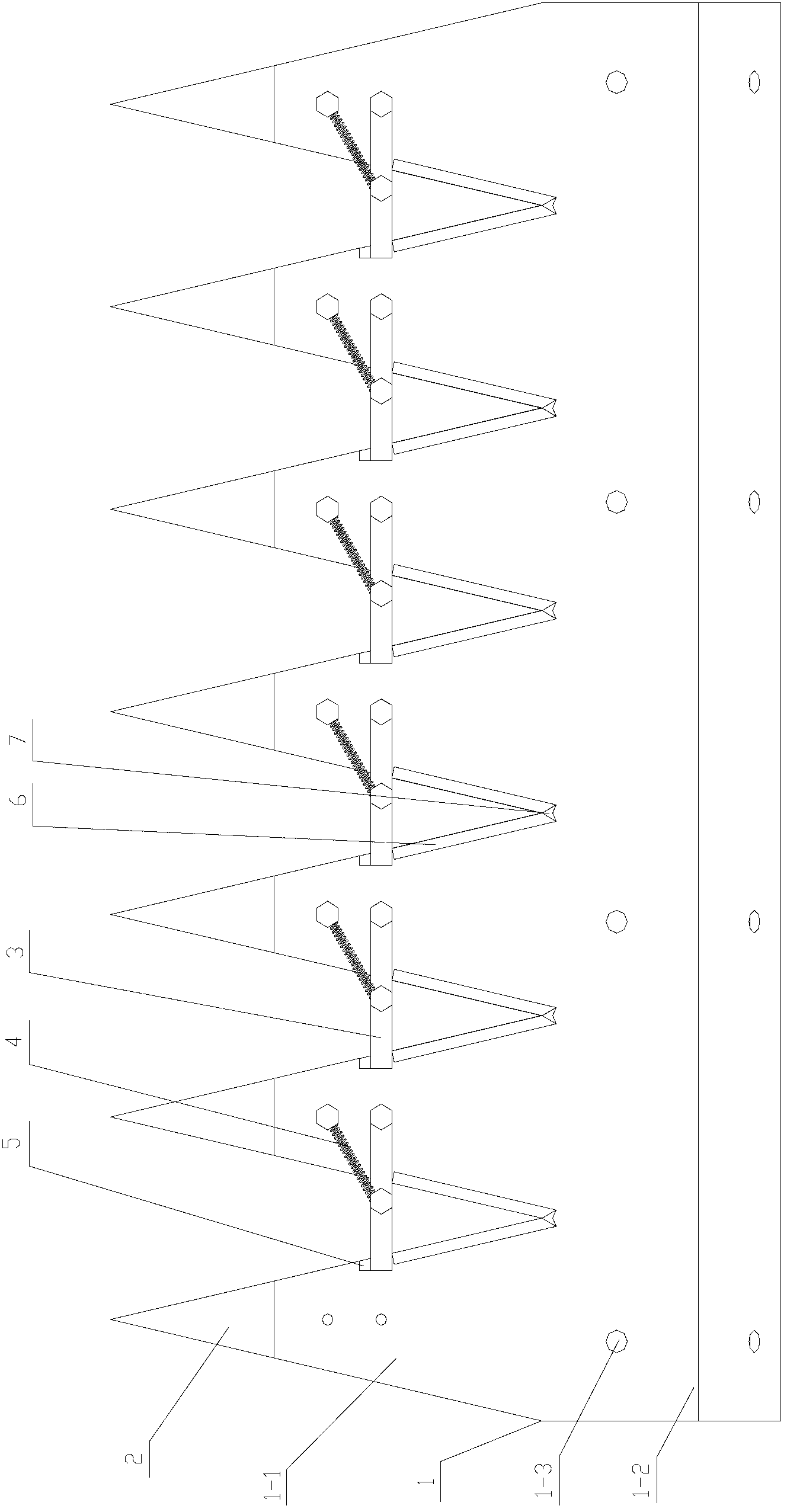

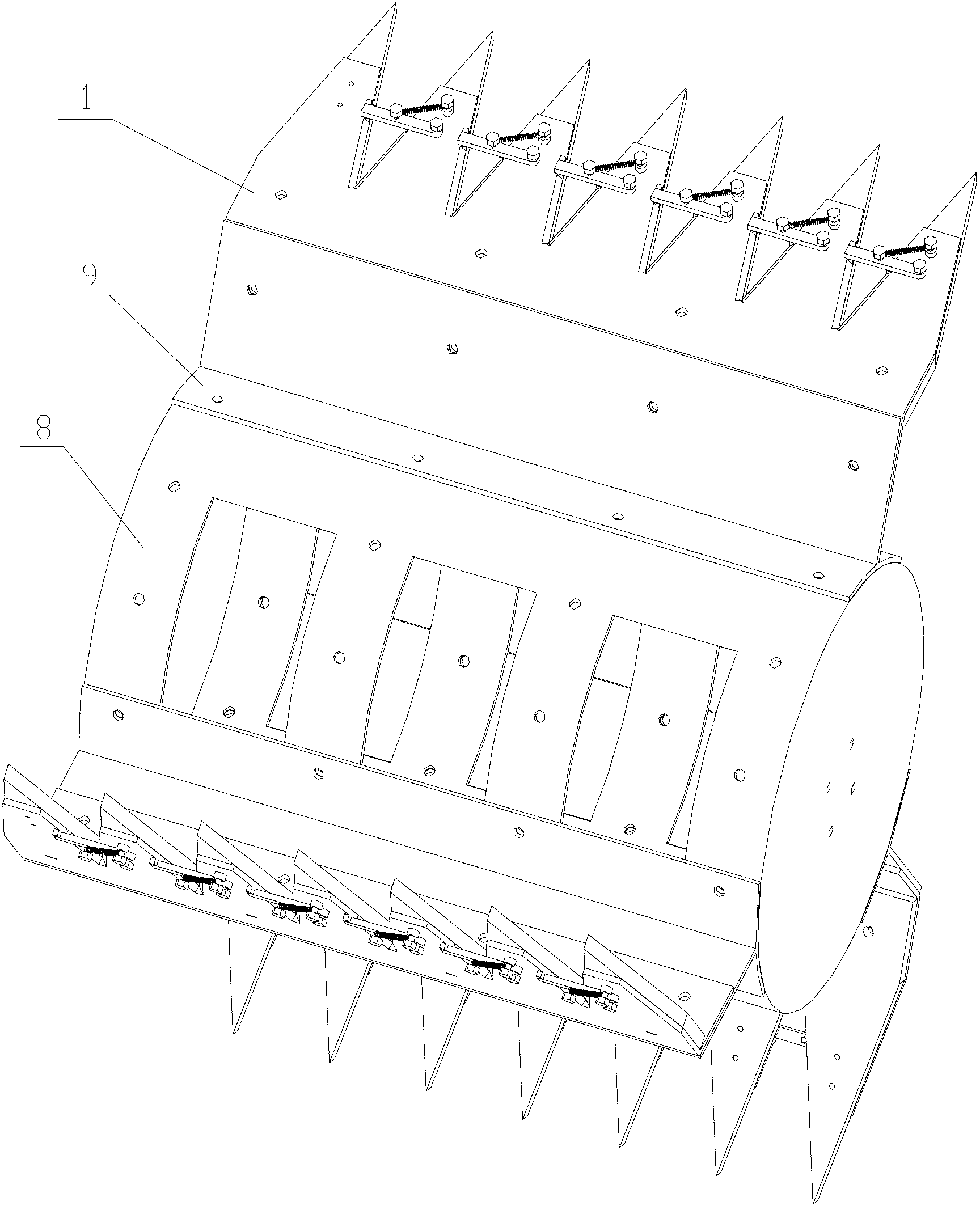

The invention provides a universal clamp device for total-length finish milling of turbine blades. By adoption of the universal clamp device for total-length finish milling of the turbine blades, the problems that a traditional total-length finish milling clamp is poor in universality and high in tool cost can be solved. The universal clamp device for total-length finish milling of the turbine blades comprises a base plate. A blade crown positioning and pressing assembly is fixedly mounted at one transverse end of the base plate, and a blade root tooth-form positioning assembly and a blade root tooth-form pressing assembly are arranged at the other end of the base plate. The universal clamp device for total-length finish milling of the turbine blades is characterized in that a universal base plate is fixedly mounted on the base plate, and key grooves which are perpendicularly staggered in the transverse direction and the longitudinal direction and connected to be distributed in a latticed mode are formed in the universal base plate; and the root tooth-form positioning assembly and the blade root tooth-form pressing assembly are connected with the key grooves in the universal base plate in an assembled mode through positioning keys, and by adjusting the positions of the positioning keys in the key grooves in the universal base plate, the universal clamp device can adapt to positioning clamping of turbine blades with different air duct lengths.

Owner:WUXI TURBINE BLADE

Tooth system

InactiveUS7690136B2Stable supportProtection wearSoil-shifting machines/dredgersRooted toothDentistry

