Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Suppress parasitic oscillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

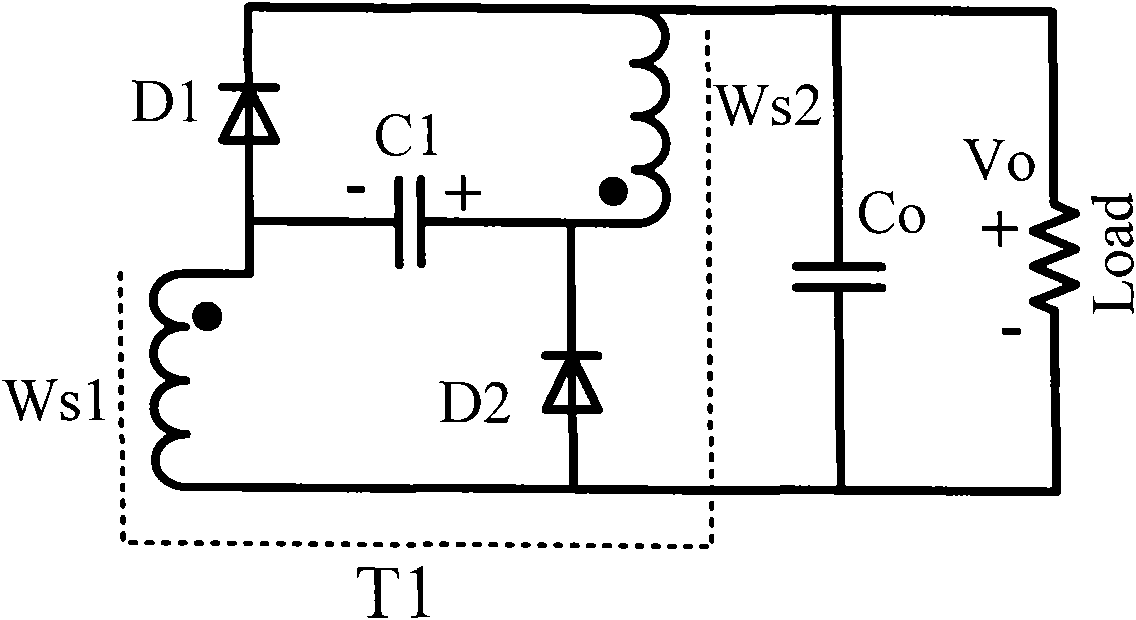

Zero-voltage switch flyback-type DC-DC power supply conversion device

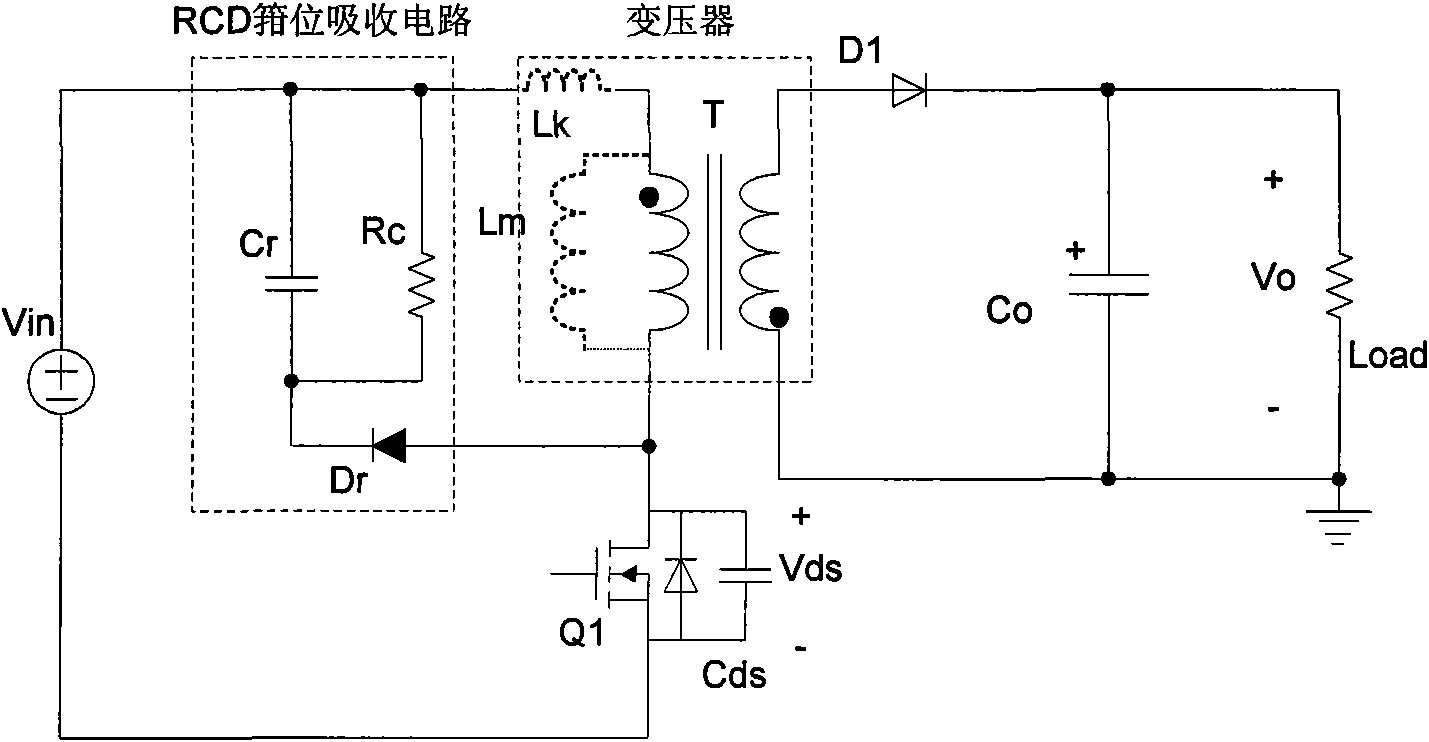

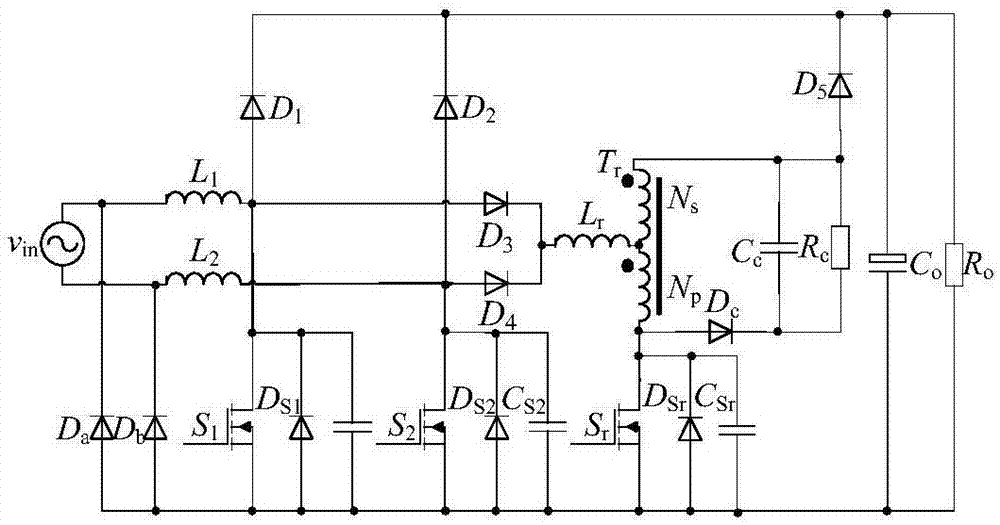

ActiveCN101572490AEasy to controlImprove efficiencyEfficient power electronics conversionDc-dc conversionCapacitanceTransformer

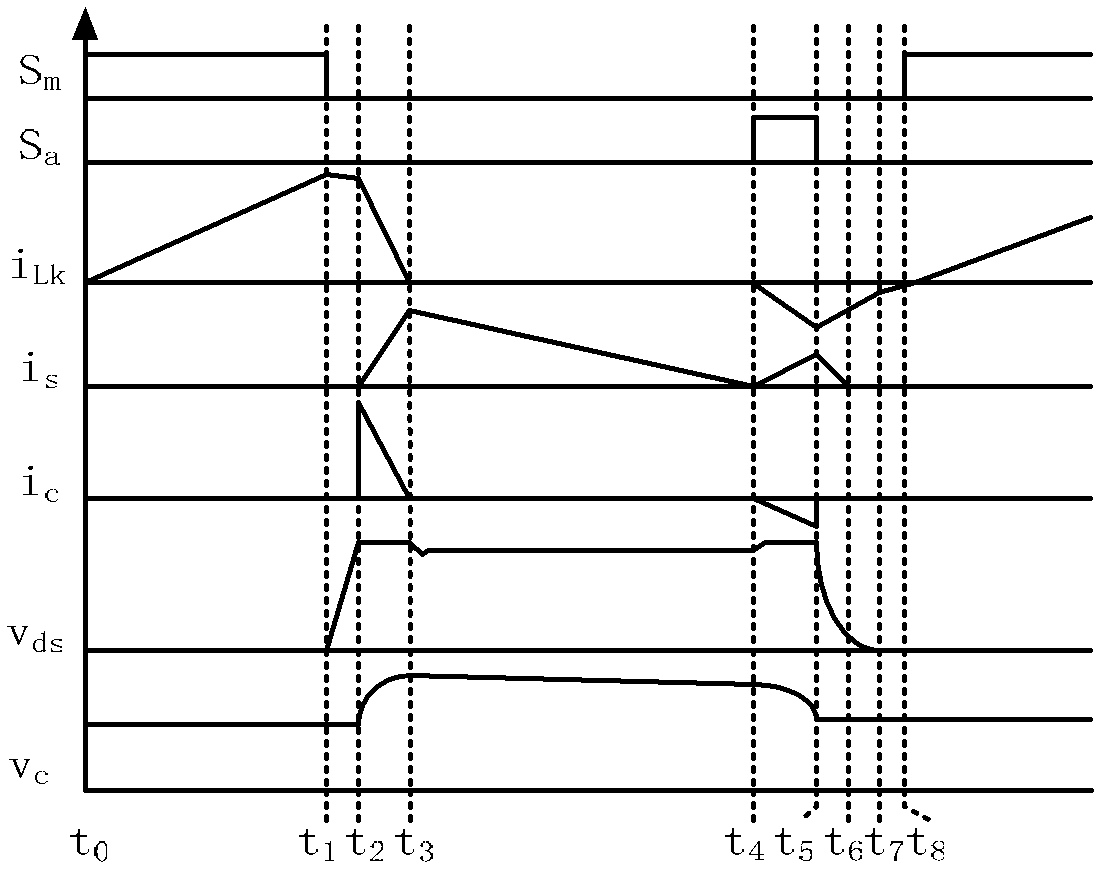

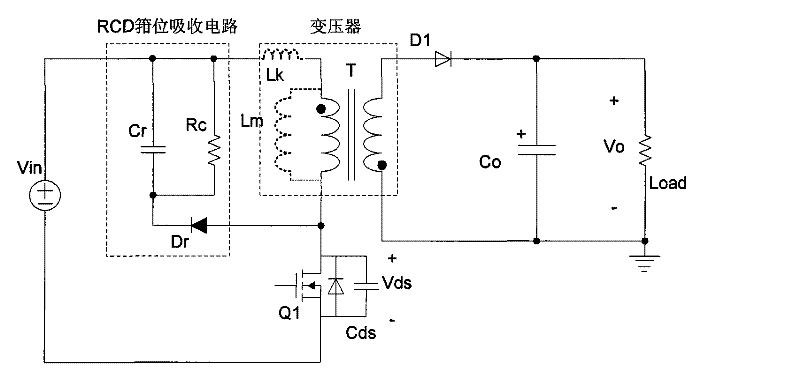

The invention relates to a DC-DC power supply conversion device, in particular to a zero-voltage switch (ZVS) flyback-type DC-DC power supply conversion device with efficient conversion, efficient light-load conversion and low standby power consumption. An auxiliary switch and an absorption capacitor are additionally arranged on the flyback circuit; the auxiliary switch and the absorption capacitor are connected in series so as to form an auxiliary branch circuit; the auxiliary branch circuit can be connected in parallel to the two ends of the primary winding of a transformer or alternatively connected in parallel to the two ends of a primary-side switch; and the auxiliary switch is conductive for a determined period of time before the primary-side switch is conductive. Compared with the prior art, the energy of the circuit leakage inductor can be absorbed and transferred to the output terminal and a soft switch for realizing the primary-side switch, so that the invention can greatly improve the circuit efficiency; the parasitic oscillation caused by the leakage inductor can be suppressed, so that the EMI (electromagnetic interference) characteristics of the circuit can be improved; and the circuit can be controlled more easily, thereby improving the light-load circuit efficiency and reducing the idle-load energy loss.

