Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "The processing method is environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

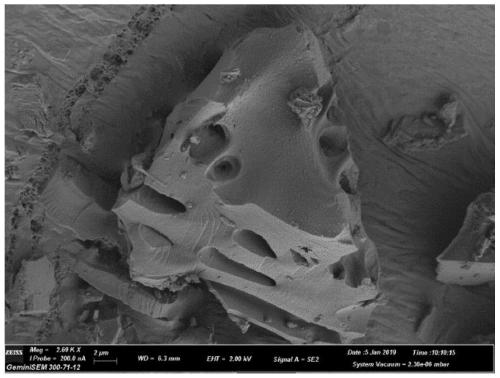

Preparation method of bacterial-cellulose-fiber-based nano-grade carbon fiber

InactiveCN103184586ALow priceWide variety of sourcesFibre chemical featuresCarbon fibersCellulose fiber

The invention relates to a preparation method of bacterial-cellulose-fiber-based nano-grade carbon fiber. According to the invention, a bacterial cellulose wet film is adopted as a substrate raw material. The prepared nano-grade carbon fiber is a product obtained after pyrolytic carbonization and graphitization of ultrafine bacterial cellulose fiber processed through an acupuncture carding refining treatment. The bacterial-cellulose-fiber-based nano-grade carbon fiber preparation method provided by the invention is safe, simple, and highly efficient, and has the advantages of wide raw material source, low price, and environment-friendly processing method. The bacterial-cellulose-fiber-based nano-grade carbon fiber obtained by processing has wide application field and great potential economic benefit.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Old wood archaizing process

The invention discloses an old wood archaizing process, comprising the following steps: dragging saw notch of material white wood, sanding white wood, bleaching, drying, sanding, coating black water, drying, sanding, wiping color, spraying water-based priming paint, sanding, and spraying water-based finishing paint. The inventive process belongs to a novel archaizing process which takes the old wood, particularly the old wooden door sheet as processing materials, makes the archaizing effect on the old wood. Not only the year of the old wood can be saved, particularly the old wood with better quality is well kept and higher quality is obtained, but also the old wood is reused and the waste is changed into valuables. The old materials are matched with the modern process and are processed, and the processing method is simple and environmental. The inventive old wood archaizing process is suitable for the archaizing process of the old timber, woodwork, old furniture except the old wooden door too.

Owner:廉江市安柏家具有限公司

Method for extracting active components from stichopus japonicus and extracts obtained by method

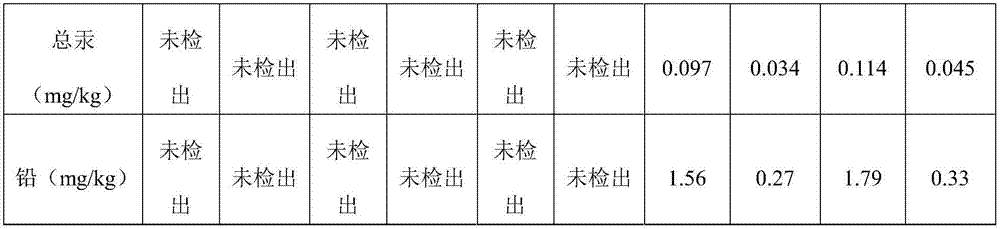

The invention discloses a method for extracting active components from stichopus japonicus and extracts obtained by the method. The extraction method comprises the following step of performing ultrasonic treatment on stichopus japonicus slurry, wherein the treatment temperature is 0-10 DEG C. According to the method, stichopus japonicus unsaturated fatty acid, vitamin E, and the like with high liposoluble properties, and active substances of stichopus japonicus collagen, stichopus japonicus polysaccharide, stichopus japonicus polypeptide and the like, in stichopus japonicus are sufficiently extracted as far as possible, so that stichopus japonicus resources are used to the maximum extent, and besides, micromolecular pollutants of heavy metal ions and the like, remaining in the bodies of the stichopus japonicus are removed; and therefore, a mild physical and biological method is used, so that the activity of effective components in the stichopus japonicus is reserved to the maximum extent, and the condition that the active components run off and the activity of the active components is changed in the processing course is avoided.

Owner:大湾汉唯(广州)医药科技集团有限公司

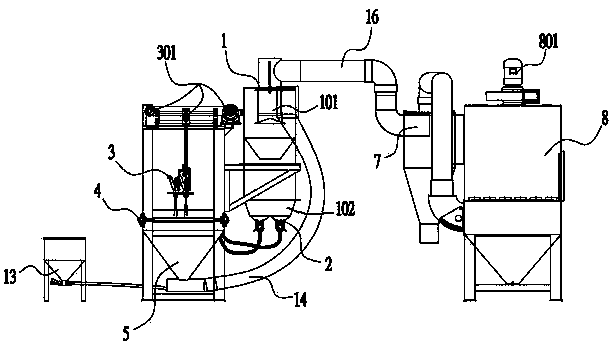

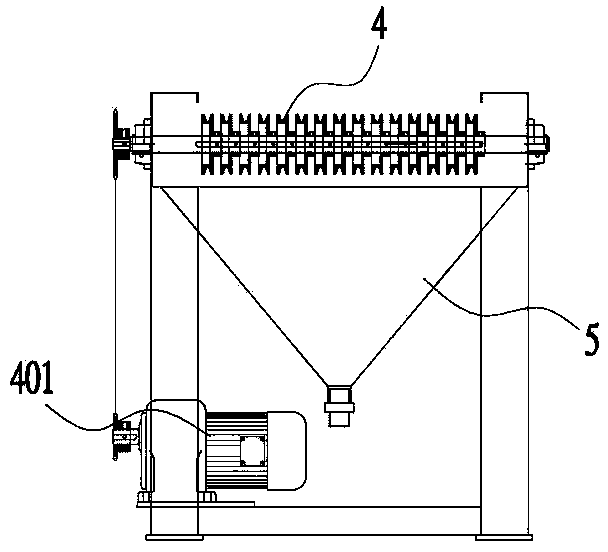

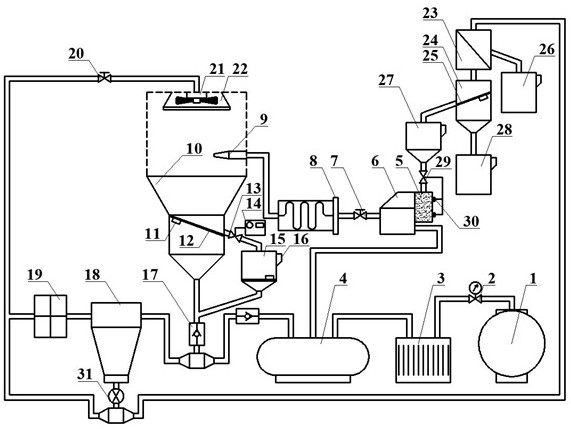

Abrasive recovery system of low-temperature micro-abrasive air jet machine tool

ActiveCN111469061AEconomical processing methodThe processing method is environmentally friendlyAbrasive machine appurtenancesAbrasive blasting machinesProcess engineeringElastic plastic

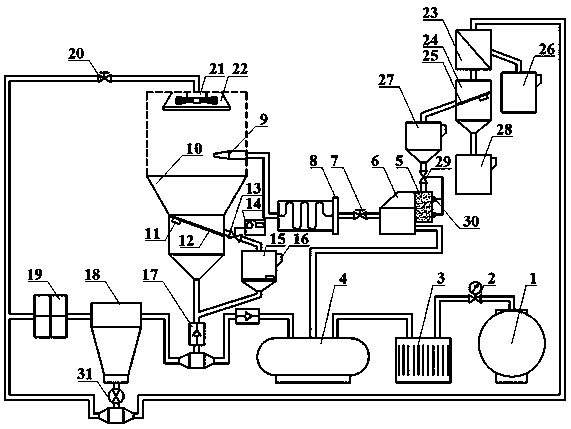

The invention relates to an abrasive recovery system of a low-temperature micro-abrasive air jet machine tool. The abrasive recovery system of the low-temperature micro-abrasive air jet machine tool is characterized by comprising a dry air generation part, a low-temperature jet generation part, a large-particle waste recovery part, an air purification part, a purified air reutilization part and anabrasive recycling and reusing part. According to the abrasive recovery system of the low-temperature micro-abrasive air jet machine tool, abrasives generated when the low-temperature micro-abrasiveair jet machine tool is used for processing elastic plastic materials such as high-molecular polymers can be recycled and reused, and the purified air can be reused, so that the effects of being moreeconomical and environment-friendly are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

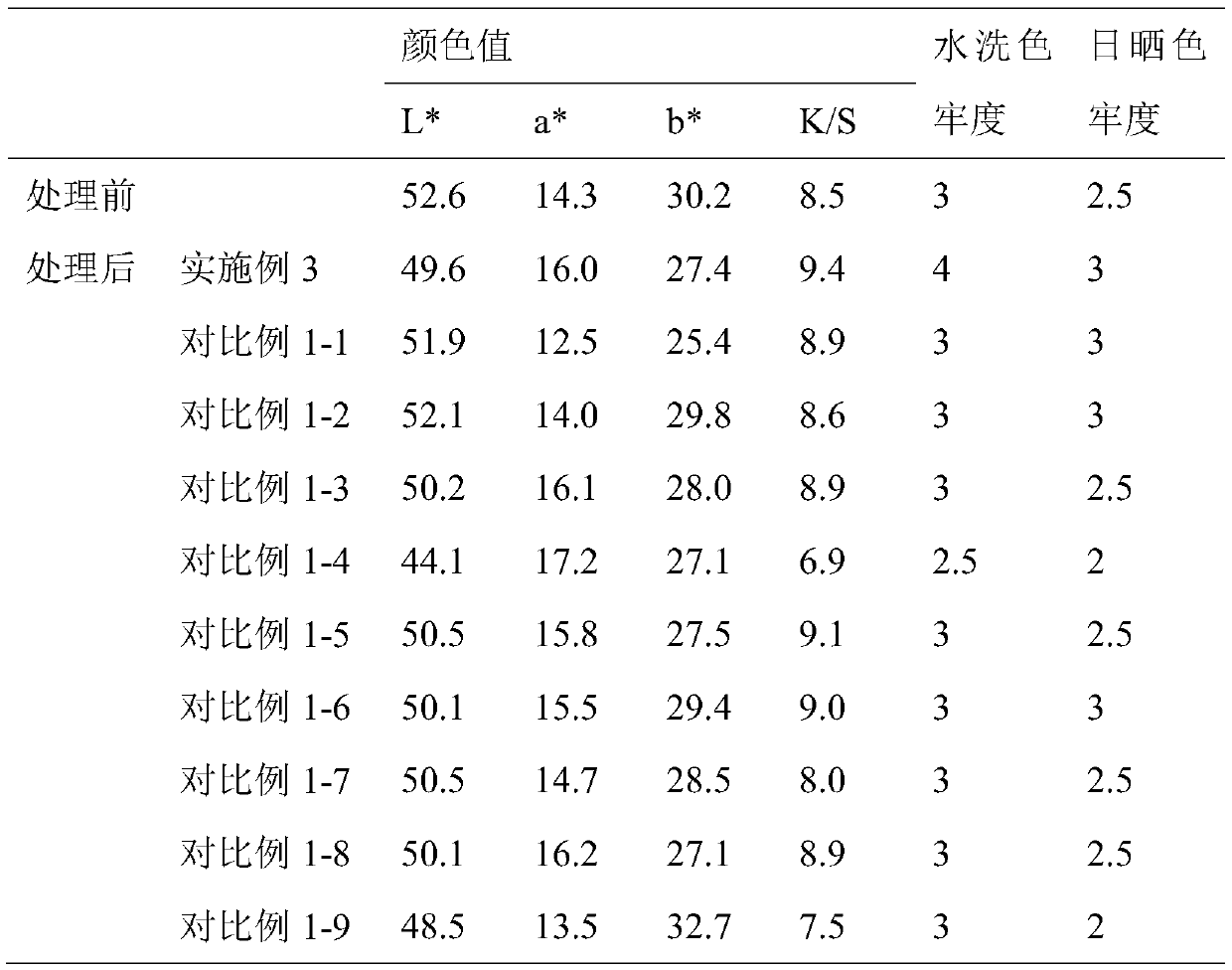

Cement bin and manufacturing process thereof

The invention discloses a cement bin and a production process thereof. The cement bin sequentially comprises an upper cone, a middle barrel and a lower cone; the upper cone is formed by assembling a plurality of upper cone splicing modules; the middle barrel is formed by assembling a plurality of middle barrel splicing modules; the lower cone comprises a tail end cone and at least one cone barrel; the cone barrel comprises a plurality of cone barrel splicing modules; a plurality of cone barrel splicing modules are assembled to form the cone barrel; both left and right sides of each cone barrel splicing module body are respectively provided with cone barrel strip flanges which are integrally formed by a hydraulic press; each two adjacent cone barrel strip flanges are installed together; both upper and lower ends of each cone barrel splicing module body are welded with cone barrel arc flanges fixedly connected with the upper end of the middle barrel. According to the invention, the production period is greatly shortened, cost is greatly reduced, all bin bodies are consistent in size, the cement bin can be produced in batches, standardization is implemented, and the cement bin is convenient to transport and can be rapidly assembled in field.

