Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Suppress buoyancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure-sensitive adhesive composition for optical film, pressure-sensitive adhesive layer for optical film, production method thereof, pressure-sensitive adhesive optical film and image display

ActiveCN101418198AExcellent productivityImprove machinabilityFilm/foil adhesivesPolarising elementsMeth-Optical thin film

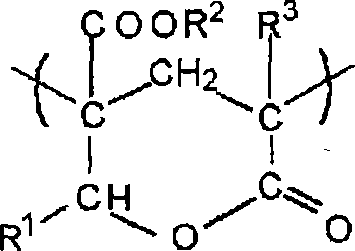

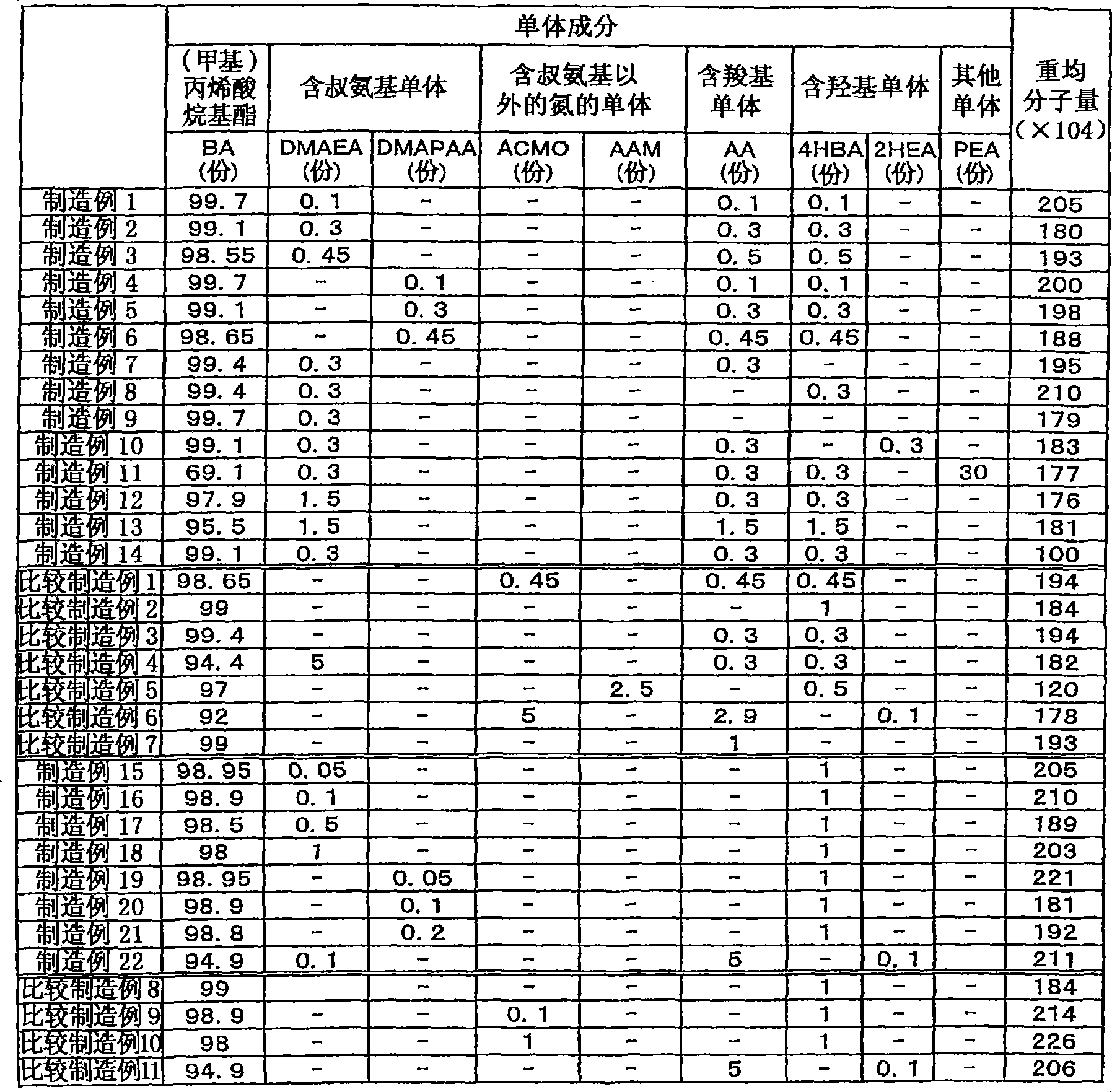

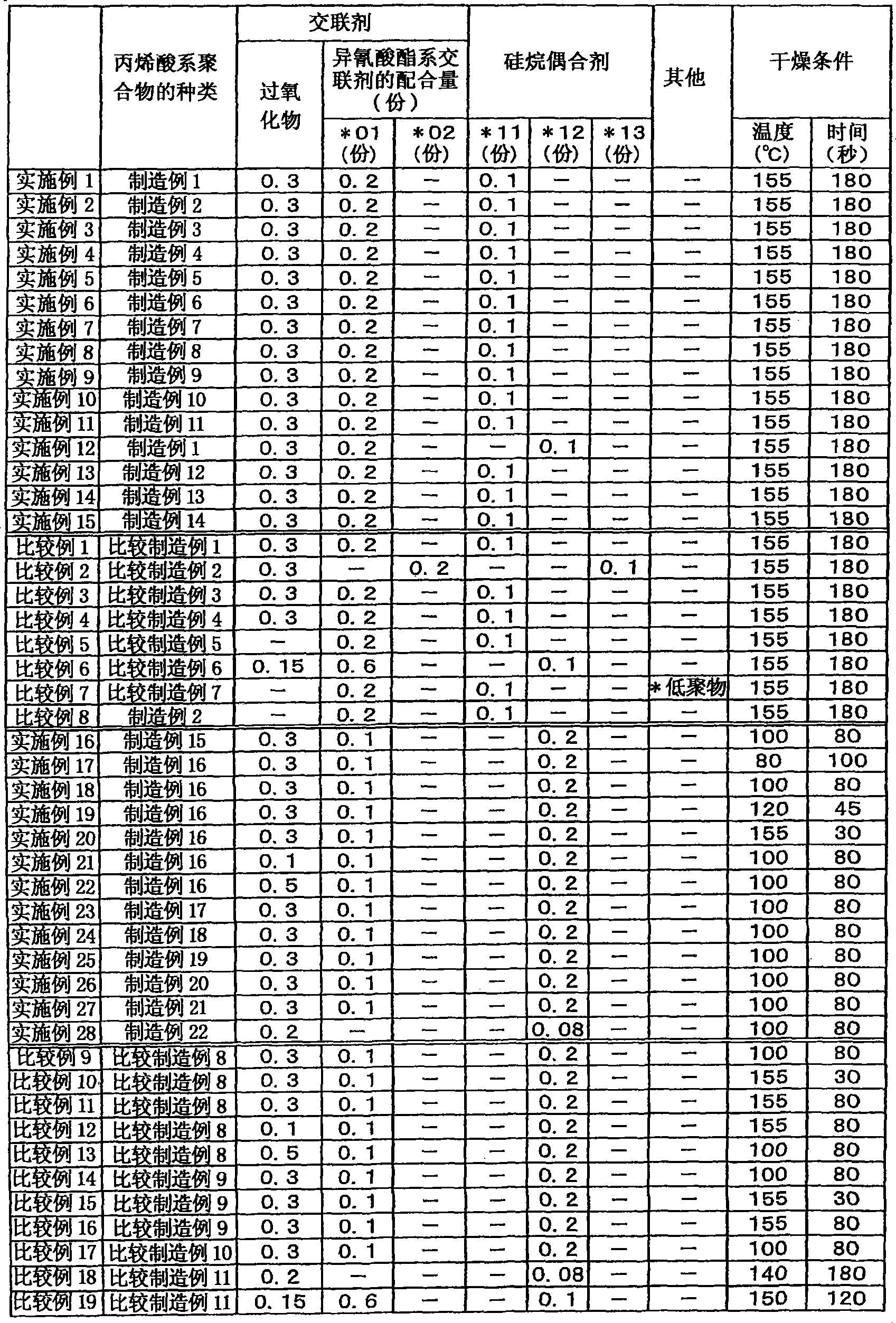

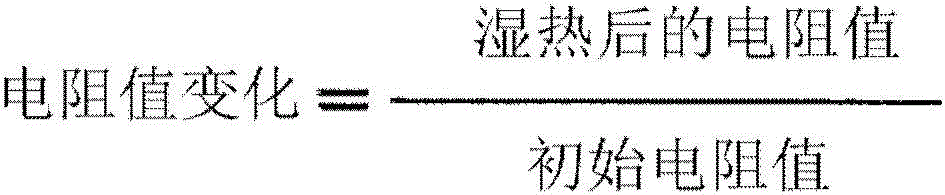

A pressure-sensitive adhesive composition can form an pressure-sensitive adhesive layer that has satisfactory reworkability such that optical films can be easily peeled from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be worked without pressure-sensitive adhesive fouling or dropout. The pressure-sensitive adhesive composition for an optical film of the present invention comprises 100 parts by weight of a (meth)acrylic polymer comprising 45 to 99.99% by weight of an alkyl (meth)acrylate monomer unit and 0.01 to 2% by weight of a tertiary amino group-containing monomer unit; and 0.01 to 2 parts by weight of a peroxide as a crosslinking agent.

Owner:NITTO DENKO CORP

Adhesive agent composition for optical films, adhesive agent layer for optical films, optical film having adhesive agent layer attached thereto, and image display device

ActiveCN106133096AIncreased durabilityPrevent peelingNon-macromolecular adhesive additivesPolarising elementsPolymer scienceMeth-

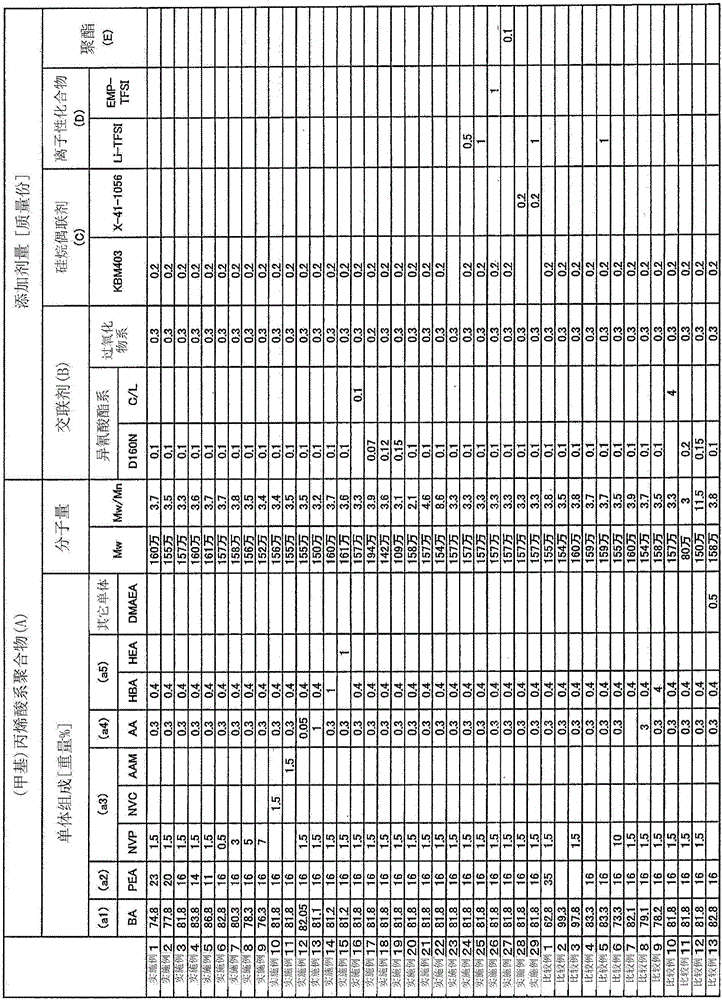

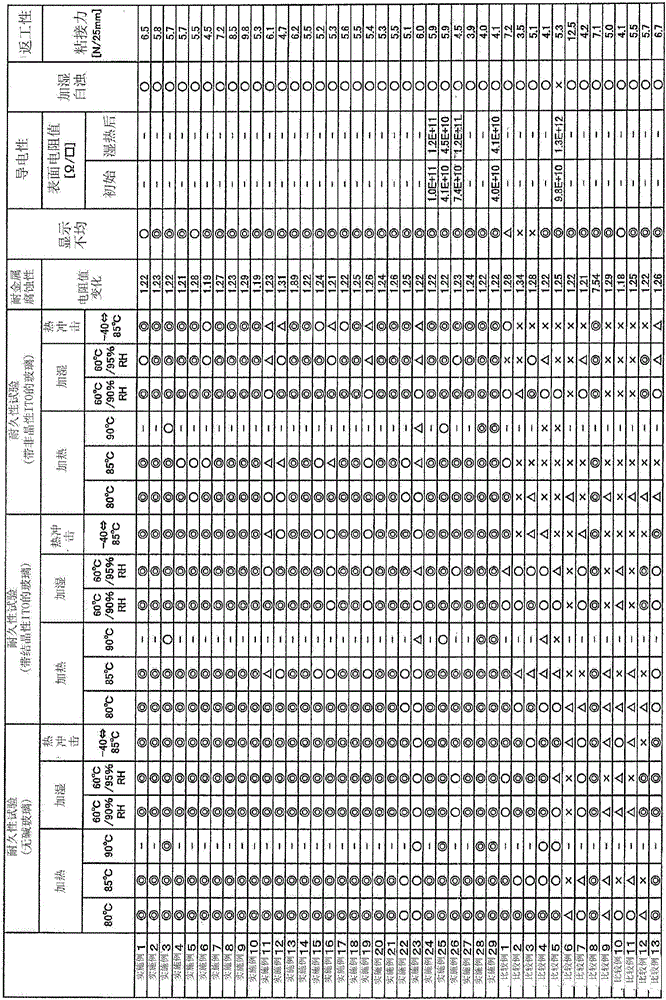

An adhesive agent composition for optical films, which comprises: a (meth)acrylic polymer (A) that contains, as monomer units, 70% by weight or more of an alkyl (meth)acrylate (a1), 3 to 25% by weight of an aromatic-ring-containing (meth)acrylate (a2), 0.1 to 8% by weight of an amide-group-containing monomer (a3), 0.01 to 2% by weight of a carboxyl-group-containing monomer (a4) and 0.01 to 3% by weight of a hydroxyl-group-containing monomer (a5) and meets such requirements that the weight average molecular weight (Mw) is 1,000,000 to 2,500,000 and the Mw / (number average molecular weight (Mn)) ratio is 1.8 to 10 inclusive; and a cross-linking agent (B) in an amount of 0.01 to 3 parts by weight relative to 100 parts by weight of the (meth)acrylic polymer (A). The adhesive agent composition can be formed into an adhesive agent layer which satisfies durability to such an extent that the adhesive agent layer does not undergo foaming, is not detached or does not get clouded under humidified conditions when applied onto a glass or a transparent conductive layer, and which can prevent the occurrence of display unevenness due to leakage of light, and which has excellent metal corrosion resistance.