Owner:DELTA ELECTRONICS SHANGHAI CO LTD

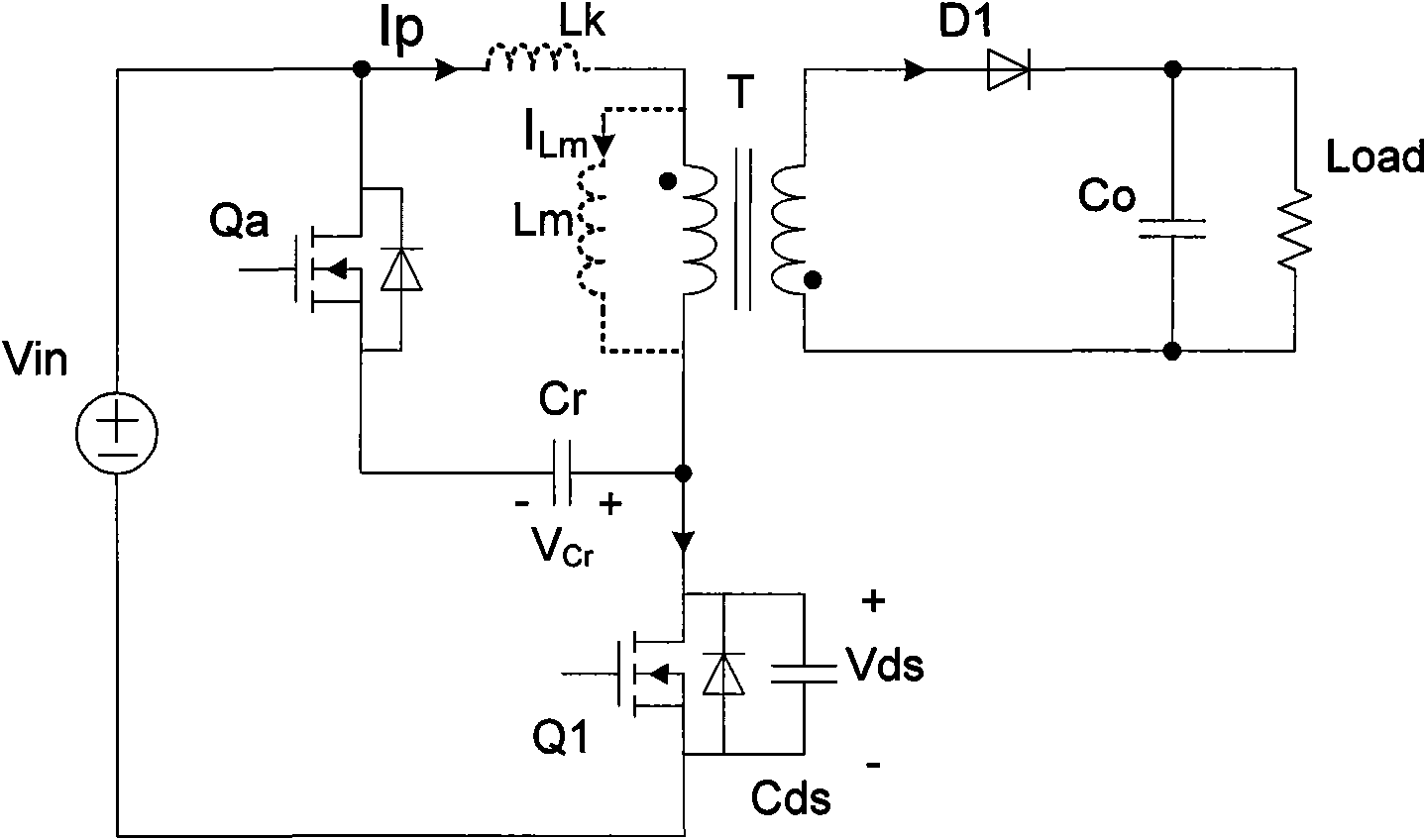

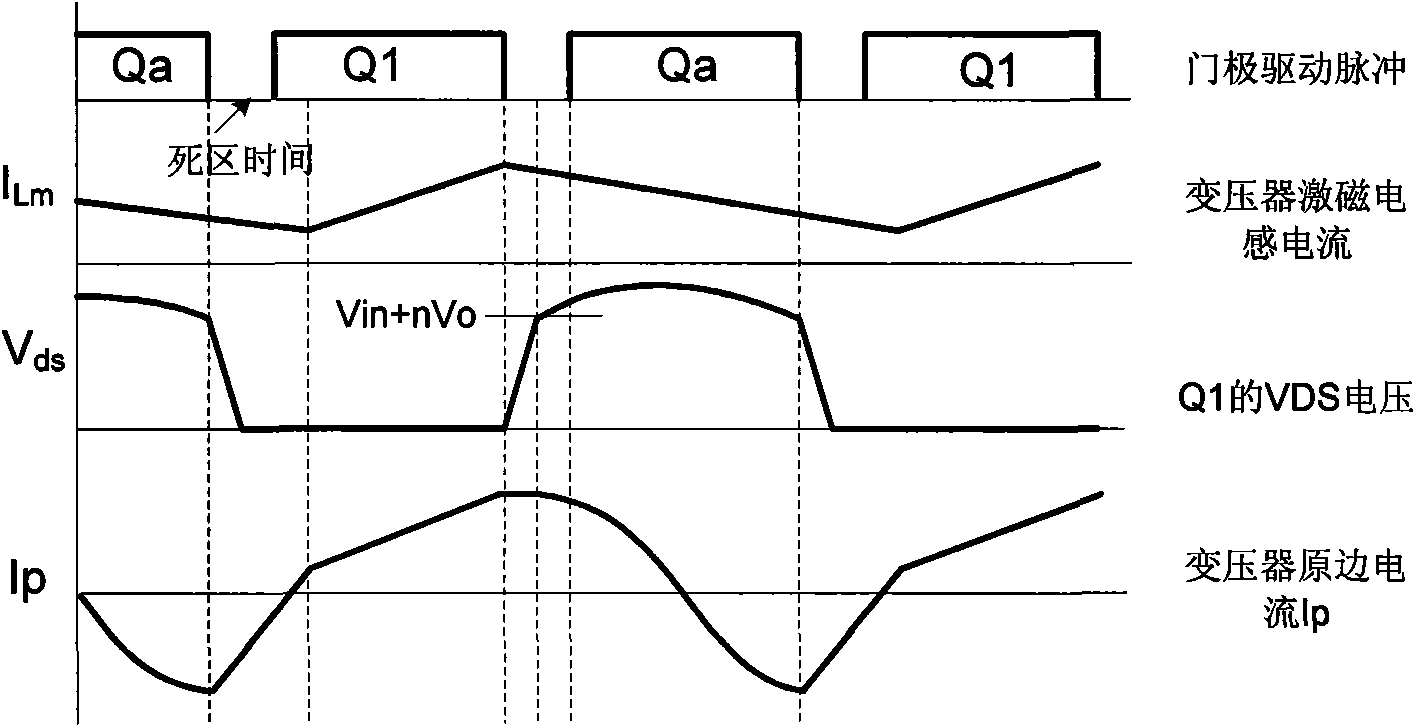

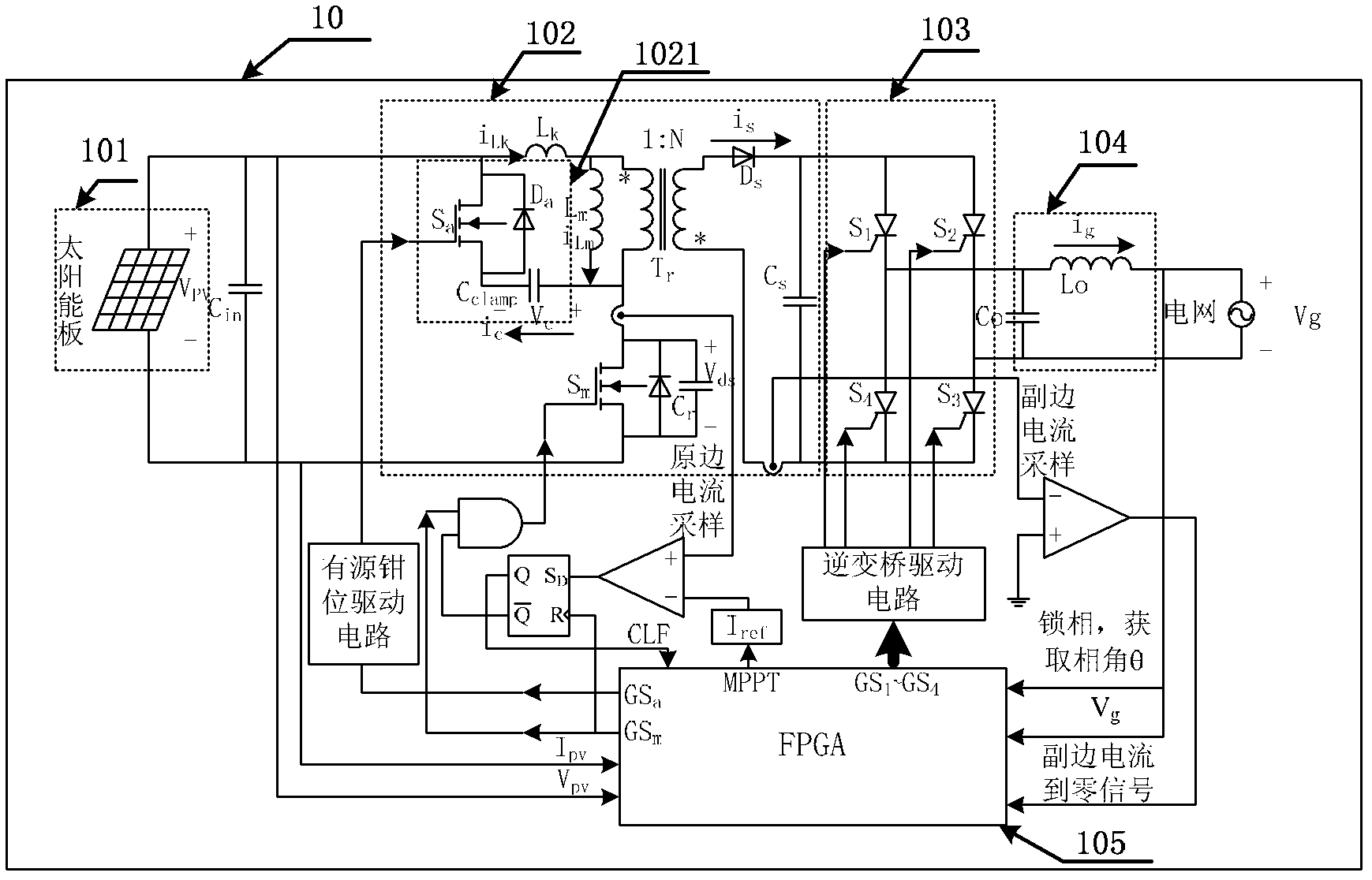

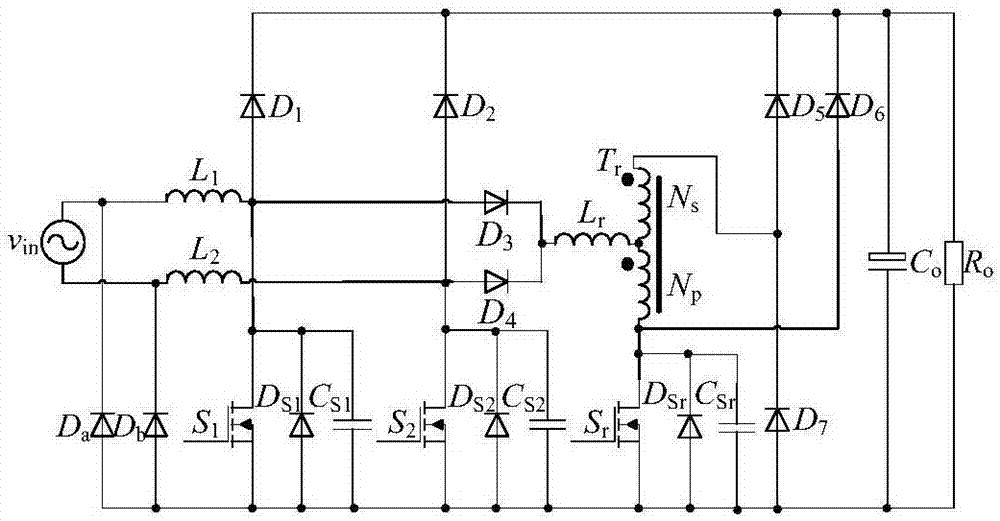

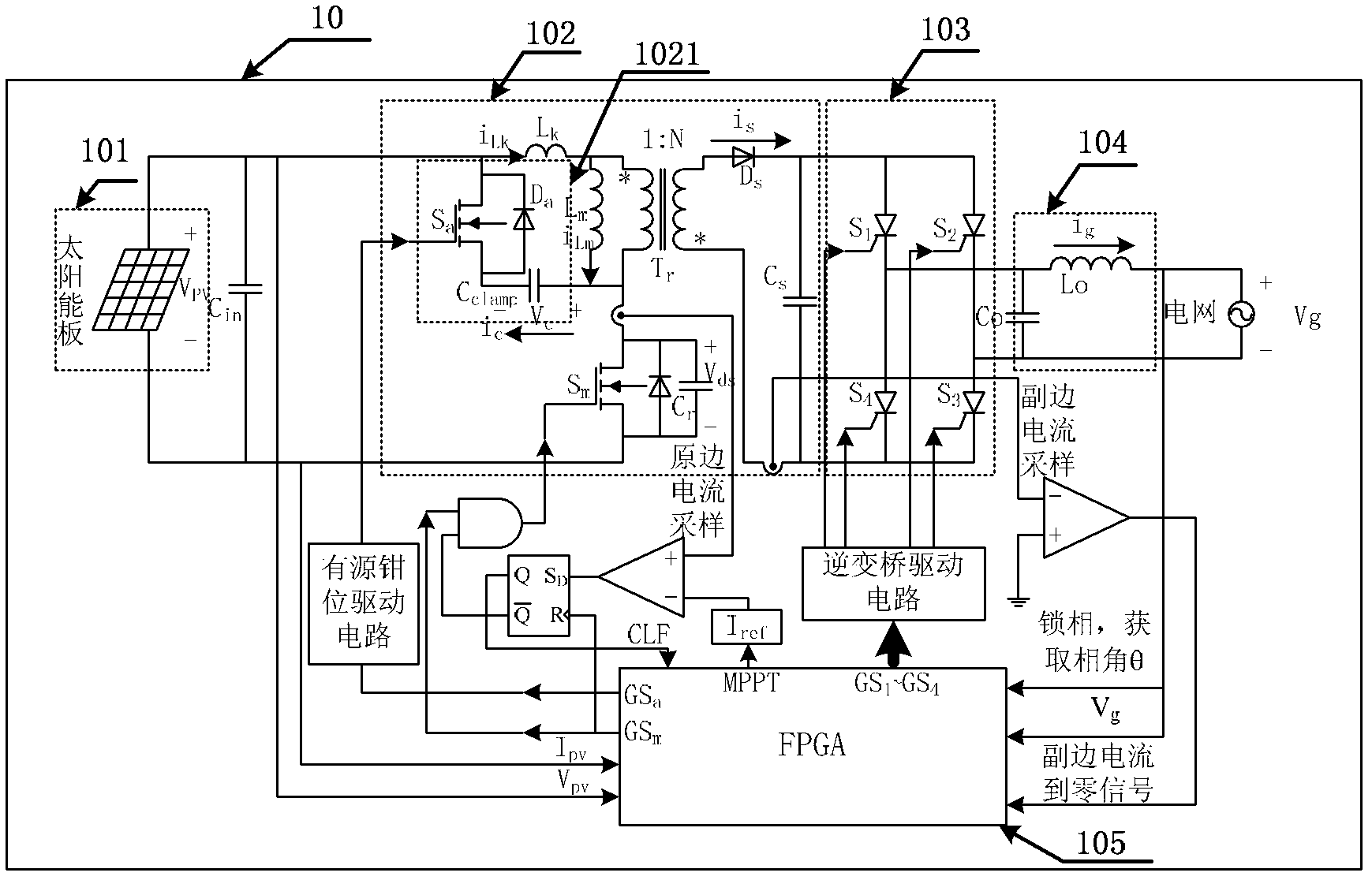

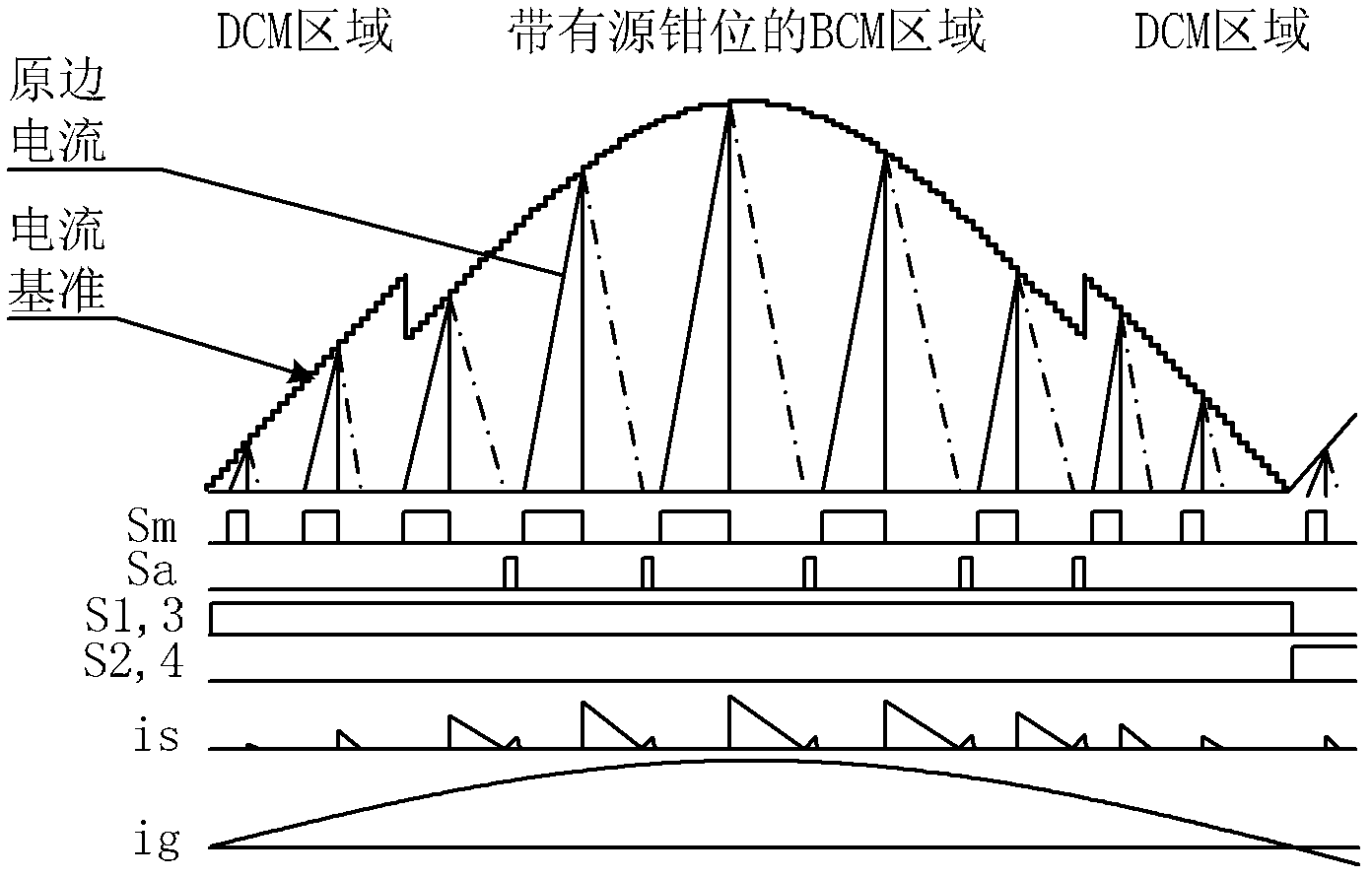

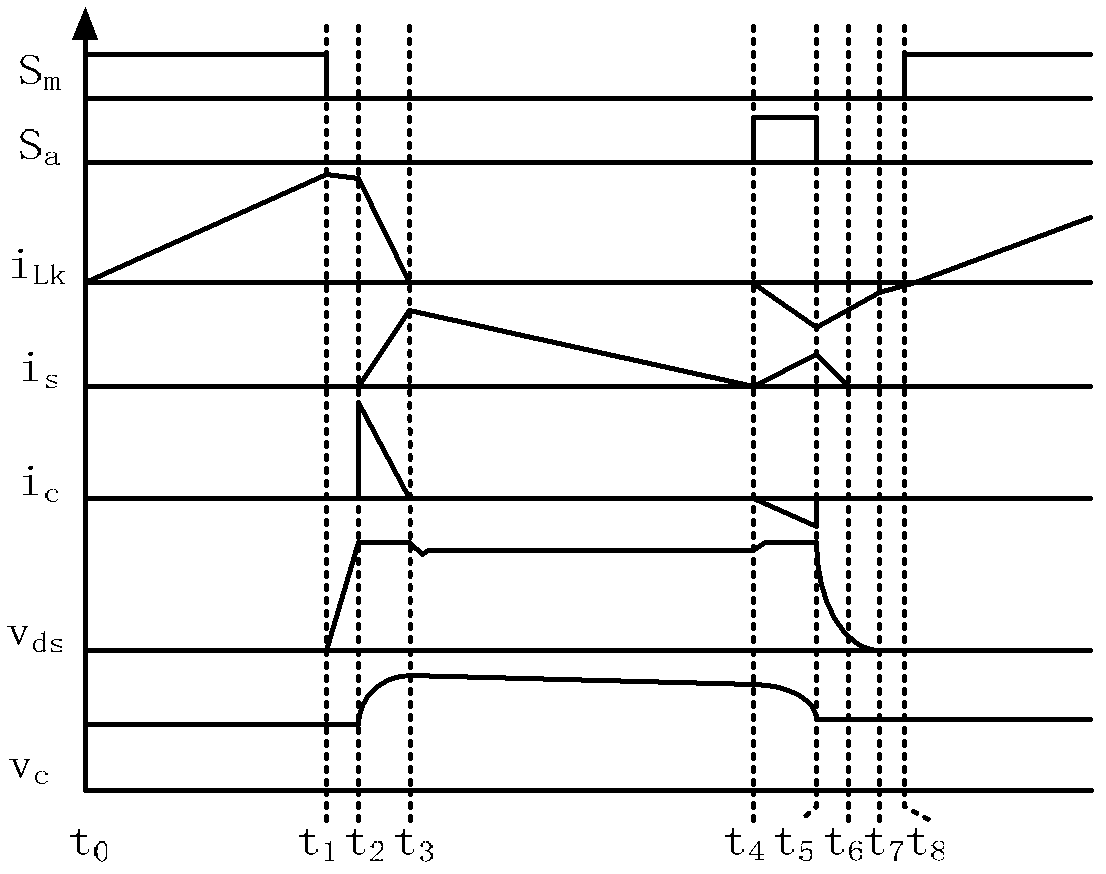

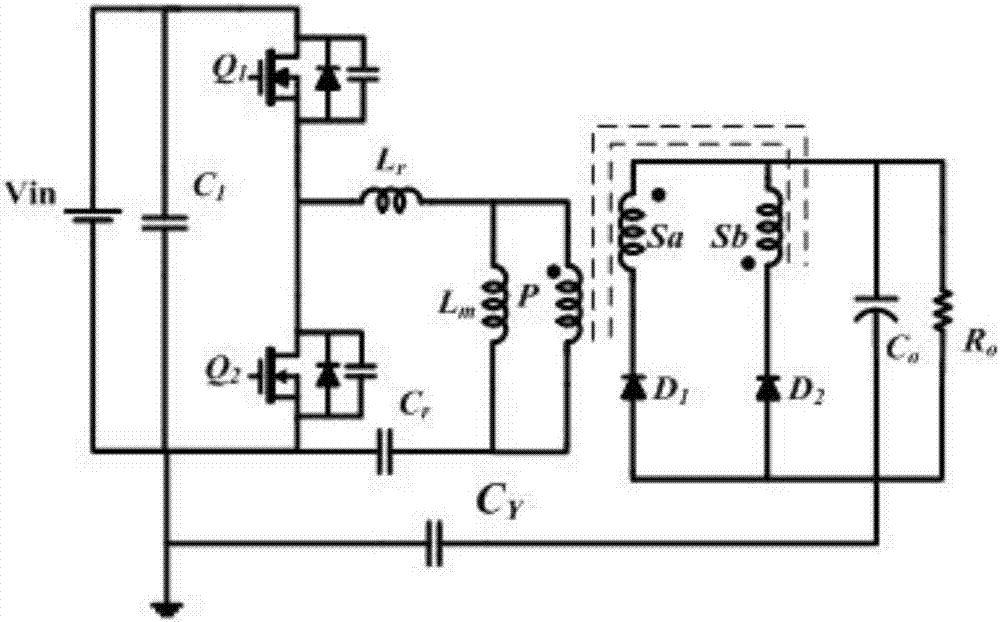

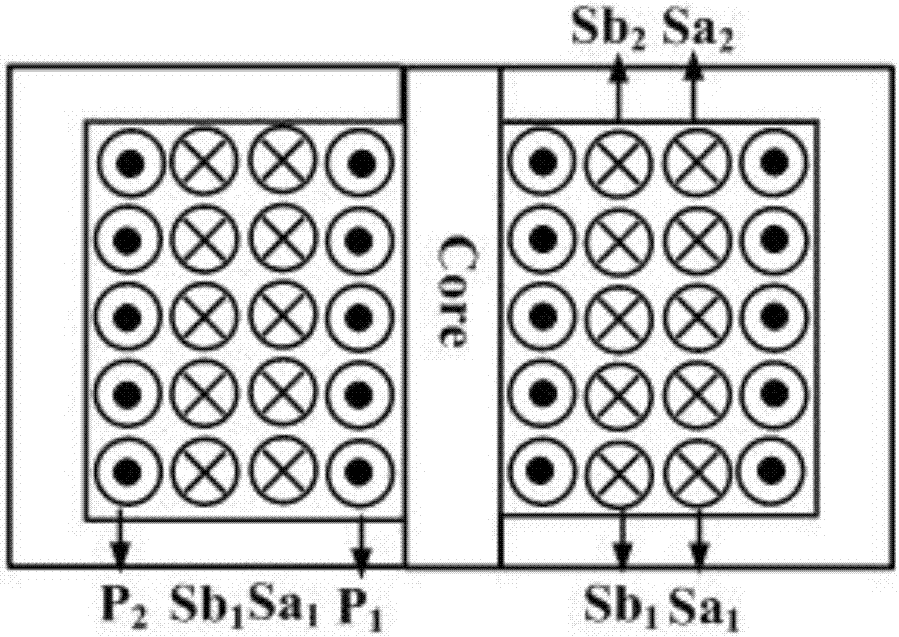

Control method applied to active-clamp flyback miniature photovoltaic grid-connected inverter device

ActiveCN102307017AImprove EMI characteristicsImprove efficiencyDc-dc conversionPhotovoltaic energy generationConstant frequencyPeak value

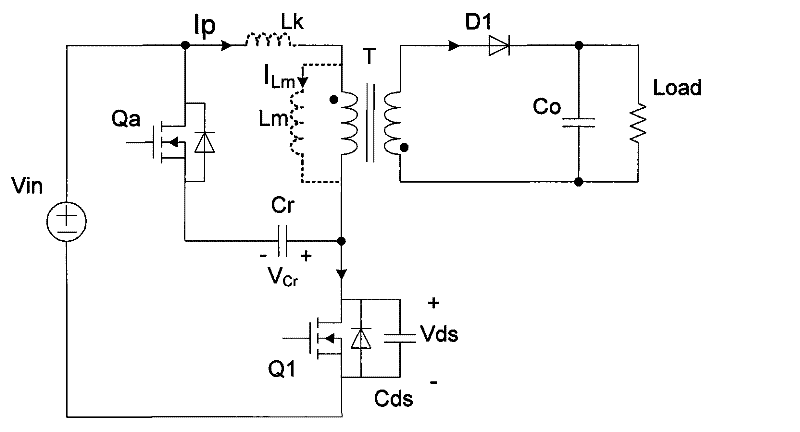

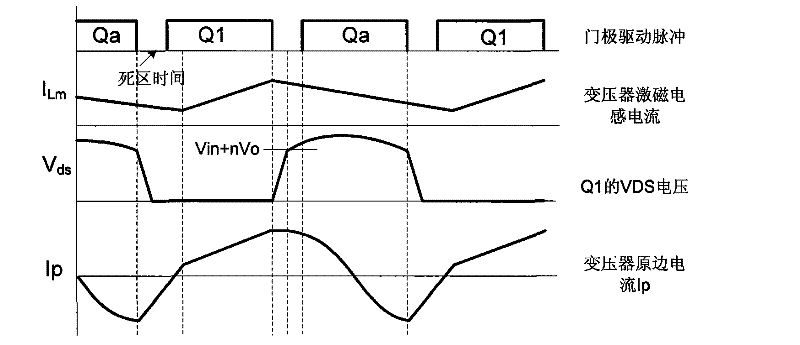

The invention relates to a control method which can be applied to an active-clamp flyback miniature photovoltaic grid-connected inverter device. The active-clamp flyback miniature photovoltaic grid-connected inverter device comprises a flyback converter and a power frequency polarity conversion circuit. In the device, a current reference is used for controlling a flyback primary-side current peak value so that the device can output a half-wave sinusoidal current, and the output voltage is clamped by a grid voltage. When the instantaneous power is lower, a constant frequency current discontinuous mode in combined with a variable frequency current critical continuous mode is adopted in the flyback control method. When the flyback converter works in a variable frequency current critical discontinuous mode, an auxiliary switching tube can be conducted for a period of time when the secondary-side current of the flyback converter reaches zero, the conduction time can be accurately controlled by a digital chip, thus realizing the leakage inductance energy feedback and the soft switch of a master switching tube under the condition of wide-range output voltages and different instantaneous powers and greatly improving the efficiency under the condition of full loads.

Owner:ALTENERGY POWER SYST

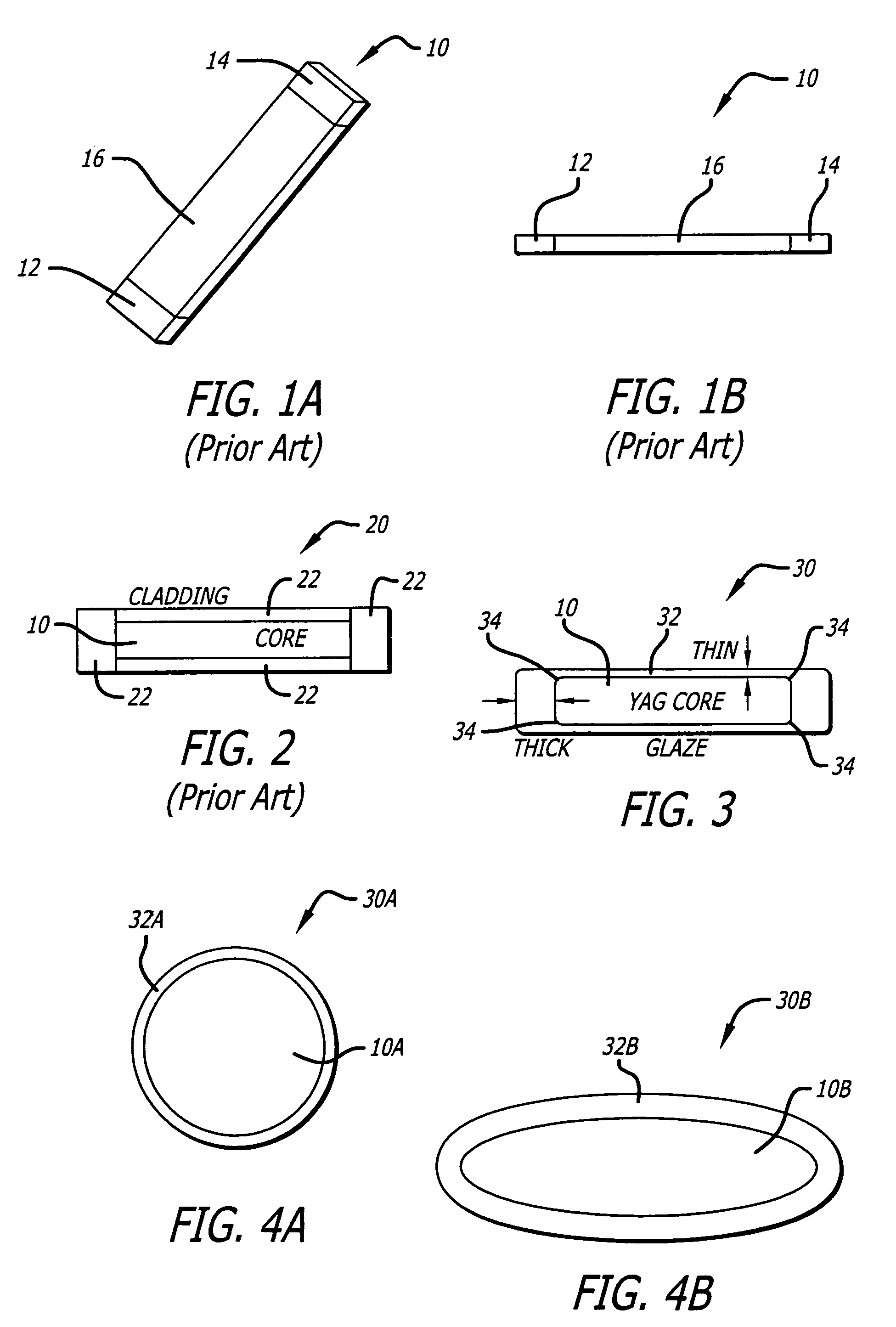

Gain media edge treatment to suppress amplified spontaneous emission in a high power laser

InactiveUS20050254536A1Minimizing thermally induced stressSuppress parasitic oscillationActive medium materialActive medium shape and constructionElastomerHigh power lasers

A novel method and apparatus for suppressing ASE and parasitic oscillation modes in a high average power laser is introduced. By roughening one or more peripheral edges of a solid-state crystal or ceramic laser gain media and by bonding such edges using a substantially high index bonding elastomer or epoxy to a predetermined electromagnetic absorbing arranged adjacent to the entire outer surface of the peripheral edges of the roughened laser gain media, ASE and parasitic oscillation modes can be effectively suppressed.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Zero-voltage switch flyback-type DC-DC power supply conversion device

ActiveCN101572490BEasy to controlImprove efficiencyEfficient power electronics conversionDc-dc conversionCapacitanceTransformer

The invention relates to a DC-DC power supply conversion device, in particular to a zero-voltage switch (ZVS) flyback-type DC-DC power supply conversion device with efficient conversion, efficient light-load conversion and low standby power consumption. An auxiliary switch and an absorption capacitor are additionally arranged on the flyback circuit; the auxiliary switch and the absorption capacitor are connected in series so as to form an auxiliary branch circuit; the auxiliary branch circuit can be connected in parallel to the two ends of the primary winding of a transformer or alternativelyconnected in parallel to the two ends of a primary-side switch; and the auxiliary switch is conductive for a determined period of time before the primary-side switch is conductive. Compared with the prior art, the energy of the circuit leakage inductor can be absorbed and transferred to the output terminal and a soft switch for realizing the primary-side switch, so that the invention can greatly improve the circuit efficiency; the parasitic oscillation caused by the leakage inductor can be suppressed, so that the EMI (electromagnetic interference) characteristics of the circuit can be improved; and the circuit can be controlled more easily, thereby improving the light-load circuit efficiency and reducing the idle-load energy loss.

Owner:DELTA ELECTRONICS (SHANGHAI) CO LTD

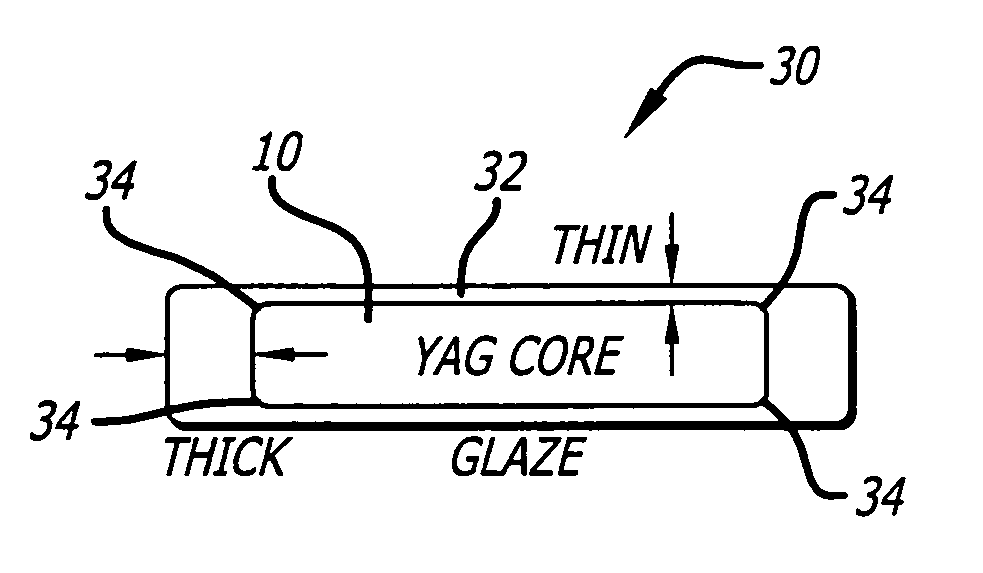

Articulated glaze cladding for laser components and method of encapsulation

ActiveUS7675952B2Suppress parasitic oscillationActive medium materialRefractive indexParasitic oscillation

A glaze encapsulated solid-state laser component. The novel laser component includes a core and a cladding of ceramic glaze disposed on a surface of the core. In an illustrative embodiment, the core is fabricated from a laser gain medium and the cladding material is a multi-oxide eutectic ceramic glaze having a refractivity slighter lower than the refractivity of the gain medium, such that the glaze layer forms a step-index refractivity interface cladding that can effectively suppress parasitic oscillations in the core gain medium. The glaze cladding can be applied by coating the core with the glaze and then firing the glaze coated core, or by fabricating pre-formed cladding strips from the ceramic glaze in a first firing cycle, mounting the pre-formed strips to the core, and then fusing the pre-formed strips to the core in a secondary firing cycle.

Owner:RAYTHEON CO

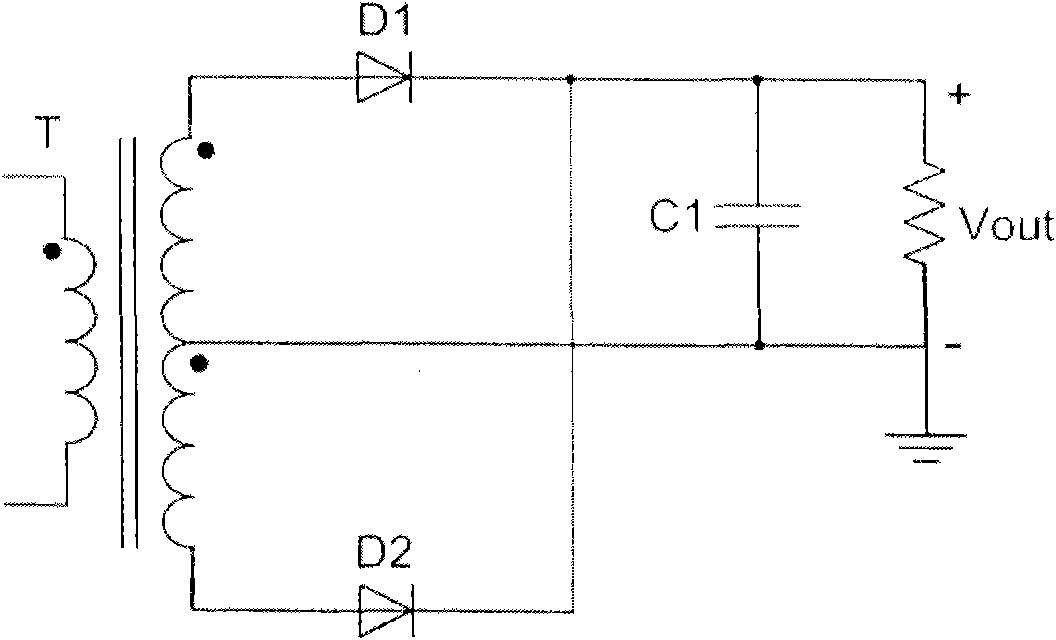

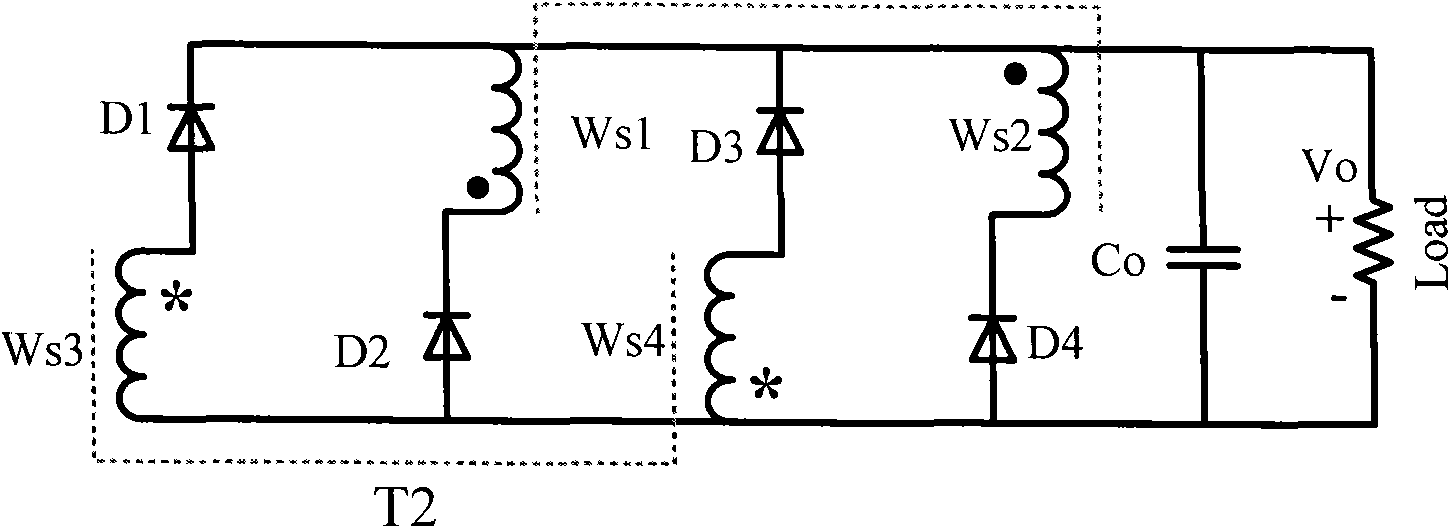

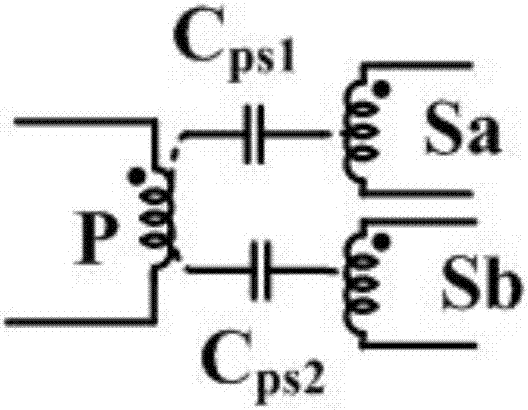

Rectifier circuit for realizing voltage clamp of rectifier tube by using double-power transformer

