Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "To achieve the effect of removing impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

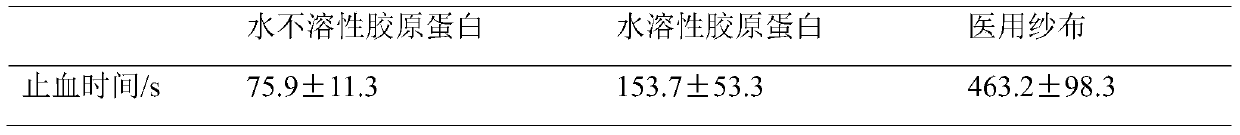

Method for extracting water-insoluble collagen from thoracic aorta of pig

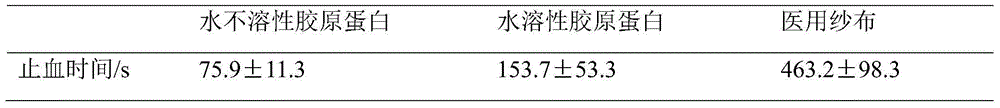

ActiveCN104805165ATo achieve the effect of removing impuritiesEasy to purifyConnective tissue peptidesPeptide preparation methodsWater insolubleHydrolysis

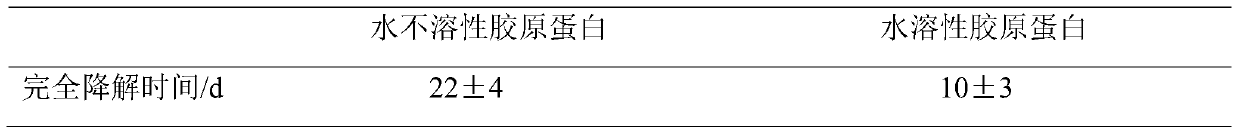

The invention relates to a method for preparing water-insoluble collagen by using thoracic aortas of pigs as raw materials through process steps such as degreasing, impurity removal, enzyme hydrolysis, salt induced precipitation and dialysis. The process steps of the method are simple, safe and easy to operate, the cost is low and the purity of the obtained product is high. Compared with water-soluble collagen, the in-vivo degradation speed of the water-insoluble collagen obtained by the invention is reduced, the blood coagulation speed is faster and the water-insoluble collagen can be used for stopping wound bleeding or preparing other medical biological materials.

Owner:JIANGNAN UNIV

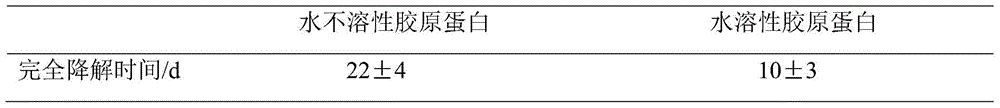

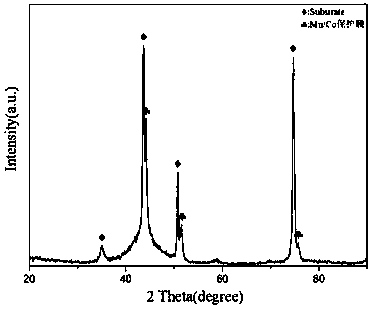

Preparation method of solid oxide fuel cell connector protective film

ActiveCN110184570AImprove antioxidant capacityImprove the performance of anti-cathode poisoningVacuum evaporation coatingSputtering coatingTectorial membraneElectric arc furnace

The invention relates to the technical field of solid oxide fuel cells, and in particular relates to a preparation method of a solid oxide fuel cell connector protective film. The preparation method comprises the following steps: placing a solid oxide fuel cell connector in a cavity; selecting an electric arc source to carry out glow cleaning on the connector; filling the cavity with inert gas andadjusting vacuum degree of the cavity; carrying out electric arc ion plating on the connector; forming an Mn / Co protective film on the surface of the connector; and oxidizing the Mn / Co protective film on the surface of the connector to generate a (Mn, Co)3O4 spinel oxide protective film. Or, the preparation method comprises the following steps: placing the solid oxide fuel cell connector in the cavity; selecting the electric arc source to carry out glow cleaning on the connector; filling the cavity with oxygen or mixed gas of oxygen and inert gas; adjusting the vacuum degree of the cavity bythe injected oxygen or mixed gas of oxygen and inert gas; carrying out electric arc ion plating on the connector; and forming the (Mn, Co)3O4 spinel oxide protective film on the surface of the connector.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

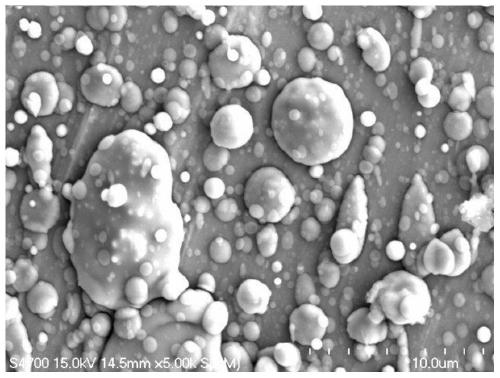

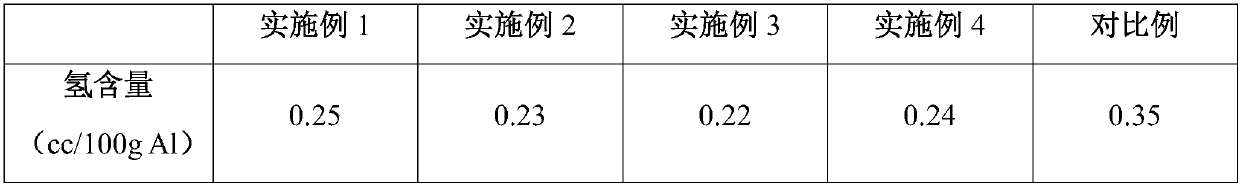

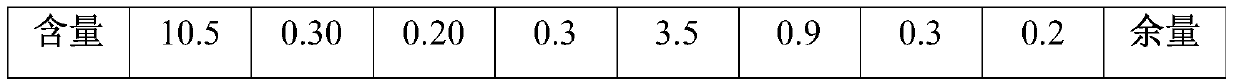

Refining method of aluminum-silicon cast aluminum alloy

The invention belongs to the field of metal materials, and relates to a refining method for an aluminum-silicon cast aluminum alloy. An aluminum alloy ingot raw material comprises the following elements in percentage by mass: 10.5-11.5% of Si, 0.3-0.5% of Mn, 0.2-0.3% of Mg, 0.3-0.6% of Fe, less than or equal to 3.5% of Cu, less than or equal to 0.9% of Zn, less than or equal to 0.3% of Sn, 0.2-0.5% of Ni and the balance of Al. Dried alum is sent into molten aluminum together with an inert gas by a spray gun, wherein the alum addition rate is 1-10%kg / t in Al, the inert gas is injected into themolten aluminum through a graphite rotor, and the bubble diameter of the prepared molten aluminum is less than 1mm. An aluminum alloy ingot obtained by refining the molten aluminum by the refining method for casting an aluminum alloy material, provided by the invention, has a hydrogen content of less than 0.25cc in 100g of Al and an impurity content of less than 200ppm in 100g of Al.