Owner:NITTO DENKO CORP

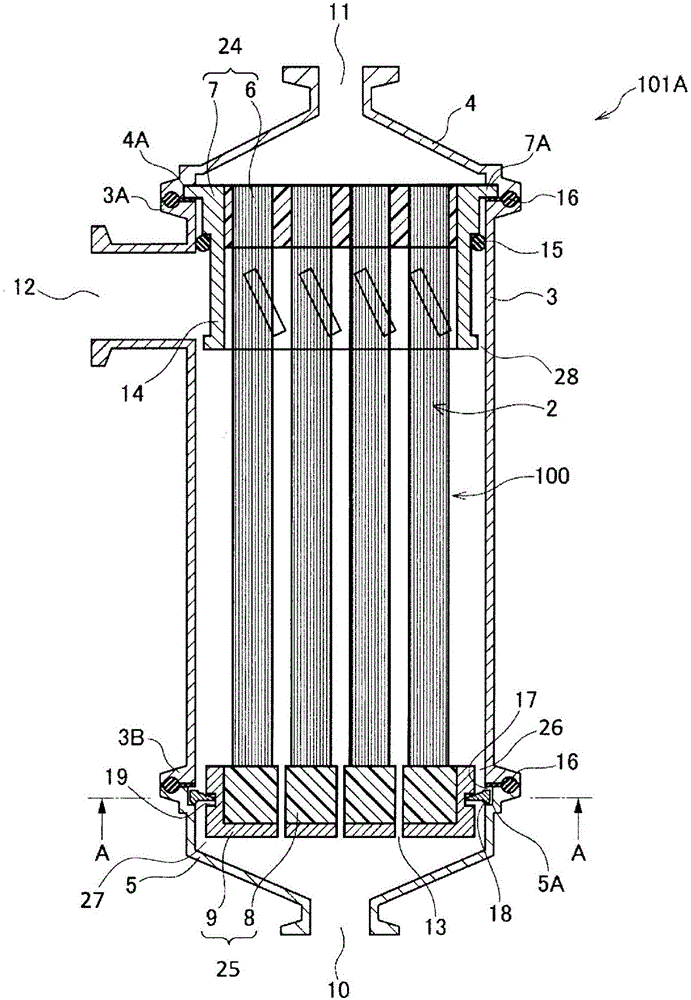

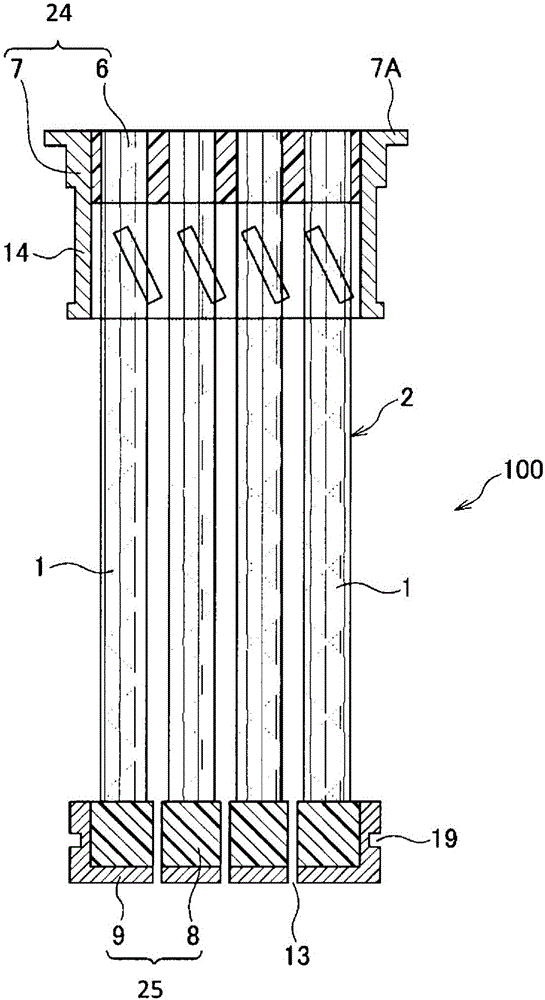

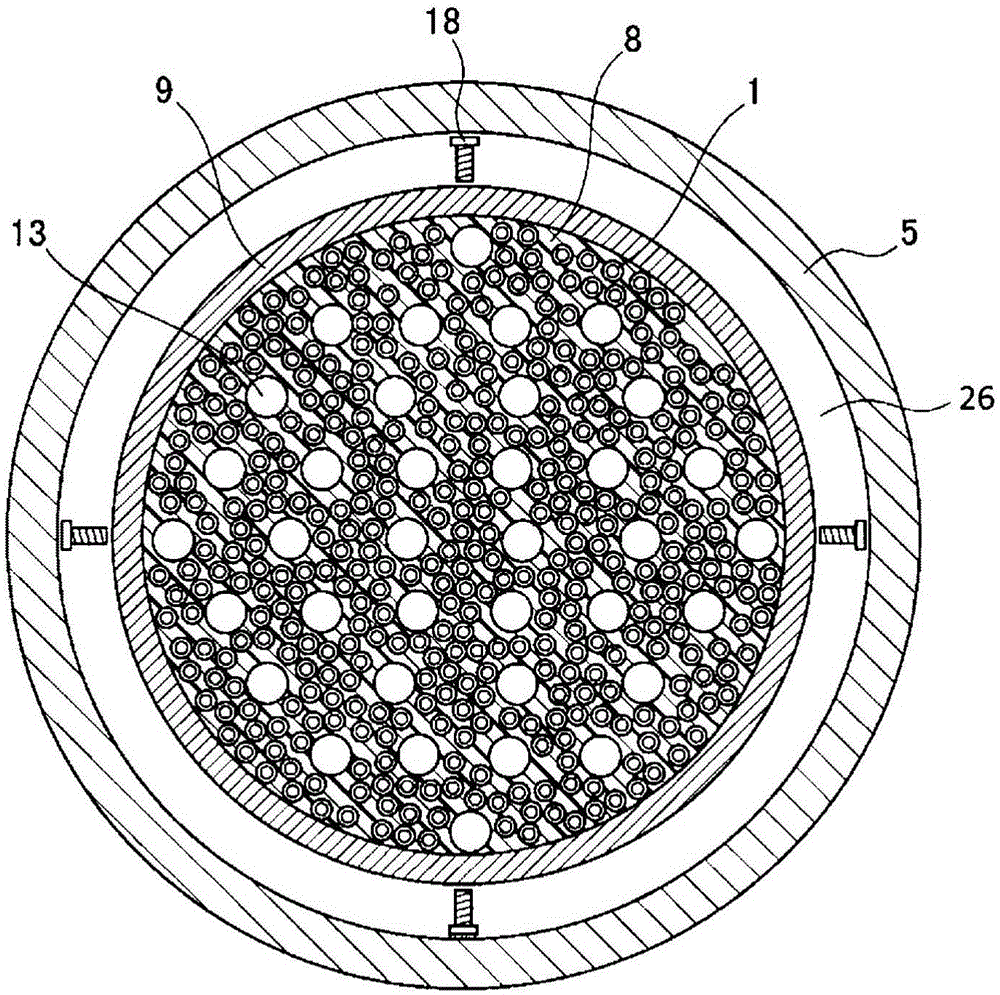

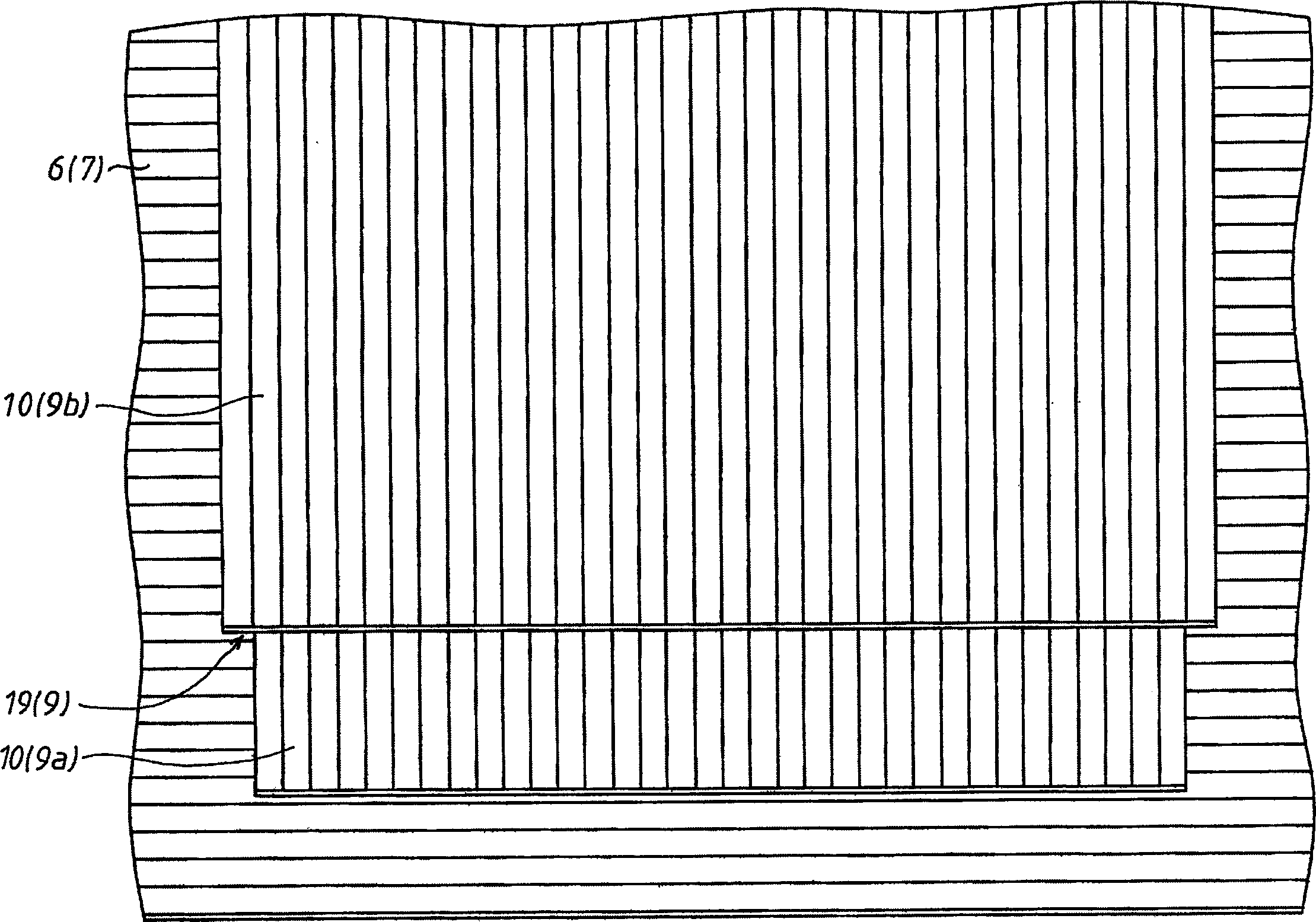

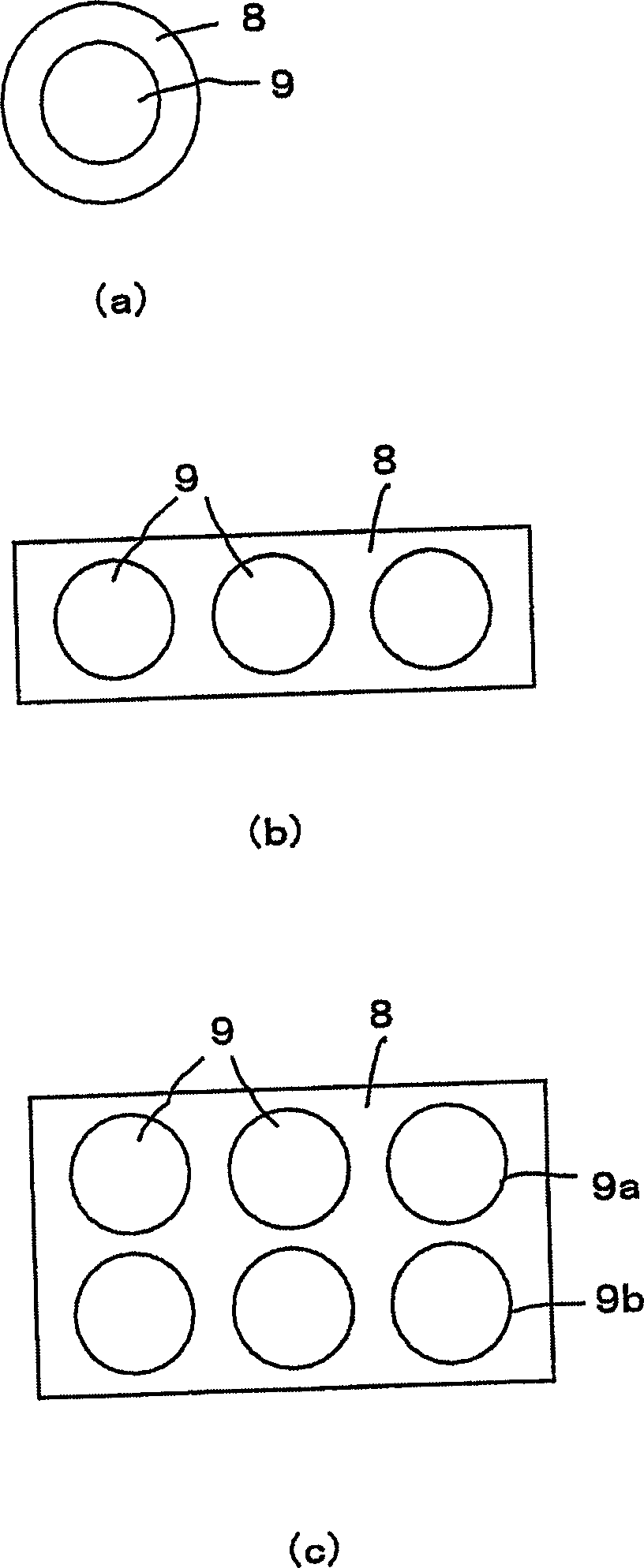

Cartridge type hollow fiber membrane module

ActiveCN105142764ASuppress buoyancyAvoid damageSemi-permeable membranesMembranesEngineeringMechanical engineering

This cartridge type hollow fiber membrane module is provided with: a housing; a plurality of hollow fiber membranes accommodated in the housing; a first potting section bundled in a state in which a first end part of the hollow fiber membranes forms an opening; a second potting section bundled in a state in which a second end part of the hollow fiber membranes forms a seal; an affixing section that affixes the first potting section attachably and detachably to the housing; a seal section that creates a watertight seal between the first potting section and the housing; and a holding section that holds the second potting section attachably and detachably to the housing and allows liquid to pass between the second potting section and the housing.

Owner:TORAY IND INC

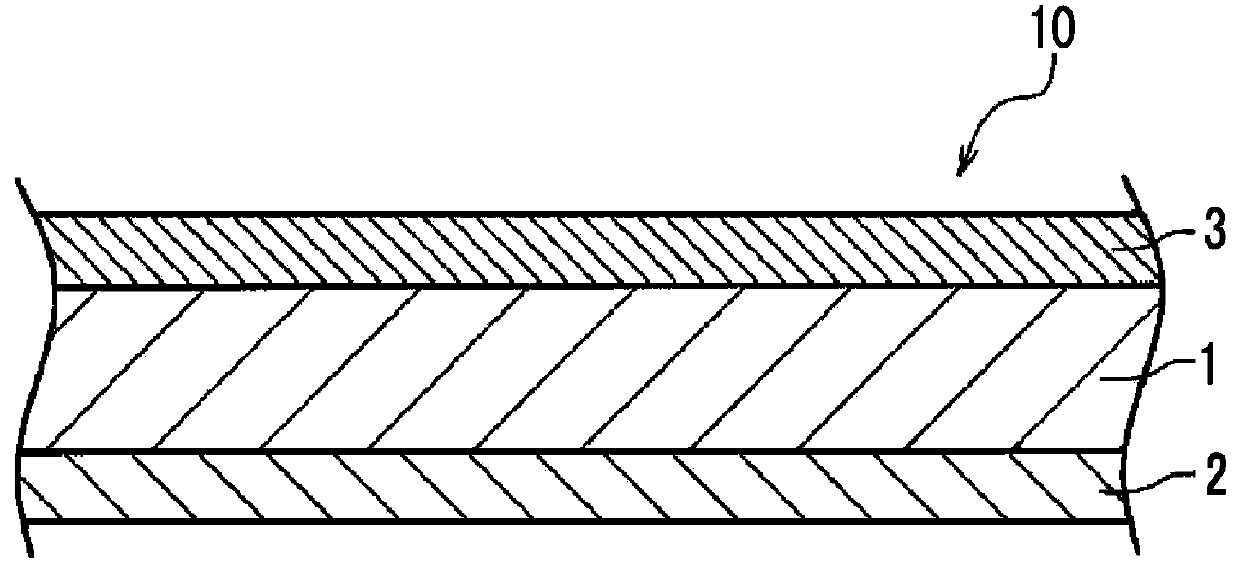

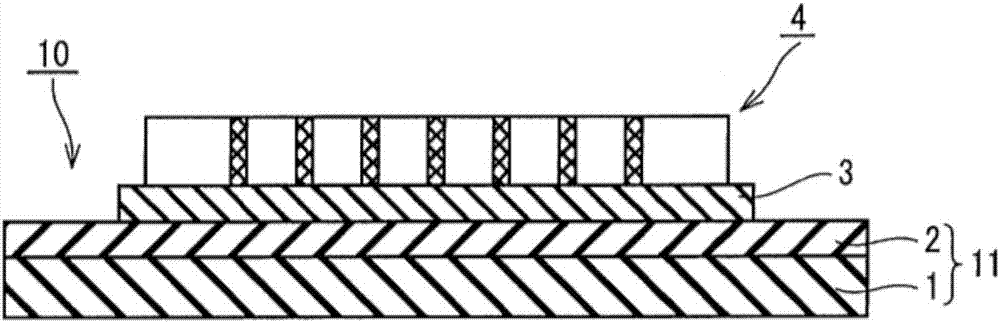

A liquid crystal panel

ActiveCN102033355APrevent optical defectsInhibit whiteningFilm/foil adhesivesPolarising elementsAcrylic resinPolarizer

The present invention provides a liquid crystal panel which is obtained through: adhibiting a first polarizing sheet (21) to one surface of a liquid crystal unit (10) through a first adhesive layer (31) with a mode that an absorption axis (21A) is parallel with a long edge (10A) of a liquid crystal unit, and adhibiting a second polarizing sheet (22) to the other surface of the liquid crystal unit (10) through a second adhesive layer (32) with a mode that an absorption axis (22A) is orthogonal with the absorption axis (21A) of the first polarizing sheet. At least one layer selected from the adhesive layers (31,32) is composed of the adhesive composition. The adhesive composition comprises 100 weight parts of acrylic resin (A) and 0.01-5 weight parts of crosslinking agent (B), wherein the acrylic resin is obtained through copolymerizing 80-96% by weight of (methyl)alkyl acrylate, 3-15% by weight of aromatic ring monomer and 0.1-15% by weight of polar functional groups and has 1000,000-2000,000 of weight average molecular weight and 3-7 of molecular weight distribution. The gel fractions of the adhesive layers are set to 60-99wt%. According to the liquid crystal panel, two surfaces of the liquid crystal unit are respectively adhibited with a pair of polarizing sheet through the adhesive layer. The liquid crystal panel can restrain white discharge even when size is enlarged.