Owner:潍坊金河机械有限公司

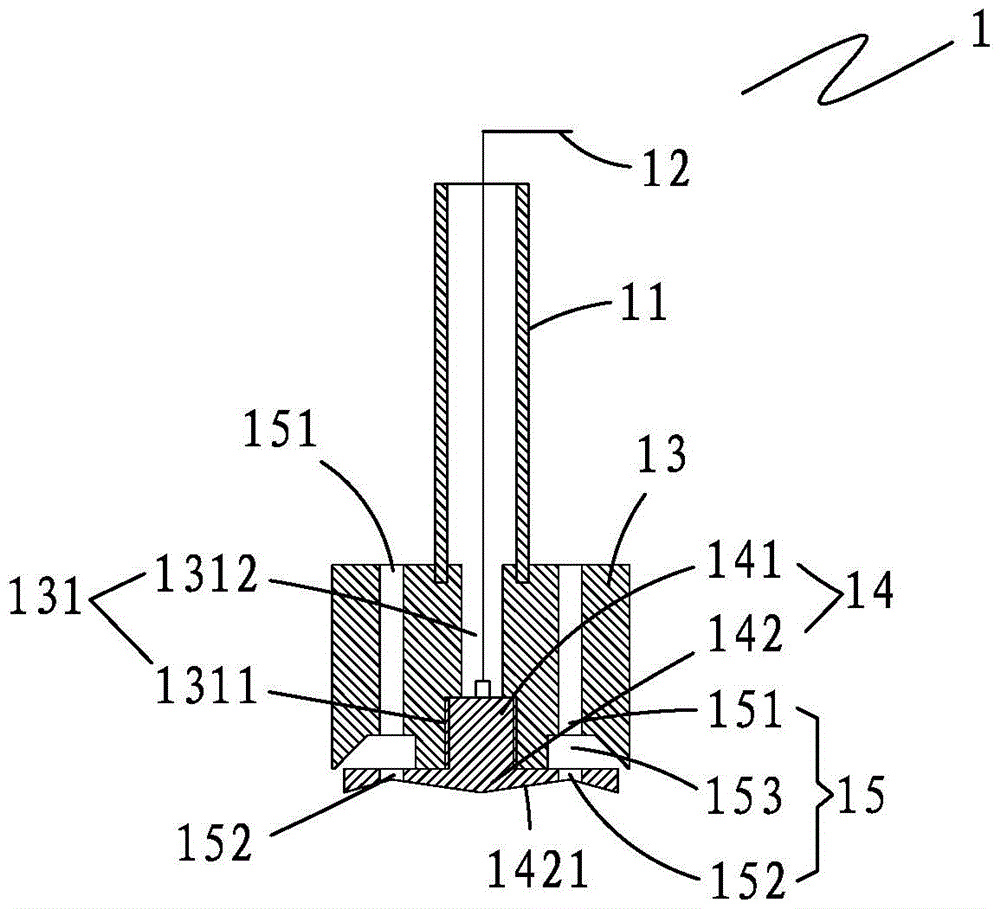

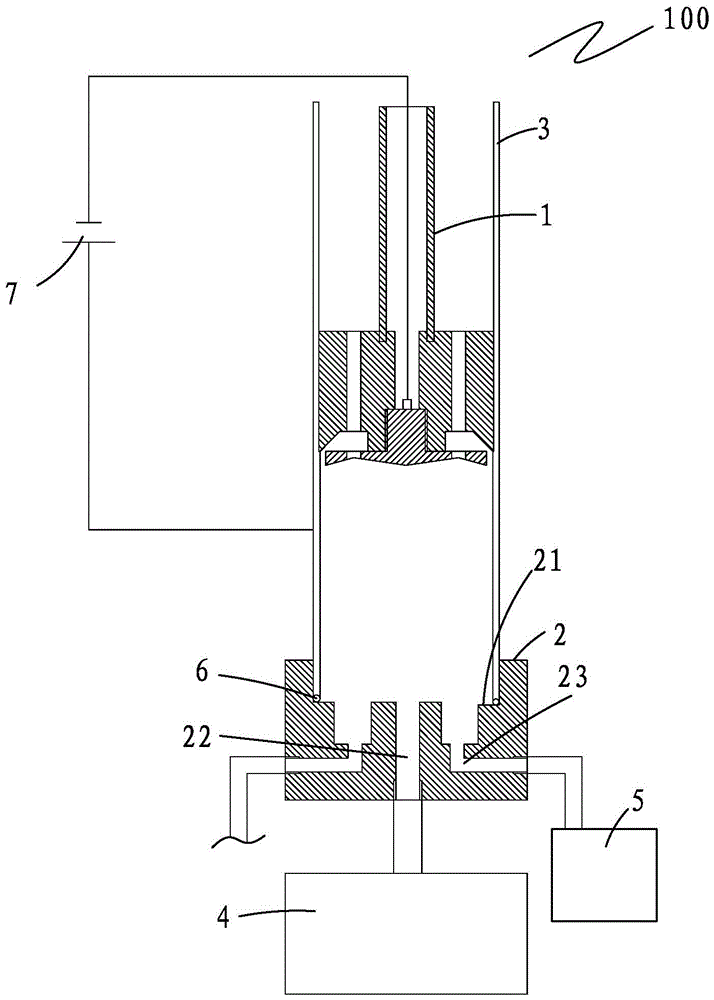

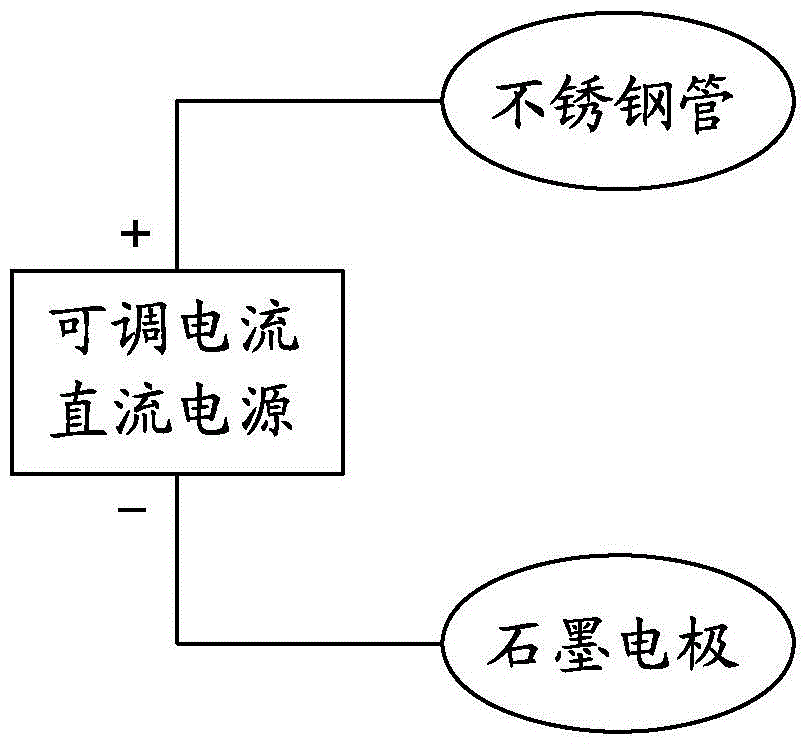

Graphite electrode and method for steel pipe inner diameter machining with graphite electrode

ActiveCN103878457AImprove work efficiencyVery economicalMachining electrodesElectrical-based machining electrodesSteel tubeGraphite electrode

The invention discloses a graphite electrode and a method for steel pipe inner diameter machining with the graphite electrode. The graphite electrode comprises an insulation shell, a connection cable, an insulation bearing plate and a graphite electrode head. The insulation shell is fixedly connected to the top end of the insulation bearing plate. One end of the connection cable penetrates through the insulation shell and is electrically connected with the graphite electrode head. The graphite electrode head comprises a connection portion and a working portion integrally connected to the bottom end of the connection portion. The connection portion is fixed to the insulation bearing plate. An electrolysis unit is composed of the graphite electrode, a bearing seat, a steel pipe, an electrolysis solution box and a sediment box. The electrolysis unit machines a stainless steel pipe inner diameter and can accurately correct the stainless steel pipe inner diameter, and the defects of wall deviation, protruding and the like caused by extrusion forming are overcome. Long stainless steel pipes with the length being more than 3 meters can be machined, the defects of traditional machining are overcome, working efficiency is high and the graphite electrode and the method for steel pipe inner diameter machining with the graphite electrode are friendly to the environment and free of pollution.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

Waxberry processed with salt and processing method thereof

InactiveCN103493950AExtended storage timeGreat tasteConfectionerySweetmeatsMonosodium glutamateGlucose polymers

The invention discloses a waxberry processed with salt and a processing method thereof. The waxberry processed with salt comprises, on the basis of 50 kg of a finished salt-processed waxberry product, 12.5 to 17.5 kg of white sugar, 0.005 to 0.02 kg of sodium cyclamate, 0.5 to 2 kg of citric acid, 0.005 to 0.015 kg of sodium saccharin, 0.005 to 0.025 kg of Ganbao, 0.05 to 0.25 kg of aspartame, 0.05 to 0.2 kg of monosodium glutamate, 0.005 to 0.0125 kg of sodium benzoate, 0.005 to 0.0125 kg of potassium sorbate, 0.005 to 0.025 kg of vanillin, 0.005 to 0.015 kg of carmine, 0.5 to 2.5 kg of glucose, 1.5 to 3 kg of salt, 1.5 to 2.5 kg of water, with the balance being waxberry. The processing method for the waxberry processed with salt comprises the following steps: 1) selection of raw materials; 2) salting; 3) rinsing; 4) batching; 5) immersion in juice; 6) opening of a pool; and 7) drying in the sun to prepare a finished product. The waxberry processed with salt provided by the invention has the advantages of long storage time, as long as one year, good taste and abundant nutrients. The processing method for the waxberry processed with salt is environment friendly and poses no pollution to the environment.