Owner:CHINA ZHONGWANG

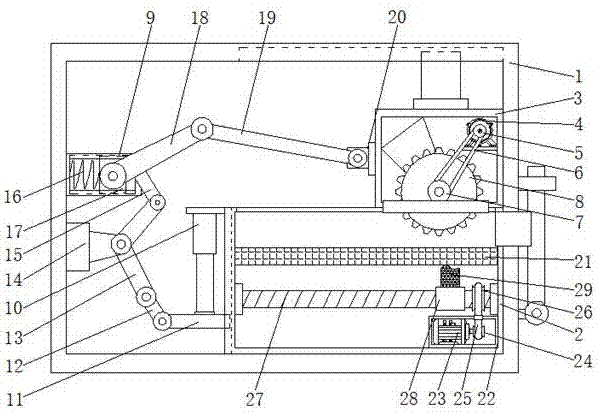

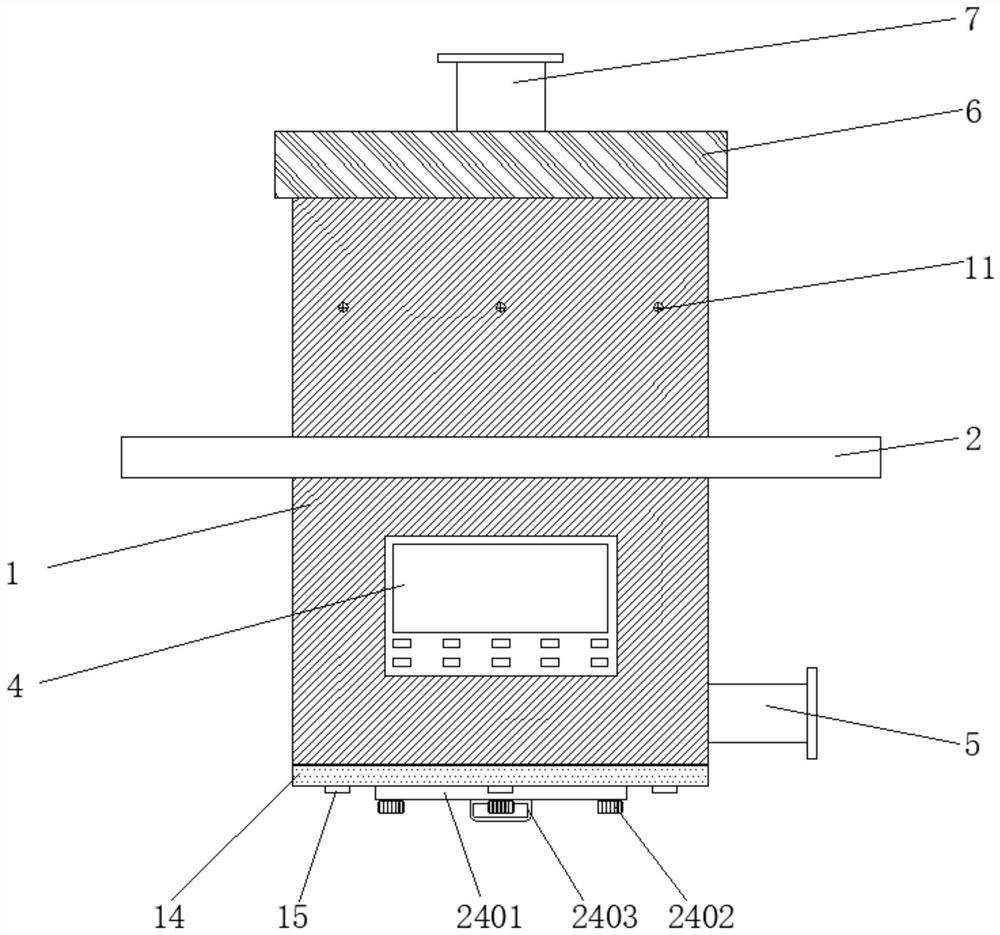

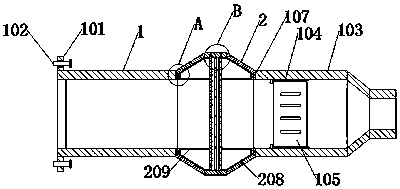

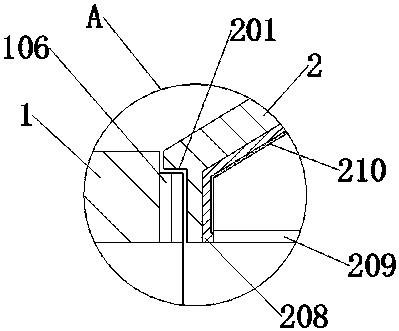

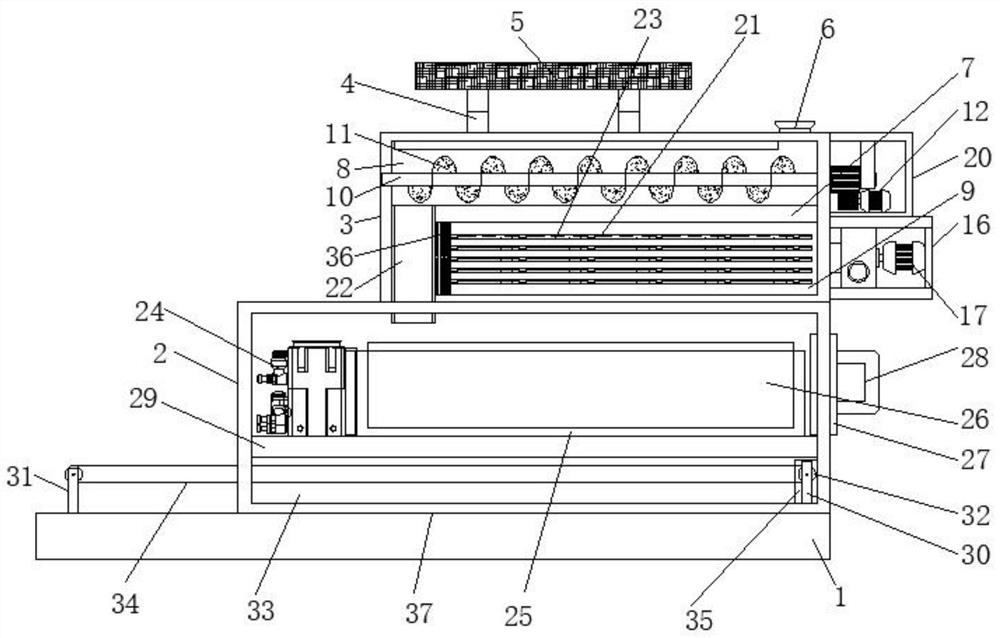

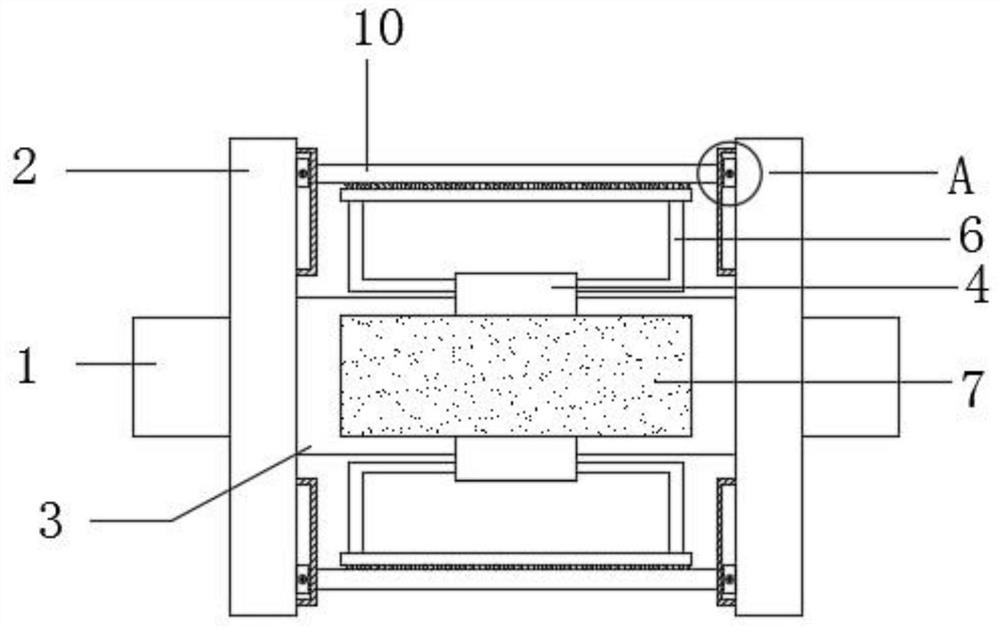

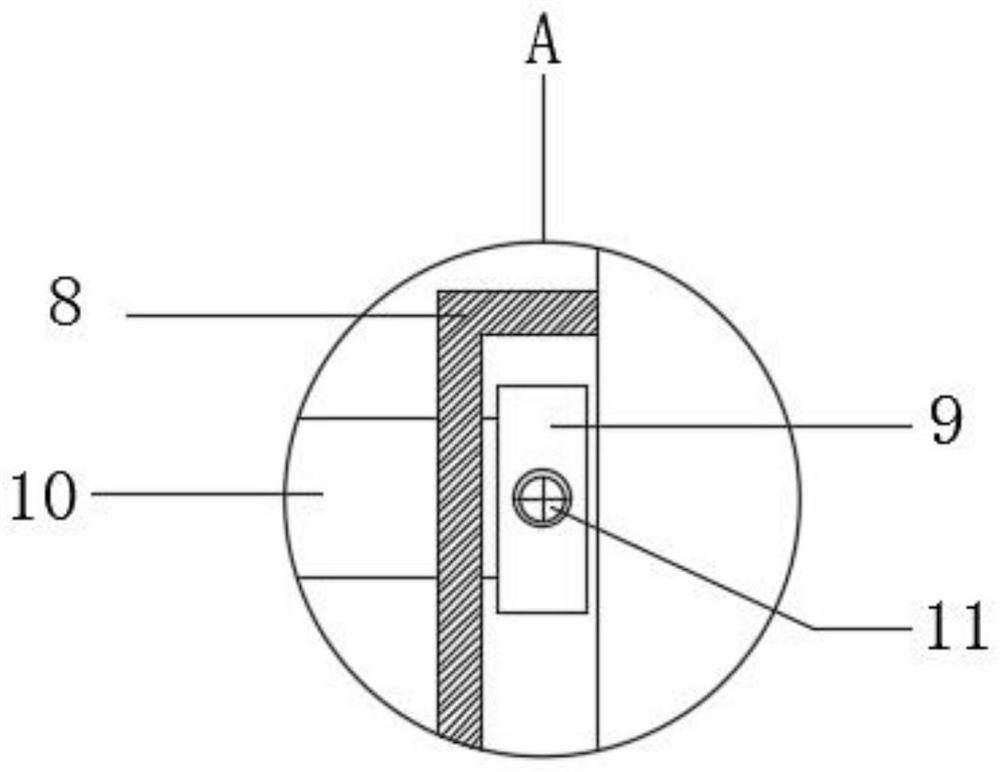

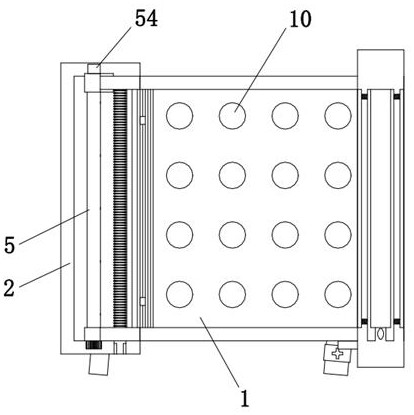

Opening device based on spun-dyed yarn

PendingCN107245774AOpen cotton is effectiveQuality assuranceFibre cleaning/opening by toothed membersFibre cleaning/opening machinesYarnSoftware engineering

The invention discloses an opening device based on spun-dyed yarn, comprising a box body; a bottom box is fixedly connected to the bottom of the inner wall of the box body, an extrusion box is connected to the top of the inner wall of the box body through a sliding plate, a first pulley is fixedly connected to an output shaft of a first motor, a second pulley is in transmission connection with the surface of the first pulley through a belt, a roller is fixedly connected to the back of the second pulley, the axis of the roller is fixedly connected with the inner wall of the extrusion box through a mandrel, the bottom of the roller penetrates the extrusion box and the bottom box sequentially and extends into the bottom box, a transverse plate is fixedly connected between the two sides of the inner wall of the bottom box, and an electric telescopic bar is fixedly connected to the top of the left of the bottom box. The invention relates to the technical field of spun-dyed yarn. The opening device based on spun-dyed yarn allows materials to be placed and picked very conveniently, allows the inside to be observed at any time, and has greatly improved stability and reduced cost.

Owner:响水县嘉禾纺织制衣有限公司

Method for separating and purifying cathepsin L in dorsal muscle of carp

The invention relates to a method for separating and purifying cathepsin L. The method comprises the following steps: dissociating out the cathepsin from crude enzyme liquid of the cathepsin L by thermal treatment, eliminating influence of other enzymes with thermal instability, and then centrifuging to obtain a crude enzyme; eliminating other cathepsin such as cathepsin B, cathepsin H, cathepsin S and the like, the property of which is similar with the cathepsin L by hydrophobic gelchromatography and ion-exchange column chromatography, collecting components with enzymatic activity and then precipitating by 70% of ammonium sulfate; re-dissolving the obtained precipitate by a buffer solution and dissociating the cathepsin L from a complex formed by the cathepsin L and a natural inhibitor thereof at the same time, removing a low molecular weight enzyme inhibitor through ultrafiltration and purification and then concentrating target enzyme; and finally carrying out size-exclusion chromatography and efficient liquid-phase separation on the obtained concentrated solution to obtain the cathepsin L. The cathepsin L (CL) obtained by the method has high purity and better activity maintenance.

Owner:ZHEJIANG UNIV

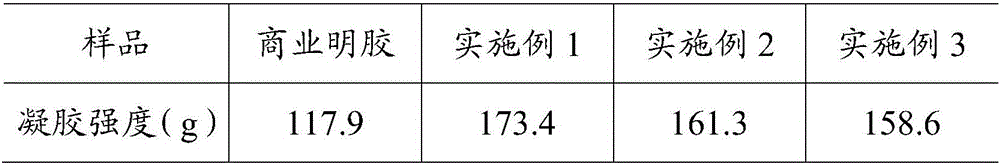

Preparation method of globefish skin gelatin

The invention provides a preparation method of globefish skin gelatin. The preparation method concretely comprises the following steps: selecting globefish skins, cleaning the globefish skins, removing impurities, and chopping the cleaned globefish skins; adding a sodium hydroxide and hydrogen peroxide composite solution, immersing the chopped globefish skins in the composite solution for 5-10h, and washing the immersed globefish skins with water until the pH value is 7-9 in order to obtain alkali treated globefish skins; adding an aqueous detergent solution with the concentration of 0.1-2%, and immersing the globefish skins for 5-10h; adding an acetic acid solution with the concentration of 0.01-1.0mol / L to carry out extraction; centrifuging the obtained solution, and collecting the obtained supernatant; adding a sodium chloride solution with the concentration of 2.0-3.0mol / L to carry out salting-out; centrifuging the obtained solution, and collecting the obtained precipitate; adding acetic acid with the concentration of 0.01-1.0mol / L to dissolve the precipitate, and carrying out dialysis to obtain a gelatin solution; and freeze-drying the gelatin solution to obtain the globefish skin gelatin. The extraction mode and the extraction conditions are mild, and reagents used in the invention are friendly to environment and have low prices, so the production cost of the globefish skin gelatin is effectively reduced, pollution is reduced, and the high-output and high-quality gelatin product is prepared.

