Precision sandblasting processing machine and processing method for thin and fragile plates

A technology of precision machining and sand blasting, applied in metal processing equipment, abrasive jet machine tools, manufacturing tools, etc., can solve the problems of waste of resources, seldom used, low production efficiency, etc., to reduce waste of resources and reduce production costs , The effect of product yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

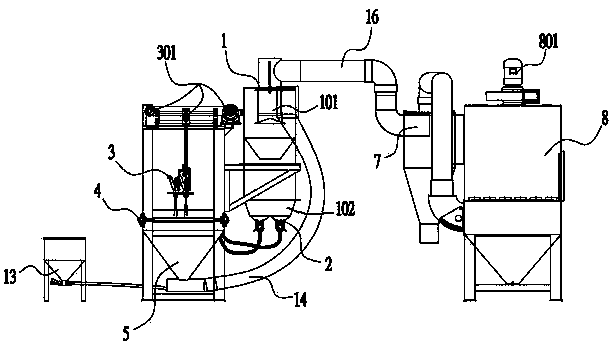

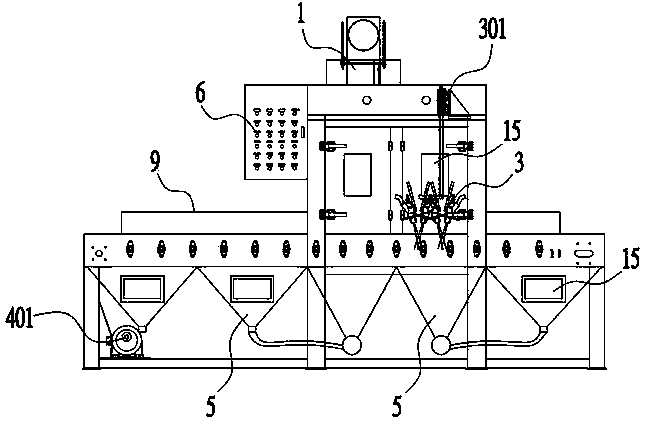

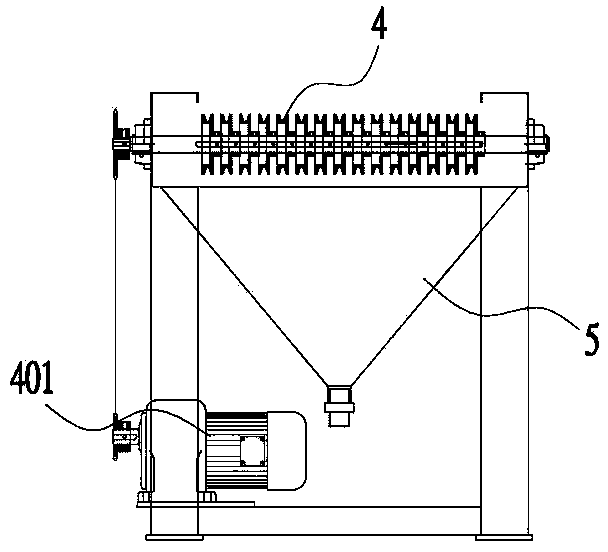

[0028] Embodiment one, such as Figure 1 ~ Figure 4 As shown, in this specific embodiment, the precision sandblasting machine for thin and fragile plates includes a body, which is provided with a primary cyclone separation device 1, a constant sand feeding device 2, a sandblasting device 3, and an air compressor (in the figure not shown), thin and fragile plate conveying device 4, sand return device 5 and control device 6; wherein: primary cyclone separation device 1 includes cyclone separator 101 and sand storage box 102 located below the cyclone separator 101, The cyclone separator 101 is used to separate sand material and dust from the sand return device 5, and the sand outlet of the sand storage box 102 is connected with the sand inlet of the constant sand feeder 2; The sandblasting device 3 transports sand material at a constant flow rate; the sandblasting device 3 is installed above the thin fragile plate conveying device 4, and is used to spray sand material to the thin...

Embodiment 2

[0035]Embodiment 2, a precision processing method for thin fragile plates, is used to process thin fragile plates into several pieces of products, and the several pieces of products respectively have shapes designed according to requirements. The processing method includes the following steps:

[0036] a. Attach a soft photosensitive film or peelable adhesive or photosensitive ink on the thin and fragile board;

[0037] b. According to the shape of several pieces of products, cover a layer of opaque negative film or graphic masking layer on the soft photosensitive film or peelable glue or photosensitive ink area outside the several pieces of products;

[0038] c. Use ultraviolet rays to irradiate the thin and fragile plates attached with soft photosensitive film or peelable glue or photosensitive ink to cure the soft photosensitive film or peelable glue or photosensitive ink in several product areas;

[0039] e. Dissolving and removing the uncured soft photosensitive film or p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com