ActiveCN101917128ASimple winding structureIncrease profitAc-dc conversion without reversalDc-dc conversionCapacitanceEngineering

Owner:SHANGHAI ELECTRIC POWER ELECTRONICS

Device and method for restraining the titanium precious stone laser amplifier parasitical surge

InactiveCN101034784AHigh amplification efficiencySuppress parasitic oscillationLaser constructional detailsAudio power amplifierLiquid state

The invention relates to a method of suppressing the titanium gem laser amplifier parasiteic oscillation and equipment, the equipment characteristicis is that including a hull shape support which is used for installing the titanium gem crystal, on the lateral wall of the hull shape support has drop liquid hole and air hole for filling the liquid matching matter. The characteristic of the invention is that the liquid mathing matter is easy to collocate, and even contact with the side face of titanium jewel, without gas bubble, have no special request of the titanium gem crystal side face, most of all easy to replace, can not cause the damage to the crystal plane, the invention also has low cost, simple operate merit.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

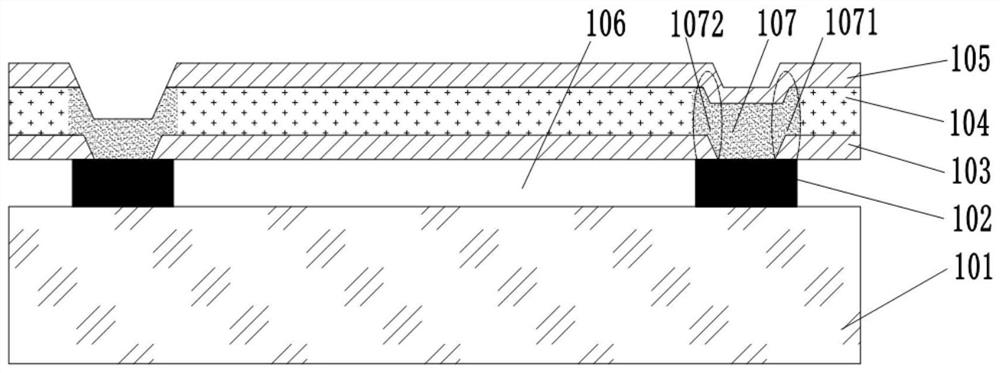

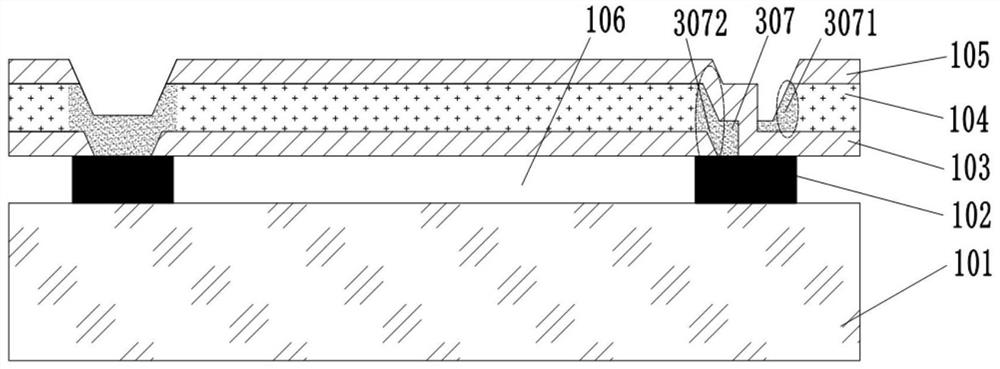

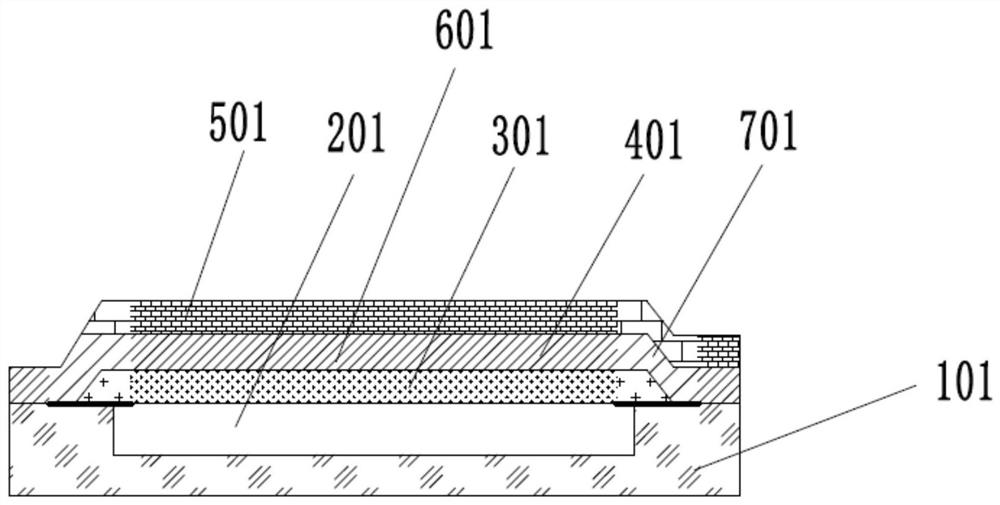

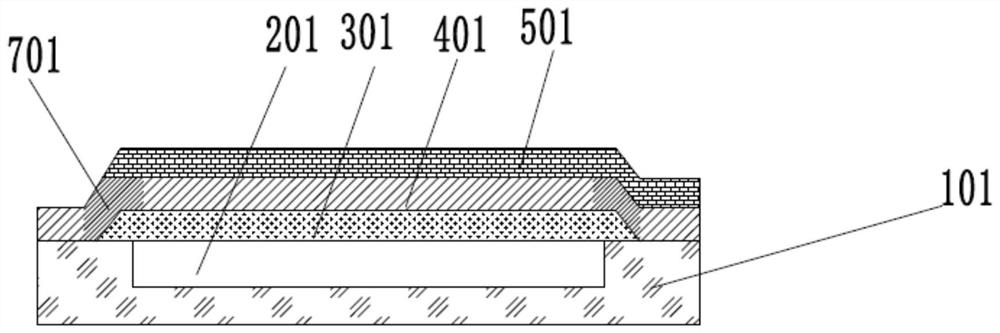

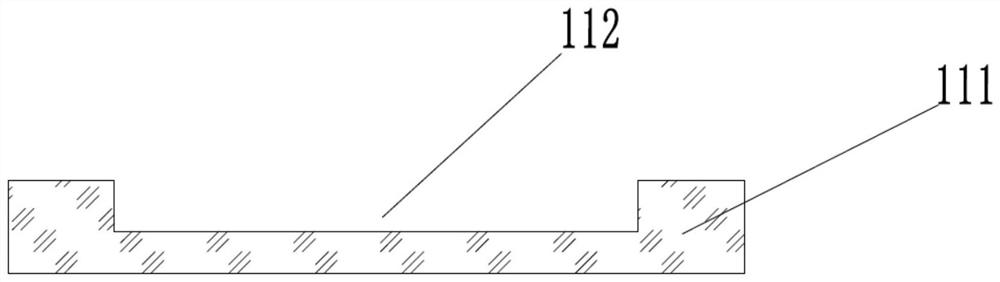

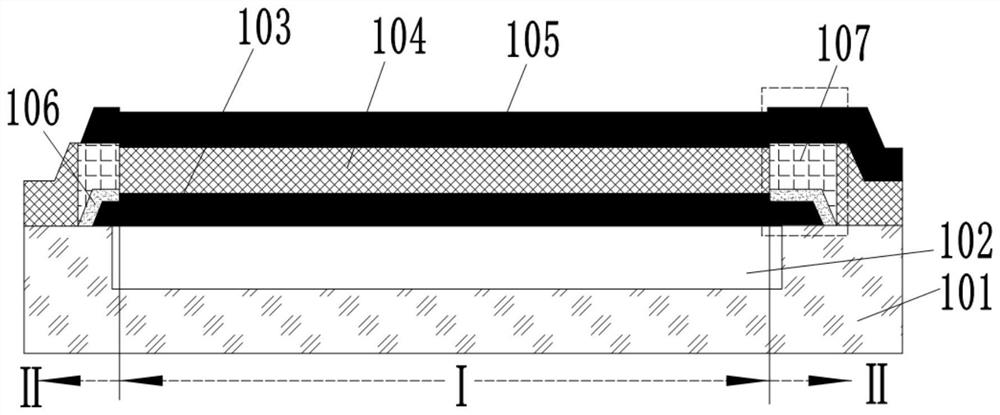

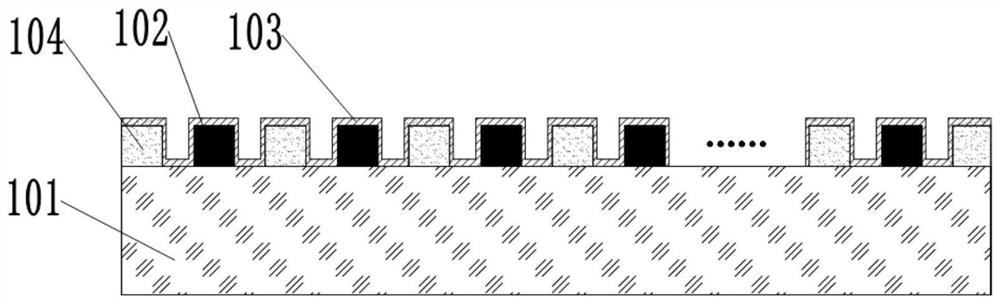

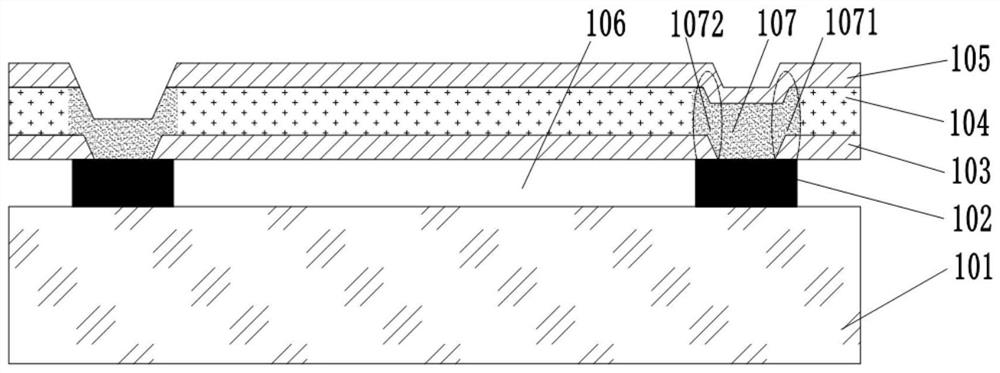

Film bulk acoustic resonator and manufacturing process thereof

ActiveCN111817679AImprove performanceNo need to worry about mechanical stabilityImpedence networksThin-film bulk acoustic resonatorThin membrane

A film bulk acoustic wave resonator comprises a bottom electrode layer, a piezoelectric layer and a top electrode layer which are arranged on the upper portion of a substrate where an acoustic wave reflection structure is located, and the portion, corresponding to the boundary of the acoustic wave reflection structure, of the piezoelectric layer is subjected to depolarization treatment to form a depolarization part. The invention further discloses a manufacturing process of the film bulk acoustic resonator. The manufacturing process comprises the following steps: manufacturing the bottom electrode layer on the substrate on which the acoustic reflection structure is formed or to be formed so as to cover the acoustic reflection structure; manufacturing a piezoelectric layer on the bottom electrode layer; carrying out depolarization processing on the part, corresponding to the boundary of the sound wave reflection structure, of the piezoelectric layer to form a depolarization part; and manufacturing a top electrode layer on the piezoelectric layer. According to the film bulk acoustic resonator and the manufacturing process thereof, transverse waves can be prevented from taking away energy from a resonance region at the upper part of the cavity of the resonator, so that the mechanical vibration strength of the resonance region is ensured, parasitic oscillation is inhibited, and theQ value of the resonator is improved.

Owner:HANGZHOU JWL TECH INC

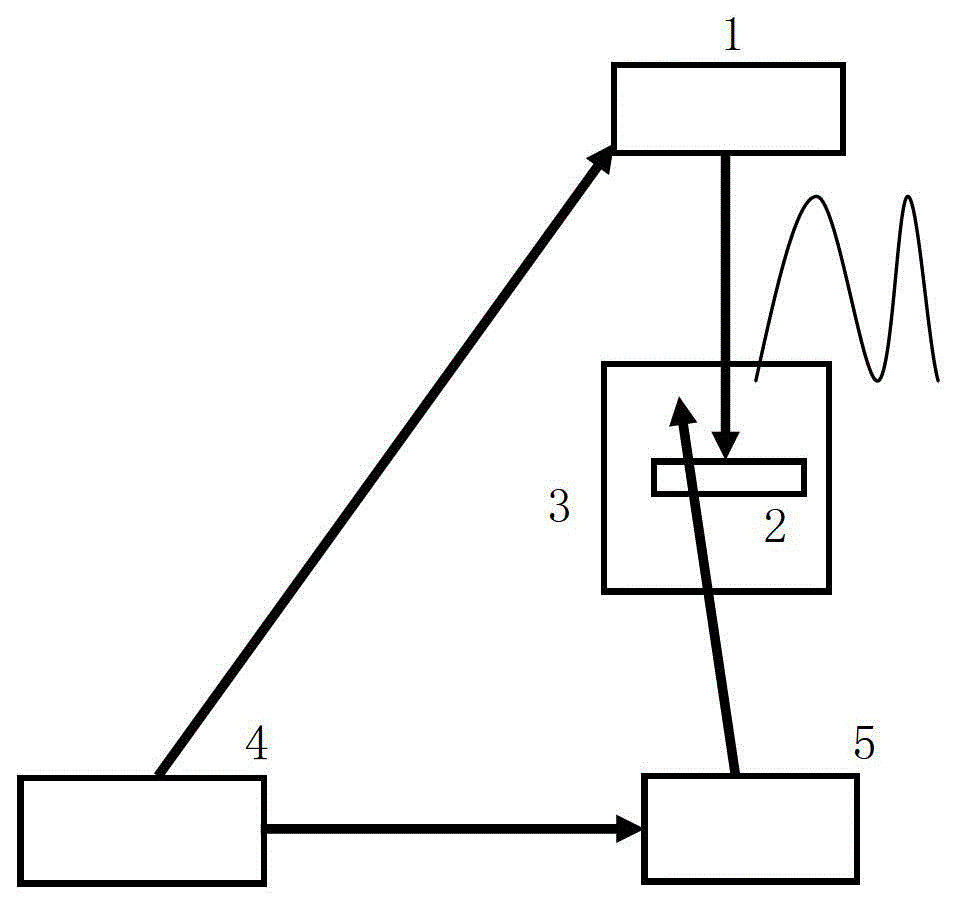

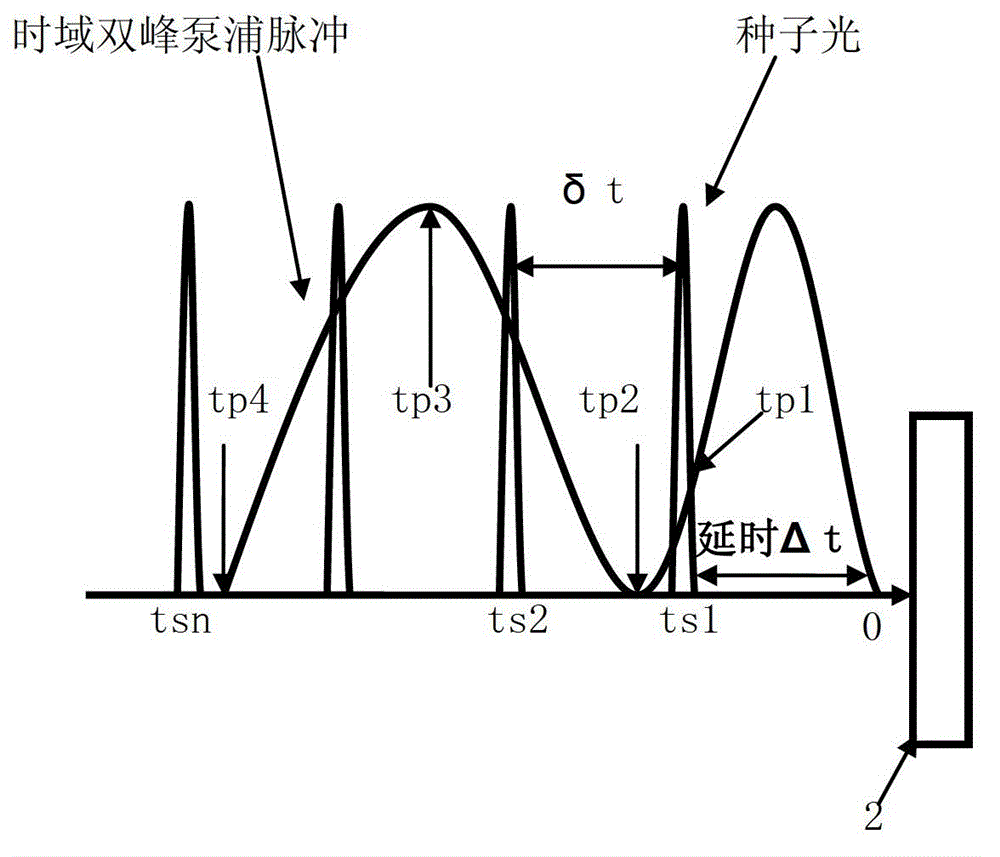

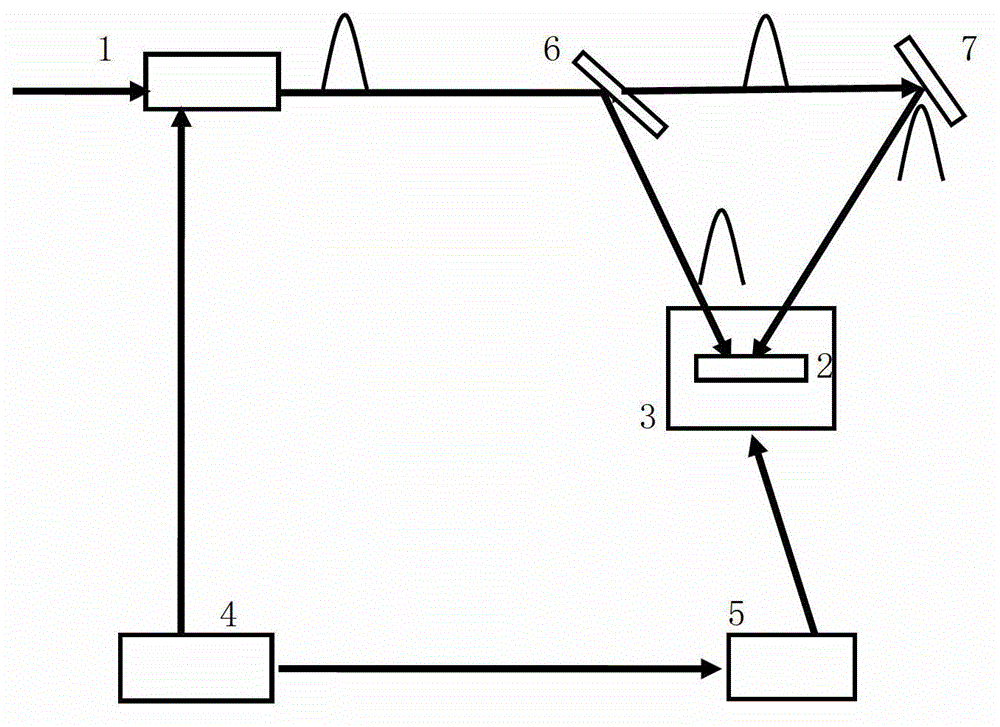

Time-domain doublet pulse pumping method for restraining parasitic oscillation of Ti sapphire multipass amplifier

ActiveCN103151698ASuppress parasitic oscillationReduce sensitivityActive medium materialNon-linear opticsTime domainAudio power amplifier

Disclosed is a time-domain doublet pulse pumping method for restraining parasitic oscillation of a Ti sapphire multipass amplifier. The properties of time-domain doublet pumping pulse are utilized, time delay of seed light is adjusted and single-pass time interval of the multipass amplifier is adjusted to amplify 800-nanometer seed light to enable crosswise transmission gain of a Ti sapphire crystal to be kept in a low level in the process of amplifying, the parasitic oscillation of the Ti sapphire is effectively restrained, and amplifying efficiency of the seed light is improved. The time-domain doublet pulse pumping method for restraining the parasitic oscillation of the Ti sapphire multipass amplifier has the advantages of being convenient to adjust, simple, high-efficient and strong in practicality.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

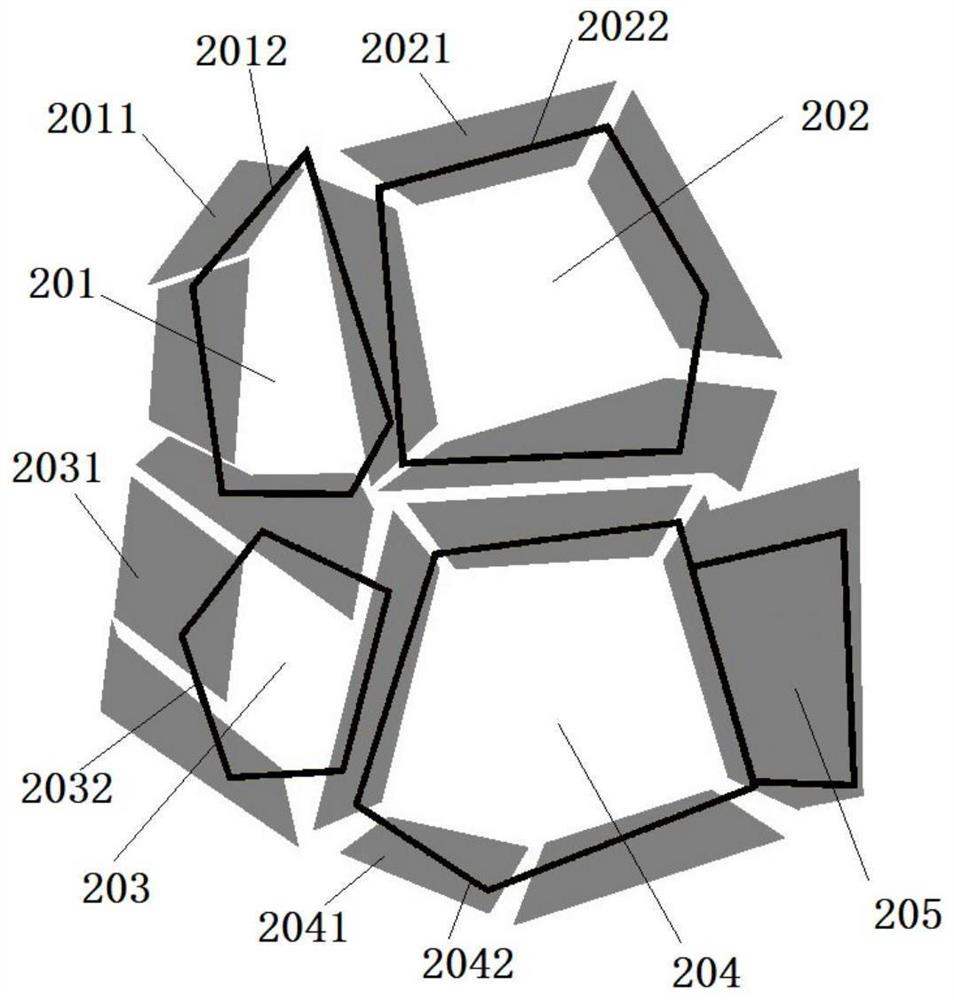

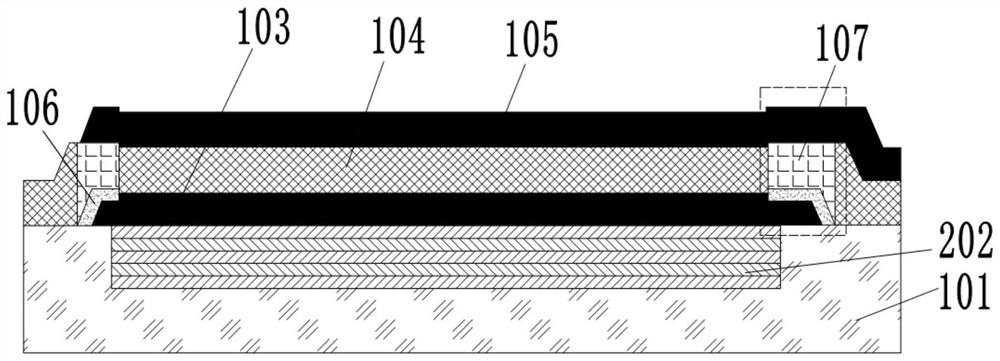

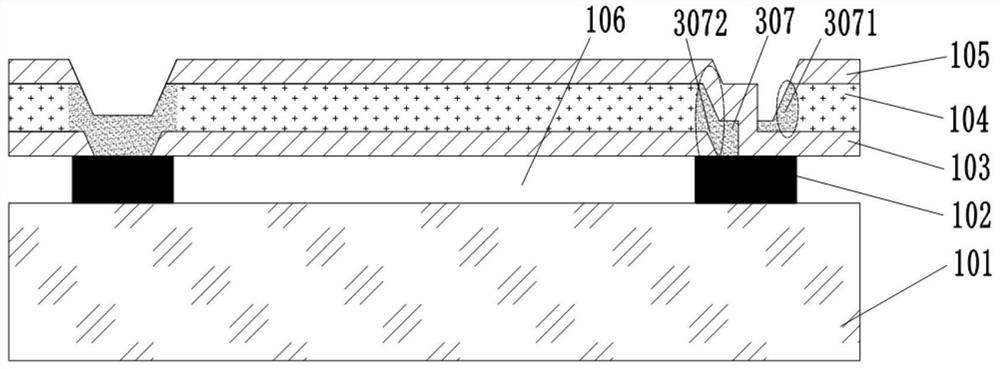

Manufacturing process of acoustic resonator and acoustic resonator

ActiveCN111865258ASuppress parasitic oscillationReduce electric field strengthImpedence networksThin membraneAcoustics

The invention discloses a manufacturing process of an acoustic resonator and the acoustic resonator. The acoustic resonator comprises a substrate, an acoustic mirror and a resonance film layer composed of a bottom electrode layer, a piezoelectric layer and a top electrode layer. An area where the resonance film layer and the acoustic mirror are overlapped in the thickness direction of the substrate is a projection area, an amorphous state part is arranged in the resonance film layer, one side of the amorphous state part is located in the projection area or coincides with the boundary of the projection area, and the other side of the amorphous state part is located outside the projection area. In a preferred embodiment, the acoustic mirror includes a cavity or Bragg reflection layer. The amorphous state part can greatly suppress parasitic oscillation of the resonator due to outward connection of the top electrode layer. The electrode layer can be directly wired in the area where the amorphous state part is located, parasitic and resonant interference generated by the bottom electrode layer, the top electrode layer and the piezoelectric layer outside the effective resonant area is avoided, and the process cost and wiring design difficulty are reduced.