A tooth system for use in an earthmoving device, includes a tooth and an adapter onto which the tooth is mounted in a detachable fashion, the tooth including a longitudinally extending tooth web, a longitudinally extending tooth base and a longitudinally extending tooth head at a distance from the tooth base, the tooth base and tooth head also extending transversely with respect to the web. The adapter includes an adapter base intended to be fixed onto an earthmoving device, such as onto the teeth bars of a draghead, and an adapter head, a longitudinally extending undercut cavity being defined between the adapter base and the adapter head, wherein the tooth base is slidably fitted within the undercut cavity and wherein the adapter head is slidably fitted between the tooth base and the tooth head for mounting or dismounting the tooth with respect; to the front end of the adapter.

Owner:IHC HOLLAND NV

Hard tooth face sugar press used reducer and hard tooth face processing method

InactiveCN1908461AExtended service lifeReduce weightToothed gearingsSolid state diffusion coatingCarbon layerEngineering

The invention relates to a speed reducer of sugar maker with rigid tooth surface, and relative rigid tooth surface treatment, wherein it comprises: the I gear axle, I large gear, II gear axle, II large axle, III gear axle, and III large gear are made from high-strength alloy steel; the rigidity of tooth surface is HRC58-62; the treatment comprises: machining the blank, and rolling tooth on it; immerging carbon, checking the depth of carbon layer and the metal structure, quenching, and tempering at low temperature to form the rigid tooth surface; then strengthening the tooth root, and refining it; abrading the tooth to form high-accuracy rigid tooth surface, whose accuracy level is not lower than six level of ISO1328 standard. And the invention has the advantages that: since all gears have rigid tooth surfaces, the abrasion resistance and load ability of gear are improved to reduce or avoid point corrosion, and prolong the service life, reduce the weight and reduce the volume.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

