Milk powder with high whey protein index II

A whey protein nitrogen and index technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of difficulty in marketization and high bacterial pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: the production of low bacterium-containing skimmed milk powder

[0044] Example V2 was repeated, but before the evaporation step, the skim milk was heat poured at 135°C for 3 seconds, so that the treated product was evaporated and heat treated as described above, and sprayed. The resulting low heat skim milk powder has a WPNI of 6.8, which is nearly sterile.

Embodiment 2

[0045] Embodiment 2: the production of whole milk powder with low bacteria content

[0046]Solids are removed from the raw milk by methods known per se, the milk is pasteurized and skimmed to obtain skim milk with a dry matter of about 9% by weight. This was heat perfused as described in Example 1. The milk fat obtained in the skimming process is subjected to high heat treatment at 125° C., and is added to skim milk again to obtain whole milk. The resulting reduced heat whole milk has a WPNI of 6.3, which is virtually sterile.

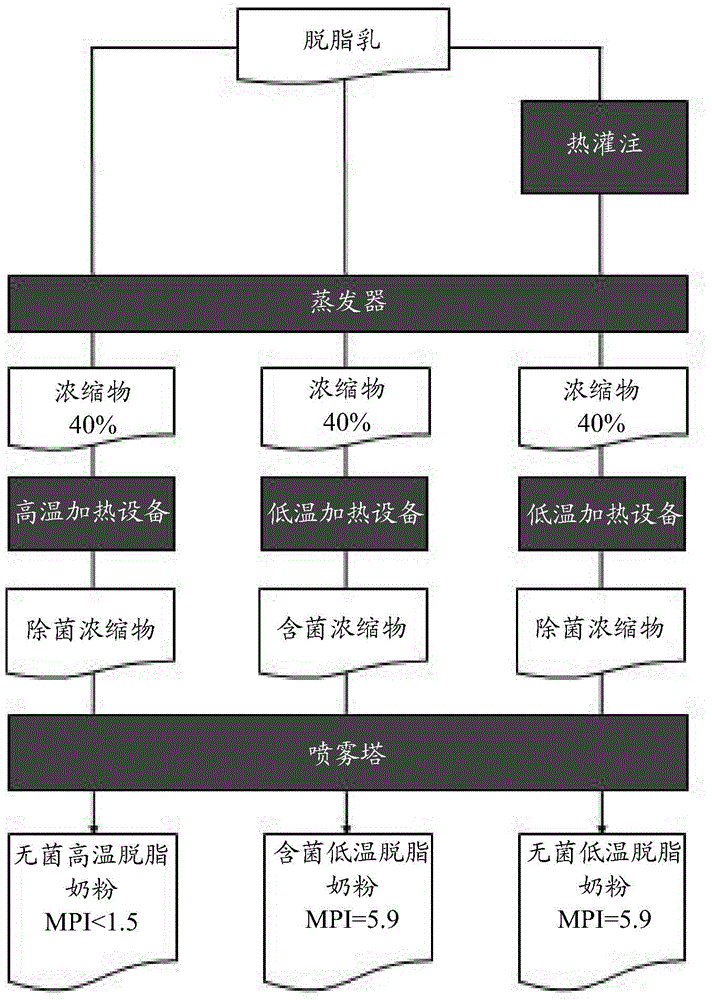

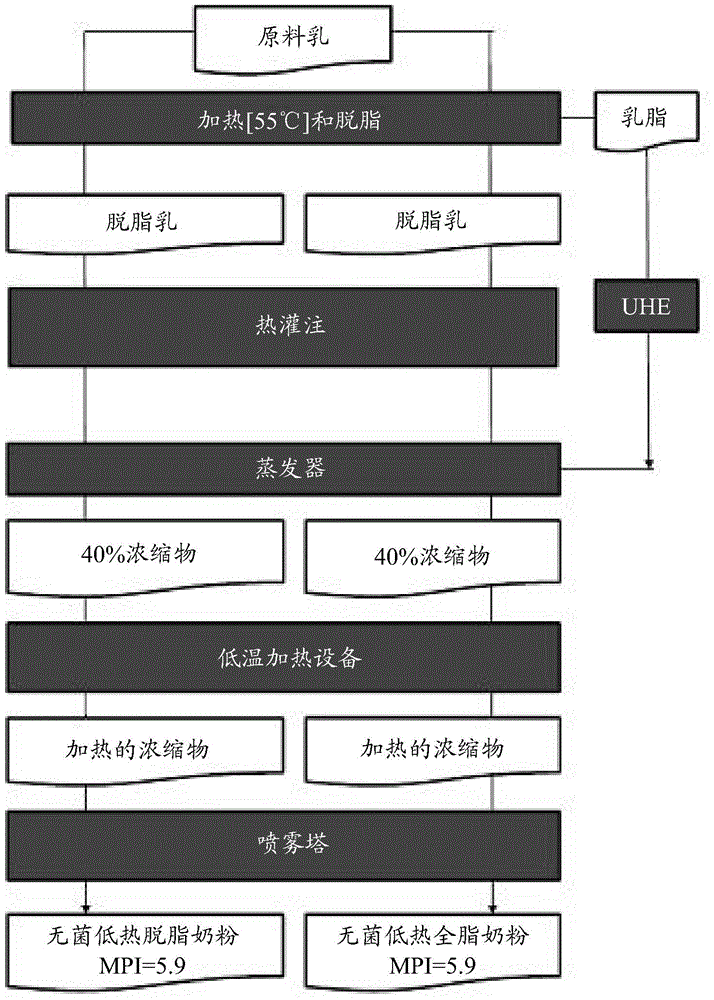

[0047] Examples V1, V2 and 1 are placed side by side in figure 1 in the flow chart. figure 2 Demonstrate the difference in the production of skim milk powder and whole milk powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com