Production method of active ginkgo nut milk powder

A production technology, the technology of ginkgo biloba, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of unbalanced nutrition, high starch content, and poor processing performance that restrict the development of ginkgo products, so as to achieve balance and nutritional function, improve The effect of nutritional function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

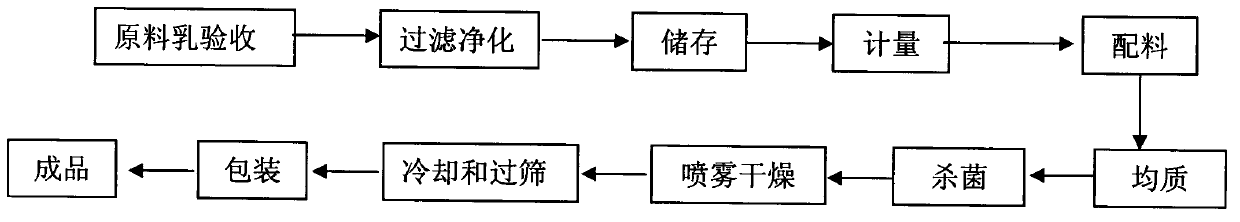

[0019] Such as figure 1 The production technology of active ginkgo fruit milk powder shown includes the following steps:

[0020] a. Ingredients

[0021] Take 100kg of fresh milk, and keep it warm for 15 minutes when the temperature is rapidly increased to 75-80°C. Into the emulsification tank, turn on the emulsification pump, add 30kg of skimmed milk powder, reduce the temperature to 40℃, add 14kg of ginkgo powder, mix well, emulsify time 30-40 minutes;

[0022] b. Homogenization process

[0023] Pump the agitated ingredients in step a into the homogenizer in the sterilized liquid, and homogenize at a working pressure of 14-20Mpa;

[0024] c. Spray drying process

[0025] Imported materials: 60-65℃, solid content 33-35%. Outlet materials: moisture content <5%, inlet air temperature 170-180°C, exhaust air temperature 75-80°C, drying room temperature 70-90°C. The powder recovery rate is 96-98%;

[0026] d. Powder extraction, cooling and sieving

[0027] Take the spray-dried milk powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com