Owner:SUMITOMO CHEM CO LTD

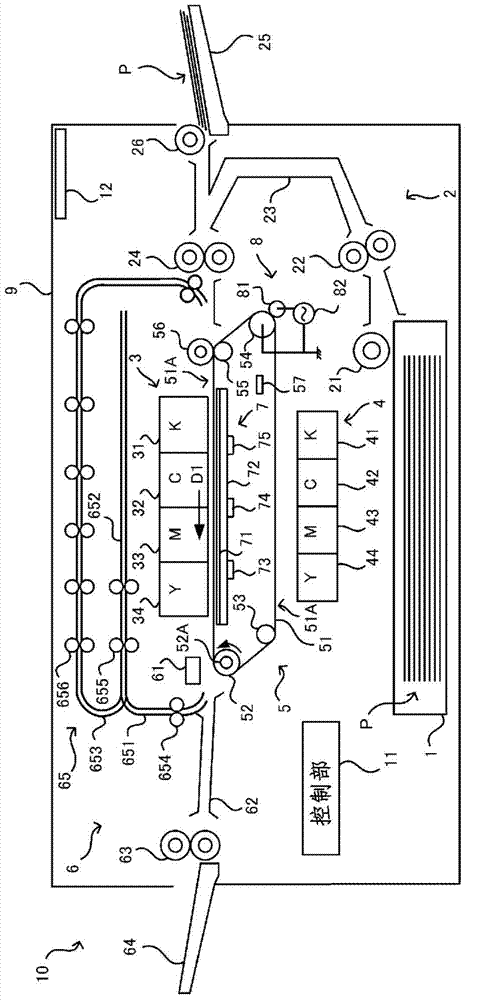

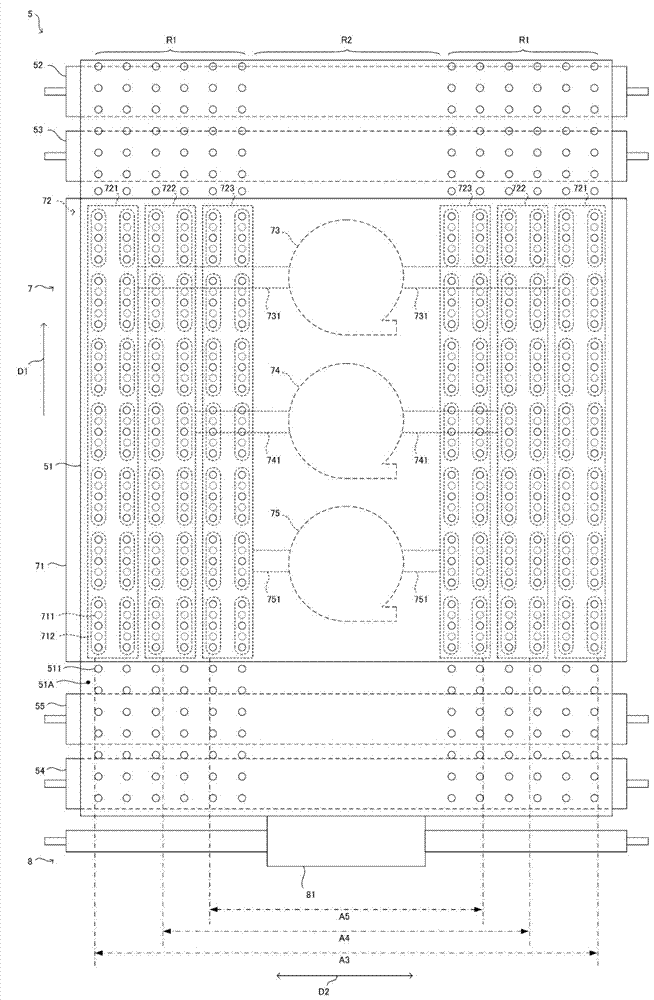

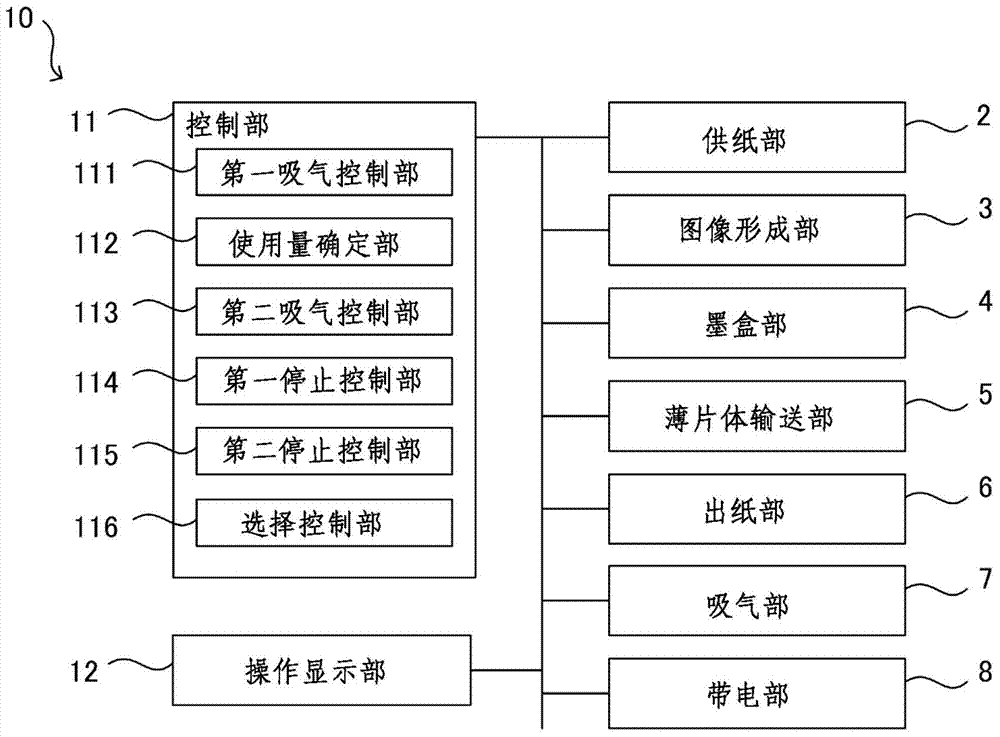

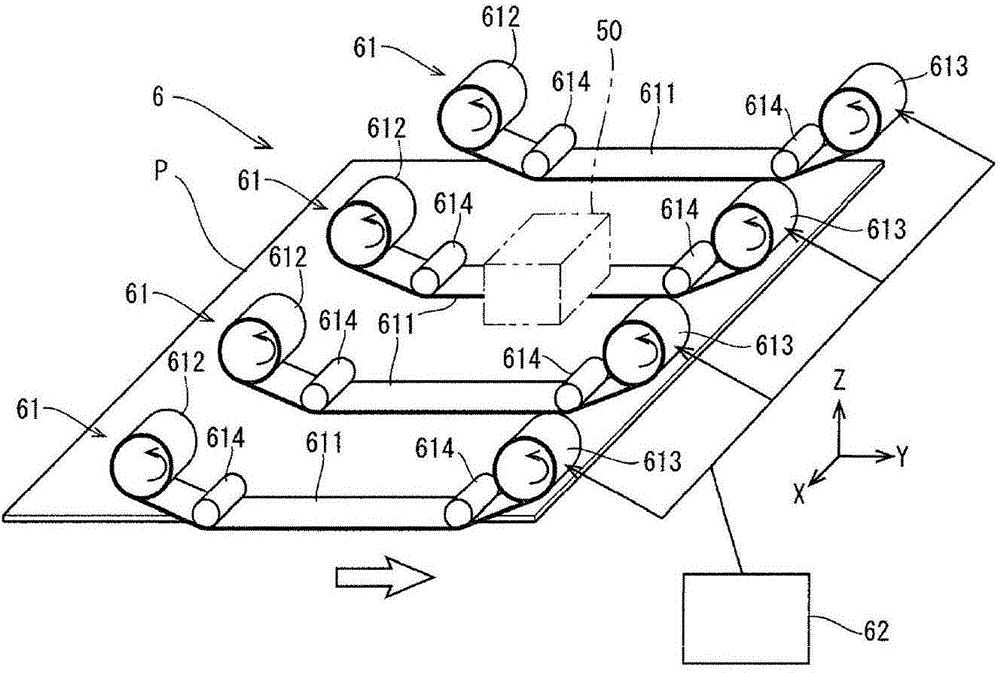

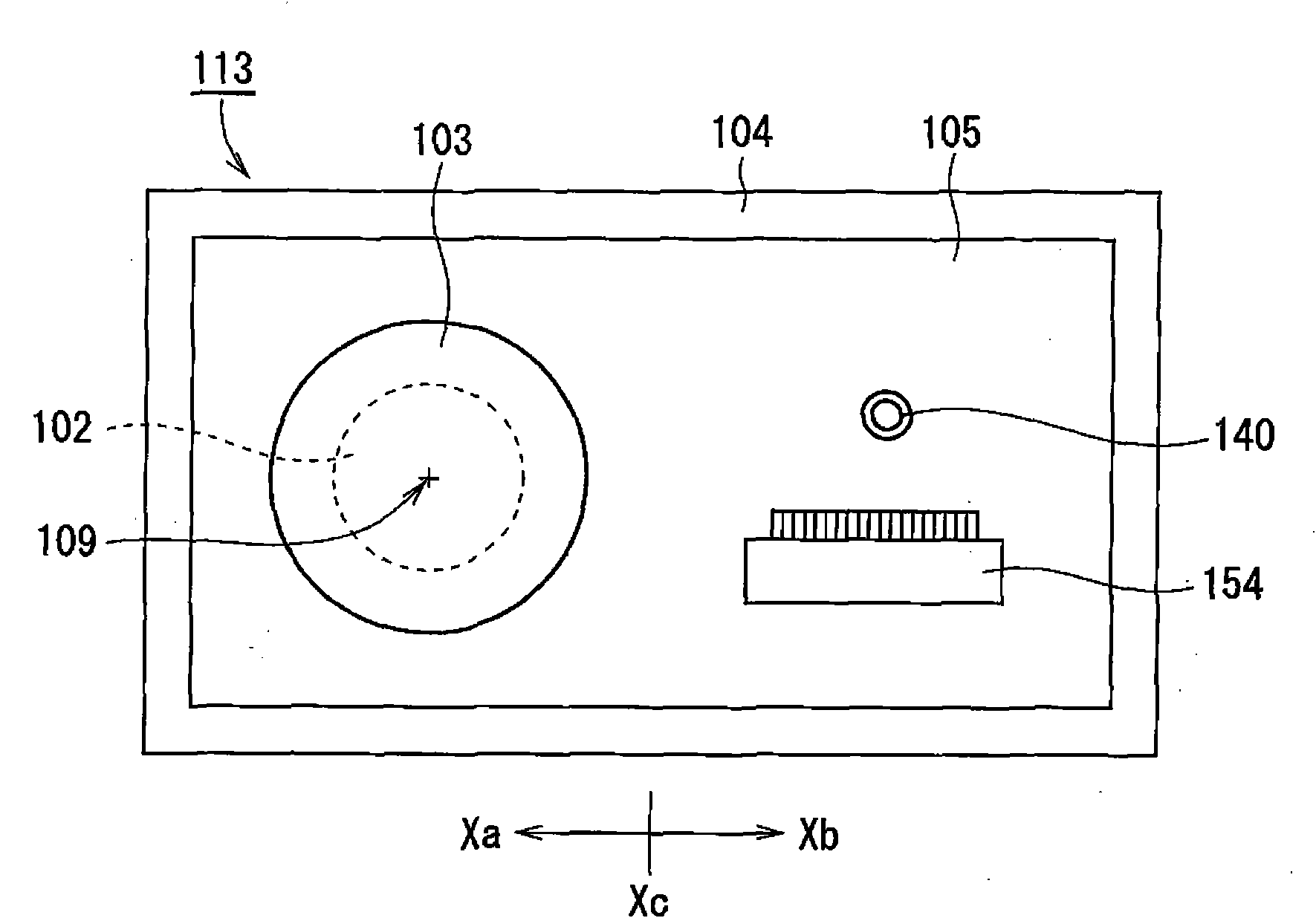

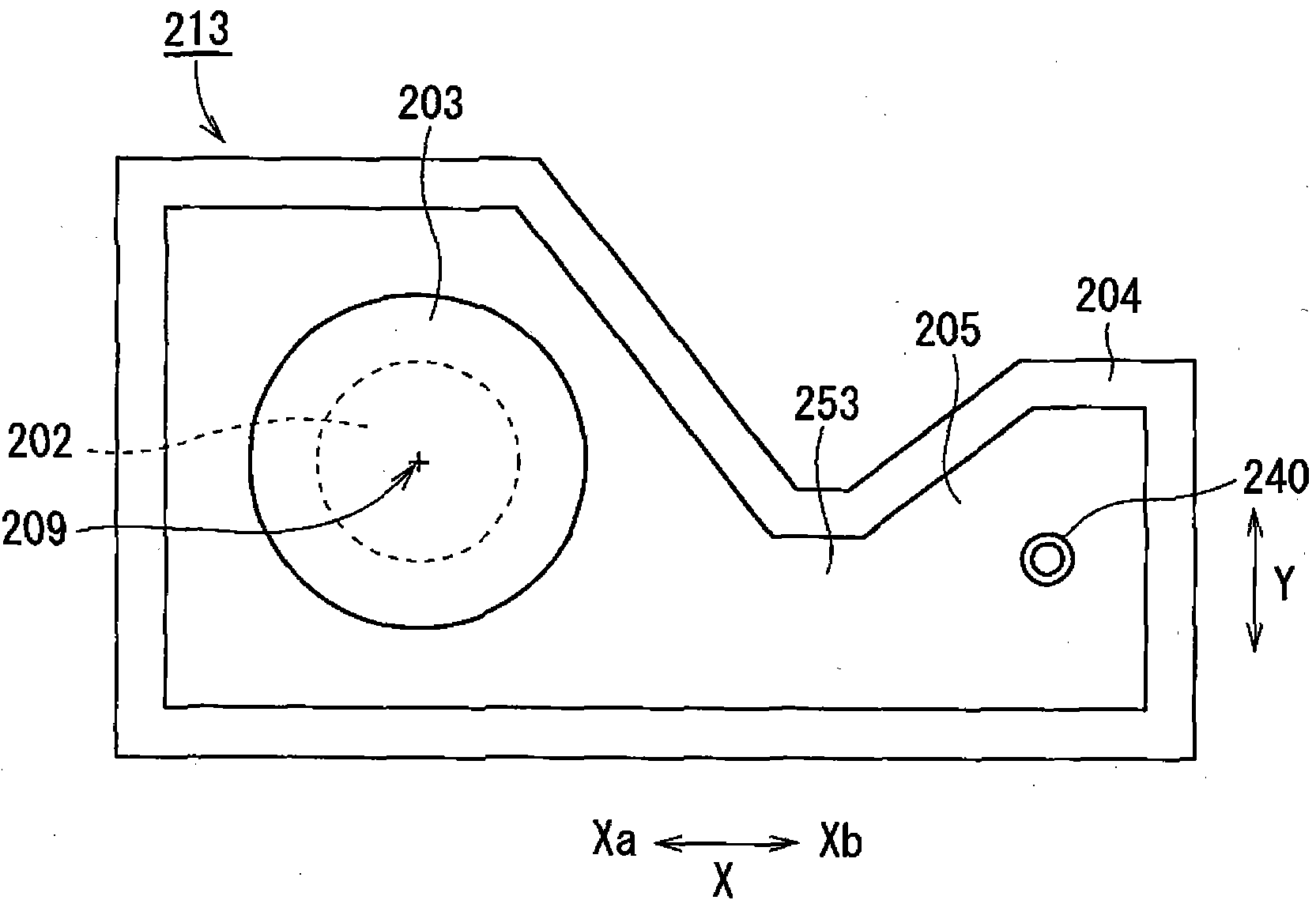

Sheet conveying device and image forming apparatus

ActiveCN104512744AInhibition-driven effectsSuppress buoyancyFunction indicatorsOther printing apparatusEngineeringMechanical engineering

A sheet conveying device includes a conveyance belt, a conveyance plate, an air intake portion, and a charging portion. The conveyance belt has a plurality of belt openings formed in a previously-set suction attraction region in end portions thereof in a width direction perpendicular to a conveyance direction of a sheet, and conveys the sheet. The conveyance plate has a plurality of platen openings formed therein at positions corresponding to the belt openings in the width direction, and is disposed on a back surface side of the conveyance belt. The air intake portion suctions air through the belt openings and the platen openings from the back surface side of the conveyance plate. The charging portion charges a previously-set electrostatic attraction region in a center portion in the width direction of the conveyance belt.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

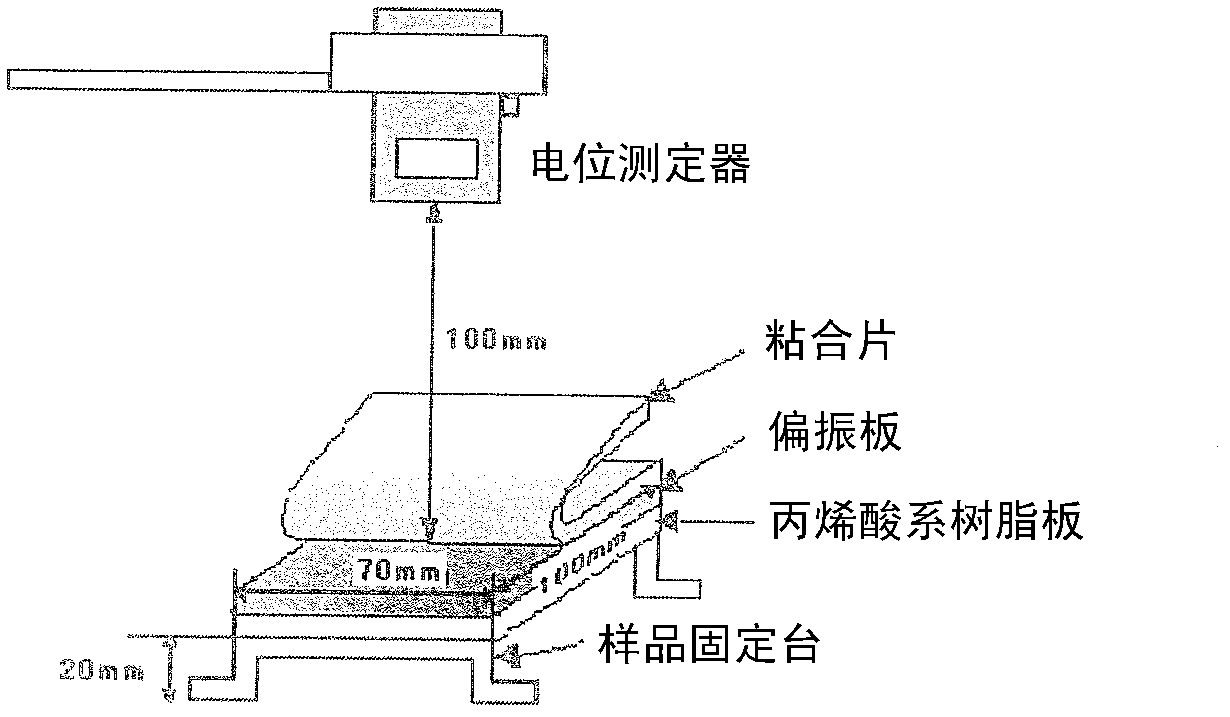

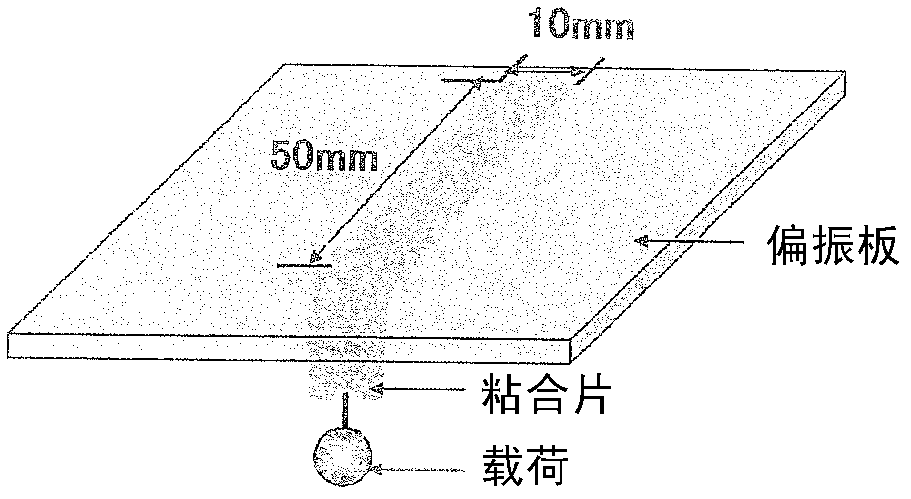

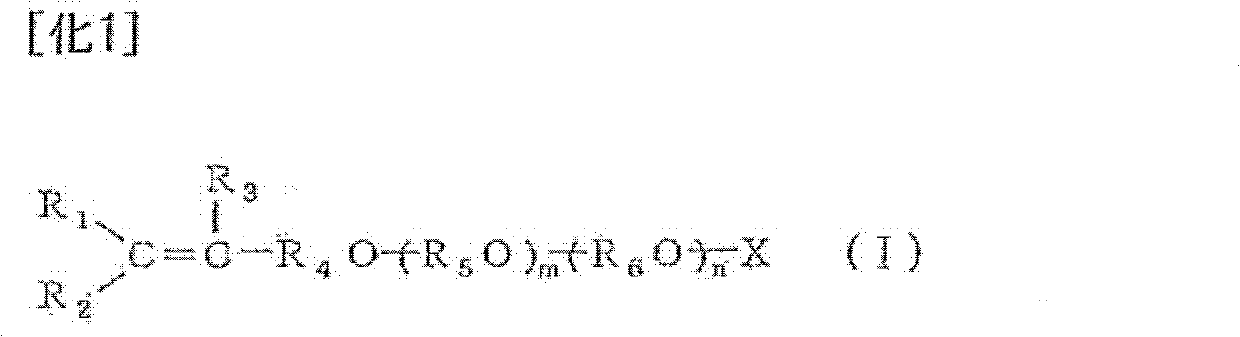

Adhesive composition, adhesive sheet, and surface protective film

InactiveCN102439107AReduce pollutionImprove anti-static effectNon-macromolecular adhesive additivesEster polymer adhesivesHydrogenChemical compound

Disclosed is an adhesive composition, which has excellent adhesion reliability and repeeling properties, and with which the prevention of static charge and the suppression of peeling-charged electrostatic potential on an adherend which is not subjected to an antistatic treatment are achieved when peeling, the adherend gets less dirty, and floating or peeling is not caused. Also disclosed are an antistatic adhesive sheet using the composition and a surface protective film using the composition. The adhesive composition comprises a (meth)acrylic polymer (a) which has 0.01 to 20 wt% of a reactive surfactant represented by general formula (I) as a monomer unit, a (meth)acrylic polymer (b) which does not contain the reactive surfactant, and an ionic compound. In formula (I), R1, R2, and R3 are the same or different and represent hydrogen or a methyl group; R4 represents an alkylene group having 0 to 30 carbon atoms (when the alkylene group has 0 carbon atoms, the compound has no R4); R5 and R6 are the same or different and represent an alkylene group having 1 to 30 carbon atoms; m represents an integer of 0 to 50; n represents an integer of 0 to 100; m+n is an integer of 1 to 150; and X represents hydrogen or an anionic hydrophilic group.

Owner:NITTO DENKO CORP

Radial tire with circumferential spirally wound belt layer

InactiveCN1708415AImprove braking effectImprove handling stabilityPneumatic tyre reinforcementsYarnEngineeringMechanical engineering

A belt layer in which one or more belt cords covered with rubber are arranged spirally wound substantially in parallel in the tire circumferential direction, and at least one layer is arranged on the outer periphery of the main body ply. The belt cord has a small increase ratio of the tensile load with respect to an increase in the elongation at a predetermined elongation or less, and a large increase ratio of the tensile load when the elongation exceeds the predetermined elongation. Therefore, since the belt cords expand together with the unvulcanized compound rubber with a small tensile load during vulcanization molding, and the expansion of the main body ply cords is not prevented, the normal shape of the raw tire is maintained and expanded, Reliably fit and vulcanize each part.

