A process for purification and treatment of wastewater from iron and steel smelting industry

A technology for industrial wastewater and iron and steel smelting, applied in chemical instruments and methods, separation methods, lighting and heating equipment, etc., can solve problems such as inability to remove impurities in wastewater, damage to the natural environment, and damage to river ecosystems, and achieve good cooling effects. The effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

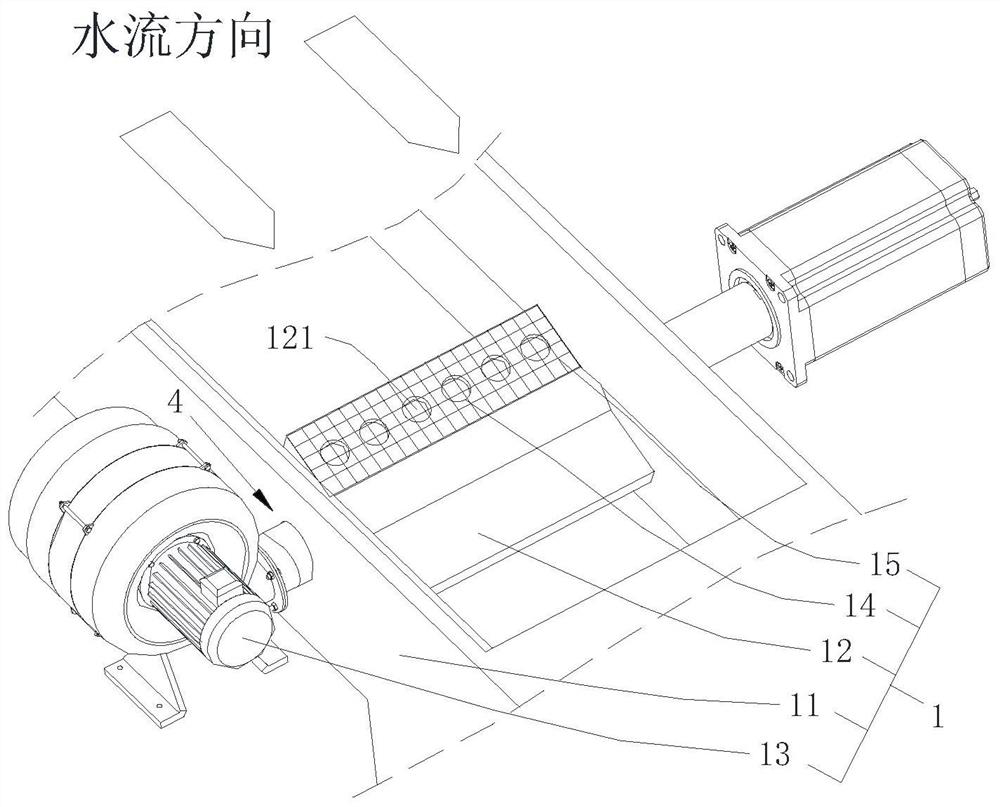

[0032] The following is attached Figure 1-7 The present invention is described in further detail.

[0033] refer to figure 2 As shown, it is an iron and steel smelting industrial wastewater purification treatment process disclosed in the present invention, which uses an iron and steel smelting industrial wastewater purification and cooling equipment, and the equipment can filter and purify the smelting industrial wastewater and reduce the temperature. Among them, the equipment includes a cooling device 1, a first-level impurity removal device 2 and a second-level impurity removal device 3. The cooling device 1 cools the smelting industrial wastewater, and the first-level impurity removal device 2 and the second-level impurity removal device 3 cooperate with each other. Impurities in smelting industrial wastewater are removed.

[0034] refer to image 3 As shown, the cooling device 1 includes a drainage pipe 11, a rotating stirring paddle 12, a blower 13, an air outlet 14,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com