Owner:HANGZHOU XINGHE TECH CO LTD

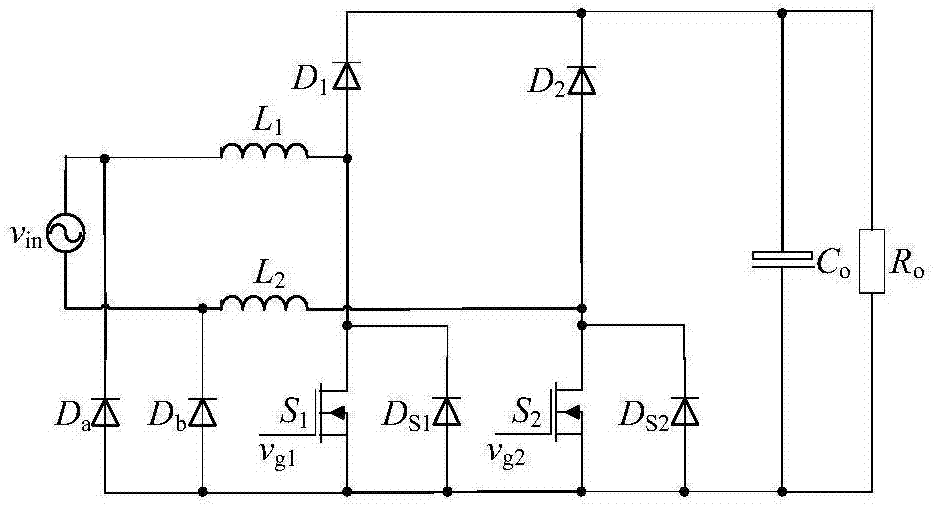

Zero-voltage transmission half bridgeless power factor correction converter

ActiveCN106877645ASimple topologyImprove machine efficiencyEfficient power electronics conversionEnergy industryParasitic capacitanceEngineering

The invention discloses a zero-voltage transmission half bridgeless Boost PFC converter. According to the invention, only by adding a rapid recovery diode D7 can an RCD clamp network be replaced; parasitic oscillation during cutting off of quasi zero current of an auxiliary switch tube is inhibited; the topology of the converter is simplified; and when the auxiliary switch tube is turned off, exciting current will be introduced into a parasitic capacitor, and is fully used by a circuit, so the overall efficiency of the converter is improved. In addition, through the provided converter, natural turning on and turning off of a zero voltage switch and a boost diode of a main switch tube are achieved; natural switching on and off of each connected diode in the circuit is also achieved; technical problems of complex topology, quite high cost and quite low overall efficiency of a converter in the prior art are solved; and the provided converter can be well popularized in actual application.

Owner:HUAZHONG UNIV OF SCI & TECH

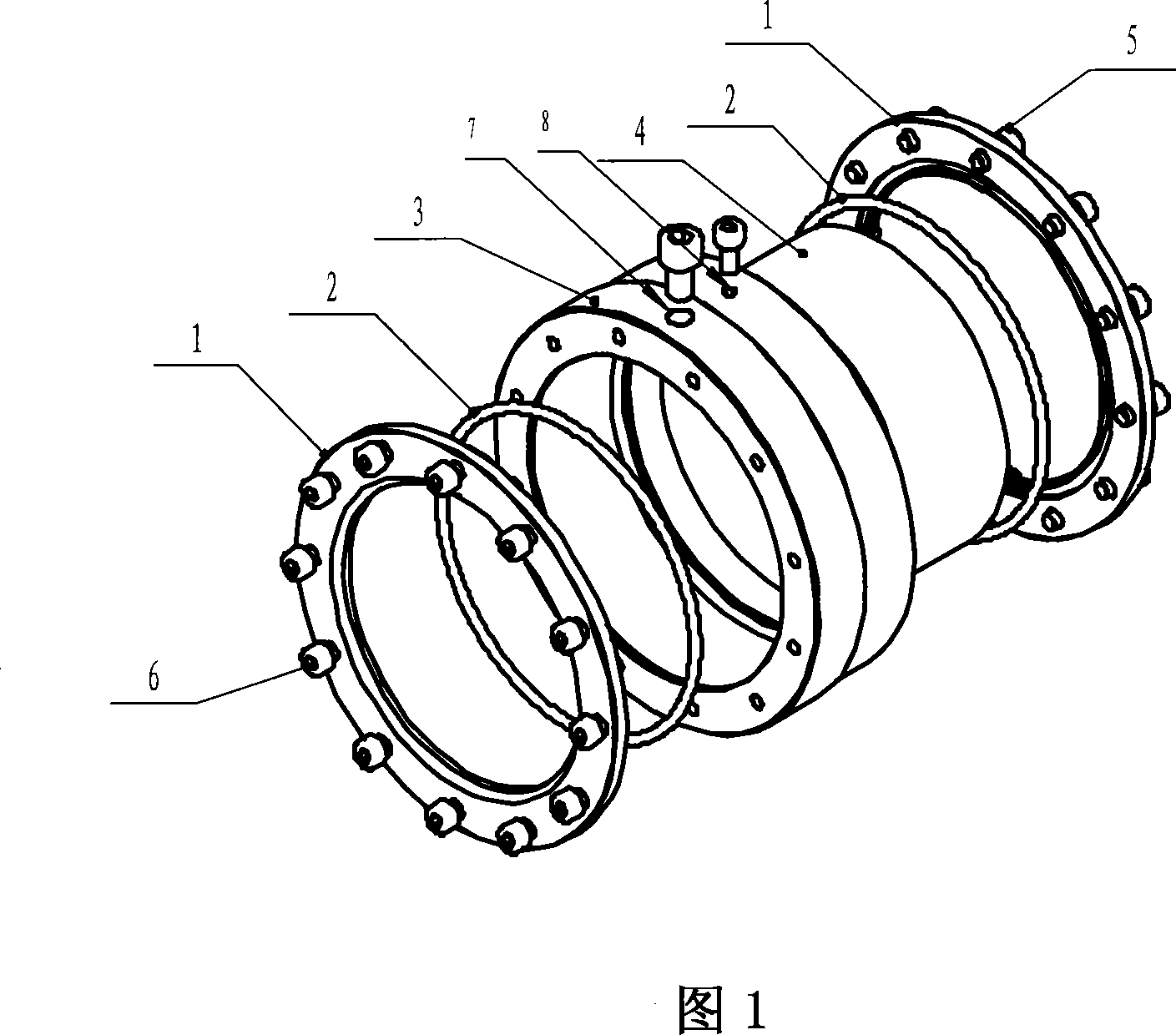

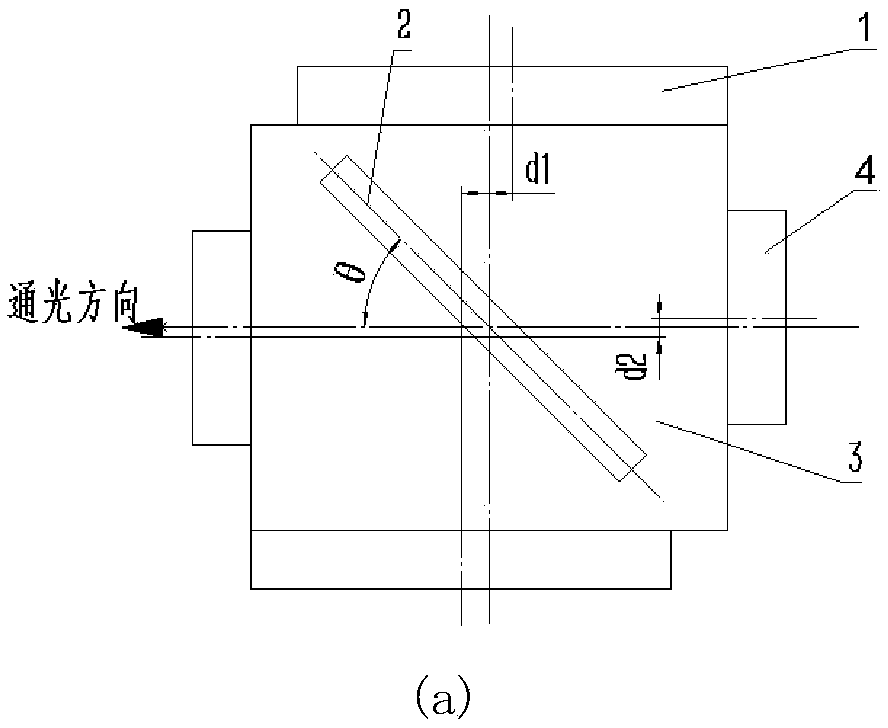

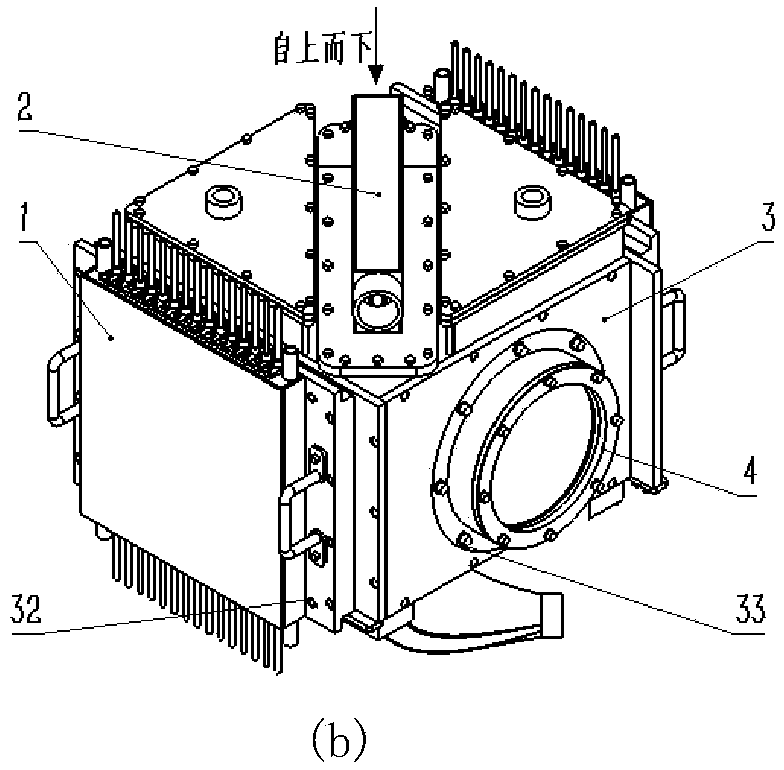

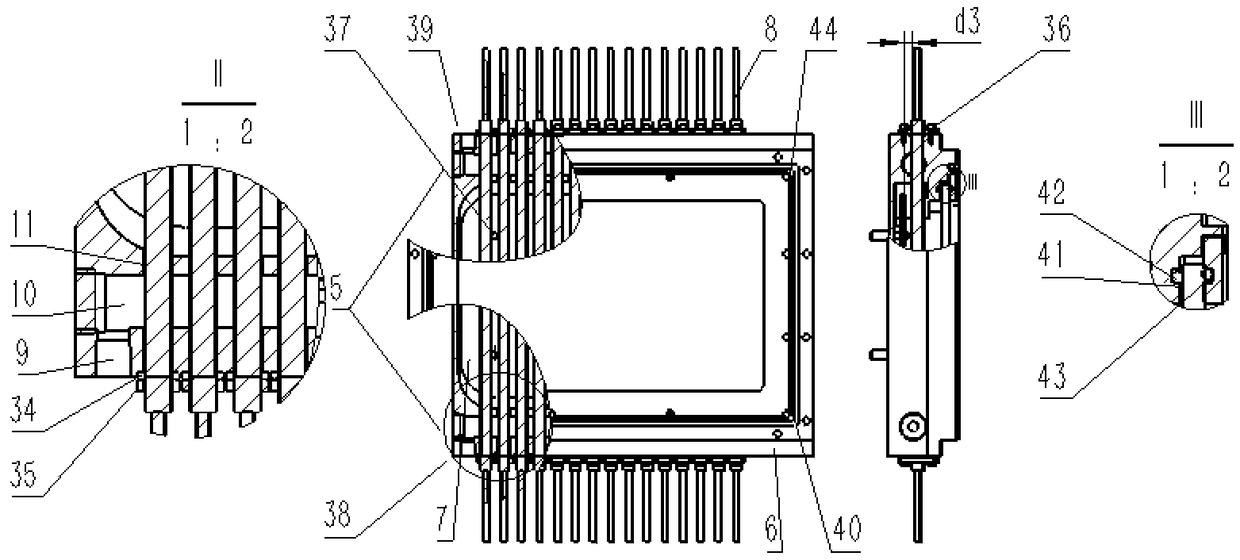

Xenon lamp-pumped liquid cooling laminated repetition frequency sheet amplifier

ActiveCN109411997AReduce spontaneous emissionLow costActive medium materialLaser cooling arrangementsHeat managementAudio power amplifier

The invention discloses a xenon lamp-pumped liquid cooling laminated repetition frequency sheet amplifier. The xenon lamp-pumped liquid cooling laminated repetition frequency sheet amplifier comprisesa lamp box assembly, a sheet frame assembly, a sheet cavity assembly and an end mirror assembly, and is characterized in that the included angle theta of the sheet frame assembly and the light transmission direction is 45 degrees for installation; the sheet frame assembly is installed inside the sheet cavity assembly from top to bottom; the lower bottom surface of the sheet frame is overlapped with the upper surface of the lower base plate of the sheet cavity; the lamp box assembly is installed on the left and right sides of the sheet cavity assembly in virtue of screw dislocation; and the end mirror assembly is centrally dislocated along the light transmission direction and is installed on the front and rear sides of the sheet cavity assembly in virtue of screws. The spontaneous radiation of the amplifier is reduced effectively by using end mirror inclination swing, xenon lamp liquid cooling, gain medium laminated liquid guide uniform cooling and sheet box air-cool clean control, theparasitic oscillation is inhibited, the energy storage efficiency and heat management are improved, and the repetition frequency sheet amplifier has the characteristics of high efficiency, high repletion frequency, low cost, high energy, high gain uniformity and stable operation.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

