Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Heated milk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heating Milk. Milk should be heated gently and slowly. Excessive heat can result in a scorched flavour and/or a film of protein on the top of the milk. You can avoid these problems in one of two ways: The double-boiler method: Place milk in the top of a double boiler or in a heat-proof bowl set over a saucepan of simmering water.

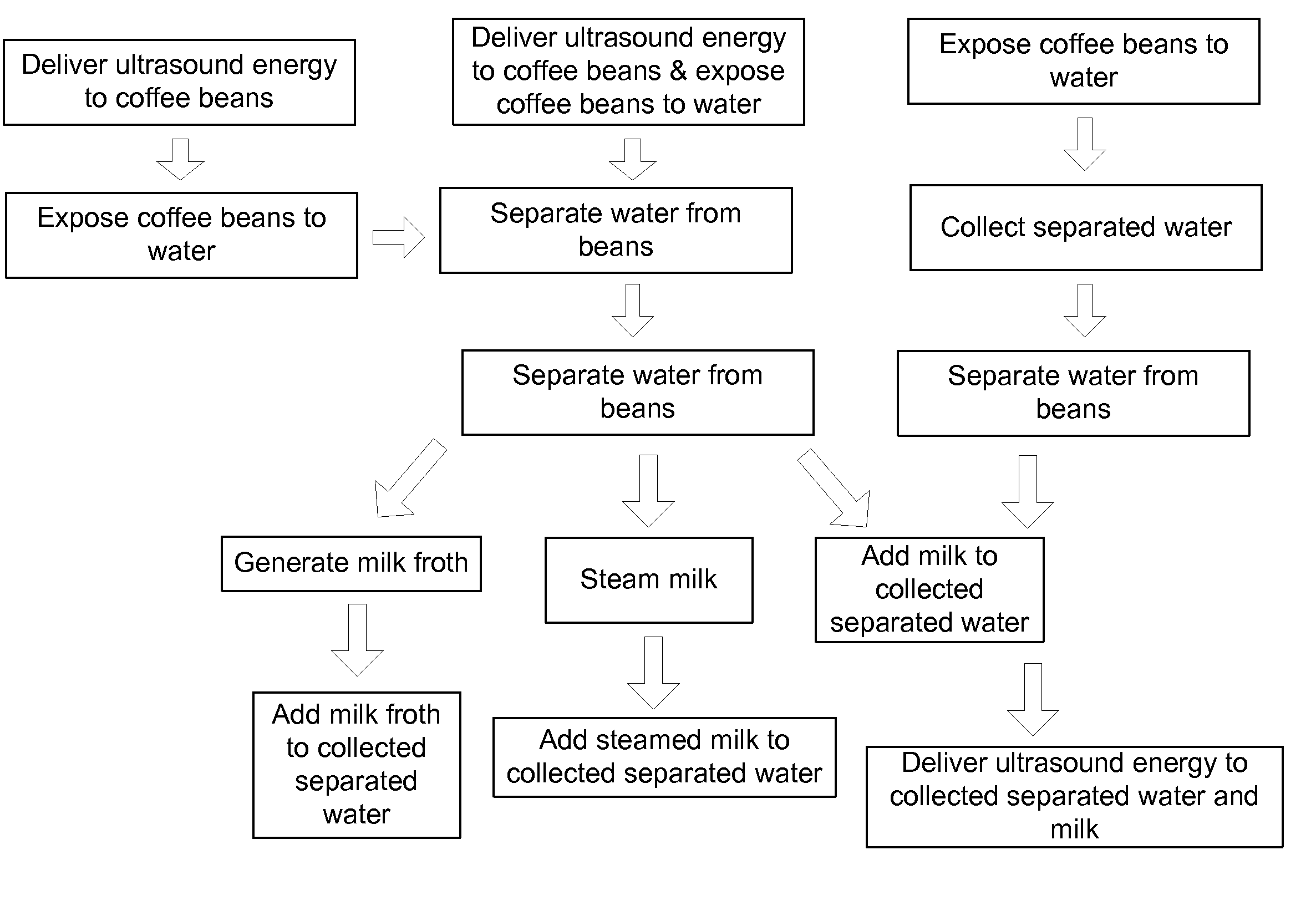

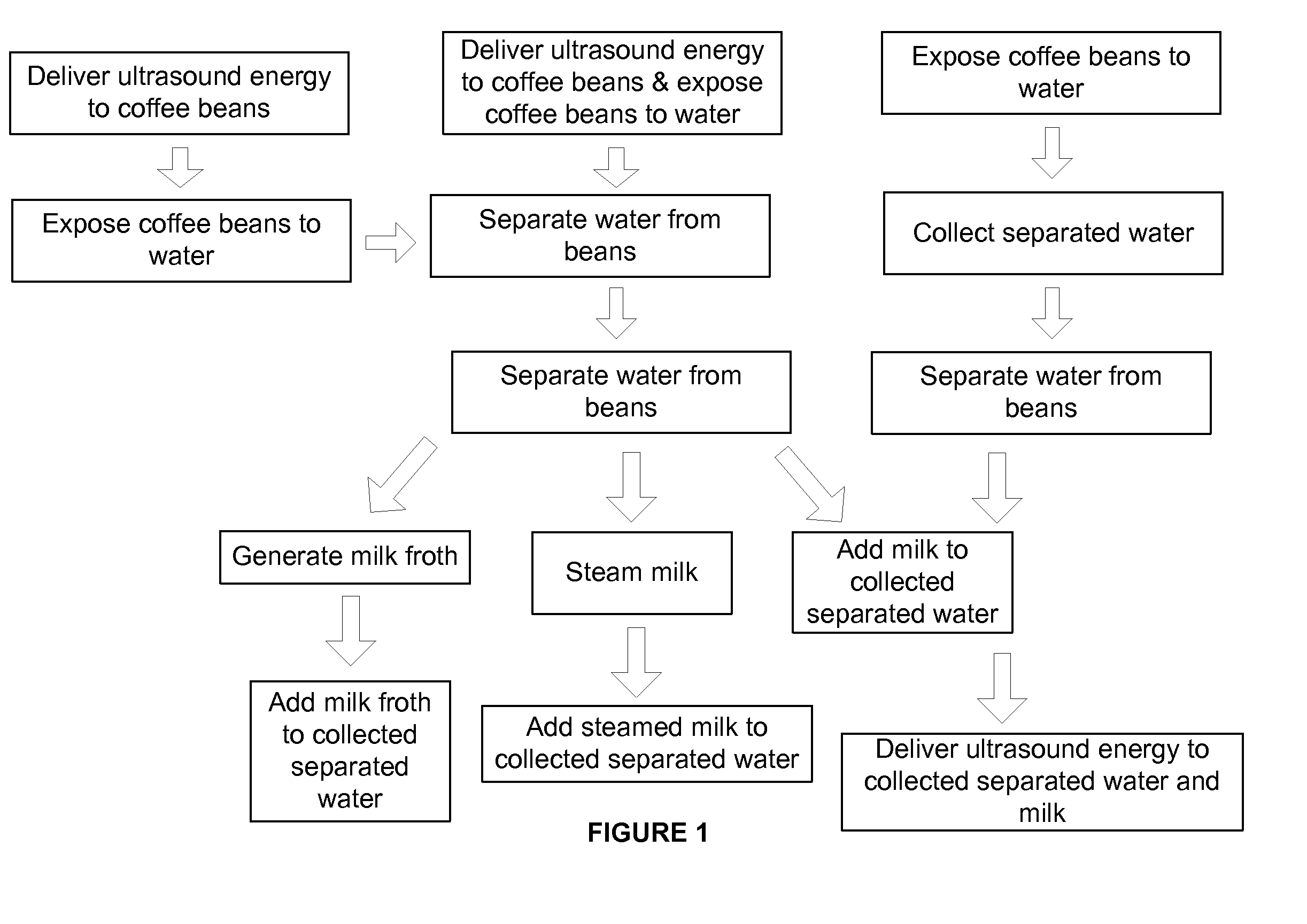

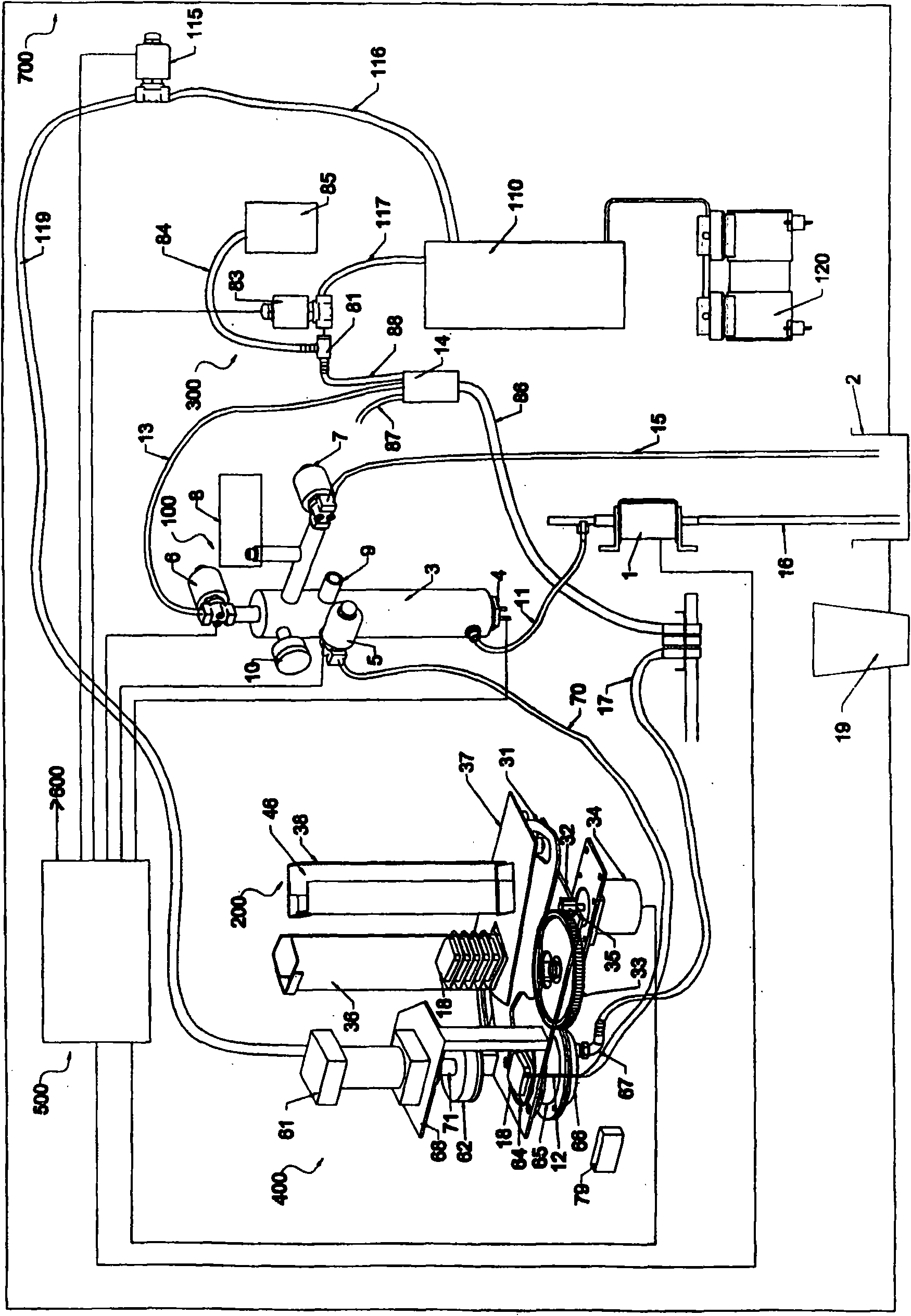

Method and Apparatus for Producing Beverages from Coffee Beans Using Ultrasound Energy

InactiveUS20080032030A1More flavorSignificant flavorBeverage vesselsCoffee extractionFlavorEngineering

Method and device for producing beverages from coffee beans using ultrasound energy is disclosed. Ultrasonic energy is delivered to coffee beans to produce an improved coffee beverage. The use of ultrasound energy may have multiple effects such as the extraction of flavor solutes from the coffee beans or the sanitization of the resulting beverage. Ultrasound energy may also be used to help mix milk with espresso in order to produce a cappuccino or a latte; the ultrasound energy may also heat the milk or produce a milk froth. The use of ultrasound energy to produce beverages from coffee beans may result in a more flavorful and safer beverage for consumption.