Owner:SUZHOU XISHAN JINLONG FOOD

Preparation method of membrane-filtrated concentrated fermented milk

InactiveCN108651621AIncrease profitRetain nutritional valueMilk preparationOther dairy technologyThermal insulationHeated milk

The invention discloses a preparation method of membrane-filtrated concentrated fermented milk. The preparation method of the membrane-filtrated concentrated fermented milk specifically comprises thefollowing steps: S1, performing quality inspection on raw-material milk; S2, treating the inspected raw-material milk by using membrane concentration equipment; S3, blending materials, and carrying out standardization; S4, carrying out degassing, namely performing degassing on the pre-heated milk material by using a degassing tank; S5, carrying out homogenization, namely performing homogenizationon the degassed milk material under a pressure of 170-180 Bar; S6, carrying out sterilization, namely performing sterilization on the homogenized milk material at 93-97 DEG C for 300 seconds; S7, carrying out cooling, namely cooling the sterilized material to be 40-43 DEG C by using a heat exchanger, and sending the cooled material into a fermentation tank; S8, carrying out inoculation, namely adding confirmed bacterial strains, under aseptic operation, into an on-line adding system, wherein the adding starts when the sterilization on the material is 1 / 3 done; S9, carrying out thermal insulation, namely performing thermally insulated fermentation on the inoculated material, at 40-42 DEG C, for 4-6 hours; S10, carrying out cooling; and S11, carrying out filling.

Owner:北京沃克特商贸有限公司

Preparation method of bacteria cellulose fiber-based carbon nanofiber knitted fabric

InactiveCN103184651AFine spatial networkHigh chemical purityWeft knittingCarbon fibresPolymer scienceCarbon fibers

The invention relates to a bacteria cellulose fiber-based carbon nanofiber knitted fabric, which is made through the following steps: adopting spinning and knitting technology to prepare a carbon nanofiber knitted fabric with a superfine bacteria cellulose fiber subjected to refining and carding treatment by the needling, and carrying out pyrolysis carbonization and graphitization. The preparation method has the benefits that the raw material source is wide; the price is low; the processing method is environment-friendly, safe, simple and efficient; the bacteria cellulose fiber-based carbon nanofiber knitted fabric gained after processing has wide application fields; and the potential economic benefit is huge.

Owner:ZHONGYUAN ENGINEERING COLLEGE

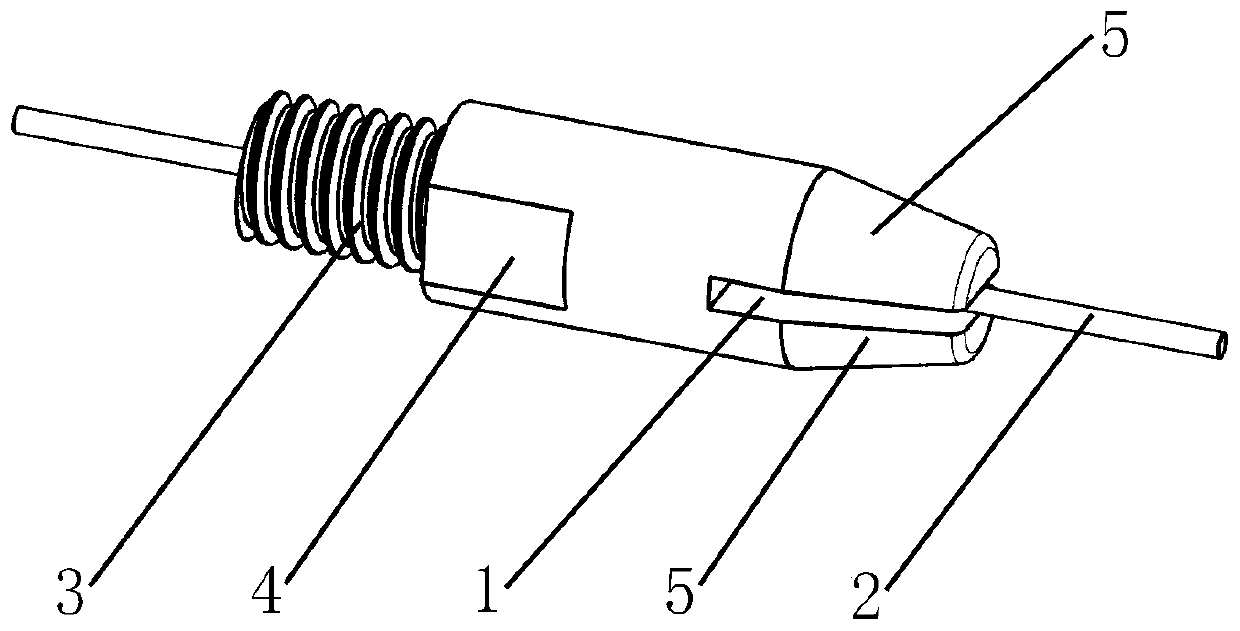

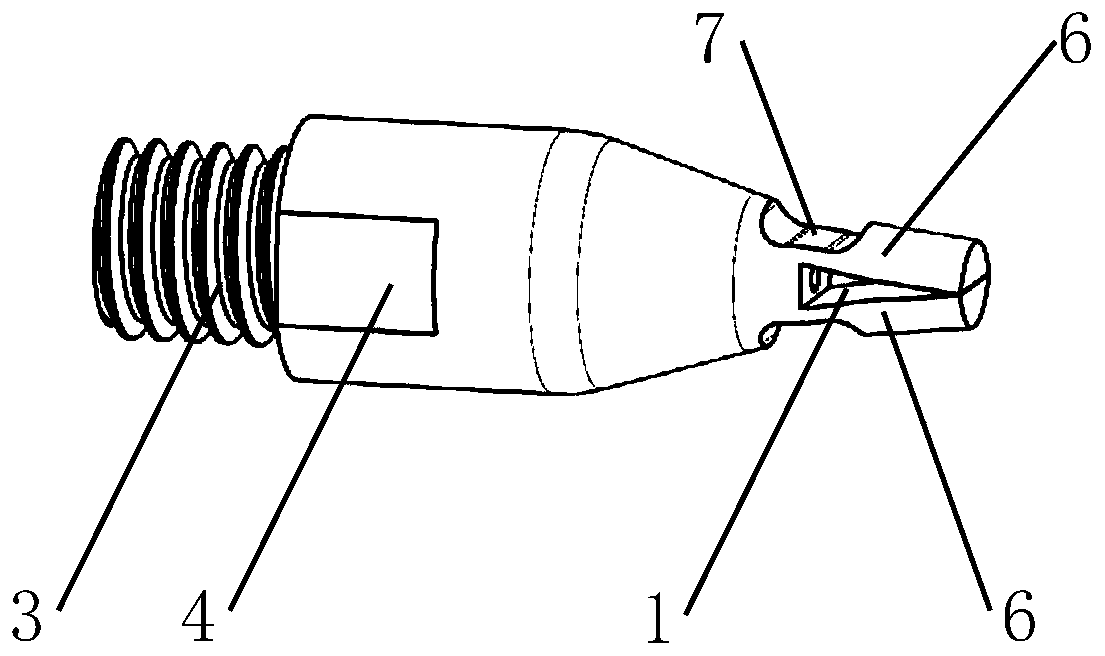

Machining method of durable welding current contact nozzle easy to machine

PendingCN110076434AExtended service lifeGood electrical conductivityElectrode accessoriesElectrically conductiveAgricultural engineering

The invention discloses a machining method of durable welding current contact nozzle easy to machine. Conductive blocks are obtained through a mode of machining a seam in the front end of the currentcontact nozzle, or is obtained through a mode of machining the thick seam and obtaining a gap, or is obtained through a mode of carrying out interference connection on two conductive block combinationblocks; according to the durable welding current contact nozzle easy to machine, the gap is formed in the front end of the current contact nozzle, so that the current contact nozzle forms the upper conductive block and the lower conductive block; according to the durable welding current contact nozzle easy to machine, materials on the two sides of the front end of the current contact nozzle are removed, a machining line passes through an edge of a welding stick passing hole to form a thickened conductive block, and the width of the thickened conductive block is narrower than that of the welding stick; and according to the durable welding current contact nozzle easy to machine, an elongated cylinder is arranged at the front end of the current contact nozzle, a large via hole is formed in the center of the current contact nozzle, a head part of the cylinder is a conductive head, a conductive hole is formed in the center of the conductive head, and the conductive hole and the large via hole are positioned on the same axis.

Owner:何强

Old wood archaizing process

The invention discloses an old wood archaizing process, comprising the following steps: dragging saw notch of material white wood, sanding white wood, bleaching, drying, sanding, coating black water, drying, sanding, wiping color, spraying water-based priming paint, sanding, and spraying water-based finishing paint. The inventive process belongs to a novel archaizing process which takes the old wood, particularly the old wooden door sheet as processing materials, makes the archaizing effect on the old wood. Not only the year of the old wood can be saved, particularly the old wood with better quality is well kept and higher quality is obtained, but also the old wood is reused and the waste is changed into valuables. The old materials are matched with the modern process and are processed, and the processing method is simple and environmental. The inventive old wood archaizing process is suitable for the archaizing process of the old timber, woodwork, old furniture except the old wooden door too.

