Experimental device used for thermal fatigue of turbine blade material

An experimental device and turbine blade technology, which is applied to measurement devices, analytical materials, instruments, etc., can solve the problems of inability to obtain key information of samples in real time, high labor and material resources consumption, and inability to achieve rapid changes, and achieve easy process automation. Control, wide range of industry adaptability, no fuel transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

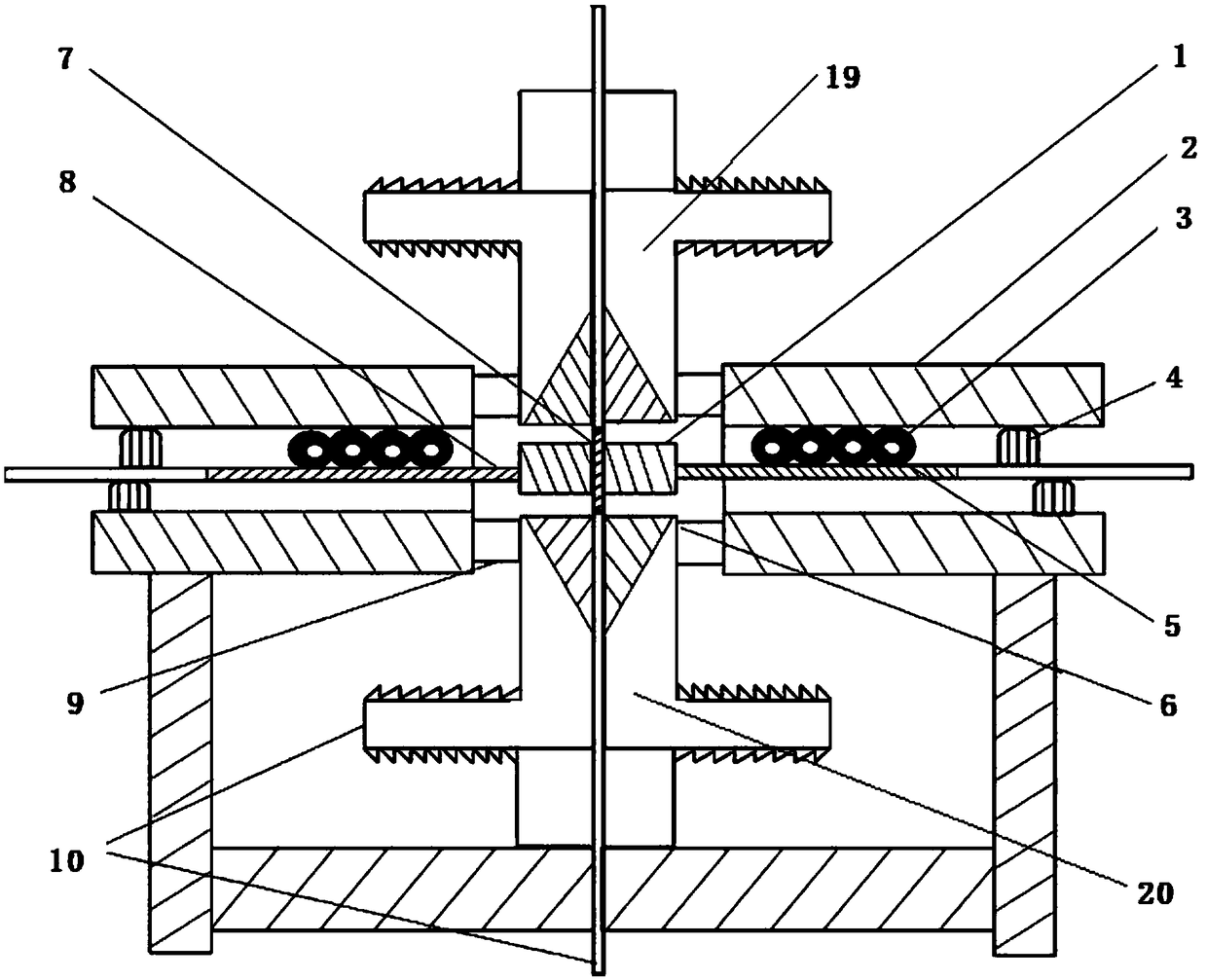

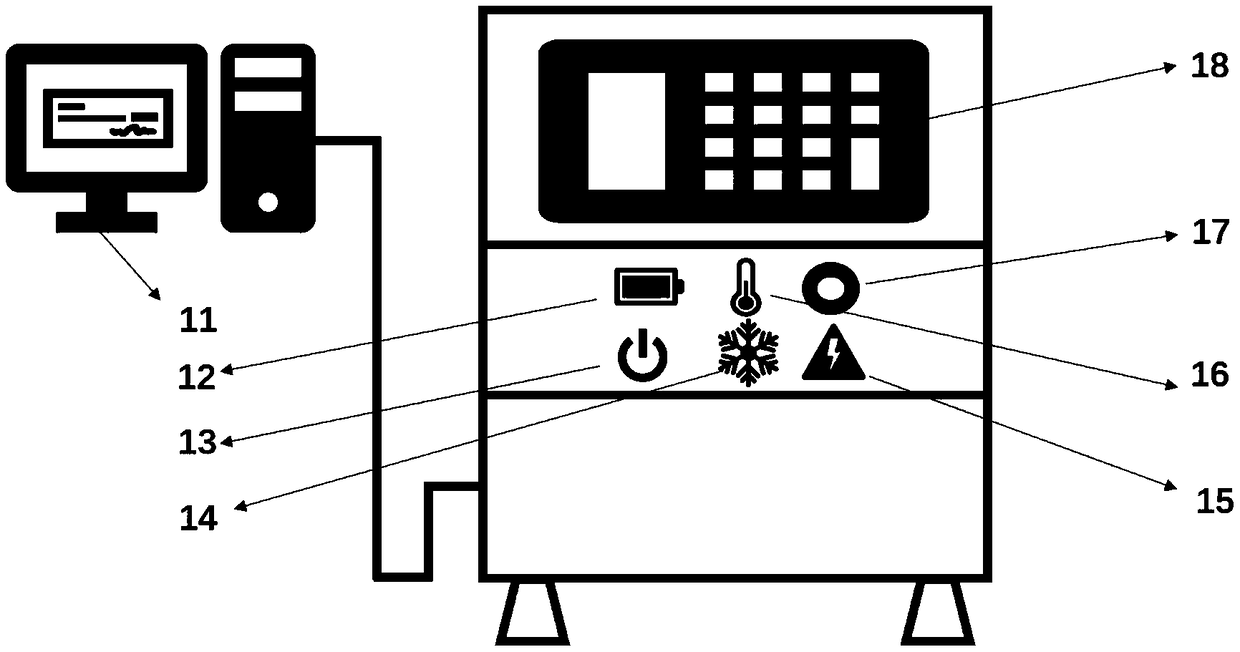