Owner:BABAEV EILAZ

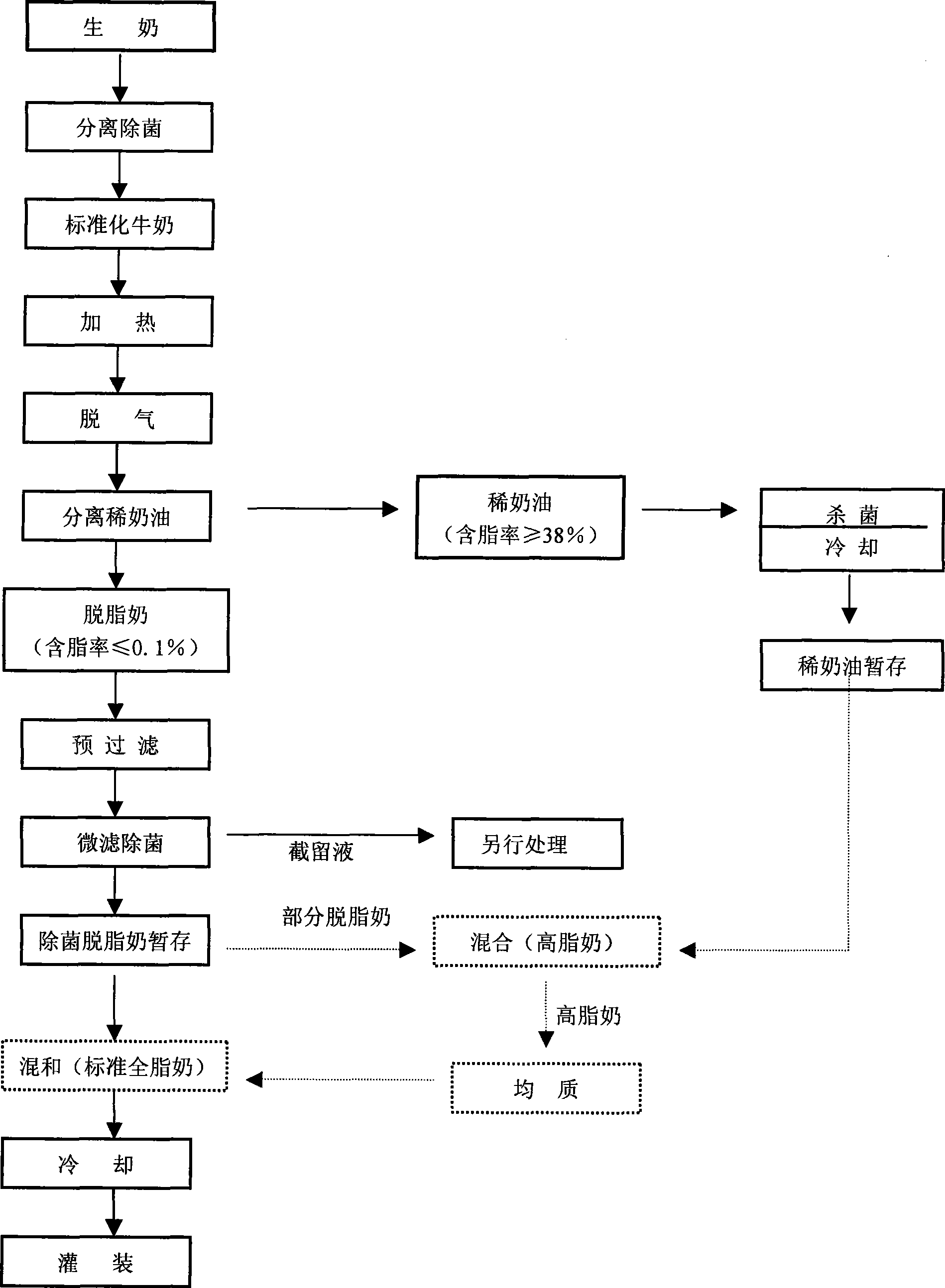

Production method of milk and milk produced by the method

Owner:BRIGHT DAIRY & FOOD

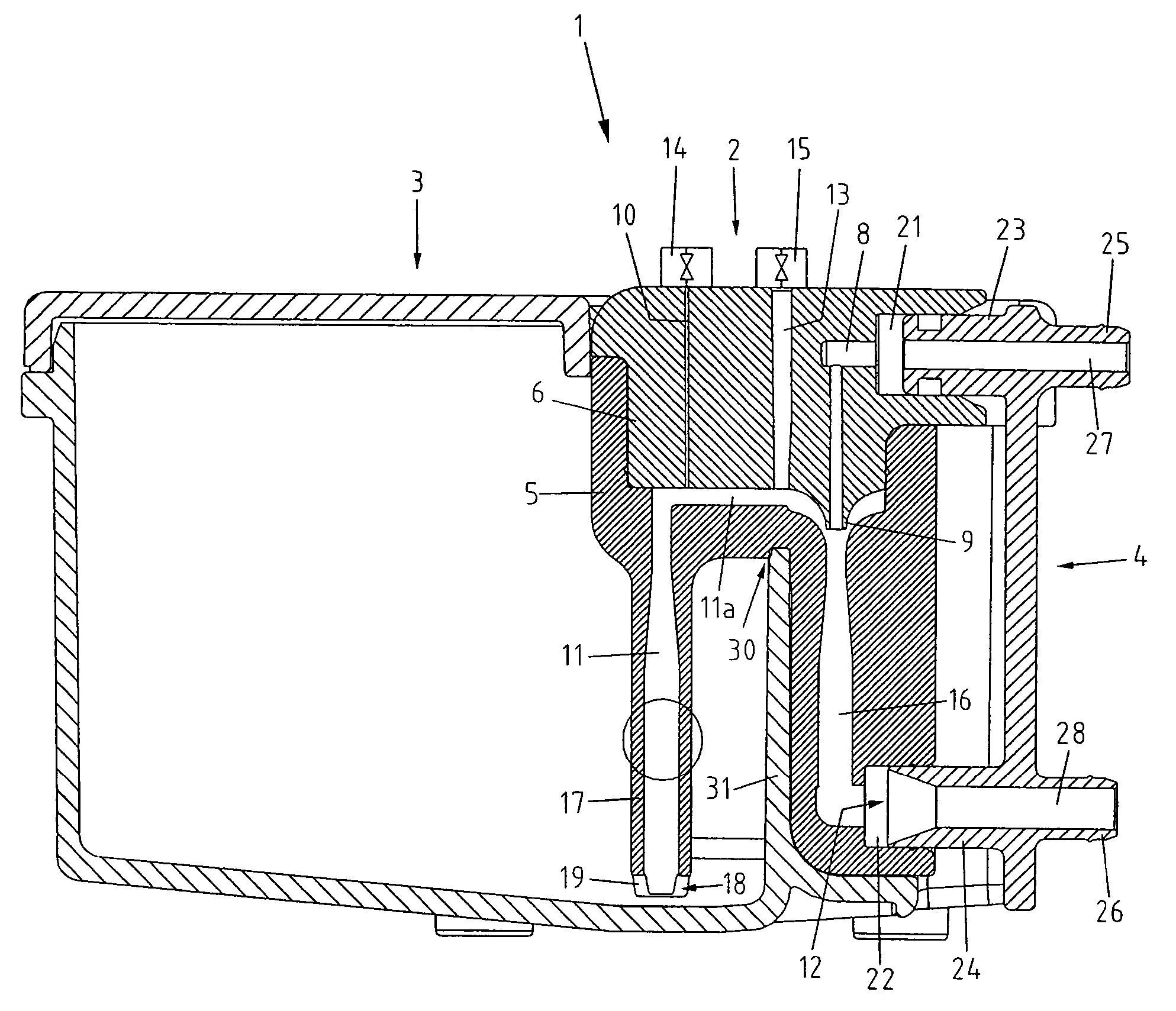

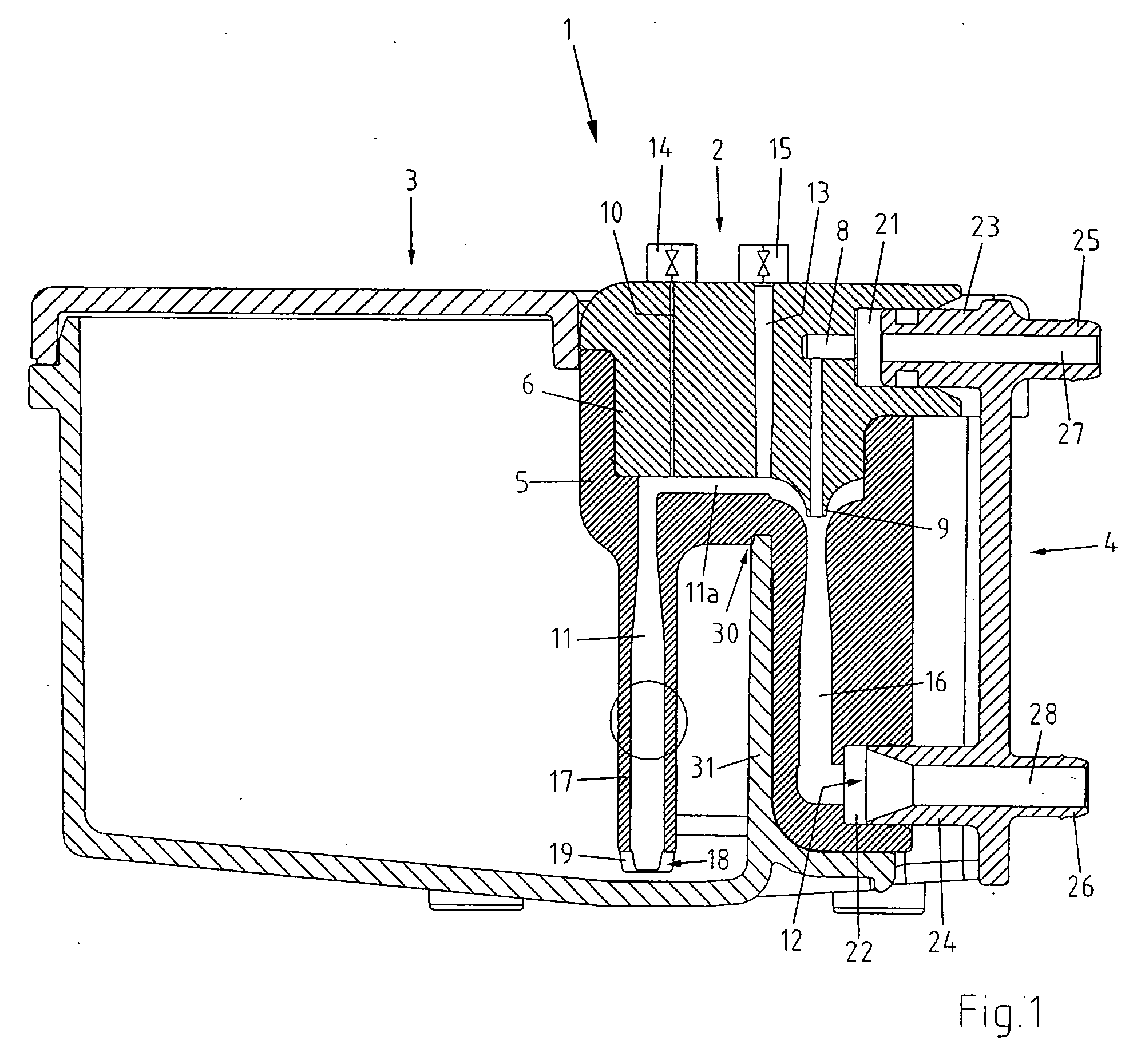

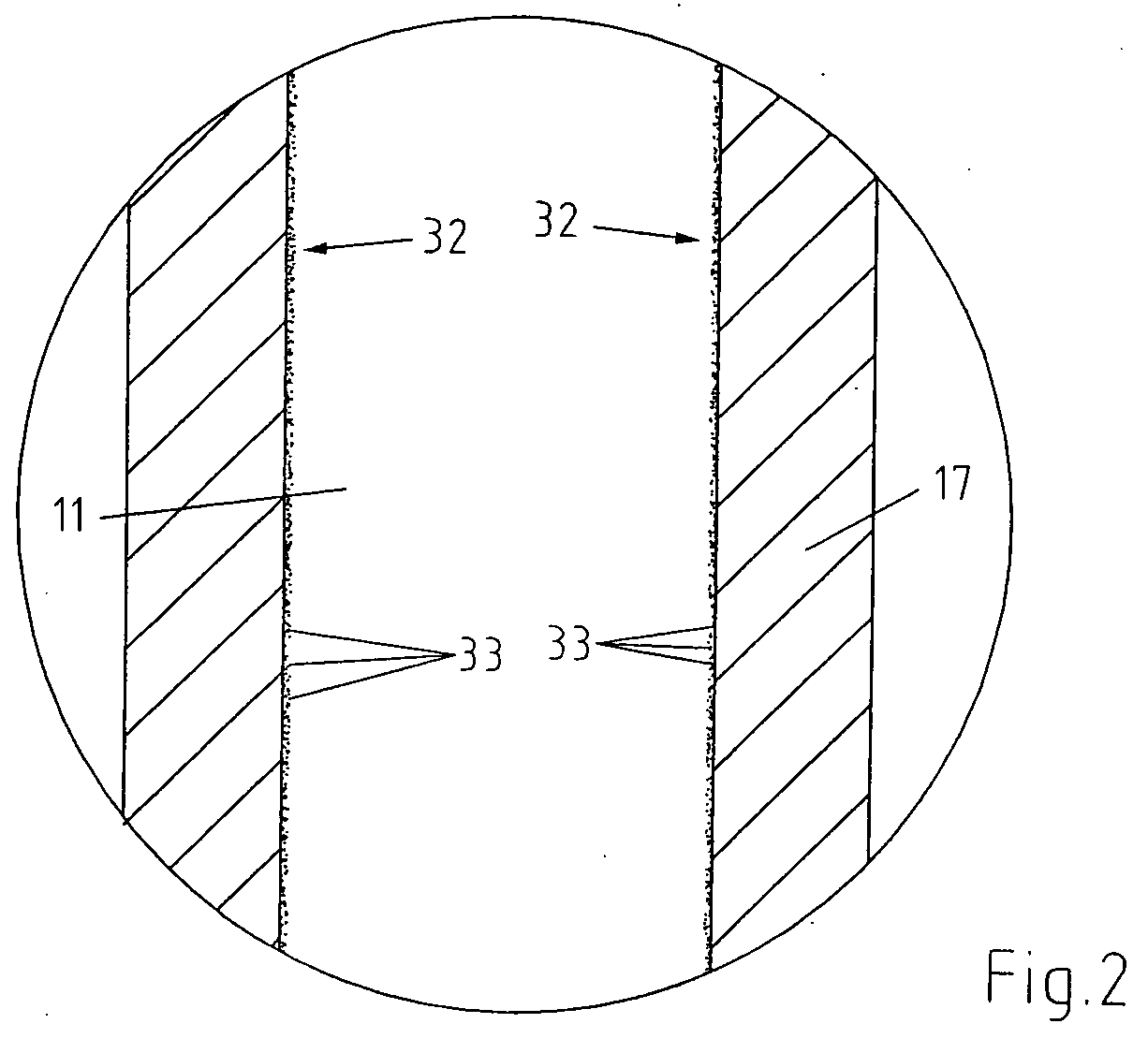

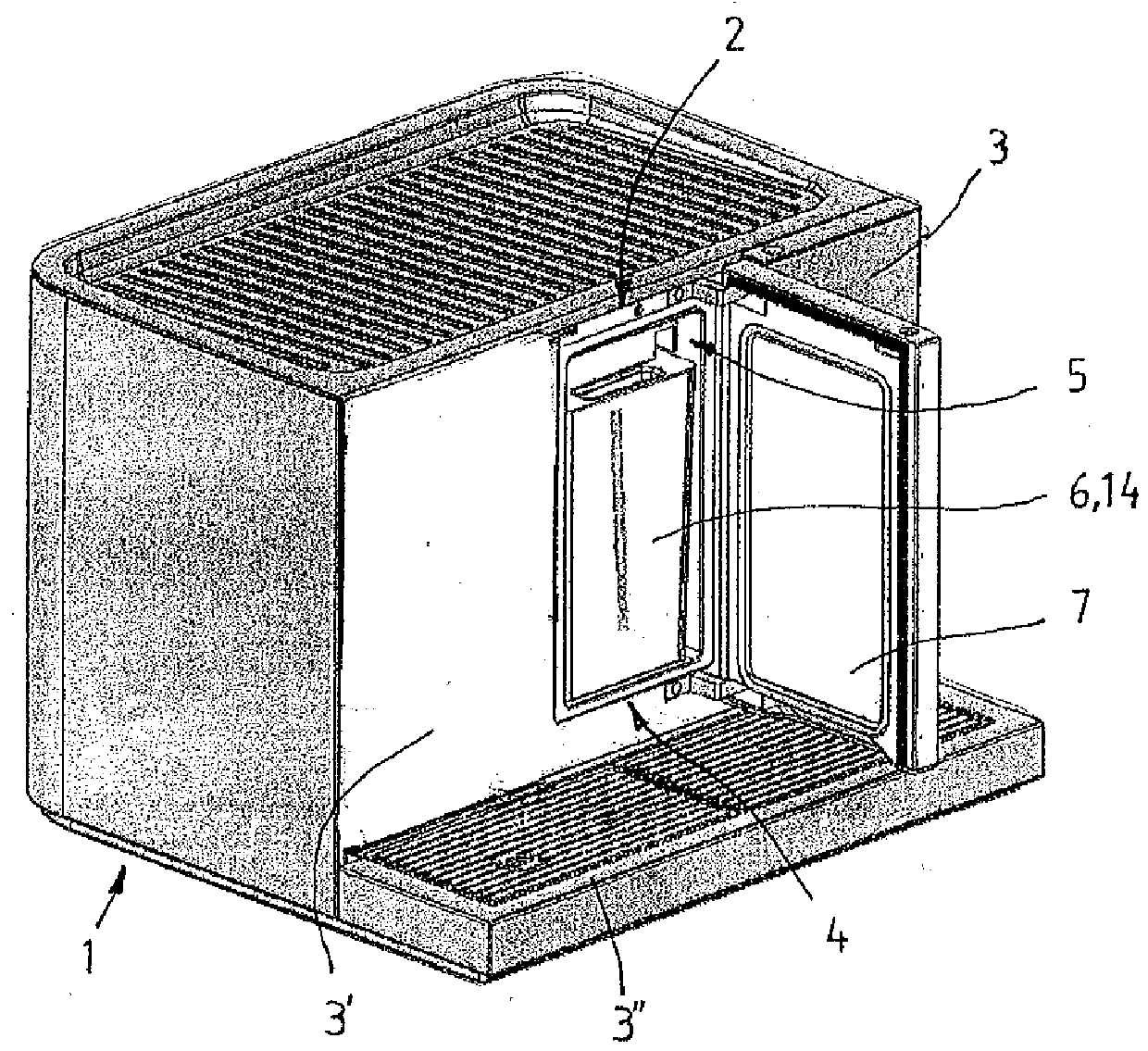

Assembly for creating milk froth and/or for heating milk

InactiveUS7322282B2Less susceptible to pollutionEasy to cleanCooking-vessel materialsMilk preservationNanoparticleHeated milk

An assembly for creating milk froth and / or for heating milk is disclosed. It comprises a foaming device and optionally a milk container and a valve assembly. The foaming device is provided with a steam supply channel, an air supply channel, a milk supply channel and a discharge opening. In order to provide for an easy cleaning of the assembly and its microbicity, at least the components and / or cavities coming into contact with milk are provided with a hydrophobic and oleophobic surface consisting of nano-particles which consist partially of silver or a silver compounds.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

An assembly for automatic fresh brewing of hot beverage and dispensing thereof

Owner:TATA GLOBAL BEVERAGES

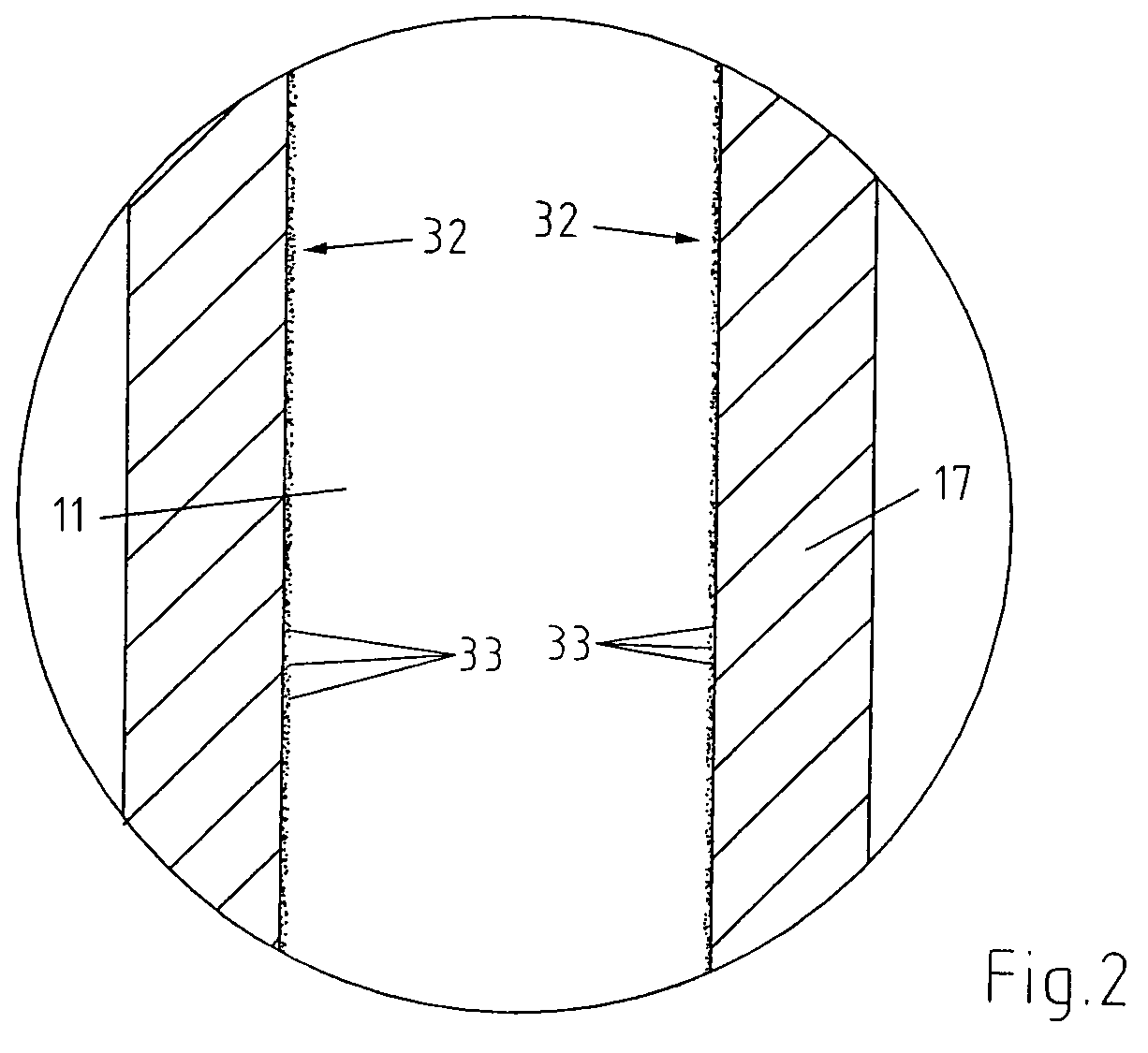

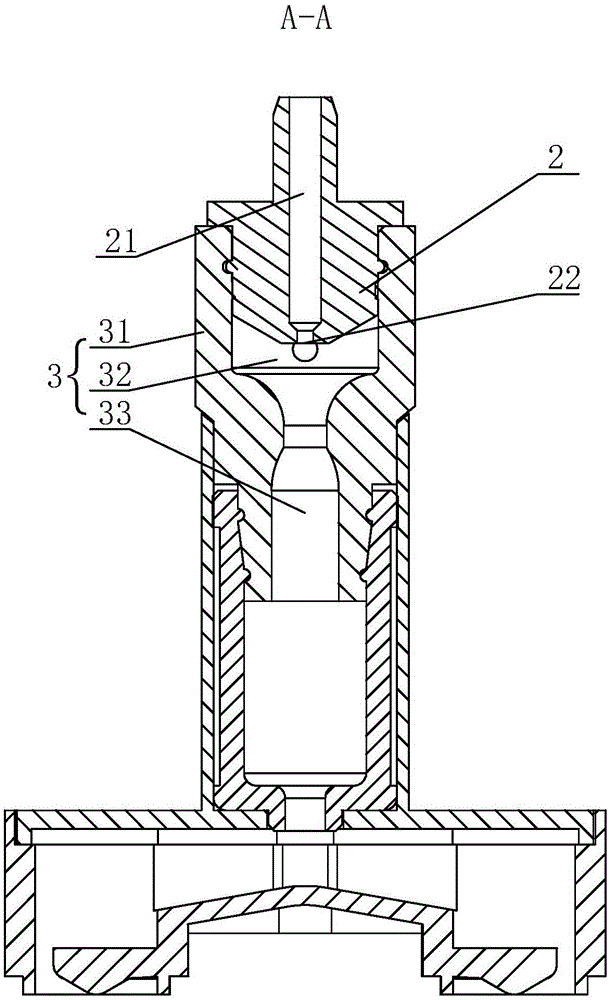

Self-cleaning mixing head for producing a milk-based mixture

InactiveUS20070242561A1Facilitates cleaning procedureFacilitate cleaning stepRotary stirring mixersMedical devicesEngineeringHeated milk

A mixing head for producing heated milk in the form of a froth or water-milk mixture. The mixing head includes a steam feed, a milk inlet, a mixing area where the steam feed and milk inlet join and the steam and milk combine, an outlet nozzle for draining the resulting mixture from the mixing head, a rinsing medium supply, a milk supply and a transfer mechanism that provides relative movement between the milk inlet and the rinsing medium supply or the milk supply for selectively bringing the milk inlet into fluid connection with the rinsing medium supply or the milk supply, such that milk or a rinsing medium, as desired, can enter the mixing head at the milk inlet.

Owner:NESTEC SA

Drinking type flavor fermented milk and making method thereof

The invention discloses drinking type flavor fermented milk and a making method thereof. The making method comprises the following steps of a, preparing 852.85-924.4 parts by weight of raw milk, taking 30% of the prepared raw milk, heating the taken raw milk to 45-50 DEG C, then putting 5-15 parts of whey protein powder in the heated raw milk, performing stirring to obtain a mixture, enabling the mixture to stand, performing hydration to obtain an emulsion 1, taking another 30% of the prepared raw milk, heating the taken raw milk to 50-55 DEG C, adding 0.5-2 parts of dried egg yolk, 10-40 parts of coffee cream, 60-90 parts of white granulated sugar in the heated raw milk, performing stirring to obtain a mixture, and cooling the mixture to 2-6 DEG C so as to obtain an emulsion 2; b, mixing the emulsion 1 with the emulsion 2, adding the residual raw milk, performing volume settling, and performing stirring so as to obtain milk liquid; c, heating the milk liquid to 65-70 DEG C, homogenizing the heated milk liquid, and then sterilizing the homogenized milk liquid; d, after the homogenized milk liquid is sterilized, cooling the sterilized milk liquid to 42-44 DEG C, inoculating 0.1-0.15 parts of a fermenting agent, performing stirring, and performing fermentation at a constant temperature; and e, through fermentation, changing the milk liquid into a base material, performing emulsion breaking on the base material, after emulsion breaking, shearing the emulsion broken base material by a shearing emulsification pump, and after shearing is completed, performing filling. Through the adoption of the drinking type flavor fermented milk and the making method thereof disclosed by the invention, the problem that food additives can be added in conventional drinking type flavor fermented milk is solved.

