Method for conducting milk foaming on milk by using ultrasonic waves

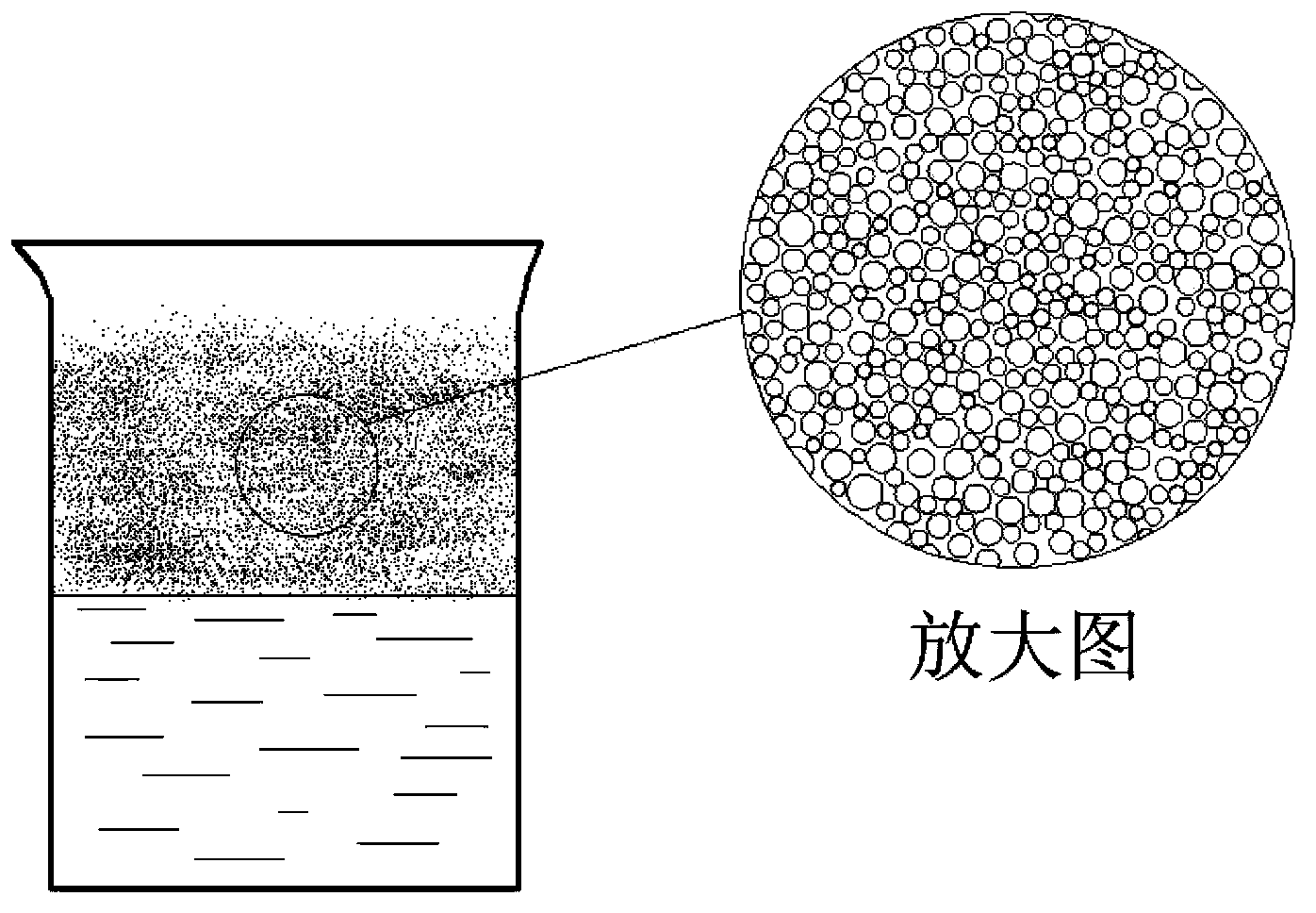

An ultrasonic and milk technology, applied in the field of milk foaming, can solve the problems of the steam-type milk foaming machine being complicated, difficult to operate, easy to burn milk, etc., and achieve the effects of simple and easy method, high heating efficiency and high quality milk foam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