Owner:FUJISEIKO

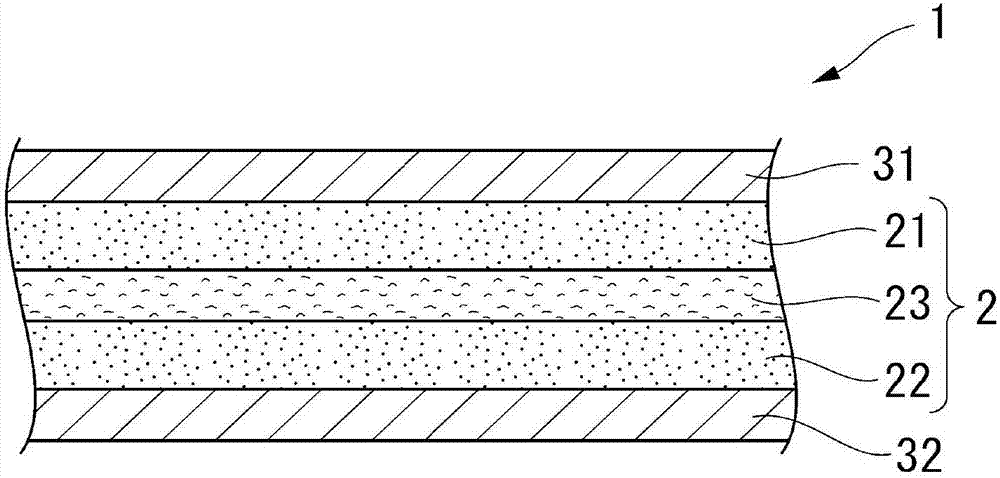

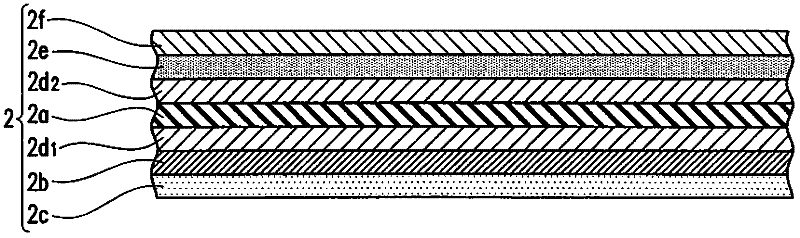

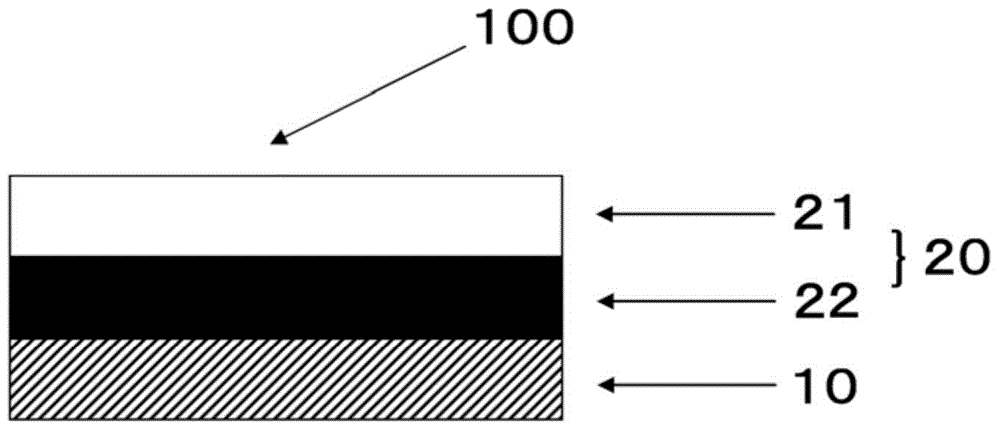

Double-surface adhesion sheet, display member and manufacturing method of display member

PendingCN107216821AExcellent step followabilityEasy to processFilm/foil adhesivesEster polymer adhesivesEngineeringGlass transition

The invention provides a double-surface adhesion sheet with excellent section difference following performance and excellent machinability, a display member obtained through using the double-surface adhesion sheet, and a manufacturing method thereof. The double-surface adhesion sheet (2) is provided with the components of a first adhesive layer (21) as an outer layer of a surface side; a second adhesive layer (22) as the outer layer of the other side; and a middle layer (23) between the first adhesive layer (21) and the second adhesive layer (22), wherein the glass transition temperature of the middle layer (23) is above 0 DEG C and below 60 DEG C.

Owner:LINTEC CORP

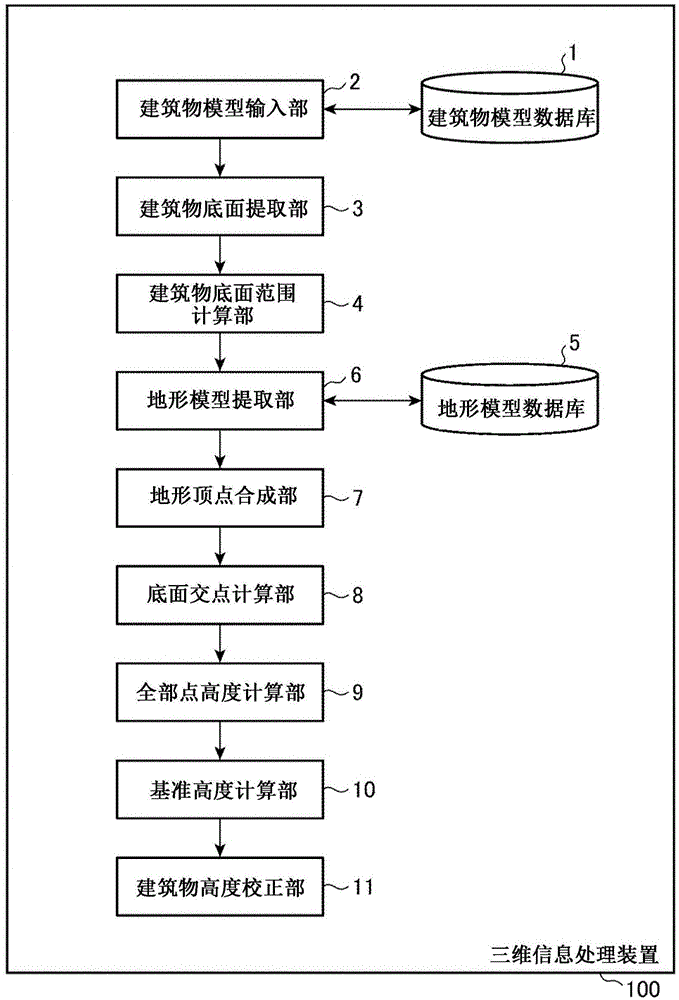

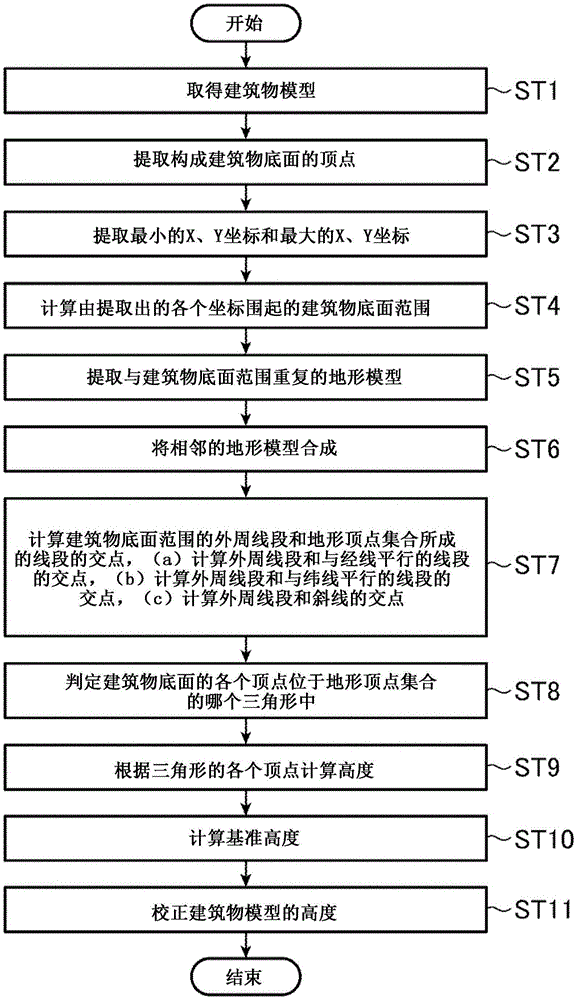

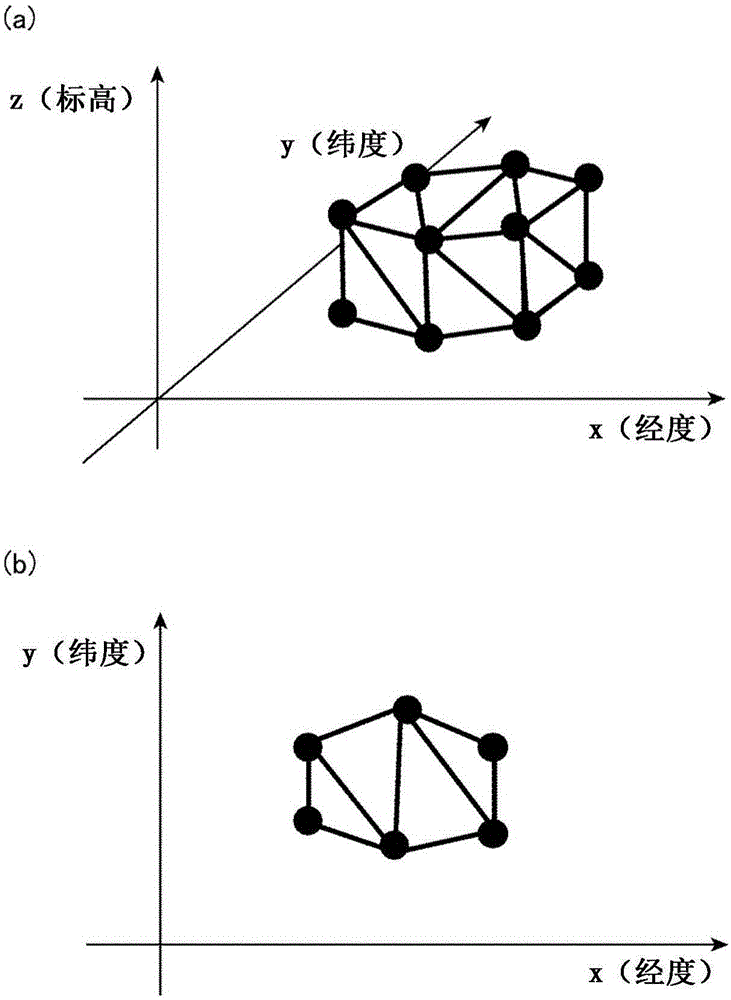

Three-dimensional information processing device

InactiveCN105074782ASuppress buoyancyInhibition of adverse conditions of excessive sinkingImage generation3D modellingTerrainInformation processing

The present invention is equipped with: a basal plane intersection point calculation unit (8) that calculates intersection points between the line segments forming a set of apexes in a terrain model generated by a terrain apex combination unit (7) and the outer perimeter line segments of the basal plane of a building model extracted by a building basal plane extraction unit (3); an all-points height calculation unit (9) that calculates the height of the terrain model at each intersection point calculated by the basal plane intersection point calculation unit (8) and each apex forming the basal plane of the building model; a reference height calculation unit (10) that calculates a reference height for the three-dimensional information of a prescribed region, from the height of the terrain model as calculated by the all-points height calculation unit (9); and a building height correction unit (11) that uses the difference between the reference height, calculated by the reference height calculation unit (10), and the height of the terrain model at the apexes forming the basal plane of the building model, as calculated by the all-points height calculation unit (9), to correct the height of the building model.

Owner:MITSUBISHI ELECTRIC CORP

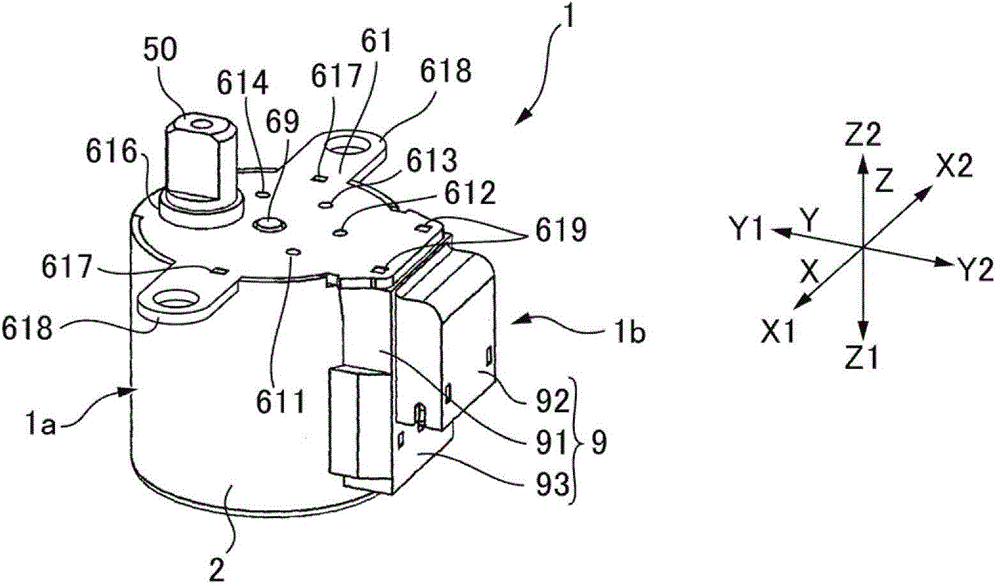

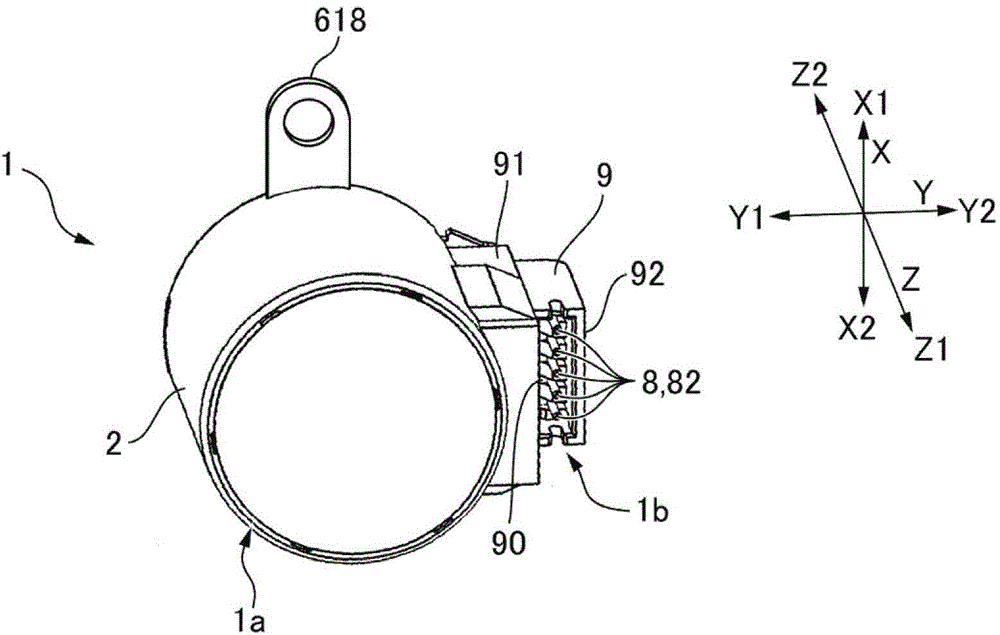

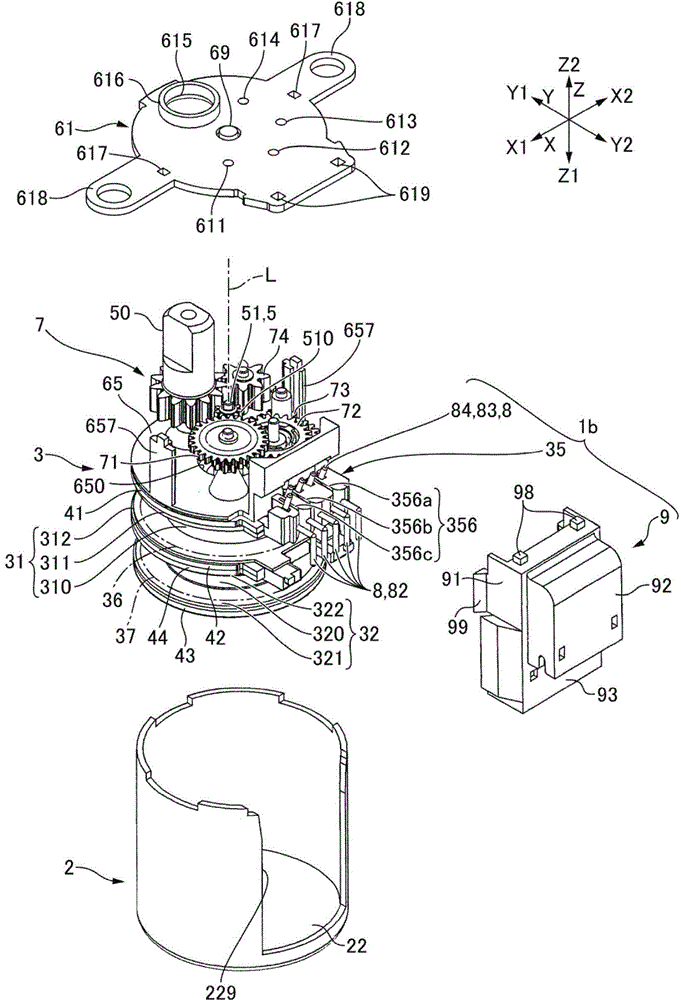

Motor

The utility model provides a motor. The motor draws and winds coiled lines of coils to a terminal block and connects the coiled lines to terminal pins so as to restrain loosed coiled lines from floating up from the terminal block. The terminal block is formed on the motor, and the terminal pins are kept on the terminal block. In a first face of the terminal block, facing a motor axis direction, and a second face, facing a radial-direction outer side, winding line arrangement grooves are formed. First groove parts of the winding line arrangement grooves extend to base parts of winding line binding parts of the terminal pins on the first face. During observation in a direction which is orthogonal to the extending direction of the first groove parts, each first groove part extends to a position which coincides with at least a part of the base part of a corresponding winding line binding part. Because the tail ends of first and second coils and the tail end of a public line are drawn and wound to the base parts of the winding line binding parts in a state of being accommodated in the coil arrangement grooves, even in a loose state, changing into a state of floating from the surface of the terminal block can also be restrained.