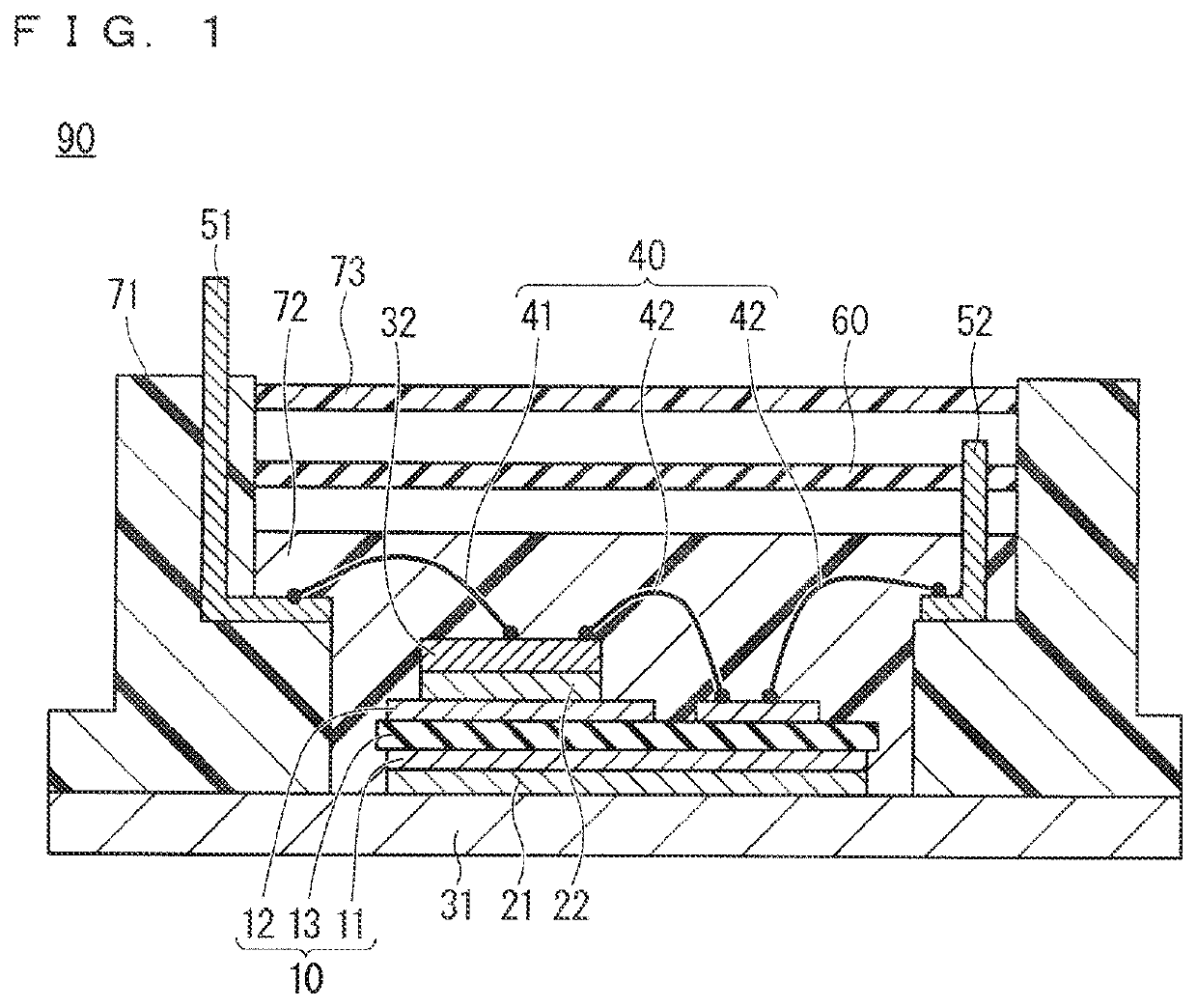

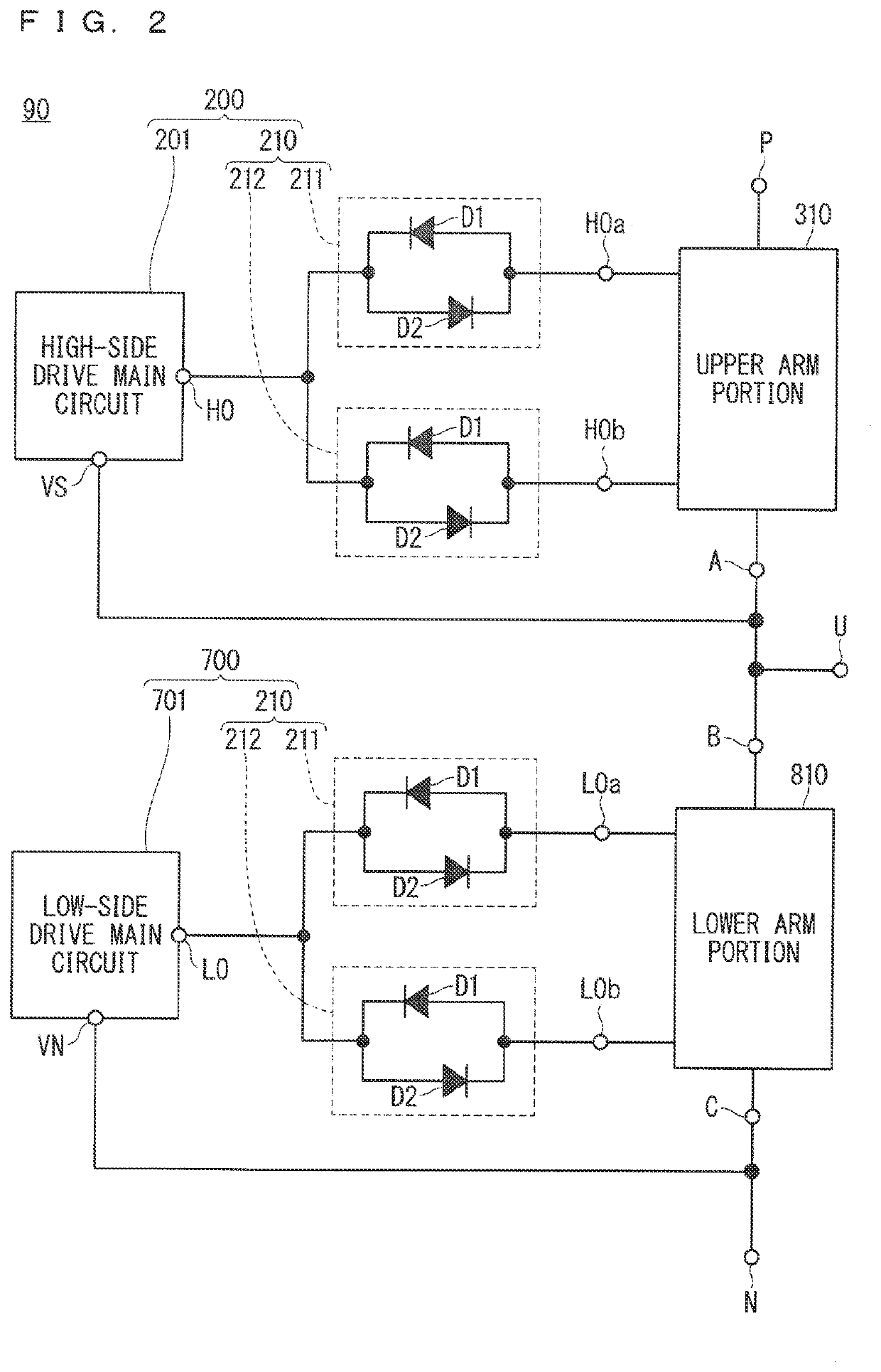

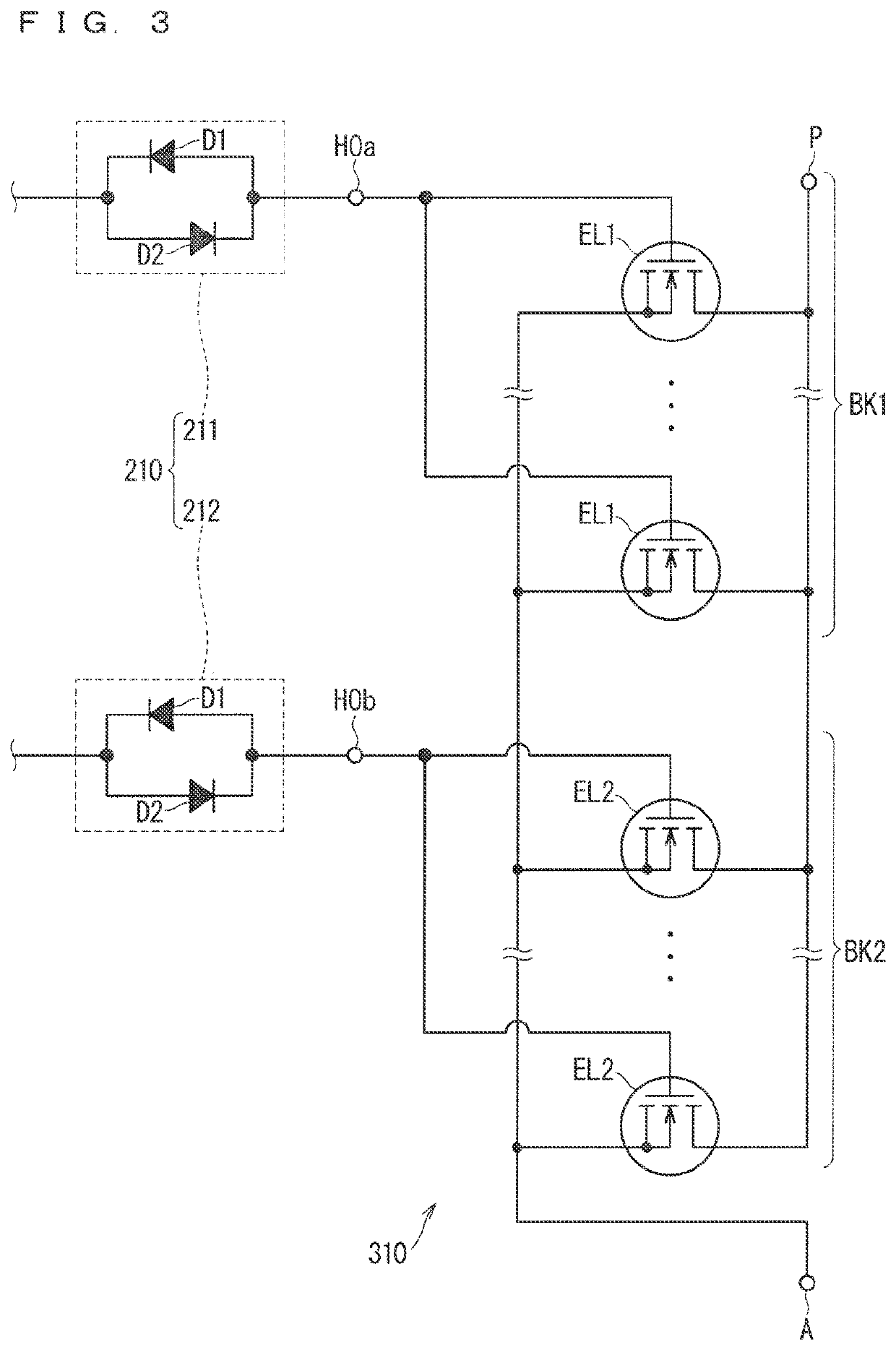

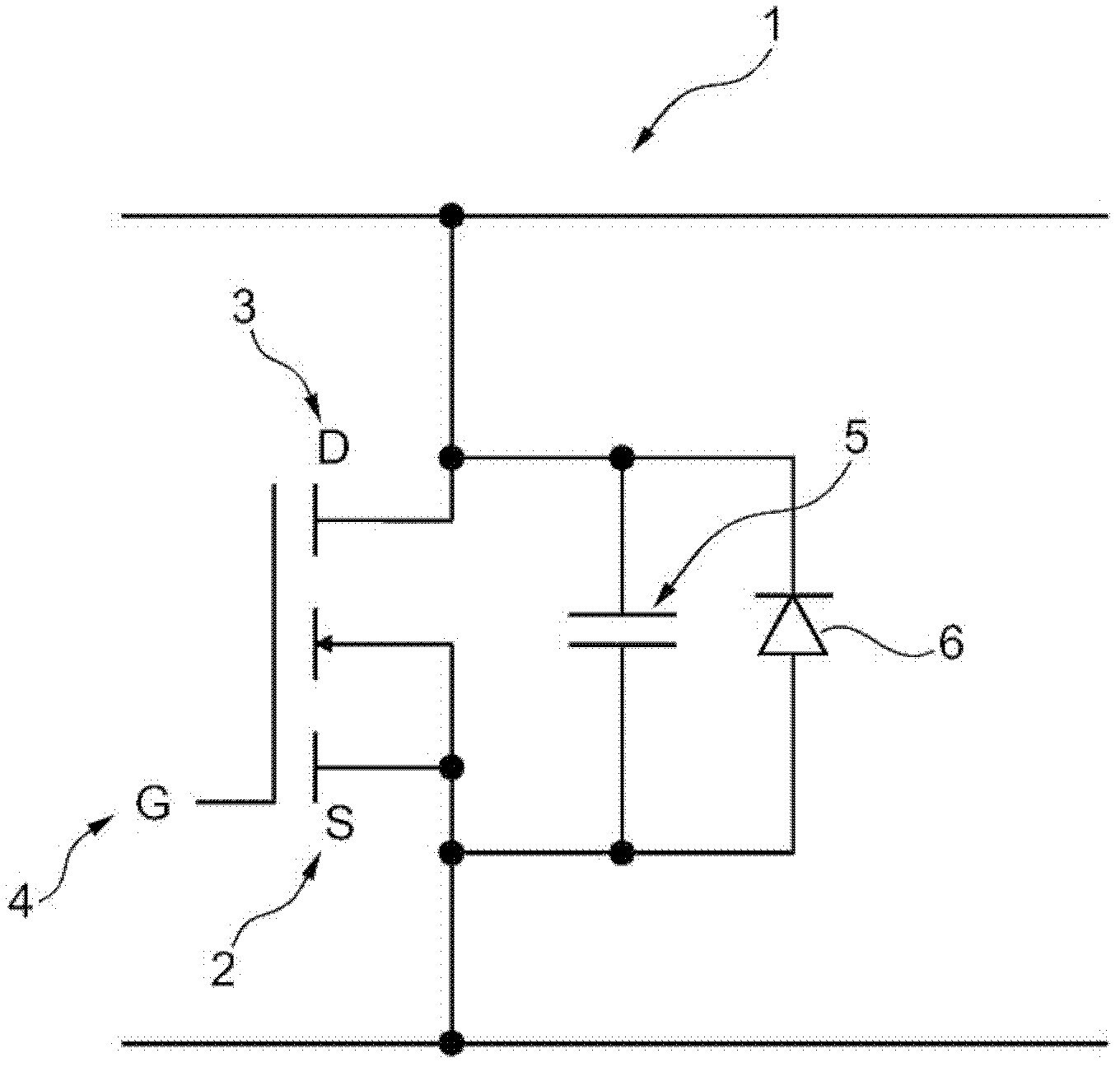

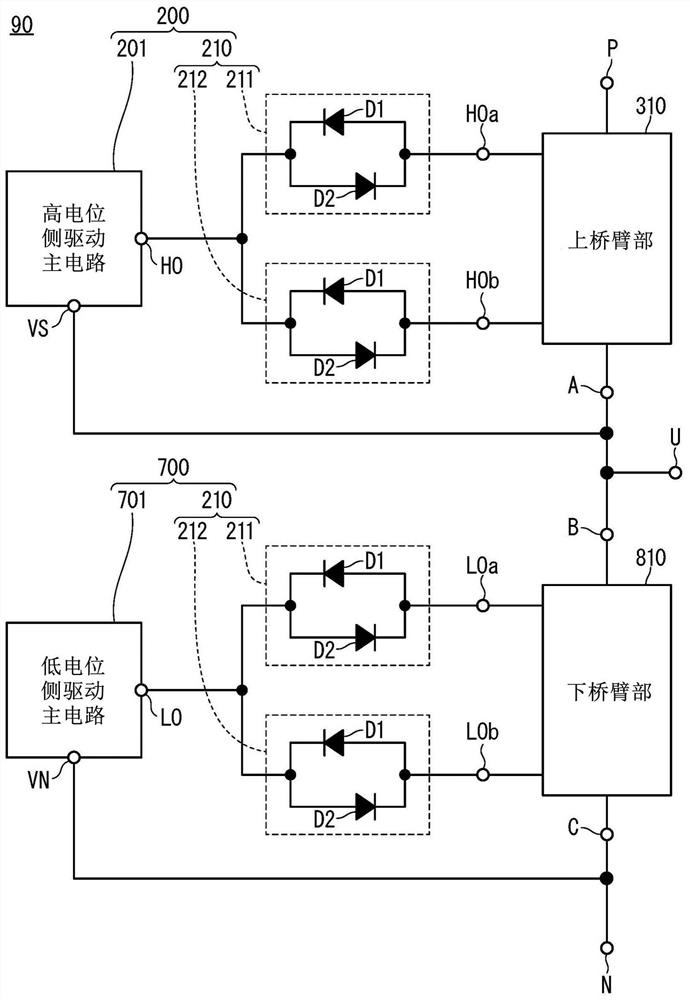

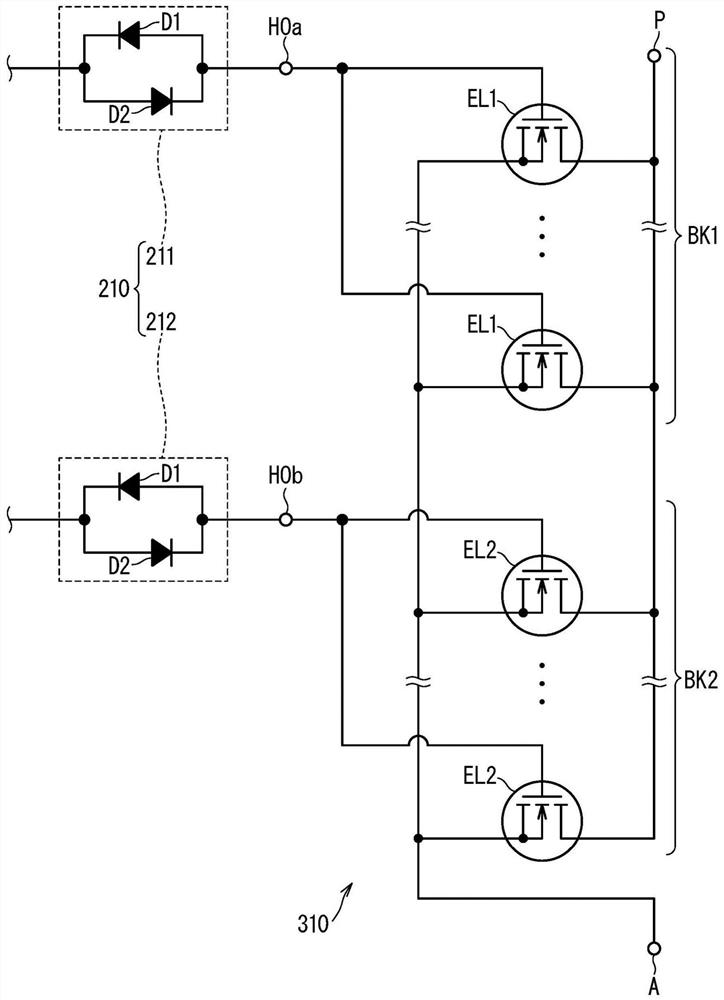

Semiconductor device

PendingUS20210366886A1Suppression problemSimple configurationSemiconductor/solid-state device detailsAc-dc conversionDevice materialHemt circuits

A plurality of semiconductor elements connected in parallel with one another include a plurality of first semiconductor elements and a plurality of second semiconductor elements. A drive circuit to provide a gate signal to each of the plurality of semiconductor elements EL includes a main circuit and a plurality of inserted circuits including a first inserted circuit and a second inserted circuit. The first inserted circuit is inserted between the main circuit and the plurality of first semiconductor dements. The second inserted circuit is inserted between the main circuit and the plurality of second semiconductor elements. Each of the first inserted circuit and the second inserted circuit includes a first diode having a forward direction toward the main circuit and a second diode connected in anti-parallel with the first diode.

Owner:MITSUBISHI ELECTRIC CORP

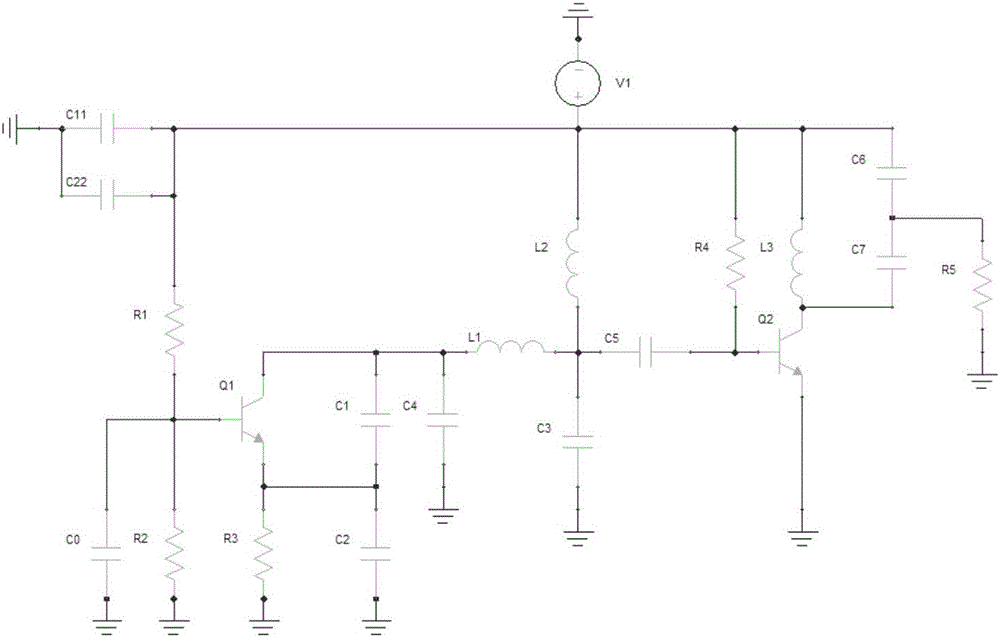

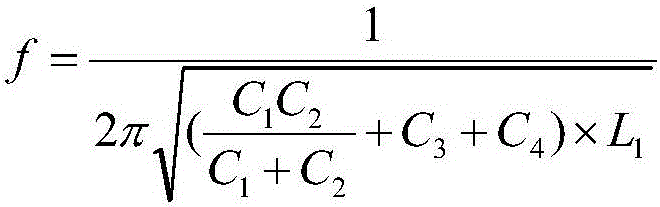

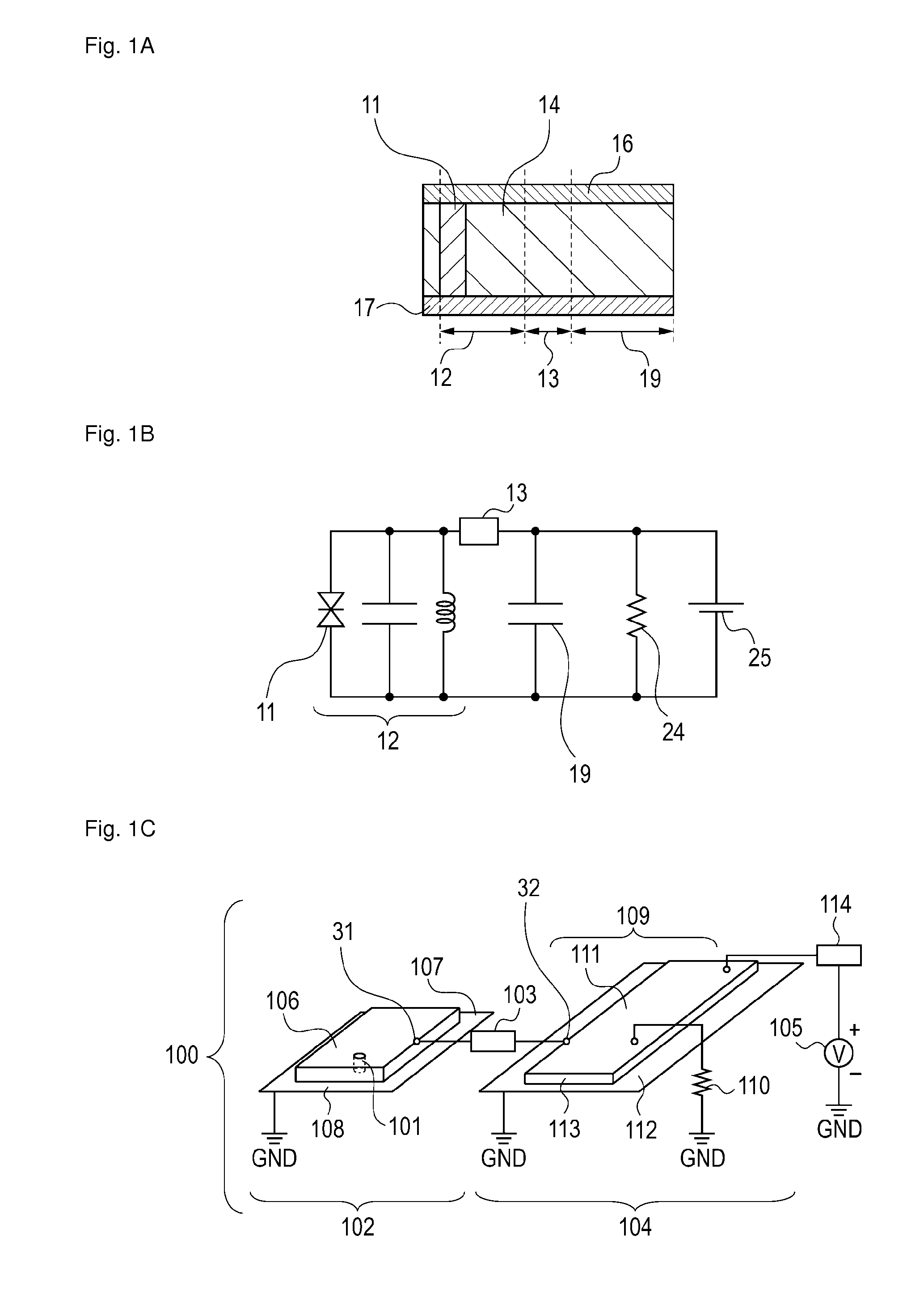

High frequency oscillator inhibiting parasitic oscillation

InactiveCN106817081ASuppress parasitic oscillationStable high frequency sine waveOscillations generatorsPhysicsCapacitance

The invention discloses a high frequency oscillator inhibiting parasitic oscillations; the high frequency oscillator comprises a DC power supply circuit, an oscillation generation circuit and a parasitic oscillation inhibition circuit; the DC power supply circuit comprises a DC voltage source V1, a high frequency choke coil L2, a first filter capacitor C11, a second filter capacitor C22, a first bias resistor R1, a second bias resistor R2 and a first bias capacitor C0; the oscillation generation circuit comprises a first transistor Q1, a first resonant capacitor C1, a second resonant capacitor C2, a third resonant capacitor C3, a fourth adjustable resonant capacitor C4, a first feedback resistor R3 and a first resonance inductor L1; the parasitic oscillation inhibition circuit comprises a first coupling capacitor C5, a second transistor Q2, a first current-limiting resistor R4, a first frequency selection capacitor C6, a second frequency selection capacitor C7, and a first frequency selection inductor L3; the high frequency oscillator can stably form high frequency sine waves, and can effectively inhibit parasitic oscillations.

Owner:HANGZHOU DIANZI UNIV

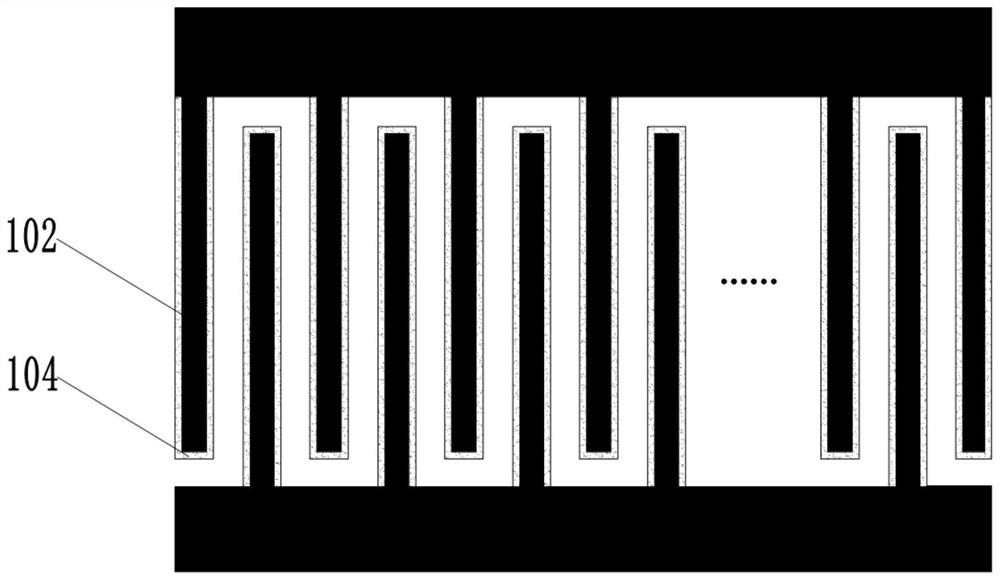

Oscillator with resonator generating terahertz wave

InactiveUS8410860B2Suppress parasitic oscillationOscillation stabilitySimultaneous aerial operationsSemiconductor/solid-state device detailsDielectricElectrical conductor

An oscillator includes a resonator section structured such that a dielectric is interposed between first and second conductors and such that the first and second conductors are electrically connected to a resonant tunneling diode, a capacitor section structured such that the dielectric is interposed between the first and second conductors, a line section configured to electrically connect the resonator section and the capacitor section in parallel to each other, and a resistor section configured to electrically connect the first and second conductors to each other. A first position of the resonator section and a second position of the capacitor section are connected to each other by the line section so that the first position and the second position are substantially electrically equivalent to each other in a wavelength range larger than a wavelength of an electromagnetic wave that resonates in the resonator section.