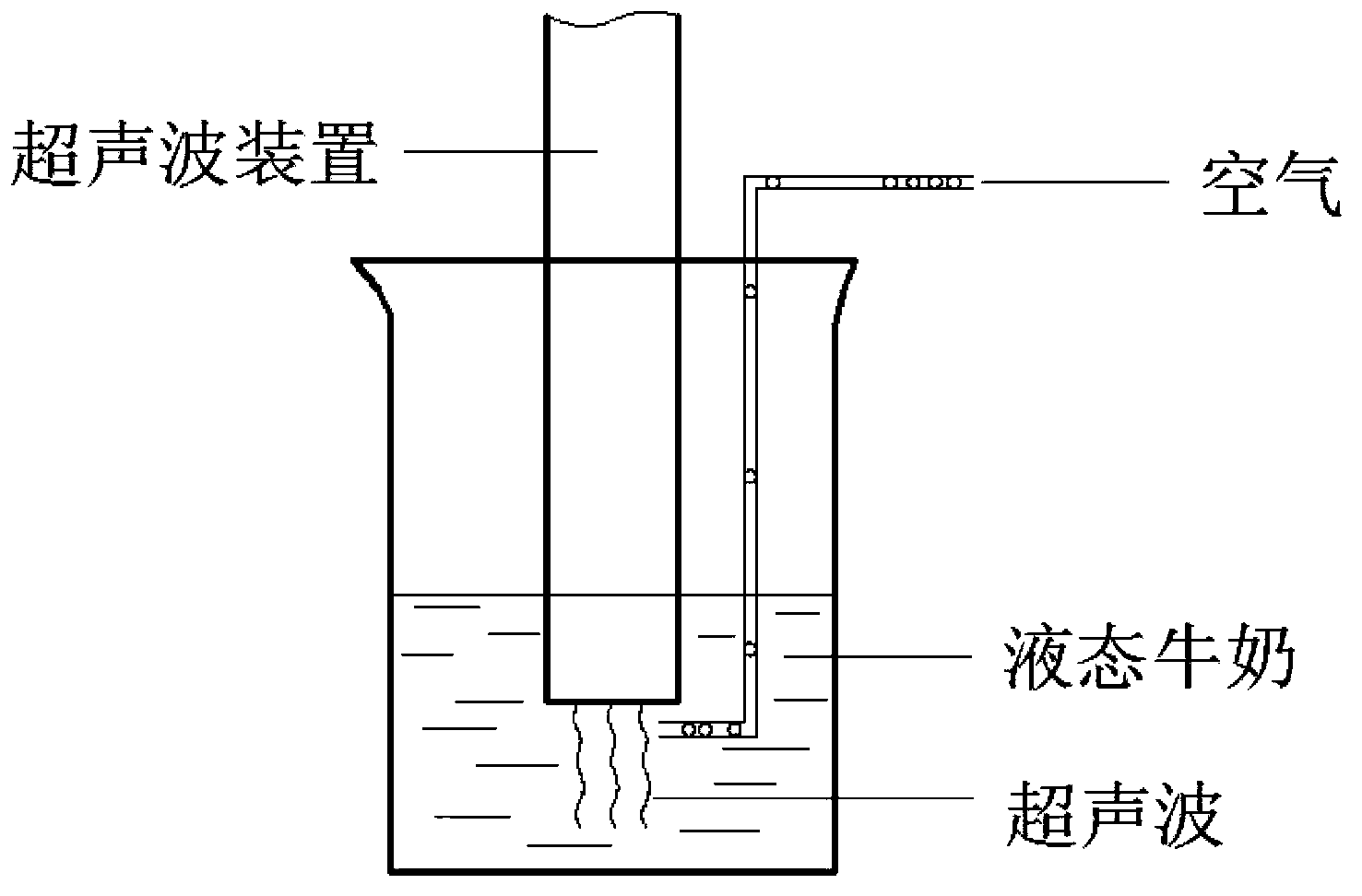

[0026] A method for frothing milk by ultrasonic waves, comprising the following steps:

[0027] Step 1: Put the milk liquid in the container;

[0028] Step 2: Place the ultrasonic device above the liquid surface of the milk or immerse it in the milk, and adjust the height of the ultrasonic device above the liquid surface of the milk or the depth of immersion into the milk;

[0029] Step 3: Run the ultrasonic device to ultrasonically treat the liquid milk;

[0030] Step 4: After the ultrasonic treatment is completed for a predetermined time, stop the operation, complete the frothing, and pour out the milk froth.

[0031] In the above step three, air is introduced into the milk while the ultrasonic device is running.

