Processing method for improving natural colored cotton color depth and colour and luster stability

A technology of natural colored cotton and processing method, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of changing the color of natural colored cotton products, no practical application, difficult industrial application, etc. The effect of high degree of improvement, low cost and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

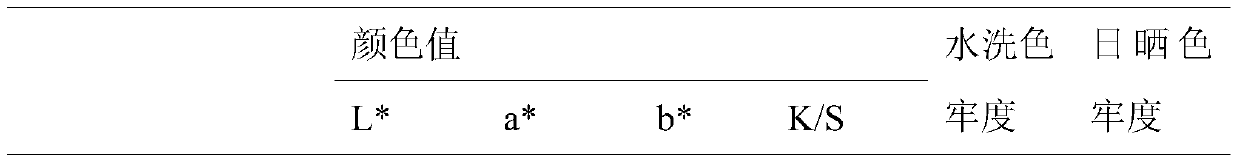

Examples

Embodiment 1

[0020] Embodiment 1, a kind of processing method that improves natural colored cotton color depth and color stability, carries out following steps successively:

[0021] 1) Pre-dry the natural colored cotton at 100°C until the moisture regain of the natural colored cotton is 4.2%.

[0022] Soak the dried natural colored cotton in liquid ammonia for 45 minutes.

[0023] 2), immerse the natural colored cotton after liquid ammonia treatment in the treatment liquid of 45 ℃, after dipping for about 5 seconds, remove excess treatment liquid, the liquid rate of the natural colored cotton after padding is 80% (mass %), and then Wind the natural colored cotton after padding into a tube and place it in a cold stack for 12 hours; obtain the natural colored cotton after color fixing treatment;

[0024] Mix gelatin, osmotic agent and water to form a protein solution, the mass concentration of gelatin in the protein solution is 1.8%, and the mass concentration of osmotic agent is 0.8%; the...

Embodiment 2

[0029] Embodiment 2, a kind of processing method that improves natural colored cotton color depth and color stability, carries out following steps successively:

[0030] 1) Pre-dry the natural colored cotton at 40°C until the moisture regain of the natural colored cotton is 13.3%.

[0031] Soak the dried natural colored cotton in liquid ammonia for 120 minutes.

[0032] 2), soak the natural colored cotton after liquid ammonia treatment in the treatment solution at 65°C, and remove the excess treatment solution after dipping for about 5 seconds. The liquid rate of the natural colored cotton after padding is 35%, and then the The natural colored cotton is wound into a tube and placed in a cold pile for 3.5 hours; the natural colored cotton after color fixing treatment is obtained;

[0033] Mix gelatin, penetrant and water to form a protein solution. The mass concentration of gelatin in the protein solution is 0.18%, and the mass concentration of the penetrant is 1.5%. Then use ...

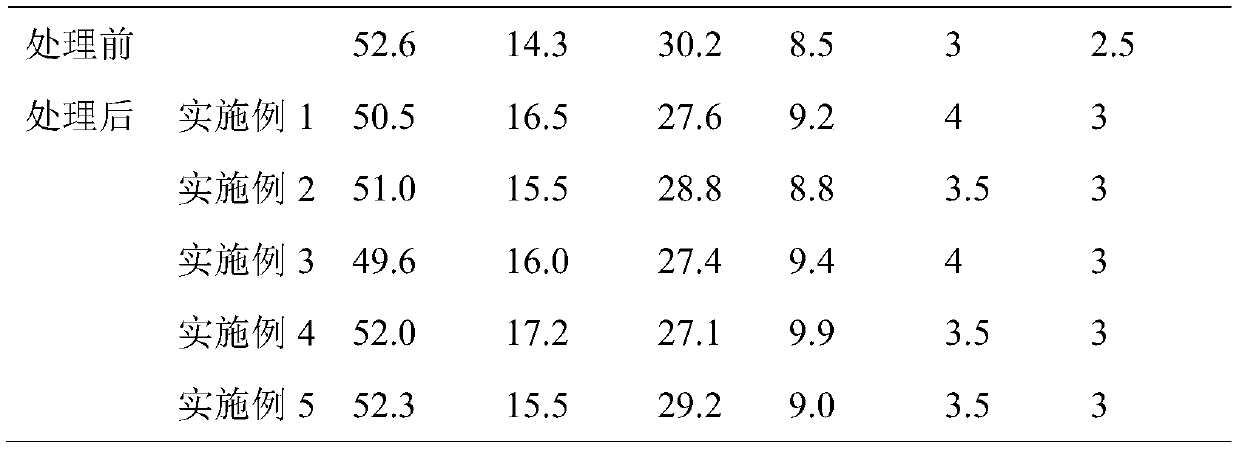

Embodiment 3

[0038] Embodiment 3, a kind of processing method that improves natural colored cotton color depth and color stability, carries out following steps successively:

[0039] 1) Pre-dry the natural colored cotton at 100°C until the moisture regain of the natural colored cotton is 9.5%.

[0040] Soak the dried natural colored cotton in liquid ammonia for 600 minutes.

[0041] 2), soak the natural colored cotton after the liquid ammonia treatment in the treatment solution at 45°C, and remove the excess treatment solution after dipping for about 5 seconds. The liquid rate of the natural colored cotton after padding is 100%. The natural colored cotton is wound into a tube and placed in a cold pile for 36 hours; the natural colored cotton after color fixing treatment is obtained;

[0042] Mix gelatin, osmotic agent and water to form a protein solution. The mass concentration of gelatin in the protein solution is 8.5%, and the mass concentration of osmotic agent is 3.5%. Then use sulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com