Owner:CANON KK

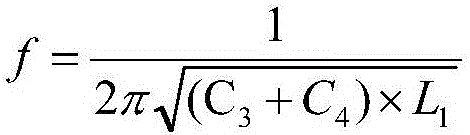

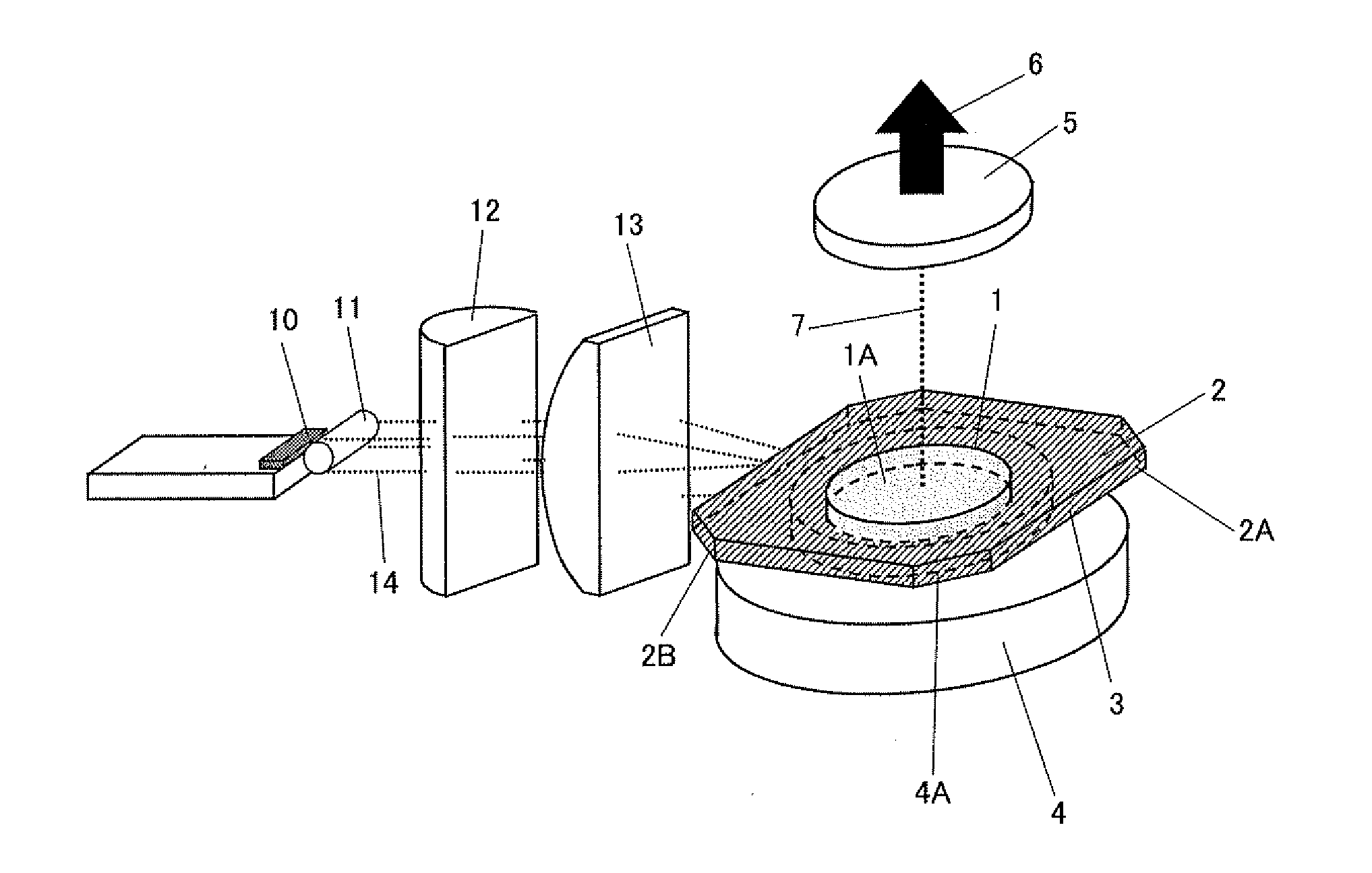

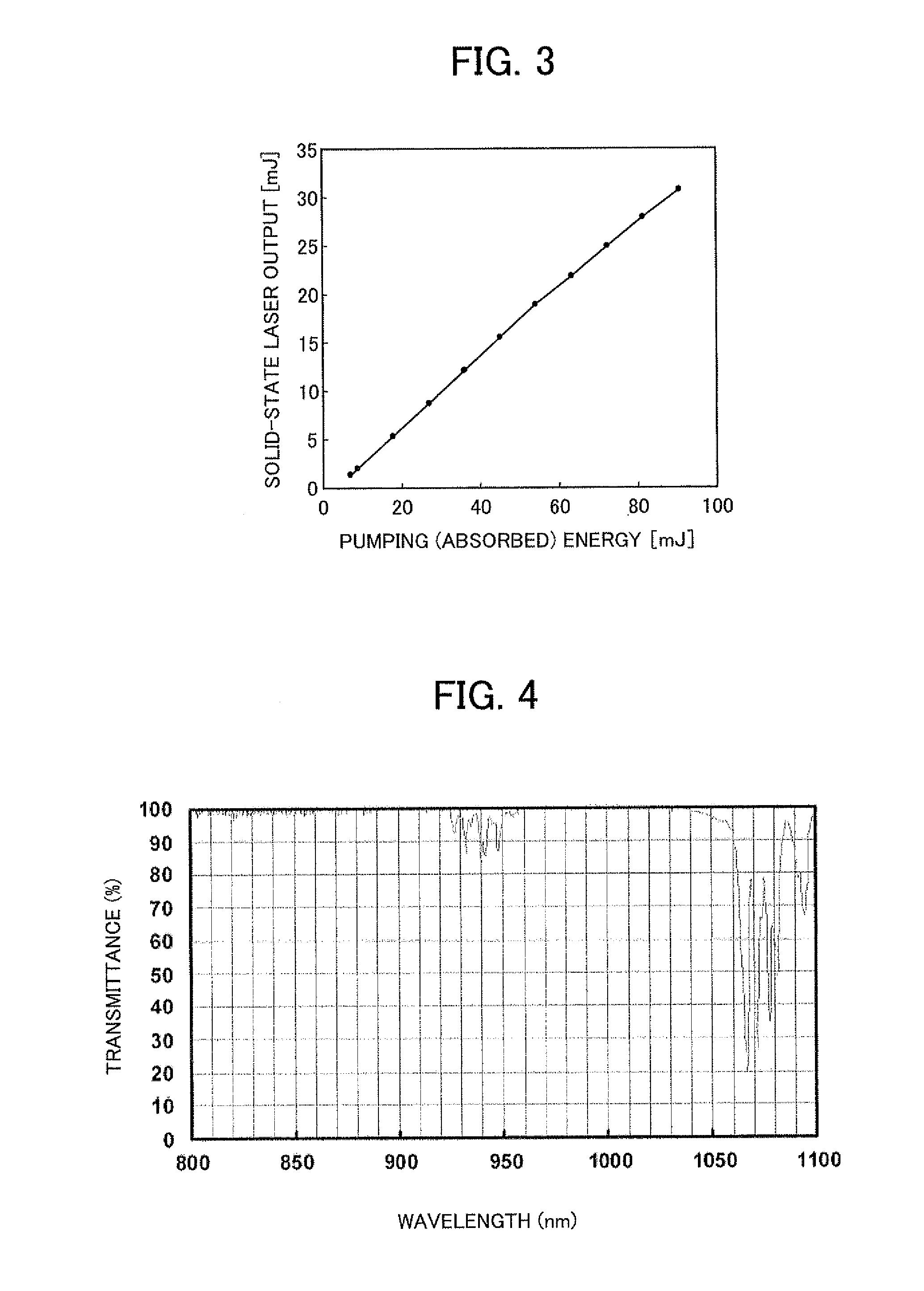

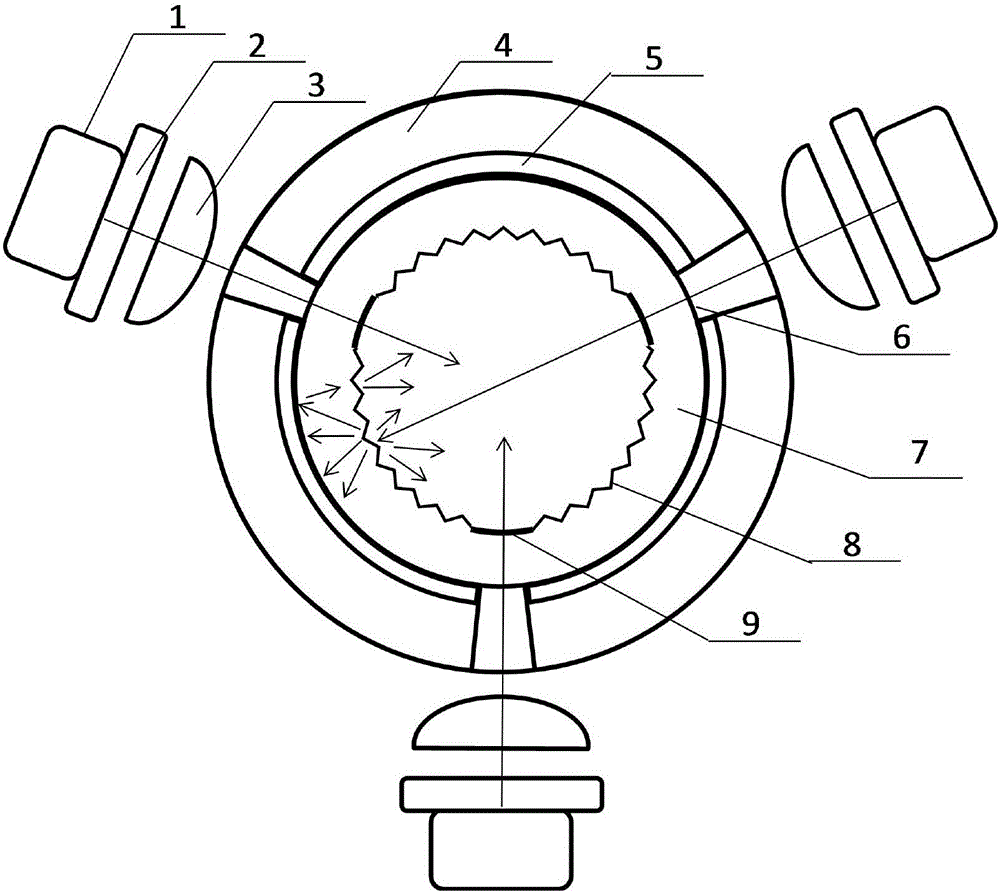

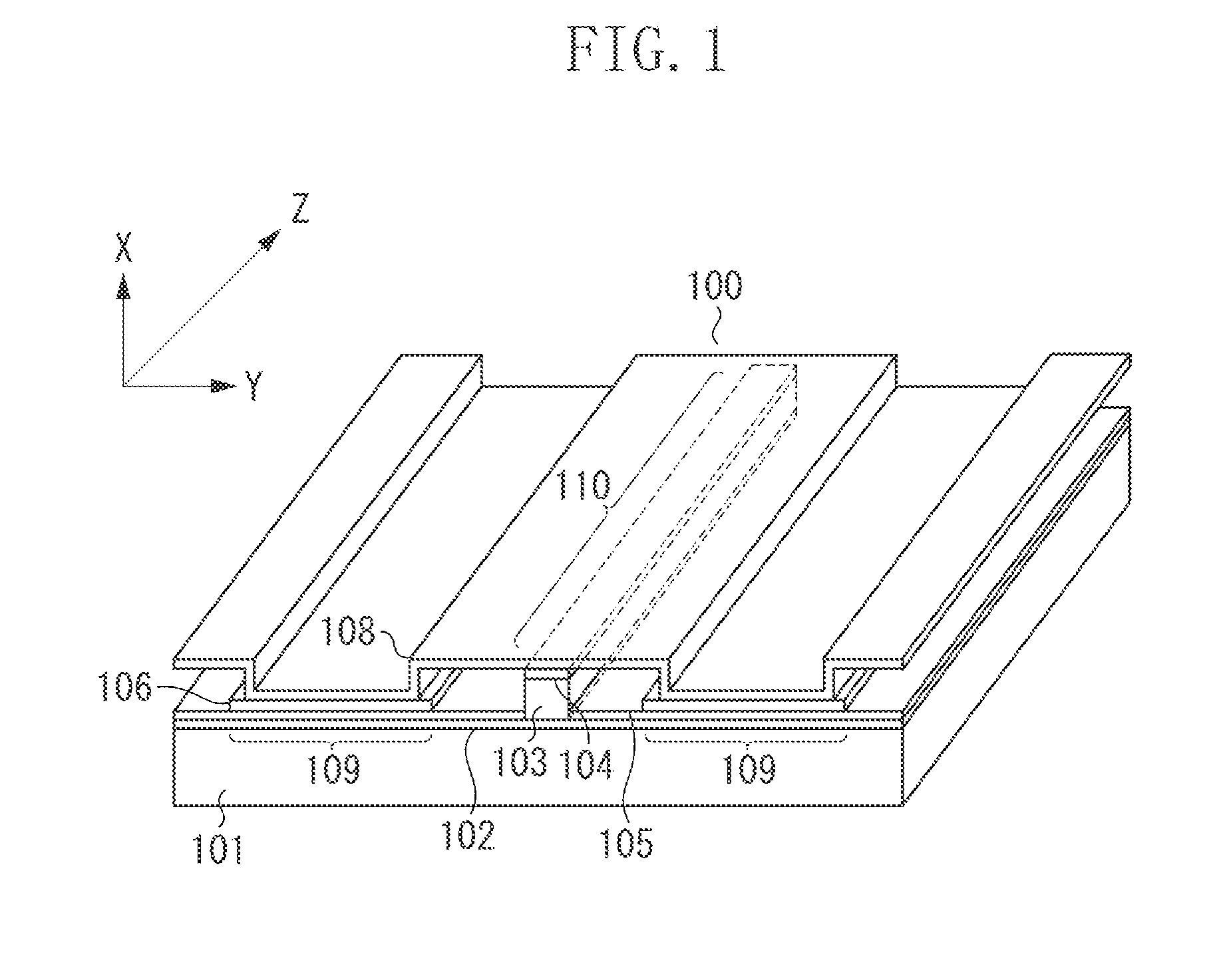

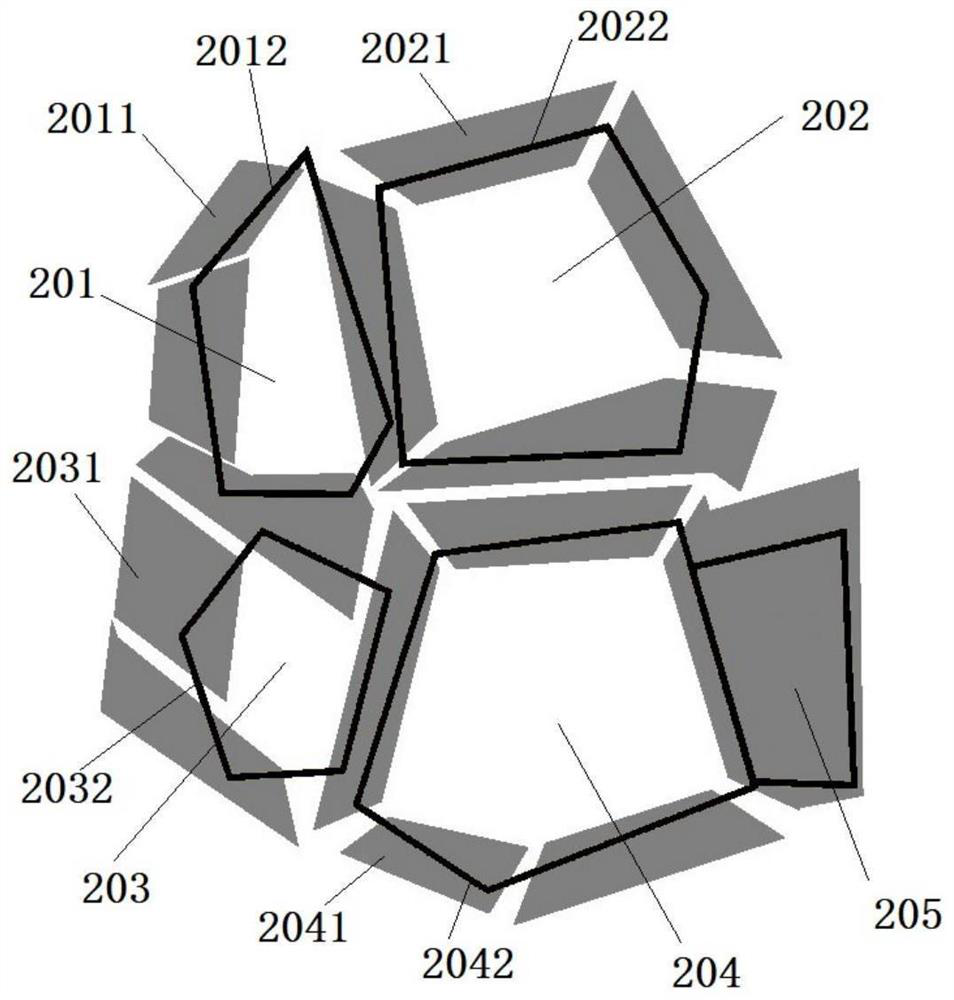

Semiconductor laser pumped solid-state laser device

ActiveUS20110176566A1Efficiently and stably emittedStable generationActive medium shape and constructionLaser cooling arrangementsSolid-state laser deviceLight guide

A compact semiconductor laser pumped solid-state laser device is provided that can suppress unnecessary parasitic oscillation in a microchip and efficiently extract energy. The semiconductor laser pumped solid-state laser device comprises: a solid-state laser core 1 disposed in the center and formed of a laser medium containing neodymium (Nd) as a laser oscillation element; a light guide region 2 integrally formed around the solid-state laser core 1, having approximately rectangular shape with four linear light entrance windows formed on the outer periphery thereof, and containing samarium (Sm) as a laser oscillation element; and a heat sink 4 disposed on one face of the light guide region 2 including the solid-state core 1, wherein laser oscillation is performed by introducing a pumping light 14 through the light entrance windows 3 and propagating the pumping light 14 through the light guide region 2 to pump the solid-state laser core 1, and wherein a laser oscillation light is extracted from the upper face of the solid-state laser core 1 opposite to the face contacting the heat sink 4.

Owner:INTER UNIV RES INST NAT INST OF NATURAL SCI

Switching Device For An X-Ray Generator

The invention relates to a switching device for an X-ray generator for providing a required output power voltage at an output of a resonance power converter. The switching device may comprise a main switch 16 and an auxiliary switch 26, wherein the main switch 16 may comprise a first internal capacitance 5 and wherein the auxiliary switch 26 may be connected in parallel to the main switch 16. Moreover, the main switch 16 may be controllable and the auxiliary switch 26 may be also controllable. Furthermore, the auxiliary switch 26 may be controllable in dependence of the main switch 16, wherein the auxiliary switch 26 may be controllable for discharging of the first internal capacitance 5 of the main switch 16.

Owner:KONINK PHILIPS ELECTRONICS NV

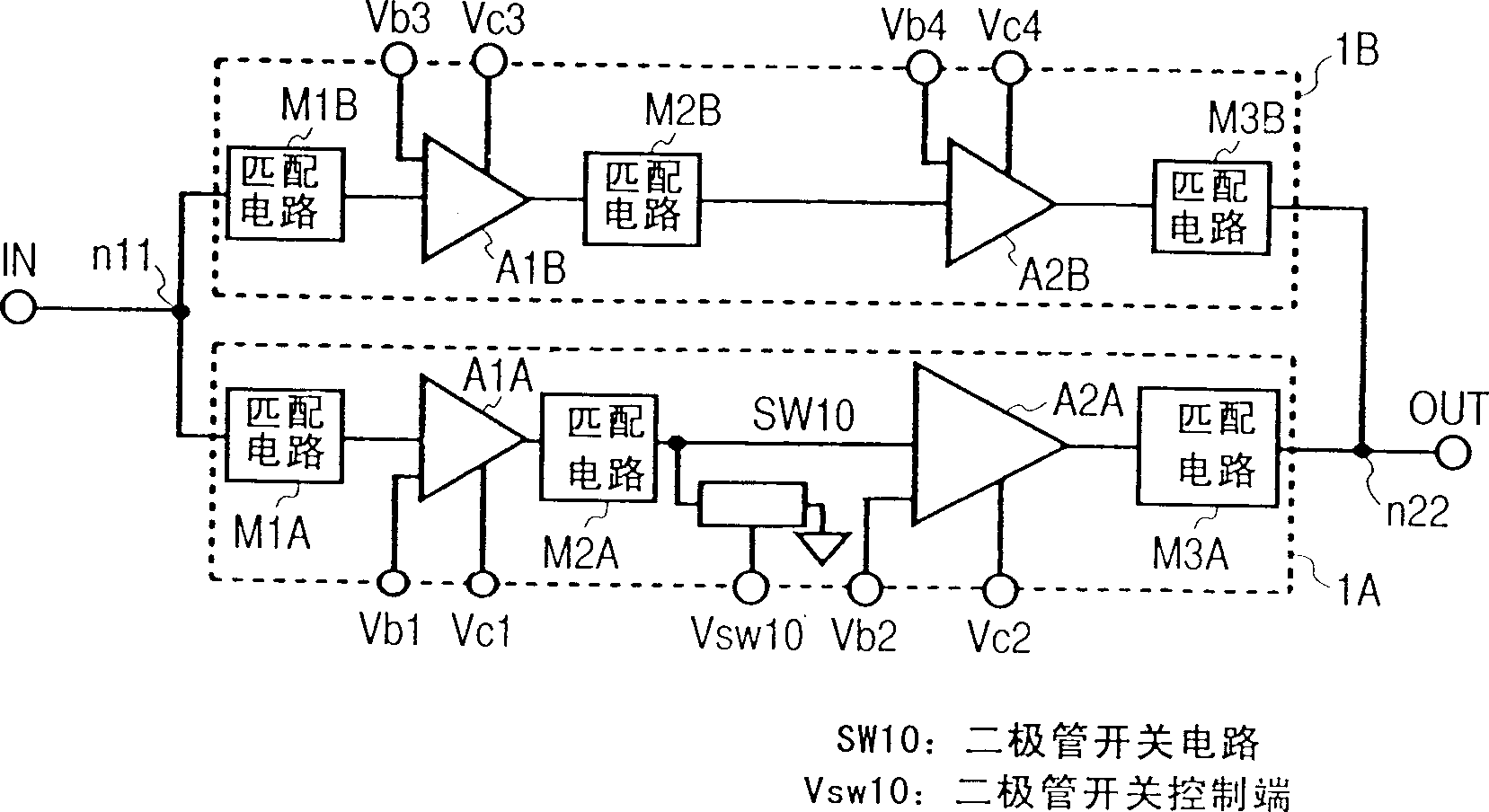

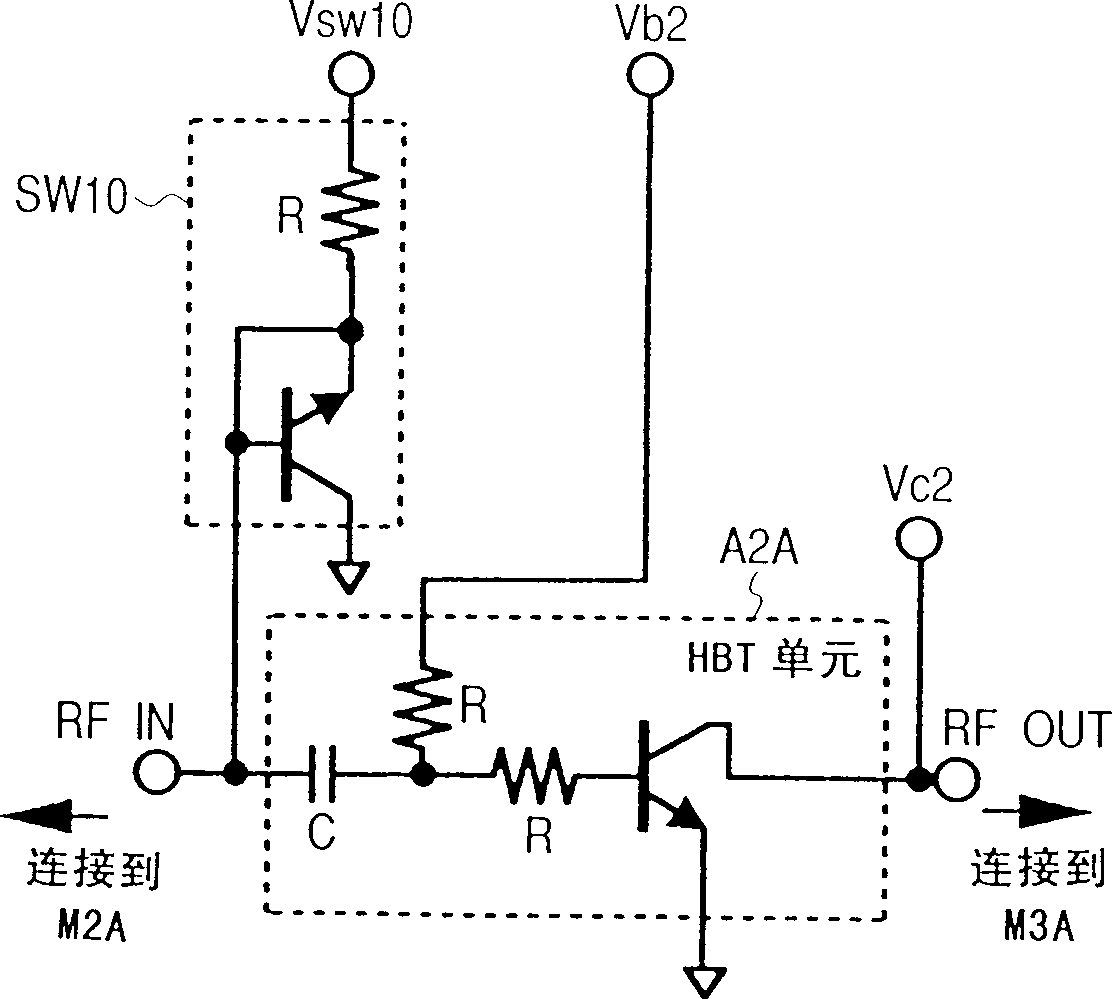

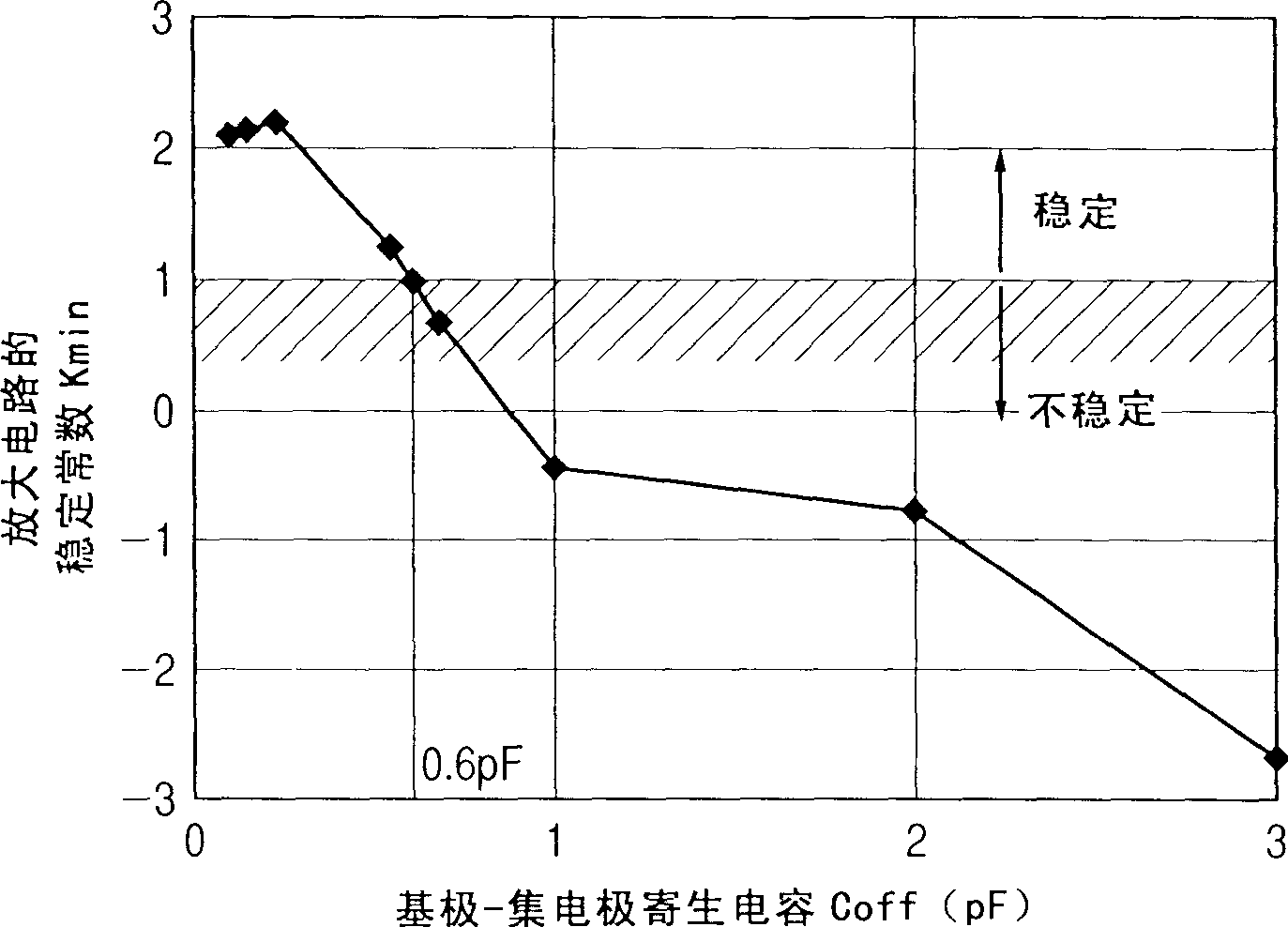

High frequency power amplifer, module of high frequency power amplifer and mobile telephone

InactiveCN1407719AReduce areaPrevent parasitic oscillationHigh frequency amplifiersGated amplifiersHigh frequency powerAudio power amplifier

To provide a small-sized high frequency power amplifier for preventing oscillation by a small number of switching circuits and outputting high power and low power with high efficiencies, a high frequency power amplifier module and a portable telephone, the high frequency power amplifier is constituted by an amplifying circuit A and an amplifying circuit B connected in parallel, a size of a transistor at an output stage of the amplifying circuit B is made to be equal to or smaller than ¼ of a size of a transistor of an output stage of the amplifying circuit A and a switching circuit is connected between a signal line forward from the output stage of the amplifying circuit A and a ground terminal.

Owner:RENESAS ELECTRONICS CORP

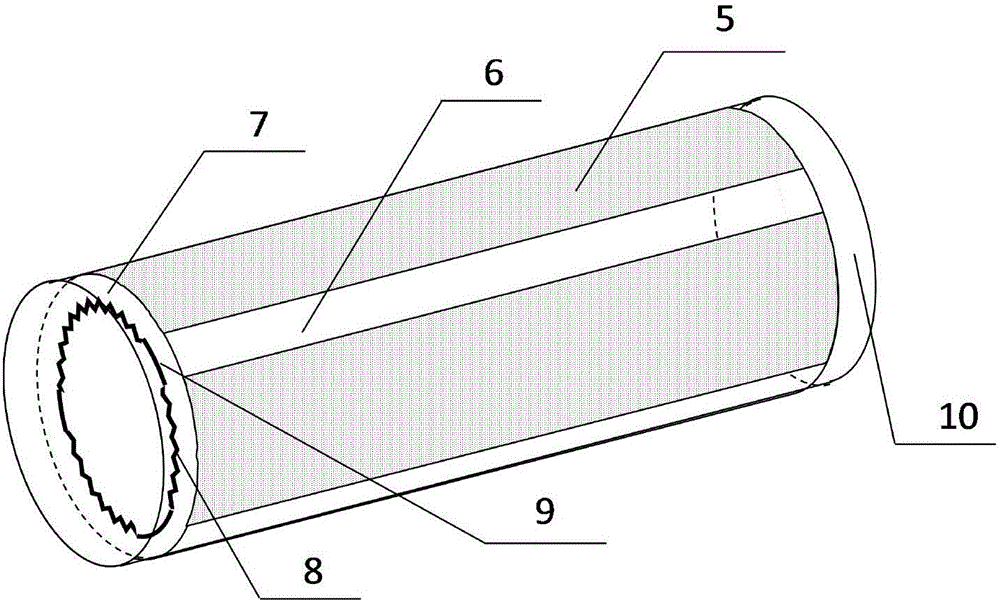

Composite wall surface sealed tube cavity used for side surface pumped alkali metal vapor laser

InactiveCN106785818ATake advantage ofWon't enterActive medium materialGas laser constructional detailsLight beamLength wave

The invention discloses a composite wall surface sealed tube cavity used for a side surface pumped alkali metal vapor laser. The composite wall surface sealed tube cavity is characterized by comprising an alkali metal vapor sealed tube cavity side wall and end windows positioned at the two ends of the alkali metal vapor sealed tube cavity side wall; a roughening region, which is used for performing roughening processing, is arranged on the inner wall surface of the alkali metal vapor sealed tube cavity side wall; the outer wall surface of the alkali metal vapor sealed tube cavity side wall is coated with high-reflective films with corresponding pumping wavelengths to form a high-reflective film region; the high-reflective films are corresponding to the roughening region; and a non-film-coated region between adjacent high-reflective films is used as an incident region of semiconductor pumped beams. By adoption of the composite wall surface sealed tube cavity, parasitic oscillation in the vapor cavity can be effectively suppressed, pumped energy loss and corresponding thermal load related therewith can be effectively reduced, and output power of a DPAL system can be improved.

Owner:SOUTH WEST INST OF TECHN PHYSICS

Control method applied to active-clamp flyback miniature photovoltaic grid-connected inverter device

ActiveCN102307017BImprove EMI characteristicsImprove efficiencyDc-dc conversionPhotovoltaic energy generationConstant frequencyPeak value

Owner:ALTENERGY POWER SYST

Manufacturing process of bulk acoustic wave resonator and bulk acoustic wave resonator

ActiveCN112202415AImprove performanceEasy wiringImpedence networksChemical treatmentElectrical field strength

The invention discloses a manufacturing process of a bulk acoustic wave resonator, which comprises the following steps: manufacturing an acoustic reflector on a substrate, and manufacturing a bottom electrode layer for covering the acoustic reflector on the substrate; carrying out chemical treatment on the peripheral part of the bottom electrode layer to form a modified layer, wherein the modifiedlayer surrounds the bottom electrode layer; manufacturing a piezoelectric layer on the bottom electrode layer; and manufacturing a top electrode layer on the piezoelectric layer. Also disclosed is abulk acoustic wave resonator including a substrate, an acoustic mirror formed on the substrate, and a bottom electrode layer, a piezoelectric layer, and a top electrode layer sequentially formed on the substrate having the acoustic mirror, wherein a portion, adjacent to an edge of the acoustic mirror, of the bottom electrode layer is chemically treated to form the modified layer. By means of the formation of the modified layer, the electric field intensity between the outer electrodes in the effective working area is weakened or eliminated, the electrodes cannot excite the piezoelectric layerbetween the electrodes to generate mechanical waves, parasitic oscillation of the resonator is restrained, and meanwhile wiring of the top electrode is greatly simplified.

Owner:HANGZHOU XINGHE TECH CO LTD

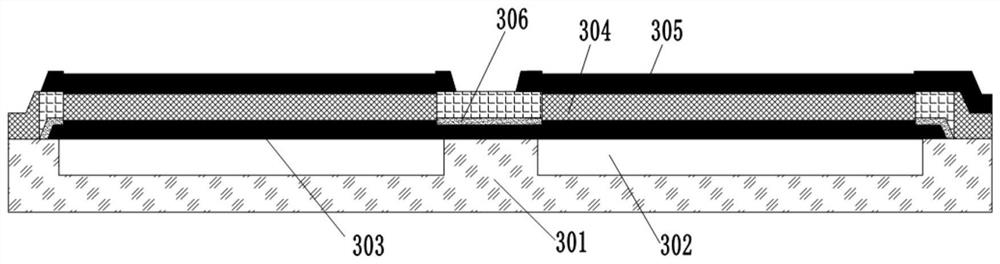

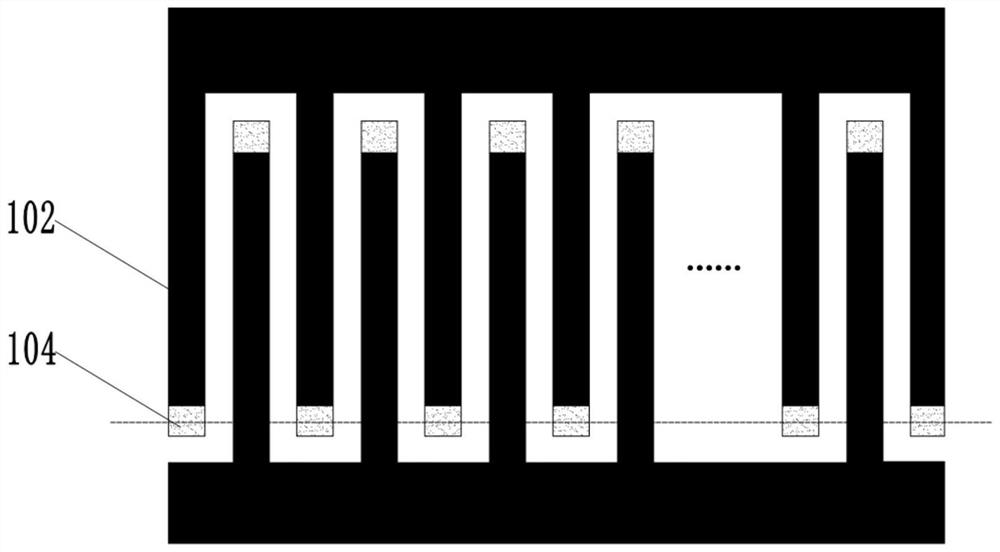

Interdigital electrode structure, manufacturing method thereof, and surface acoustic wave device having the structure

ActiveCN111934644BImprove performanceNo need to change thicknessImpedence networksEngineeringSurface acoustic wave

An interdigital electrode structure is disclosed. The interdigital electrode structure is disposed on a substrate, wherein the ends of the interdigital electrodes in the interdigital electrode structure are implanted with ions to form a doped part. Also disclosed is a surface acoustic wave device, which includes the above interdigitated electrode structure, and the surface acoustic wave device is a filter or a resonator. In addition, a method for manufacturing an interdigital electrode structure is also disclosed, including preparing a substrate with a piezoelectric layer; fabricating an interdigital electrode on the substrate; and performing ion implantation on the interdigital electrode to form a The end forms a doped portion. The doped part is formed by ion implantation at the end of the interdigitated electrode, which improves the electric field gradient at the end of the electrode without changing the weight of the agent and does not adjust the thickness of the interdigitated electrode, suppresses parasitic oscillations, and ultimately improves the performance of the surface acoustic wave device. .