Owner:DALIAN POLYTECHNIC UNIVERSITY

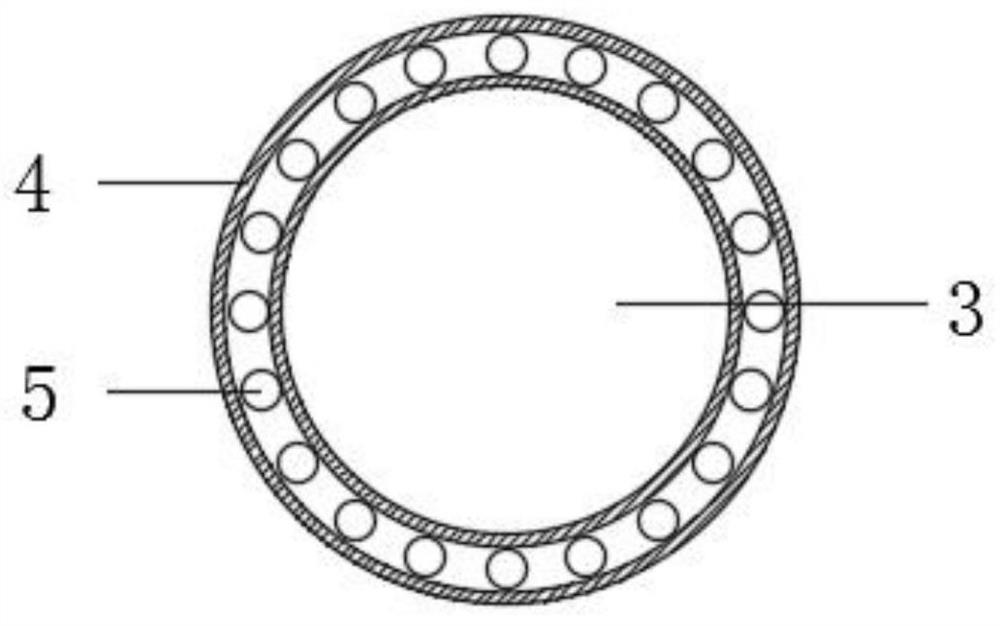

Cylindrical filter capable of conveniently treating impurities on filter screen

InactiveCN112870800AEasy to handleEasy to operateStationary filtering element filtersEngineeringStructural engineering

The invnetion discloses a cylindrical filter capable of conveniently treating impurities on a filter screen. The cylindrical filter comprises a cylindrical filter body and an impurity cleaning mechanism, an annular mounting plate is fixed to the outer side of the cylindrical filter body, and a liquid outlet pipeline penetrates through the right end face of the bottom of the cylindrical filter body. A filter cylinder is fixed to the inner side of the cylindrical filter body through a first fixing bolt, a bottom cover is fixed to the bottom of the cylindrical filter body through a second fixing bolt, a compression spring is fixed to the inner side wall of a limiting sleeve, the outer end of the compression spring is connected with a supporting frame, and the impurity cleaning mechanism penetrates through the bottom cover. According to the cylindrical filter capable of conveniently treating impurities on the filter screen, after a fourth fixing bolt is screwed off, a second handle can be held by hand to integrally disassemble a supporting plate and a plug column, at the moment, the impurities can be discharged through an impurity discharging channel, the effect of removing the impurities is conveniently achieved, and in the process of filtering liquid through the filter screen, the impurities remain on the upper end face of the filter screen, and after the top cover is screwed off, impurities on the filter screen can be cleaned.

