Milk module for generating milk foam or milk beverages, preferably for installing into coffee machine

A technology for milk beverages and coffee machines, applied in the field of milk modules, can solve problems such as structural construction difficulties and limitations, and achieve the effects of simple cleaning, simple and accurate rationing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

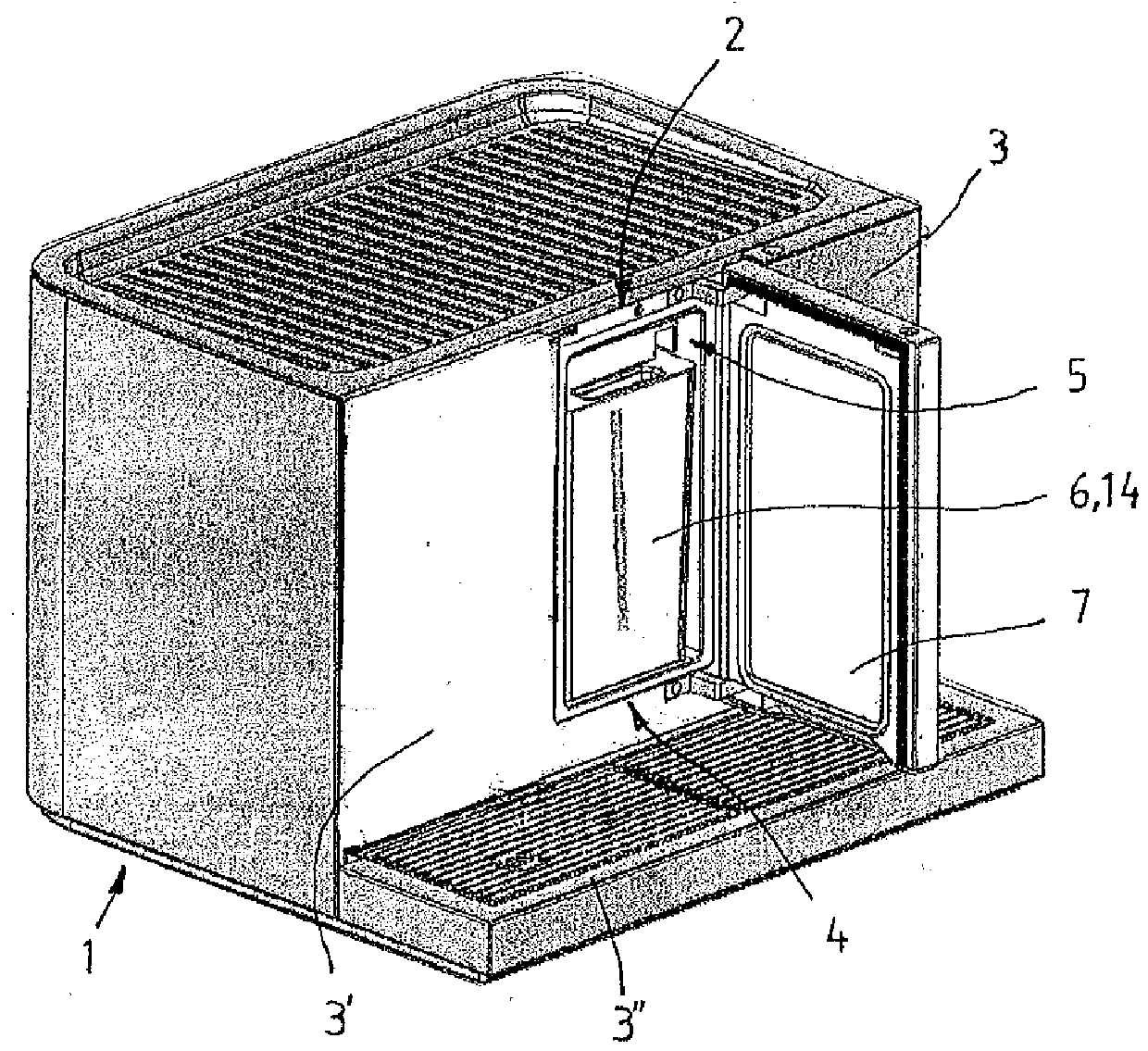

[0018] exist figure 1 The coffee machine 1 with a housing 3 shown in is used for the automatic production of coffee or coffee-containing beverages as well as mixed beverages consisting of coffee and milk or milk foam. The coffee machine consists of a coffee module for producing coffee (of which only the opening 3' in the housing 3 for mounting this module is shown exactly) and a milk module 2 for preparing milk or milk froth, which can be independent of each other are mounted side by side in the common housing 3 in a space-saving manner. The coffee module 1 itself consists of conventional components and is not explained in detail. On the front side in the housing 3 is only shown a drip container (Abtropfschale) 3'', on which a cup or the like for filling coffee and / or milk or milk froth can be placed.