Owner:HANGZHOU JWL TECH INC

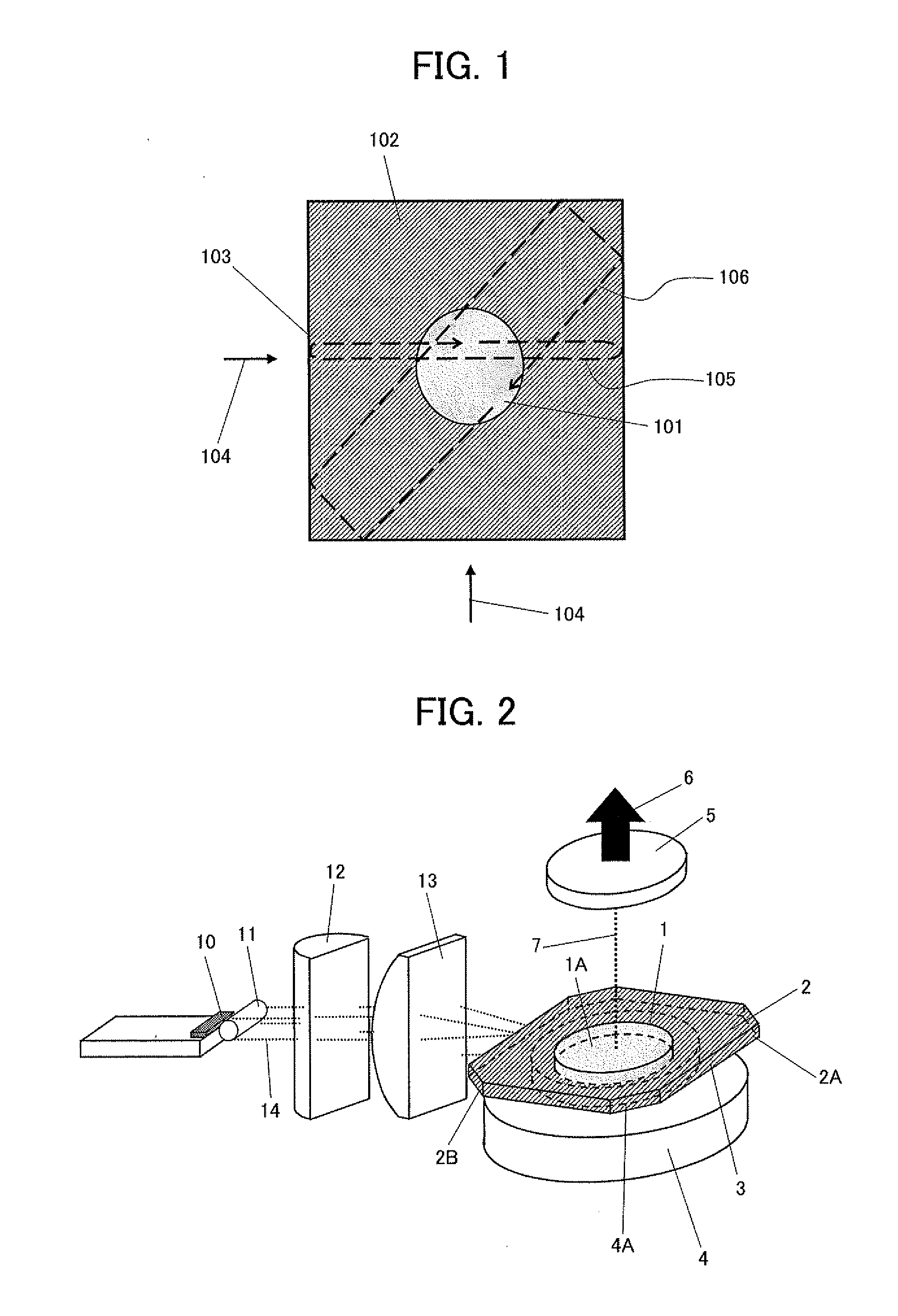

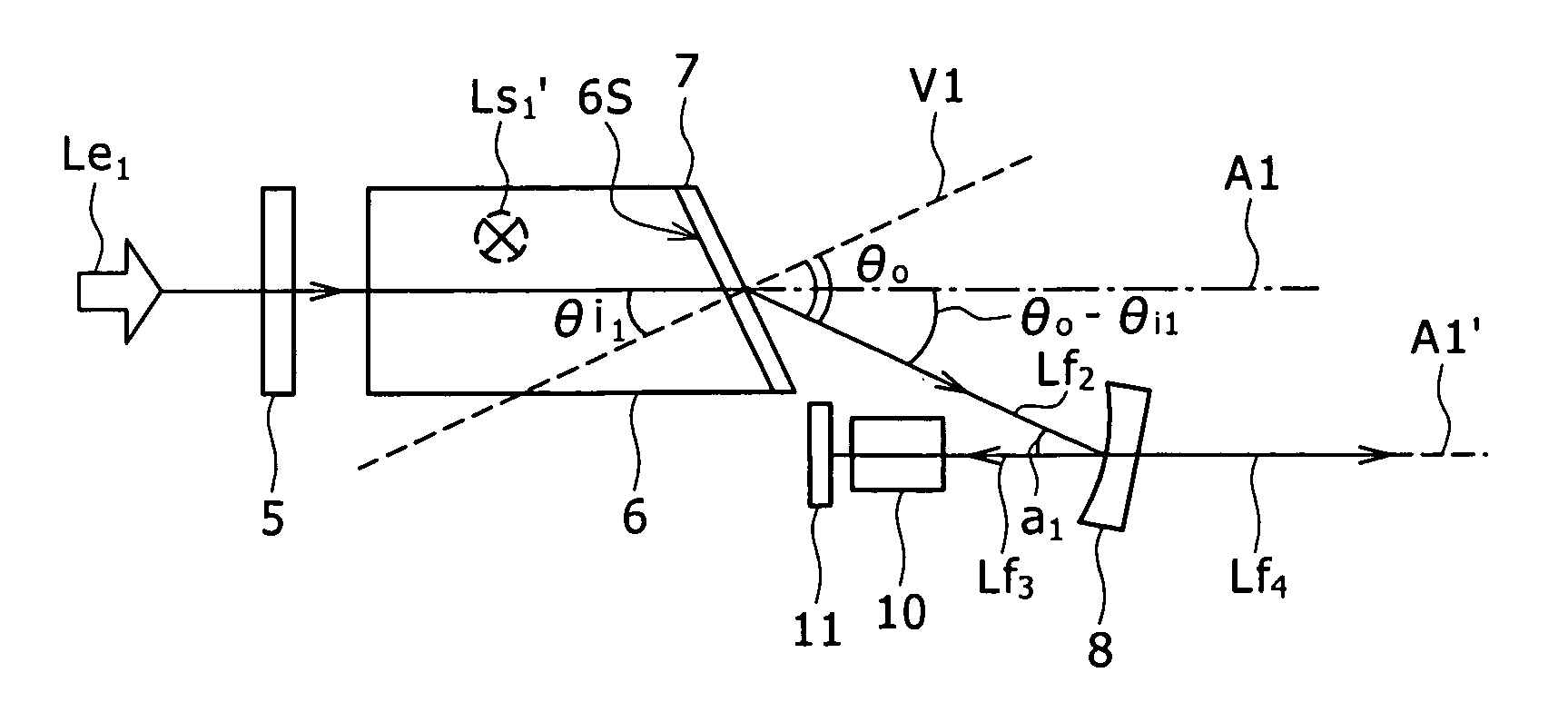

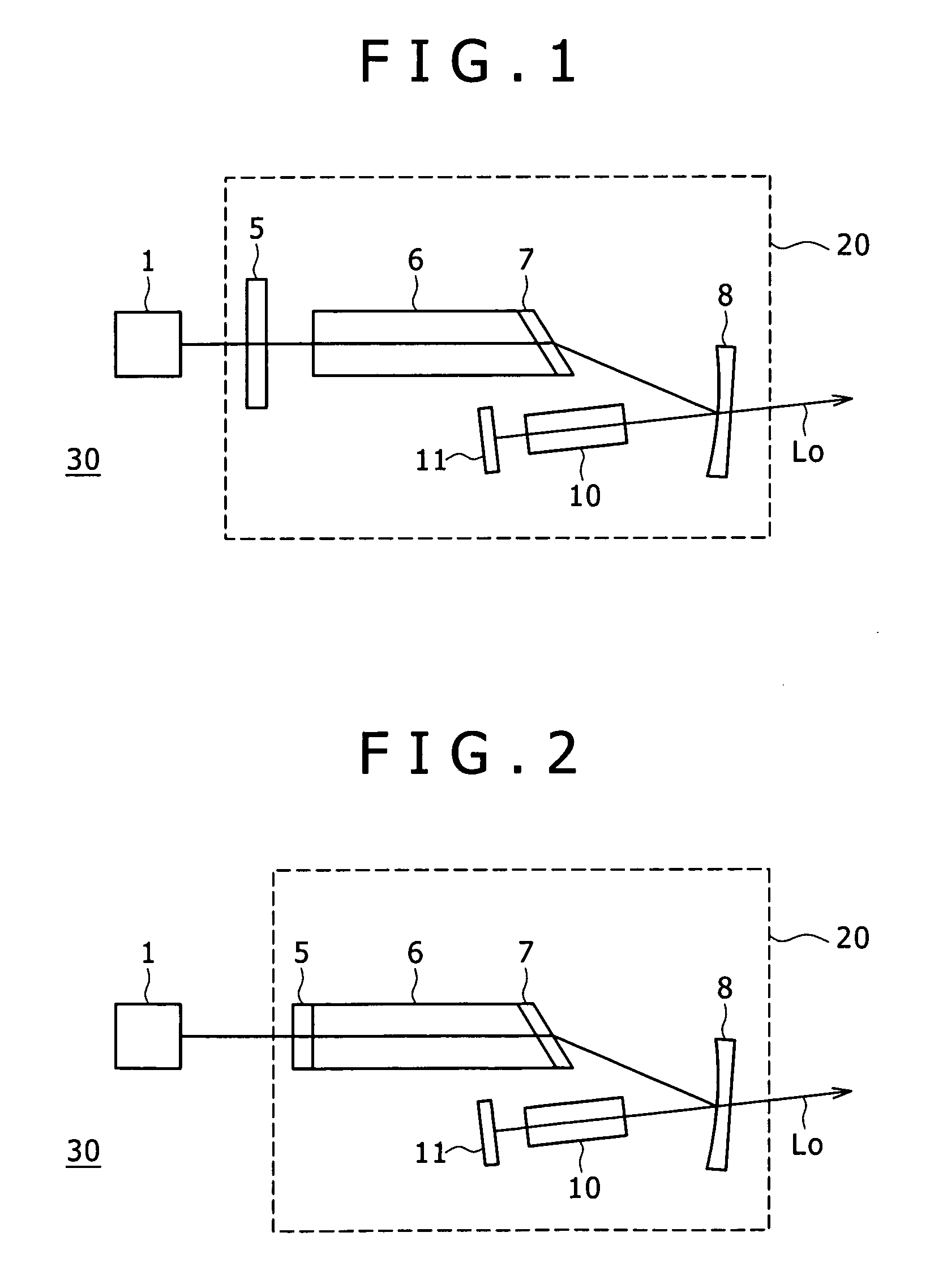

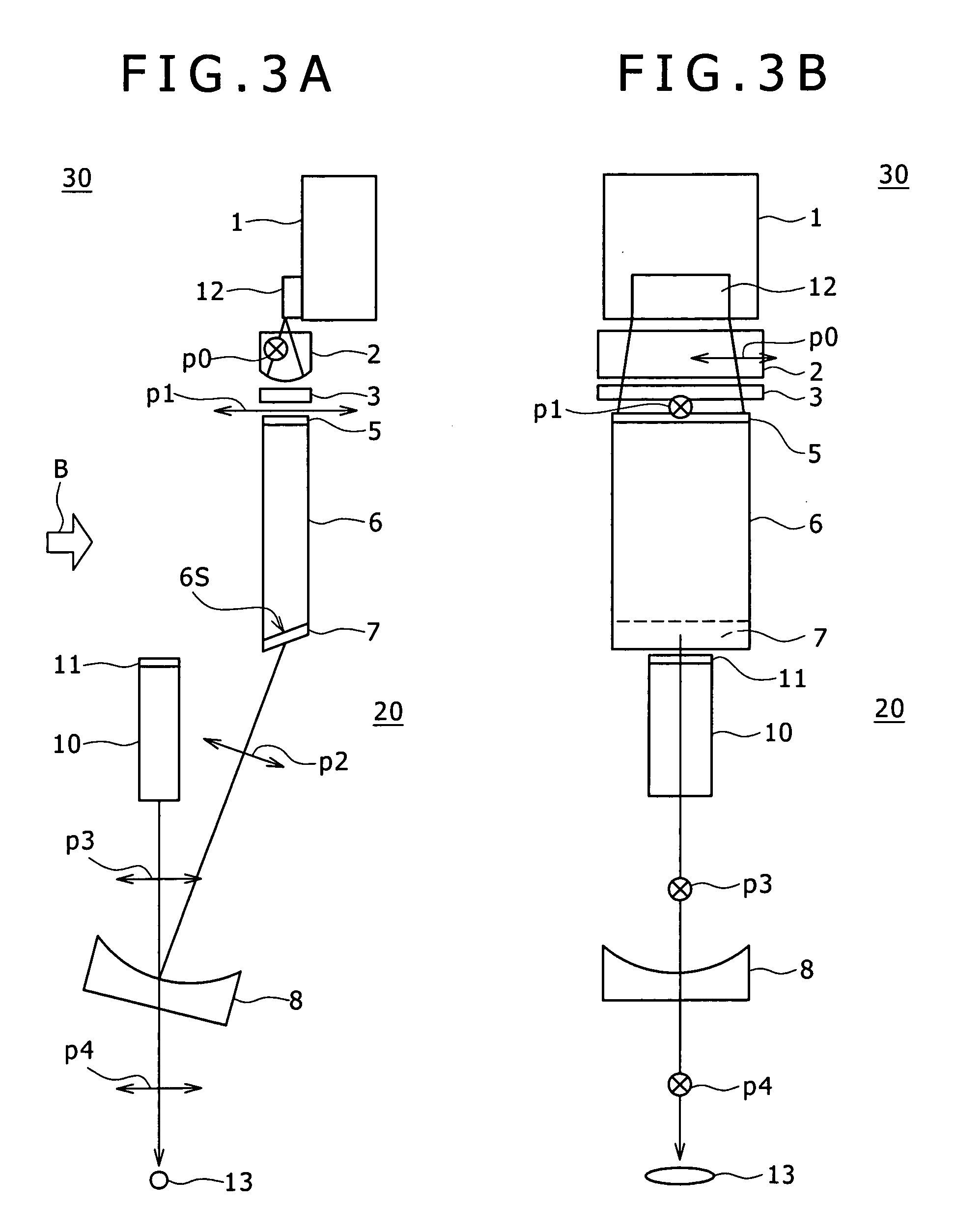

Laser light source device and image generating device using same

InactiveUS20090052481A1Suppress parasitic oscillationReduce the overall heightLaser detailsOptical elementsLaser lightLength wave

Disclosed herein is a laser light source device including a pumping light source; a pair of resonator mirrors; a laser medium and a wavelength converting element within a resonator formed by the resonator mirrors; the laser medium being pumped by light in a transverse multi-mode pattern, the wavelength converting element being irradiated with a linear fundamental wave obtained by oscillation of the laser medium, and a linear converted wave being output; a reflecting part for folding back a resonant light path, the reflecting part being disposed on the light path between the laser medium and the wavelength converting element; an end surface of one of the laser medium and the wavelength converting element being formed as an inclined surface at other than a Brewster angle; and a polarizing film disposed on the inclined surface.