Owner:岚山环保科技(上海)有限公司

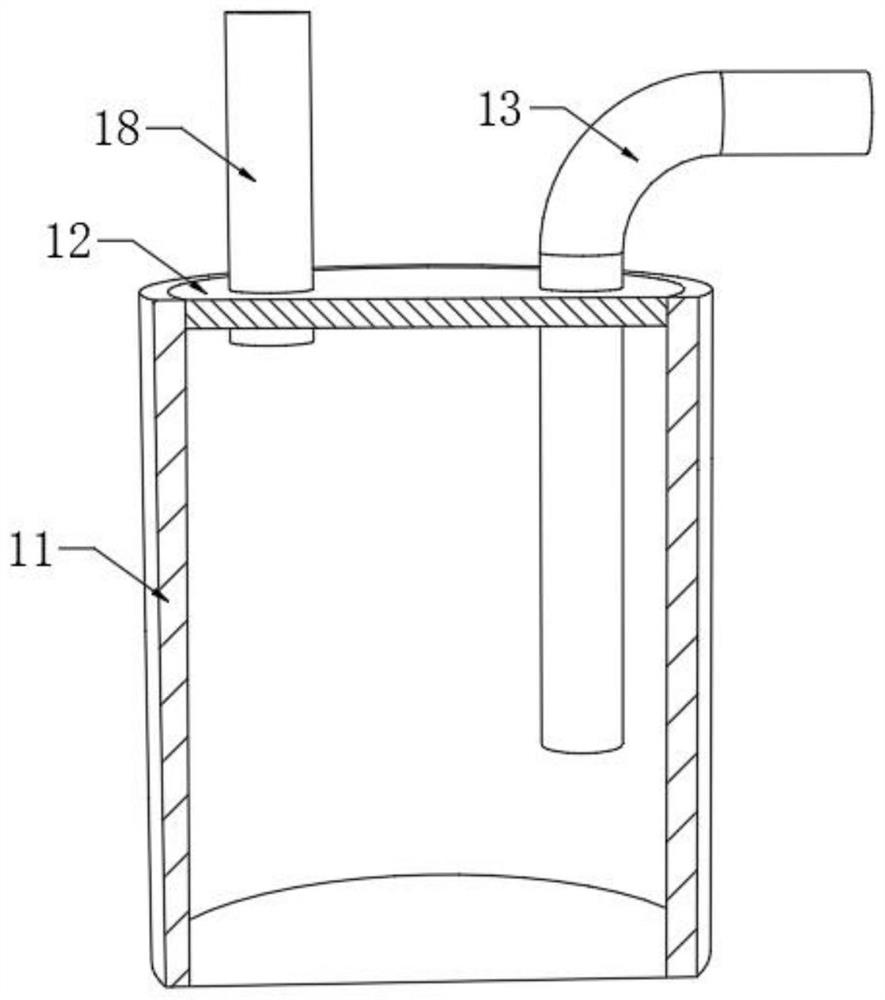

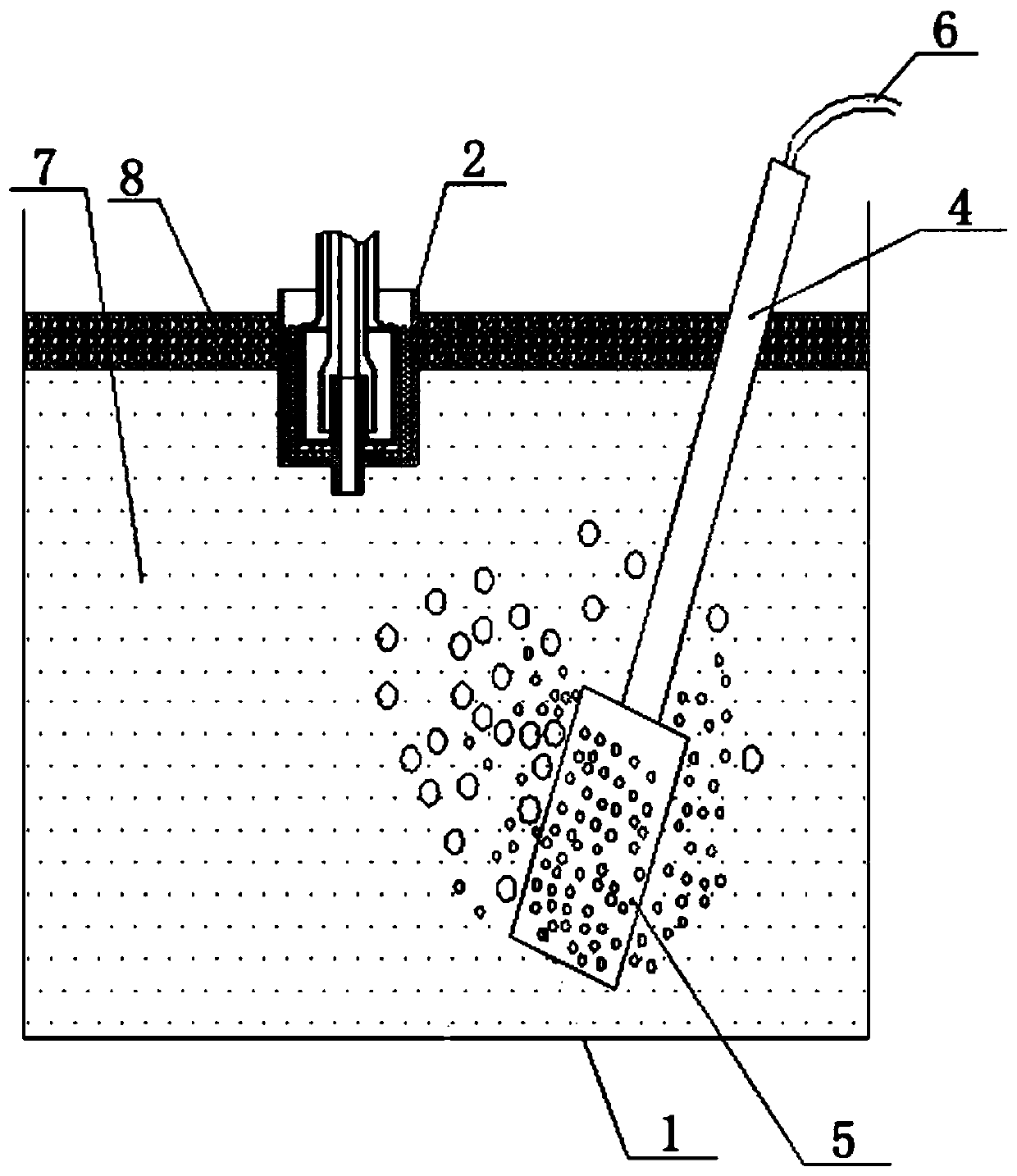

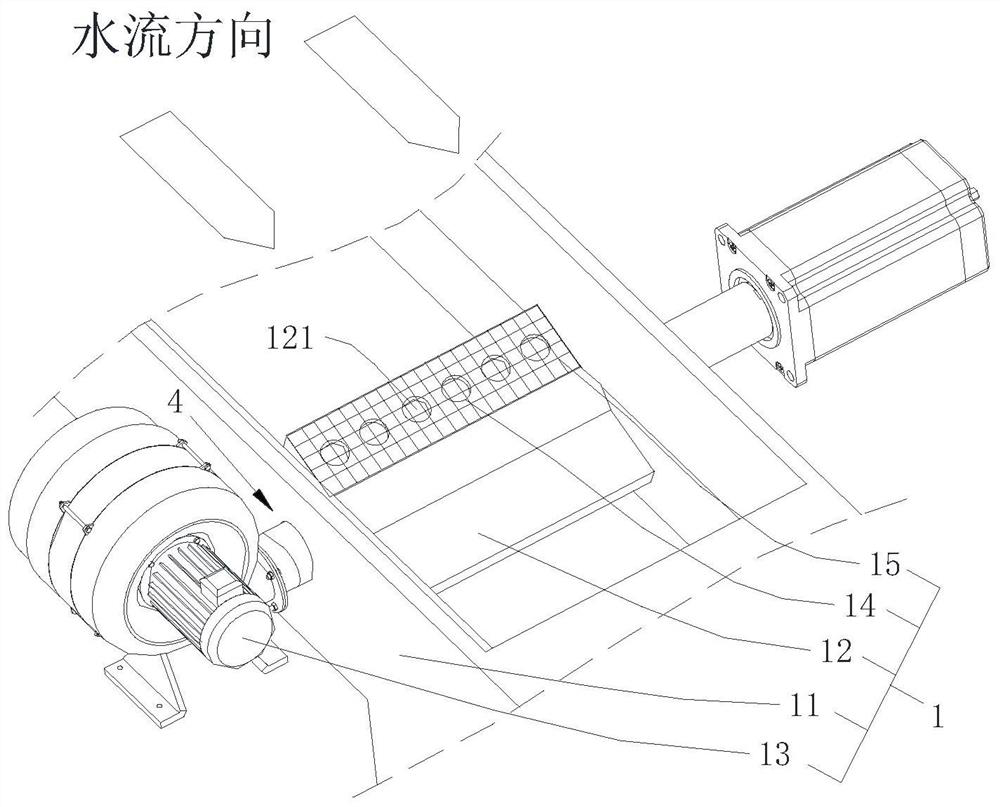

Automatic pollution discharge device for aquaculture

ActiveCN113511738AEnough dissolved oxygenTo achieve the effect of removing impuritiesSpecific water treatment objectivesWater aerationSuspended particlesParticulates

The invention discloses an automatic pollution discharge device for aquaculture, and relates to the technical field of pollution discharge devices. The device comprises a treatment pond and a sewage discharging pond, wherein the sewage discharging pond is arranged beside the treatment pond; a sewage discharging pipe is arranged on the lower portion of the sewage discharging pond in a penetrating mode; a scraping assembly, a first baffle, a spraying assembly, a transmission assembly, a brushing assembly and a locking assembly are arranged on the treatment pond; a plurality of air inlet holes are evenly formed in the bottom of the treatment pond; a notch is formed in one side of the upper portion of the treatment pond; the first baffle is arranged in the notch in a sliding mode; the spraying assembly is arranged above the sewage discharging pond; the brushing assembly is arranged between the spraying assembly and the sewage discharging pond; and the transmission assembly is arranged between the U-shaped plate and the spraying assembly. According to the device, air is uniformly conveyed into micro-polluted water from the bottom of the treatment tank to provide sufficient dissolved oxygen for a water body, and bubbles can adsorb suspended particles with small particle sizes in sewage in the rising process, so that the effect of removing impurities is achieved, and the practicability of the device is improved.

Owner:莱州明波水产有限公司 +2

Settling device of inhalable particulate matters in automobile tail gas

InactiveCN111379611AAvoid incomplete combustionReduced service life impactExhaust apparatusSilencing apparatusParticulatesThreaded pipe

The invention discloses a settling device of inhalable particulate matters in automobile tail gas. The settling device comprises a connecting pipe and a particulate matter treatment box, wherein a connecting flange is fixed to the left end of the outer side of the connecting pipe, at least five connecting rods which are annularly arranged at equal intervals are inserted on the outer side of the right face of the connecting flange, and a threaded pipe I communicating with the connecting pipe is fixed to the right end of the connecting pipe; the left side and the right side of the particulate matter treatment box are provided with threaded openings which communicate with the particulate matter treatment box, and the threaded pipe I is screwed into the threaded openings, so that the particulate matter treatment box is in threaded connection with the right end of the connecting pipe; and two left and right parallel iron wire meshes are vertically fixed to the middle of the interior of theparticulate matter treatment box, and insulating plates located in the particulate matter treatment box are fixed to the inner wall of the two iron wire meshes. The settling device has the beneficialeffects that particulate matters in the tail gas are sufficiently removed, the particulate matters are conveniently collected while the particle removal effect is improved, and the particulate mattersare prevented from being discharged in the tail gas.

Owner:福州妙笔生花工业设计有限公司

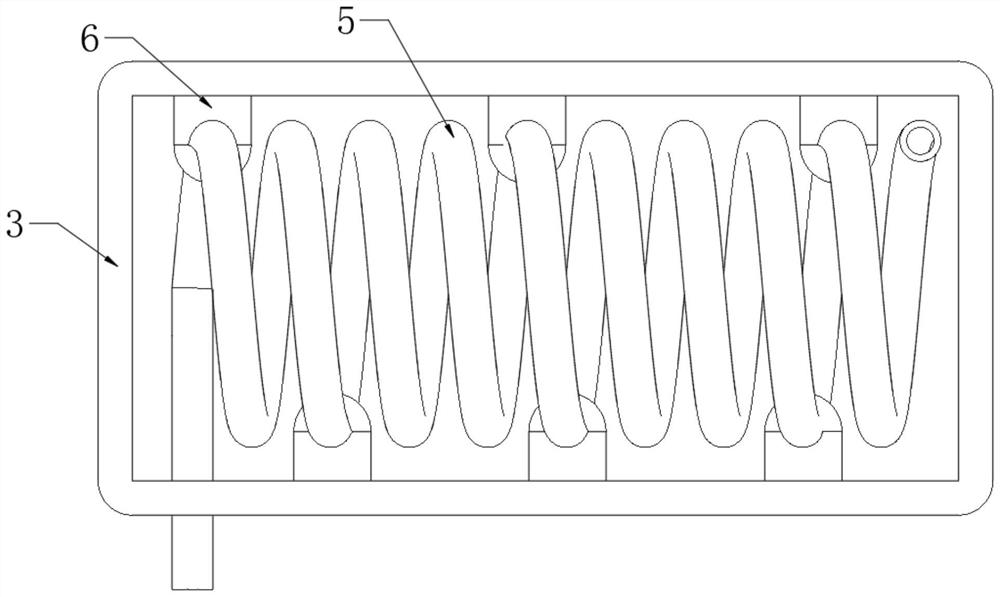

Hydrogen refueling station-based hydrogen purification device

ActiveCN113184809AIncreased cooling contact areaTo achieve the effect of removing impuritiesHydrogen separation at low temperatureHydrogen/synthetic gas productionStraight tubeMixed gas

The invention provides a hydrogen refueling station-based hydrogen purification device comprising a bottom plate, supporting columns and a cooling box; the four supporting columns are fixedly connected to one side of the upper surface of the bottom plate at equal intervals; the cooling box is fixedly connected to the tops of the four supporting columns; a box cover is fixedly connected to the top of the inner wall of the cooling box, and the cooling box is provided with a spiral condensation pipe; and the two sides of the inner wall of the cooling box are fixedly connected with fixed bases at equal intervals correspondingly, and the outer surfaces of the spiral condensation pipe is fixedly mounted on the plurality of fixed bases correspondingly. A traditional straight condensation pipe is arranged to be the spiral condensation pipe in a threaded spiral shape, on one hand, the cooling contact area can be increased, on the other hand, mixed gas is liquefied and attached to the pipe wall through the centrifugal effect of the spiral condensation pipe, and the effect of removing impurities is achieved; and finally, a filtering mechanism is additionally arranged at the gas outlet end of the spiral condensation pipe to further filter out liquefied impurities, and the purpose of further purifying hydrogen is achieved.

Owner:深圳国氢新能源科技有限公司

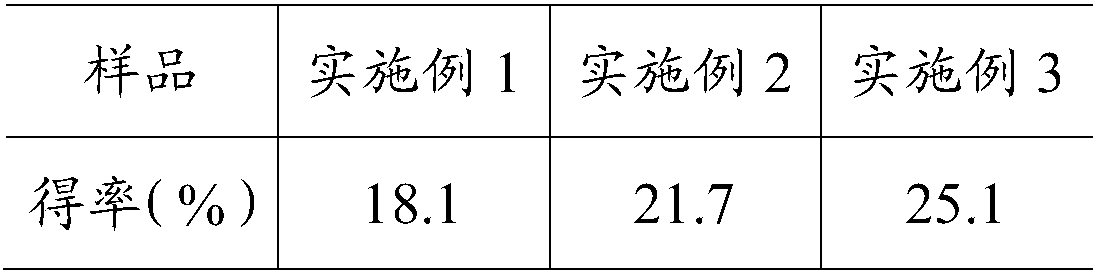

Method for removing impurities in production process of high-purity dihydroartemisinic acid

InactiveCN110563573ATo achieve the effect of removing impuritiesSpeed up filteringCarboxylic compound separation/purificationImpurityEnergy consumption

The invention relates to the field of medicinal chemistry, in particular to a method for removing impurities in the production process of high-purity dihydroartemisinic acid. The method comprises thefollowing steps: (1) extracting and standing; (2) filtering and removing impurities; (3) concentrating; (4) extracting to remove impurities; (5) acidification; (6) extracting, standing and removing impurities; (7) concentration. The method for removing the grease impurities and the black colloidal impurities in the production process of the high-purity dihydroarteannuic acid is low in energy consumption, easy to operate, free of special equipment, small in investment and capable of effectively removing the impurities in the production process of the dihydroarteannuic acid.

Owner:长沙艾康生物科技有限公司 +1

A kind of preparation method of puffer fish skin gelatin

The invention provides a preparation method of globefish skin gelatin. The preparation method concretely comprises the following steps: selecting globefish skins, cleaning the globefish skins, removing impurities, and chopping the cleaned globefish skins; adding a sodium hydroxide and hydrogen peroxide composite solution, immersing the chopped globefish skins in the composite solution for 5-10h, and washing the immersed globefish skins with water until the pH value is 7-9 in order to obtain alkali treated globefish skins; adding an aqueous detergent solution with the concentration of 0.1-2%, and immersing the globefish skins for 5-10h; adding an acetic acid solution with the concentration of 0.01-1.0mol / L to carry out extraction; centrifuging the obtained solution, and collecting the obtained supernatant; adding a sodium chloride solution with the concentration of 2.0-3.0mol / L to carry out salting-out; centrifuging the obtained solution, and collecting the obtained precipitate; adding acetic acid with the concentration of 0.01-1.0mol / L to dissolve the precipitate, and carrying out dialysis to obtain a gelatin solution; and freeze-drying the gelatin solution to obtain the globefish skin gelatin. The extraction mode and the extraction conditions are mild, and reagents used in the invention are friendly to environment and have low prices, so the production cost of the globefish skin gelatin is effectively reduced, pollution is reduced, and the high-output and high-quality gelatin product is prepared.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Degerming device for dairy products

The invention discloses a degerming device for dairy products. The degerming device for dairy products comprises a motor, a box cover, a main box body and a heating and stirring box, wherein a fixed rod is mounted in the heating and stirring box; a groove is formed in the middle of the fixed bar; a middle shaft is movably mounted in the groove; a stirring plate is mounted on the surface of the middle shaft; a latch is mounted on the top end of the middle shaft, and is engaged to a latch mounted at the output end of a motor; a pulley is arranged on the outer surface of the latch, and is movablymounted in a pulley groove; the motor is mounted in the box cover; the box cover is rotatably mounted at the top end of the main box body through a hinge; a pair of rotary calipers is mounted on oneside of the box cover, and the rotary calipers are locked in a slot to be fixed; hook blocks are arranged in two sides of the heating and stirring box; and hooks are fixed in the hook blocks. The device carries out electric heating and stirring at the same time, so that raw and auxiliary materials are sterilized uniformly, and the raw and auxiliary materials are boiled and impurities on the surfaces of the raw and auxiliary materials are adsorbed and removed by means of a filter membrane.