Owner:KUNMING XUELAN MILK

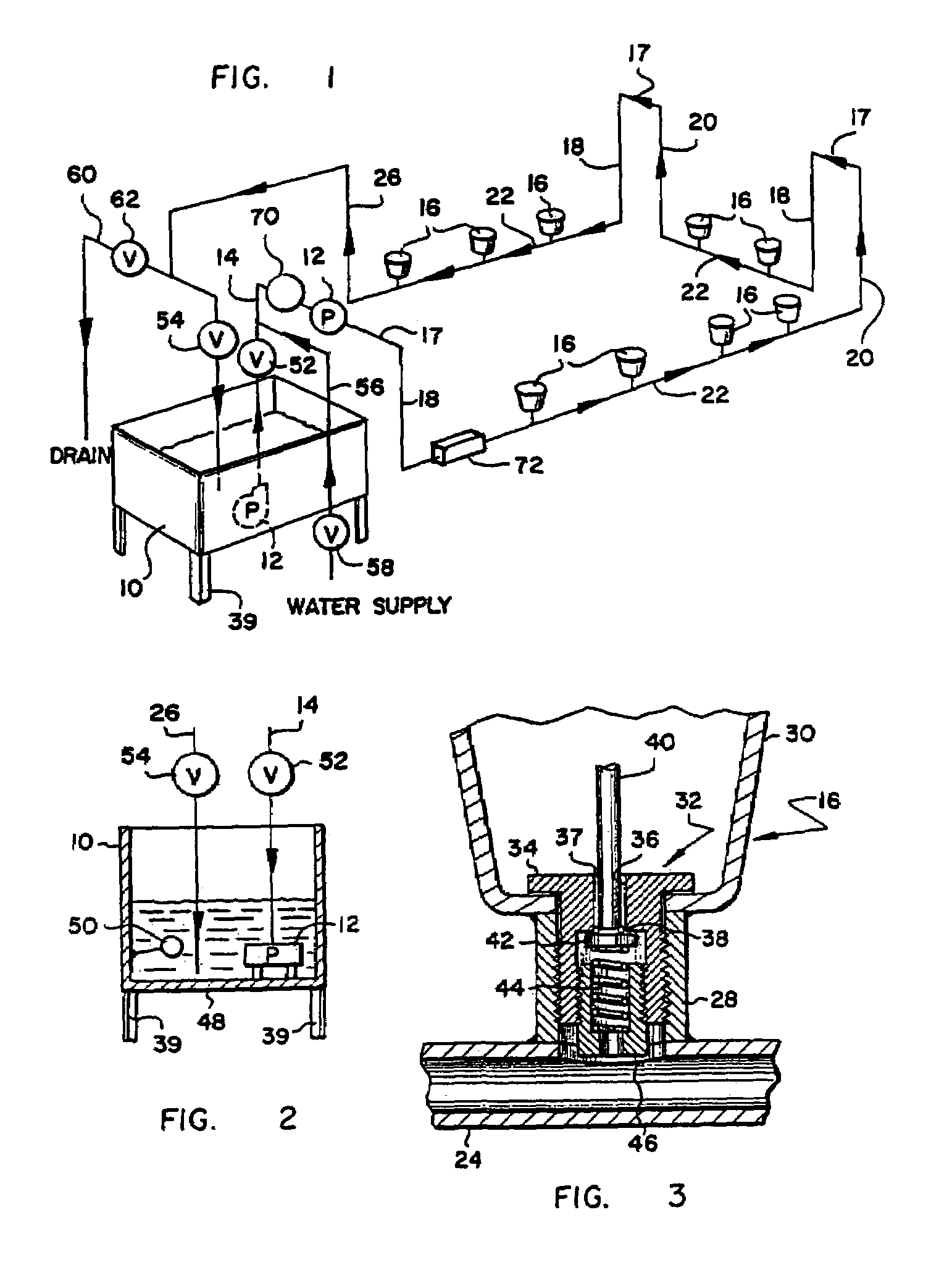

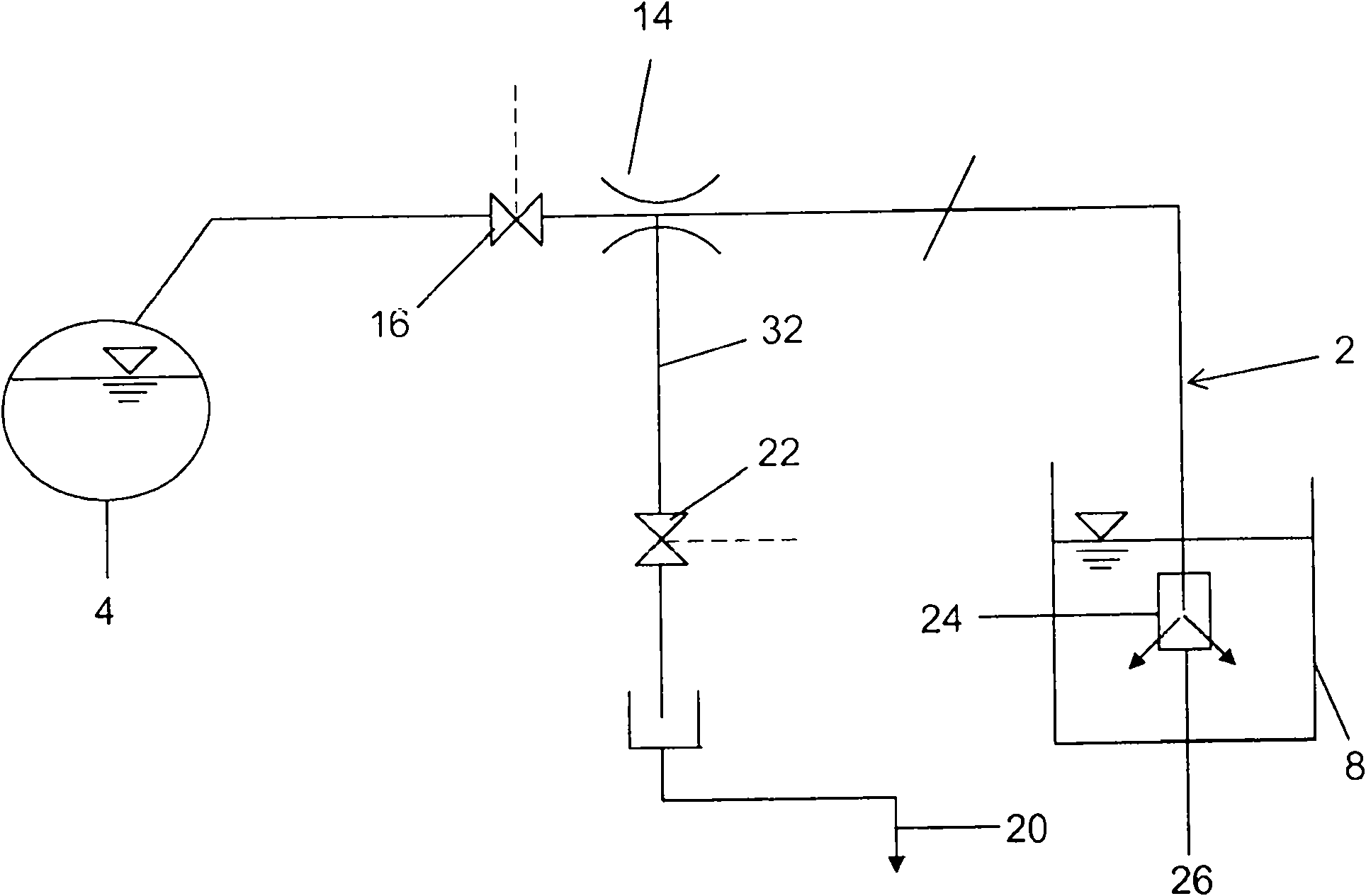

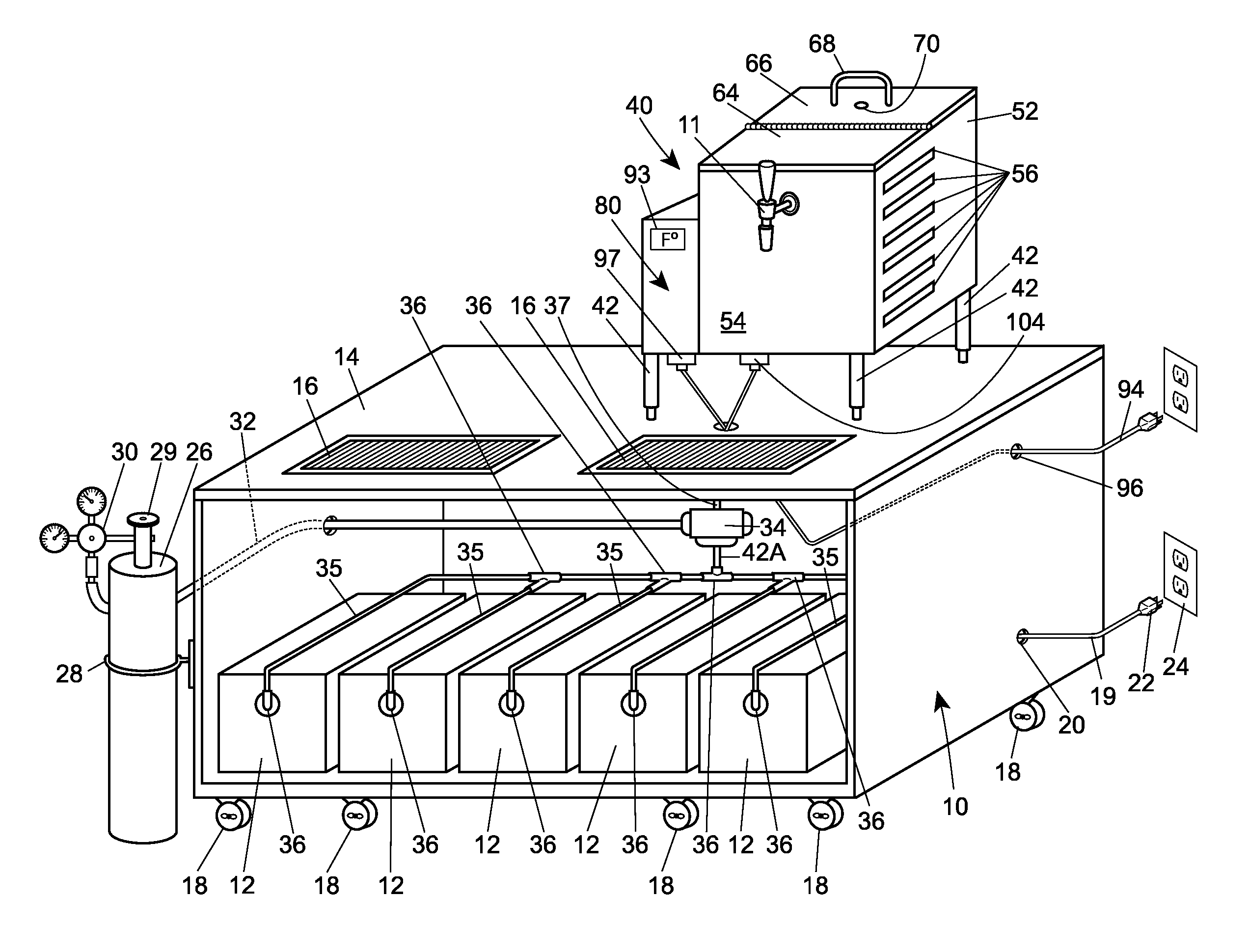

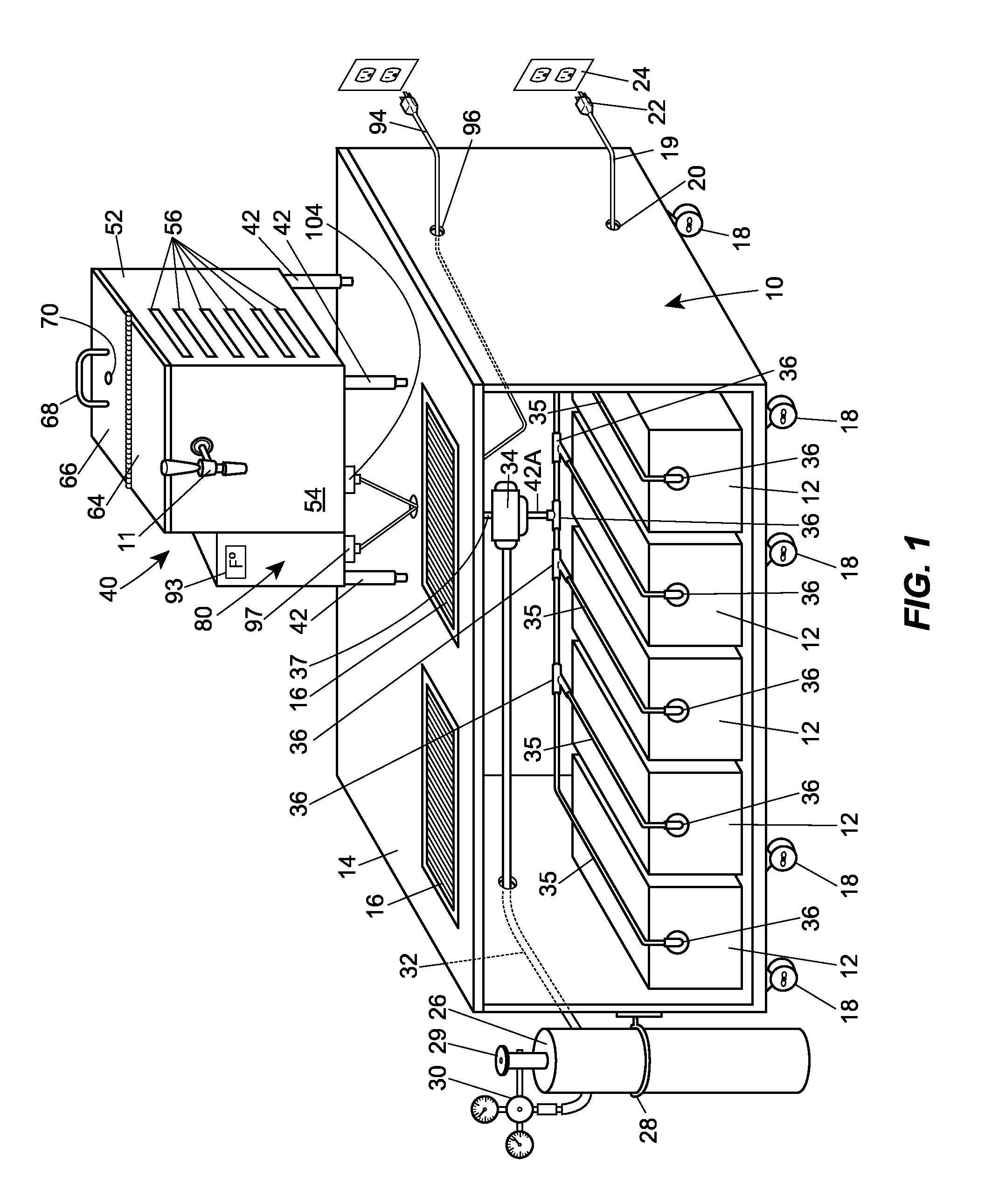

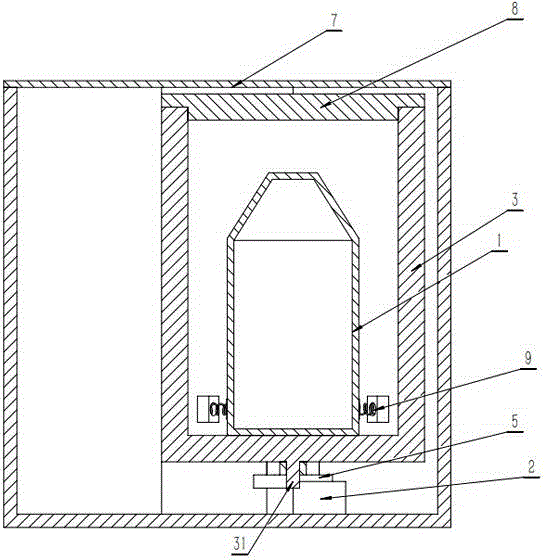

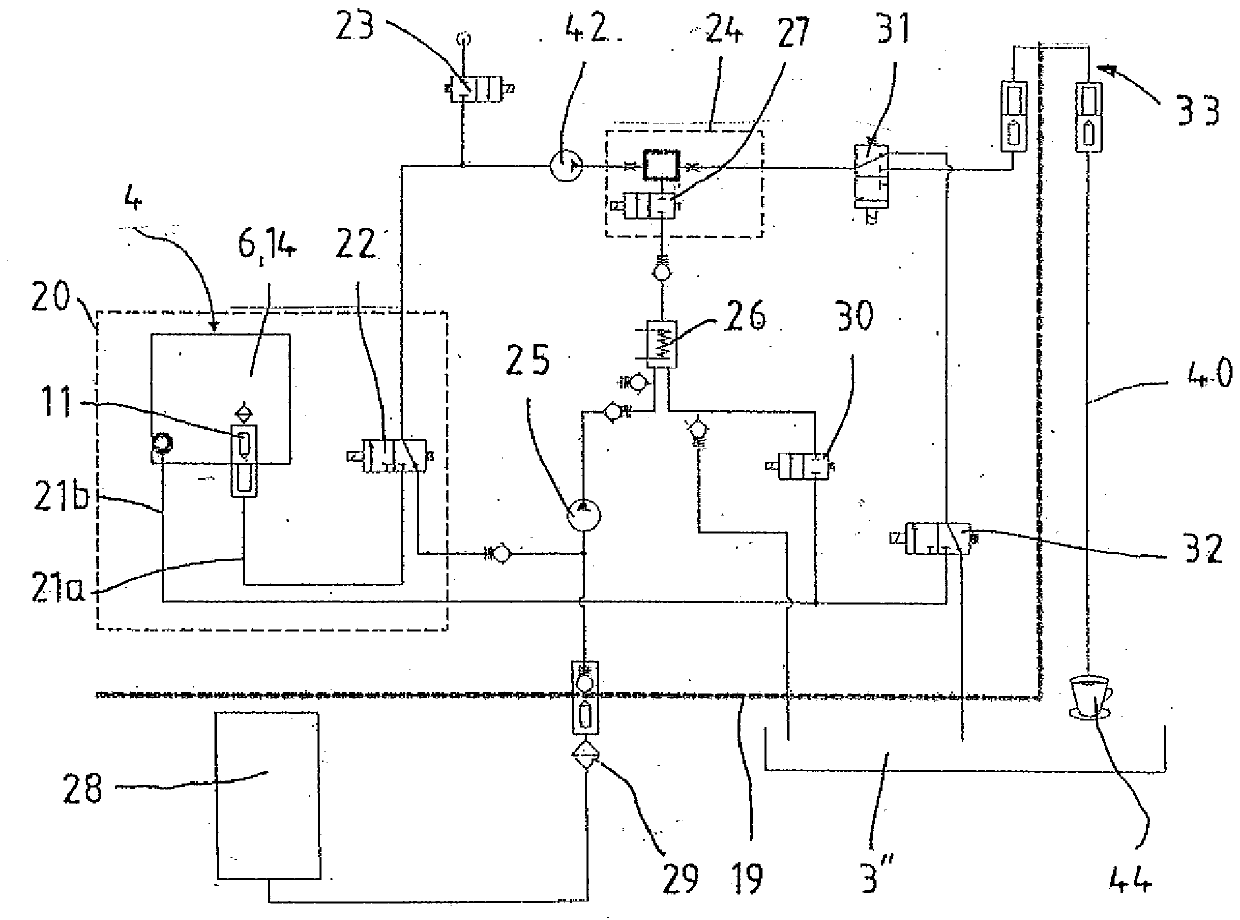

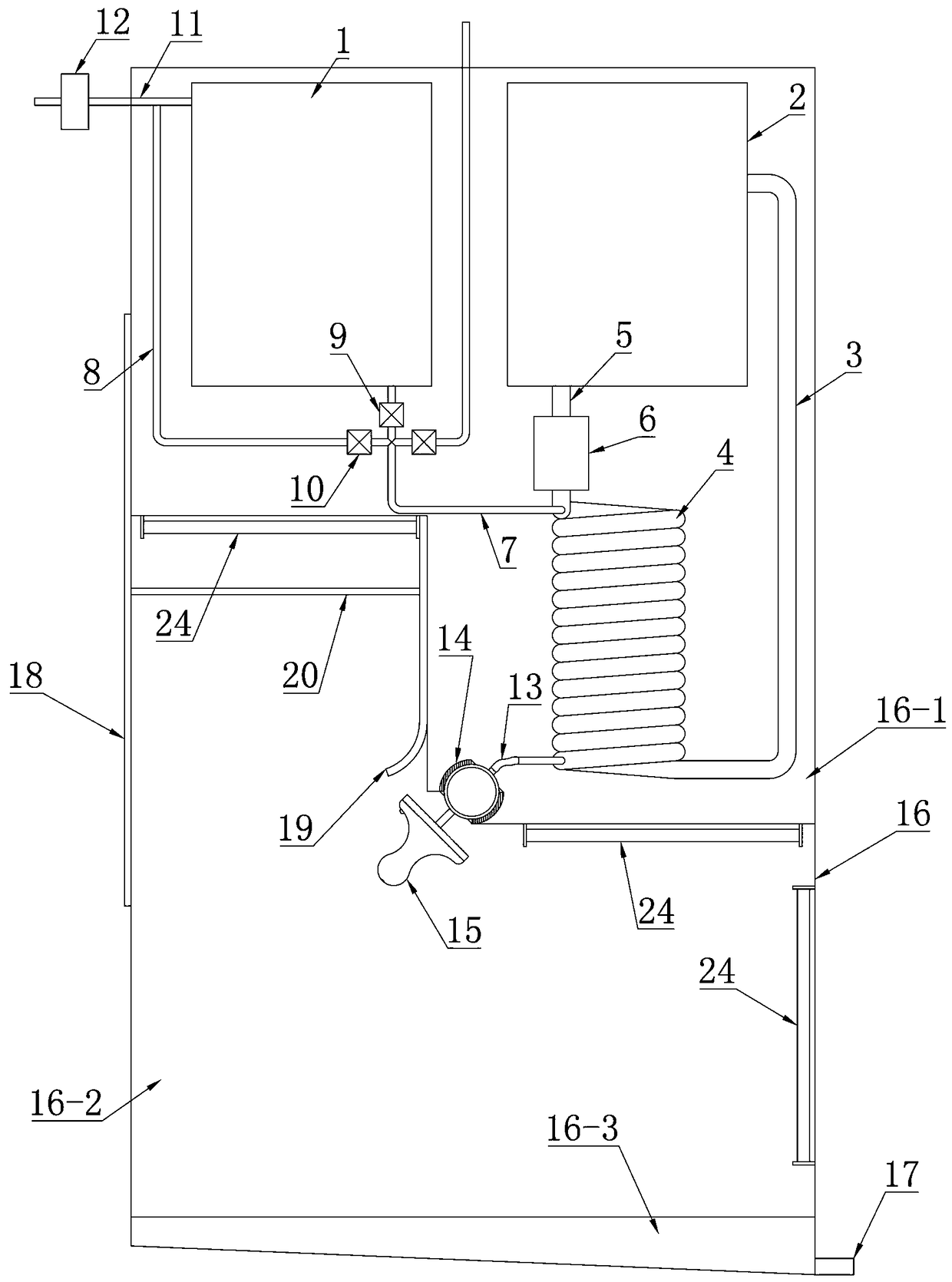

Heated milk supply system for livestock

A system for supplying heated milk or other liquids to individual drinkers from which animals, particularly baby pigs, can drink on a need basis by actuating a valve in the drinker that allows the milk to flow into the drinker. The system has a plurality of drinkers within a closed system in which the milk is supplied from a reservoir, heated to a minimum predetermined temperature range and pumped to each drinker which is positioned so that milk is continuously circulated through the drinker any time the circulating pump is running. This not only keeps the heated milk from spoiling, but it also prevents the drinkers from becoming clogged and permits the entire system to be cleaned in place.

Owner:SOPPE JOHN

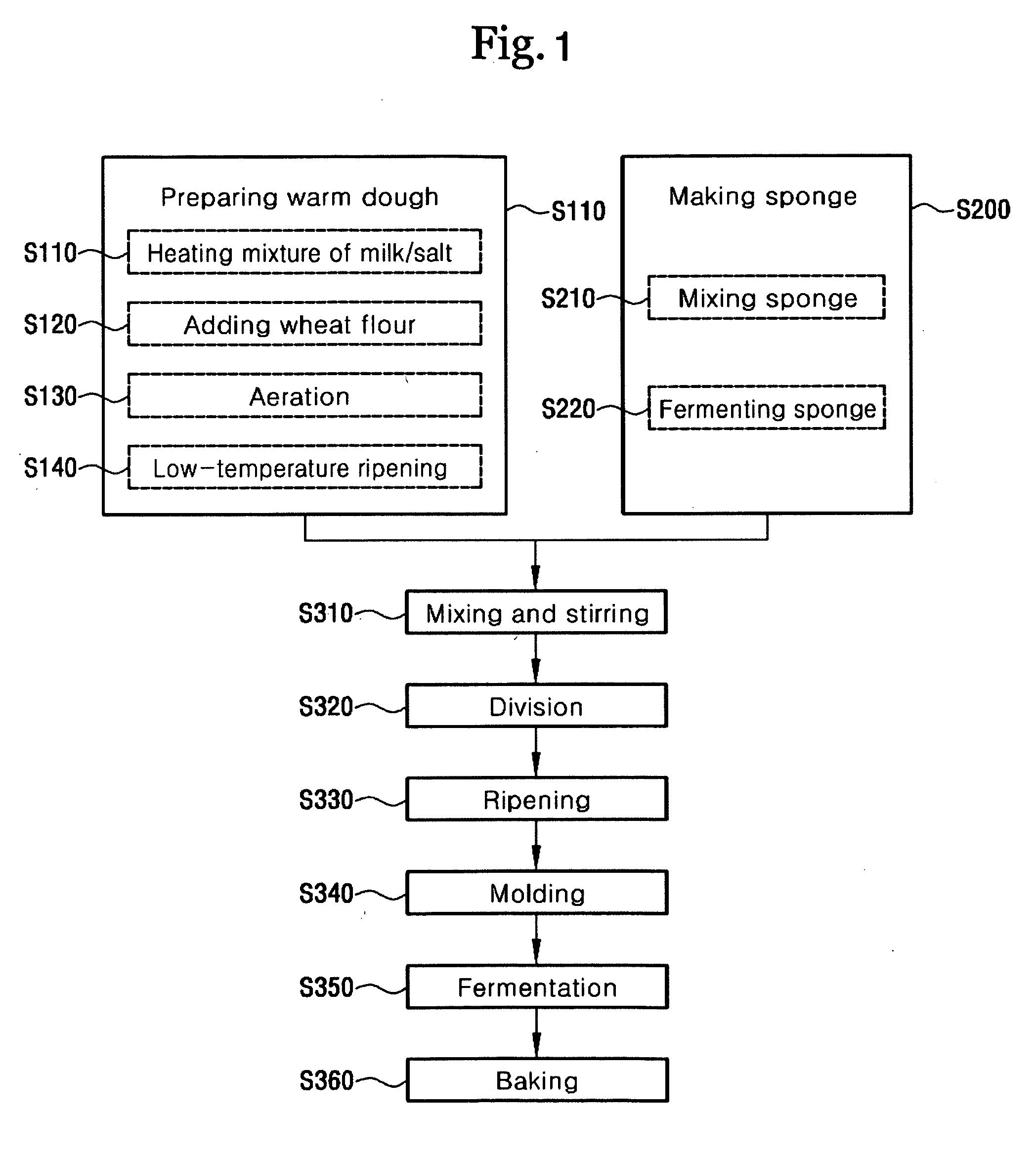

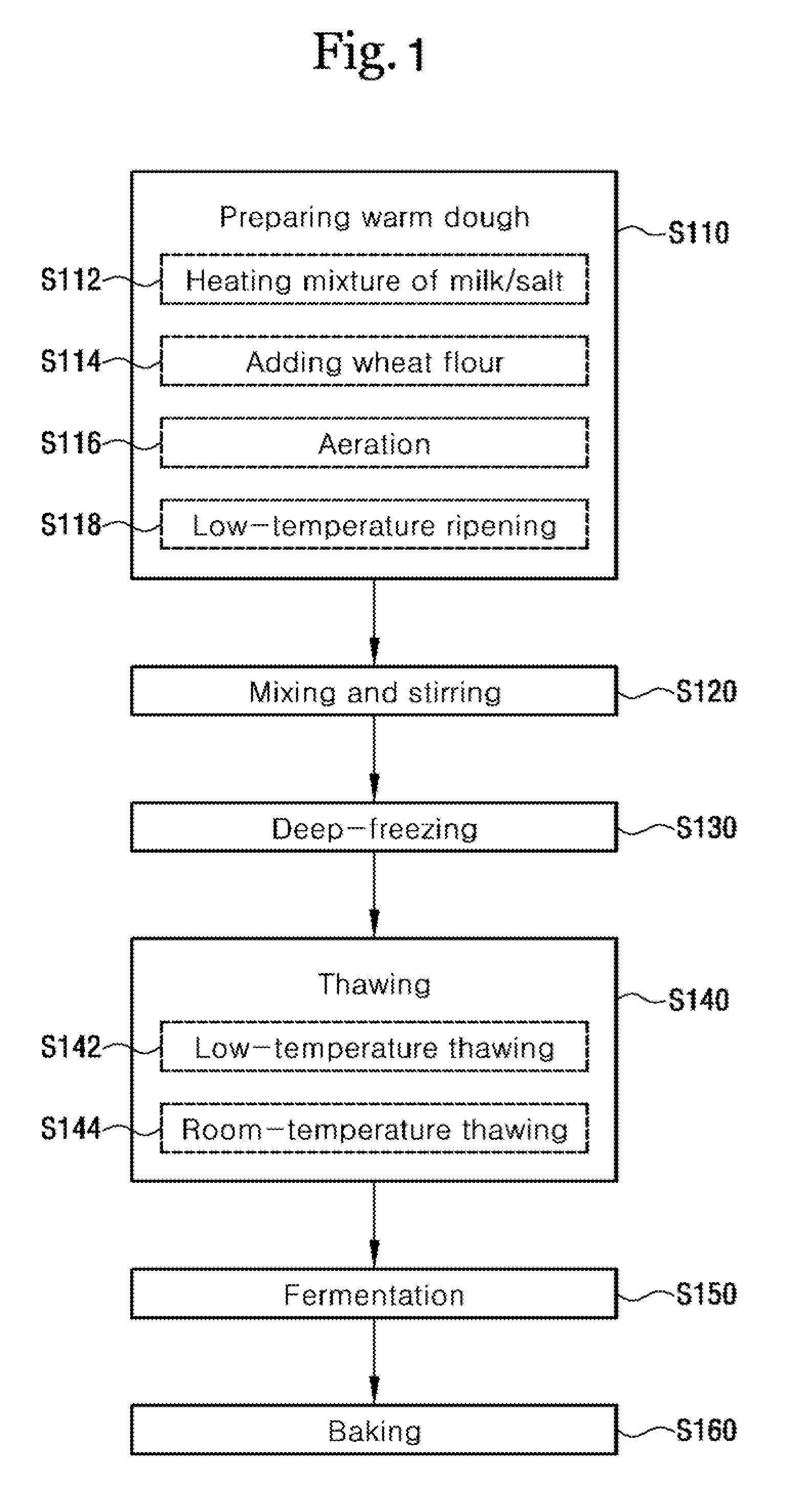

Method of making bread

ActiveUS20100255149A1High activityIncrease powerMilk preparationPre-baking dough treatmentSugarHeated milk

A method of making bread is provided. The method includes a warm dough making process in which a warm dough is formed by heating a mixture of milk and salt, adding wheat flour to the heated mixture, aerating the resulting mixture, and ripening the resulting mixture at low-temperature, a sponge making process in which a sponge is formed by mixing wheat flour, dried yeast, yeast food, bread improver, salt, and water and fermenting the mixture, a dough mixing process in which a dough is formed by mixing the warm dough and the sponge with wheat flour, salt, butter, dried yeast, dried milk, sugar, egg, and water and stirring the mixture, a division process in which the dough is divided into equal-sized pieces, a ripening process in which the divided dough is rolled out and ripened for a predetermined period of time, a molding process in which the resulting dough is molded to fit a bread pan, a fermentation process in which the molded dough is placed in the bread pan to be fermented, and a baking process in which the fermented dough is heated.