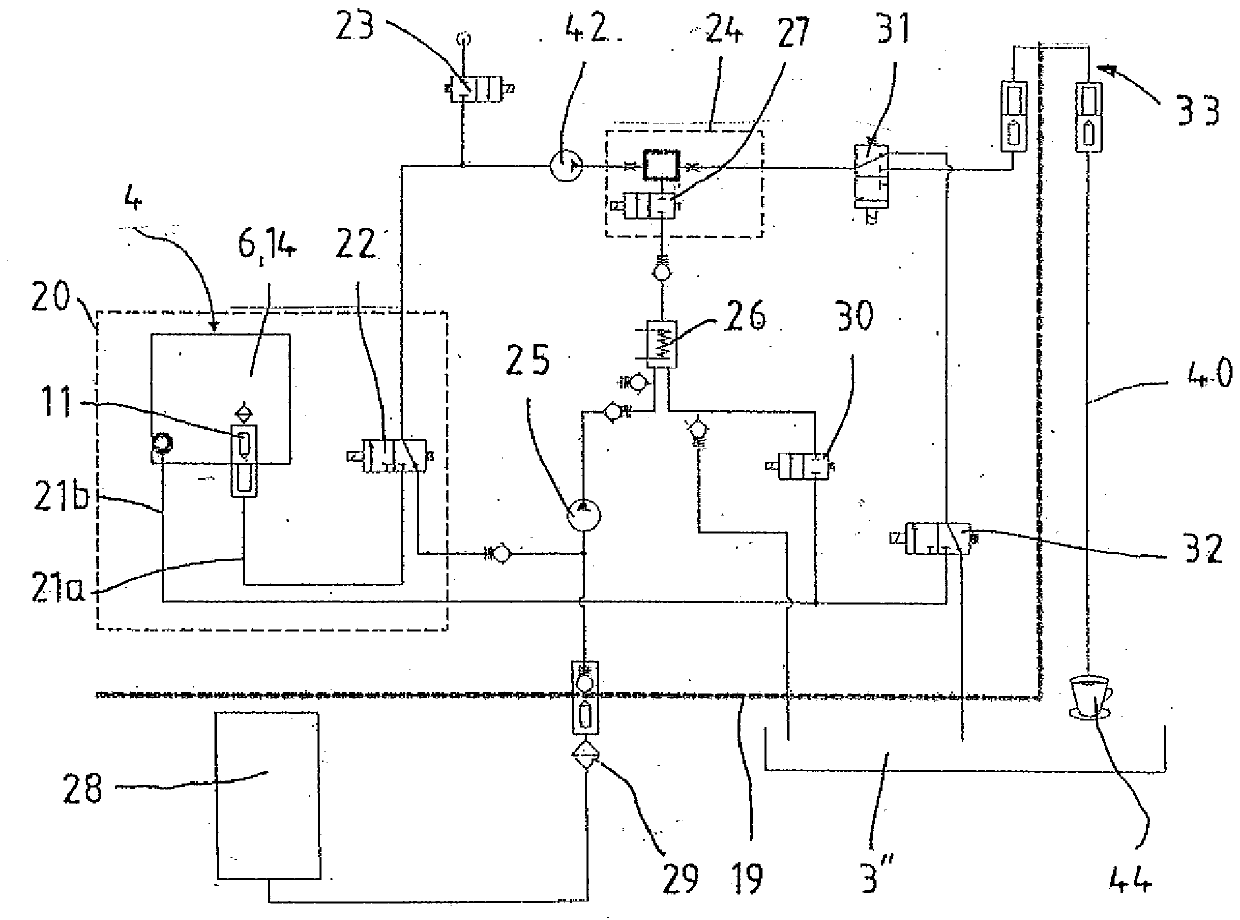

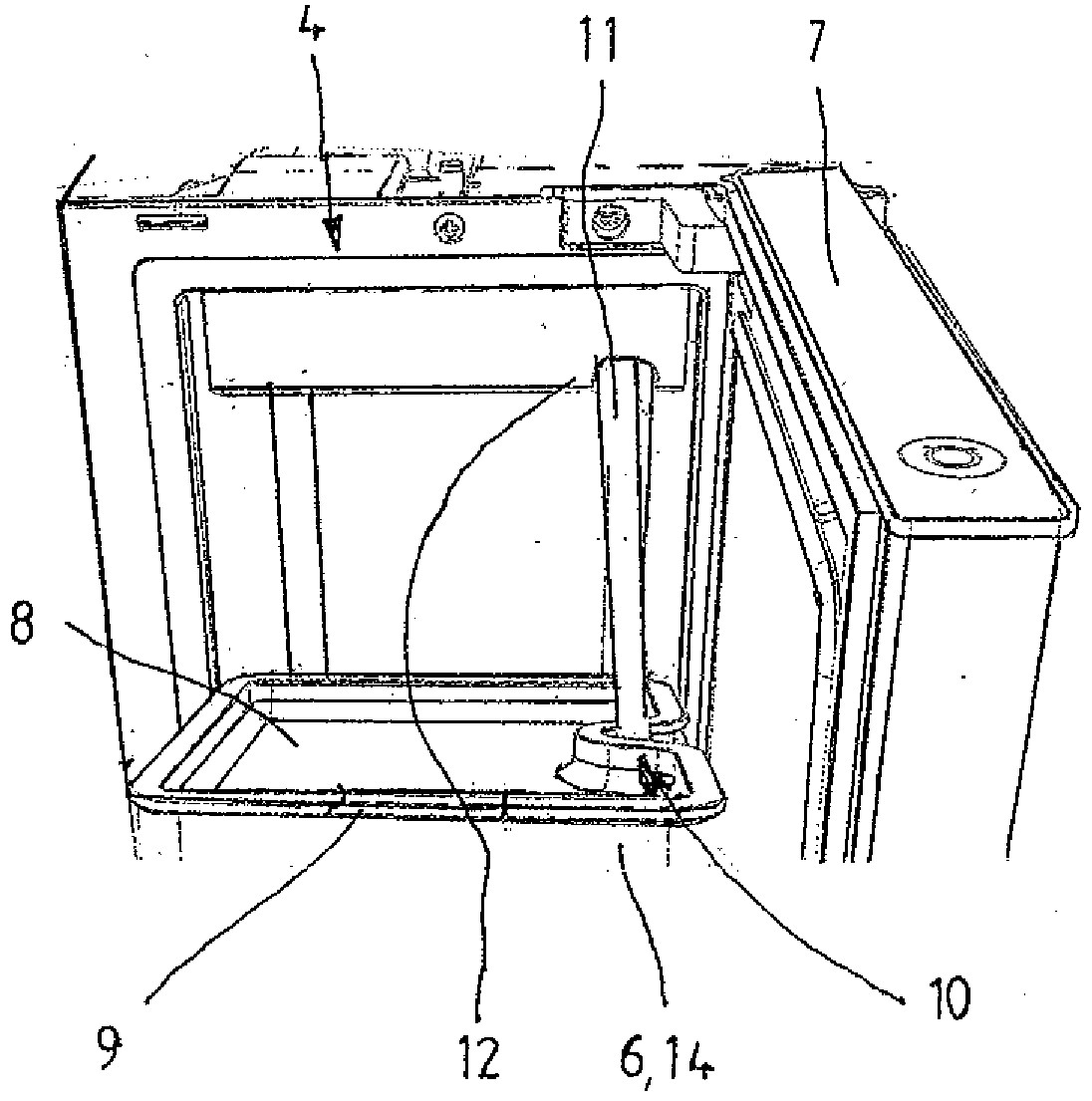

[0019] The milk module 2 , which can be installed in the housing 3 , is equipped with a cooling box 4 , the cooling chamber 5 of which can accommodate a milk container 6 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com