Owner:海宁市立派商贸有限公司

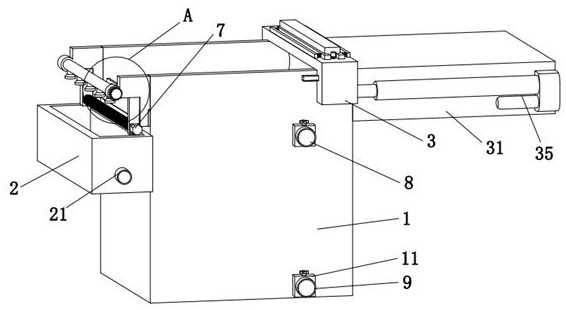

Extrusion type abnormal fiber sorting structure

ActiveCN105734727AAccurate exclusionTo achieve the effect of removing impuritiesFibre cleaning/openingFiberEngineering

The invention provides an extrusion type abnormal fiber sorting structure, relates to the field of textile machinery, and solves the problem of sorting of abnormal fibers in raw cotton. The extrusion type abnormal fiber sorting structure comprises a cotton conveying pipe, a rotating wheel, an abnormal fiber collecting box, a pushing module and an abnormal fiber detecting module; a rotating groove for allowing the rotating wheel to rotate is formed in the cotton conveying pipe, and an opening for allowing the abnormal fibers to eliminate is formed in the corresponding surface of the rotating groove; the rotating wheel comprises a rotating motor; the abnormal fiber collecting box comprises a turning plate shaft, a turning plate and a reset spring; a corresponding opening is formed in a position where the abnormal fiber collecting box is corresponding to a cotton conveying pipe opening; the pushing module comprises a telescopic rod; the abnormal fiber detecting module is fixedly mounted in the rotating wheel; cotton silk inside a raw cotton block is enabled to fully expose through extrusion so as to conduct accurate detection; the raw cotton block is quantitatively detected and separated to prevent the wrong elimination of available raw cotton.

Owner:WUJIANG ZHENYU SEWING EQUIP

Method for removing gallium from primary aluminum by using vacuum distillation

ActiveCN109609779ATo achieve the effect of removing impuritiesLow boiling pointProcess efficiency improvementAluminum canVacuum distillation

The invention provides a method for removing gallium from primary aluminum by using vacuum distillation. The method comprises the following steps that (1) the primary aluminum is placed into a vacuumsmelting furnace, and the vacuum smelting furnace is subjected to vacuumizing until the air pressure is 0.1-20 Pa; (2) heating is carried out, the pressure is kept to be 0.1-20 Pa; and when the temperature reaches 900-1100 DEG C, the heat is preserved and smelting is carried out, and the gallium in the primary aluminum is evaporated to enter a condenser; and (3), furnace cooling is carried out. According to the method, the gallium-containing primary aluminum is used as a raw material, smelting and purifying of the aluminum can be simply and effectively realized, and the purified aluminum withthe content of gallium less than 50 ppm is obtained; and no waste gas is generated in the production process, so that no pollution is caused to the environment.

Owner:NORTHEASTERN UNIV

Energy-saving ginkgo leaf fixation dryer

PendingCN111888382AReach deliveryTo achieve the effect of removing impuritiesGinkgophyta medical ingredientsPlant ingredientsAgricultural engineeringGinkgo biloba

The invention discloses an energy-saving ginkgo leaf fixation dryer. The dryer comprises a bearing plate, a second box body is fixedly mounted at the upper part of the bearing plate, a first box bodyis fixedly mounted at the upper part of the second box body, a liftable adjusting bracket is fixedly mounted at the upper part of the first box body, a solar panel is arranged at the upper part of theadjusting bracket, a feeding port is formed in the upper portion of the first box body and located in the right side of the adjusting bracket, a grid plate is fixedly installed in the first box bodyand divides the first box body into a material conveying cavity and a temperature control cavity, a rotating rod is rotatably installed in the material conveying cavity, and a transmission blade is arranged outside the rotating rod. The invention relates to the technical field of ginkgo leaf processing. The energy-saving ginkgo leaf fixation dryer is good in drying effect, resources are reasonablyutilized, the energy-saving effect is achieved, impurities on ginkgo leaves are removed, and the effect of the ginkgo leaf fixation drying machine is better.

Owner:JIANGSU BESCON PHARMA

Method for preparing n-eicosane by normal pressure chaining

InactiveCN101987807AHigh purityHigh yield and purityHydrocarbon from halogen organic compoundsChemical modification purification/separationBrominePotassium permanganate

The invention relates to a method for preparing n-eicosane by normal pressure chaining, which comprises the following steps of: (1) weighing bromodecane for later use; (2) weighing metal sodium and cutting the metal sodium into small and thin strips for later use; (3) reacting the bromodecane and the metal sodium completely; (4) precipitating and separating an organic phase; (5) obtaining n-eicosane product by distilling, rectifying and passivating. In the preparation method in the invention, strong oxidizers such as concentrated sulfuric acid and acidic potassium permanganate are used for oxidizing unsaturated organic substances and alcoholic impurities to remove impurities, so that the purity of a product is improved; the raw materials for the preparation are fully supplied in the market, the purity and yield of the obtained product both are relatively high, and production efficiency is improved to a certain extent.

Owner:TIANJIN CHEM REAGENT RES INST

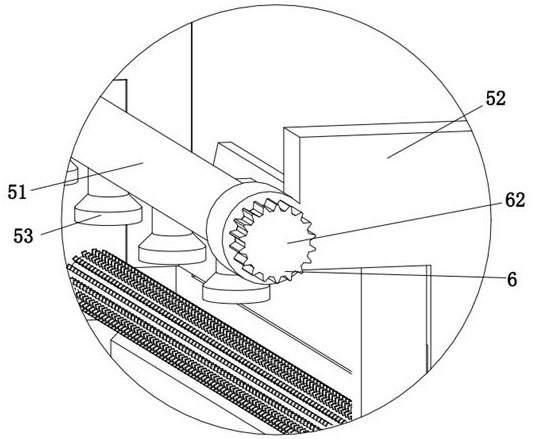

High-speed stranding machine for producing cables

ActiveCN111863356AAdjust the diameterTo achieve the effect of removing impuritiesCleaning using toolsCable/conductor manufactureStructural engineeringMachine

The invention belongs to the technical field of stranding machines. The invention especially relates to a high-speed stranding machine for producing cables. The machine comprises a connecting drum, and one side of the connecting drum is fixedly connected with a side connecting plate; a rotating shaft is fixedly connected to one side, away from the connecting drum, of the side connecting plate; thesurface of the rotating shaft is sleeved with a lantern ring, a transmission ball is arranged on the inner wall of the lantern ring, connecting rods are fixedly connected to the two sides of the lantern ring, cleaning brushes are fixedly connected to the ends, away from the lantern ring, of the connecting rods, a fixed side plate is fixedly connected to the inner wall of the side connecting plate, a chute is formed in the fixed side plate, and a sliding block is slidably connected to the inner wall of the chute. By arranging the sliding block, when the size of the coil needs to be adjusted, the sliding block can slide in the fixed side plate, when the sliding block slides, the coil sleeve rod is driven to move, after adjustment, the fixing screw is inserted into the through holes of the fixed side plate and the sliding block to be fixed, and therefore the effect of adjusting the diameter of the coil is achieved.

Owner:JIANGSU FUCHUAN ELECTRICAL & MECHANICAL

Aquaculture automatic sewage device

ActiveCN113511738BEnough dissolved oxygenTo achieve the effect of removing impuritiesSpecific water treatment objectivesWater aerationSuspended particlesParticulates

The invention discloses an automatic sewage discharge device for aquaculture, and relates to the technical field of sewage discharge devices. It includes a treatment pool and a sewage pool. The sewage pool is arranged on the side of the treatment pool. A sewage pipe is opened through the lower part of the sewage pool. The treatment pool is equipped with a scraping assembly, a first baffle, a spray assembly, Transmission assembly, scrubbing assembly and locking assembly, the bottom of the processing pool is evenly opened with several air inlets, a gap is opened on one side of the upper part of the processing pool, the first baffle is slidably set in the gap, the The spray assembly is arranged above the sewage discharge tank, the brushing assembly is arranged between the spray assembly and the sewage discharge pond, and the transmission assembly is arranged between the rectangular plate and the spray assembly. By uniformly transporting air from the bottom of the treatment tank into the slightly polluted water, sufficient dissolved oxygen is provided for the water body, and the air bubbles can absorb suspended particles with small particle sizes in the sewage on the way up to achieve the effect of removing impurities and improve the performance of the device. practicality.