Owner:PARIS CROISSANT

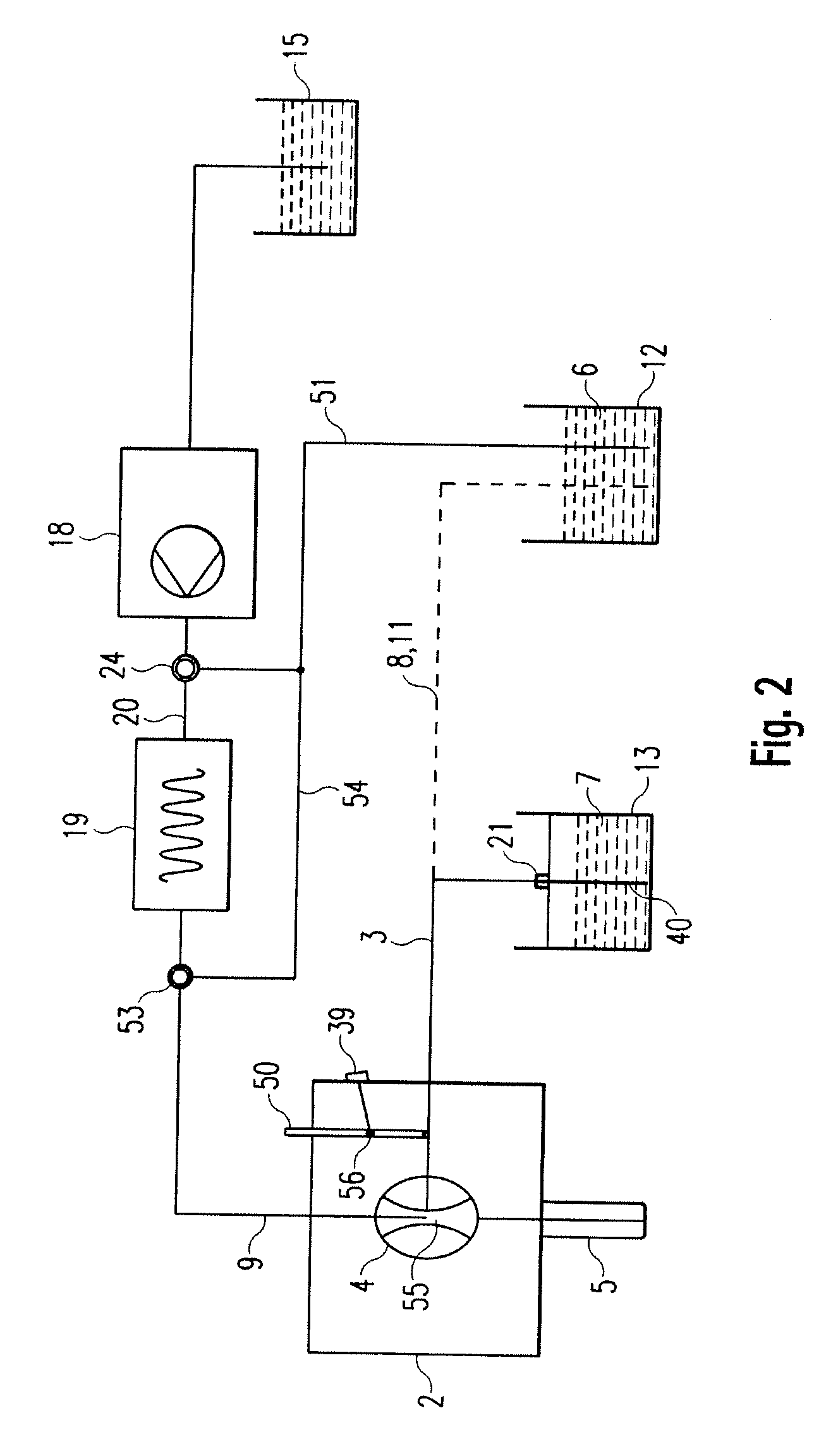

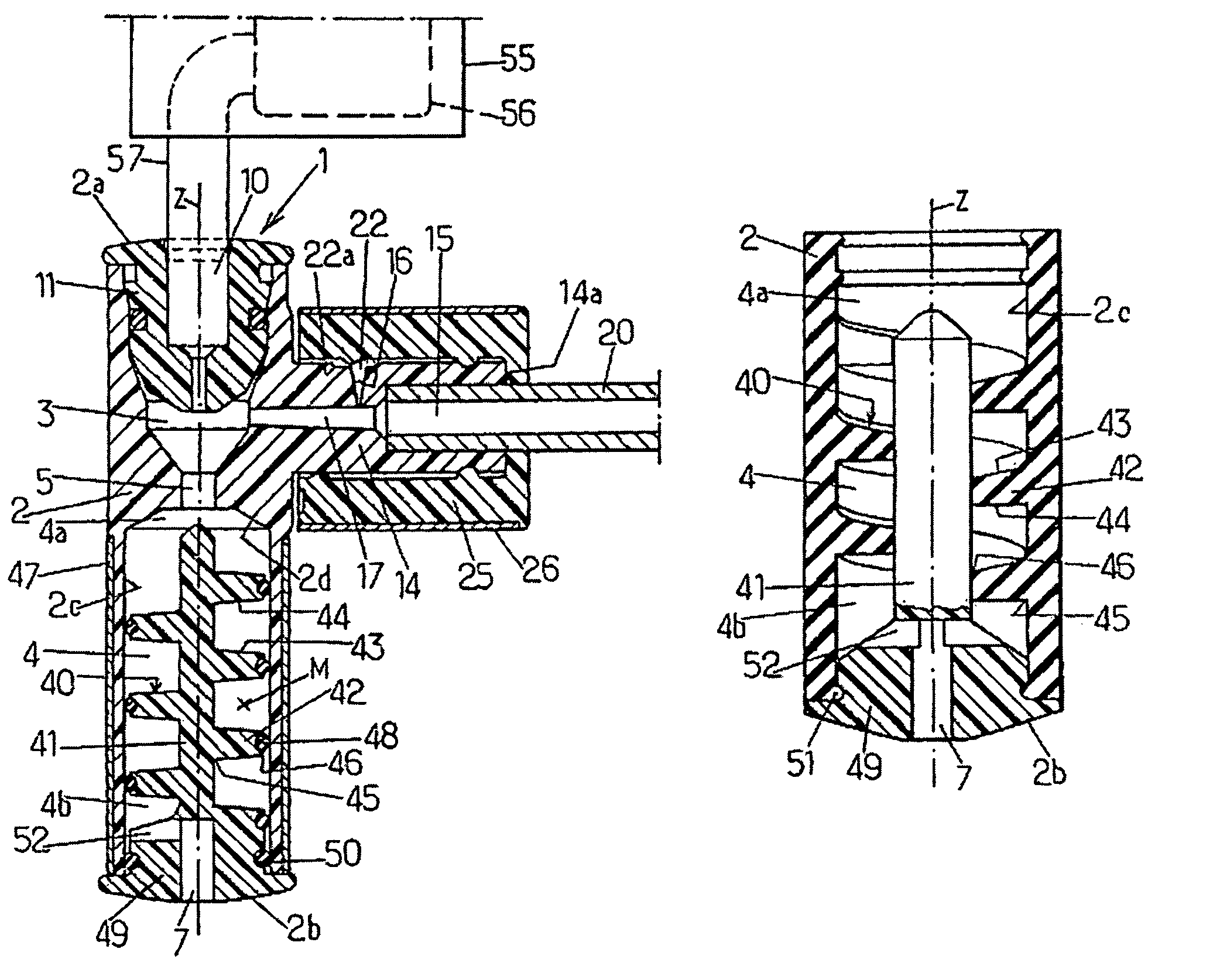

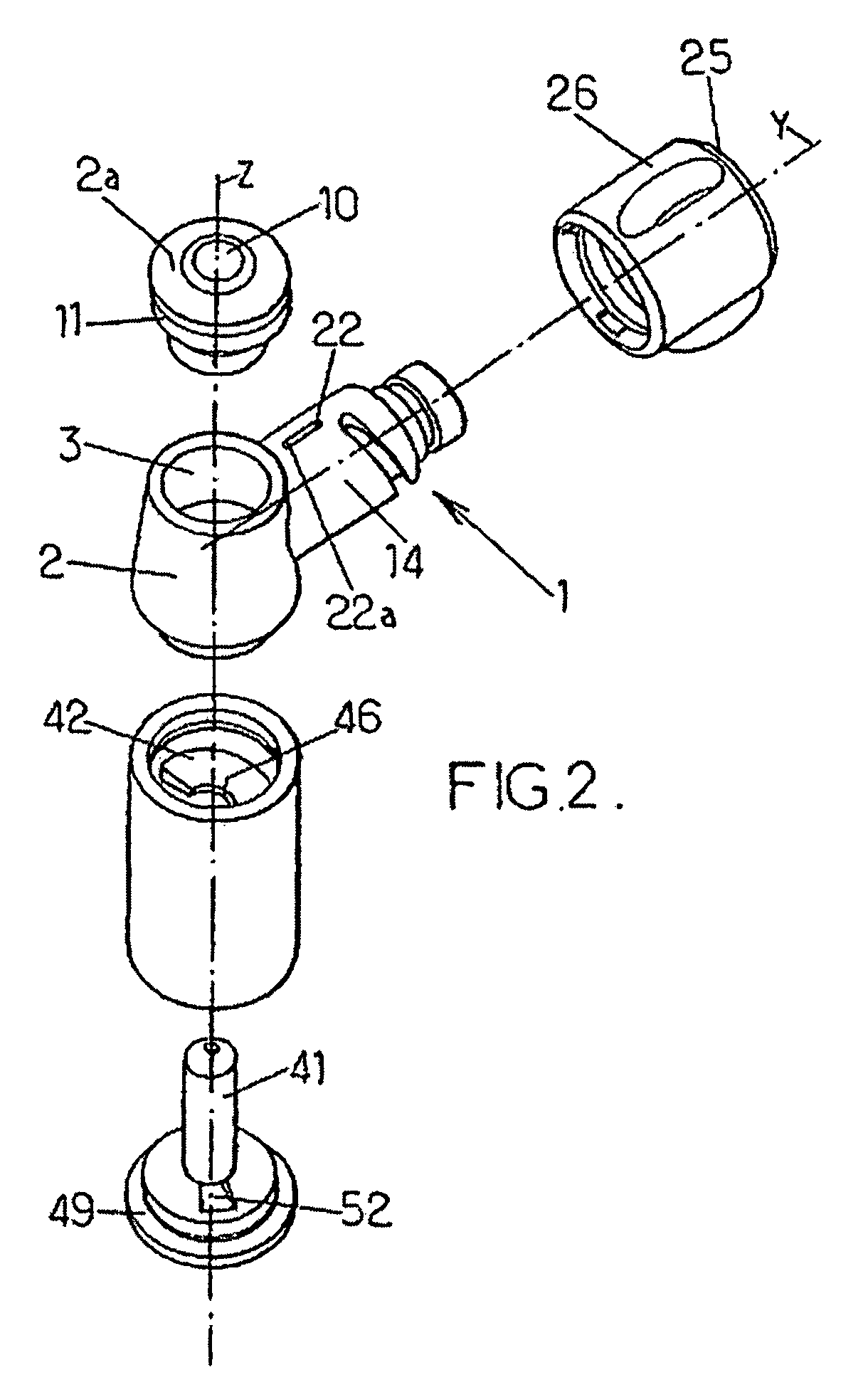

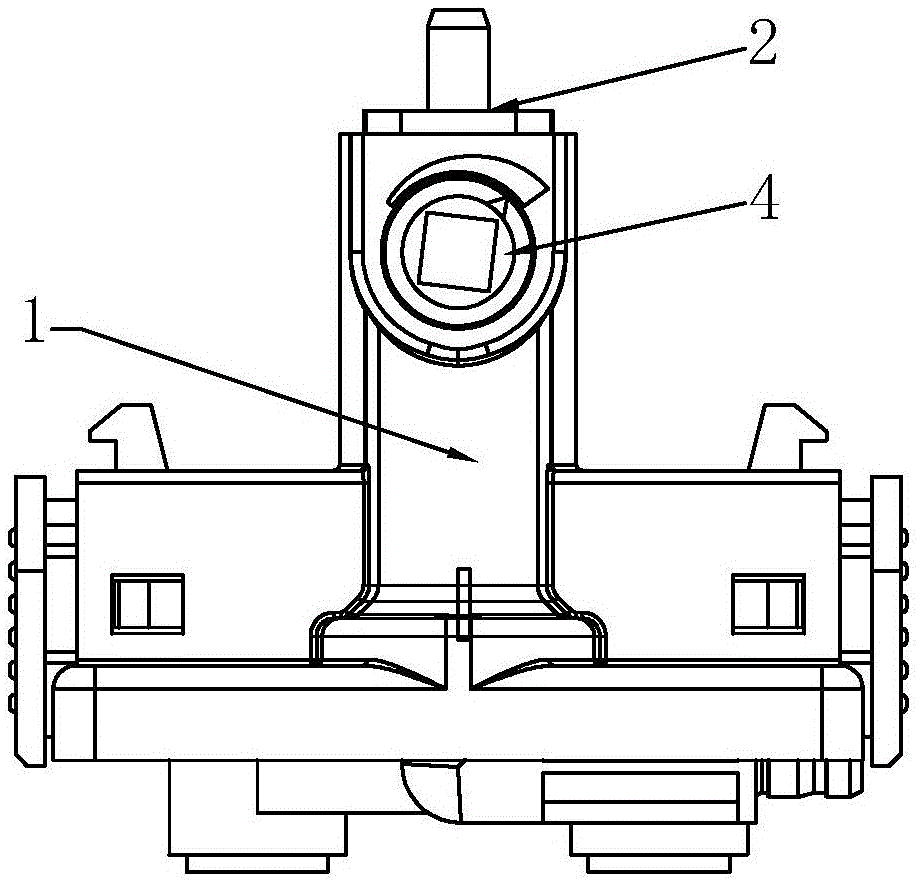

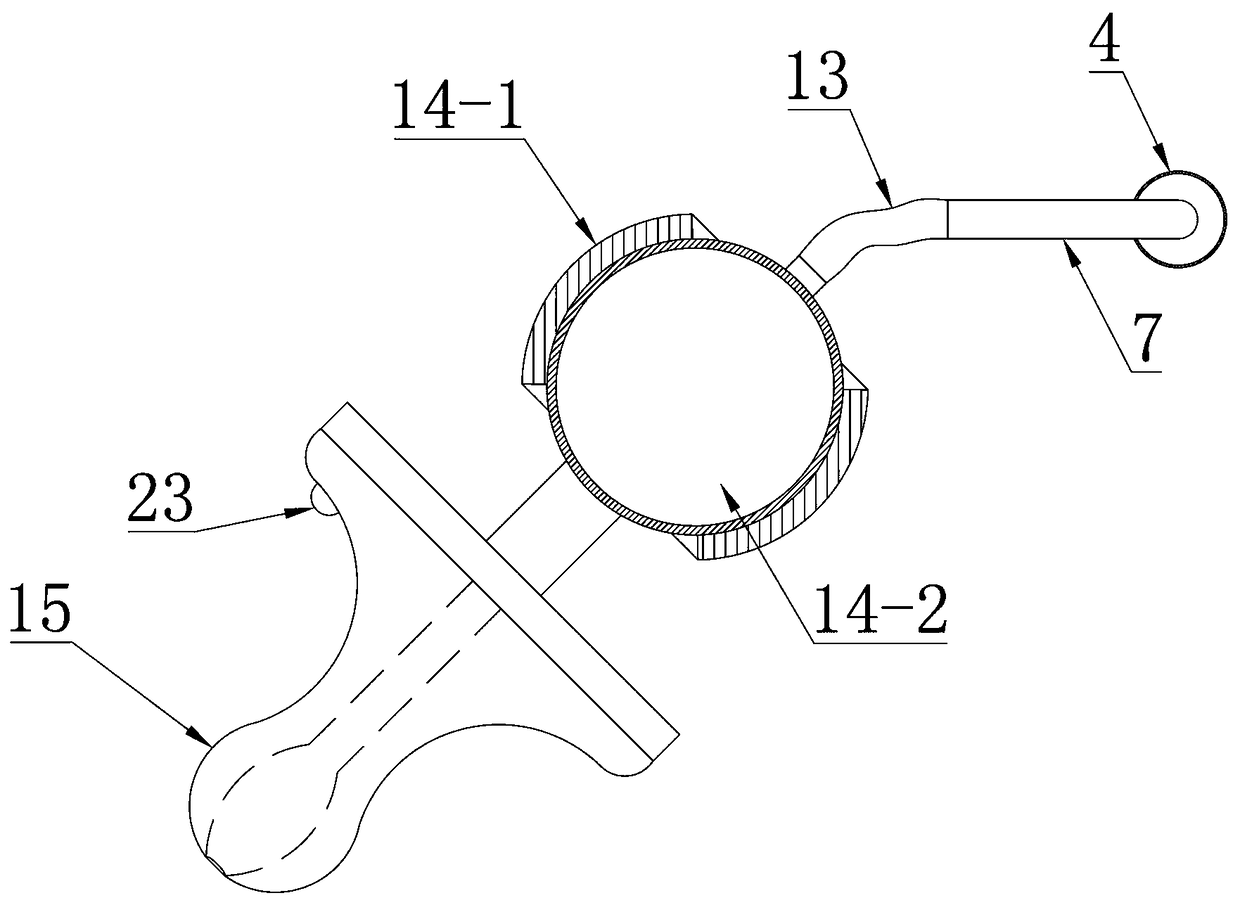

Device for heating milk and coffee machine comprising same

InactiveUS8061264B2Increase heatIncrease output temperatureMilk preservationFlow mixersEngineeringHeated milk

A device for heating milk includes a body (2) having: a steam injecting conduit and a milk conduit emerging into a suction chamber; and a heating chamber (4) extending from an outlet of the suction chamber to an outlet (7) through which the heated milk can flow outside said body (2). The heating chamber (4) includes a globally helical inner conduit (40). A coffee machine including such a device is also disclosed.

Owner:SEB SA

Assembly for creating milk froth and/or for heating milk

InactiveUS20060174772A1Less susceptible to pollutionEasy to cleanCooking-vessel materialsMilk preservationNanoparticleCompound (substance)

An assembly for creating milk froth and / or for heating milk is disclosed. It comprises a foaming device and optionally a milk container and a valve assembly. The foaming device is provided with a steam supply channel, an air supply channel, a milk supply channel and a discharge opening. In order to provide for an easy cleaning of the assembly and its microbicity, at least the components and / or cavities coming into contact with milk are provided with a hydrophobic and oleophobic surface consisting of nano-particles which consist partially of silver or a silver compounds.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