Owner:廉江市安柏家具有限公司

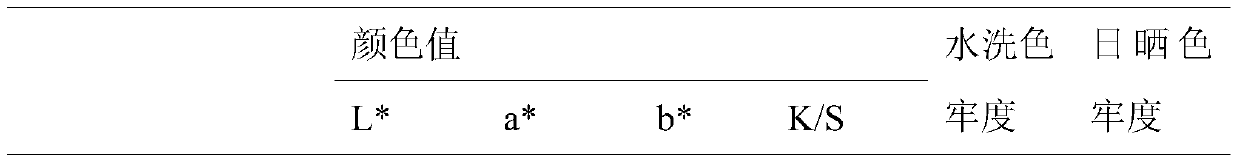

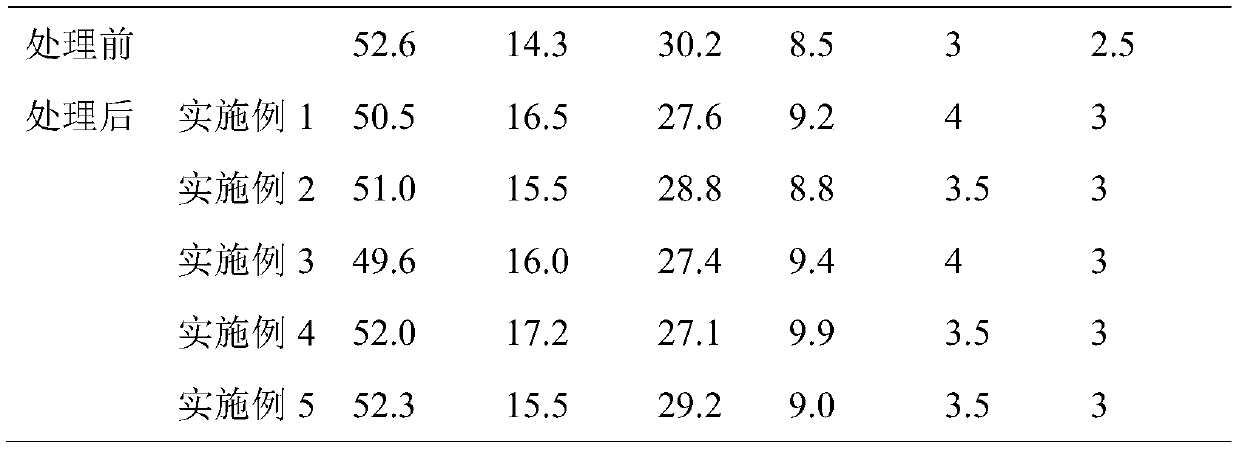

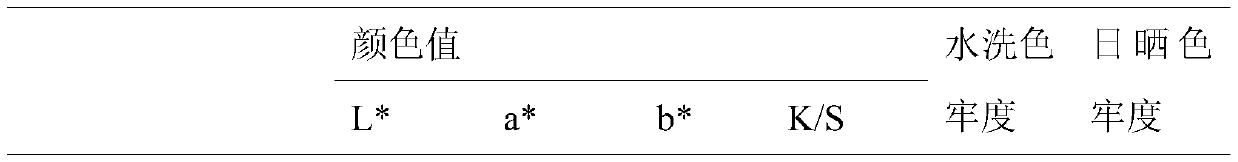

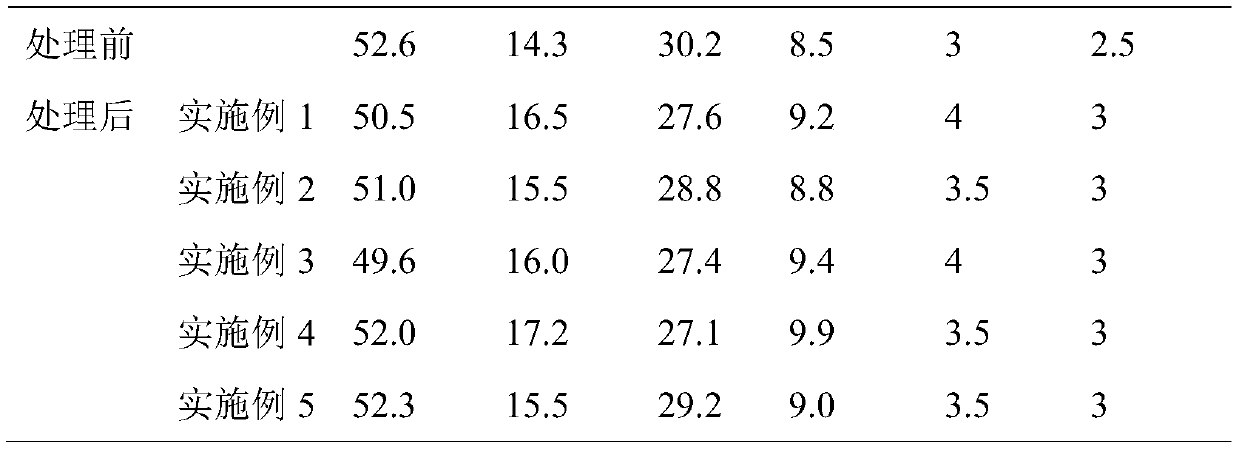

Processing method for improving natural colored cotton color depth and colour and luster stability

The invention discloses a processing method for improving the natural colored cotton color depth and colour and luster stability. The method comprises the steps that natural colored cotton obtained after color fixing is washed and dried; the natural colored cotton is dried, then the natural colored cotton obtained after drying is subjected to liquid ammonia treatment, and the natural colored cotton after liquid ammonia treatment is obtained; gelatin, penetrant and water are mixed to form a protein solution, then the protein solution is adjusted to reach the pH being 2.0-7.0, and a treatment solution is obtained; the natural colored cotton obtained after liquid ammonia treatment is put in the treatment solution for padding at 15-70 DEG C, so that the liquid-carrying rate of natural coloredcotton obtained after padding is 30-150%, and then cold reactor placement is conducted; the natural colored cotton after fixing treatment is obtained. By means of the method, the color of the naturalcolored cotton can become brighter, and the color is obviously deepened and become more uniform; the color fastness to washing and sunshine can be effectively improved.

Owner:ZHEJIANG SCI-TECH UNIV

Lower cone body of cerement bin and manufacturing process of lower cone body

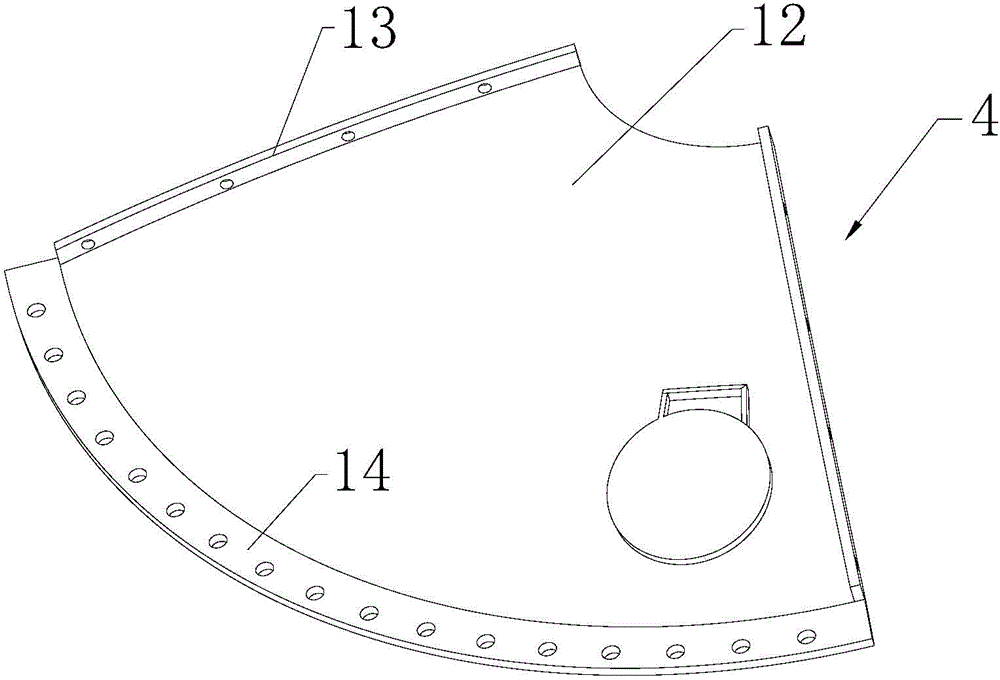

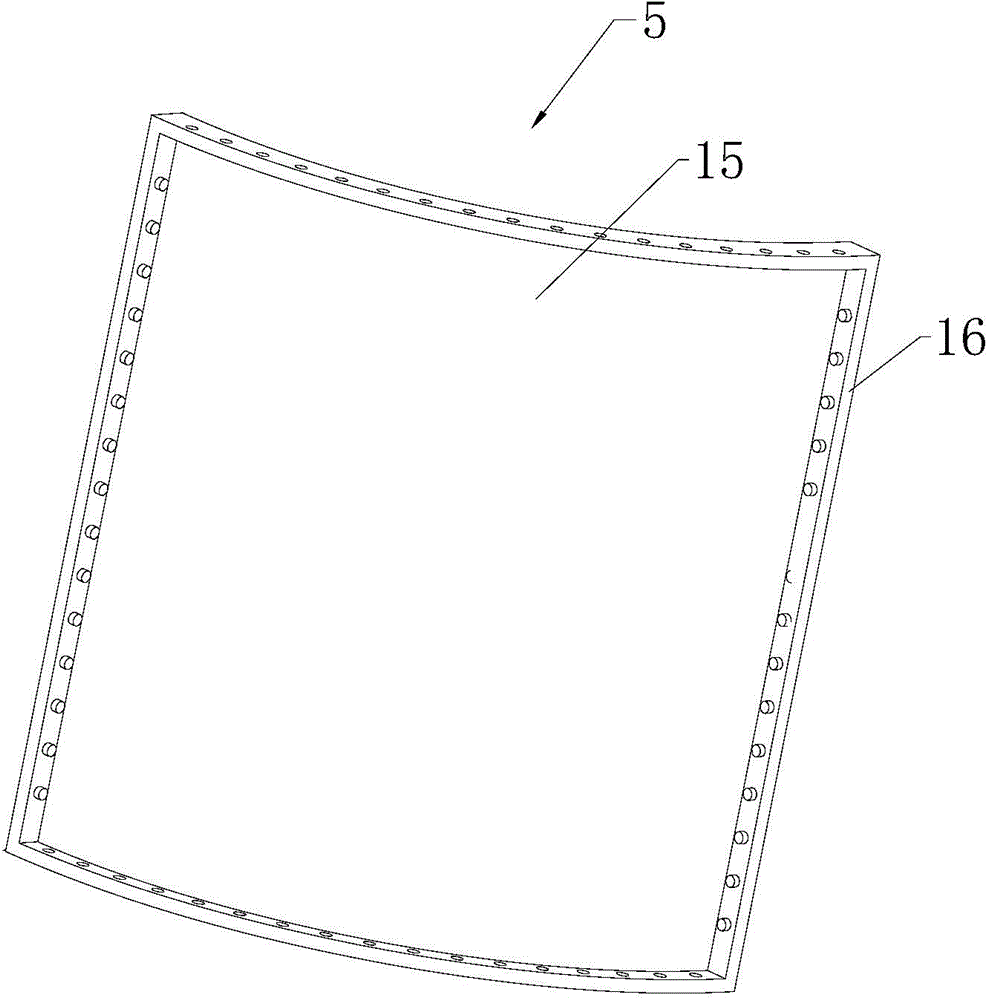

InactiveCN104370012ASame sizeNo manual welding requiredLarge containersCircular conePulp and paper industry

The invention provides a lower cone body of a cerement bin and a manufacturing method of the lower cone body. The lower cone body comprises a tail end tail cone body and at least one cone cylinder, wherein the cone cylinder and the tail end cone body are installed together through a fastening piece. The cone cylinder comprises a plurality of cone cylinder splicing modules, wherein the cone cylinder splicing modules are assembled to form the cone cylinder. Each cone cylinder splicing module comprises a cone cylinder splicing module body, wherein cone cylinder strip-shaped flanges are arranged on the left side and the right side of the cone cylinder splicing module body respectively, and the cone cylinder strip-shaped flanges are integrally formed through a hydraulic machine. The cone cylinder strip-shaped flanges of every two adjacent cone cylinder splicing modules are installed together through fastening pieces. Cone cylinder arc-shaped flanges are welded to the upper end and the lower end of each cone cylinder splicing module body respectively. Each cone cylinder arc-shaped flange is fixedly connected with the upper end of a middle cylinder of the cerement bin. By means of the lower cone body and the manufacturing method, the production cycle is greatly shortened, cost is greatly reduced, all bin bodies are the same in size, the lower cone bodies can be produced in batches, standardization is achieved, transportation is convenient, and the lower cone body can be rapidly assembled on site.