Owner:莱州明波水产有限公司 +2

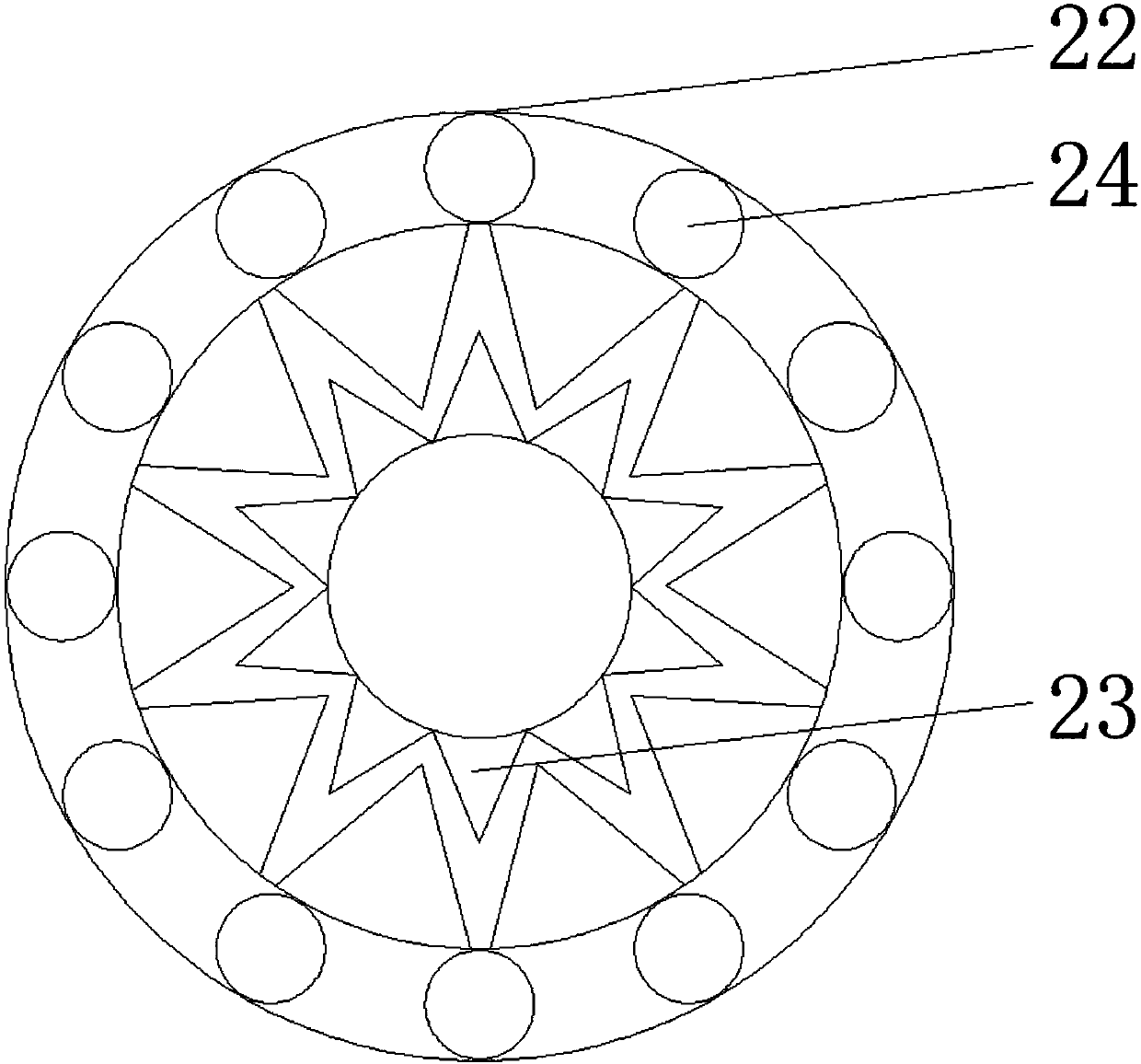

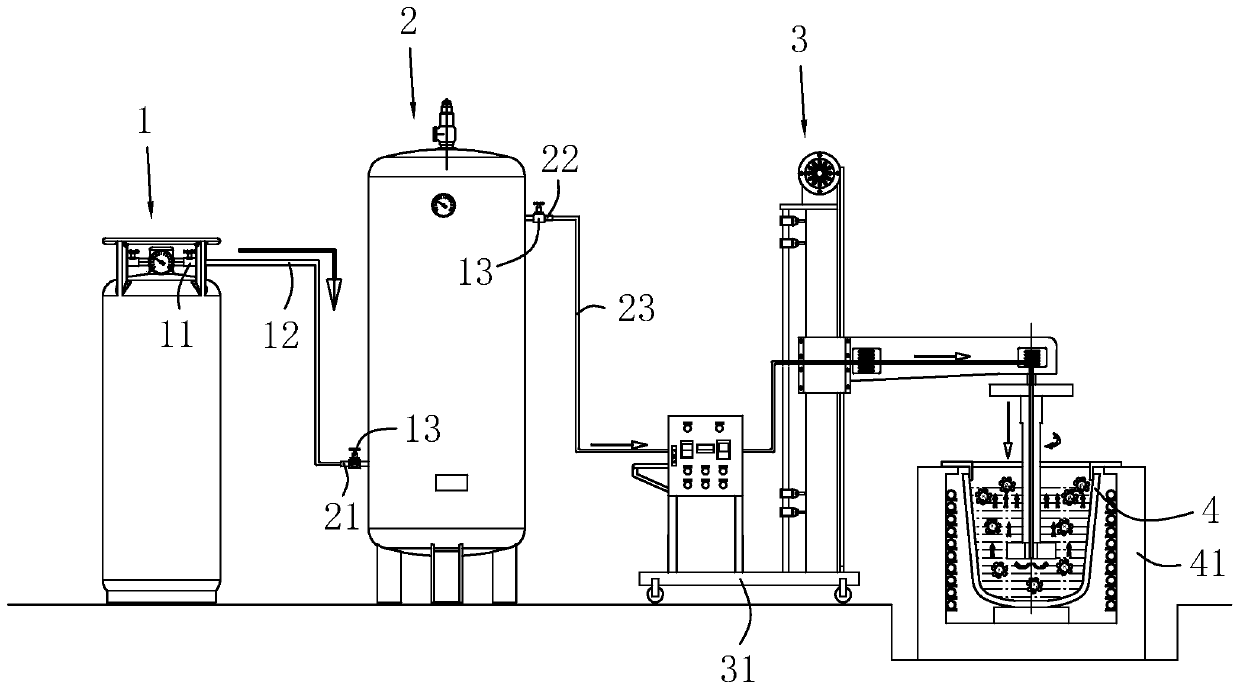

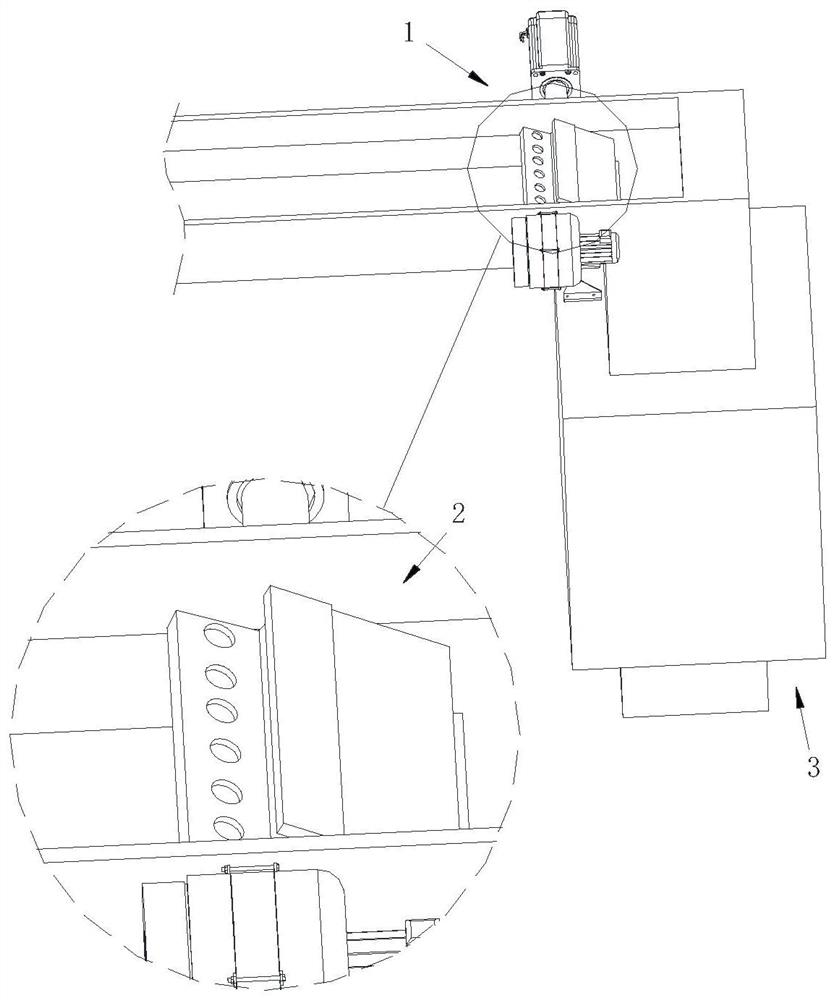

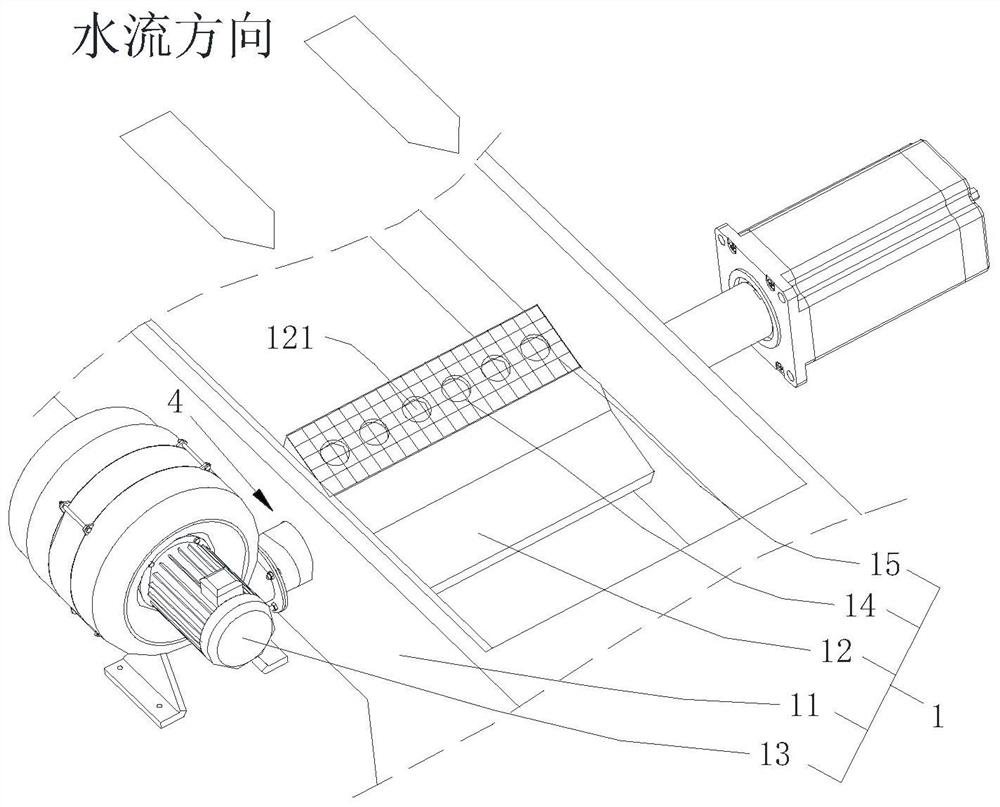

Equipment for refining waste gas and waste slag in aluminum alloy through high-purity liquid nitrogen

The invention relates to equipment for refining waste gas and waste slag in an aluminum alloy through high-purity liquid nitrogen, and belongs to the technical field of aluminum alloy waste gas and waste slag treatment equipment. A high-purity liquid nitrogen bottle, a gas storage tank, a gas removing machine and a furnace body are included and sequentially arranged. The high-purity liquid nitrogen bottle is provided with a gas supply pipe. A gas inlet pipe is arranged at the bottom of the gas storage tank. A gas outlet pipe is arranged at the upper portion of the gas storage tank. The gas removing machine comprises a bottom plate. The bottom plate is provided with a stand column. The stand column is provided with a beam. A first motor is arranged in the beam. The drive end of the first motor is provided with a graphite rotor. The graphite rotor is provided with a graphite rotation disc. A first pipeline is arranged between the gas supply pipe and the gas inlet pipe in a commutation manner. The gas outlet pipe is provided with a second pipeline passing through the beam. A channel for the second pipeline to pass through is formed in the graphite rotor and the graphite rotation disc.Through surface tension of nitrogen, after hydrogen in aluminum liquid is adsorbed, the aluminum liquid is discharged, exhausted gases are mainly hydrogen and nitrogen and are harmless, and hurt to the human bodies from the harmful gases is prevented.

