Design for three-circular-arc tooth profiles of continuous conjugate cup-shaped or silk-hat-shaped harmonic gear

A harmonic gear and three-arc technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem that the involute tooth profile is not the best tooth profile for harmonic gear transmission, etc. Achieve the effect of improving bearing capacity and transmission accuracy, uniform distribution, and improving meshing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

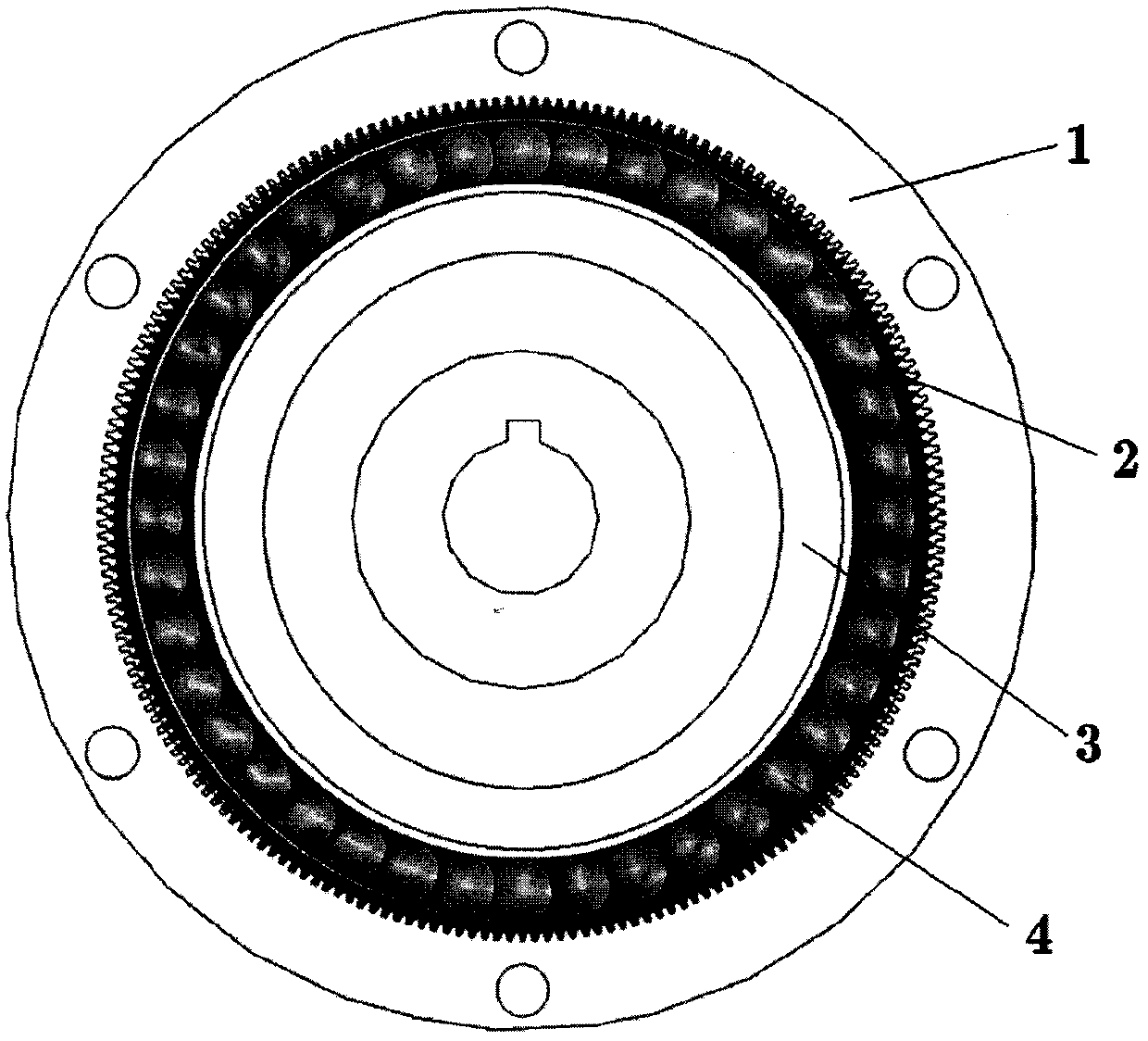

[0027] The present invention has a cup-shaped harmonic gear with three arc tooth profiles (see attached figure 1 , 2 ), consisting of rigid wheel 1, flexible wheel 2, wave generator 3 and flexible bearing 4. The wave