Owner:潍坊金河机械有限公司

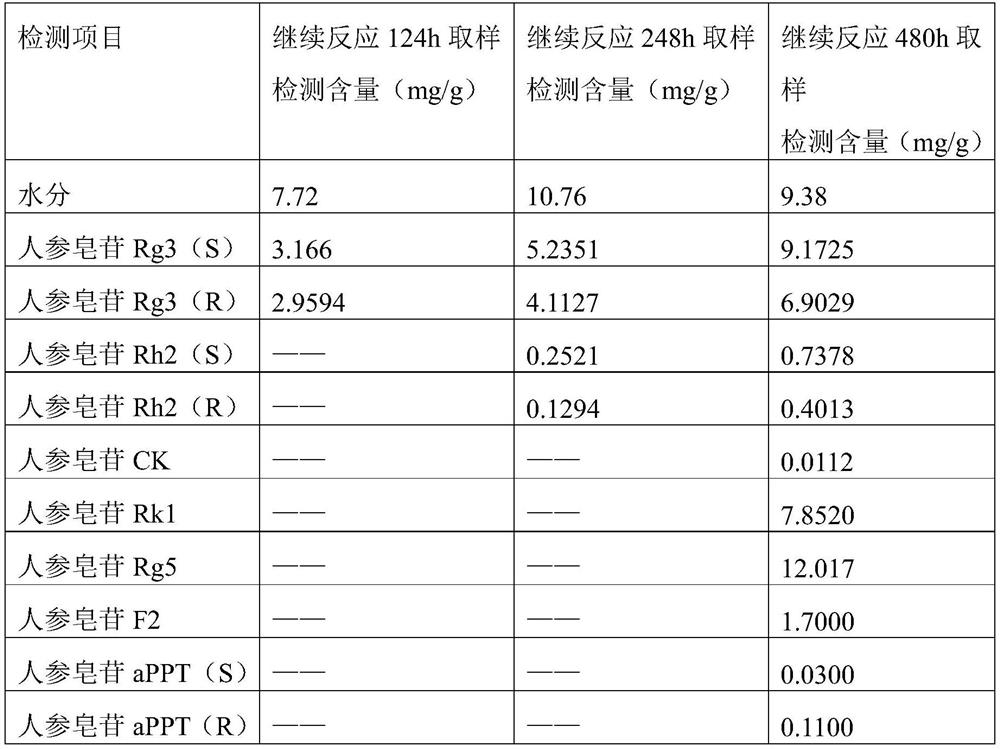

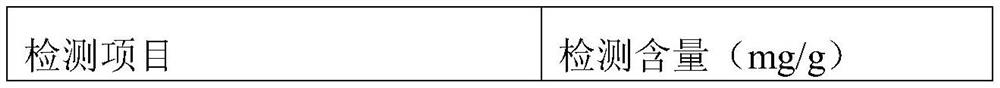

Processing method of black ginseng

PendingCN112353829AThe processing method is environmentally friendlySimple processing methodAntinoxious agentsImmunological disordersBiotechnologyCarbonization

The invention provides a processing method of black ginseng. The processing method comprises the following steps: cleaning fresh ginseng, and removing moisture on the outer surface; then performing drying until the water content is 60%-80%; then putting the dried ginseng into a sealed tank body, starting to heat, controlling the temperature to be 55-65 DEG C, and performing reacting for 20-24 hours under the temperature condition; and performing heating to 80-90 DEG C, and performing reacting for 360-480 hours at the temperature to obtain a dark brown product, namely the black ginseng. The method is environment-friendly, simple and safe; in the processing process, bacterial growth can be inhibited, mildewing is avoided, and the carbonization phenomenon caused by high-temperature drying isavoided; the conversion rate of the protoginsenoside converted active saponin is greatly improved, and the conversion rate of the protoginsenoside converted active saponin reaches about 90%; the processed black ginseng has relatively high rare saponin and is free of harmful substance residues; and the content of the rare saponin component in the backginseng is higher than that of the prototype ginsenoside converted rare saponin component in the black ginseng processed by the traditional process.

Owner:尊草(威海)生物科技有限公司

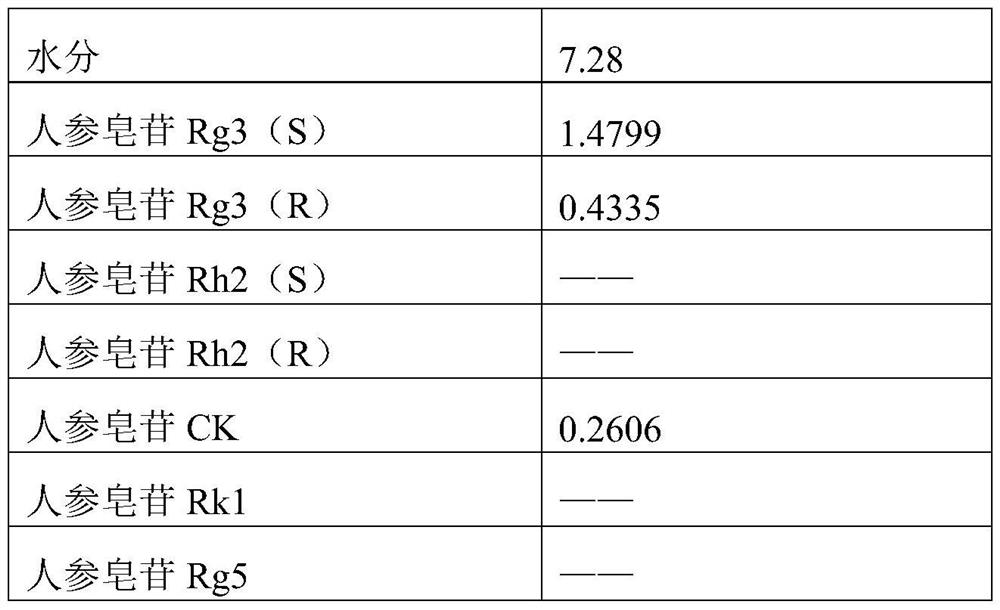

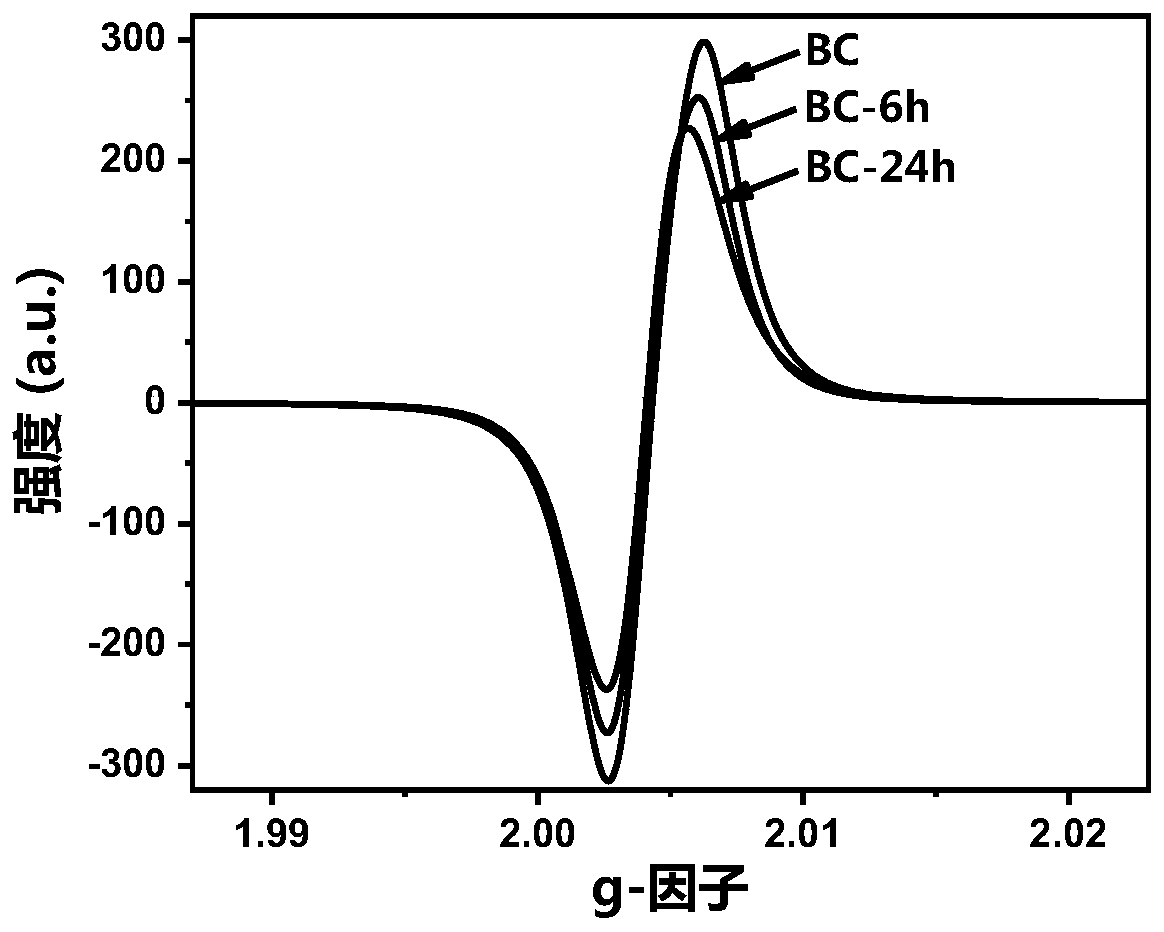

A method for removing arsenic from calcium-rich and high-arsenic groundwater by using biochar

ActiveCN110143661BImprove adsorption capacityReduce secondary pollutionWater contaminantsContaminated soil reclamationSoil scienceArsenic pollution

The invention discloses a method for removing arsenic in calcium-rich high-arsenic groundwater by using biochar, belonging to the field of arsenic pollution treatment for groundwater. The method comprises the following steps: adding biochar into alkaline calcium-rich high-arsenic groundwater, and carrying out a stirring reaction for at least 4 hours to remove arsenic dissolved in the groundwater,wherein the concentration of arsenic contained in the groundwater is 0.1-10 mg / L, and the concentration of calcium ions is 20-2000 mg / L. According to the invention, the specific calcium-rich high-arsenic groundwater is used as the object in which arsenic is to be removed; oxidizing active groups on the surface of the biochar are employed to oxidize low-valent arsenite in the groundwater into high-valent arsenate, and the generated arsenate reacts with the calcium ions and biochar to formation an arsenic-calcium-biochar precipitate; so the characteristic that the groundwater is rich in calciumand is alkaline is fully utilized, oxidation and adsorption means are organically combined to achieve the purpose of integrated removal of arsenic from the groundwater, and the method can effectivelysolve the common problems of low efficiency, high operating cost, complicated operation and the like in conventional methods for removing arsenic in groundwater.

Owner:HUAZHONG UNIV OF SCI & TECH

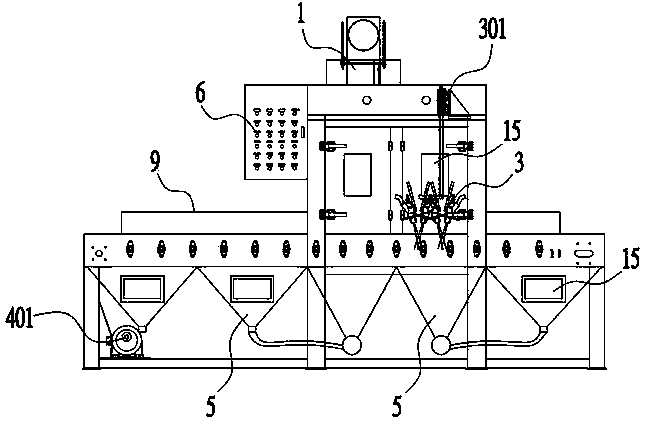

Precision sandblasting processing machine and processing method for thin and fragile plates

InactiveCN102699823BAchieve precision machiningReduce wasteAbrasive feedersAbrasive machine appurtenancesCycloneEtching

The invention discloses an accurate sand-blasting processing machine for thinned fragile slabs and a machining method. The accurate sand-blasting processing machine comprises a primary cyclone separation device, a constant sand feeder, a sand blasting device, an air compressor, a thinned fragile slab conveying device, a sand recycling device and a control device, wherein the primary cyclone separation device is used for separating sand materials and dust from the sand recycling device and feeding the sand materials to the constant sand feeder; the constant sand feeder is used for conveying the sand materials at a constant flow velocity to the sand blasting device; the sand blasting device is used for jetting the sand materials to the thinned fragile slabs; the air compressor is used for supplying compressed air to the sand blasting device; the thinned fragile slab conveying device is used for horizontally conveying the thinned fragile slabs; the sand recycling device is arranged under the thinned fragile slab conveying device and is used for receiving the sand materials and the dust, and the output end of the sand recycling device is communicated with the primary cyclone separation device; and the control device is used for controlling each device to operate. When the accurate sand-blasting processing machine is used for processing the thinned fragile slabs to a plurality of products with specific shapes, the chemical etching is avoided, the environmental protection is realized, the product cost is low, and the production speed is high, and the processing accuracy and product yield are high.