Owner:成都科汇模具有限公司

Digital jet printing machine for finished clothes

InactiveCN114211877AReduce congestionTo achieve the effect of removing impuritiesTypewritersLiquid storage tankEngineering

The invention belongs to the field of digital jet printing machines, and particularly relates to a finished garment digital jet printing machine which comprises a printing machine body. The printing machine body comprises an ink box; a liquid containing groove is fixedly connected into the ink box. A first liquid through hole is formed in the bottom of the liquid containing groove; the bottom of the liquid containing groove is fixedly connected with the supporting shaft. A meshing block is arranged in the supporting shaft; a meshing rod is arranged in the meshing block; a spring is arranged at the bottom of the meshing rod; a pressure sensor and a baffle are arranged at the bottom of the liquid storage tank; a cleaning bag is arranged at the bottom corner of the liquid storage tank; the cleaning bag is fixedly connected with the air delivery pipe; an ink bag is arranged in the liquid containing groove. A nozzle is arranged at the bottom of the ink box; a push rod is arranged in the printing machine body; the inner wall of the ink bag is cleaned by the cleaning liquid under the pressure effect, the effect of removing impurities is achieved, the situation that the first liquid through hole is blocked due to impurity accumulation on the inner wall of the ink bag is reduced, and the possibility of line breakage or no ink discharge in the working state is further reduced.

Owner:魏忆楠

Method for separating and purifying cathepsin L in dorsal muscle of carp

InactiveCN101886065BTo achieve the effect of removing impuritiesEasy to purifyHydrolasesThermal instabilityCathepsin O

The invention relates to a method for separating and purifying cathepsin L. The method comprises the following steps: dissociating out the cathepsin from crude enzyme liquid of the cathepsin L by thermal treatment, eliminating influence of other enzymes with thermal instability, and then centrifuging to obtain a crude enzyme; eliminating other cathepsin such as cathepsin B, cathepsin H, cathepsinS and the like, the property of which is similar with the cathepsin L by hydrophobic gelchromatography and ion-exchange column chromatography, collecting components with enzymatic activity and then precipitating by 70% of ammonium sulfate; re-dissolving the obtained precipitate by a buffer solution and dissociating the cathepsin L from a complex formed by the cathepsin L and a natural inhibitor thereof at the same time, removing a low molecular weight enzyme inhibitor through ultrafiltration and purification and then concentrating target enzyme; and finally carrying out size-exclusion chromatography and efficient liquid-phase separation on the obtained concentrated solution to obtain the cathepsin L. The cathepsin L (CL) obtained by the method has high purity and better activity maintenance.

Owner:ZHEJIANG UNIV

Steel smelting industrial wastewater purification treatment process

ActiveCN111821760AImprove cooling effectIncrease contact areaDirect contact heat exchangersHeat transfer modificationIndustrial waste waterProcess engineering

The invention relates to a steel smelting industrial wastewater purification treatment process, and relates to the technical field of metal smelting. Iron and steel smelting industrial wastewater purifying and cooling equipment is used, the equipment comprises a cooling device, a primary impurity removing device and a secondary impurity removing device, the cooling device is used for cooling smelting industrial wastewater, and the primary impurity removing device and the secondary impurity removing device are matched with each other to remove impurities in the smelting industrial wastewater; the process has the advantages of being good in impurity removal effect, high in operation efficiency and good in cooling performance.

Owner:SHANXI TONGCAI IND & TRADE

Copper alloy liquid purifying device and method used for up-drawing continuous casting

The invention discloses a copper alloy liquid purifying device and method used for up-drawing continuous casting. The purifying device comprises a bottom blowing impurity removing device arranged at the bottom of the interior of a heat insulation bin of an up-drawing continuous casting furnace and / or a filtering and purifying device arranged at the end portion of an up-drawing continuous casting crystallizer, wherein the filtering and purifying device is located in the heat insulation bin of the up-drawing continuous casting furnace. The purifying method includes the steps that inert gas is blown to the bottom of the interior of the heat insulation bin of the up-drawing continuous casting furnace containing copper alloy liquid through the bottom blowing impurity removing device, and / or after the copper alloy liquid flows into the filtering and purifying device to be filtered, the copper alloy liquid then enters the up-drawing continuous casting crystallizer. By means of the copper alloy liquid purifying device and method used for up-drawing continuous casting, due to the fact that the copper alloy liquid is purified, impurities and gas in the copper alloy liquid can be prevented from entering a copper alloy wire rod, and therefore the quality of the copper alloy wire rod is effectively improved, large-length continuous drawing of ultrathin copper alloy wires is better achieved,and the wire breaking rate is reduced; and transformation on the structure of an up-drawing furnace body and the crystallizer is avoided, operability is good, implementation is easy, and safety and reliability are achieved.

Owner:CHINALCO KUNMING COPPER

A method for extracting water-insoluble collagen from pig thoracic aorta

ActiveCN104805165BTo achieve the effect of removing impuritiesEasy to purifyConnective tissue peptidesPeptide preparation methodsWater insolubleDigestion

The invention relates to a method for preparing water-insoluble collagen by using porcine thoracic aorta as raw material through degreasing, impurity removal, enzymatic hydrolysis, salting out, dialysis and other technical steps. The process steps of the method are simple, safe and easy to operate, the cost is low, and the obtained product has high purity. Compared with the water-soluble collagen, the degradation rate of the water-insoluble collagen obtained in the present invention is reduced in vivo, and the coagulation speed is faster, and can be used for wound hemostasis or preparation of other medical biomaterials.

Owner:JIANGNAN UNIV

A high-speed stranding machine for producing cables

ActiveCN111863356BAdjust the diameterTo achieve the effect of removing impuritiesCleaning using toolsCable/conductor manufactureStructural engineeringMachine

The invention belongs to the technical field of stranding machines, in particular to a high-speed stranding machine for producing cables. The side is fixedly connected with a rotating shaft, the surface of the rotating shaft is sleeved with a collar, the inner wall of the collar is provided with a transmission ball, the two sides of the collar are fixedly connected with a connecting rod, and the end of the connecting rod far away from the collar is fixedly connected with a cleaning brush. The inner wall of the side connecting plate is fixedly connected with a fixed side plate, the inside of the fixed side plate is provided with a chute, and the inner wall of the chute of the fixed side plate is slidably connected with a slider. In the present invention, by setting the slider, when the size of the coil needs to be adjusted, the slider can slide in the fixed side plate. When the sliding of the slider drives the coil rod to move, after the adjustment is completed, the fixing screw is inserted into the fixed side plate. The side plate and the through hole of the slider are fixed, thereby achieving the effect of adjusting the diameter of the coil.

Owner:JIANGSU FUCHUAN ELECTRICAL & MECHANICAL

A kind of refining method of aluminum-silicon series cast aluminum alloy

The invention belongs to the field of metal materials, and relates to a refining method for an aluminum-silicon cast aluminum alloy. An aluminum alloy ingot raw material comprises the following elements in percentage by mass: 10.5-11.5% of Si, 0.3-0.5% of Mn, 0.2-0.3% of Mg, 0.3-0.6% of Fe, less than or equal to 3.5% of Cu, less than or equal to 0.9% of Zn, less than or equal to 0.3% of Sn, 0.2-0.5% of Ni and the balance of Al. Dried alum is sent into molten aluminum together with an inert gas by a spray gun, wherein the alum addition rate is 1-10%kg / t in Al, the inert gas is injected into themolten aluminum through a graphite rotor, and the bubble diameter of the prepared molten aluminum is less than 1mm. An aluminum alloy ingot obtained by refining the molten aluminum by the refining method for casting an aluminum alloy material, provided by the invention, has a hydrogen content of less than 0.25cc in 100g of Al and an impurity content of less than 200ppm in 100g of Al.