Owner:SANKYO SEIKI MFG CO LTD

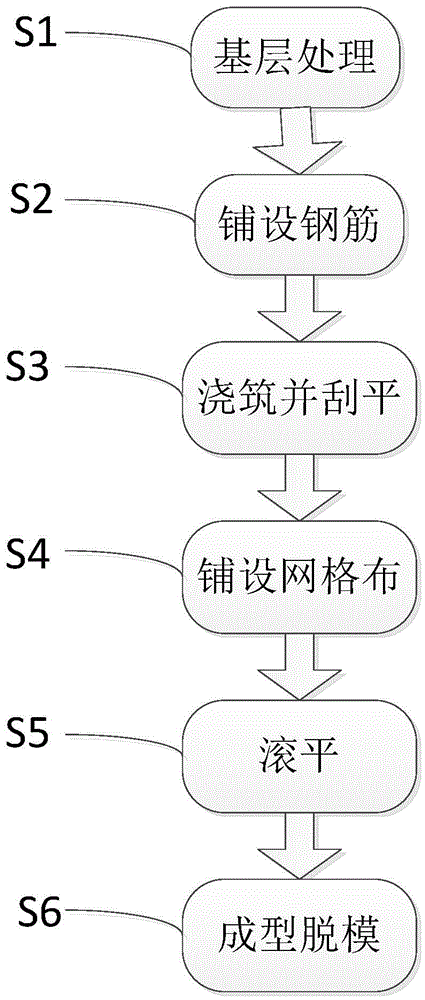

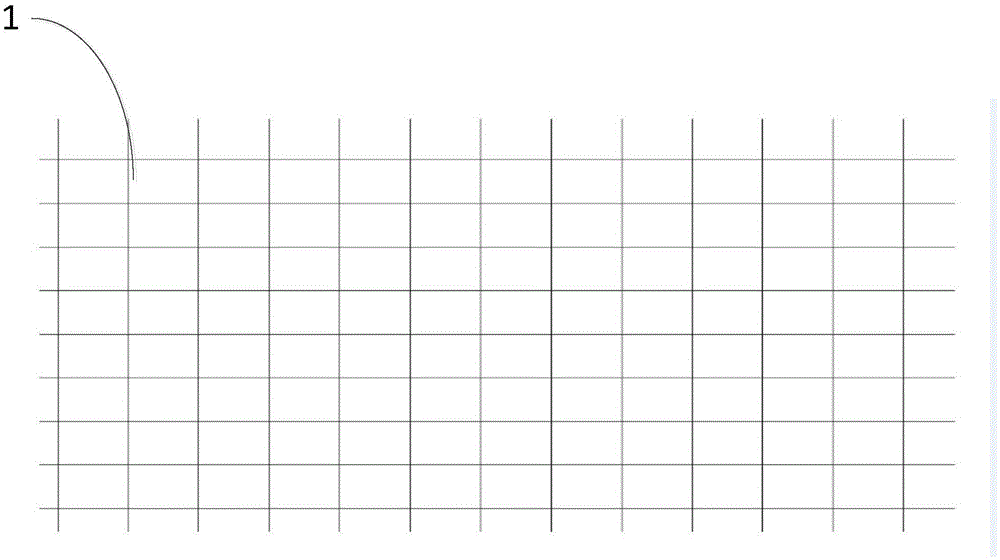

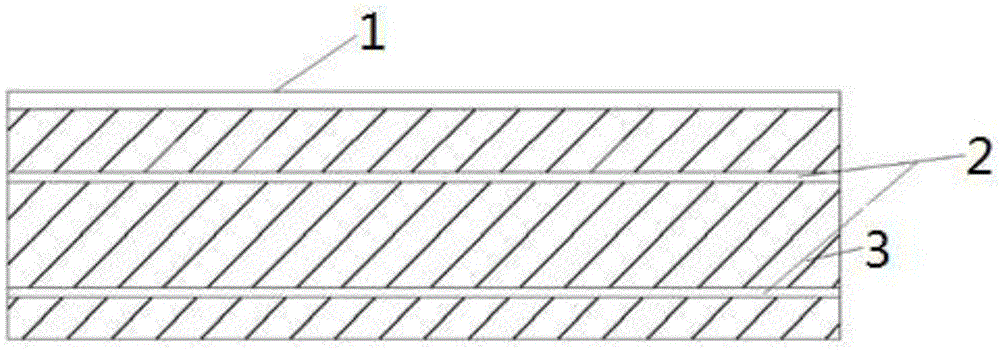

Construction method restraining floating of ceramsite concrete and prefabricated part

InactiveCN105538501ASuppress buoyancyEasy constructionConstruction materialCeramic shaping apparatusExpanded clay aggregateEngineering

The invention provides a construction method restraining floating of ceramsite concrete. The construction method comprises the following steps that firstly, base layer treatment is carried out, a die is adjusted to the horizontal position, and a release agent is brushed in the die after cleaning; secondly, a reinforcing mesh is laid, and at least one layer of reinforcing mesh is laid in the die; thirdly, ceramsite concrete is poured and slicked, the stirred ceramsite concrete is poured into the die, and slicking is carried out; fourthly, gridding cloth is laid, and the gridding cloth is laid on the ceramsite concrete; fifthly, rolling flattening is carried out, and the surface of the ceramsite concrete is rolled till the gridding cloth is completely covered with cement mortar; and sixthly, forming and die releasing are carried out, the ceramsite concrete is maintained, and die releasing is carried out. In addition, the invention provides a prefabricated part obtained through the construction method restraining floating of ceramsite concrete, the problem of floating of ceramsite in concrete is well solved through the prefabricated part, and the beneficial effects of the smooth surface and the good performance are achieved.

Owner:CHINA MINSHENG ZHUYOU

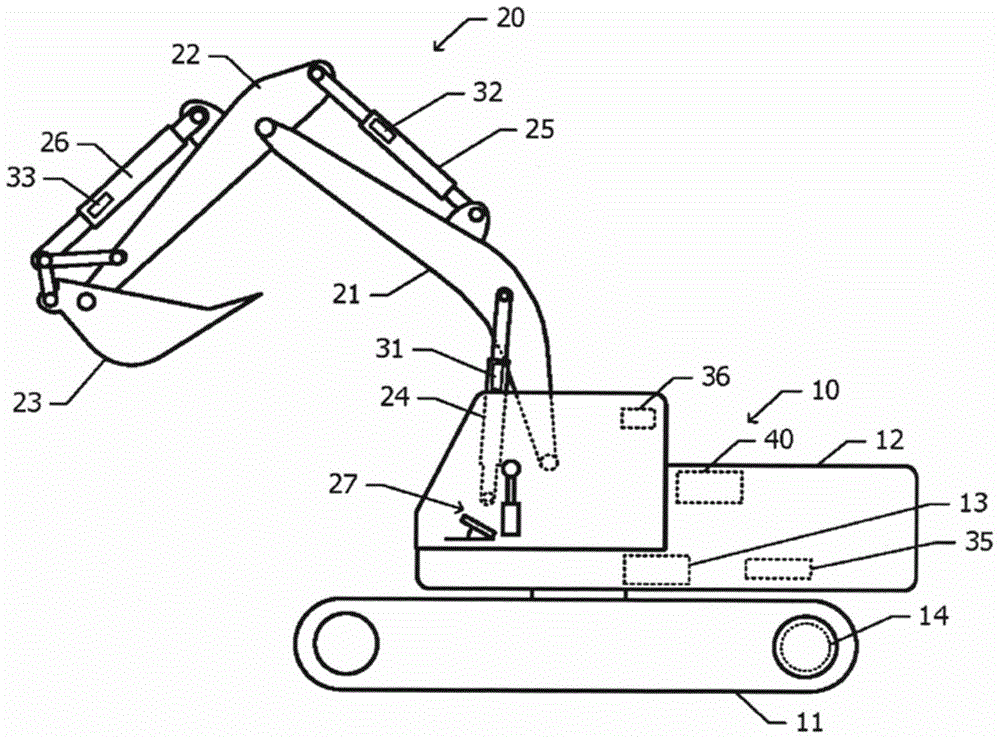

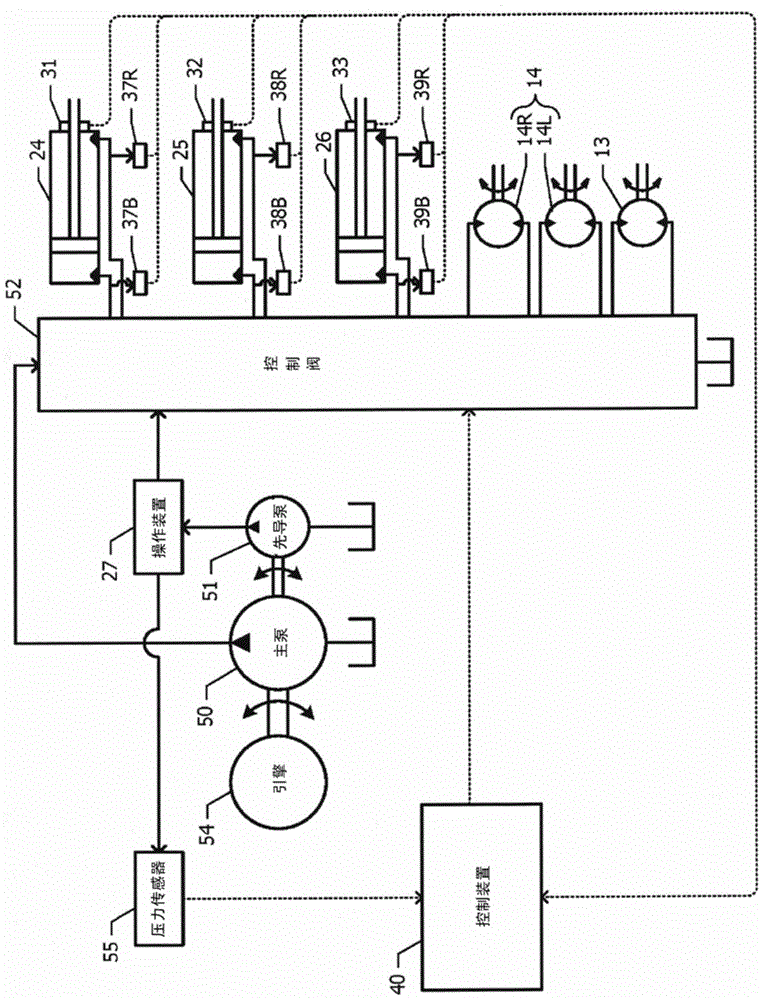

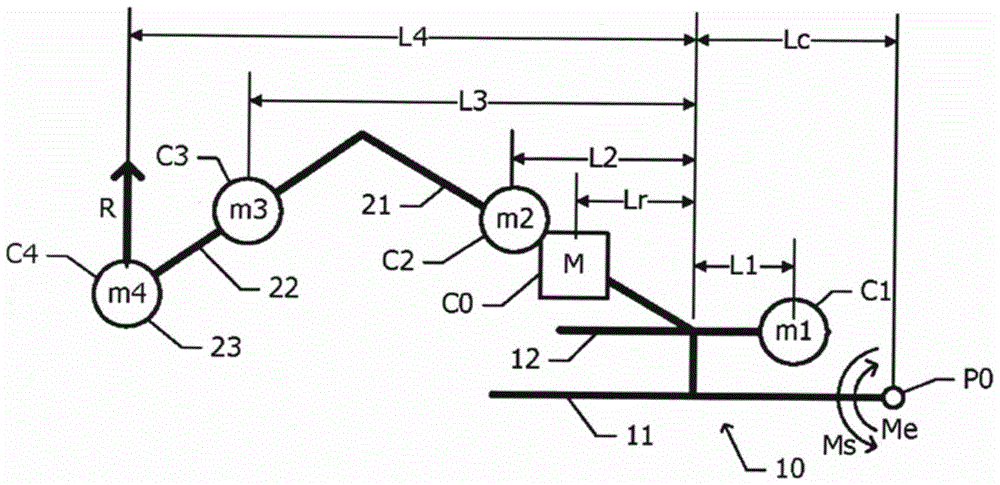

Excavator

ActiveCN106013316ASuppress buoyancyBig digging forceSoil-shifting machines/dredgersEngineeringExcavator

The invention provides an excavator which inhibits floation and has high excavation force. An upper revolving body can be revolvably supported on the lower travel body. A revolve driving apparatus enable the upper revolving body to revolve relative to the lower travel body. The upper revolving body is provided with accessory which revolves along with the upper revolving body. If work conditions are satisfied, a control apparatus drives the revolve driving apparatus to work, so that the upper revolving body is revolved to the direction causing floation of the lower travel body due to excavation reactive force applied on an acting point of the accessory.

Owner:SUMITOMO HEAVY IND LTD

Method for increasing recovery rates of lead and zinc during lead-zinc sulfide ore dressing-smelting joint application

ActiveCN102002602ASuppress buoyancyHigh recovery rateFlotationProcess efficiency improvementFoaming agentSlag

The invention discloses a method for increasing recovery rates of lead and zinc during lead-zinc sulfide ore dressing-smelting joint application. The method is implemented by the following steps of: performing floatation on lead-zinc sulfide ore to obtain lead concentrate, adding an appropriate amount of inhibitor in the flotation process to inhibit zinc and adding a collector and a foaming agent; and after floatation, selectively leaching zinc metal out of the lead concentrate by pressure acid leaching, performing liquid and solid separation on leached ore pulp and introducing metal zinc into solution so as to obtain lead-enriched slag. The floatation of zinc is restrained intentionally in the floatation process of the lead-zinc sulfide ore, so that the recovery rate of the lead concentrate is increased and the recovery rate of lead metal is over 90 percent; and the metal zinc is selectively leached out of the lead concentrate by pressure acid leaching and lead sulfide is insoluble in dilute sulphuric acid but leaves in a slag phase, so that the zinc leaching rate is over 98 percent in the pressure acid leaching process of the lead concentrate.

Owner:云南永昌铅锌股份有限公司

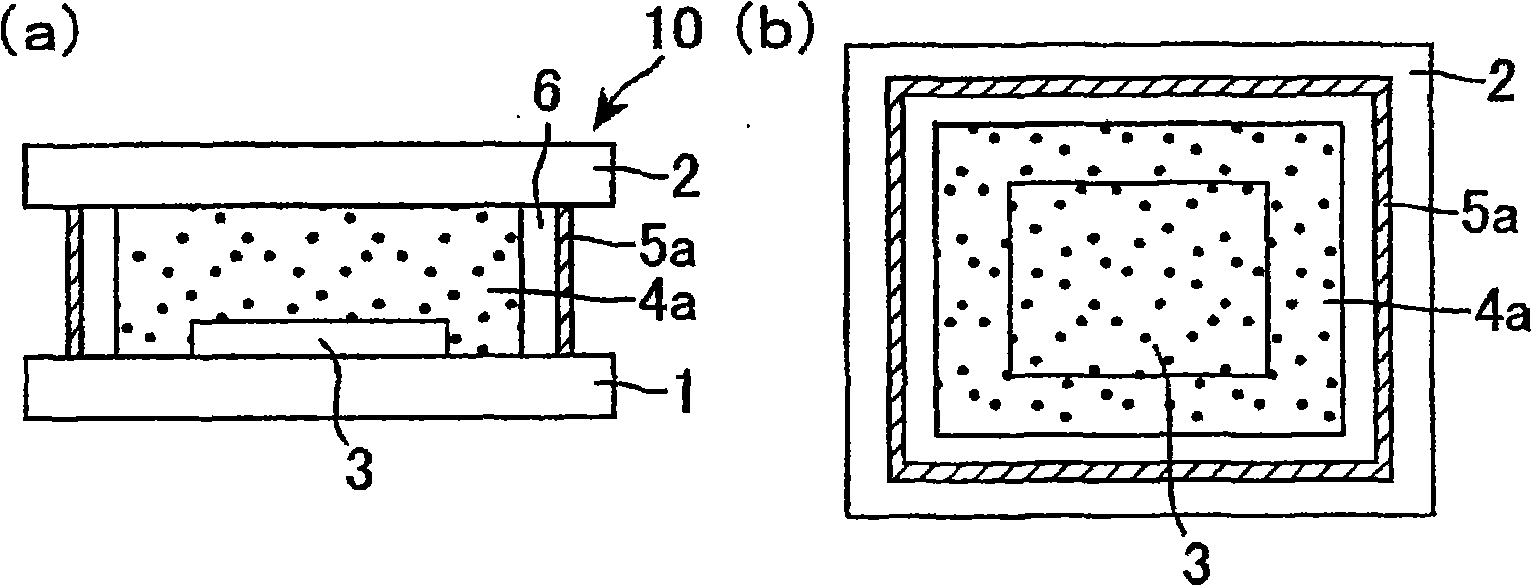

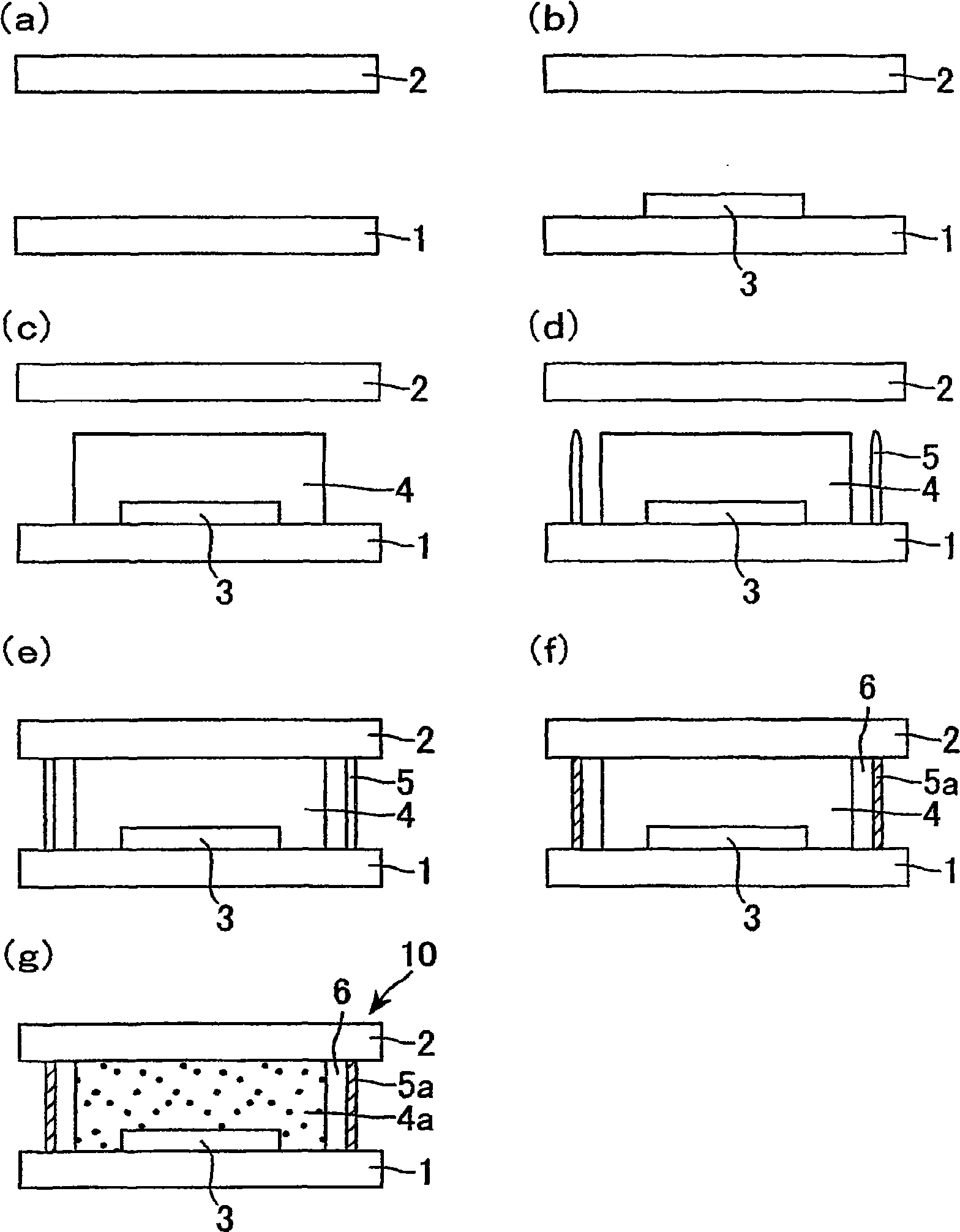

Organic electroluminescence panel, organic electroluminescence display, organic electroluminescence illumination and method of manufacturing them

ActiveCN101548578ALuminous properties are stableSuppress buoyancyElectroluminescent light sourcesSolid-state devicesOrganic electroluminescenceChemistry

The present invention provides an organic electroluminescence device that can maintain a stable light emitting characteristic for a long time, an organic electroluminescence panel provided with the organic electroluminescence element, an organic electroluminescence display, organic electroluminescence illumination and a method of manufacturing them. The organic electroluminescence panel is provided with a device substrate, a sealing substrate set opposite to the device substrate and an organic electroluminescence element formed on the sealing substrate side of the device substrate. The organic electroluminescence panel is comprised of a first sealing member to seal the device substrate and the sealing substrate and a second sealing member to coat the organic electroluminescence element at a position separated from the first sealing member, wherein a space defined between the first and second sealing members is reduced in pressure or is in a vacuum state.

