Hard tooth face sugar press used reducer and hard tooth face processing method

A processing method and technology of hard tooth surface, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of short service life, bulky, tooth surface wear, etc., to improve the accuracy level and reduce the volume , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

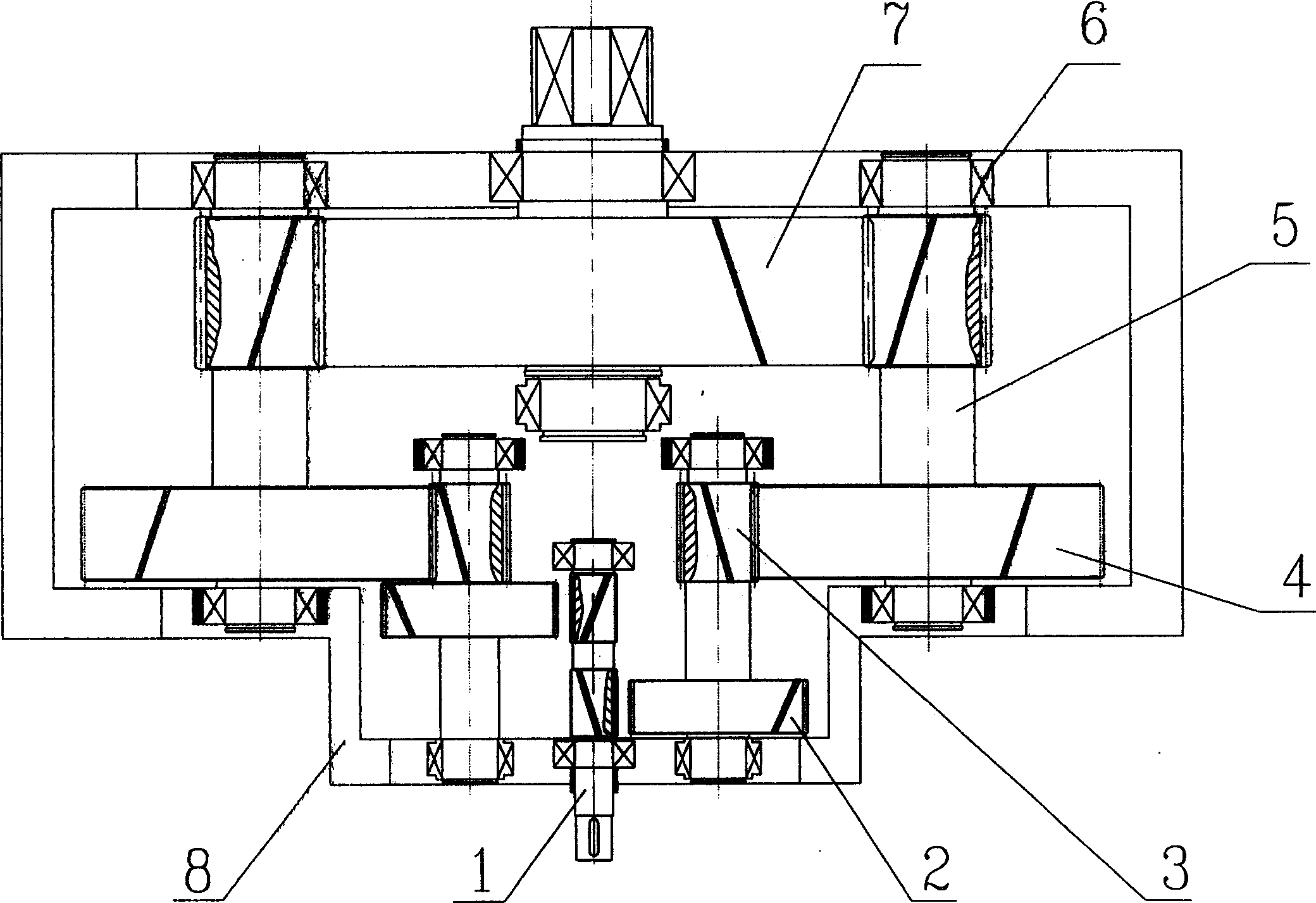

[0014] Depend on figure 1 It can be seen that the structure of the sugar press reducer is: the first-stage gear shaft 1, the first-stage large gear 2, the second-stage gear shaft 3, the second-stage large gear 4, the third-stage gear shaft 5, and the third-stage The gear parts in the large gear assembly 7 are all made of high-strength high-quality alloy steel 20CrNi2MoA, and the hardness of the tooth surface is HRC58-62. They are respectively positioned in the box body 8 through the bearing 6, and are formed according to the double-shunt mode of the central drive power. In this embodiment, the diameter of the addendum circle of the herringbone gear on the first stage gear shaft 1 is φ320mm, and the weight is 0.6 tons; the diameter of the addendum circle of the first stage large gear 2 is φ990mm, and the weight is 0.9 tons; The diameter of the addendum circle of the II-stage gear shaft 3 is φ500mm, and the weight is 0.9 tons; the diameter of the addendum circle of the II-stage ...

Embodiment 2

[0017] Take high-quality, high-strength, and high-quality alloy steel 20CrNi2MoA forgings for normalizing, take samples to test the chemical composition and do mechanical and mechanical performance experiments; after confirming that the material is qualified, the rough car blank is subjected to ultrasonic flaw detection inspection, and hobbing is carried out with a special round-head grinding hob, and then enters Heat treatment process, carburizing and inspecting the workpiece after gear hobbing, carburizing layer depth and metallographic structure, quenching, low-temperature tempering to form a hard tooth surface, and then undergoing root shot peening treatment, finishing each part, and finally grinding the teeth to form High-precision hard tooth surface, the gear accuracy grade is not lower than the 6th grade of ISO1328 international standard. During the specific implementation, the carburizing temperature is 920-930°C, the effective carburizing layer depth of the teeth is 0....

Embodiment 3

[0019] Taking the overall reduction ratio and rated output torque of Example 1 as the design technical requirements, medium-hard tooth surface materials are used. The medium-hard tooth surface materials of large gears at all levels are 35CrMo. The heat treatment is quenched and tempered. The tooth surface hardness ranges from HB250 to 300, the pinion nitriding material is 35CrMoVA, the heat treatment is nitriding after quenching and tempering, the precision is grade 7, and the tooth surface hardness is HV500-550. According to the design of ISO6336-1996 (calculation of bearing capacity of cylindrical spur gear and helical gear) and ISO1328-1997 (international gear accuracy standard in the 1990s), the calculation results of the gear sizes of the reducer at all levels are as follows:

[0020] The addendum circle diameter of the herringbone gear on the first stage gear shaft 1 is φ370mm, which is 50mm larger than the corresponding carburizing and quenching gear, and the increase ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com