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , an experimental device for thermal fatigue of turbine blade materials, including an induction coil heating system, a temperature test acquisition system, a cooling system, and a test control platform;

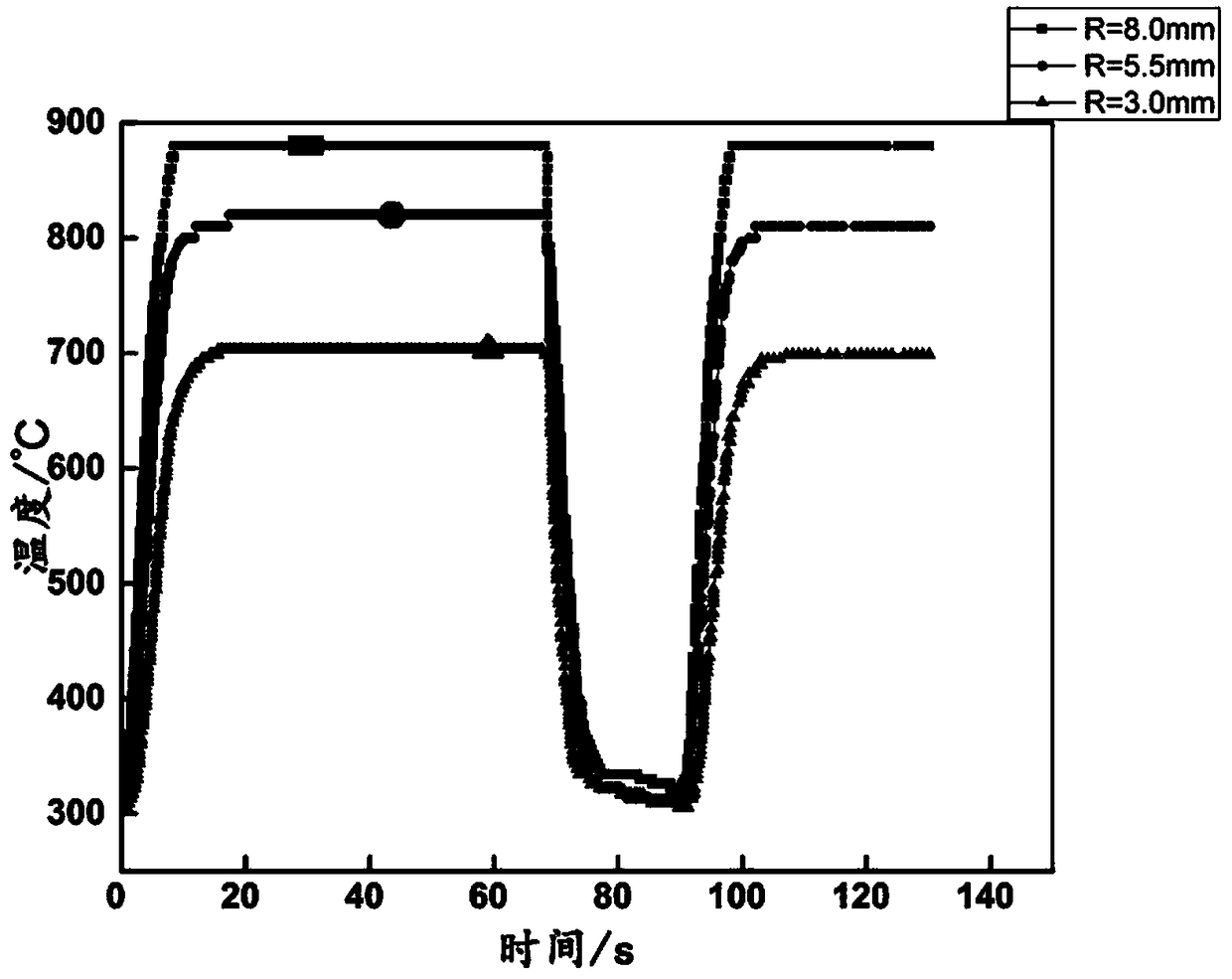

[0026] The induction coil heating system adopts a two-way surround heating method with a symmetrical structure, including a special induction coil (2) and an AC power supply. The heating range of the induction coil (2) is 25°C-1200°C, and the heating temperature per second can reach 50°C- 100°C, the induction coil (2) can be made into different shapes according to the different sizes of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com