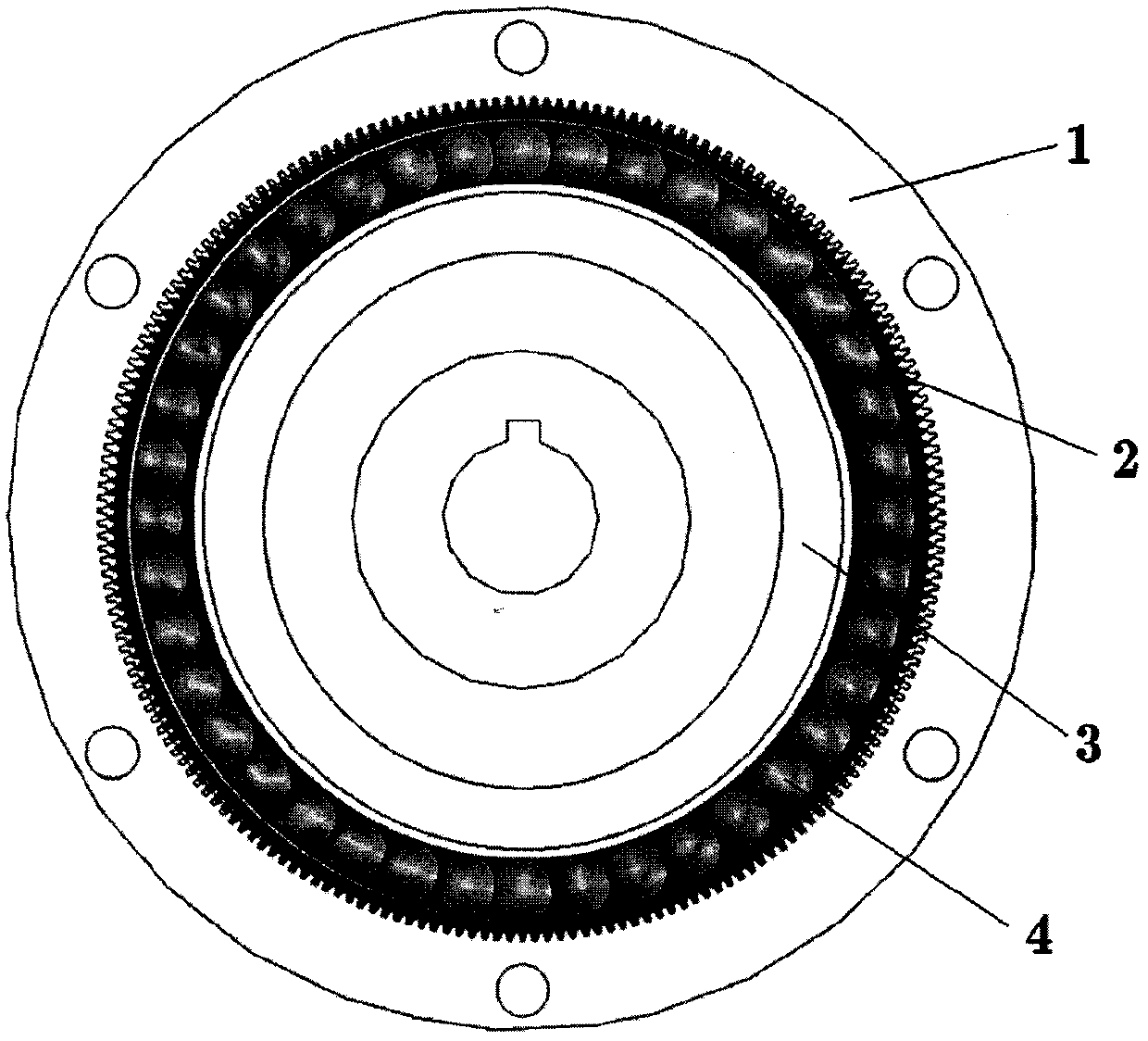

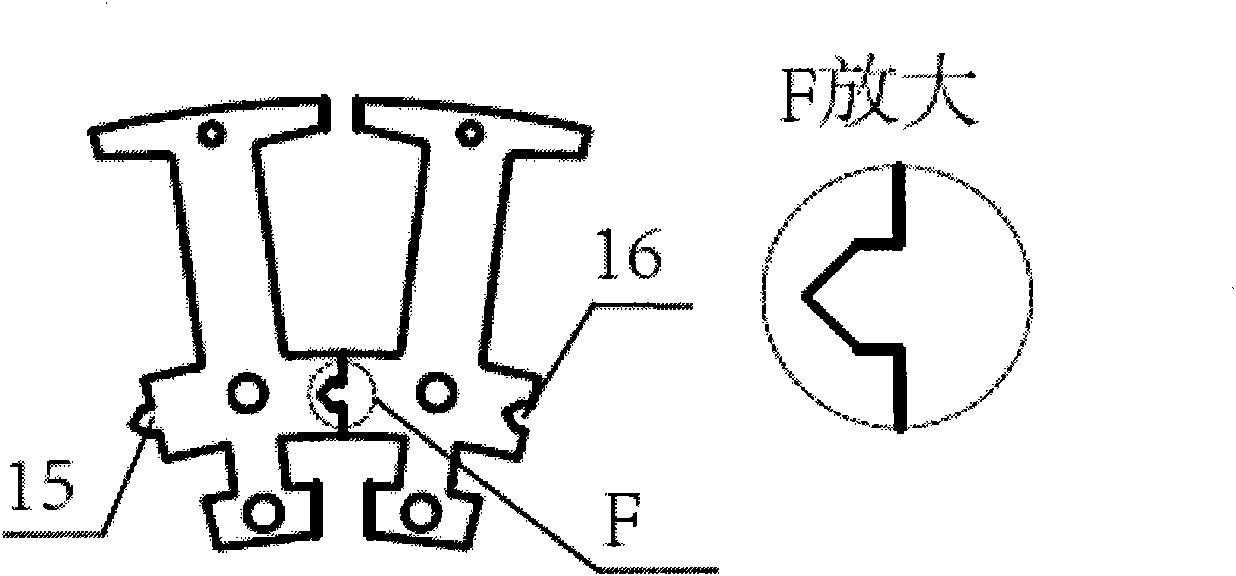

Modularized combined motor stator structure and application thereof

InactiveCN101951041AIncrease slot fill rateImprove fault toleranceMagnetic circuit stationary partsModular compositionManufacturing cost reduction

The invention discloses a modularized combined motor stator structure which comprises a cylindrical or annular stator bracket and stator tooth iron cores, wherein T-shaped grooves the bottom parts of which are wide and the opening parts of which are narrow are uniformly distributed on the outer surface of the cylindrical stator bracket or the inner surface of the annular stator bracket; each stator tooth iron core is formed by laminating and fastening stator tooth punching sheets; each stator tooth iron core comprises a tooth crown, a tooth body, a tooth yoke and a tooth root; the tooth root of each stator tooth iron core is respectively arranged in each groove of the stator bracket; the shape of each tooth root is matched with the shape of each T-shaped groove of the stator bracket; all the stator tooth iron cores are fixed with the stator bracket into a whole by utilizing fasteners which pass through the upper through holes of tooth roots and the upper through holes of annular press plates positioned at the two ends of the stator bracket; the stator tooth iron cores installed on the stator bracket are sequentially wound with coils alternately; an insulated winding frame is arranged between each coil and each stator tooth iron core; and the coils on all the stator tooth iron cores are connected in series or in parallel to form a stator winding of a motor. The invention can effectively improve the space factor of the motor and reduce the manufacturing cost.

Owner:ZHEJIANG UNIV

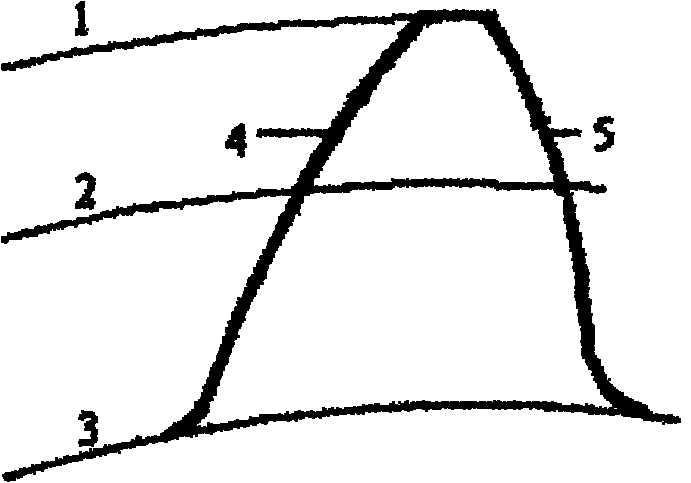

