Corrugated film and manufacturing method thereof

A manufacturing method and a corrugated membrane technology are applied to the corrugated membrane and the manufacturing field thereof, which can solve the problems of consuming a lot of manpower and material resources, prone to wire breakage, and high energy consumption for aeration, and achieve an environmentally friendly processing and manufacturing method, a simple processing and manufacturing method, and a high working efficiency. pressure wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

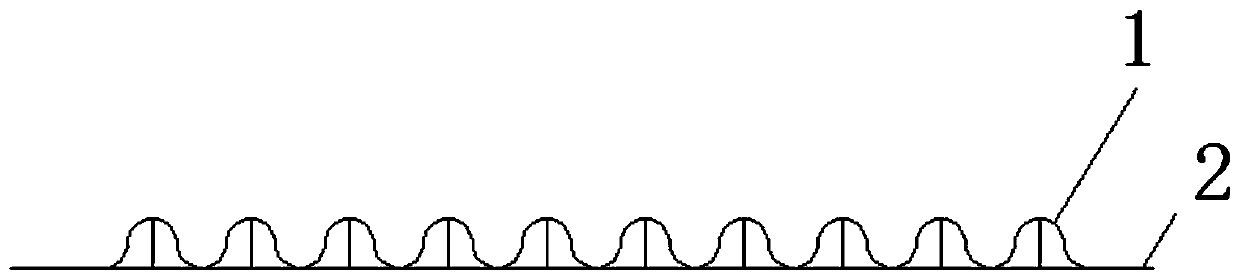

[0031] figure 1 A schematic structural diagram of the corrugated membrane provided in Embodiment 1 of the present invention; as figure 1 As shown, in the corrugated membrane provided in the first embodiment of the present invention, a support structure 2 is provided inside the corrugated membrane 1 .

[0032] Specifically, the support structure 2 is a support member disposed inside the corrugated membrane 1 .

[0033] Specifically, the support is a T-shaped support.

[0034] In the present application, the support structure 2 is provided inside the corrugated membrane 1, which greatly improves the compression resistance performance of the corrugated membrane 1, so that the applicable working pressure of the corrugated membrane 1 is wider.

[0035] It should be noted that, the support member in this embodiment is a T-shaped support member only for illustration, and other support members may also be used, which will not be repeated here.

Embodiment 2

[0037] figure 2 A schematic structural diagram of the corrugated membrane provided in Embodiment 2 of the present invention; as figure 2 As shown, in the corrugated membrane provided in the second embodiment of the present invention, a support structure 2 is provided inside the corrugated membrane 1 .

[0038] Specifically, the support structure 2 is a support member disposed inside the corrugated membrane 1 .

[0039] Specifically, the support is a cross-shaped support.

[0040] In the present application, the support structure 2 is provided inside the corrugated membrane 1, which greatly improves the compression resistance performance of the corrugated membrane 1, so that the applicable working pressure of the corrugated membrane 1 is wider.

[0041] It should be noted that, the supporting member in this embodiment is a cross-shaped supporting member only for illustration, and other supporting members may also be used, which will not be repeated here.

Embodiment 3

[0043] The corrugated film provided in the third embodiment is a further improvement of the corrugated film provided in the first embodiment. figure 1 On the basis of the corrugated membrane provided in the third embodiment, a support structure 2 is provided inside the corrugated membrane 1 .

[0044] Specifically, the support structure 2 is a support member disposed inside the corrugated membrane 1 .

[0045] Specifically, the support is a T-shaped support.

[0046] In the present application, the support structure 2 is provided inside the corrugated membrane 1, which greatly improves the compression resistance performance of the corrugated membrane 1, so that the applicable working pressure of the corrugated membrane 1 is wider.

[0047] It should be noted that, the support member in this embodiment is a T-shaped support member only for illustration, and other support members may also be used, which will not be repeated here.

[0048] Specifically, the corrugated shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com