Owner:广东旭泰智能表面处理有限公司

Processing method for improving color depth and color stability of natural colored cotton

The invention discloses a processing method for improving the natural colored cotton color depth and colour and luster stability. The method comprises the steps that natural colored cotton obtained after color fixing is washed and dried; the natural colored cotton is dried, then the natural colored cotton obtained after drying is subjected to liquid ammonia treatment, and the natural colored cotton after liquid ammonia treatment is obtained; gelatin, penetrant and water are mixed to form a protein solution, then the protein solution is adjusted to reach the pH being 2.0-7.0, and a treatment solution is obtained; the natural colored cotton obtained after liquid ammonia treatment is put in the treatment solution for padding at 15-70 DEG C, so that the liquid-carrying rate of natural coloredcotton obtained after padding is 30-150%, and then cold reactor placement is conducted; the natural colored cotton after fixing treatment is obtained. By means of the method, the color of the naturalcolored cotton can become brighter, and the color is obviously deepened and become more uniform; the color fastness to washing and sunshine can be effectively improved.

Owner:ZHEJIANG SCI-TECH UNIV

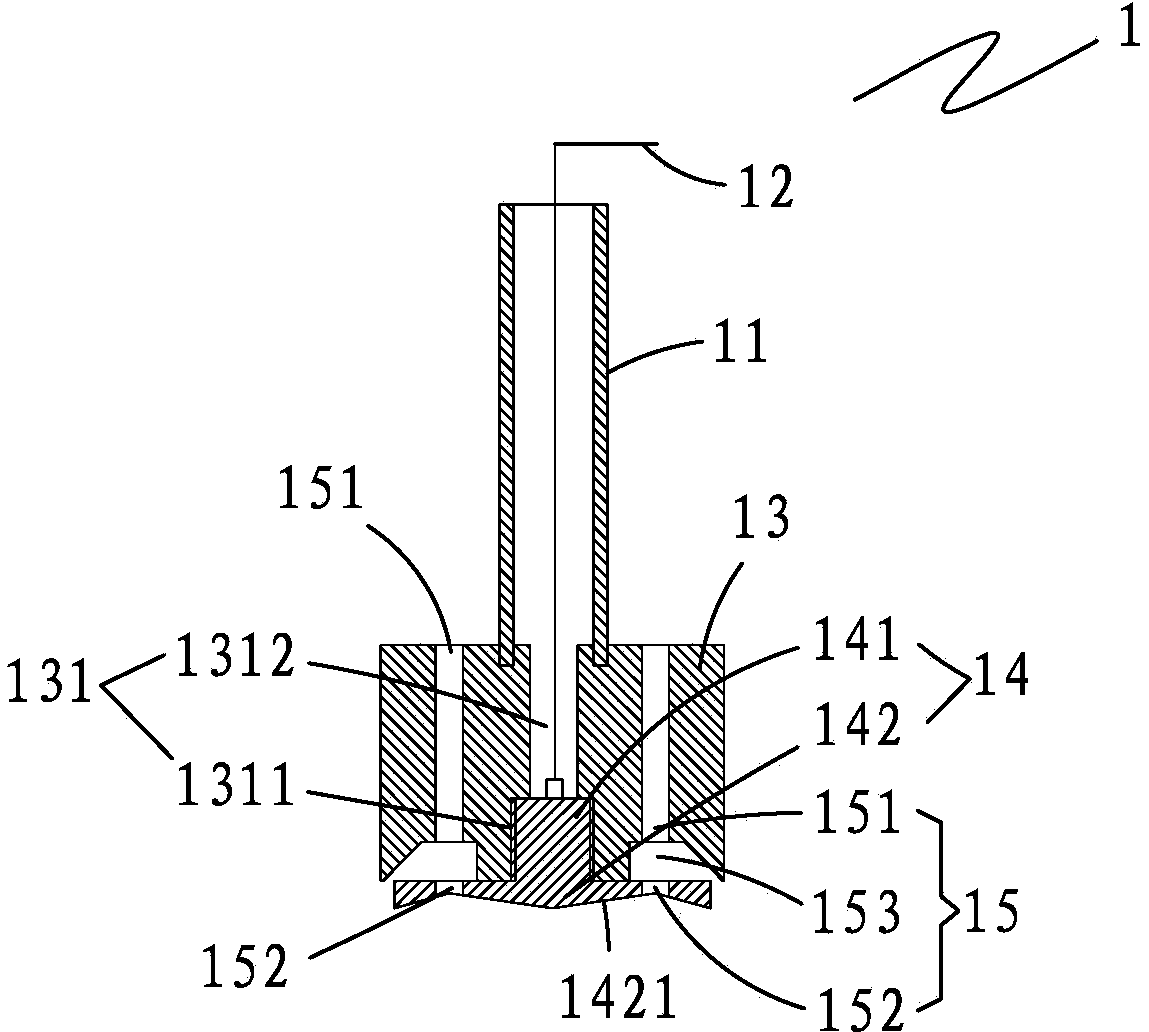

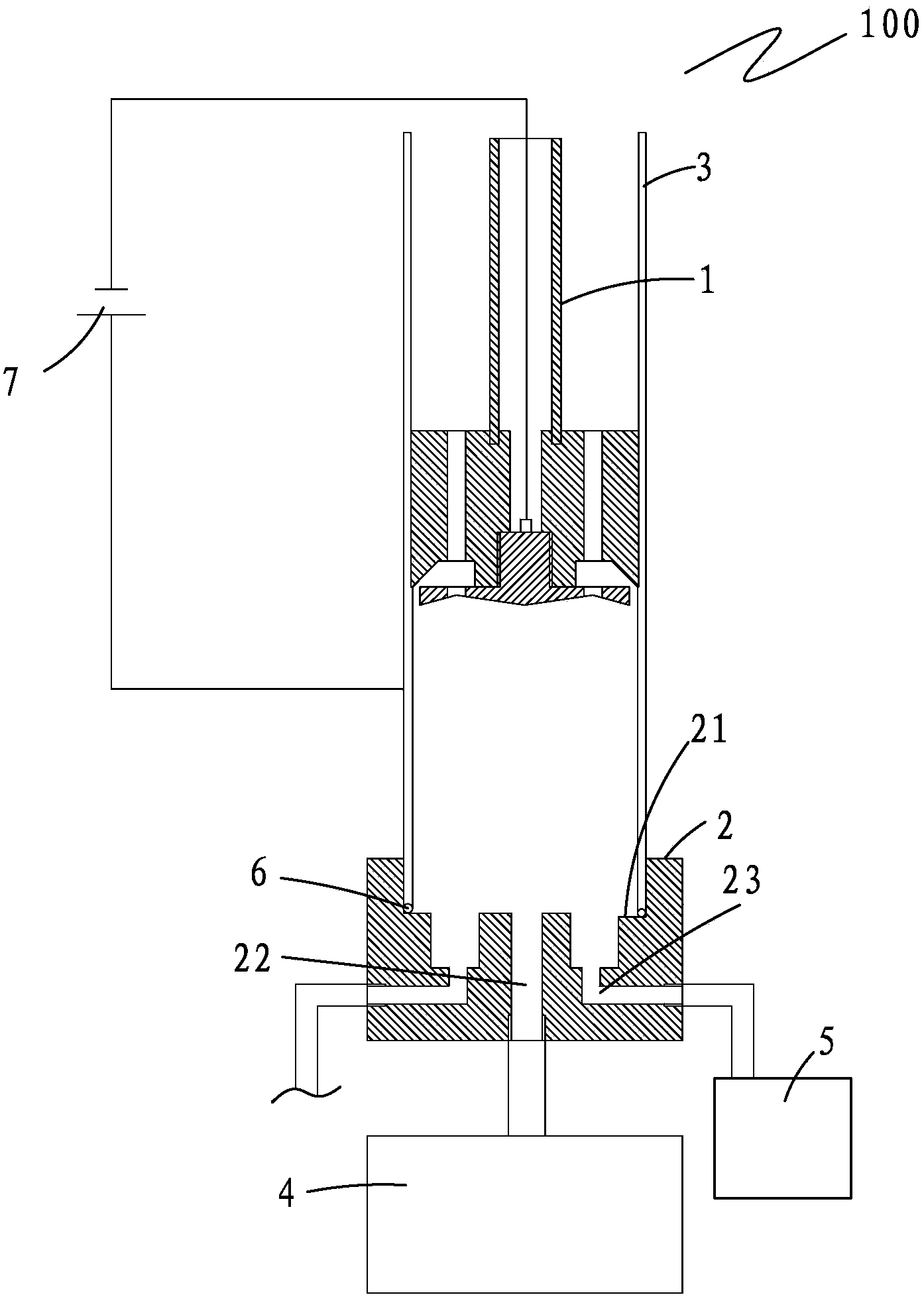

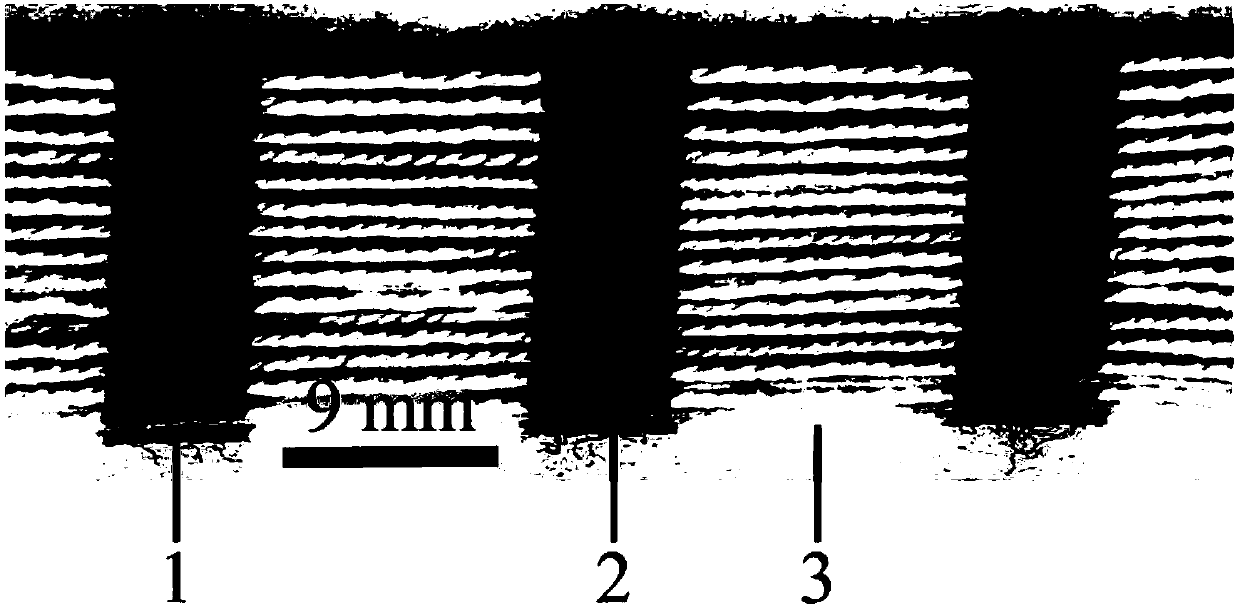

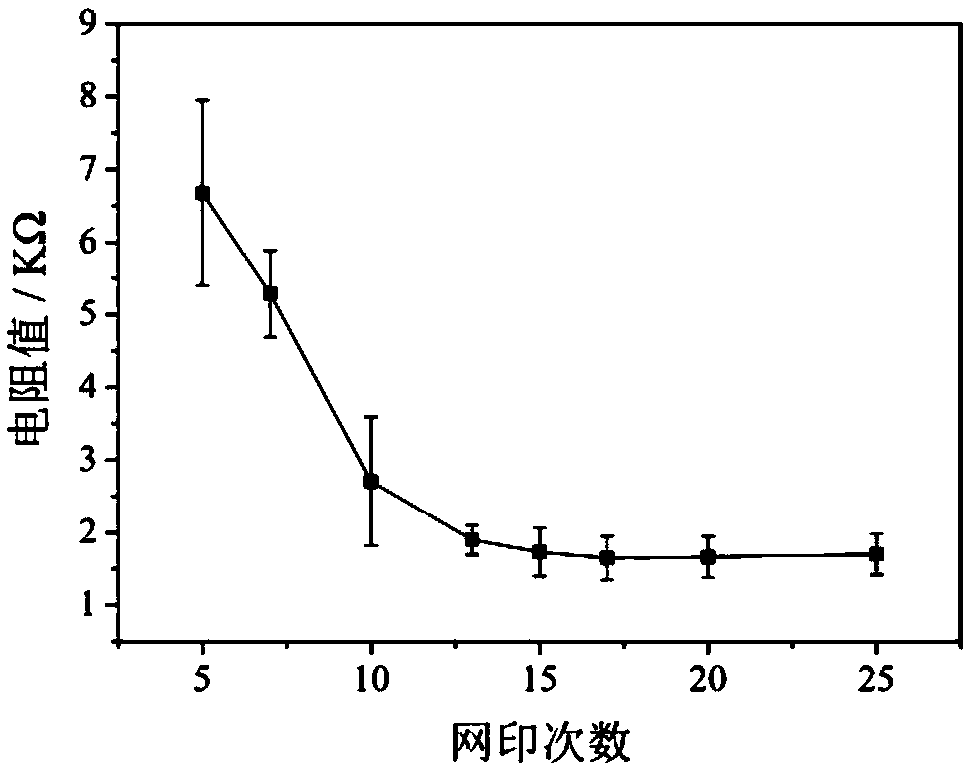

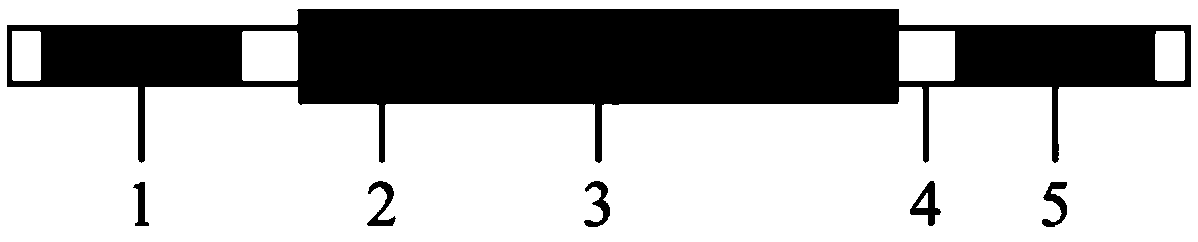

Capillary micro-channel assistant wire base microfluidic bipolar electrode electrochemical luminescence device and application

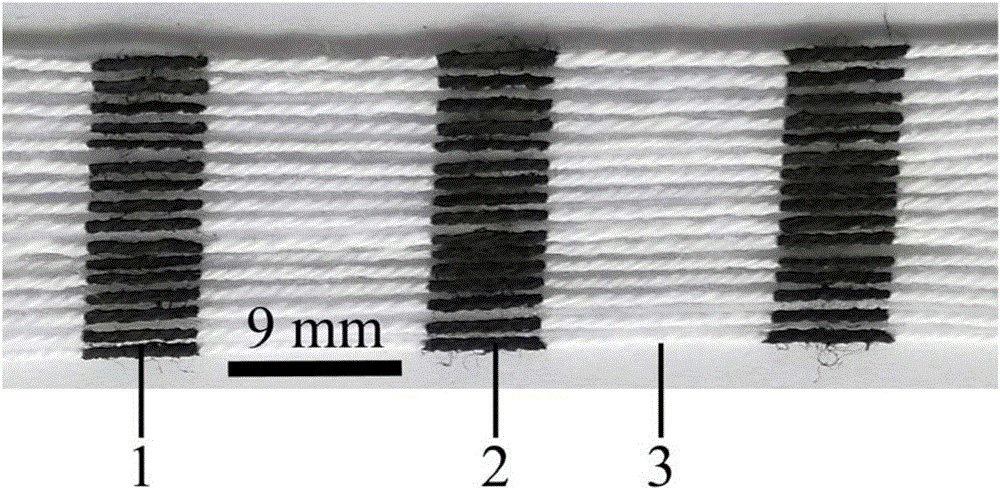

ActiveCN106353303AHigh resolutionControllable intervalChemiluminescene/bioluminescenceEngineeringLuminescence

The invention discloses a capillary micro-channel assistant wire base microfluidic bipolar electrode electrochemical luminescence device, and a preparation method and the application thereof. The luminescence device consists of a capillary and a patterning line electrode, wherein the patterning line electrode consists of not less than three wire base electrodes and bare wire areas; the wire base electrodes are manufactured by conductive carbon paste; the wire base electrodes on two sides are driving electrodes; the wire base electrode between the driving electrodes is a bipolar electrode; an area between the every two wire base electrodes is the bare wire area; the capillary coats the patterning line electrode, needs to coat all bipolar electrodes, and simultaneously can not be in contact with the driving electrode. According to the luminescence device, the capillary micro-channel is applied to the line of the patterning carbon electrode for the first time to manufacture the capillary micro-channel assistant wire base microfluidic bipolar electrode electrochemical luminescence device. The integration device has the remarkable advantages that the loading speed of a sample is high and the samples can be evenly distributed on the patterning wire electrode.