Owner:SHARP KK

Insert, holder, and cutting tool using said insert and holder

ActiveCN102387883APrevent rotationHigh repeatabilityLathesTurning toolsEngineeringMechanical engineering

Owner:KYOCERA CORP

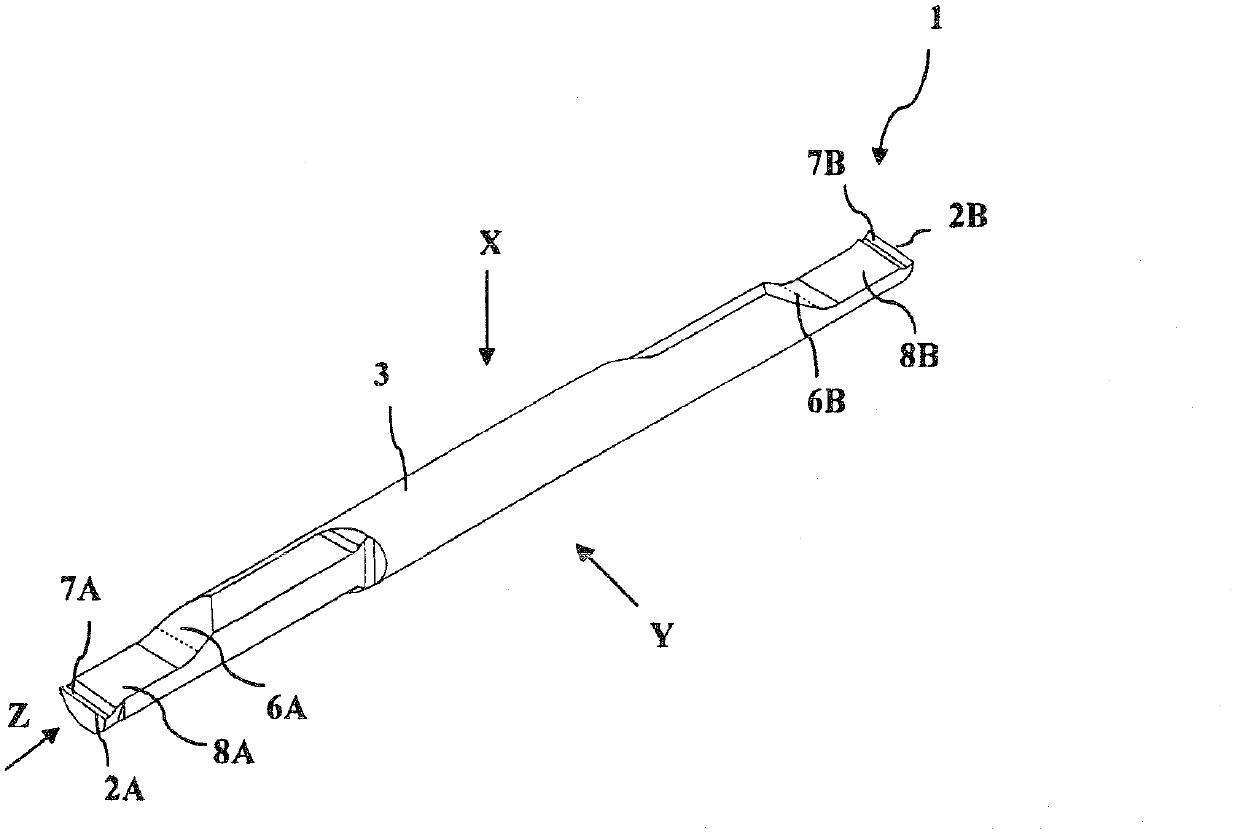

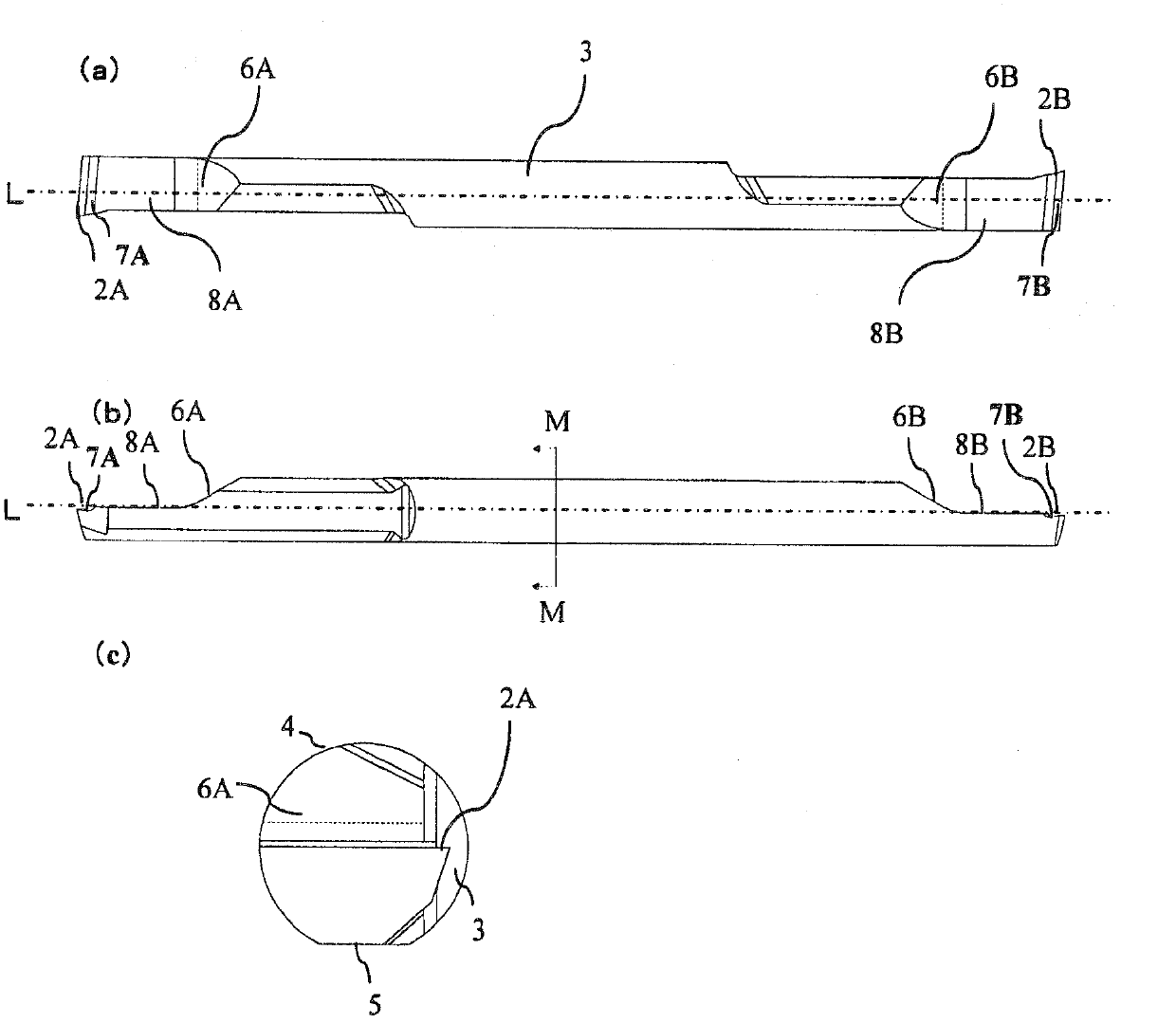

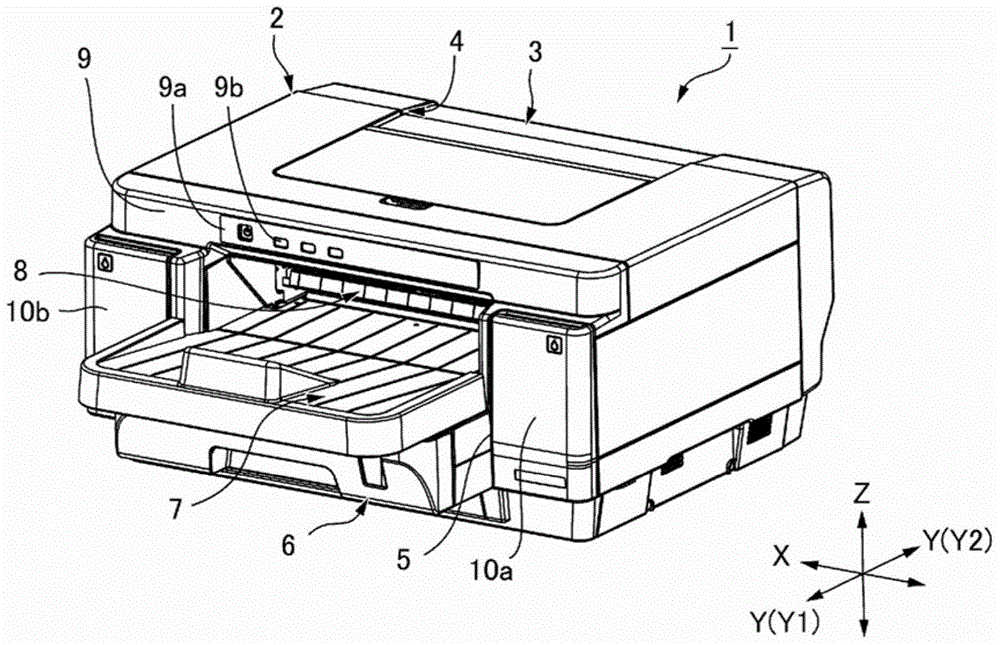

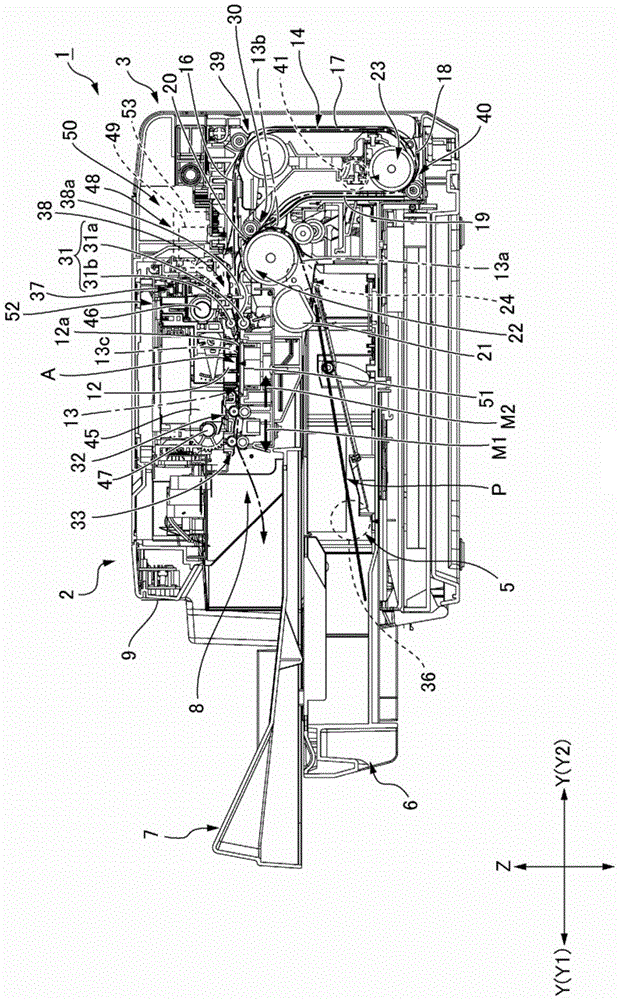

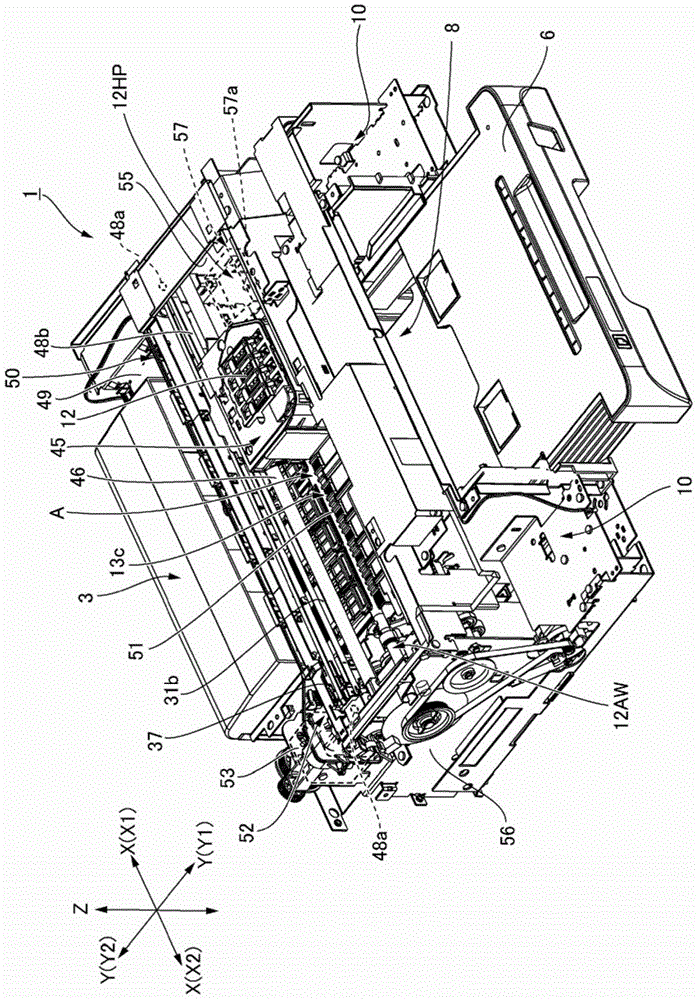

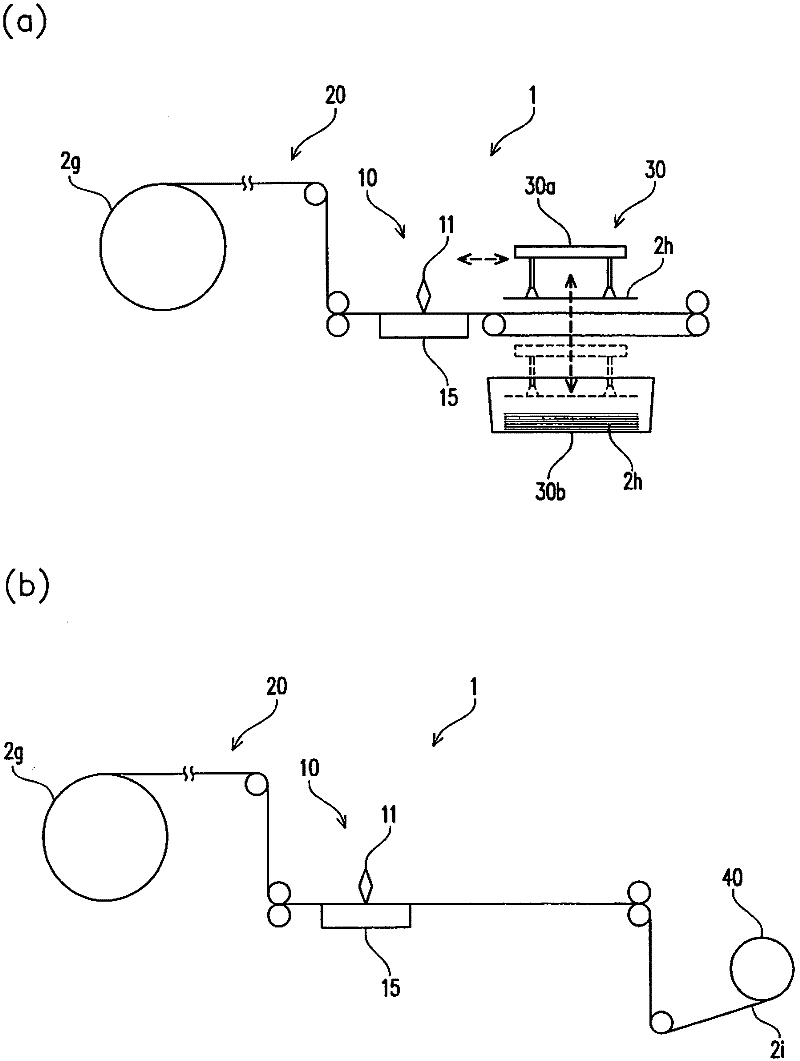

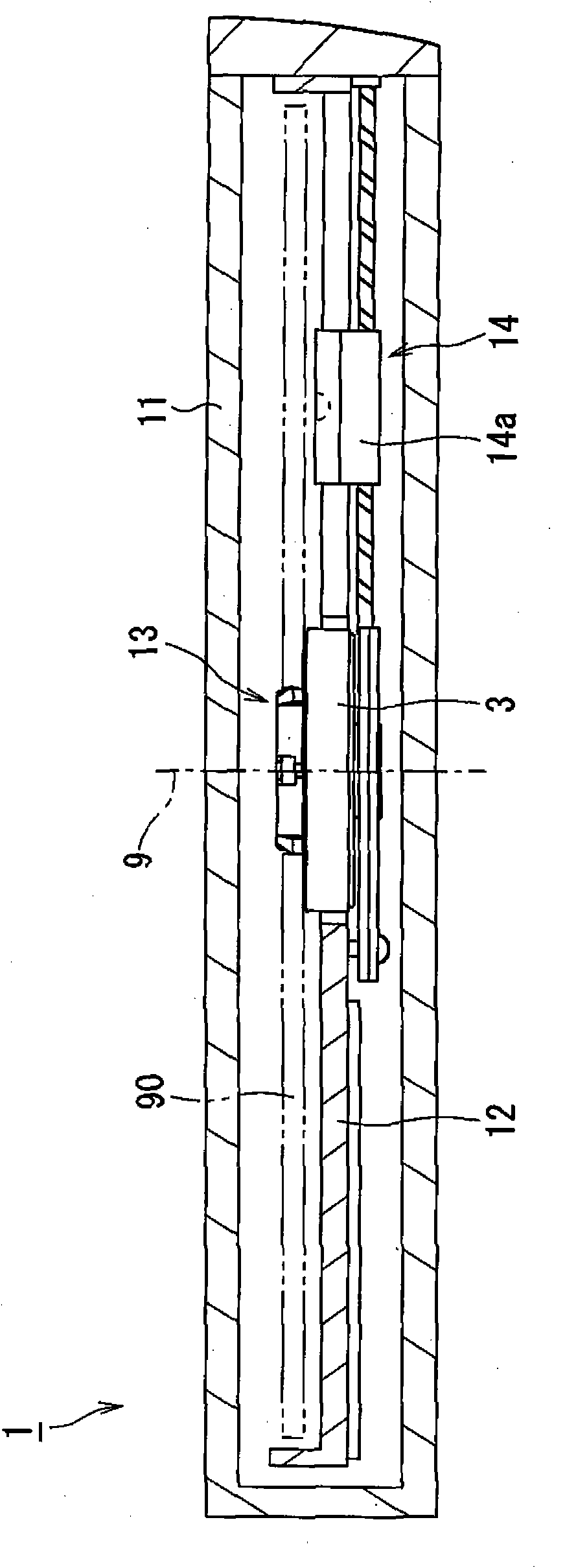

Control method of a serial printer, and serial printer

InactiveCN104626767APrevent movementMovement prevention or suppressionPower drive mechanismsOther printing apparatusTransverse axisPulp and paper industry

A control method of a serial printer enables easily removing the printing paper when a paper jam occurs, and can prevent or suppress damage to the printhead when removing the printing paper. A serial printer 1 conveys printing paper P by a conveyance mechanism 22 including a second paper feed roller pair 31 located upstream from the print position A in the first conveyance direction M1. If a paper jam of the printing paper P is detected when the printhead 12 is at a position opposite the horizontal conveyance path portion 13c of the paper conveyance path 13, conveyance of the printing paper P first stops, and the printhead 12 is then moved on the vertical axis Z away from the horizontal conveyance path portion 13c. Next, the printhead 12 is moved on the transverse axis X to a away position 12AW outside the horizontal conveyance path portion 13c, and nipping of the printing paper P by the second paper feed roller pair 31 is then released.