Precision forming method for straight/helical tooth cylinder gear with corners easy to fill and die

InactiveCN105436390AReduce complexityHigh strengthForging/hammering/pressing machinesWheelsGear wheelEngineering

The invention discloses a precision forming method for a straight / helical tooth cylinder gear with corners easy to fill and a die. During a closed die forging upsetting stage, a cylindrical blank is manufactured into an intermediate process part with lower corners not tidy enough in an upsetting mode; a volume protruding relative to a tooth outline is reserved near each lower corner of the intermediate process part; during an ejection-out stage, a lower convex die moves upwards, due to the function of a lateral wall conical surface of a concave die, the lower corners, not tidy enough, of the intermediate process part are deformed again, the protruding volumes transfer towards the lower corners, and forming of the lower corners is completed. According to the structure of the concave die, the conical surface with the bottom surface outline larger than the gear tooth top outline is used for expanding a concave die cavity near each lower corner, a cylindrical die cavity of the corresponding portion becomes a big-end-down prism-frustum-shaped die cavity, and the tooth root and the parts far away from the lower corners still keep the cylinder die cavity. By means of the precision forming method for the straight / helical tooth cylinder gear with the corners easy to fill and the die, the problems that according to traditional cylindrical gear precision forming, the gear tooth corners are not full enough, forming force is large, the structure of the die is complex, the service conditions are bad, the service life of the die is short, and the requirements for motions of equipment are complex are solved.