Owner:SONY CORP

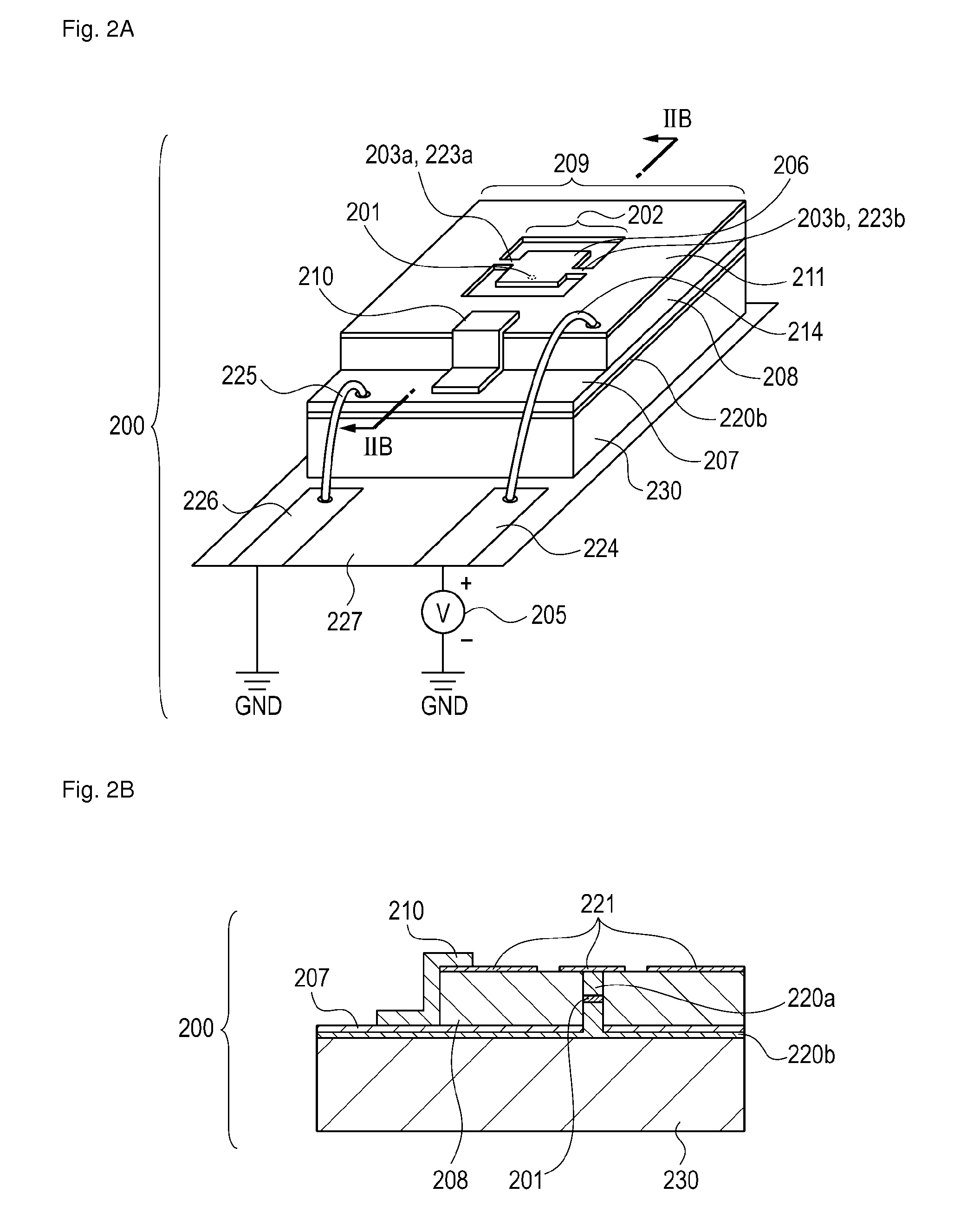

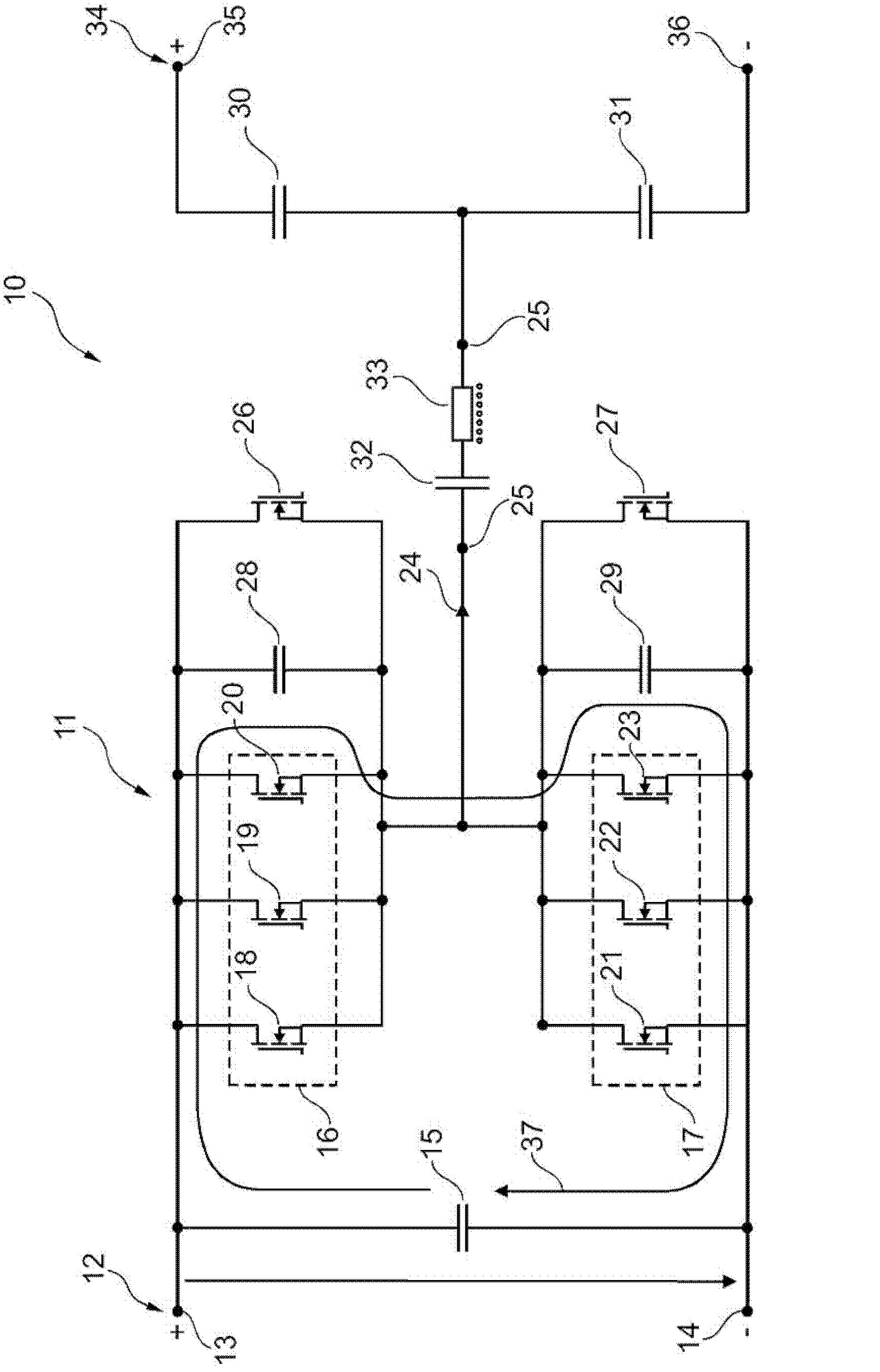

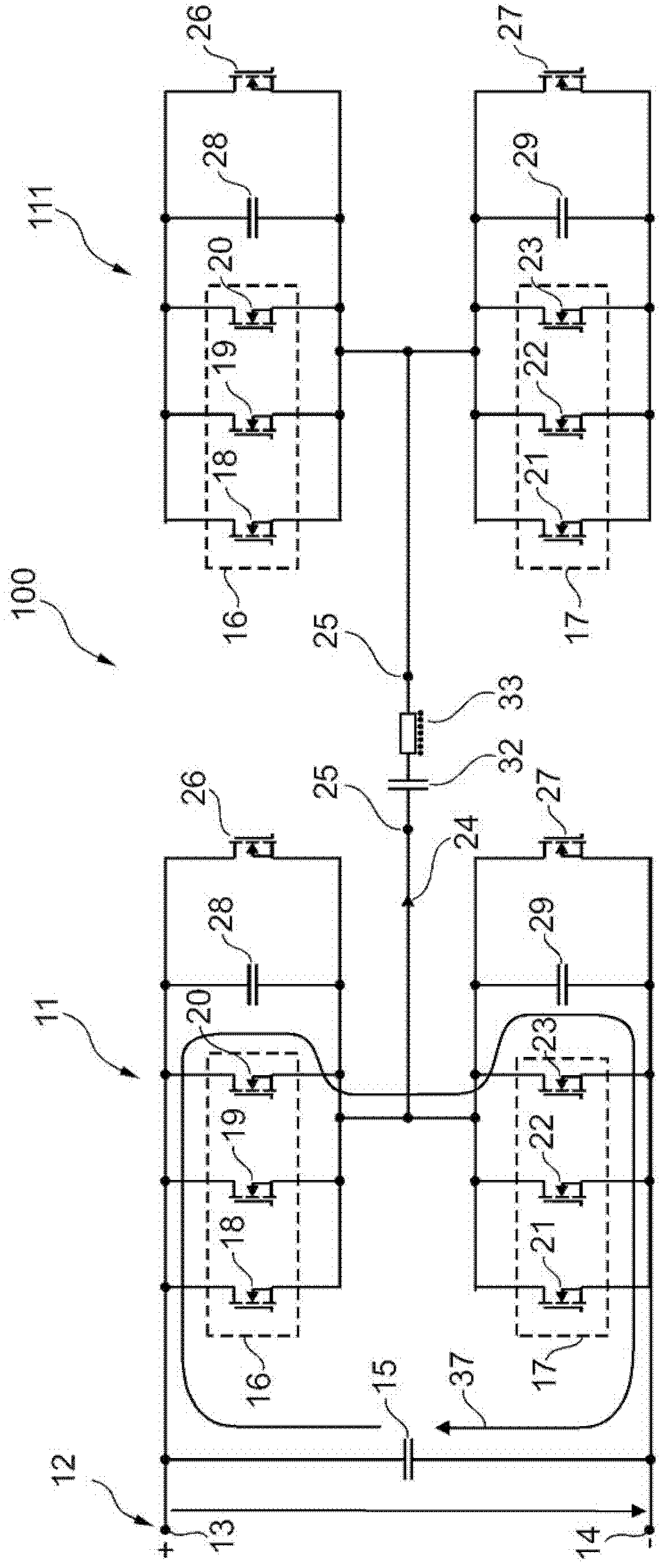

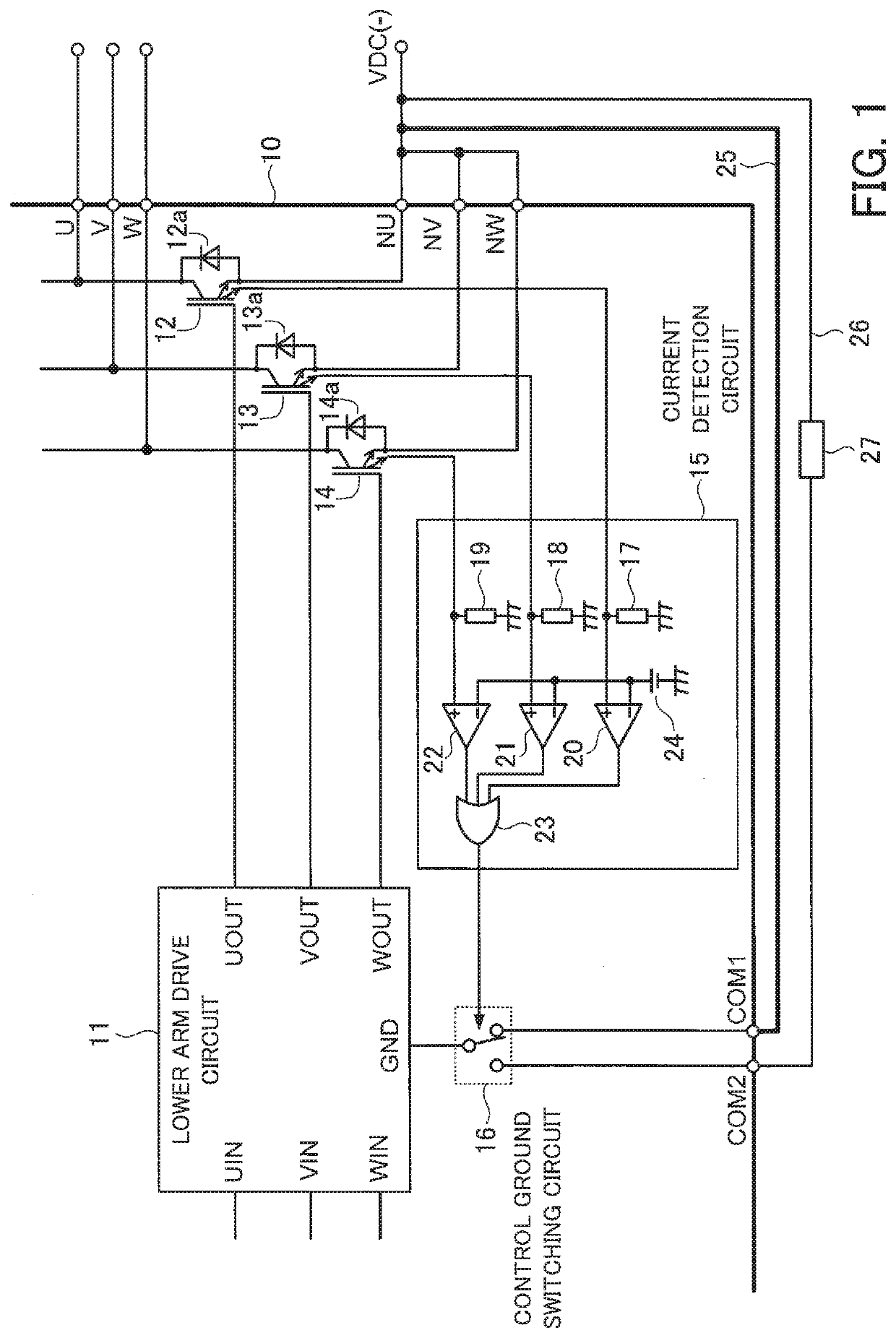

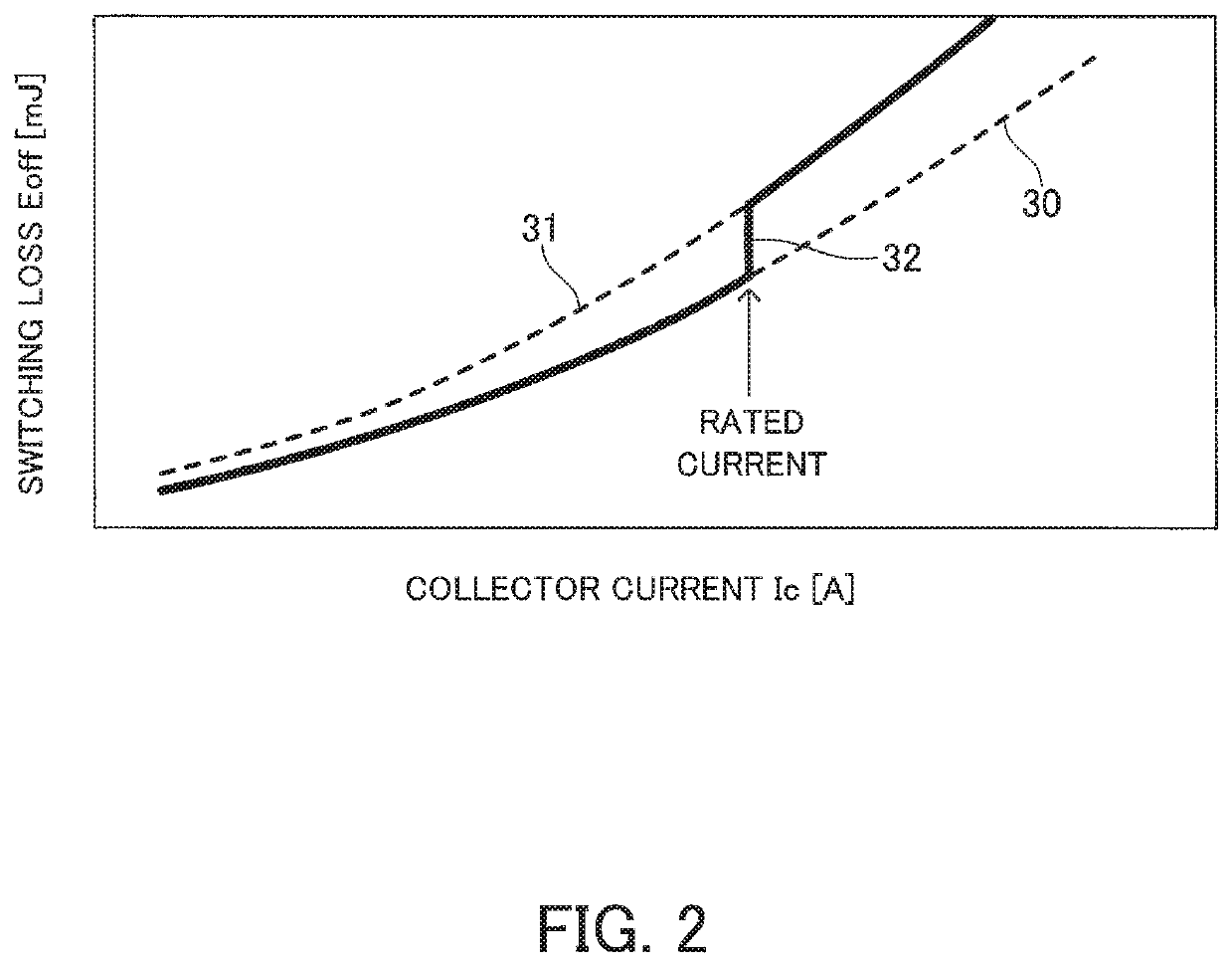

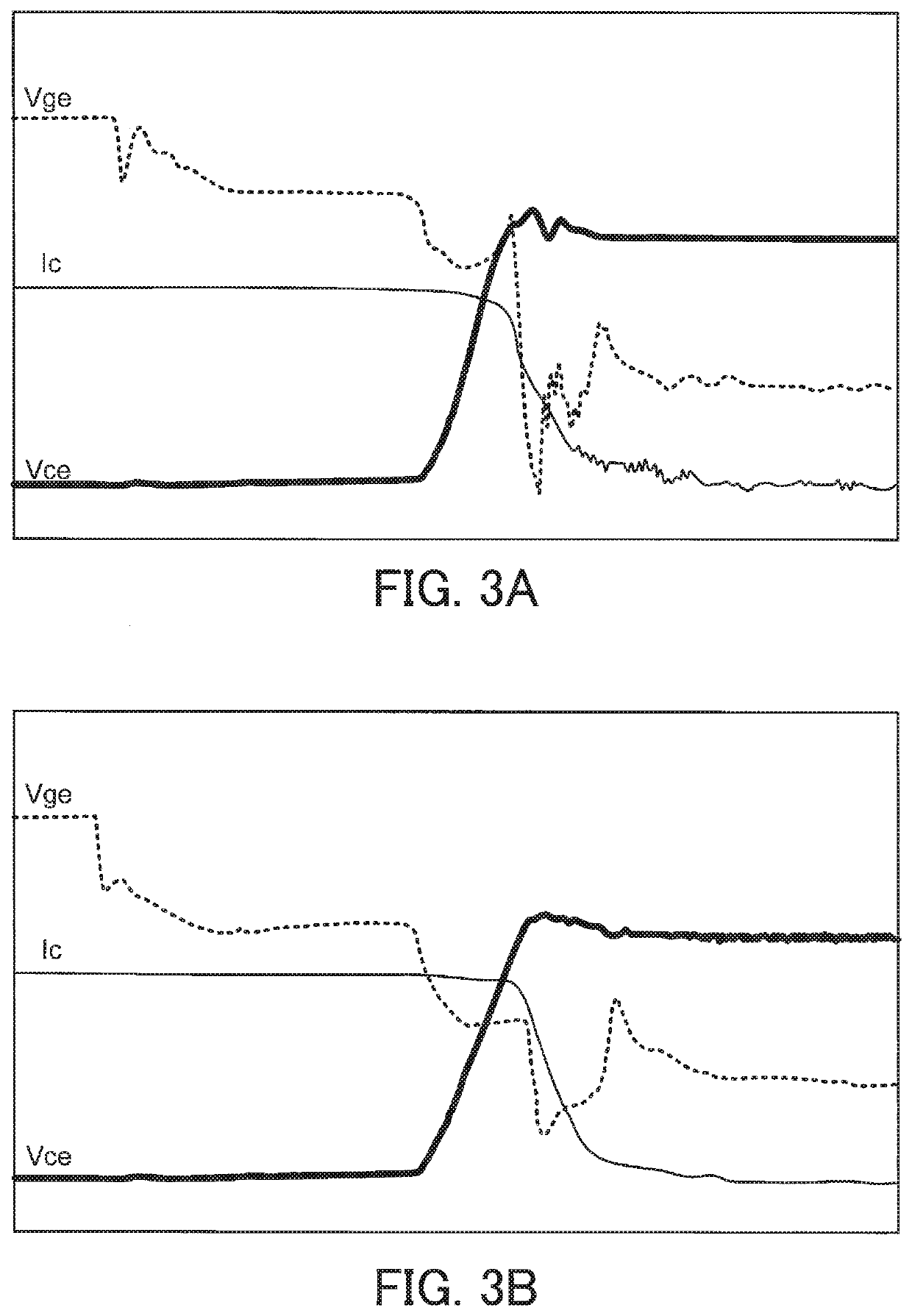

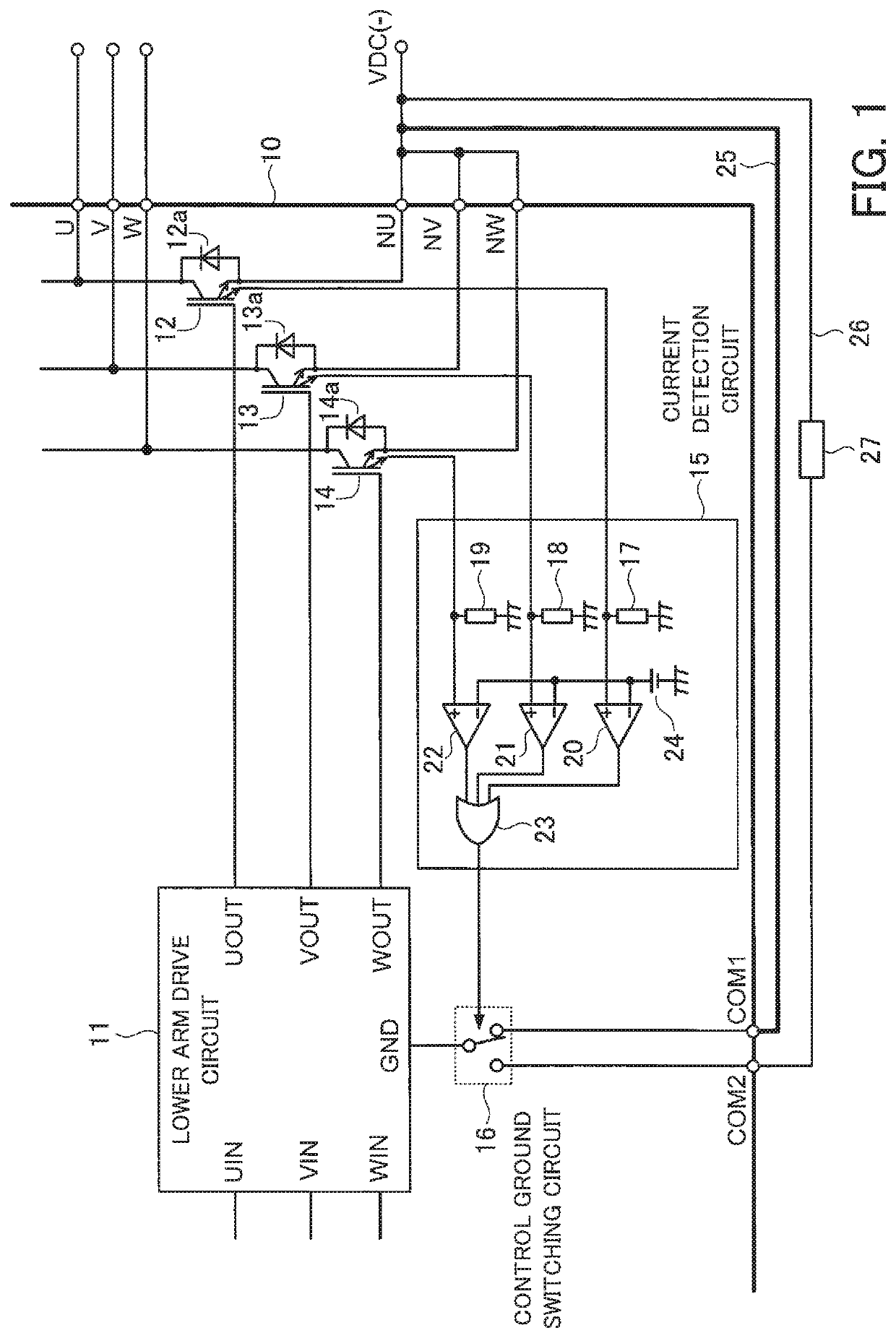

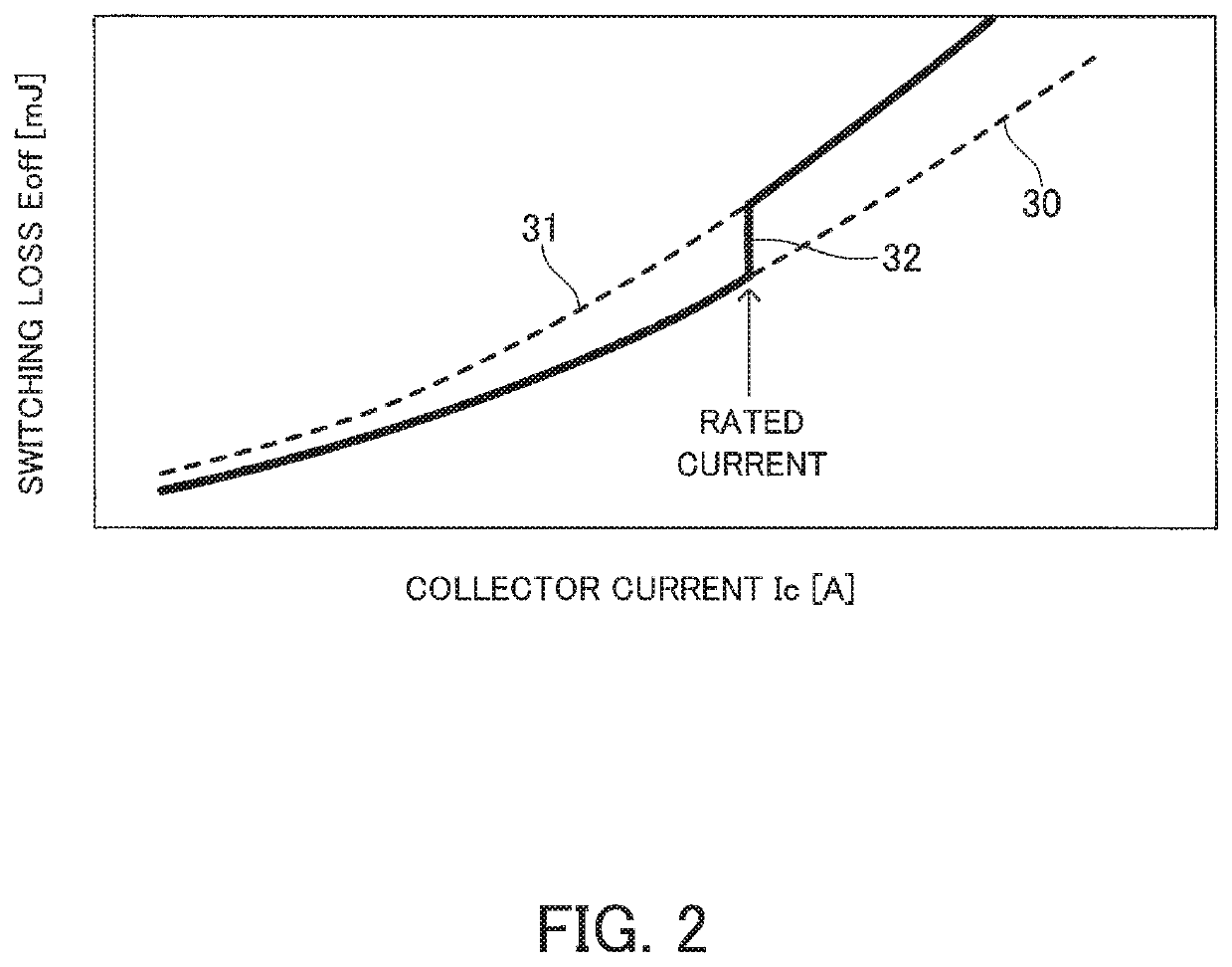

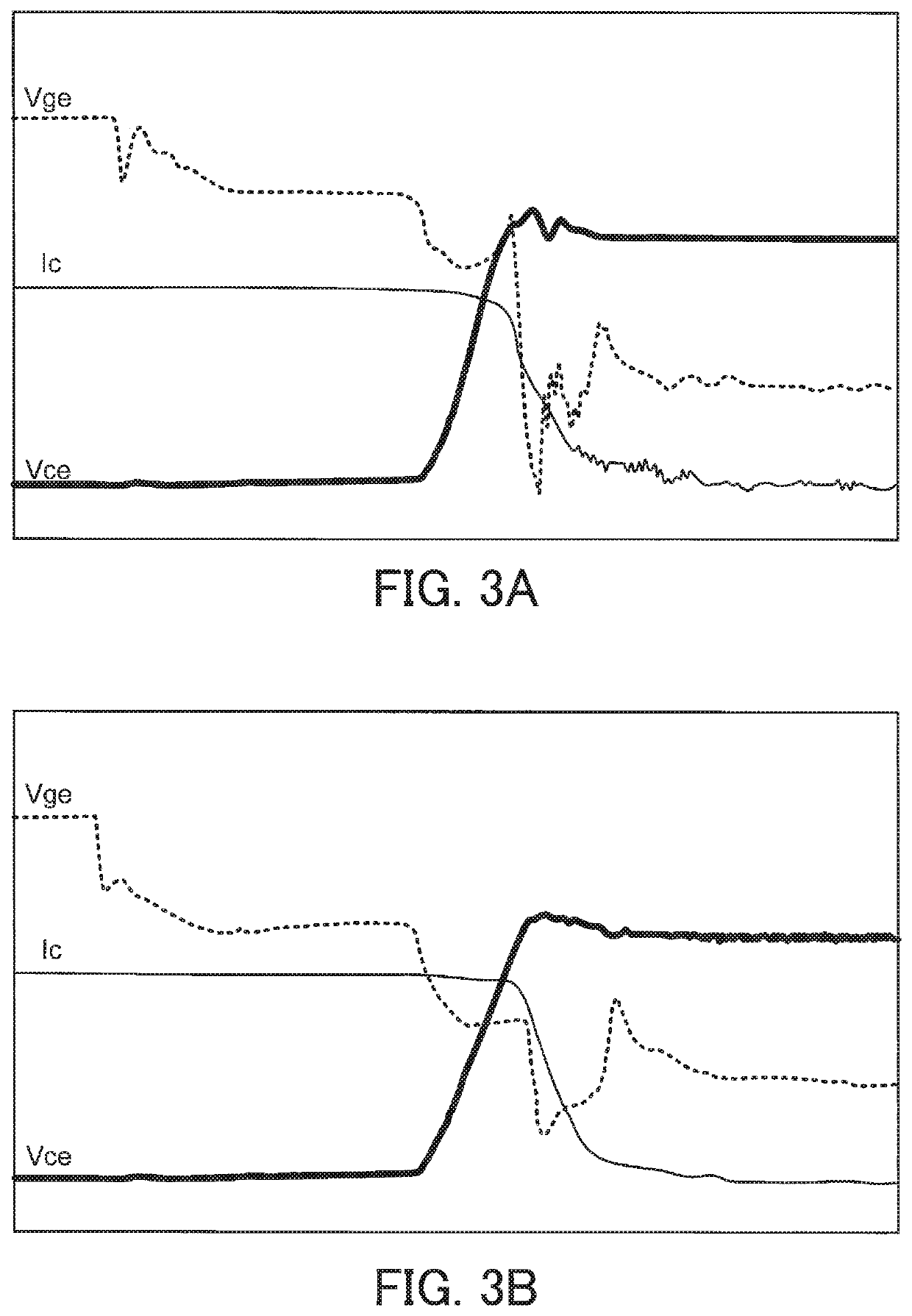

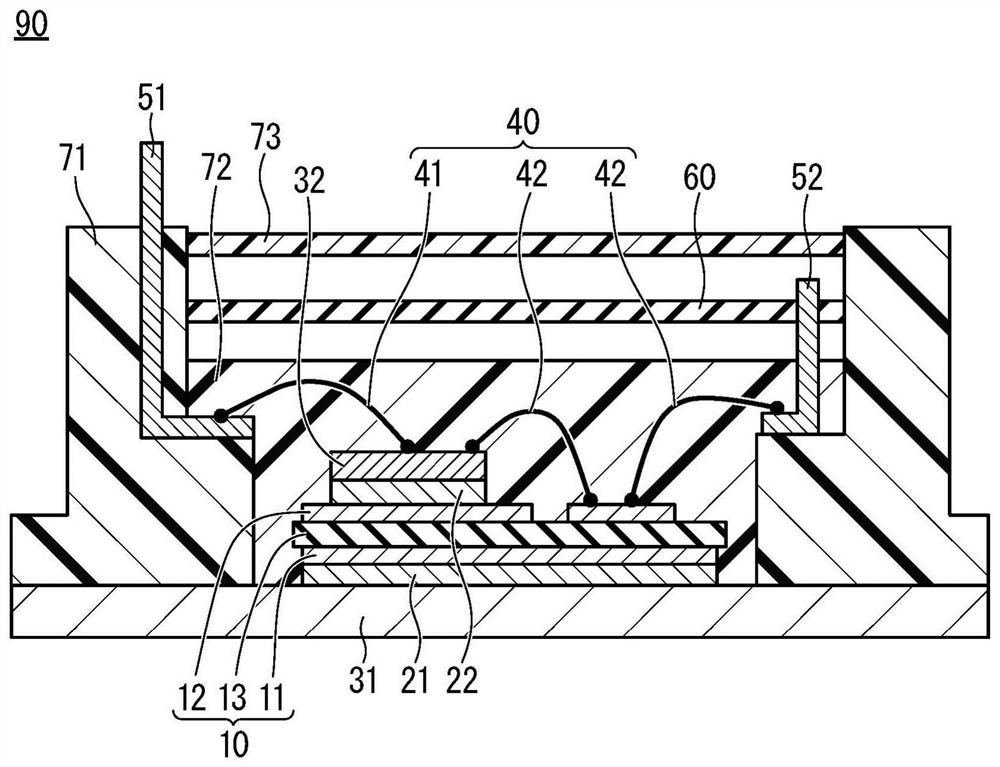

Power module with built-in drive circuit

ActiveUS20200321901A1Suppress parasitic oscillationEasy to operateAC motor controlAc-dc conversionControl engineeringHemt circuits

A power module including a half bridge circuit having first and second switching elements respectively included in an upper arm and a lower arm thereof, and upper and lower arm drive circuits which respectively drive the first and second switching elements. The power module includes a first ground terminal on a ground side of the second switching element, a second ground terminal connected, via a first ground wiring, to the first ground terminal, a third ground terminal connected, via a second ground wiring including a dumping resistor, to the first ground terminal, a current detection circuit detecting a current flowing through the second switching element, and a control ground switching circuit which performs switching according to a value of the current detected by the current detection circuit, so as to connect a ground terminal of the lower arm drive circuit to the second or third ground terminal.

Owner:FUJI ELECTRIC CO LTD

Power module with built-in drive circuit

ActiveUS11050358B2Suppress parasitic oscillationEasy to operateAC motor controlAc-dc conversionControl engineeringHemt circuits

A power module including a half bridge circuit having first and second switching elements respectively included in an upper arm and a lower arm thereof, and upper and lower arm drive circuits which respectively drive the first and second switching elements. The power module includes a first ground terminal on a ground side of the second switching element, a second ground terminal connected, via a first ground wiring, to the first ground terminal, a third ground terminal connected, via a second ground wiring including a dumping resistor, to the first ground terminal, a current detection circuit detecting a current flowing through the second switching element, and a control ground switching circuit which performs switching according to a value of the current detected by the current detection circuit, so as to connect a ground terminal of the lower arm drive circuit to the second or third ground terminal.

Owner:FUJI ELECTRIC CO LTD

oscillator

ActiveUS20160020730A1Difficult to applySuppress parasitic oscillationElectric pulse generatorOscillations generatorsCapacitanceInductance

An oscillator includes a resonator configured to resonate an electromagnetic wave in a resonant axis direction and a capacitance unit electrically connected in parallel to the resonator. The resonator includes a negative resistor, a first conductive layer, and a second conductive layer, where the negative resistor has a gain to the electromagnetic wave and is disposed between and in contact with the first conductive layer and the second conductive layer. At a resonant frequency fLC generated by an inductance Ls which the wiring configured to electrically connect the capacitance unit to the resonator and the capacitance unit constitute, and an inner capacitance Cwg of the resonator, a conductance including the inductance Ls, a resistance component Rs of the wiring and the capacitance unit, and a capacitance C of the capacitance unit is equal to or higher than an absolute value Gwg of negative conductance of the negative resistor.

Owner:CANON KK

er, yb co-doped fiber for improving laser efficiency in 1.5μm band

ActiveCN105158844BImprove conversion efficiencySuppress parasitic oscillationOptical fibre with multilayer core/claddingOptical waveguide light guideEngineeringParasitic oscillation

The invention relates to an Er / Yb co-doped fiber for improving 1.5 mum laser efficiency, and is suitable for the laser communication field. The fiber comprises a fibre core, an inner wrapping layer, an outer wrapping layer and a coating layer from the inside out. The fibre core is formed by straight core and a section of spiral core; and fibre loss can be changed by adjusting spiral pitch of the spiral core and offset amount of a center shaft, and thus fibre loss in 1 mum wave band is allowed to be larger than fibre loss in 1.5 mum wave band. The features above allow the Er / Yb co-doped fiber to be applied to a high-power Er / Yb co-doped fiber laser, and thus the problem of 1 mum parasitic oscillation is effectively solved, and 1.5 mum laser output power is improved.

Owner:XUZHOU NORMAL UNIVERSITY

A thin-film bulk acoustic resonator and its manufacturing process

ActiveCN111817679BImprove performanceNo need to worry about mechanical stabilityImpedence networksThin-film bulk acoustic resonatorThin membrane

A thin film bulk acoustic resonator is disclosed, comprising a bottom electrode layer, a piezoelectric layer and a top electrode layer arranged on the upper part of the substrate where the acoustic wave reflection structure is located, wherein the part of the piezoelectric layer corresponding to the boundary of the acoustic wave reflection structure passes through the retrograde Polarization treatment to form a depolarized portion. Also disclosed is a manufacturing process of a thin film bulk acoustic resonator, comprising making a bottom electrode layer on a substrate on which an acoustic wave reflection structure is formed or to be formed to cover the acoustic wave reflection structure; making a piezoelectric layer on the bottom electrode layer; The part of the layer corresponding to the boundary of the acoustic wave reflection structure is depolarized to form a depolarized part; and the top electrode layer is made on the piezoelectric layer. The thin-film bulk acoustic resonator and its manufacturing process can inhibit the shear wave from taking energy away from the resonant area above the cavity of the resonator, thereby ensuring the mechanical vibration strength of the resonant area, suppressing parasitic oscillation, and improving the Q value of the resonator.

Owner:HANGZHOU JWL TECH INC

Semiconductor device

PendingCN113691109ASimple structureReduce in quantitySemiconductor/solid-state device detailsAc-dc conversionDevice materialHemt circuits

Provided is a semiconductor device in which parasitic oscillation between a plurality of semiconductor elements connected in parallel with each other can be suppressed by a simple configuration. The plurality of semiconductor elements (EL) connected in parallel include a plurality of first semiconductor elements (EL1) and a plurality of second semiconductor elements (EL2). A drive circuit (200) for supplying a gate signal to each of a plurality of semiconductor elements (EL) includes a main circuit (201) and a plurality of insertion circuits (210) including a first insertion circuit (211) and a second insertion circuit (212). The first insertion circuit (211) is inserted between the main circuit (201) and the plurality of first semiconductor elements (EL1). A second insertion circuit (212) is inserted between the main circuit (201) and the plurality of second semiconductor elements (EL2). Each of the first insertion circuit (211) and the second insertion circuit (212) includes a first diode (D1) forward facing the main circuit (201) and a second diode (D2) reversely connected in parallel with the first diode (D1).

Owner:MITSUBISHI ELECTRIC CORP

Low-EMI asymmetrical centre tap rectification circuit

ActiveCN107248815AReduce distractionsEliminates or alleviates the draught effectEfficient power electronics conversionDc-dc conversionCapacitanceMagnetizing inductance

The invention relates to the field of DC / DC conversion, and aims at providing a low-EMI asymmetrical centre tap rectification circuit. The primary side of the low-EMI asymmetrical centre tap rectification circuit is a half-bridge LLC topology, the back stage is a centre tap rectification circuit; the windings at the primary and secondary sides of a power transformer adopt a staggered wound winding structure; the same-name end of the transformer winding is defined as a positive end and the other end is defined as a negative end; the negative pole of a first rectification diode and a negative end of a second secondary-side winding are connected with the positive end of an output filtering capacitor; the positive pole of a second rectification diode and the negative end of a first secondary-side winding is connected with the negative end of the output filtering capacitor; the positive pole of the first rectification diode is connected with the positive end of the first secondary-side winding; and the negative pole of the second rectification diode is connected with the positive end of the second secondary-side winding. The low-EMI asymmetrical centre tap rectification circuit reduces common-mode current and interference caused by the common-mode current, removes or relieves a current extraction effect from the common-mode current between the primary and secondary sides of the transformer to the current of an excitation inductor, reduces dead time of a bridge wall switch tube and improves the conversion efficiency of a converter.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com