Owner:SEIKO EPSON CORP

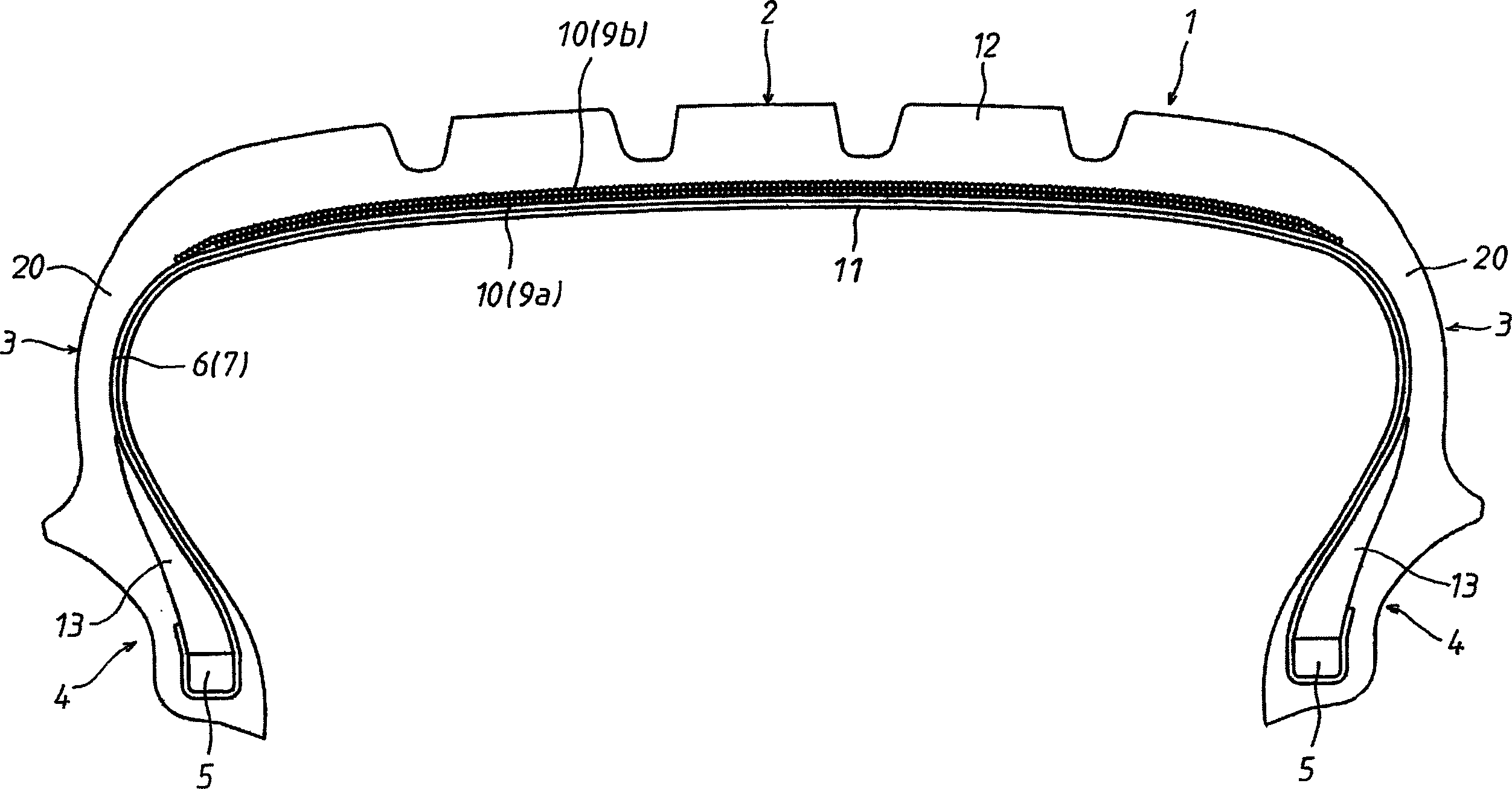

Tire and tire manufacturing method

ActiveCN102470697AFast curingSuppress buoyancyWithout cord reinforcementWith multiple inflatable chambersEngineeringUltimate tensile strength

The present invention provides a tire configured by joining together tire forming members consisting of a thermoplastic material, wherein the joined sections have sufficient strength. A molten thermoplastic material (43) for welding is extruded toward the portions to be joined of two half tire bodies (17A) which are butted against each other face to face and consist of a first thermoplastic material, and one half tire body (17A) and the other half tire body (17A) are welded together by the thermoplastic material (43) for welding. The half tire bodies (17A) are welded together without melting the half tire bodies (17A), and as a result, the thermoplastic material which forms the half tire bodies (17A) is prevented from degrading and the joined portions have sufficient strength.

