Production method of milk and milk produced by the method

A milk and raw milk technology, applied in the milk field, can solve the problems of reducing quality and flavor, increasing heat treatment intensity, short shelf life of pasteurized milk, etc., and achieving the effect of no heat loss and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

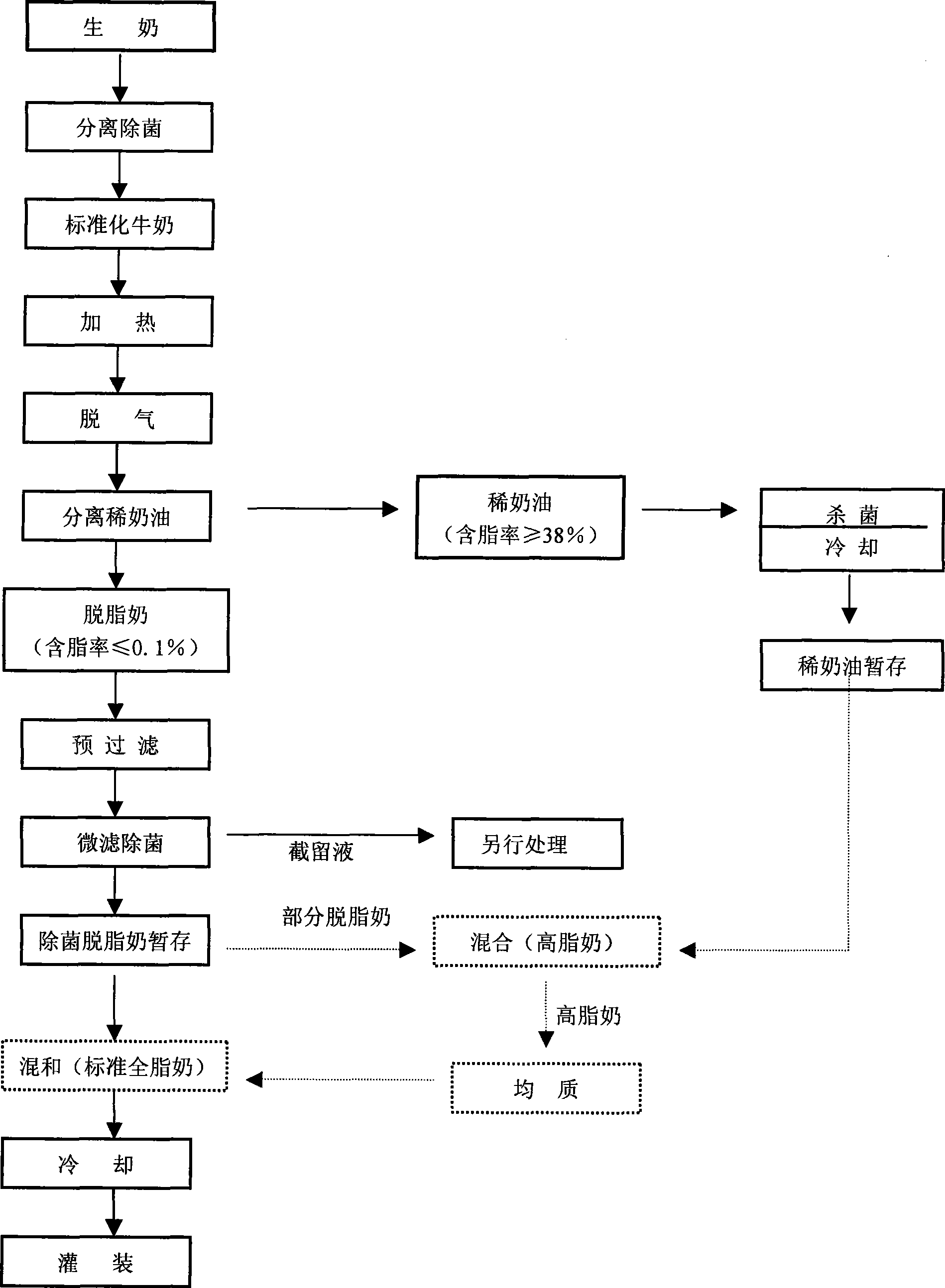

[0039] The process steps are as follows:

[0040] 1. Raw milk is sterilized by centrifugal sterilization machine: 5000rpm, slag discharge = 30kg milk / time×1 time / 15 minutes, 20 tons per hour;

[0041] 2. Standardized milk, using falling film evaporator for falling film concentration, the parameters are shown in the table below:

[0042] project parameter Water evaporation, kg / h 1250 Material handling capacity, kg / h 1680 Feed concentration, % 11.0 Output concentration, % 44.0 First effect evaporation temperature, ℃ 50-55 Absolute pressure inside the first effect evaporator, Pa 20000 Second effect evaporation temperature, ℃ 50-53 Absolute pressure inside the second effect evaporator, Pa 15000 Three-effect evaporation temperature, ℃ 44-48 Three-effect evaporator cavity absolute pressure, Pa 10000

[0043] Physical and chemical indicators after standardization: fat ≥ 3.4%, protein ≥ 3.05%, non-fat milk sol...

Embodiment 2

[0054] The process is as follows:

[0055] 1. Raw milk is centrifugally sterilized by a sterilizer: 4800rpm, slag discharge = 40kg milk / time×1 time / 10 minutes, 25 tons per hour;

[0056] 2. Standardized milk, adopt falling film evaporator to carry out falling film concentration, the same as in Example 1, physical and chemical indicators after standardization: fat ≥ 4.0%, protein ≥ 3.60%, non-fat milk solid ≥ 9.6%;

[0057] 3. Heat milk to 50°C and vacuum degassing;

[0058] 4. Separate the milk into cream and skim milk, and the fat content of the skim milk is less than 0.05%;

[0059] 5. Skim milk is pre-filtered through a membrane with a pore size of 20 μm;

[0060] 6. Skim milk is sterilized by microfiltration, ceramic membrane filtration parameters: pore size 0.8μm, flow rate 5m / s, filtration temperature 55°C, VCF=20;

[0061] 7. The cream is sterilized and stored after cooling. The sterilization conditions are 137°C, 5s, and the cooling temperature is 30°C;

[0062] 8....

Embodiment 3

[0067] The process is as follows:

[0068] 1. Raw milk is sterilized by centrifugal sterilization machine: 4500rpm, slag discharge = 30kg milk / time×1 time / 20 minutes, processing 25 tons per hour;

[0069] 2. Standardized milk, the same as in Example 1, physical and chemical indicators after standardization: protein ≥ 3.10%, non-fat milk solids ≥ 8.3%;

[0070] 3. Heat the milk to 50°C and degas it in vacuum at low temperature;

[0071] 4. Separate milk into cream and skim milk, the fat content of skim milk is less than 0.1%;

[0072] 5. Skim milk is pre-filtered through a membrane with a pore size of 20 μm;

[0073] 6. Skim milk is sterilized by microfiltration, ceramic membrane filtration parameters: pore size 1.4μm, flow rate 10m / s, filtration temperature 55°C, VCF=100;

[0074] 7. The cream is sterilized and stored after cooling. The sterilization conditions are 125°C, 15s, and cooled to 10°C;

[0075] 8. Mix 50% skimmed milk (prepared in step 6) with 40% cream (prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com