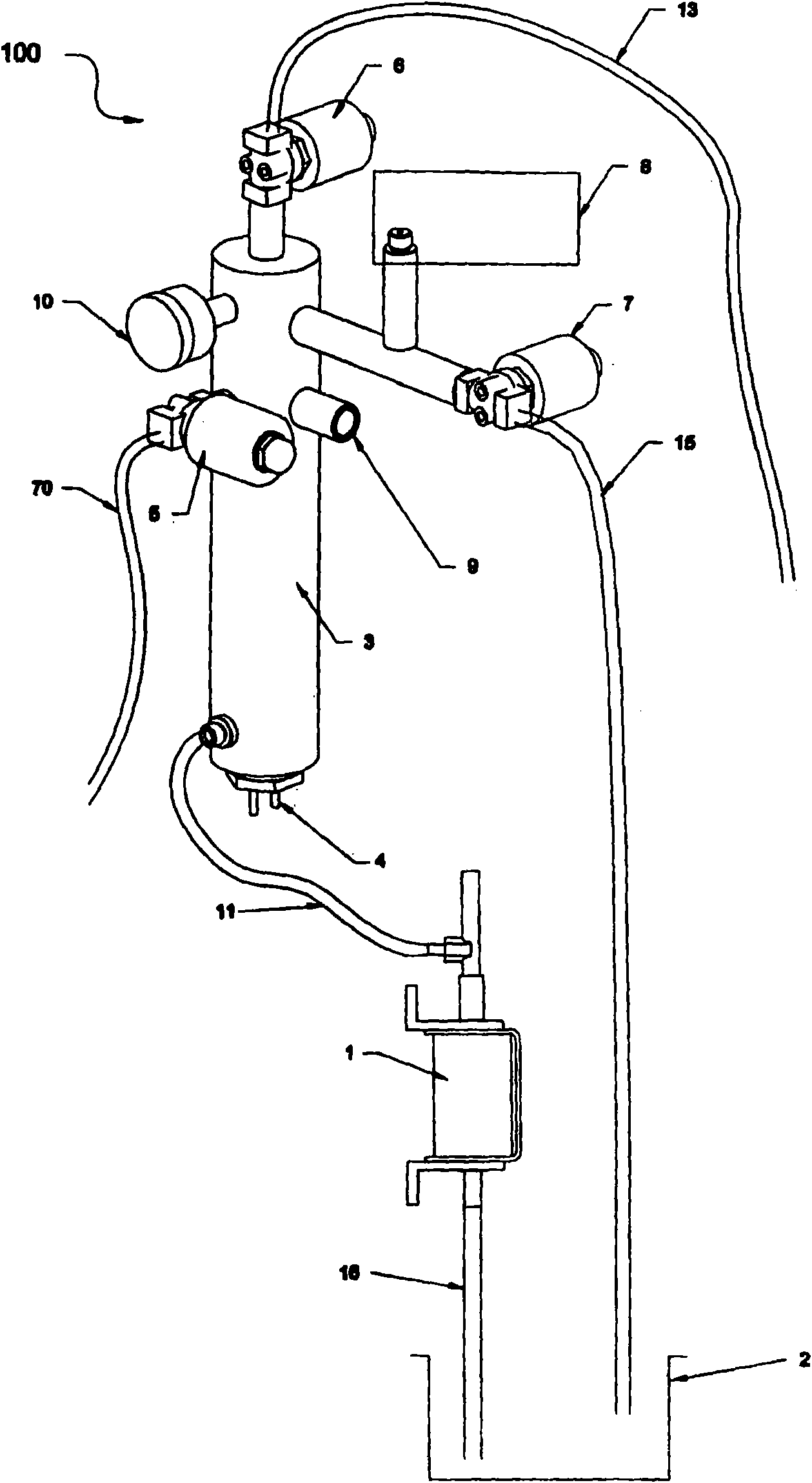

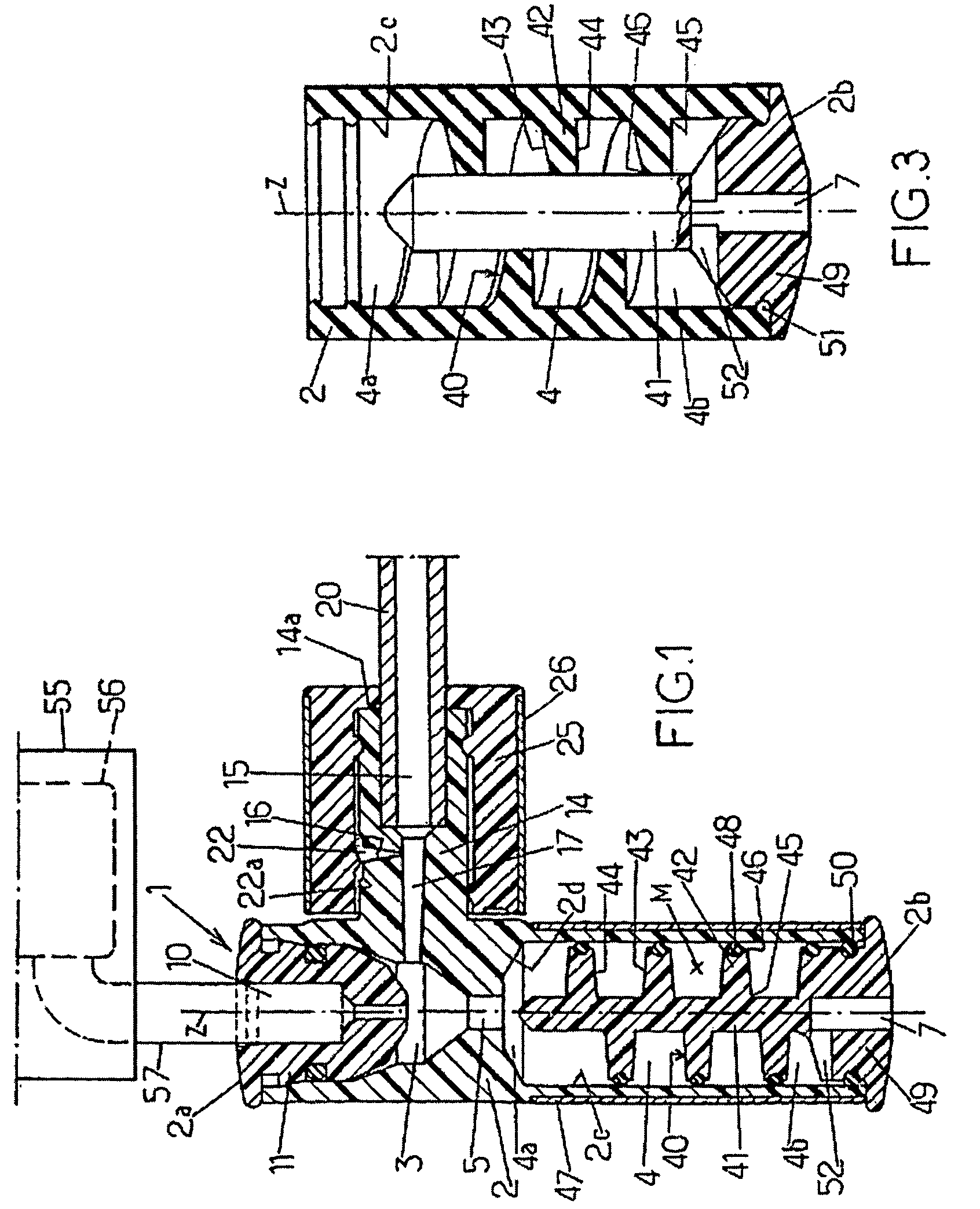

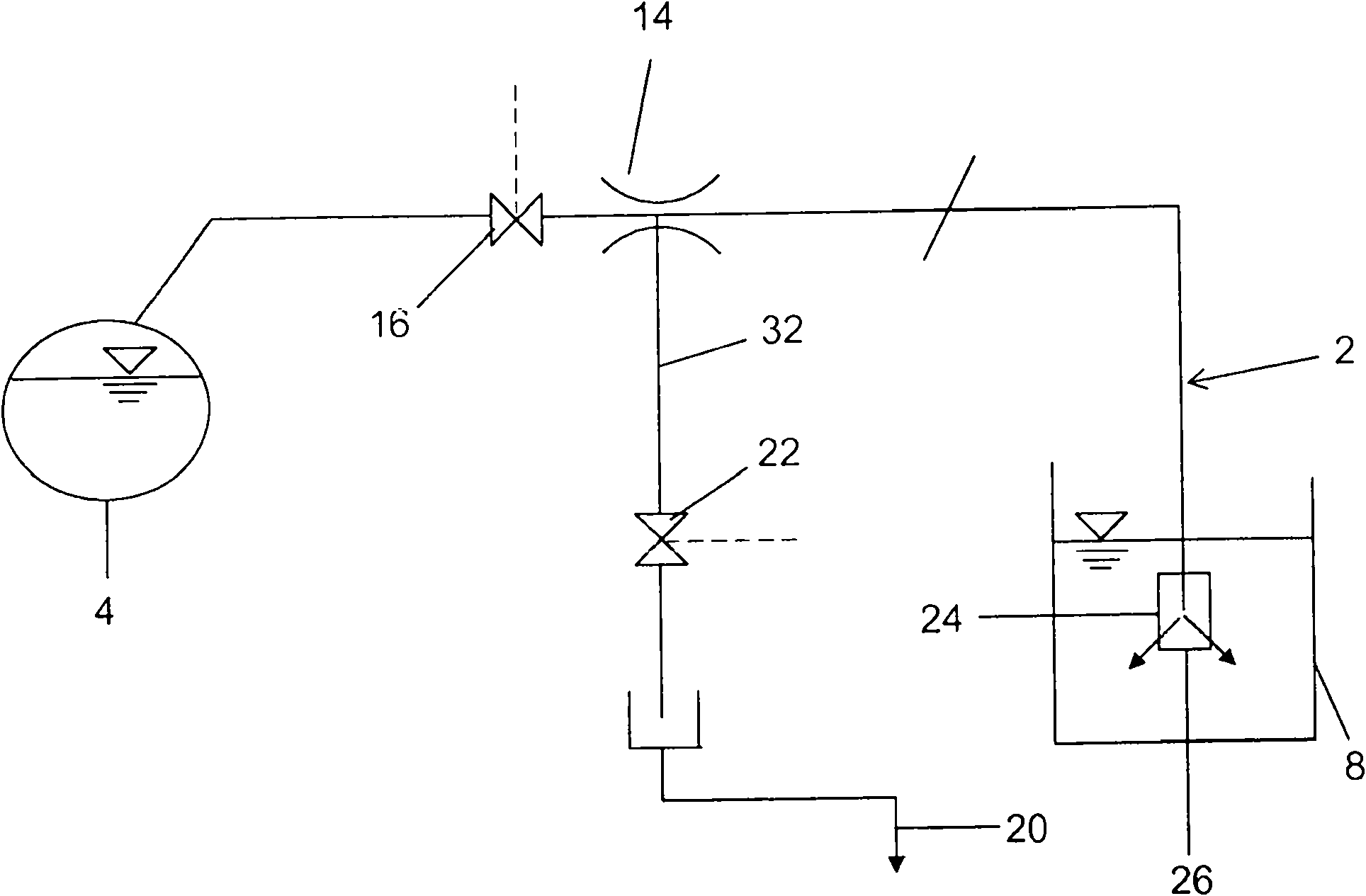

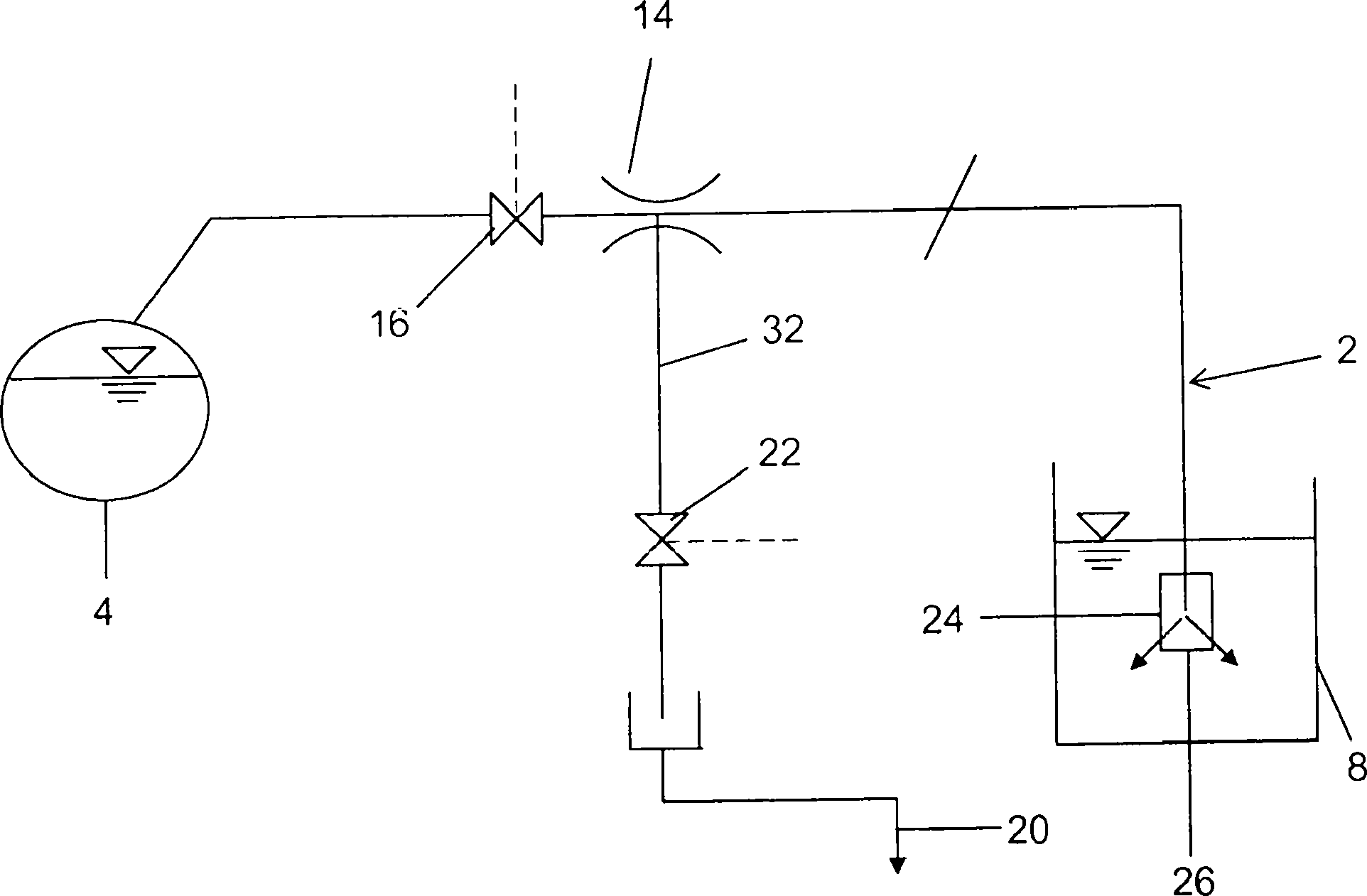

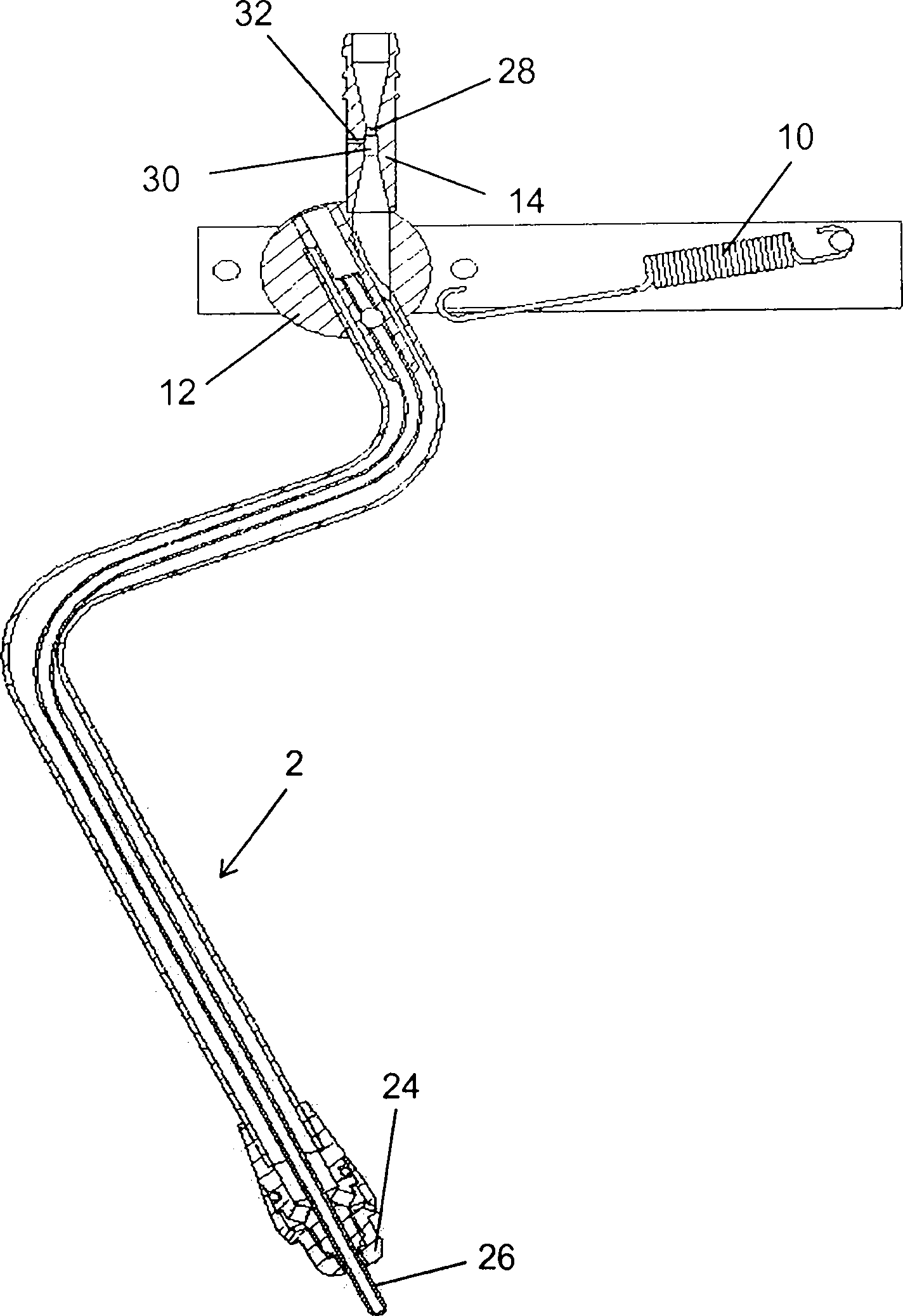

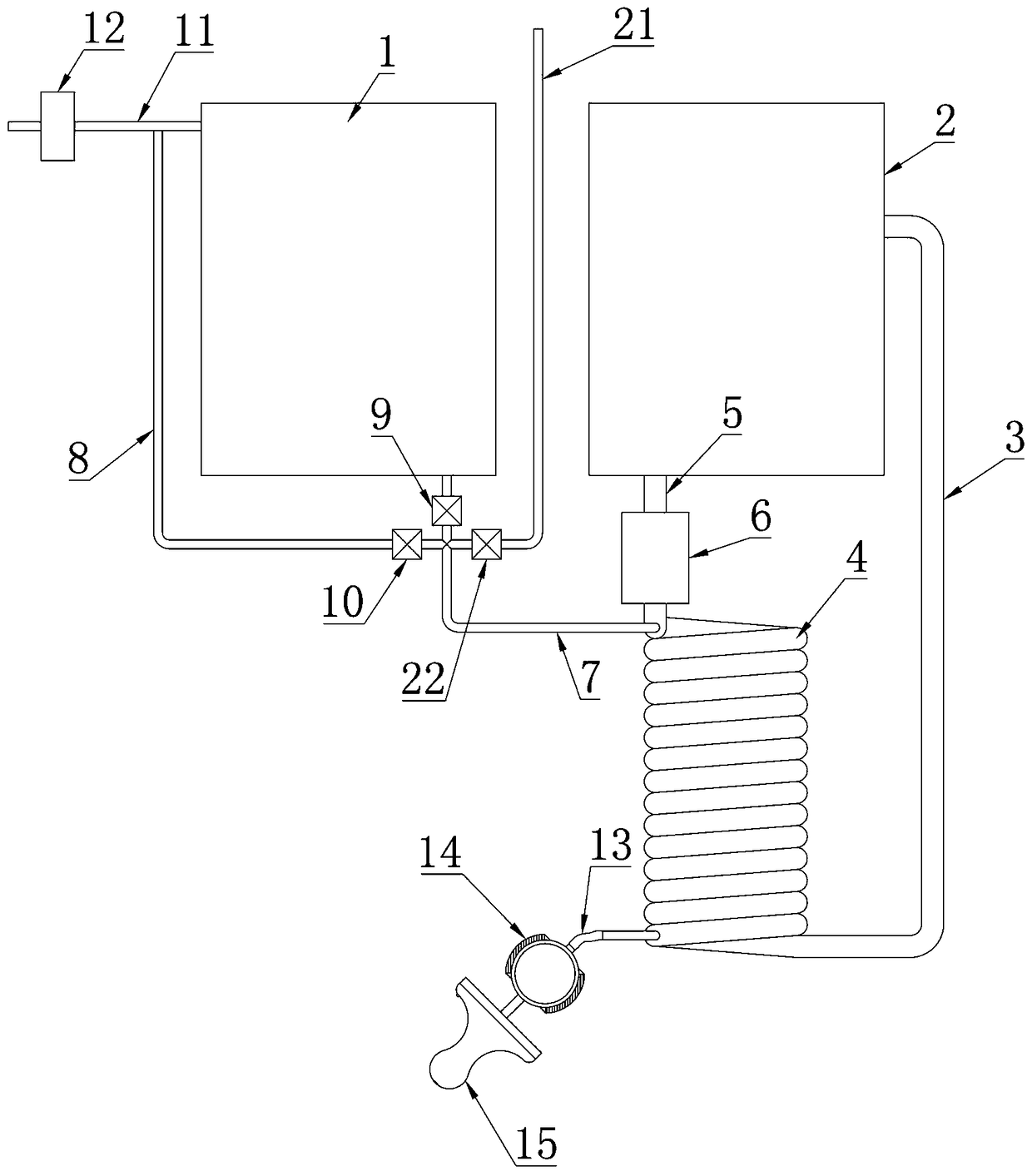

Milk frothing method and milk frothing device for implementing the method

A milk frothing method, by subjecting the milk to a step of merely heating by a flow of steam which emerges from a lance (2) immersed in the milk and raises it to a predetermined temperature less than the final temperature of the frothed milk to be obtained, then subjecting the already partly heated milk to a heating and frothing step by a flow of steam and air which is drawn in through a venturi tube (14) by the same steam flow, characterized by preceding the merely heating step by a cleaning and moisture eliminating step, in which said venturi tube (14) is traversed by a flow of steam and of air entrained by said steam and by controlling the steam flow by a normally closed solenoid valve (16) and the air flow by a normally open solenoid valve (22).

Owner:ELEKTRA SRL

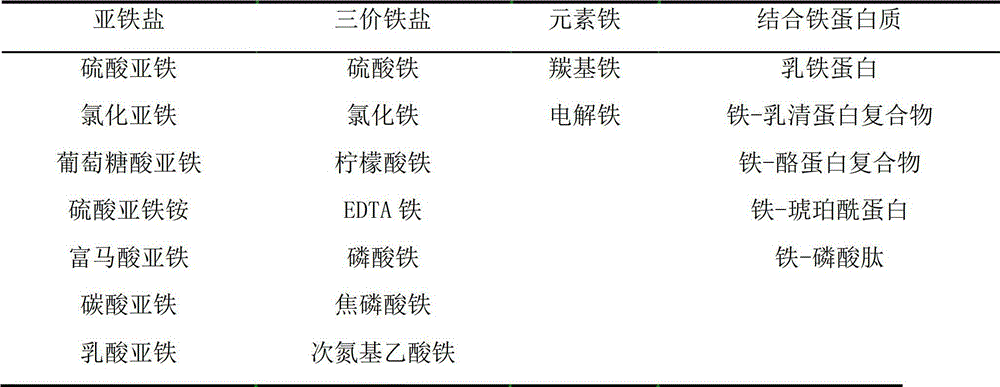

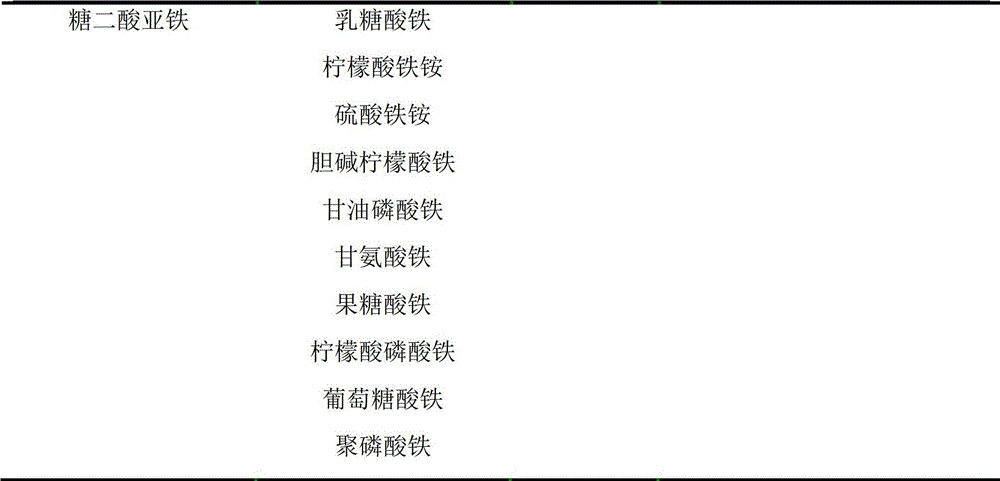

Method for preparing co-precipitated ferric hydroxide yoghourt

InactiveCN102940037AImprove absorption rateAcidity is not lowMilk preparationSolubilityFerric hydroxide

The invention discloses a method for preparing a co-precipitated ferric hydroxide yoghourt. The method comprises the following steps of preparing a yoghourt starter, preparing co-precipitated ferric hydroxide slurry by a co-precipitation method, heating milk to a temperature of 50 to 60 DEG C, adding white granulated sugar into the heated milk, adding the co-precipitated ferric hydroxide slurry into the heated milk with fully stirring, carrying out homogenization by ultrasonic wave to obtain iron-fortified milk, carrying out sterilization at a temperature of 90 to 95 DEG C for 5 minutes, fast cooling to a temperature of 42 to 45 DEG C, inoculating the cooled iron-fortified milk with the yoghourt starter under aseptic conditions, carrying out fermentation at a temperature of 42 DEG C for 5 hours, taking out the yoghourt semi-finished product, cooling the yoghourt semi-finished product at a temperature of 4 DEG C, and cooking for 12 to 24 hours to obtained the co-precipitated ferric hydroxide yoghourt. The co-precipitated ferric hydroxide has the characteristics of small particle size, good solubility in an acid, high iron absorptivity, simple preparation processes, low cost, low influence on product sensory properties, and good safety. Through utilization of the co-precipitated ferric hydroxide in a yoghourt, the problem of low iron element content of the common yoghourt is solved, and an original local flavor and a taste of a yoghourt are retained to the maximum degree.

Owner:SICHUAN AGRI UNIV

Preparation method of membrane-filtrated concentrated fermented milk

InactiveCN108651621AIncrease profitRetain nutritional valueMilk preparationOther dairy technologyThermal insulationHeated milk

The invention discloses a preparation method of membrane-filtrated concentrated fermented milk. The preparation method of the membrane-filtrated concentrated fermented milk specifically comprises thefollowing steps: S1, performing quality inspection on raw-material milk; S2, treating the inspected raw-material milk by using membrane concentration equipment; S3, blending materials, and carrying out standardization; S4, carrying out degassing, namely performing degassing on the pre-heated milk material by using a degassing tank; S5, carrying out homogenization, namely performing homogenizationon the degassed milk material under a pressure of 170-180 Bar; S6, carrying out sterilization, namely performing sterilization on the homogenized milk material at 93-97 DEG C for 300 seconds; S7, carrying out cooling, namely cooling the sterilized material to be 40-43 DEG C by using a heat exchanger, and sending the cooled material into a fermentation tank; S8, carrying out inoculation, namely adding confirmed bacterial strains, under aseptic operation, into an on-line adding system, wherein the adding starts when the sterilization on the material is 1 / 3 done; S9, carrying out thermal insulation, namely performing thermally insulated fermentation on the inoculated material, at 40-42 DEG C, for 4-6 hours; S10, carrying out cooling; and S11, carrying out filling.

