Machining method of durable welding current contact nozzle easy to machine

A manufacturing method and technology of contact tip, which are applied to electrode accessories, characteristics of welding rods, etc., can solve the problems of complex conductive inner core structure, single manufacturing method, low production efficiency, etc., and achieve shortened production time, low production cost and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

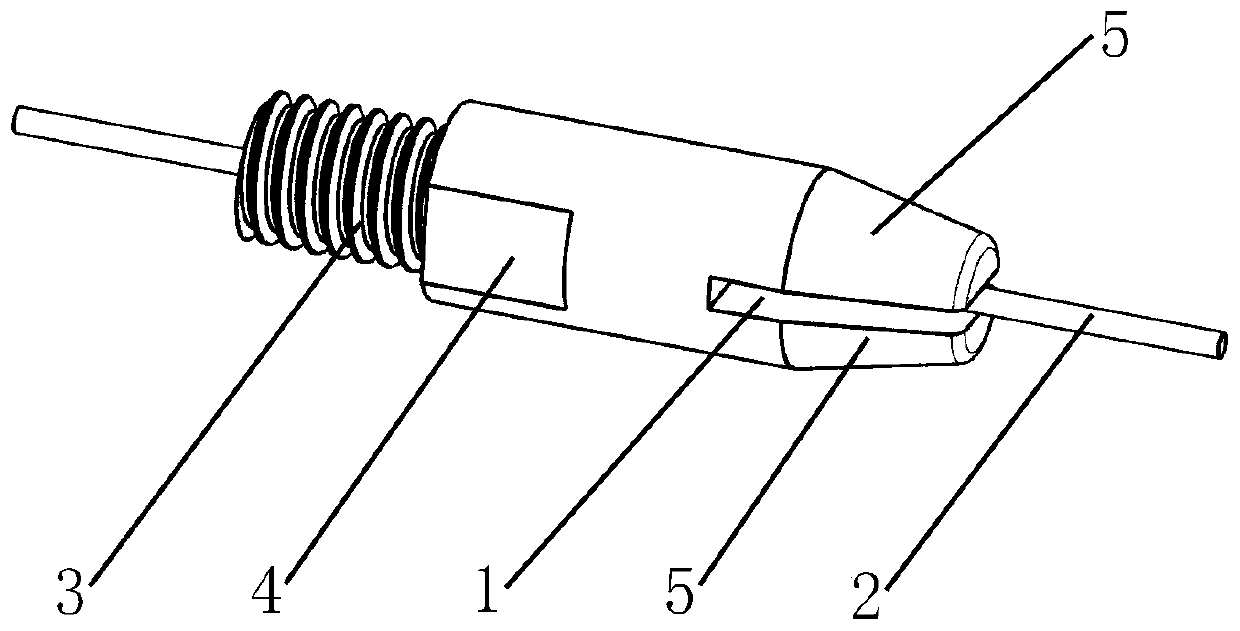

[0054] Embodiment 1: as figure 1 Shown, open a long about 2-30 millimeters long, wide about 0.01-6 millimeter straight shape gap 1 at the front end of common conductive tip. The gap 1 needs to pass through the center of the inner hole of the contact tip, and divide the front end of the contact tip into two upper and lower conductive blocks 5 . In order to avoid the misalignment of gap 1 and the inner hole of the contact tip caused by machining errors and reduce the difficulty of processing, a cutting piece with a thickness slightly larger than the diameter of the inner hole of the contact tip is selected. In this way, the width of the gap 1 cut out is larger than that of the inner hole. Even if there is a deviation during processing, the inner hole of the contact tip and the gap 1 will not be misaligned. Finally, the upper and lower conductive blocks 5 are properly pressed inward, so that the heads of the two conductive blocks 5 are closed, and the easy-to-process and durable...