Owner:SOUTH CHINA NORMAL UNIVERSITY

A kind of black gold plate and processing method thereof

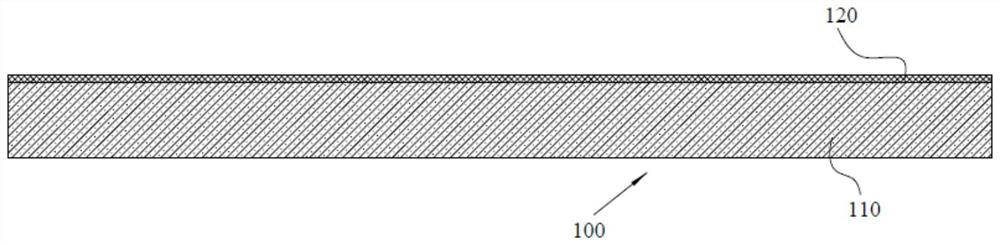

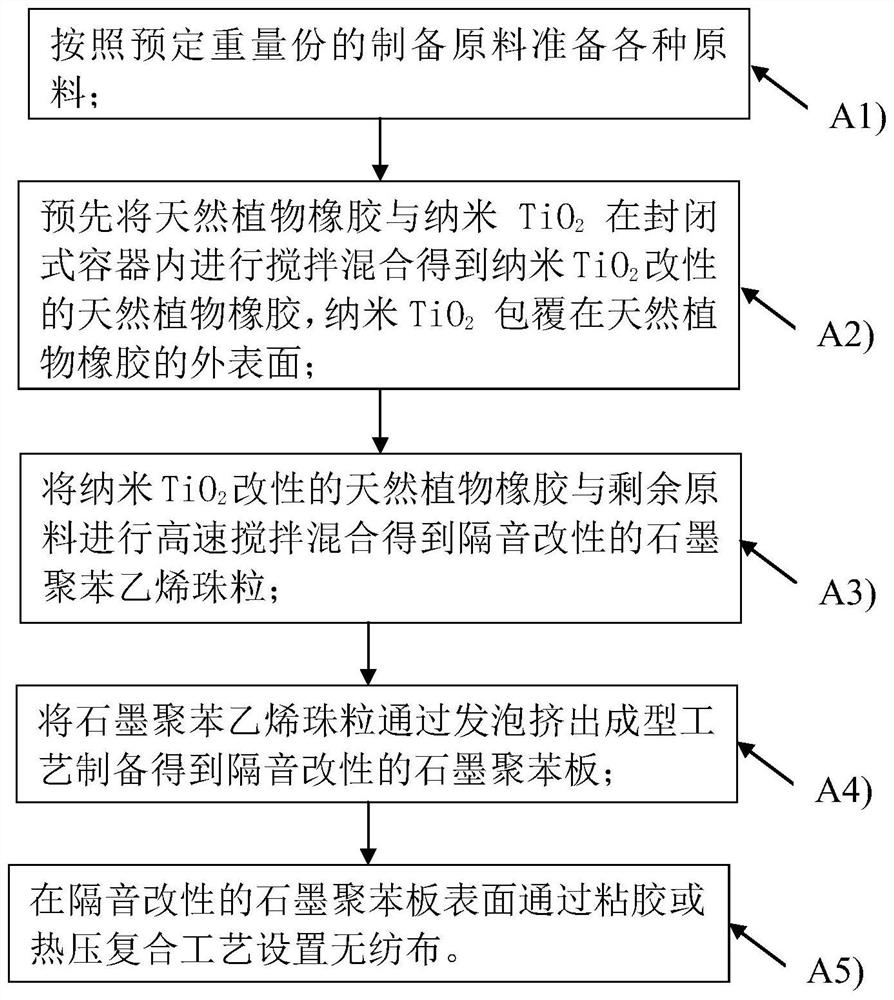

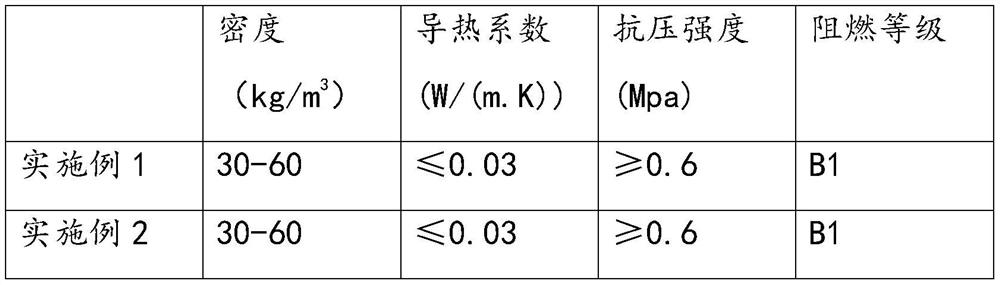

ActiveCN110843303BIsolation from transmitted noiseImprove installation strengthSynthetic resin layered productsLaminationPolymer sciencePolystyrene

The invention discloses a black gold board, comprising a sound insulation modified graphite polystyrene board, a non-woven fabric is compounded on the surface of the sound insulation modified graphite polystyrene board, wherein the sound insulation modified graphite polystyrene board adopts The following raw materials in parts by weight are prepared by foaming extrusion molding process: 50-70 parts of polystyrene resin particles; 8-15 parts of graphite particles; nano-TiO 2 15-35 parts of modified natural vegetable rubber, the nano-TiO 2 The outer surface of the natural vegetable rubber is evenly coated by premixing; 8-12 parts of foaming agent; the present invention also relates to a processing method of the black gold plate; the present invention simultaneously has the advantages of light weight, heat preservation, compact structure and high installation strength , Excellent sound insulation and flame retardant effect, at the same time, the processing method is simple and environmentally friendly, no organic solvent is required, and it is easy to implement in mass production.

Owner:江苏银辉生态科技有限公司

A kind of processing method of walnut handicraft

The invention relates to a processing method for walnut handicrafts, belonging to the technical field of handicrafts processing. It includes multiple processes such as walnut fruit raw material pretreatment, cutting, drying and assembly. Using its natural texture and natural color, it is refined through multiple processes. The product is firm and not easy to break, beautiful and unique in shape, simple, elegant and natural , exquisite and translucent, luxurious and stylish, with extremely high artistic appreciation value and collection value; at the same time, the raw material processing technology of the present invention is excellent, and it can kill a large number of bacteria and insect eggs remaining on the surface of walnut fruit. Among them, all water-based products are used, which effectively avoids the release of a large amount of VOC gas from solvent-based products, which is healthy and environmentally friendly; the processing technology of the present invention enhances the life of walnut handicrafts, making them have certain flame-retardant and moth-proof functions. Easy to promote applications.