Owner:北京沃克特商贸有限公司

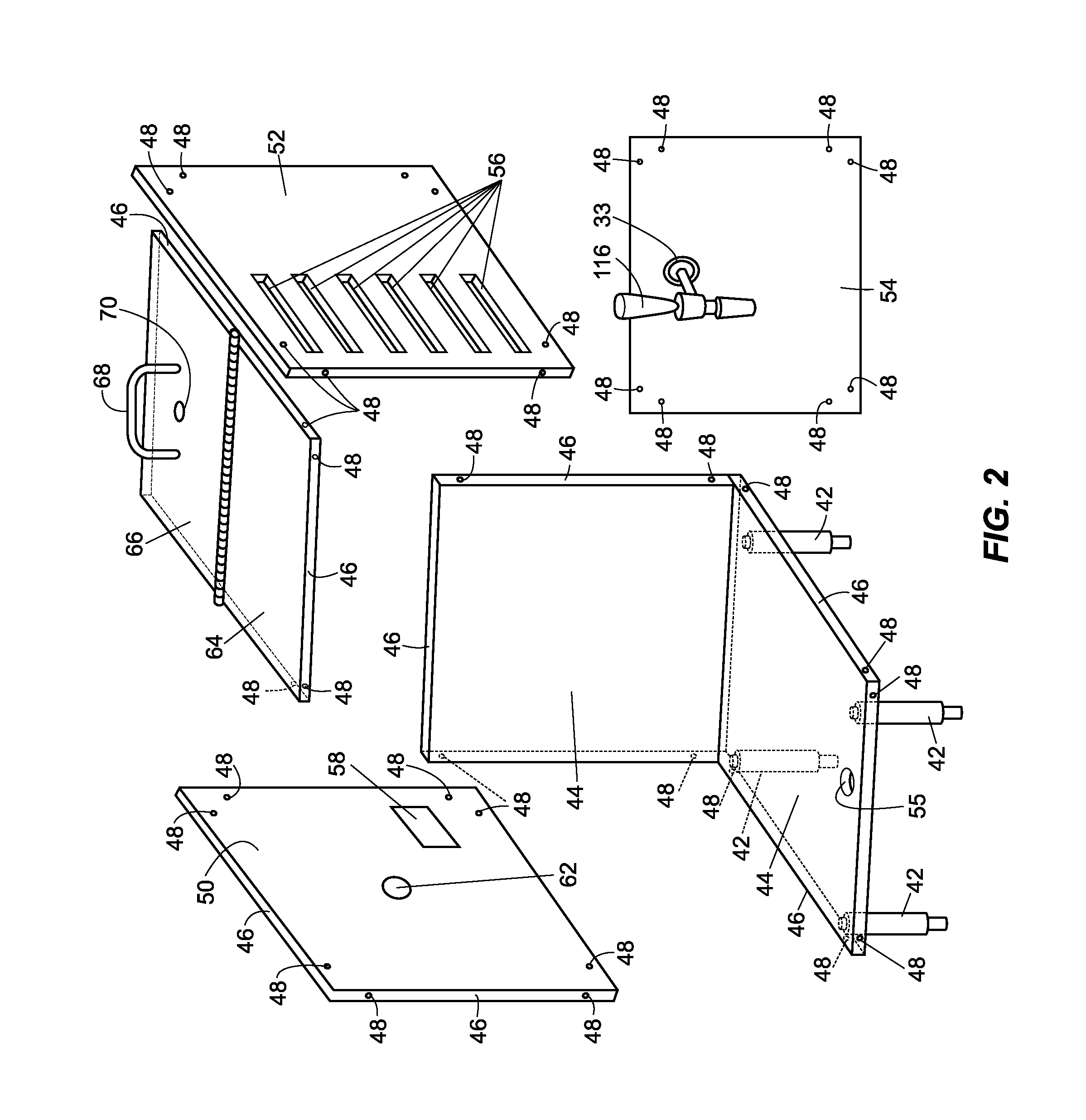

Device for dispensing hot milk

A heated beverage, such as hot chocolate milk is dispensed by providing a refrigerated insulated cabinet having a plurality of beverage storage bags therein for storing refrigerated chocolate milk. Compressed CO2 draws the milk through a pump and pushes it through a flat plate heat exchanger and out to a spigot. The CO2 regulates the flow rate of the milk being dispensed. A heat exchange fluid, e.g., glycol is heated by a heating element and circulated through the flat plate heat exchanger to heat the milk as it passes through the flat plate heat exchanger. A thermostat maintains the heat exchange fluid and heated beverage at a desired temperature.

Owner:GOURMET DISPENSING

Milk strawberry cultivating method for increasing fertility

InactiveCN106613258ASimple structureBoosts milk odor concentrationAnimal corpse fertilisersExcrement fertilisersFragariaIncreased fertility

The invention relates to a milk strawberry cultivating method for increasing fertility. The method comprises the steps of heating milk to 100 DEG C or above, and mixing the heated milk with water according to a ratio of 1:500 to obtain first mixed liquid; conducting mixed fermentation on, by weight, 10 parts of chicken manure, 6 parts of maize glue, 6 parts of soybean meal, 2 parts of pod shell powder and 1 part of blast furnace slag, and mixing the mixed fertilizer obtained through fermentation with water according to a ratio of 1:10 to obtain second mixed liquid; mixing the first mixed liquid and the second mixed liquid according to a ratio of 1:1 to obtain a fertilizer; irrigating strawberry once at an interval of 8-10 days after the strawberry is planted, and conducting drying on a strawberry cultivated land on the day before the irrigation. According to the method, compared with the prior art, organic materials of the soybean meal, the maize glue, the pod shell powder and the like can be degraded into nutrients needed by plants under a microbial action in the soil, and components of humus, the blast furnace slag and the like can also improve the soil structure, loosen the soil texture and increase fertility of the soil; the first mixed liquid can improve the radiance of the surface of the strawberry, improve milk odorousness of the strawberry, and improve the mouthfeel.

Owner:LIUZHOU TIANZI HORTICULTURE

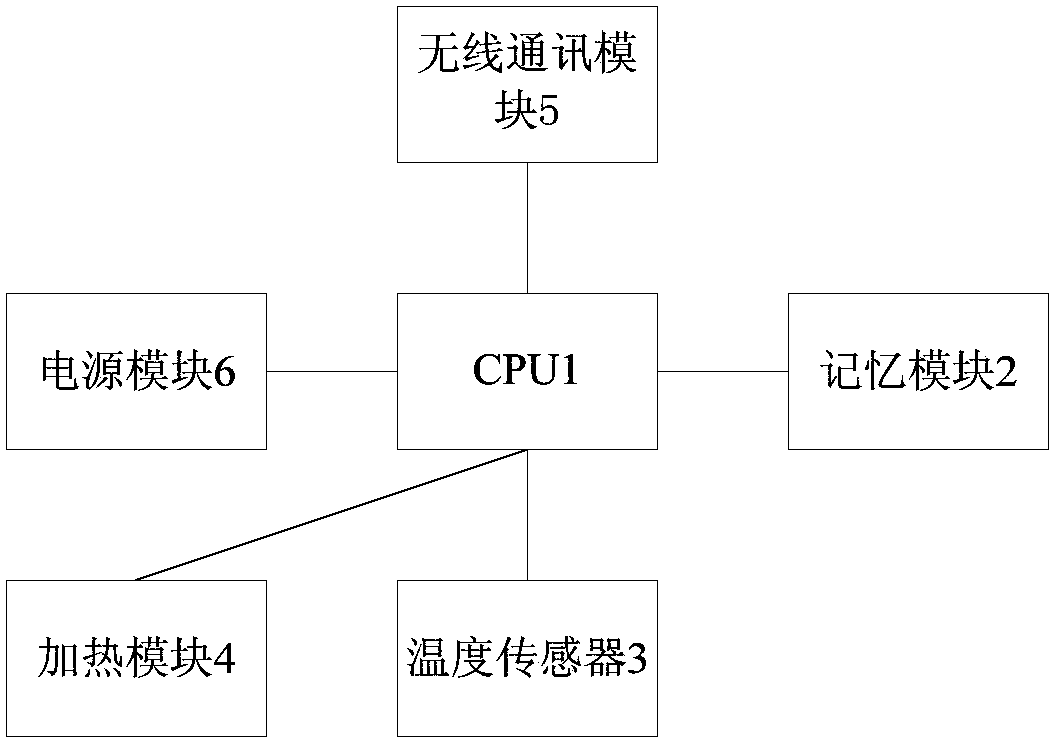

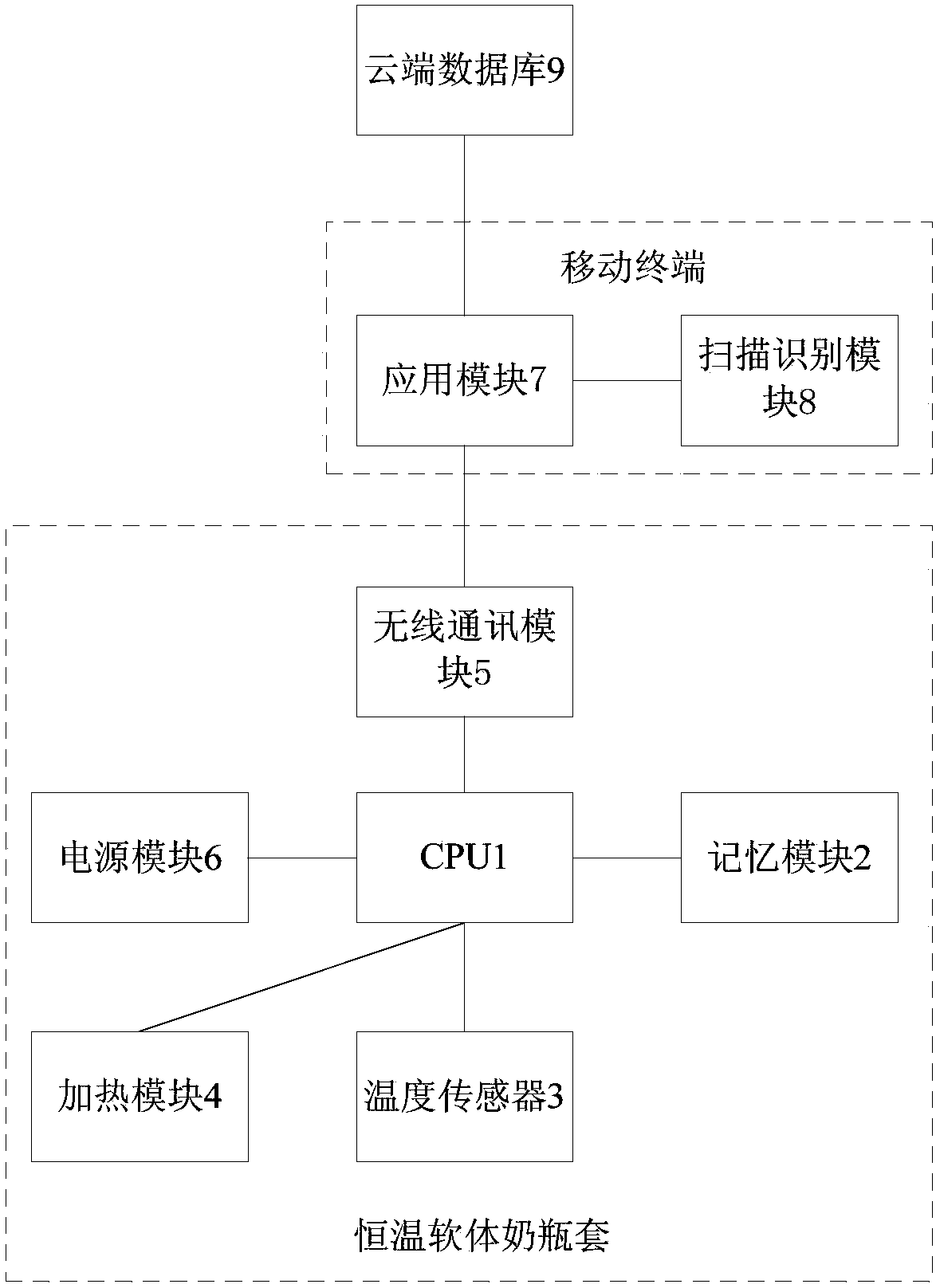

Constant-temperature soft milk bottle sleeve, milk bottle constant temperature system and constant temperature control method

InactiveCN107648052AReduce lossIncrease heating contact areaFeeding-bottlesDomestic articlesEngineeringBottle

The invention discloses a constant-temperature soft milk bottle sleeve, a milk bottle constant temperature system and a constant temperature control method. The constant-temperature soft milk bottle sleeve is made of a soft heat insulation material; a CPU (Central Processing Unit), and a memory module, a temperature sensor, a hating module, a wireless communication module and a power supply modulewhich are connected with the CPU are built in the constant-temperature soft milk bottle sleeve; the memory module is used for storing constant temperature mode data corresponding to the current milkpowder model number; the milk bottle constant temperature system comprises a mobile terminal, a cloud database and the constant temperature soft milk bottle sleeve; the mobile terminal comprises a scanning recognition module and an application module; the scanning recognition module is connected with the application module; the application module communicates with the cloud database through a wireless network; and the application module is also connected with the wireless communication module. During the implementation, the constant-temperature soft milk bottle sleeve, the milk bottle constanttemperature system and the constant temperature control method provided by the invention have the advantages that the heating contact area can be increased; the heating efficiency is improved; the heat loss of the heated milk bottle can be reduced; the carrying is convenient; the constant-temperature soft milk bottle sleeve is suitable for outdoor environment; the remote operation can be realized; and various heating modes are realized.

Owner:深圳市极客宝贝智能科技有限公司

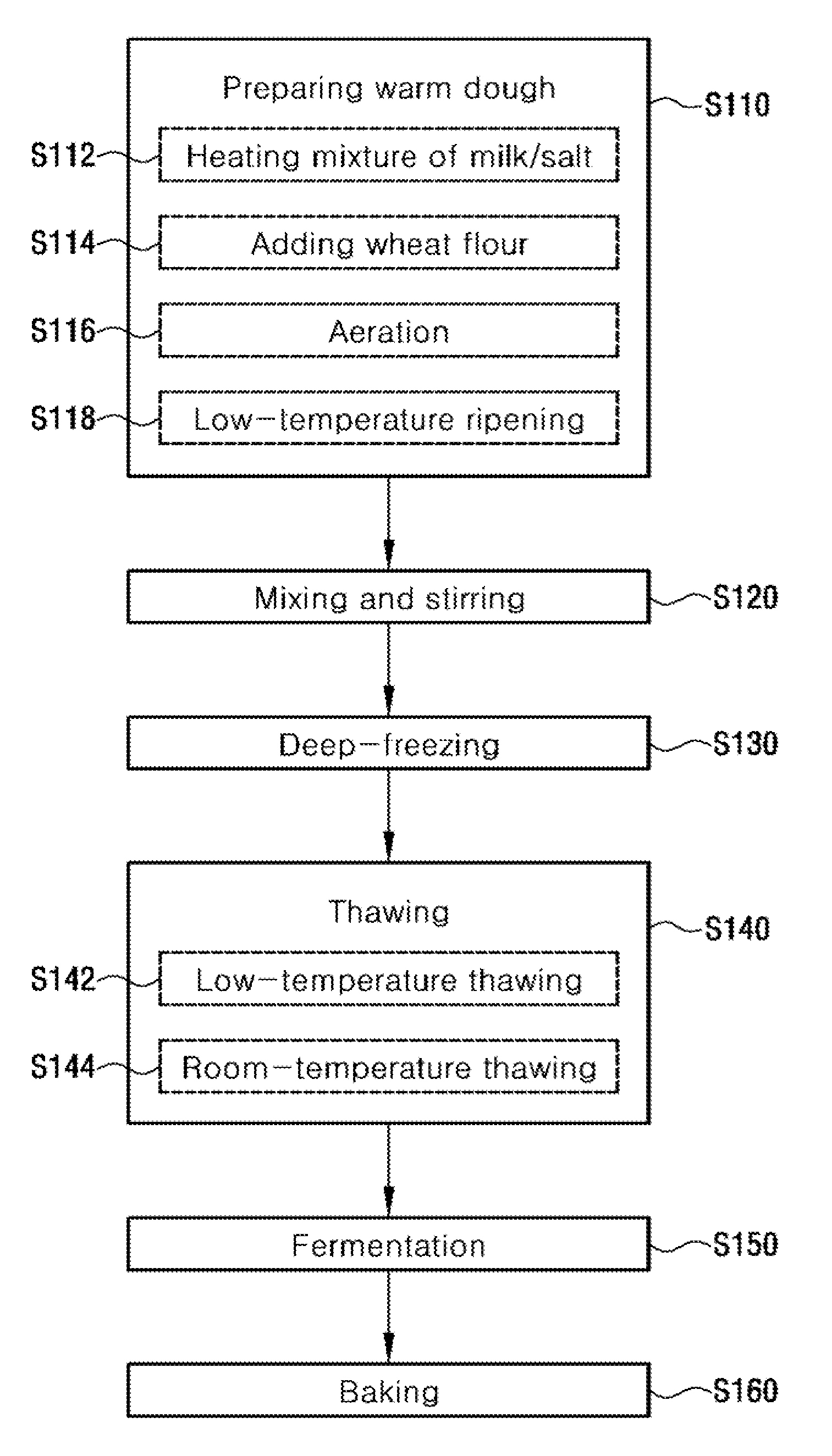

Method of making bread

ActiveUS20100255148A1High activityIncrease powerMilk preparationPre-baking dough treatmentDeep frozenHeated milk

A method of making bread is provided. The method includes a warm dough making process in which a warm dough is formed by heating a mixture of milk and salt, adding wheat flour to the heated mixture, aerating the resulting mixture, and ripening the resulting mixture at low temperature, a dough mixing process in which a dough is formed by mixing the resulting dough of the warm dough making process with wheat flour, dried yeast, refined sugar, refined salt, whole milk powder, bread improver, processed butter, milk, egg, and water, and stirring the mixture, a deep-freezing process in which the resulting dough is divided into equal-sized pieces and the divided dough pieces are deep-frozen, a thawing process in which the deep-frozen dough is thawed, a fermentation process in which the thawed dough is placed in a bread pan to be fermented, and a baking process in which the fermented dough is heated.

Owner:PARIS CROISSANT

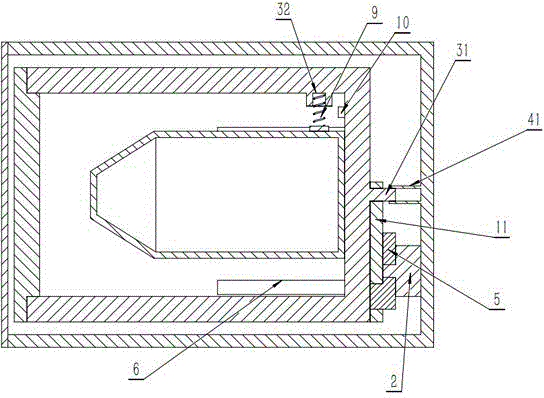

Rapidly-heated milk electric heater

The invention relates to the field of domestic small appliances, and in particular to a milk heater. In order to overcome the shortcomings in the prior art, the milk electric heater capable of conducting even and rapid heating is provided. The rapidly-heated milk electric heater comprises a motor, a heating cavity, an outer shell, an eccentric gear, a heating pipe, an outer shell cover and a heating cavity cover; a heating cavity boss is arranged at the bottom of the heating cavity, and the eccentric gear is provided with an eccentric gear positioning column and a fixing hole; and the motor is installed at the bottom of the outer shell, the heating pipe is installed on the inner wall of the heating cavity, the heating cavity boss is connected with a conveying belt so as to be installed on the outer shell in a sliding mode, and the eccentric gear is connected with the motor through the fixing hole and is connected with the conveying belt through the eccentric gear positioning column. The motor rotates to drive a milk bottle through the eccentric gear to swing back and forth, milk and water are mixed back and forth for temperature uniformity, heating is even, and temperature rise is rapid.

