Milk frothing method and milk frothing device for carrying out the method

A steam flow, Venturi tube technology, applied in the direction of beverage preparation devices, applications, household appliances, etc., can solve the problems of device functionality and sanitation loss, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

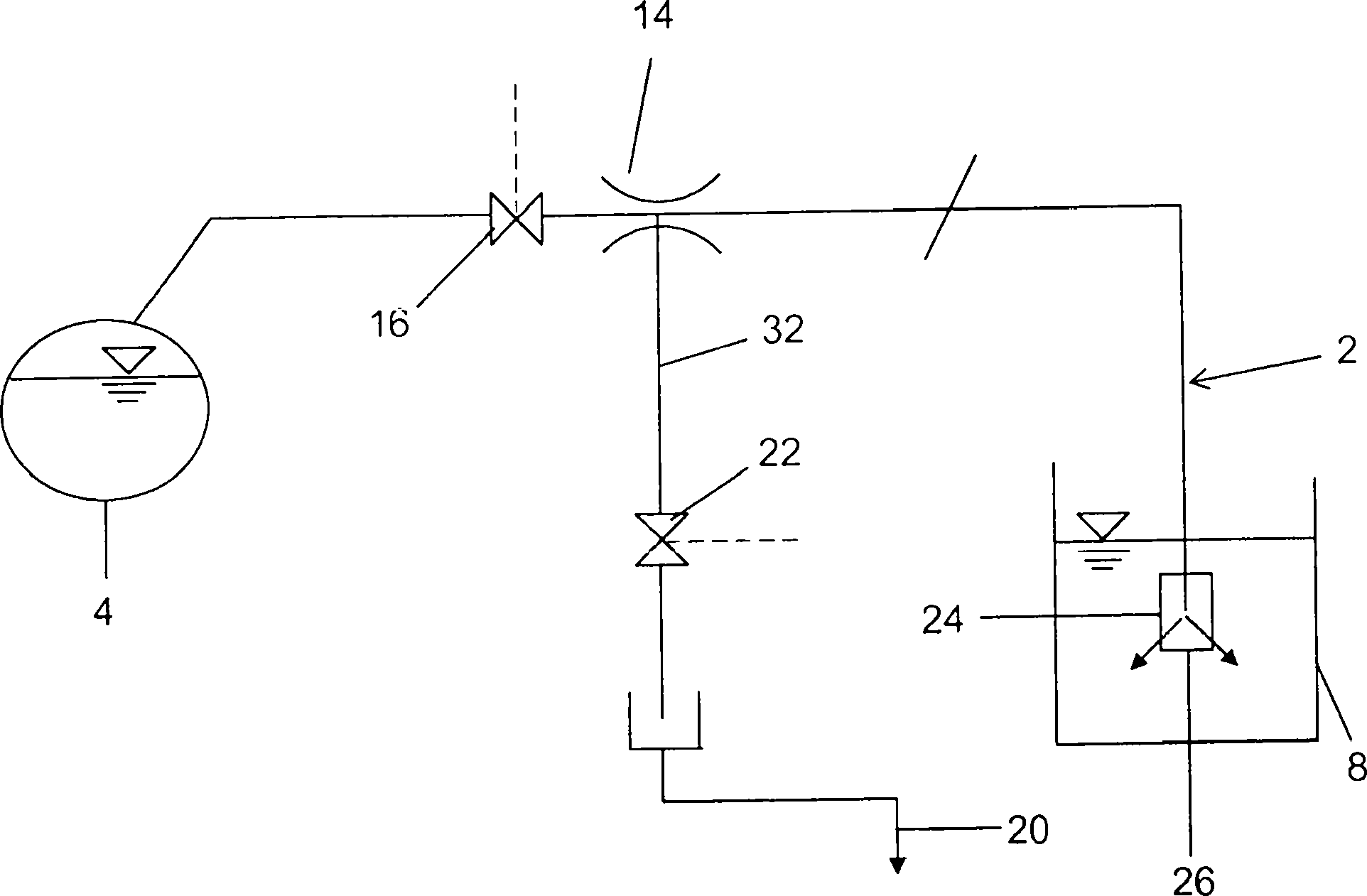

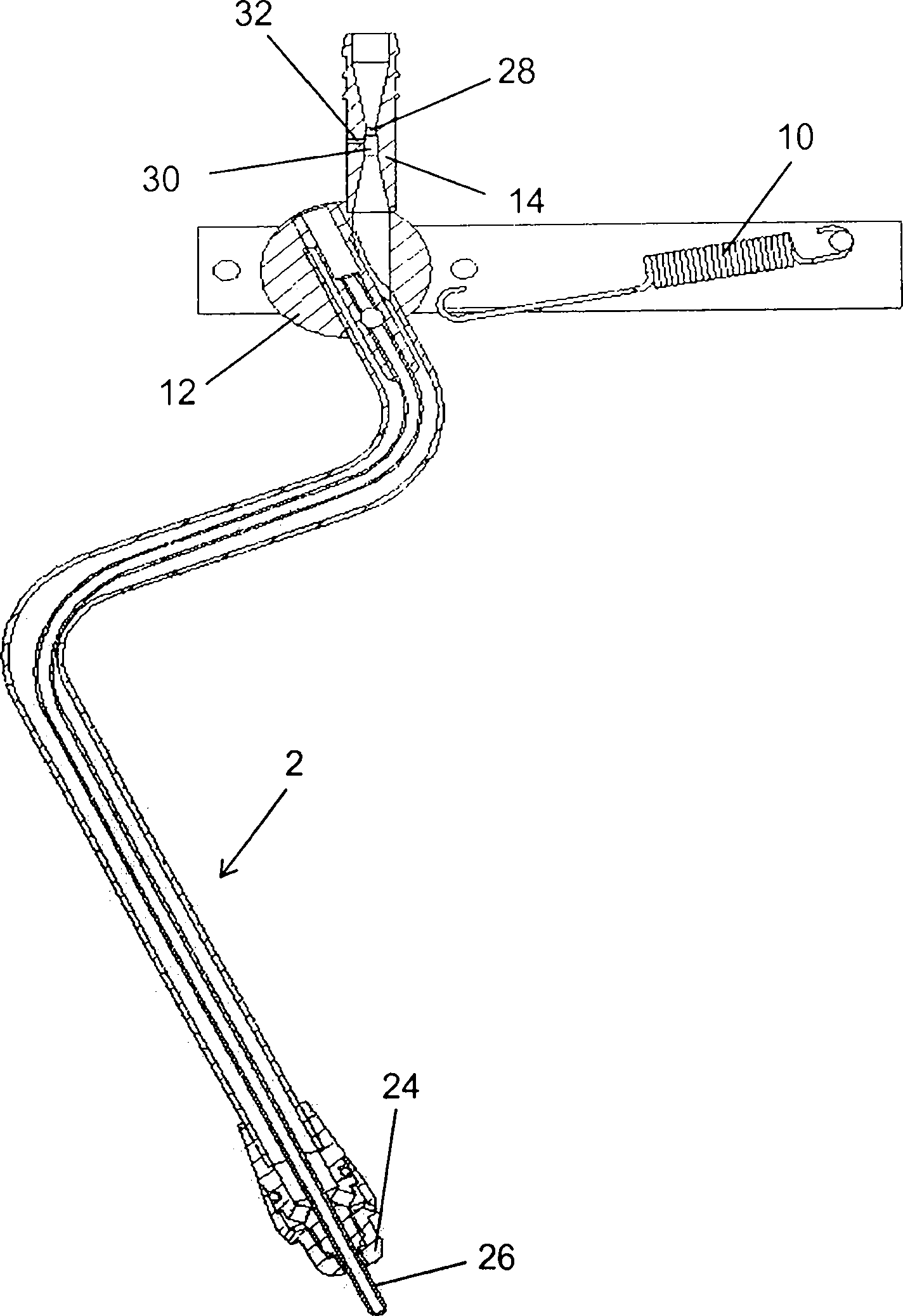

[0016] As can be seen from the figure, the milk frothing device according to the invention comprises a gun 2 applied to a conventional coffee machine, which gun has been provided with a steam generating boiler 4 .

[0017] The gun 2 is hinged to the coffee machine structure so that it can be turned from an operating position (with its lower end facing the shelf on which the jug 8 containing the milk to be frothed rests) to a forwardly extended position so that the gun Can be inserted into and extracted from the jug.

[0018] The gun is held elastically in its operative state by a spring 10 which is preferably associated with an articulation joint 12 by which the gun 2 is hinged to the coffee machine structure.

[0019] The gun 2 incorporates a small venturi 14 of the convergent-divergent type, the upstream side of which is connected to the steam generating boiler 4 via a normally closed (NC) solenoid valve 16 which The control unit controls the operating cycle of the milk fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com