Embodiment 2

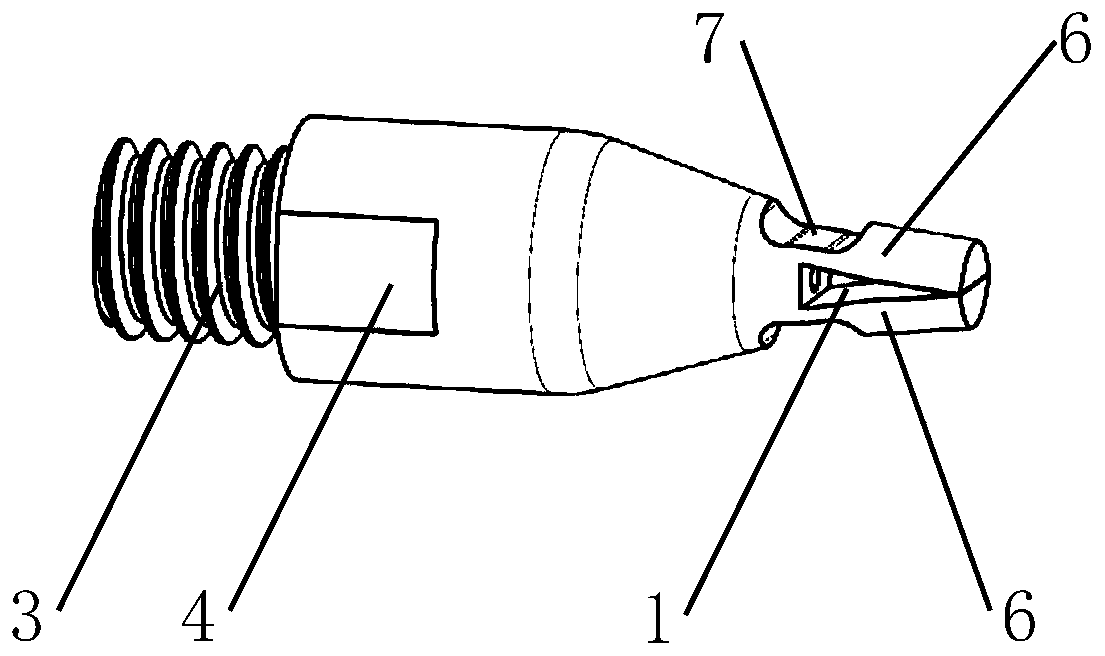

[0055] Embodiment 2: as figure 2 As shown, in this embodiment, high-strength, high-conductivity copper alloy materials such as chrome-zirconium copper, phosphor bronze, tin bronze, etc. should be selected to make easy-to-process and durable contact tips. In order to facilitate processing, the front end of the contact tip is first processed into a cylinder, the cylinder is about 2-30 mm long, and the diameter of the cylinder is 2.5-5 times that of the welding wire 2. Two mutually symmetrical gaps 7 are opened at the rear end of the cylinder, so that the material thickness of the remaining part between the two gaps 7 is 2-4 times of the diameter of the welding wire 2 . Process the notch 1 with a cutting sheet, the notch 1 passes through the center of the inner hole of the conductive tip, and is parallel to the notch 7, the heel of the notch 1 is in the middle or the middle rear of the notch 7, the purpose is to press the elastic conductive block 6 When closed, the heel of the ...

Embodiment 3

[0057] Embodiment 3: as image 3As shown, in order to further increase the service life of the contact tip, more material must be provided for the wear of the contact tip. The diameter of the cylinder at the front end of the contact tip is increased to 3.2-5 times the diameter of the welding wire 2, and the length of the cylinder is about 4-15 mm. Cut off the material on both sides of the cylinder, first cut 2-10 mm straight from the front to the back, and then cut obliquely toward the outer edge of the contact tip. The parts cut off on both sides have a symmetrical structure. The remaining part of the material in the middle forms a thickened conductive block 8, and the width of the thick conductive block 8 is slightly smaller than the diameter of the welding wire 2. There is a positioning arc surface 9 inside the thickened conductive block 8, and the positioning arc surface 9 constrains the welding wire 2 to ensure the accuracy of the wire output. The heads of the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com