generator 3 is equipped with a flexible bearing 4; after the wave generator 3 is installed in the flexspline 2, the cross section of the flexspline becomes elliptical, and the teeth of the flexspline 2 and rigid spline 1 are completely meshed in the long axis area. Complete detachment of the minor axis region; figure 2 Projection from the end shows fully engaged - fully disengaged meshing state.

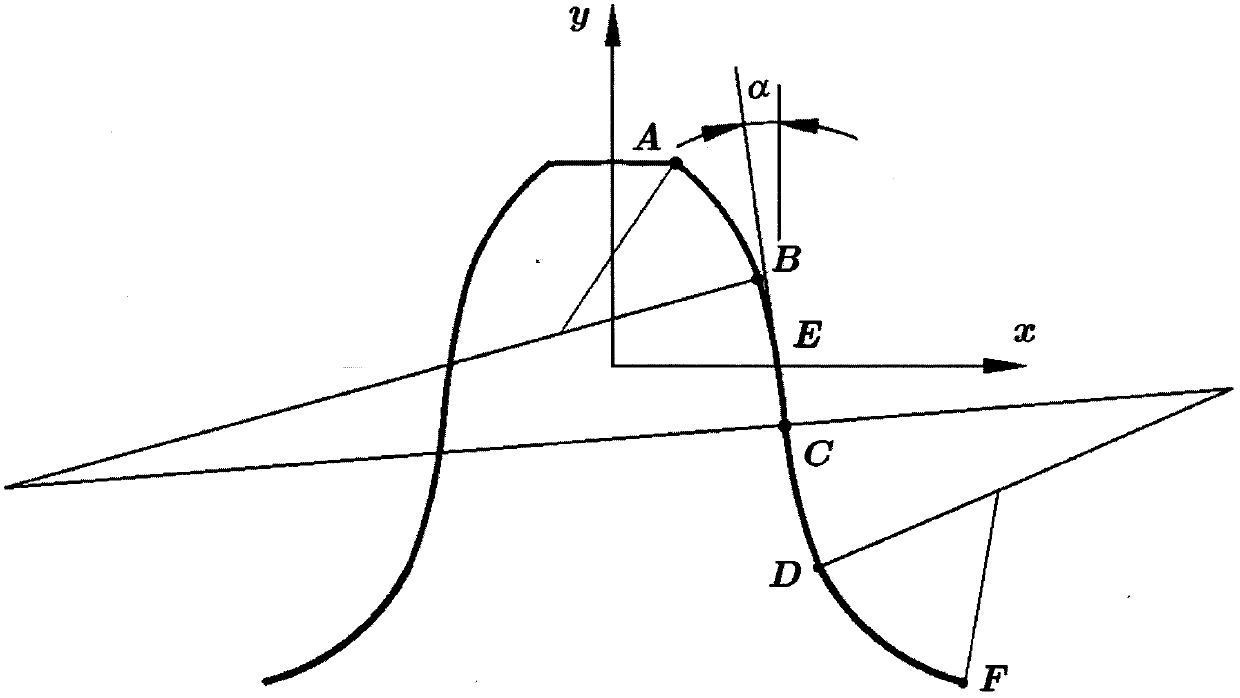

[0028] The present invention has the tooth profile design method (tooth profile design method for short) of three-arc tooth profile harmonic gear, the three-arc tooth profile (refer to image 3 ), which consists of the upper arc segment AB on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com