Owner:NANCHANG UNIV

Non-full-symmetry involute gear, gear cutting hob special for same, and machining method of non-full-symmetry involute gear

ActiveCN104889501ADifferent bending strengthPortable liftingGear teeth manufacturing toolsHobbingInvolute gear

The invention discloses a non-full-symmetry involute gear, a gear cutting hob special for the same, and a machining method of the non-full-symmetry involute gear. The method includes five steps which include: preparing a gear blank which can be used for hobbing, selecting the gear cutting hob special for the non-full-symmetry involute gear, and the like. The axial tooth profile of the gear cutting hob comprises a left tooth profile and a right tooth profile, wherein the left tooth profile comprises linear segments HI, IJ and KL and an arc-shaped segment JK, and the right tooth profile comprises linear segments PO, ON and ML and an arc-shaped segment NM. The end face tooth groove tooth profile of the non-full-symmetry involute gear comprises an involute segment AB, an involute segment EF, a tooth groove left tooth root curve BG and a tooth groove right tooth root curve GE. The non-full-symmetry involute gear has the advantage that the left side and the right side of the teeth of the gear can have different tooth root bending strength. The gear cutting hob can obtain different involute starting points of the a left tooth face and a right tooth face and different tooth root curve curvature radiuses while the left tooth face and the right tooth face of the gear are allowed to have different grinding amount, and defects such as grinding bosses are avoided favorably.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Ultrasonic phased array detection method for fir type blade roots of nuclear main turbine

InactiveCN105445374ARealize full coverage detectionEasy to formulateAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear powerSteam turbine blade

The invention belongs to the technical field of nondestructive detection of a steam turbine for a nuclear power station, particularly relates to an ultrasonic phased array detection method for fir type blade roots of a nuclear main turbine and aims to adopt an ultrasonic phased array detection technology to overcome the defects of small space between blades, complicated blade root structure, signal identification difficulty and the like of conventional ultrasonic detection in a state that blades of a low-pressure rotor of the nuclear main turbine are not dismounted. Four scanning modes are adopted for cross scanning to realize full-area coverage of first tooth roots of the blades and partial coverage of second and third tooth roots, and the defects are accurately quantified, so that the accident of breakage of the blade roots of the blades of the nuclear main turbine is prevented. The method is characterized by comprising steps of system calibration, detection starting and display judgment and quantification. The method has the advantages as follows: ultrasonic detection is carried out without dismounting and mounting of the blades, and the maintenance time is shortened; the four scanning modes are adopted for cross scanning and mutually complemented, and full-area coverage detection of the first tooth root parts of the fir type blade roots is realized; fan-shaped scanning and deep focusing can be realized.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

Stator arrangement for an axial-flow machine

ActiveUS20190252930A1Simple and safe installationWindingsMagnetic circuit stationary partsRooted toothElectric machine

A stator arrangement for an axial-flow machine includes a stator having stator teeth circumferentially distributed concentrically and axially separated from a rotor by an air gap. The stator teeth have two axially-opposite end portions and a tooth core therebetween. Each tooth core is wound with at least one coil winding. The first end portion facing the rotor forms a tooth tip having a tip cross-sectional area larger than the core cross-sectional area. The second end portion, turned away from the rotor, forms a tooth root, having a root cross-sectional area, which is joined to a reflux plate. The tooth tip of each stator tooth as well as the reflux plate respectively has at least one recess for at least one tooth securing device, and each stator tooth is securely joined by the at least one tooth securing device to the reflex plate in at least axial direction.

Owner:MIBA SINTER AUSTRIA

Cutting tooth for earth working equipment

ActiveCN1955383AReduce storage costsReduce installation riskSoil-shifting machines/dredgersRooted toothEngineering

Cutting tooth has foot to sit in a seat on the ground treatment appliance and at least one main cutting part is located on the cutting foot on the head side to treat the ground material. To enlarge the treatment area of the main cutting piece situated on the foot, a further post cutting piece is provided. It has a different cutting design compared to the main cutting piece. The post cutting piece has a pin blade. The main cutting piece has at least one wedge-shaped blade.

