Laminated glass for use in vehicles

A technology for laminated glass and vehicles, applied in vehicle parts, glass/slag layered products, coatings, etc., can solve problems such as inconvenience in use, and achieve good thermal insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

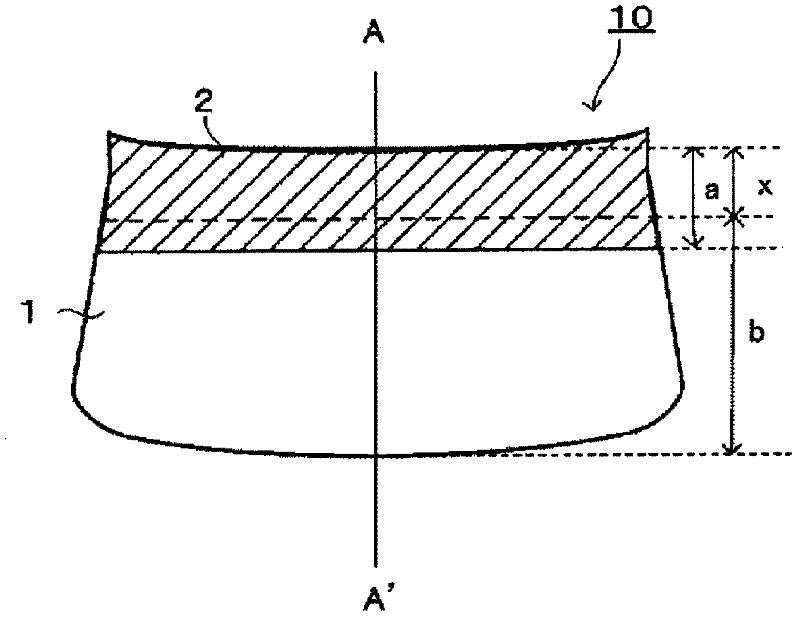

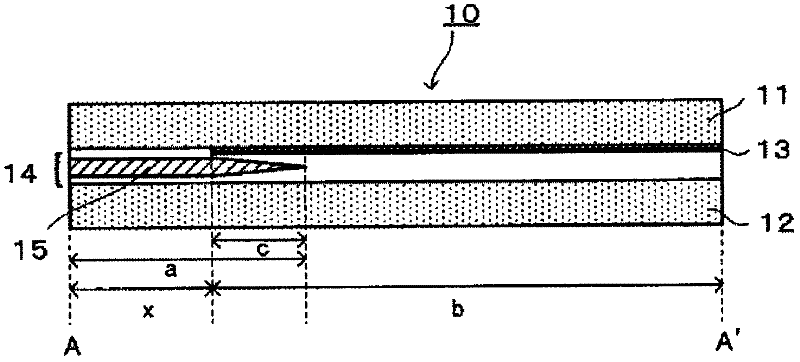

[0111] [Example 1] (Case 1 in which a heat ray reflecting film is provided on glass)

[0112] On 300mm×300mm colorless transparent soda lime silica glass (manufactured by Asahi Glass Co., Ltd. (manufactured by Asahi Glass Co., Ltd.)) with a thickness of 2mm, two layers of silver (Ag) layers are formed by magnetron sputtering. Heat-treated heat-ray reflective film. Table 1 shows the layer structure material, film thickness and composition of each layer of the multilayer heat ray reflective film.

[0113] In addition, when forming the above-mentioned heat ray reflecting film, a 300 mm×110 mm band-shaped masking was performed along one edge of the glass (the edge referred to as the "upper edge" in the laminated glass described later). That is, a strip-shaped metal covering of 300 mm×110 mm was prepared, and a strip-shaped covering of 300 mm×110 mm was provided along one edge of the glass. As a result, the heat ray reflecting film is not provided in the portion where the cover i...

Embodiment 2

[0129] [Example 2] (Case 2 in which a heat ray reflecting film is provided on glass)

[0130] In the same manner as in Example 1 above, a heat ray reflecting film was provided on colorless transparent soda lime silica glass (manufactured by Asahi Glass Co., Ltd.) with a thickness of 300 mm×300 mm and a thickness of 2 mm. Using this glass with a heat ray reflective film, as an interlayer, except for using the interlayer prepared below in which ITO was added to the colored portion, the same operation as in the above-mentioned Example 1 was performed to obtain a laminated glass test piece for vehicles (hereinafter, simply referred to as "Laminated glass for vehicles").

[0131]

[0132] To prepare 100 parts by weight of polyvinyl butyral resin, 0.28 parts by weight of indium oxide (ITO) particles mixed with tin and 0.014 parts by weight of trioctyl phosphate were dispersed in 10 parts by weight of triethylene glycol- The plasticizer dispersion obtained by di-ethylhexanoate (3G...

Embodiment 3

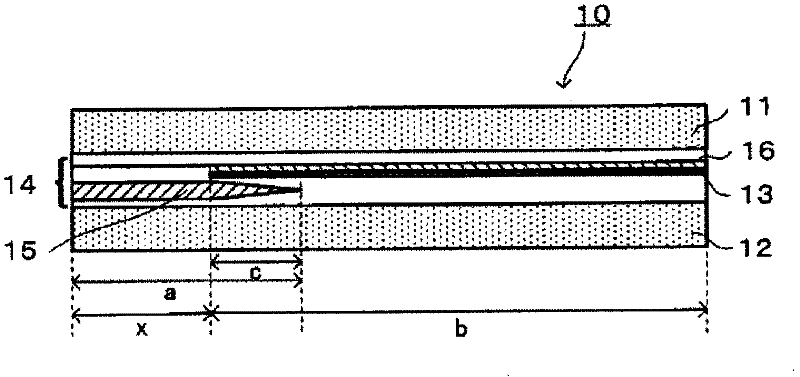

[0135] [Example 3] (case where a thin film provided with a heat ray reflecting film is enclosed in an interlayer film)

[0136]300mm x 300mm thickness 0.76mm interlayer with colored portion (trade name: S-1ec, Sekisui Chemical Co., Ltd. (Sekisui Chemical Industry Co., Ltd.) (hereinafter, film A) and a non-colored interlayer film (trade name: saflex AR11, Solutia Japan) with a thickness of 0.38 mm of 300 mm × 300 mm Company (Solusia Japan Co., Ltd.)) (hereinafter, film B), a 300 mm x 190 mm thickness of 0.05 mm heat reflection film (trade name: XIR-70, Shaohua Technology Co., Ltd. (Southwall Technologies)) was installed as follows And obtained with the above image 3 A 300 mm×300 mm interlayer film for laminated glass for vehicles having the same cross-sectional structure as the interlayer film 14 . The upper end of the heat ray reflective film is located 110 mm below the upper edge of the interlayer film used as the upper edge when used in laminated glass for vehicles, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com