Owner:渠莉

Milk heating cup

Owner:SHANGHAI SHANGDE EXPERIMENTAL SCHOOL

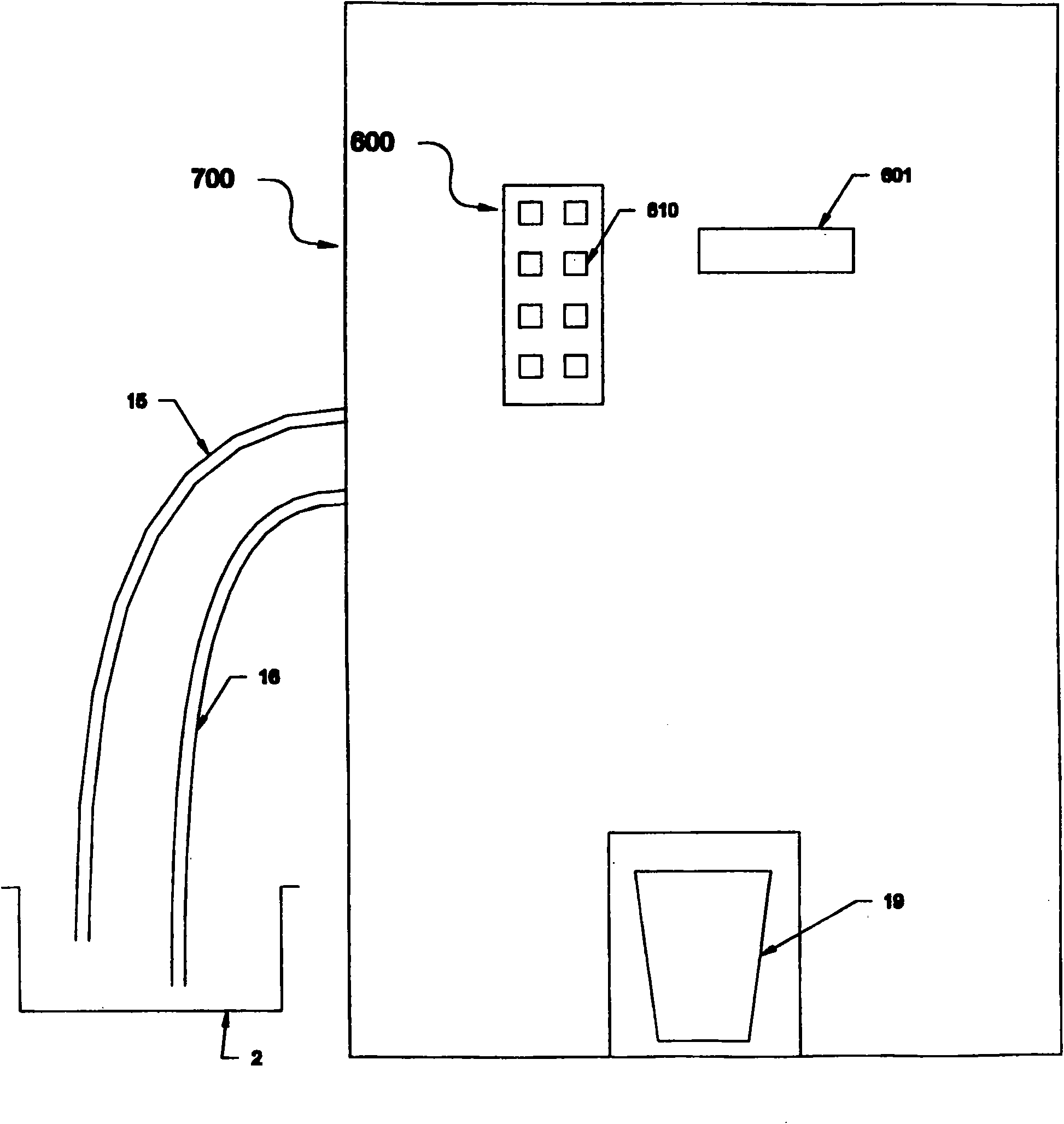

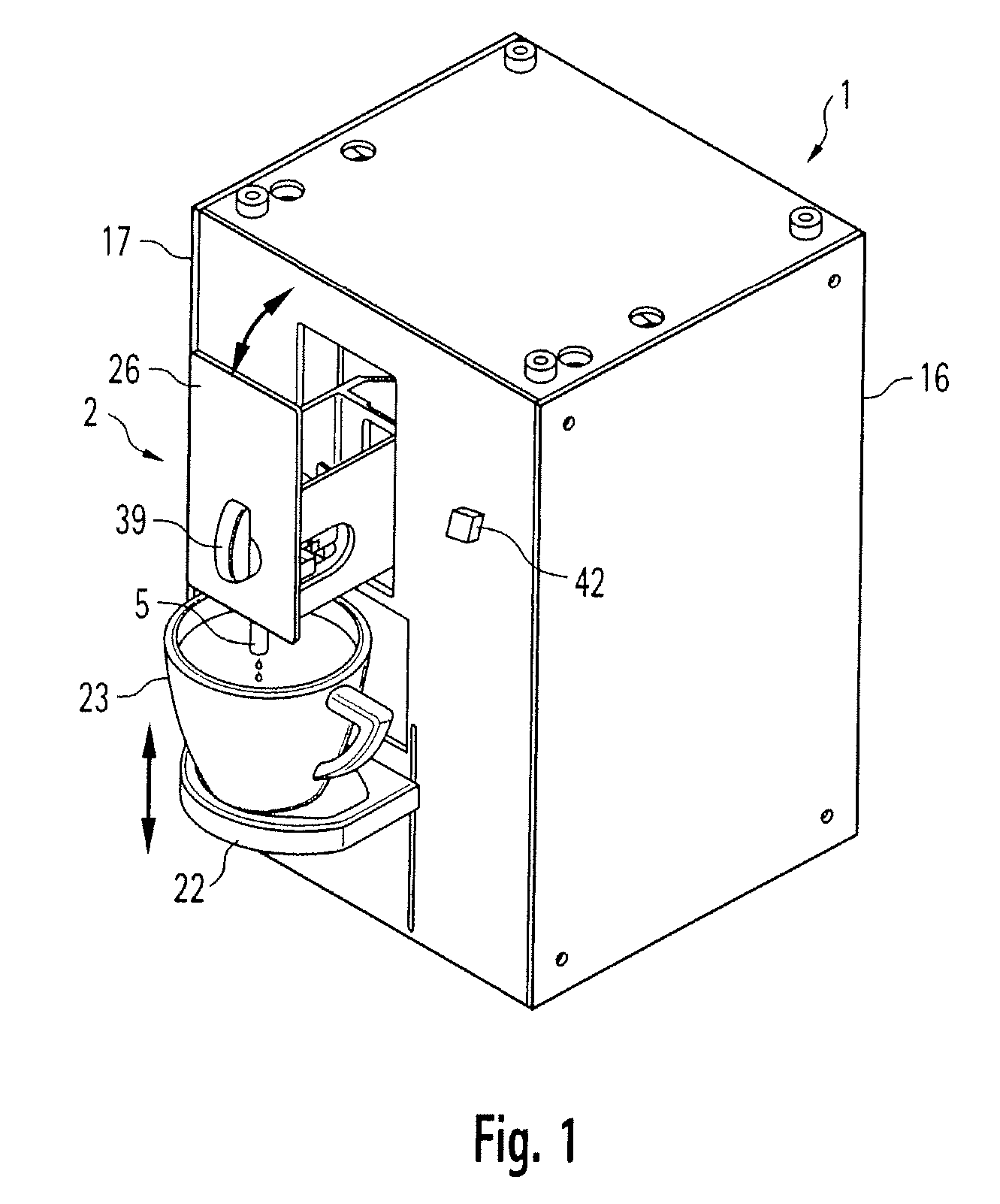

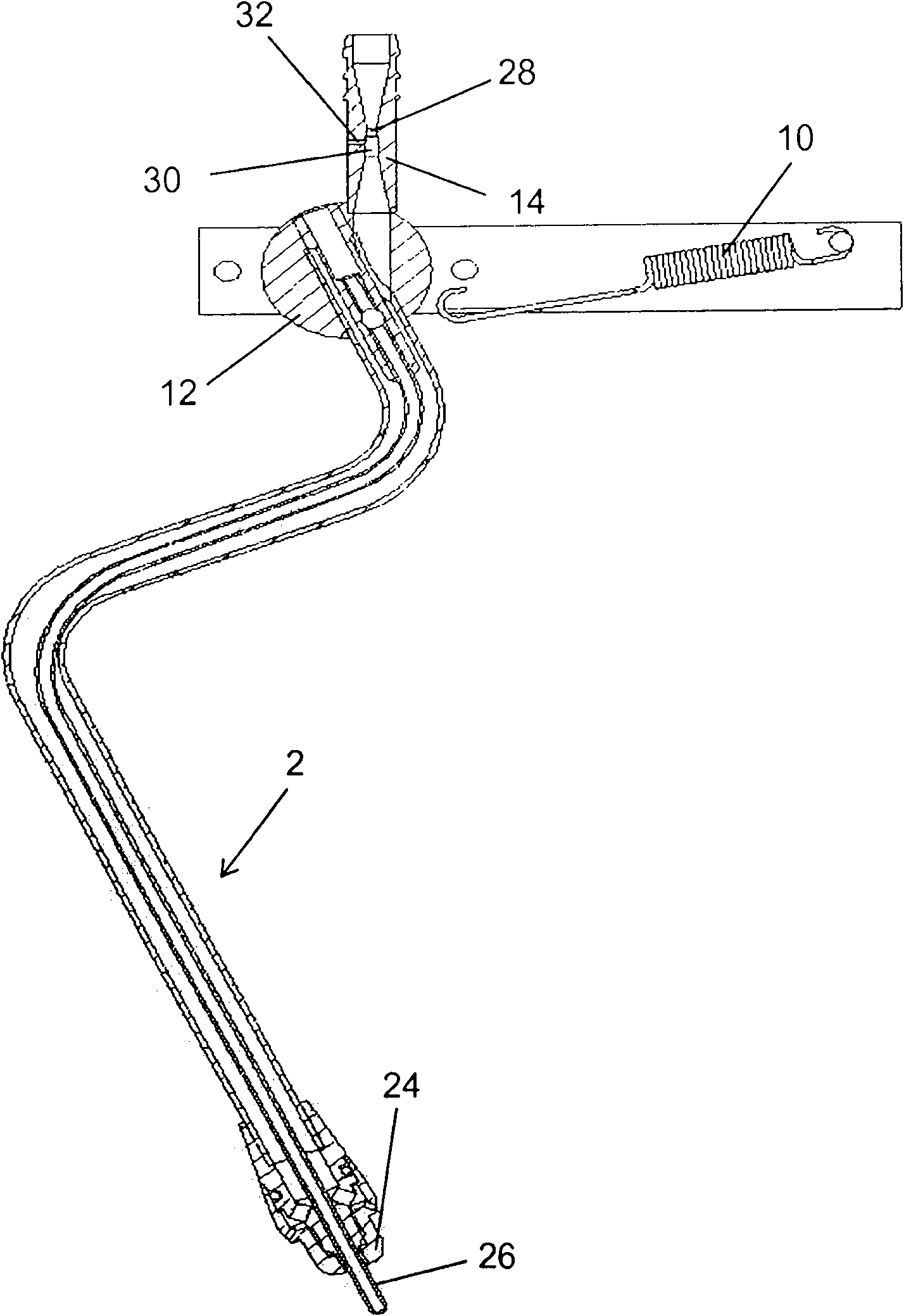

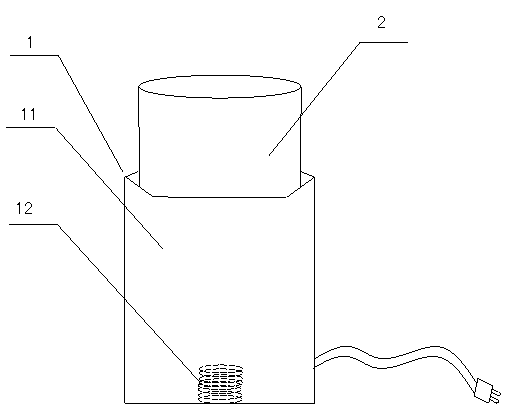

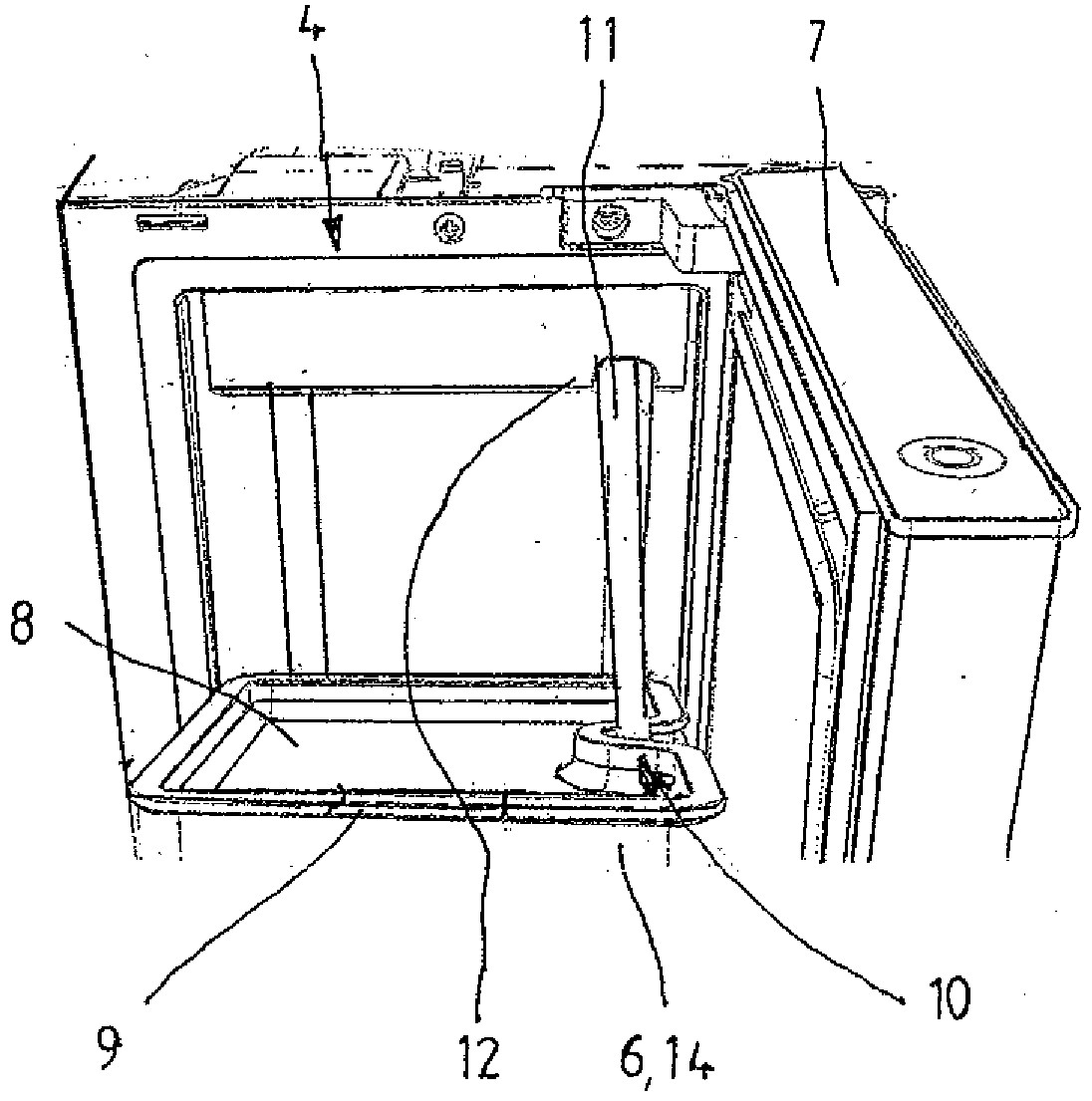

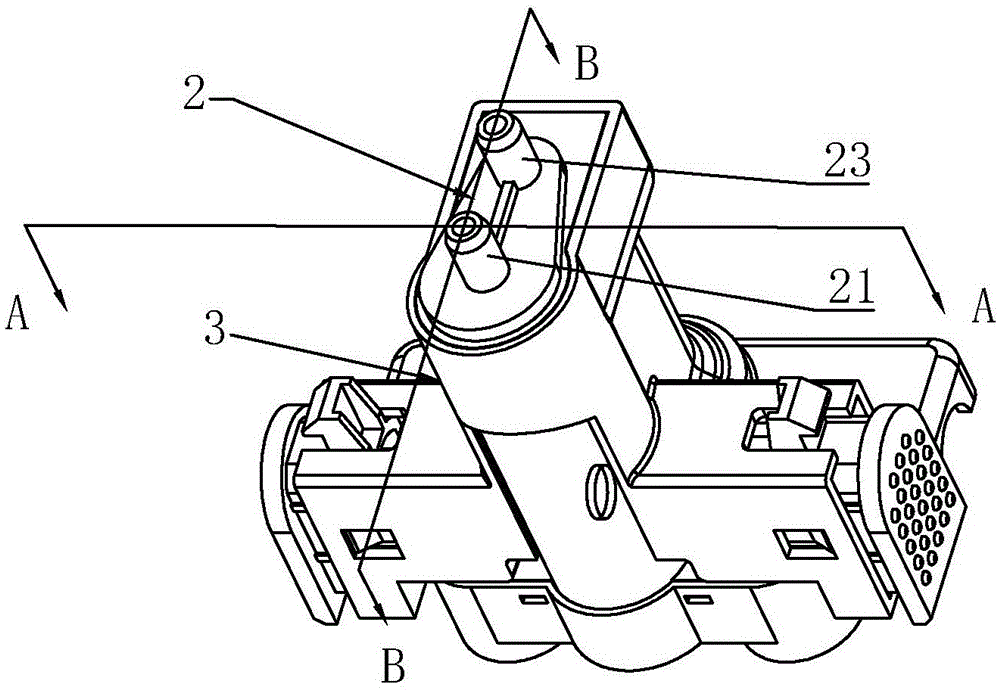

Milk module for generating milk foam or milk beverages, preferably for installing into coffee machine

A milk module (2) for generating milk foam or milk beverages, preferably for installing into a coffee machine, is designed as an independent unit. The milk module (2) comprises a cooling chamber (5) which is connected to a cooling assembly for receiving a milk container (6), a conveyor pump (42), a device for generating the steam, a device (24) for heating milk or for generating the milk foam, anda connection means. The heated milk or the generated milk foam can be conveyed through a discharge line to the coffee outlet in the coffee machine by the connection means. In a very advantageous manner, a cleaning container (14) with a cleaning agent can be positioned into the cooling chamber (5) instead of the milk container (6). For this purpose, a suction tube is provided which is mounted in the region of the refrigerated box (4) in a pivotal manner forwards or rearwards, which hangs freely at the bottom, and which in the forwards-pivoted position can be contactlessly inserted into the milk container (6) or the cleaning container (14) from the top when same is installed.

Owner:STEINER WEGGIS AG

Method for Producing Cheese Using Heat Treated Milk and a Protein Hydrolysate

InactiveUS20090081329A1Reduction and elimination of increase in milk clotting timeReduces and eliminates increased curd weaknessMilk preparationMilk preservationProtein hydrolysatesHeated milk

The present invention describes a method of producing curd or cheese from a milk composition consisting of the following steps:—heating the milk, —adding to the heat treated milk a protein hydrolysate, —adding to the heat treated milk a coagulant to form a gel, and—processing the formed gel into a cheese curd and separating the whey from the curd.

Owner:DSM IP ASSETS BV

Milk frothing method and milk frothing device for carrying out the method

A milk frothing method, by subjecting the milk to a step of merely heating by a flow of steam which emerges from a lance (2) immersed in the milk and raises it to a predetermined temperature less than the final temperature of the frothed milk to be obtained, then subjecting the already partly heated milk to a heating and frothing step by a flow of steam and air which is drawn in through a venturi tube (14) by the same steam flow, characterized by preceding the merely heating step by a cleaning and moisture eliminating step, in which said venturi tube (14) is traversed by a flow of steam and of air entrained by said steam and by controlling the steam flow by a normally closed solenoid valve (16) and the air flow by a normally open solenoid valve (22).

Owner:ELEKTRA SRL

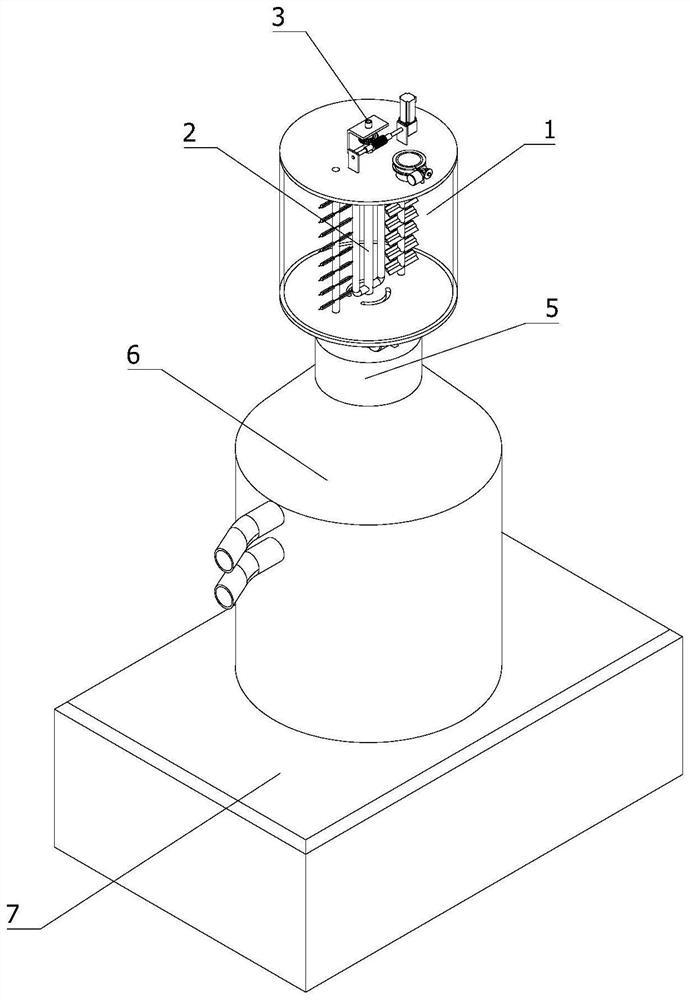

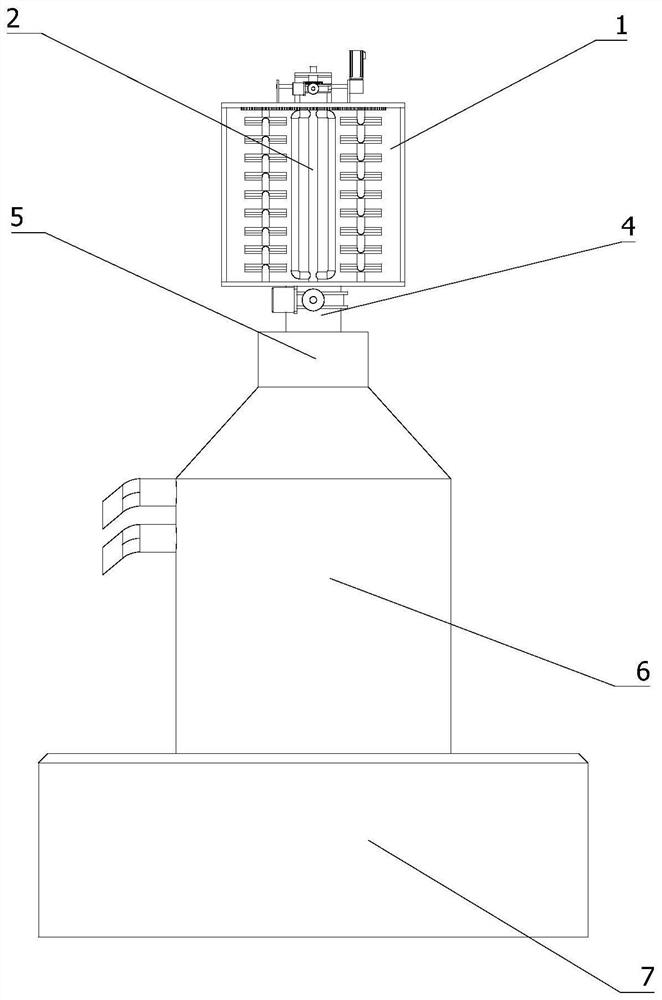

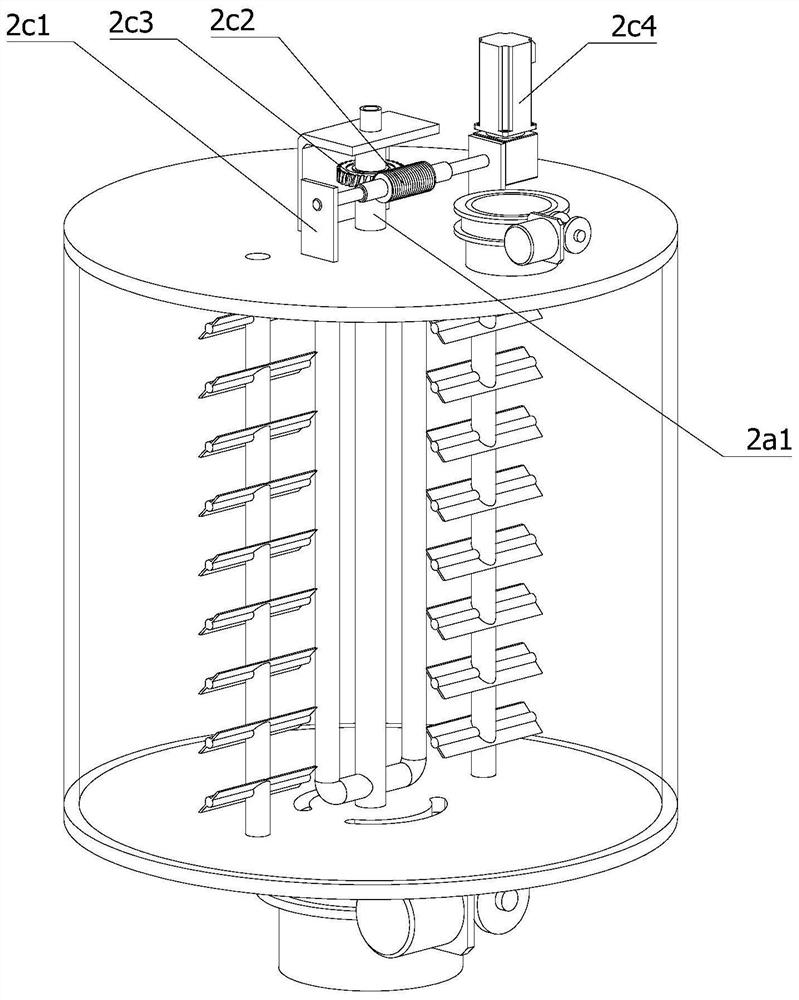

Milk separator with heating function

InactiveCN111903532AUniform heating effectImprove post-separation effectMilk treatmentThermodynamicsProcess engineering

The invention relates to the technical field of milk processing equipment, in particular to a milk separator with a heating function. The milk separator comprises a preheating barrel, a stirring mechanism, a heating mechanism, a liquid inlet pipe, a storage box, a separation mechanism and a driving mechanism; the preheating barrel is erected at the upper end of the liquid inlet pipe and used for preheating and stirring unseparated milk; the working end of the stirring mechanism is rotatably mounted in the preheating barrel, and the stirring mechanism is used for stirring the unseparated milk;the heating mechanism stretches into the stirring mechanism and is used for preheating the unseparated milk in the preheating barrel; the liquid inlet pipe is mounted at the upper end of the storage box, communicates with the preheating barrel and the storage box and is used for temporarily storing the milk heated by the preheating barrel; the feeding end of the storage box is connected with the discharging end of the liquid inlet pipe, and the storage box is used for storing the heated milk; the separation mechanism is mounted below the storage box and used for separating and degreasing the milk; and the driving mechanism is mounted at the bottom of the separation mechanism and used for driving the separation mechanism to work. The milk separator is uniform in heating effect and saves theuse cost.