Owner:BAUER MASCH GMBH

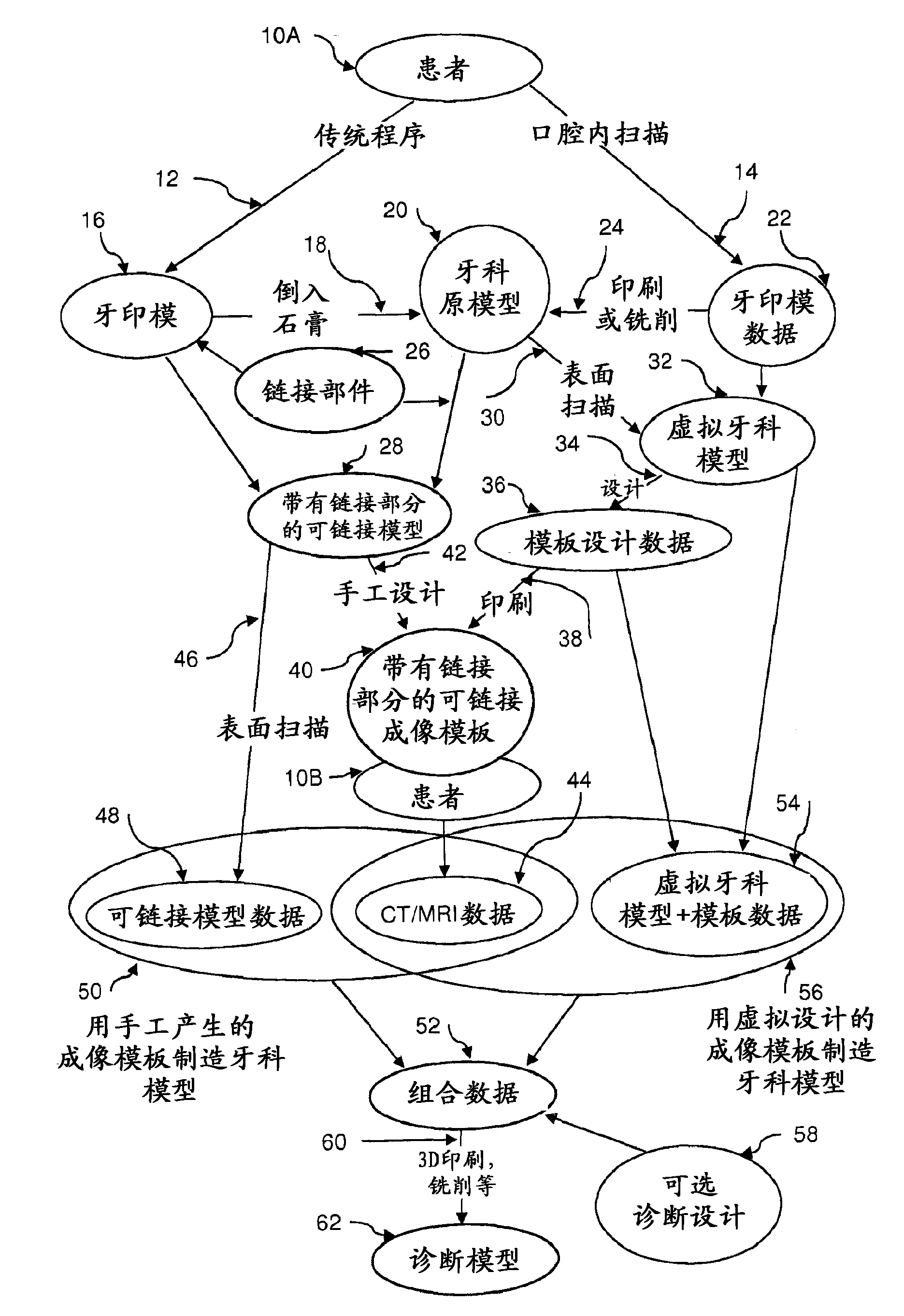

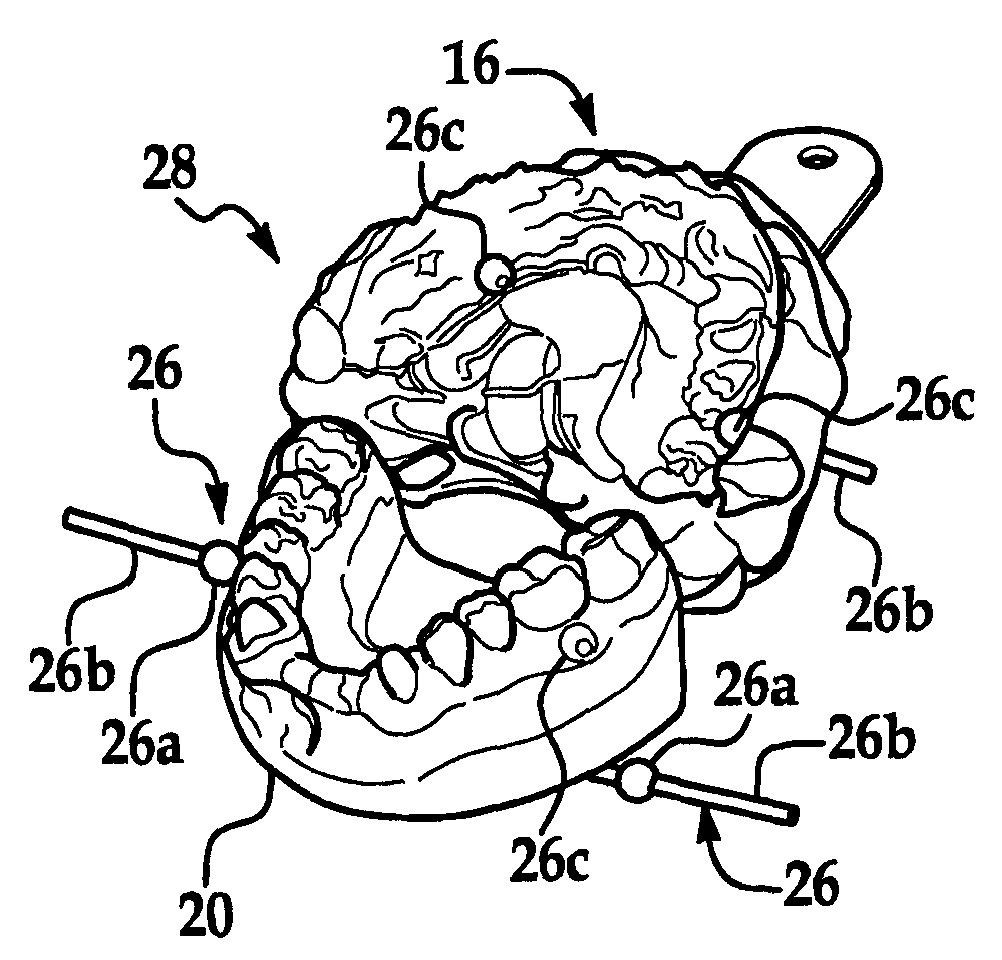

Dental device and method for linking physical and digital data for diagnostic, treatment planning, patient education, communication, manufacturing, and data transfer purposes

A dental device and / or process include at least one scaled and shaped linking component (26) to be supported by a dental model (28) or an imaging template (40). The process includes scaling, aligning, and orienting data (50, 56) from different data acquisition sources (44, 48, 54) with the scaled and shaped linking component (26), and combining the data (50, 56) from different data acquisition sources into a master data file (52). A method of making a diagnostic model (62) can include virtually designing an imaging template (36) including at least one linking component (26) made at least partially of a radio opaque material, and three-dimensionally printing the virtually designed template (40).; The diagnostic model (62) can include at least one of an exposed bone structure portion (70a, 76a), a removable gum tissue portion (72, 76b), a removable bone structure portion (76c), a visualization portion illustrating a root (76d), bone density (76f), an internal bone structure (76g), a nerve channel (76h), a nerve ending (76i), a sinus cavity (76j), a blood vessel (76k), an artery (761), and diagnostic teeth (76r).