Owner:CHINA ZHONGWANG

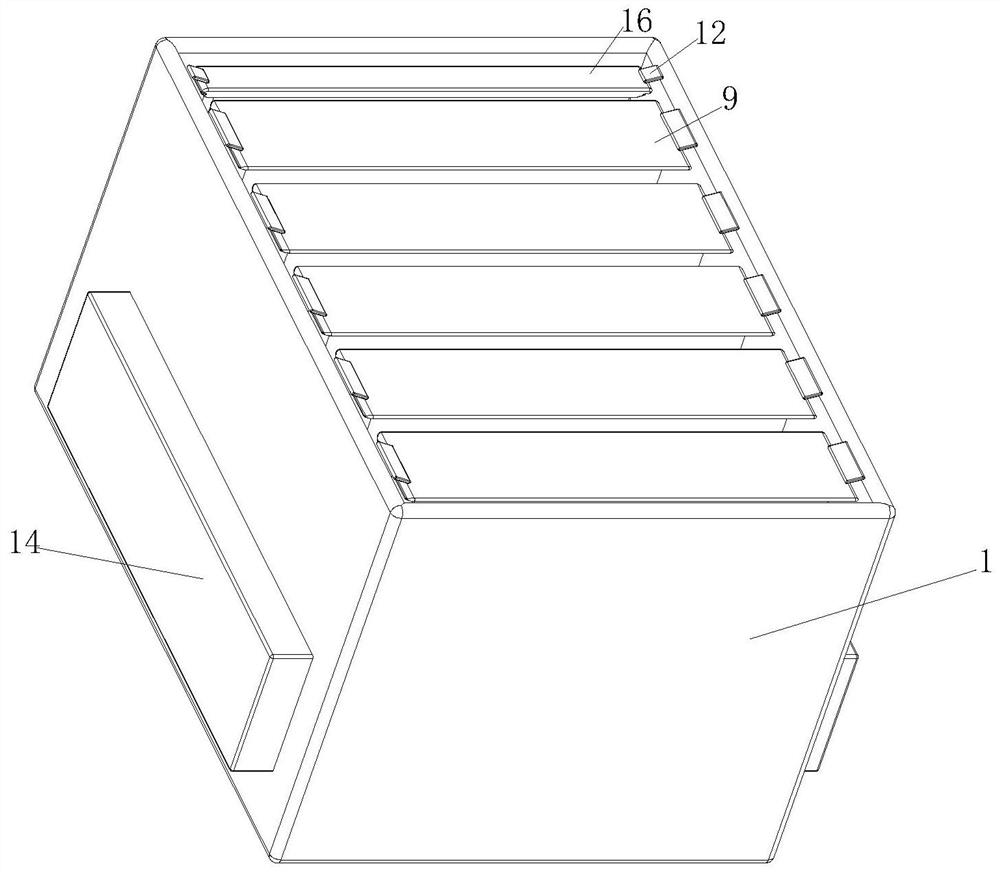

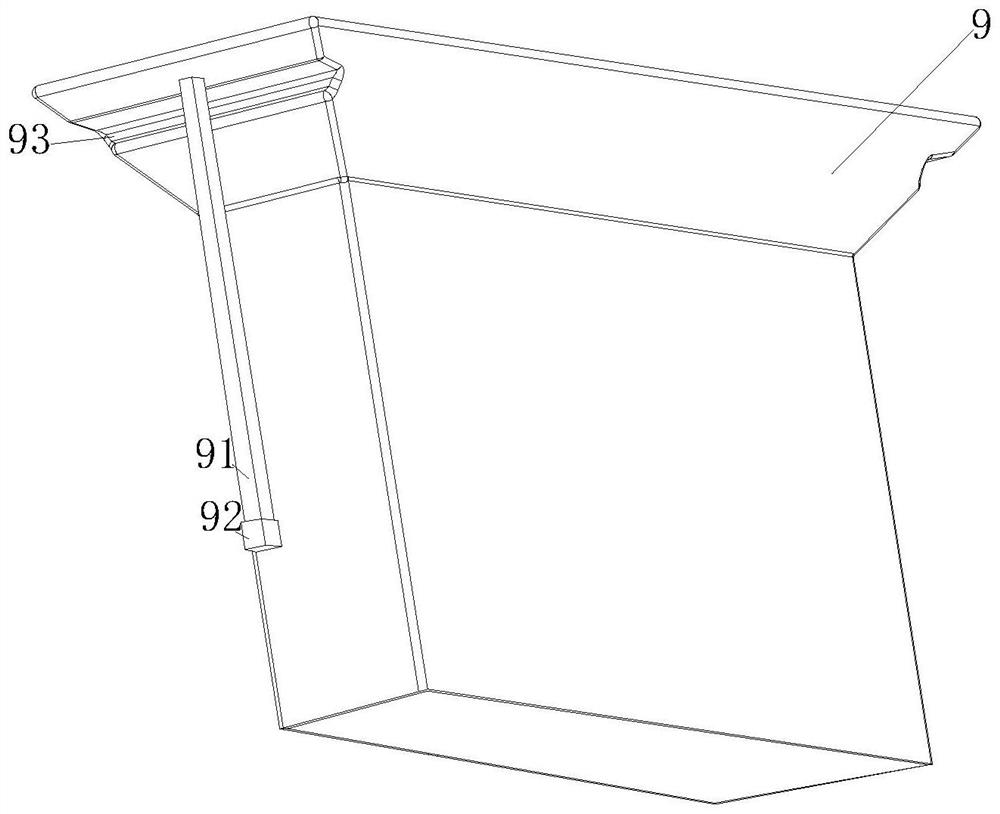

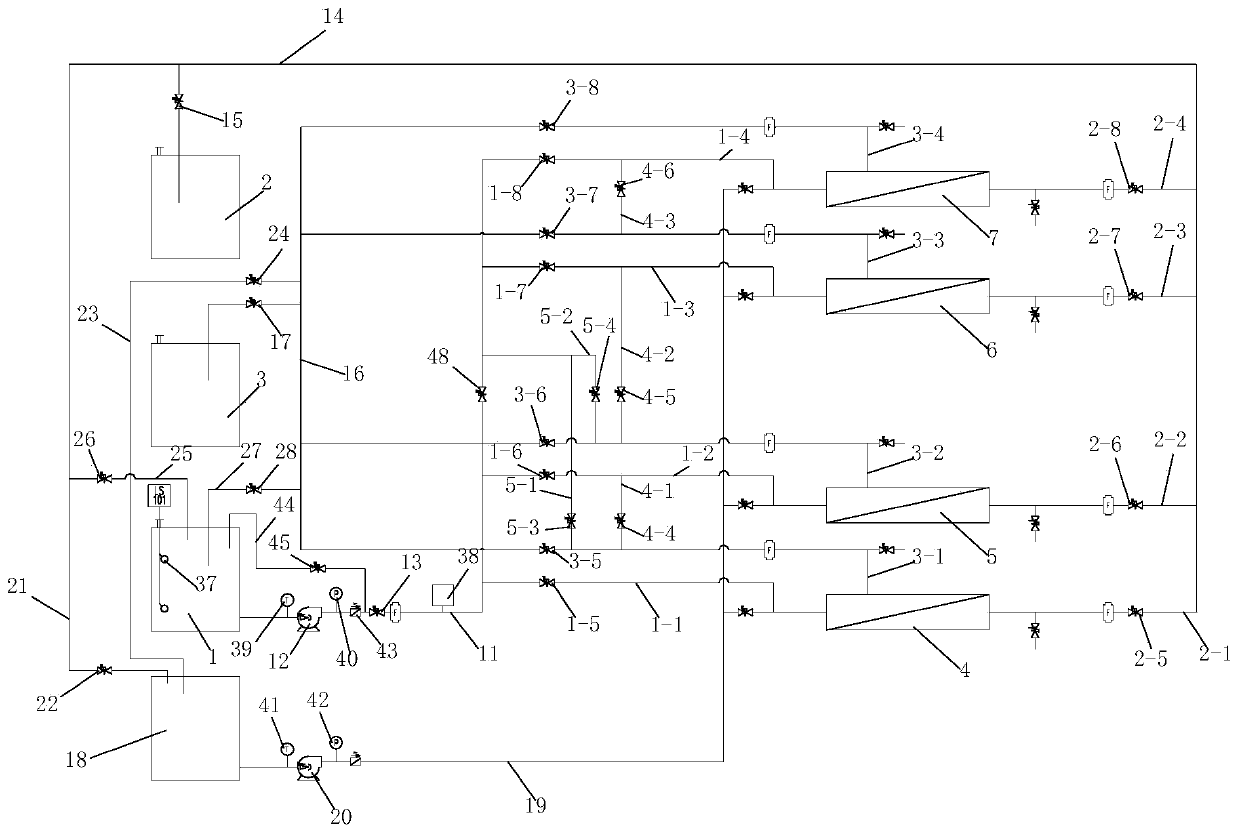

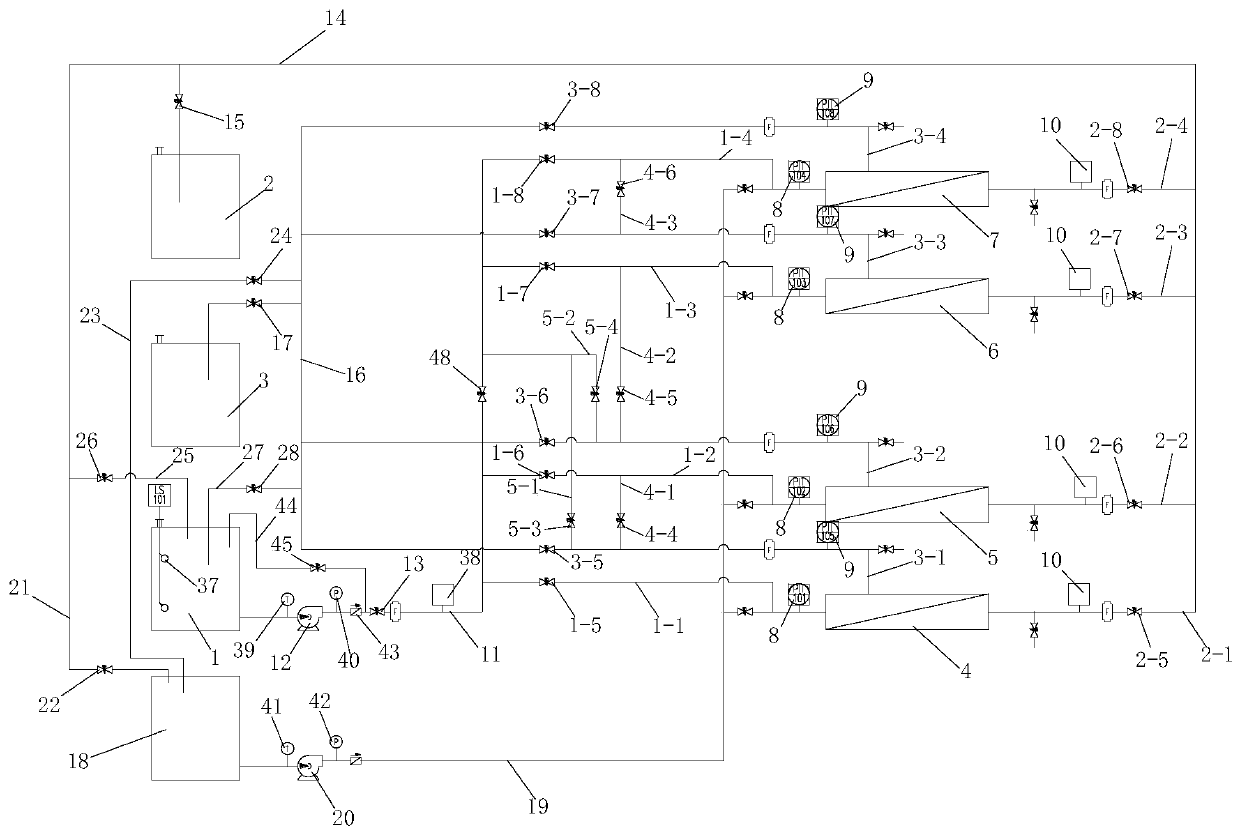

Adjustable section type reverse osmosis membrane detection system

PendingCN111111457AMeet the functional requirements of performance testingReach clarificationSemi-permeable membranesReverse osmosisWater production

The invention discloses an adjustable section type reverse osmosis membrane detection system. The system comprises a raw water tank, a water production tank, a concentrated water tank, an electric control device, and a first reverse osmosis membrane device, a second reverse osmosis membrane device, a third reverse osmosis membrane device and a fourth reverse osmosis membrane device which are connected in parallel. The system is provided with the four groups of reverse osmosis membrane devices, and four operation modes of any one-way or multi-way operation can be realized through valve adjustment; the raw water tank, the water production tank and the concentrated water tank are arranged, and switching between continuous self-circulation operation and non-self-circulation operation of the system can be achieved through valve adjustment.

Owner:BEIJING BODA WATER

A process for purification and treatment of wastewater from iron and steel smelting industry

ActiveCN111821760BImprove cooling effectIncrease contact areaDirect contact heat exchangersHeat transfer modificationIndustrial waste waterProcess engineering

The present invention relates to a process for purification and treatment of industrial wastewater in iron and steel smelting, and relates to the technical field of metal smelting. It uses a purification and cooling equipment for industrial wastewater in iron and steel smelting. The equipment includes a cooling device, a primary impurity removal device and a secondary impurity removal device. , wherein the cooling device cools the smelting industrial wastewater, and the first-level impurity removal device and the second-level impurity removal device cooperate with each other to remove impurities in the smelting industrial wastewater; the present invention has good impurity removal effect, high operating efficiency and cooling good performance.

Owner:SHANXI TONGCAI IND & TRADE

A method for removing gallium from primary aluminum by vacuum distillation

ActiveCN109609779BTo achieve the effect of removing impuritiesLow boiling pointProcess efficiency improvementGalliumWaste gas

A method for removing gallium from primary aluminum by vacuum distillation, which is carried out according to the following steps: (1) put the primary aluminum in a vacuum smelting furnace, and evacuate until the air pressure is 0.1-20Pa; (2) raise the temperature and keep the pressure at 0.1-20Pa 20Pa; smelting with heat preservation at 900-1100°C, the gallium in the primary aluminum is evaporated into the condenser; (3) cooling with the furnace. The invention uses primary aluminum containing gallium as a raw material, can realize the smelting and purification of aluminum simply and effectively, and obtains purified aluminum containing less than 50 ppm gallium; no waste gas is generated during the production process, and there is no pollution to the environment.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com