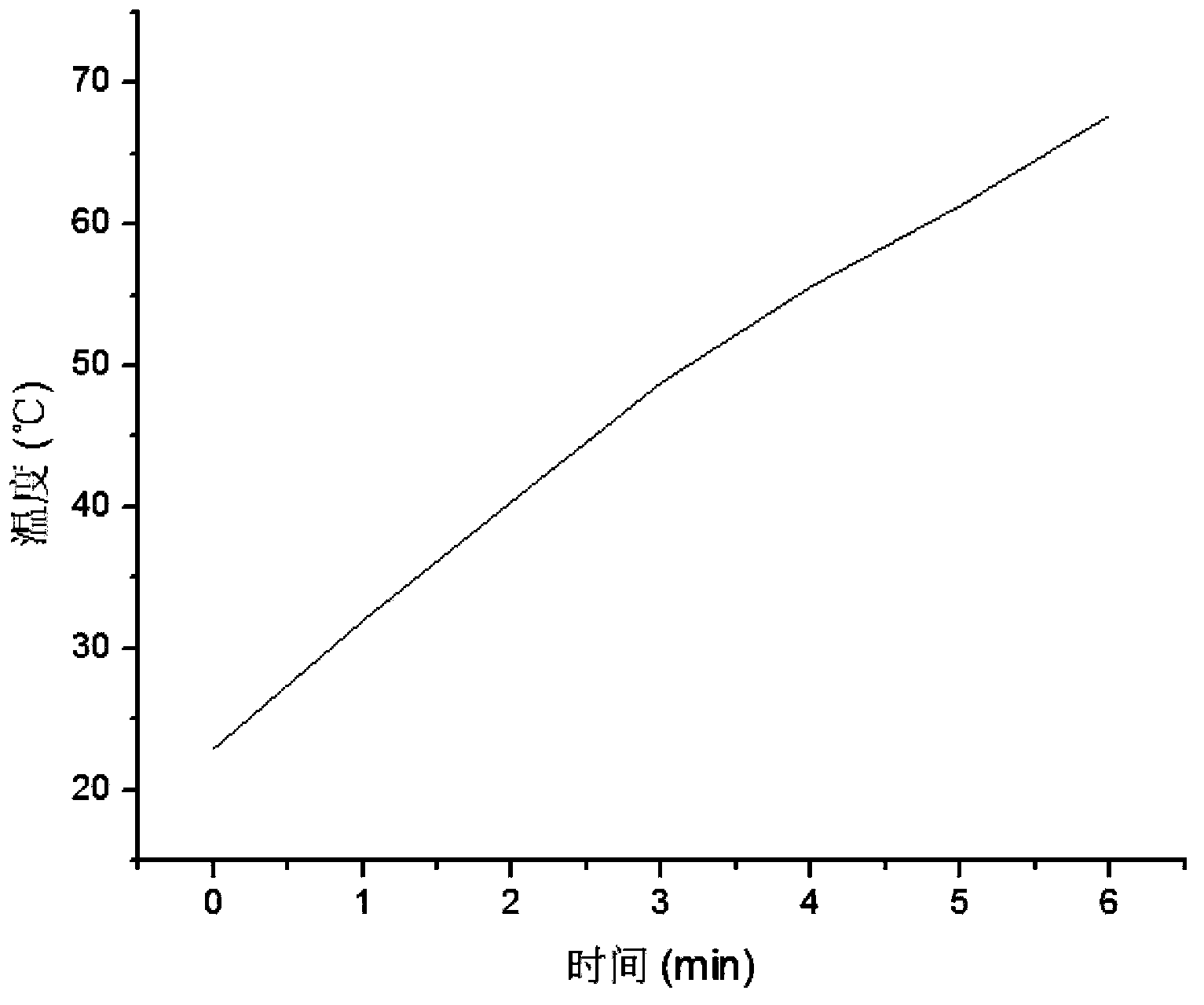

[0032] The frequency of the ultrasonic device is between 20K-40KHz; the power of the ultrasonic device is between 100W-1000W. Milk types include whole, semi-skimmed, and whole-skimmed; milk treatments include pasteurization and pasteurization. Ultrasonic proce...

Embodiment 2

[0045] The milk used in embodiment two is ordinary pure milk. The specific parameters are shown in Table 2.

[0046] Table 2

[0047] factor

parameters

ultrasonic frequency

20K-40KHz

Ultrasonic power

500-800W

milk consumption

100ml

Initial temperature of milk

10-15℃

Immersion depth

5-15mm

processing time

20s-60s

[0048] The method for producing milk froth described in the present embodiment comprises the following steps:

[0049] 1. According to the amount of milk and the initial temperature parameters in Table 2, take the liquid milk and place it in an open cup or an open container;

[0050] 2. Adjust the frequency and power parameters of the ultrasonic device according to Table 2;

[0051] 3. Place the ultrasonic device in liquid milk;

[0052] 4. Adjust the ultrasonic device to the specified height according to the immersion depth parameters in Table 2;

[0053] 5. According to ...

Embodiment 3

[0058] The milk used in Embodiment 3 is ordinary pure milk. The specific parameters are shown in Table 3.

[0059] table 3

[0060] factor

parameters

ultrasonic frequency

20-40KHz

Ultrasonic power

800-1000W

milk consumption

300ml

Initial temperature of milk

20-25℃

Immersion depth

15-25mm

processing time

120s-240s

[0061] The method for producing milk froth described in the present embodiment comprises the following steps:

[0062] 1. According to the amount of milk and initial temperature parameters in Table 3, take liquid milk and place it in an open cup or container;

[0063] 2. Adjust the frequency and power parameters of the ultrasonic device according to Table 3;

[0064] 3. Place the ultrasonic device in liquid milk;

[0065] 4. Adjust the ultrasonic device to the specified height according to the immersion depth parameters in Table 3;

[0066]5. According to table 3 processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com