Milk separator with heating function

A separator and heating mechanism technology, which is applied in the field of milk separators, can solve the problems that the heating effect needs to be improved, the heating degree of milk is not uniform, etc., and achieves the effects of stable structure, uniform heating effect and simple heating structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055]The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

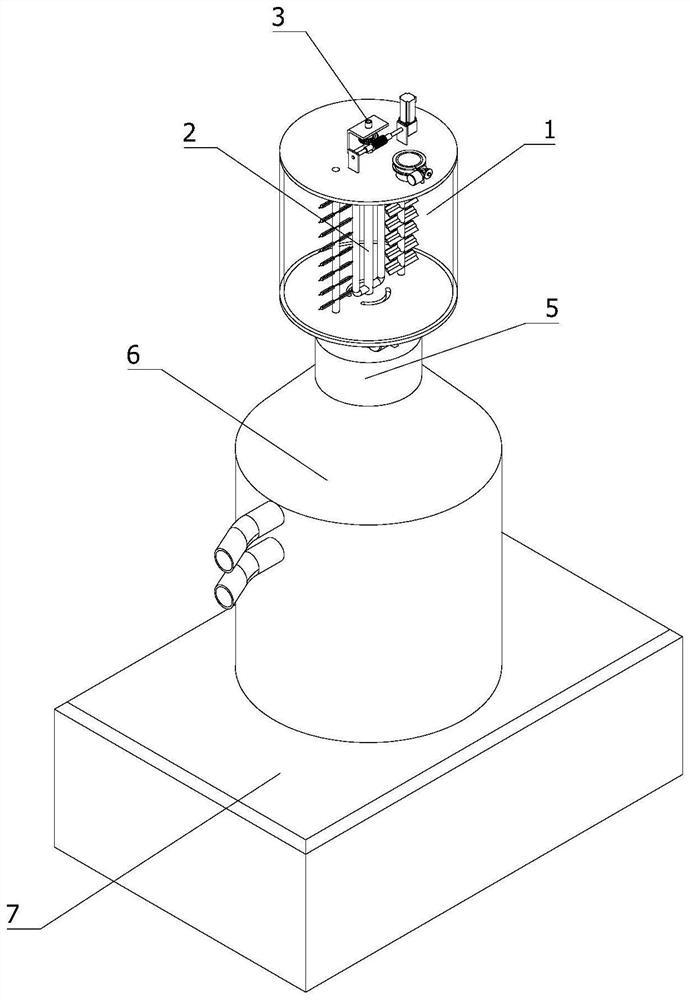

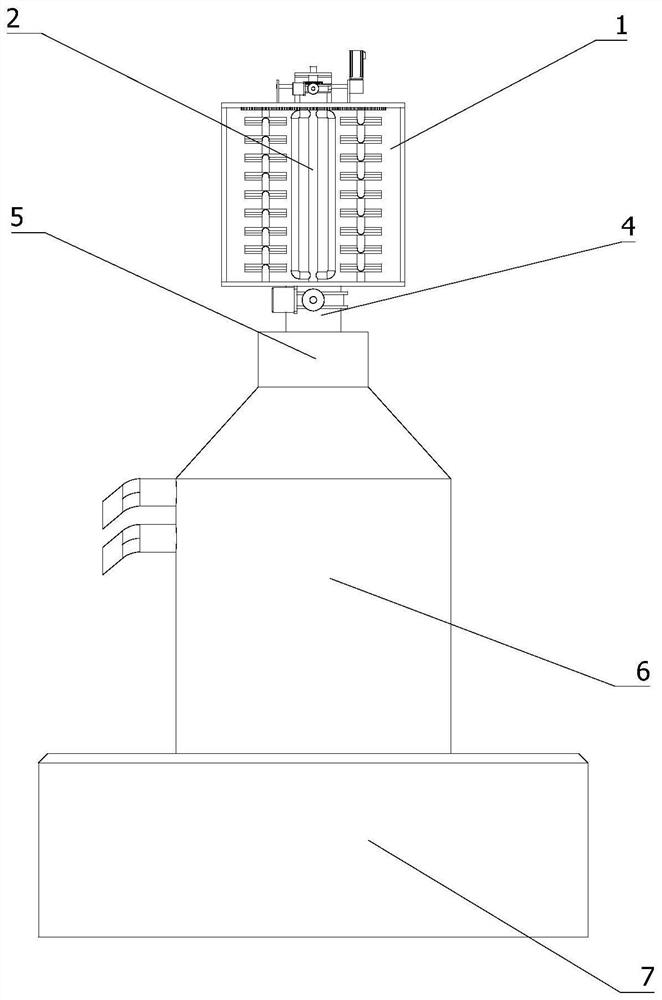

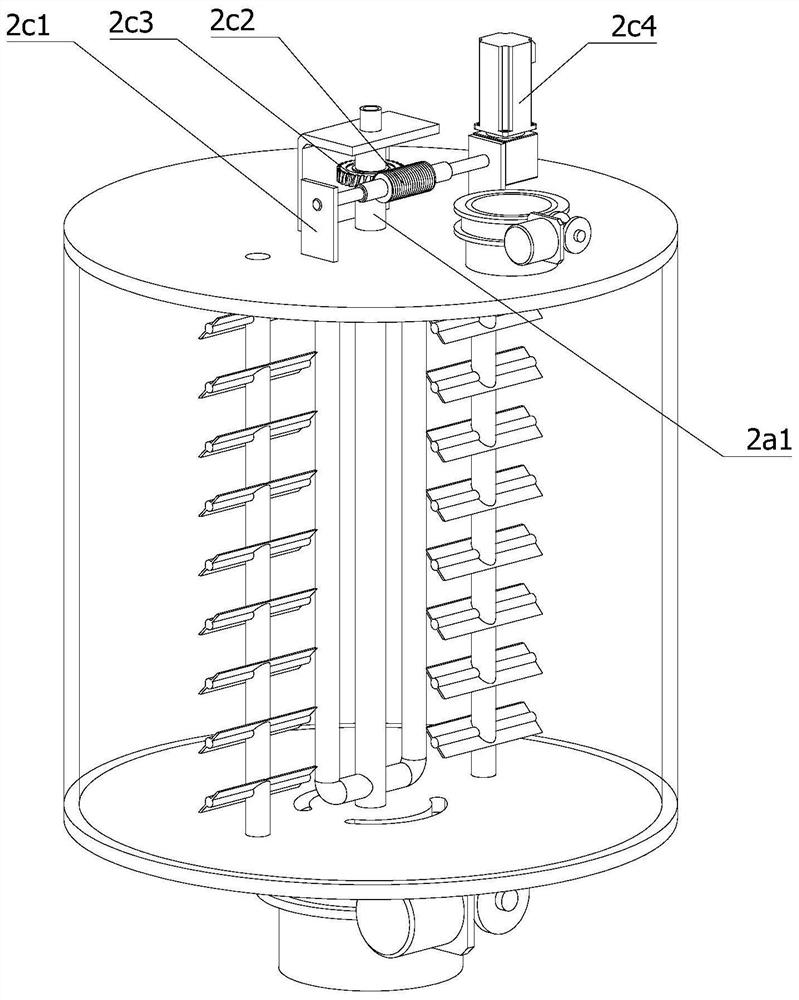

[0056] Such as figure 1 and figure 2 As shown, a milk separator with heating function includes: preheating barrel 1, stirring mechanism 2, heating mechanism 3, liquid inlet pipe 4, storage box 5, separating mechanism 6 and driving mechanism 7;

[0057] The preheating barrel 1 is erected on the upper end of the liquid inlet pipe 4 and communicates with the feed end of the storage box 5 through the liquid inlet pipe 4. The top is provided with a feed pipe for feeding materials, and the bottom is provided with a discharge hole for discharging materials. Equipped with liquid level sensor and temperature sensor for preheating and stirring the unseparated milk;

[0058] A stirring mechanism 2, the working end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com