Owner:IBUR

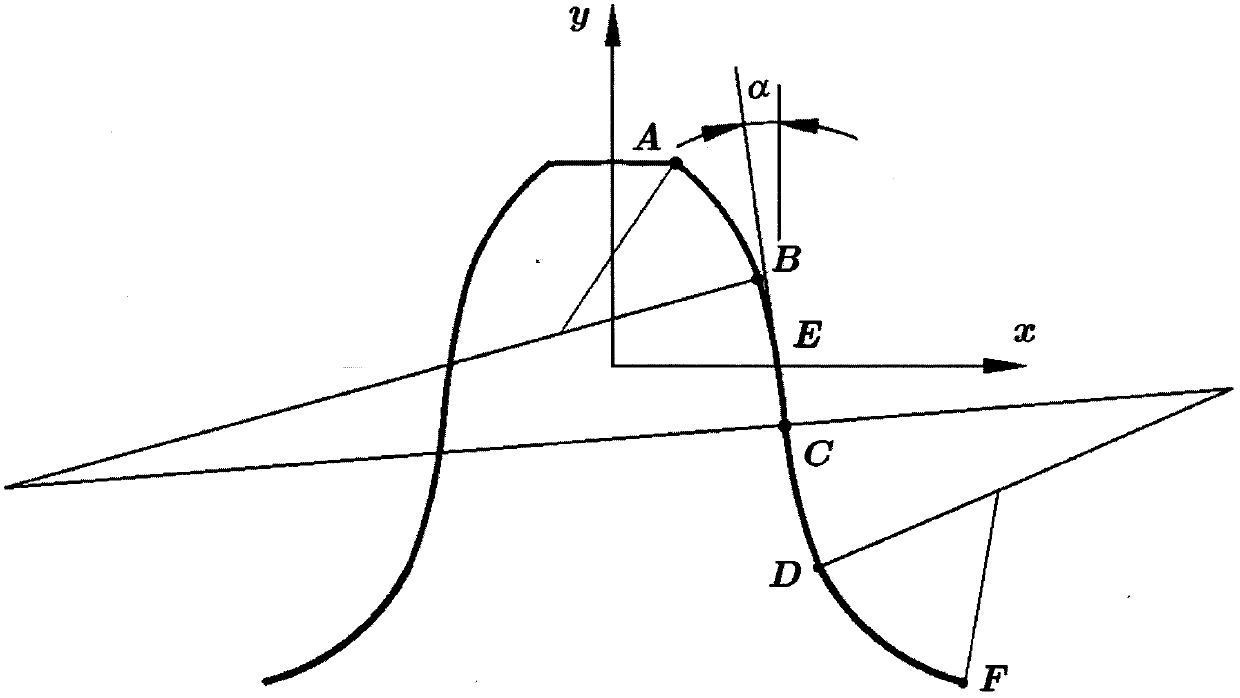

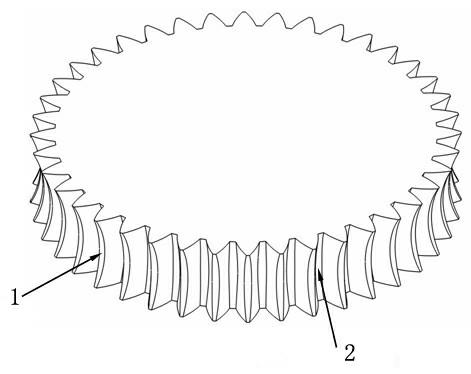

Arc cycloid harmonic tooth profile, generation method and device thereof and storage medium

ActiveCN112283317AEliminate interferenceHigh bending fatigue strengthGearingPortable liftingRooted toothEngineering

The invention relates to an arc cycloid harmonic tooth profile, a generation method and device thereof and a storage medium. The method comprises the steps that a flexible gear coordinate system is established; according to the shape tooth profile parameters of a flexible gear tooth top arc, a flexible gear common tangent, a flexible gear tooth bottom horizontal cycloid and a flexible gear tooth root transition arc, corresponding flexible gear tooth profile coordinates are determined correspondingly; a corresponding flexible gear tooth profile is determined according to the flexible gear toothprofile coordinates and preset harmonic transmission parameters, and rigid gear tooth profile points are determined according to the flexible gear tooth profile; and parameter fitting is performed onthe rigid gear tooth profile points, and a corresponding rigid gear tooth profile curve equation is determined. The flexible gear tooth top adopts arc curves, so that the tooth profile bearing capacity is ensured; the flexible gear tooth bottom adopts a flat cycloid curve, so that the gear tooth meshing conjugate interval and the tooth root bending fatigue strength are increased; sharp point contact and tooth profile interference of the flexible gear in the engaging-in and engaging-out processes are reduced by adopting a tooth root transition arc; and the actual meshing condition is considered, a conjugate rigid gear curve is solved by utilizing a harmonic drive envelope conjugate theory, and complete conjugation is ensured.