Owner:宝金安 +1

Original-flavor sauce and processing method thereof

The invention relates to an original-flavor sauce which comprises the following raw materials in parts by weight: 1-300 parts of hot pepper, 1-100 parts of onions, 1-100 parts of garlic bulbs, 1-400 parts of edible oil, 0.1-30 parts of edible salt, 0.1-50 parts of white granulated sugar, and 0.1-30 parts of white spirit. The original-flavor sauce has the characteristics of being fresh and delicious in taste, safe to eat and long in shelf life, and can also achieve high-efficiently antiseptic and fresh-keeping effects without addition of any additive; furthermore, the original-flavor sauce is rich in nutritional ingredients such as vitamins, capsaicin, protein, mineral substances and the like, thus being suitable for all consumers to eat, and providing safe, relieved and delicious seasoning for people; in addition, a processing method has the characteristics of being high-efficiency, environment-friendly and cost-saving; and compared with the prior art, the working efficiency is greatly improved, and the production cost is saved.

Owner:刘少英

A graphite electrode and a method for processing the inner diameter of a steel pipe using the graphite electrode

ActiveCN103878457BAccurate correction of inner diameterMake up for processing defectsMachining electrodesElectrical-based machining electrodesGraphite electrodeElectrolysis

The invention discloses a graphite electrode and a method for steel pipe inner diameter machining with the graphite electrode. The graphite electrode comprises an insulation shell, a connection cable, an insulation bearing plate and a graphite electrode head. The insulation shell is fixedly connected to the top end of the insulation bearing plate. One end of the connection cable penetrates through the insulation shell and is electrically connected with the graphite electrode head. The graphite electrode head comprises a connection portion and a working portion integrally connected to the bottom end of the connection portion. The connection portion is fixed to the insulation bearing plate. An electrolysis unit is composed of the graphite electrode, a bearing seat, a steel pipe, an electrolysis solution box and a sediment box. The electrolysis unit machines a stainless steel pipe inner diameter and can accurately correct the stainless steel pipe inner diameter, and the defects of wall deviation, protruding and the like caused by extrusion forming are overcome. Long stainless steel pipes with the length being more than 3 meters can be machined, the defects of traditional machining are overcome, working efficiency is high and the graphite electrode and the method for steel pipe inner diameter machining with the graphite electrode are friendly to the environment and free of pollution.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

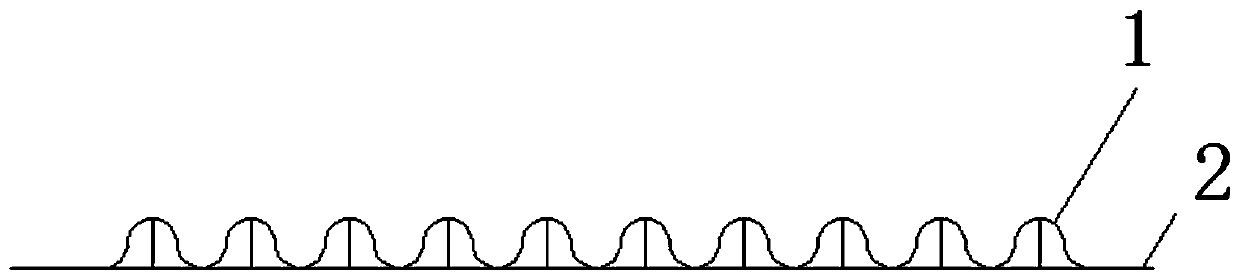

Corrugated film and manufacturing method thereof

ActiveCN108525525BImprove stress resistanceStress from workSemi-permeable membranesMembranesComposite materialComposite membrane

The invention discloses a corrugated film. A support structure is arranged in the corrugated film. The corrugated film has the advantages that through the support structure in the corrugated film, compressive property of the corrugated film is improved greatly, and the applicable working pressure of the corrugated film is increased. The invention further provides a manufacture method of the corrugated film. The manufacture method includes preparing a composite film, performing hot extrusion on the prepared composite film to form corrugation, and performing press fit on the composite film and the support structure to acquire the corrugated film. A brand-new corrugated-film manufacture method is provided besides coating-based film formation methods, and can be applied to corrugated films which cannot be easily dissolved by solvents and cannot be processed by coating methods. The manufacture method has the advantages that the manufacture method is simpler than the prior art, chemical rawmaterial preparation steps, coating steps and coagulation bath are omitted, water is saved, environmental protection is achieved, and pollutants are avoided.

Owner:BEIJING ORIGIN WATER FILM TECH

DN black golden board and processing method thereof

ActiveCN110843303AIsolation from transmitted noiseImprove installation strengthSynthetic resin layered productsLaminationPolymer scienceFoaming agent

The invention discloses a DN black golden board, which comprises a sound-insulation modified graphite polyphenyl board. Non-woven cloth is combined with the surface of the sound-insulation modified graphite polyphenyl board. The sound-insulation modified graphite polyphenyl board is prepared by a foaming-extrusion moulding technology and comprises following raw materials in parts by weight: 50 to70 parts of polystyrene resin particle, 8 to 15 parts of graphite particle, 15 to 35 parts of nano TiO2 modified natural vegetable rubber, and 8 to 12 parts of a foaming agent. Nano TiO2 is premixed and then evenly coated on the outer surface of natural vegetable rubber. The invention also relates to a processing method of the DN black golden board. The DN black golden board is light, compact, andfire retardant, and has a thermal-insulation property and a soundproof property, the installation strength is high; at the same time, the processing method is simple and environmentally friendly anddoes not need any organic solvent; massive production is easy to perform; and the DK black golden board is a very good thermal-insulation soundproof material.

Owner:江苏银辉生态科技有限公司

Garlic-flavor sauce and processing method thereof

InactiveCN107048333AGreat tasteFood safetyAlcoholic food ingredientsLipidic food ingredientsVegetable oilFood flavor

The invention provides garlic-flavor sauce, prepared from the following raw materials in parts by weight: 1-30 parts of chili, 1-10 parts of garlic, 0.1-5 parts of fermented soya beans, 0.1-5 parts of minced ginger, 0.1-3 parts of edible salt, 0.1-3 parts of white wine and 1-30 parts of vegetable oil. The garlic-flavor sauce provided by the invention has the advantages of good mouthfeel, edible safety and long shelf life, the sauce has efficient antiseptic and freshness-preserving effects without adding any additive, so a safe food is provided for people; and the processing method has the characteristics of high efficiency, environmental protection and simple operation, effectively prolongs the shelf life of the sauce, greatly improves the working efficiency and reduces the production cost.

Owner:刘少英

Preparation method of bacterial-cellulose-fiber-based nano-grade carbon fiber

InactiveCN103184586BLow priceWide variety of sourcesFibre chemical featuresCarbon fibersEconomic benefits

The invention relates to a preparation method of bacterial-cellulose-fiber-based nano-grade carbon fiber. According to the invention, a bacterial cellulose wet film is adopted as a substrate raw material. The prepared nano-grade carbon fiber is a product obtained after pyrolytic carbonization and graphitization of ultrafine bacterial cellulose fiber processed through an acupuncture carding refining treatment. The bacterial-cellulose-fiber-based nano-grade carbon fiber preparation method provided by the invention is safe, simple, and highly efficient, and has the advantages of wide raw material source, low price, and environment-friendly processing method. The bacterial-cellulose-fiber-based nano-grade carbon fiber obtained by processing has wide application field and great potential economic benefit.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Preparation method of bacteria cellulose fiber-based carbon nanofiber knitted fabric

InactiveCN103184651BFine spatial networkHigh chemical purityWeft knittingCarbon fibresPolymer scienceCarbon fibers

The invention relates to a bacteria cellulose fiber-based carbon nanofiber knitted fabric, which is made through the following steps: adopting spinning and knitting technology to prepare a carbon nanofiber knitted fabric with a superfine bacteria cellulose fiber subjected to refining and carding treatment by the needling, and carrying out pyrolysis carbonization and graphitization. The preparation method has the benefits that the raw material source is wide; the price is low; the processing method is environment-friendly, safe, simple and efficient; the bacteria cellulose fiber-based carbon nanofiber knitted fabric gained after processing has wide application fields; and the potential economic benefit is huge.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of corrosion-resistant and wear-resistant self-lubricating surface treatment method

ActiveCN106756771BFor long-term storageSolve the problem that it is not convenient to add greaseSolid state diffusion coatingAdditivesConvex structureWear resistant

The invention discloses a corrosion-resisting wear-resisting self-lubricating surface treatment method. The method has the following specific steps that (1), reticular structure treatment is conducted, specifically, the part surface is processed to form an honeycomb concave-convex structure, and meanwhile a protruded peak of the honeycomb structure is inactivated; (2), corrosion-resisting wear-resisting treatment is conducted, specifically, a corrosion-resisting wear-resisting material is added to the part surface processed by the reticular structure to be resistant to corrosion and wearing; and (3), lubricating treatment is conducted, specifically, the part surface is lubricated through a lubricating material. According to the corrosion-resisting wear-resisting self-lubricating surface treatment method, the corrosion-resisting wear-resisting self-lubricating part surface can be manufactured, the overall processing method is environmentally friendly, low in energy consumption and simple in technological process, a corrosion-resisting wear-resisting self-lubricating layer similar to the honeycomb surface structure is formed, and thus the friction working condition of the high speed, the heavy load, the large contacting surface and inconvenience of lubricating-grease adding is improved.

Owner:XCMG HYDRAULICS CO LTD

Capillary microchannel-assisted line-based microfluidic bipolar electrode electrochemiluminescence device and its application

ActiveCN106353303BHigh resolutionControllable intervalChemiluminescene/bioluminescenceEngineeringElectrochemiluminescence

The invention discloses a capillary micro-channel assistant wire base microfluidic bipolar electrode electrochemical luminescence device, and a preparation method and the application thereof. The luminescence device consists of a capillary and a patterning line electrode, wherein the patterning line electrode consists of not less than three wire base electrodes and bare wire areas; the wire base electrodes are manufactured by conductive carbon paste; the wire base electrodes on two sides are driving electrodes; the wire base electrode between the driving electrodes is a bipolar electrode; an area between the every two wire base electrodes is the bare wire area; the capillary coats the patterning line electrode, needs to coat all bipolar electrodes, and simultaneously can not be in contact with the driving electrode. According to the luminescence device, the capillary micro-channel is applied to the line of the patterning carbon electrode for the first time to manufacture the capillary micro-channel assistant wire base microfluidic bipolar electrode electrochemical luminescence device. The integration device has the remarkable advantages that the loading speed of a sample is high and the samples can be evenly distributed on the patterning wire electrode.

Owner:SOUTH CHINA NORMAL UNIVERSITY

A low-temperature micro-abrasive air jet machine tool abrasive recovery system

ActiveCN111469061BEconomical processing methodThe processing method is environmentally friendlyAbrasive machine appurtenancesAbrasive blasting machinesProcess engineeringAir purification

The invention relates to an abrasive recovery system of a low-temperature micro-abrasive air jet machine tool. The abrasive recovery system of the low-temperature micro-abrasive air jet machine tool is characterized by comprising a dry air generation part, a low-temperature jet generation part, a large-particle waste recovery part, an air purification part, a purified air reutilization part and anabrasive recycling and reusing part. According to the abrasive recovery system of the low-temperature micro-abrasive air jet machine tool, abrasives generated when the low-temperature micro-abrasiveair jet machine tool is used for processing elastic plastic materials such as high-molecular polymers can be recycled and reused, and the purified air can be reused, so that the effects of being moreeconomical and environment-friendly are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com