Owner:顾炳潮

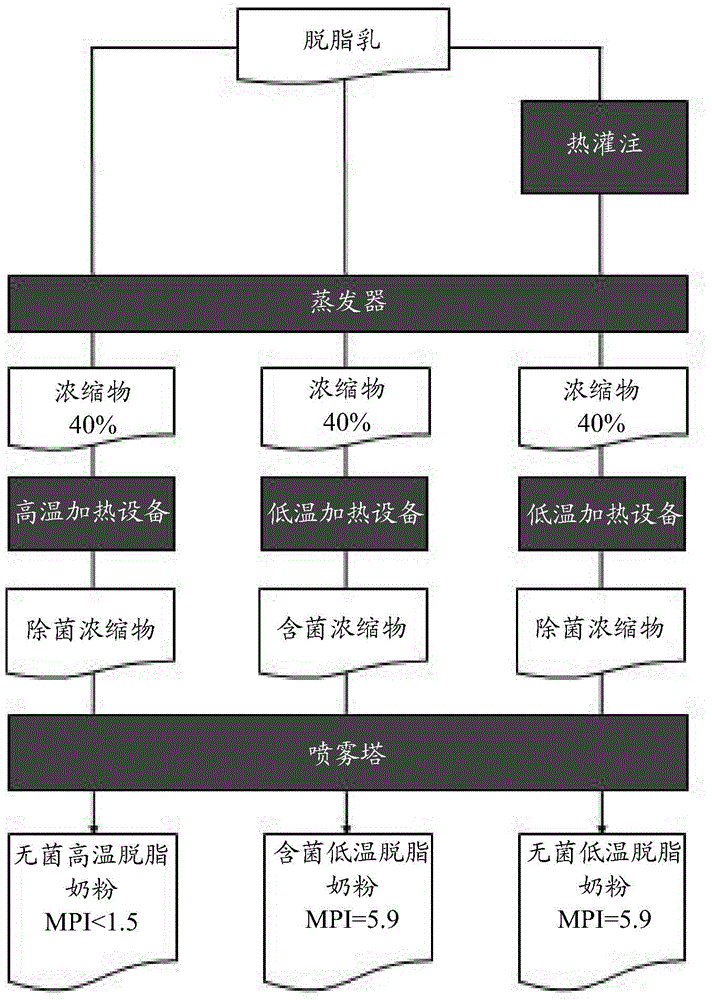

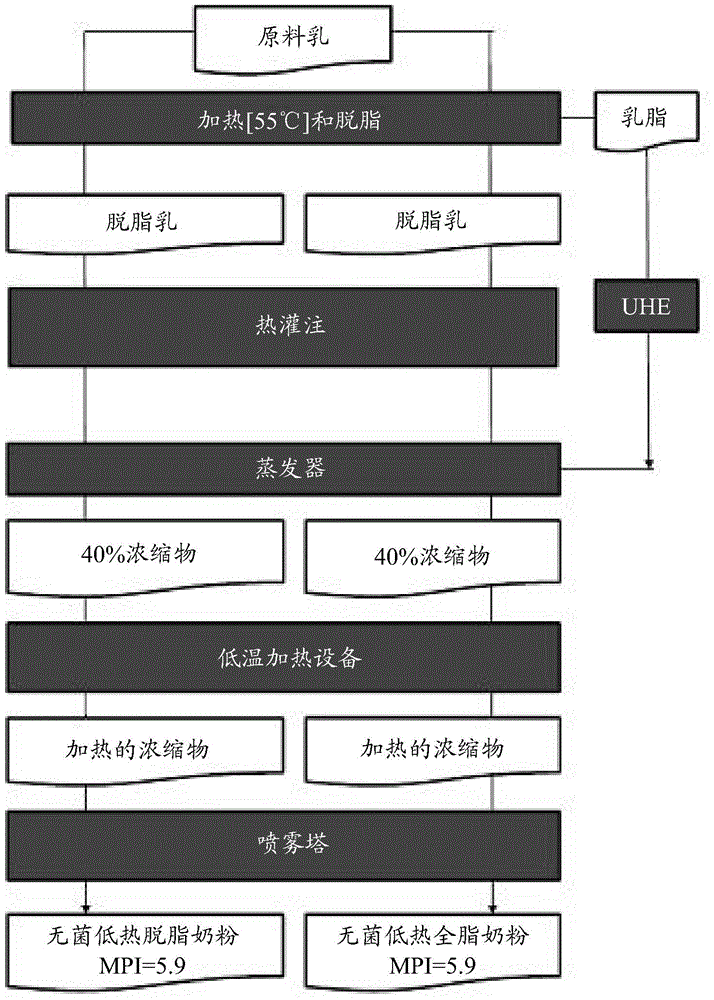

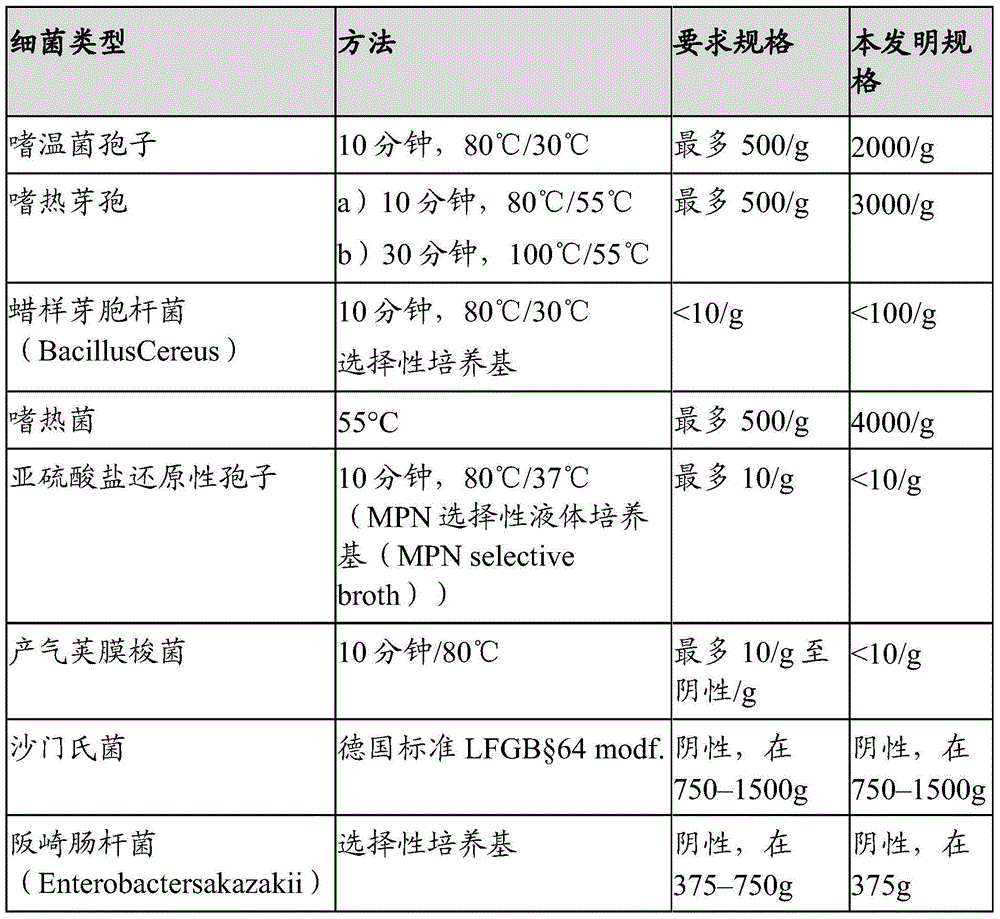

Milk powder with high whey protein index II

The invention provides a method for producing low bacterial milk powder with whey protein nitrogen index (WPNI) of at least 2. The method is below: (a) removing solids from a raw milk by a known method, and then separating cream; (b) conducting hot infusion on the obtained skim milk; (c) concentrating the heated milk to 30-50 wt.% of dry matter; (d) if necessary, subjecting the obtained concentrate to heat treatment for at least 15 s at a temperature of at least 72 DEG C; and (e) subjecting the product from heat treatment to spraying treatment at 100-120 DEG C to obtain a dry powder.

Owner:DMK DEUT MILCHKONTOR

Milk maker and coffee machine

The invention relates to a milk maker. The milk maker comprises a milk input device, a steam input device and a mixing device, wherein the milk input device and the steam input device are both mounted on the mixing device; a milk input channel is formed in the milk input device, and a steam input channel is formed in the steam input device; the mixing device comprises a mixing chamber and a milk output channel which are formed in a mixing device body, and the mixing chamber is communicated with the milk input channel and the steam input channel respectively; a venturi nozzle is assembled on the steam input channel, and an adjusting valve used for adjusting the amount of milk input into the mixing chamber is assembled in the connection position of the milk input channel and the mixing chamber. The adjusting valve is adopted to adjust the amount of milk input into the mixing chamber, steam injected into the mixing chamber is unchangeable, and the amount of mixed milk is different, so that the temperatures of the heated milk are different, accordingly, hot milk with different temperatures can be made by the milk maker according to different requirements, and different demands for milk taste are met.

Owner:SUZHOU KALERM COFFEE MASCH TECH CO LTD

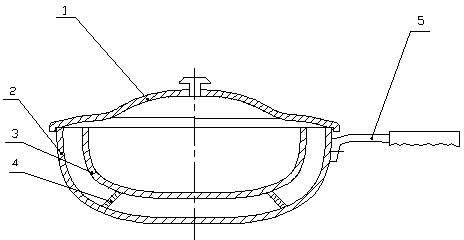

Double-layer milk pan

The invention discloses a double-layer milk pan, belonging to the technical field of daily use articles. The double-layer milk pan comprises an outer layer pan body (2), wherein the outer layer pan body (2) is provided with a pan cover (1); a pan handle (5) is fixed to the outer layer pan body (2). The double-layer milk pan is characterized in that an inner layer pan body (3) is fixedly supported in the outer layer pan body (2) through a support frame (4). When the double-layer milk pan is in use, water is filled between the outer layer pan body and the inner layer pan body, so that milk is prevented from being over cooked during heating. By using the double-layer milk pan, egg cakes can be steamed for infants.

Owner:胡山

Milk strawberry yield increase planting method

InactiveCN106673908AImprove soil fertilityPromote differentiationAnimal corpse fertilisersExcrement fertilisersSurface brightnessFragaria

The invention relates to a milk strawberry yield increase planting method which comprises the following steps: heating milk to 100 DEG C or above, and mixing the heated milk and water according to the ratio of 1:500 to obtain a first mixed solution; carrying out mixed fermentation on 12 parts by weight of dry rabbit manure, 10 parts by weight of lotus leaf straw powder, 4 parts by weight of wood ash powder, 2 parts by weight of bone powder and 1 part by weight of blast-furnace cinder, and mixing the fermented mixed fertilizer and water according to the ratio of 1:10 to obtain a second mixed solution; mixing the first mixed solution and second mixed solution according to the ratio of 1:1 to obtain a fertilizer; and after planting strawberries, irrigating every 8-10 days, wherein the strawberry planting soil is dried one day before irrigation. Compared with the prior art, the added duck manure and the like increase the soil productivity, can promote differentiation of flower buds, enhance the stress tolerance of plants, and are capable of decomposing pesticide residues in soil, improving the soil and increasing the yield. The first mixed solution can increase the surface brightness of the strawberries and enhance the milk odor intensity and mouthfeel of the strawberries.

Owner:LIUZHOU GENGQING TECH

Self-help feeding device for sucking tiger

ActiveCN108849599ASelf cateringMeet physiological needsAnimal feeding devicesHeated milkControl valves

The invention relates to a self-help feeding device for a sucking tiger. The device comprises a heat preservation bin used for containing milk, a hot water tank used for providing hot water, a spiralpipe used for making the milk and the hot water perform heat exchange and a nipple; the bottom of the spiral pipe is connected with the hot water tank of the hot water through a water outlet pipe, thetop of the spiral pipe is connected with the hot water tank through a water return pipe, and a booster pump is arranged on the water return pipe; a discharge pipe is arranged at the bottom of the heat preservation bin, and the discharge pipe enters the spiral pipe through the top of the spiral pipe and penetrates out of the bottom of the spiral pipe to be connected with the nipple; a first control valve is arranged on the discharge pipe, and a supercharging device is arranged on the heat preservation bin or the discharge pipe, a sensing device detecting sucking of the sucking tiger is arranged on the nipple, and the sensing device, the supercharging device, the first control valve and the booster pump are connected with a controller. By means of the device, the action of the sucking tigercan be detected, rapidly heated milk can be provided, and the sucking tiger self-help feeding purpose is achieved.

Owner:东北大学秦皇岛分校

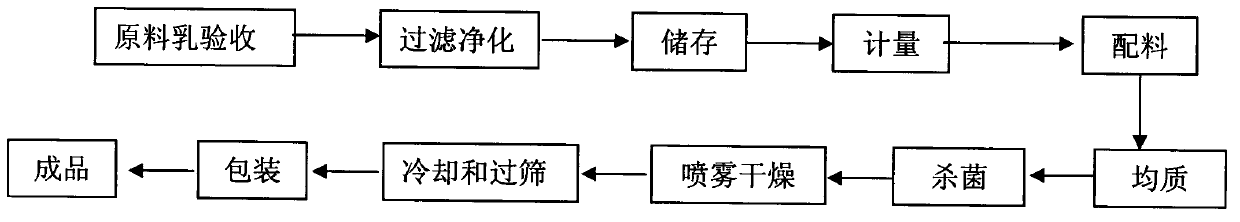

Production method of active ginkgo nut milk powder

InactiveCN103859038AKeep active ingredientsBalance and improve nutritional functionMilk preparationGinkgo nutMoisture

The invention relates to a production method of active ginkgo nut milk powder. The production method comprises following steps: a, material preparation, wherein 100kg of fresh milk is heated to a temperature of 75 to 80 DEG C quickly, the temperature is maintained for 15min, the heated milk is delivered into an emulsification tank, an emulsification pump is turned on, 30kg of dried skim milk is added, the temperature is reduced to 40 DEG C, 14kg of ginkgo nut powder is added, and obtained mixture is mixed uniformly, and is subjected to emulsification for 30 to 40min; b, homogenizing, wherein the mixture obtained via step a is delivered into a homogenizer through a sterilized feed pump, and is subjected to homogenizing at a working pressure of 14 to 20Mpa; c, spray drying, wherein the temperature of the mixture at a material inlet ranges from 60 to 65 DEG C, and solid content ranges from 33 to 35%, moisture content of the mixture at a material outlet is less than 5%, inlet air temperature ranges from 170 to 180 DEG C, outlet air temperature ranges from 75 to 80 DEG C, the temperature of a drying chamber ranges from 70 to 90 DEG C, and powder recovery rate ranges from 96 to 98%; and d, powder discharging, cooling, and sieving, wherein milk powder obtained via spray drying is discharged, is cooled to a temperature below 30 DEG C quickly, is sieving using a mechanical vibration screen of 40-60 meshes so as to separate blocks, is stored for 12 to 24h, and then is packaged.

Owner:南通康威尔生物化工有限公司

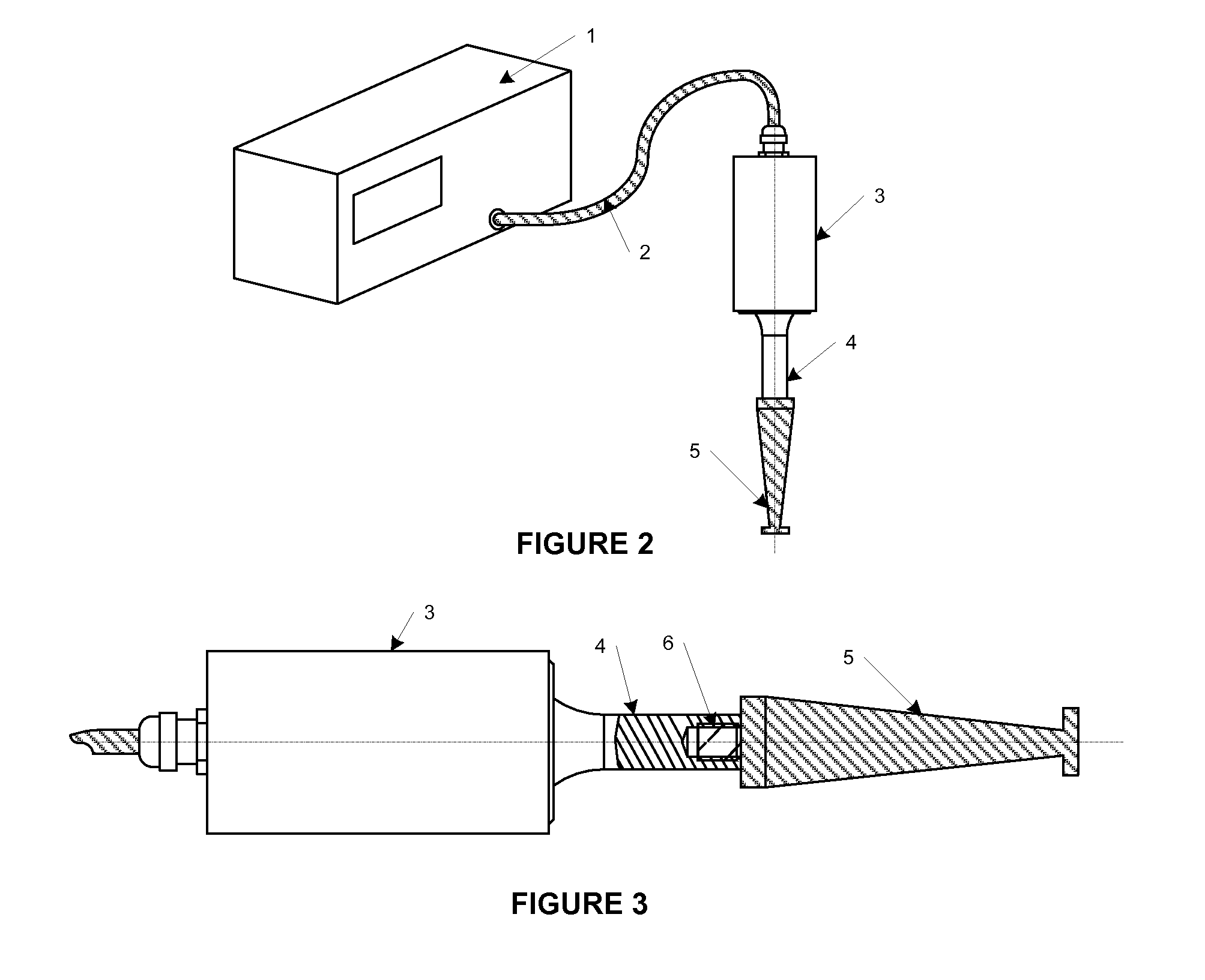

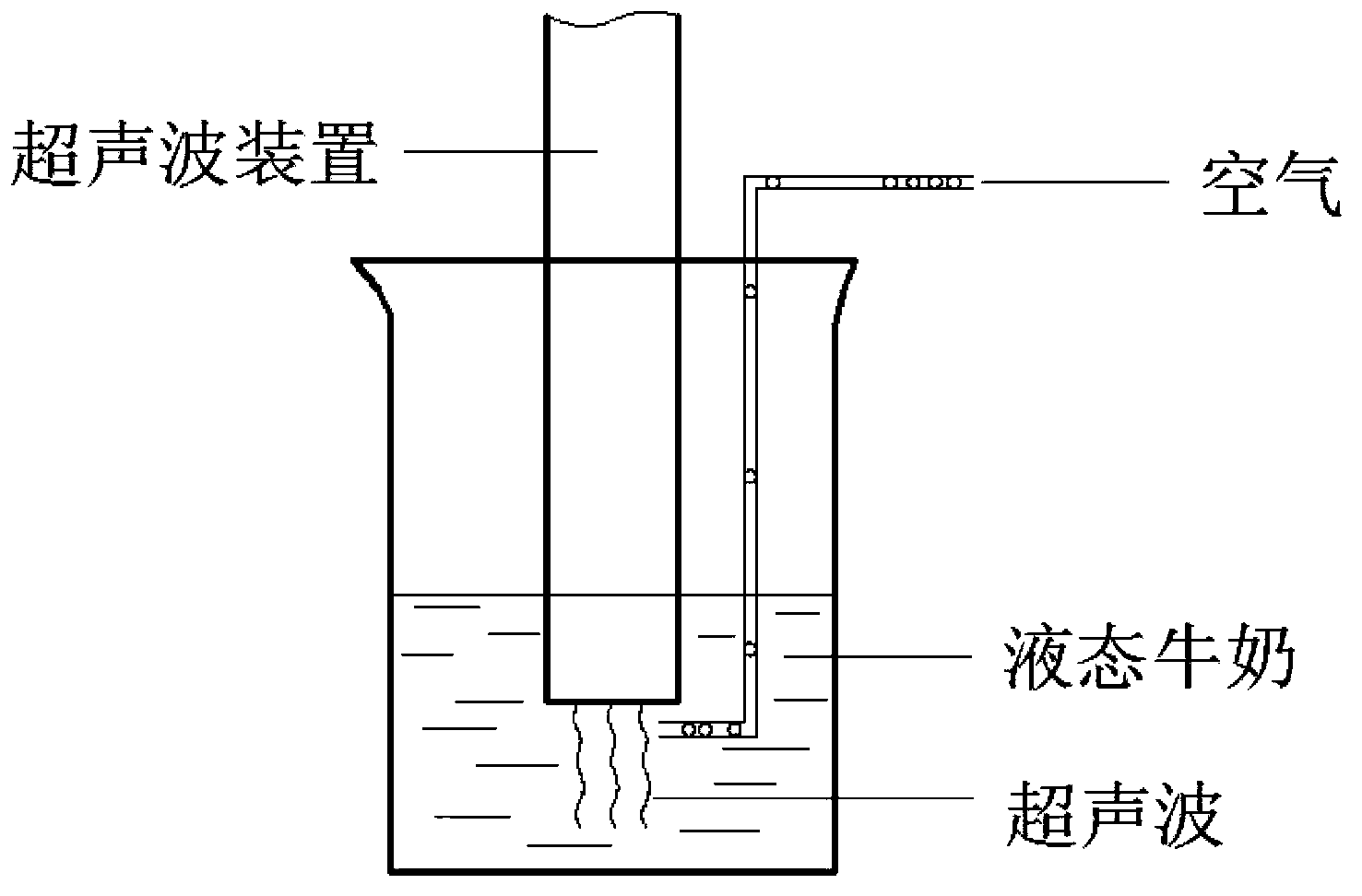

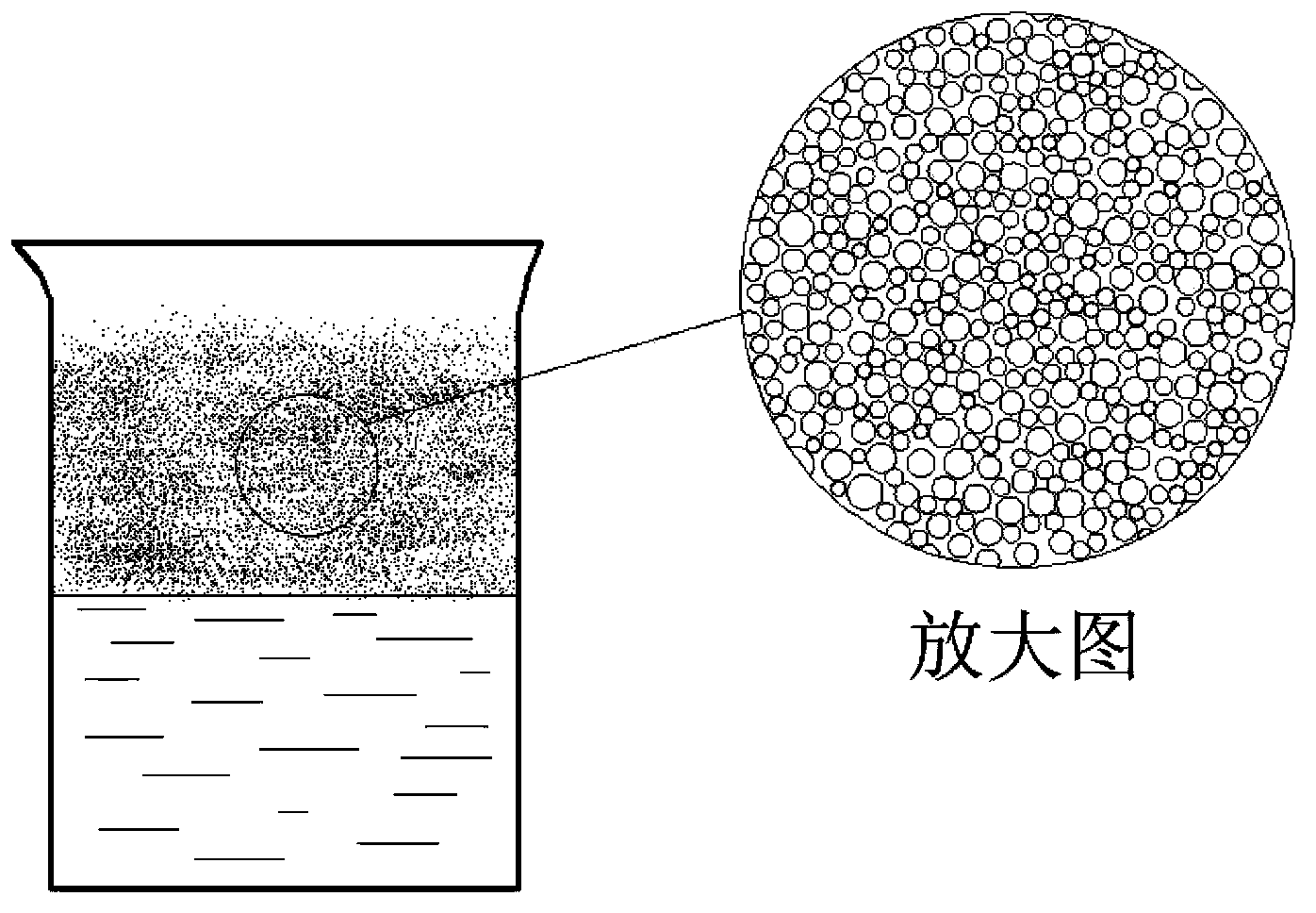

Method for conducting milk foaming on milk by using ultrasonic waves

The invention discloses a method for conducting milk foaming on milk by using ultrasonic waves. The method includes the steps that milk liquid is put in a container; an ultrasonic unit is placed above the liquid level of the milk or is soaked into the milk, and the height of the ultrasonic unit above the liquid level of the milk or the depth of the ultrasonic unit soaked into the milk is adjusted to the specified position; the ultrasonic unit is operated, and ultrasonic treatment is conducted on the liquid-state milk; after scheduled time when the ultrasonic treatment is completed, the operation is stopped, foaming is achieved, milk foam is poured out, and then the milk foam which is fine, smooth, dense and good in stability is achieved. By means of the method for conducting milk foaming on the milk by using the ultrasonic waves, the generated milk foam is high in quality, multiple in amount, fine, smooth, dense, heavy in milk taste and good in stability; the milk foam can be generated, the milk and the milk foam can be heated as well, and heating efficiency is high; the quality even effect can be achieved for the milk, and the taste of the milk and the taste of the milk foam can be enhanced; the milk foam generating method is simple and practicable, and operation is convenient.

Owner:GUANGDONG MASTER GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com