Owner:WUHAN UNIV OF TECH +2

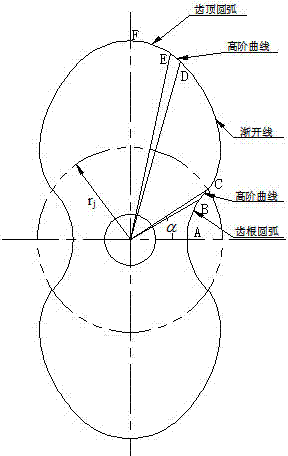

Flow-constant cam pump rotor profile and generation method thereof

ActiveCN103195704AExtended service lifeSmooth and safe deliveryRotary piston pumpsRotary piston liquid enginesRooted toothInvolute

The invention relates to a flow-constant cam pump rotor profile and a generation method thereof. A main profile of a rotor adopts an involute (CD), a tooth root part and a tooth crest part are formed by arc sections (AB and EF), transition curves are high stage curves (BC and DE) connecting the involute and the arc sections, five sections of curves are connected end to end to form one fourth of the rotor profile, and the entire cam pump rotor profile can be obtained according to a symmetry principle. The generation method of the cam pump rotor profile comprises the steps of: (1) determining a base radius, applying a geometric formula of a figure to elicit the arc radiuses of the high stage curves (BC and DE) of the tooth root and the tooth crest according to the rotor meshing principle, and thereby obtaining the main involute (CD) under the condition of the given pressure angle; and (2) applying the high stage curves (BC and DE) in the joint parts of the arc curves and the involute from the optimized aspect, so as to connect the curves end to end.

Owner:青岛罗德通用机械设备有限公司

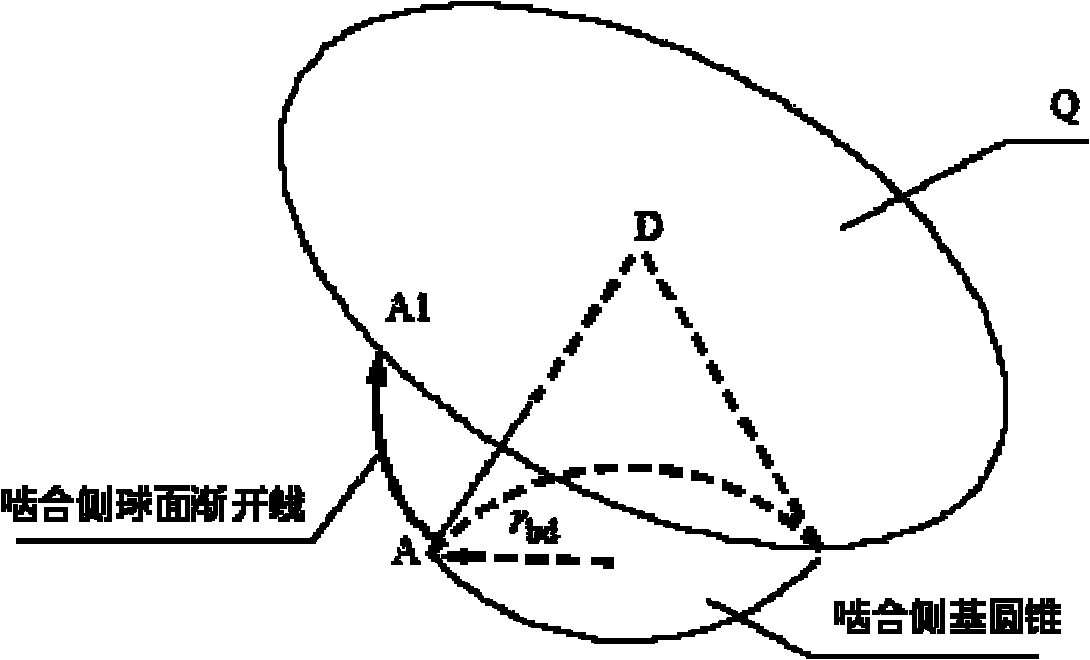

Plastic cone gear

InactiveCN102155528AGood transmission effectReduce volumePortable liftingGearing elementsGear wheelRooted tooth

The invention provides a plastic cone gear which can increase the fatigue resistance strength of a dedendum and basically does not affect the impact resistance performance of the dedendum; the plastic cone gear is characterized in that a meshing pendant group circular conical surface is worked out by taking rbd as a radius, a first occurrence surface is tangent to the meshing side base conical surface, and a line segment AD is a tangent line of the first occurrence surface and the meshing side base conical surface. When the first occurrence surface purely rolls without slipping along the meshing side base conical surface, the locus of a point A is a meshing side tooth profile curved surface of the plastic cone gear. A non-meshing side base conical surface is worked out by taking rbc as a radius, a second occurrence surface is tangent to a non-meshing side base conical surface, and a line segment BC is a tangent line of the second occurrence surface and the non-meshing side base conical surface. When the second occurrence surface purely rolls without slipping along the non-meshing side base conical surface, the locus of a point B is a non-meshing side tooth profile curved surface of the plastic cone gear. The wheel gear reference circle modulus and tooth depth modulus of the plastic cone gear are unequal; and the design method of big tooth addendum coefficients is adopted.

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com