Owner:BRIDGESTONE CORP

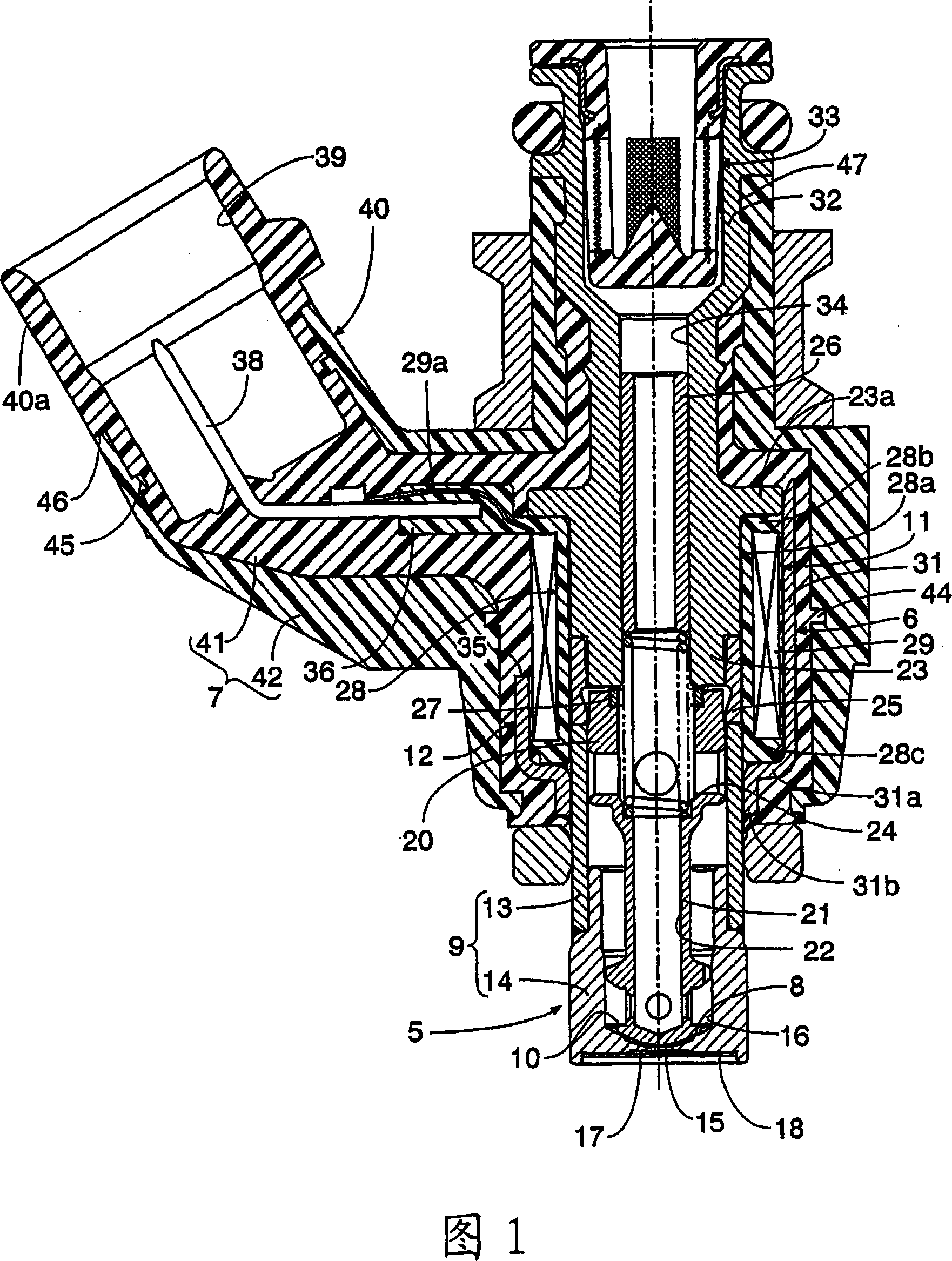

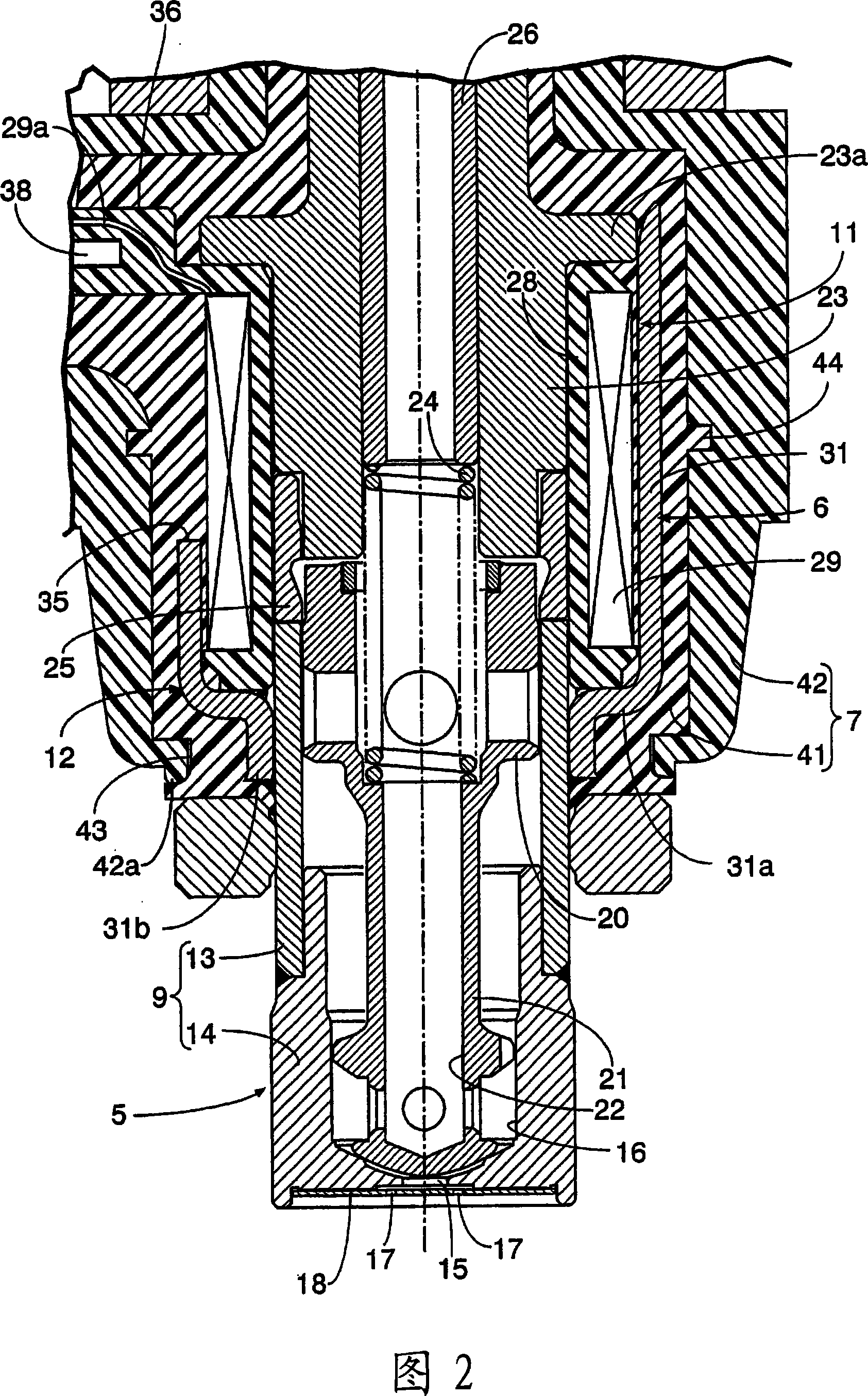

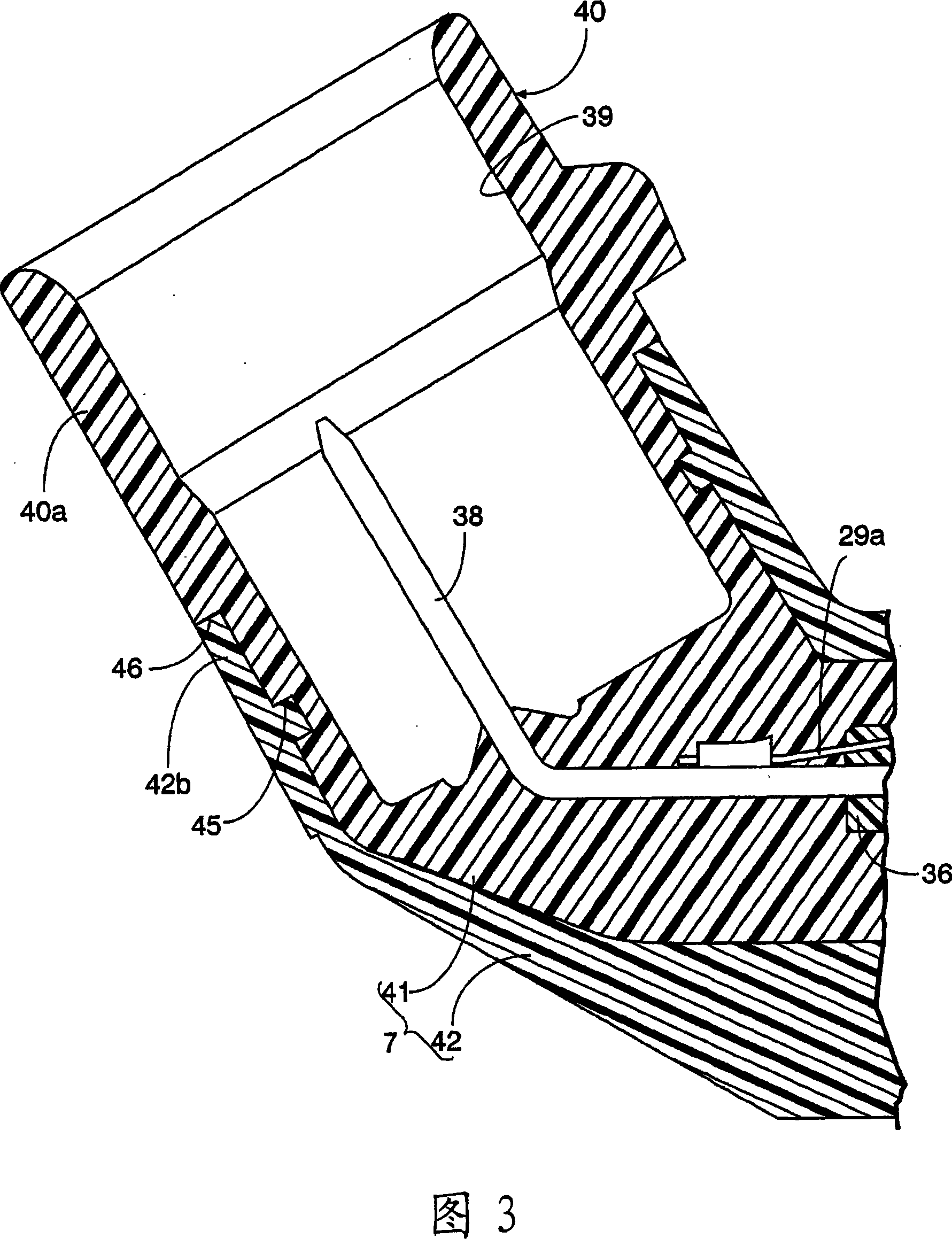

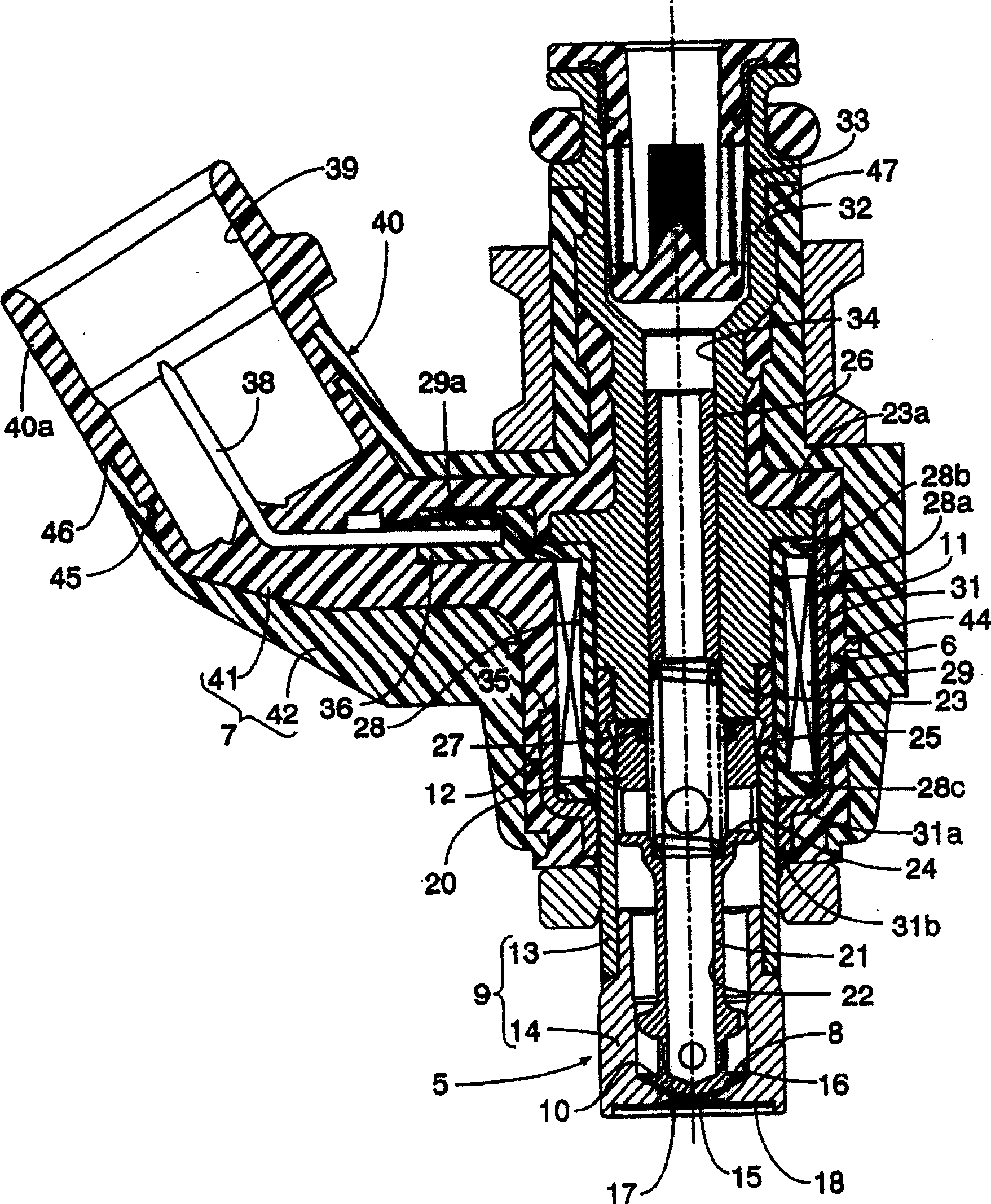

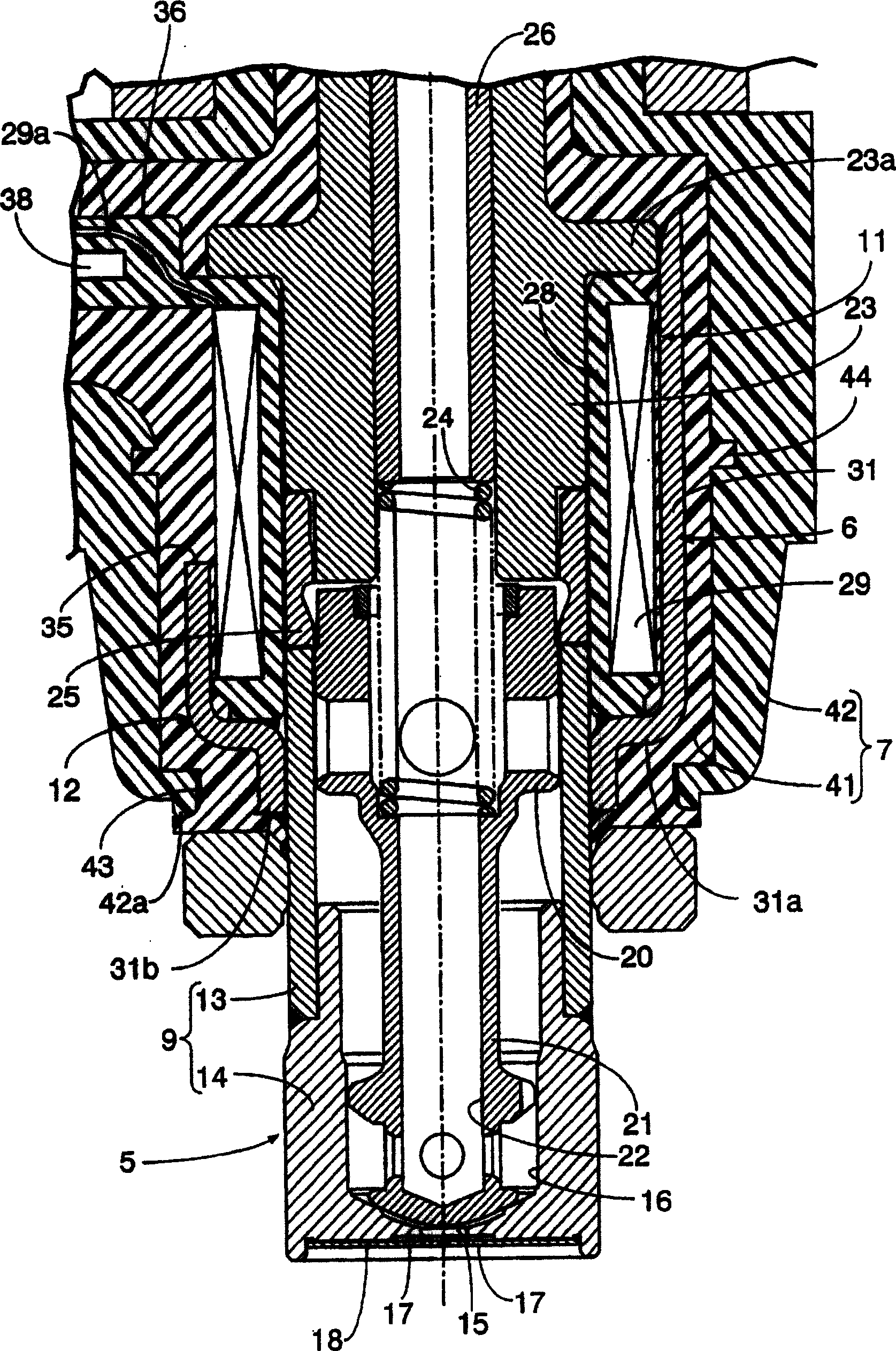

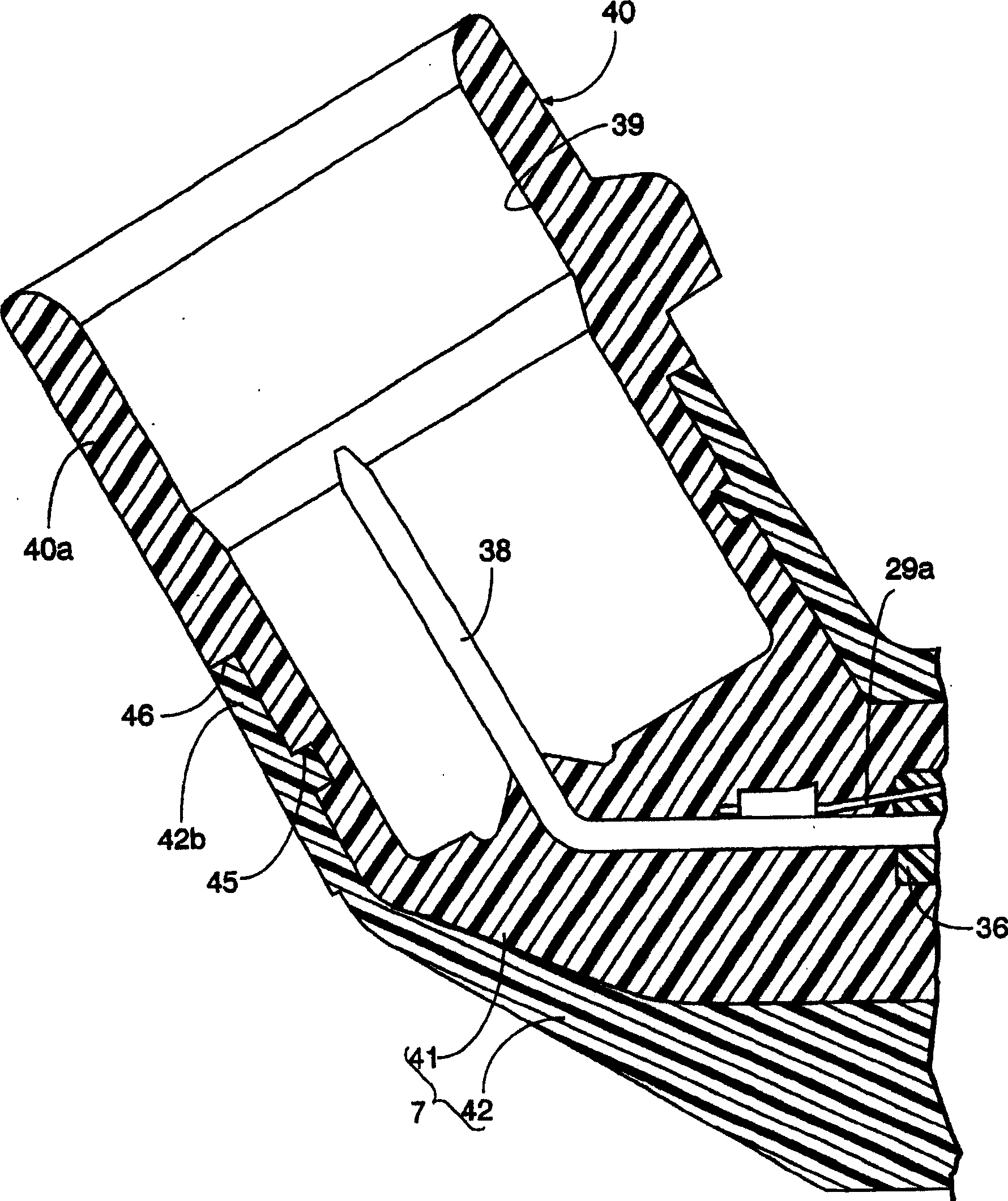

Solenoid fuel injection valve

ActiveCN101027474AAvoid it happening againFirmly connectedFuel injection apparatusMachines/enginesEngineeringSynthetic resin

In an electromagnetic fuel injection valve in which a first resin-molded layer that is made of a synthetic resin, covers a solenoid section, and forms a coupler main portion that defines a framework of a power-receiving coupler is covered by a second resin-molded layer made of a synthetic resin that is different from that of the first resin-molded layer so that an outer face of the coupler main portion is exposed from a middle part up to the extremity of the coupler main portion, an endless engagement groove (45) is provided on the outer periphery of the middle part of the coupler main portion (40a) of the first resin-molded layer (41), the second resin-molded layer (42) engaging with the endless engagement groove (45), and an extending portion (42b) extending further outward than the engagement groove (45) is formed in the second resin-molded layer (42) so that the extending portion (42b) makes contact with an outer face of the coupler main portion (40a) when in a non-engaged state and covers the coupler main portion (40a). This prevents a gap or a bulge from occurring in a boundary section between the two resin-molded layers, thus improving the connectivity of a power-supplying coupler to a power-receiving coupler and the merchantability.

Owner:HITACHI ASTEMO LTD

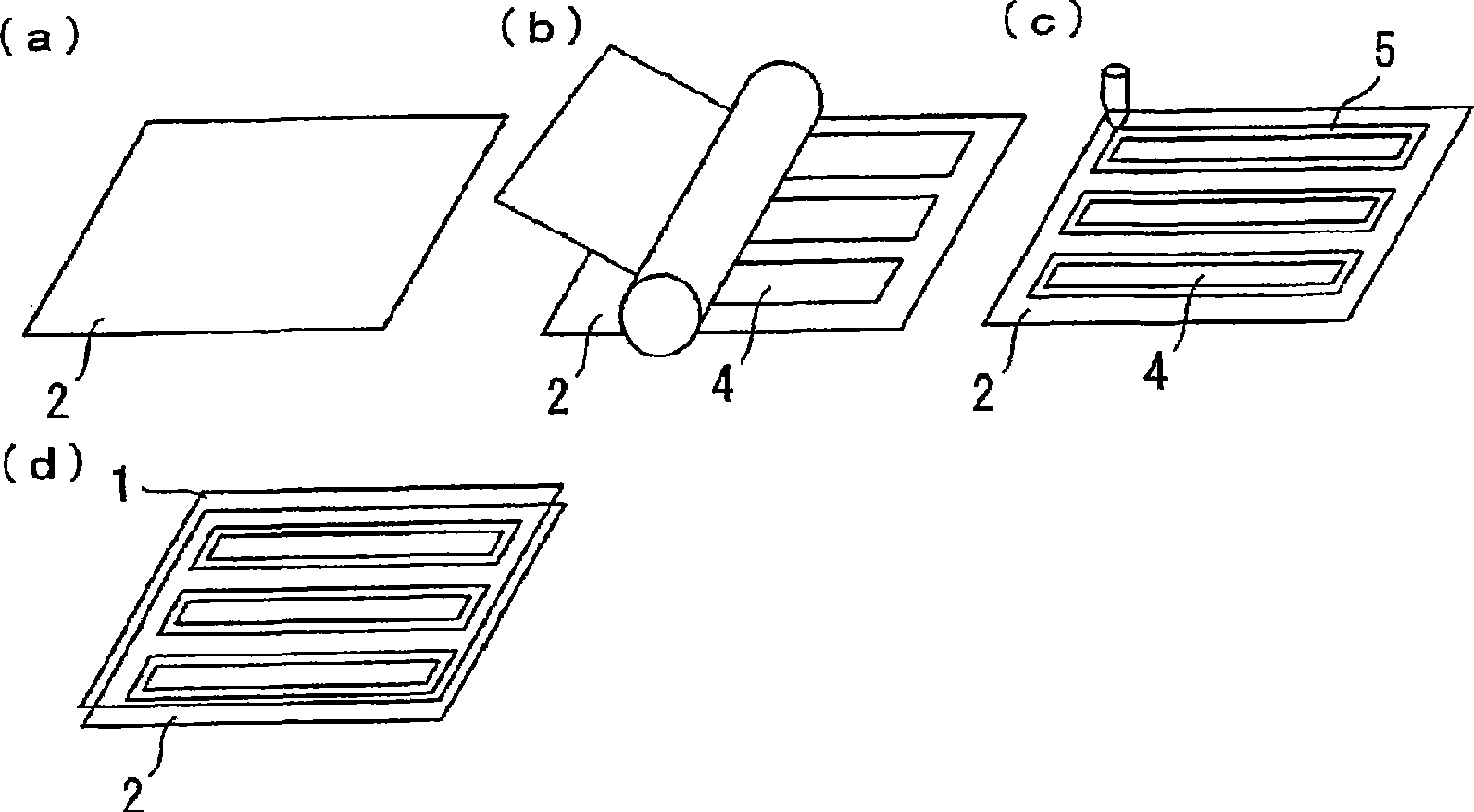

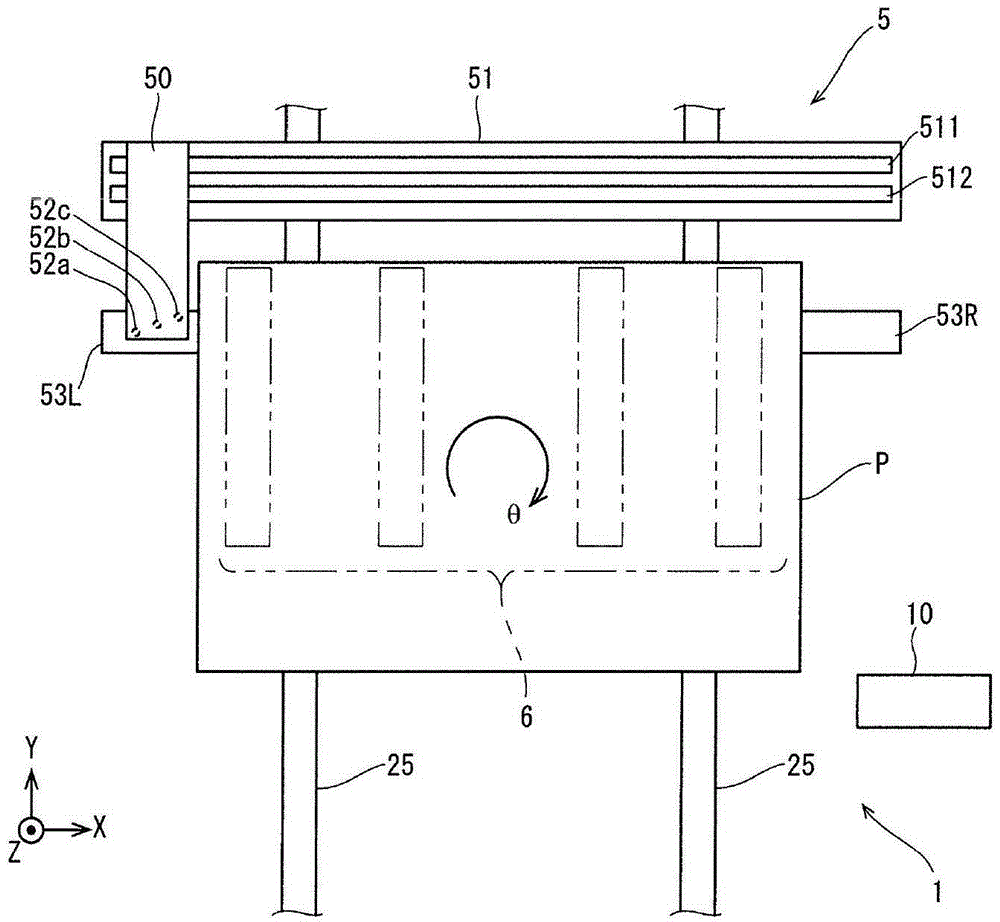

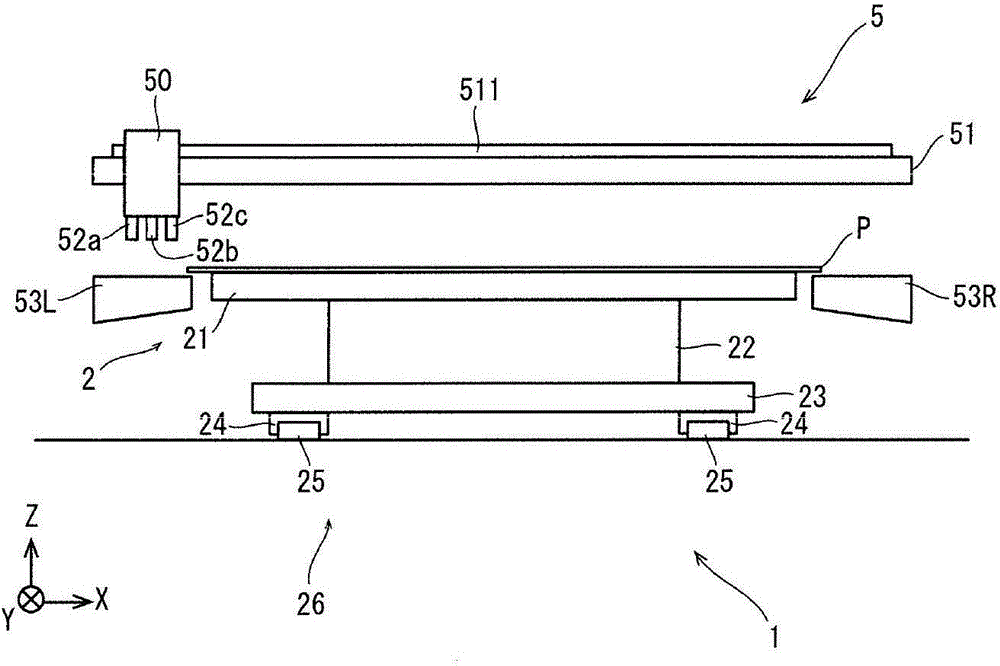

Coating device and coating method

InactiveCN104415884AGood efficiencyEfficient formationLiquid surface applicatorsCoatingsEngineeringMasking tape

The invention provides a coating device and a coating method to enable a non-coated area for a liquid material to be formed on a substrate in an efficient and effective manner. The coating device (1) enables a non-coated area, without coating of an organic electroluminescent liquid (3), on a substrate (P). The coating device (1) comprises a platform (21), a holding substrate (P), a nozzle unit (50) spraying the organic electroluminescent liquid (3) toward the main surface of the substrate (P), a nozzle moving mechanism (51) and a platform moving mechanism (26) that enable the nozzle unit (50) to relatively move in a main scanning direction (X-axis direction) and a subsidiary scanning direction (+Y direction) via the substrate (P) held by the platform (21), and a masking mechanism (6) for providing a masking tape (611) in a way that the portion of the main surface of the substrate (P) is opposite to the corresponding non-coated area and also enabling the masking tape (611) to move along with the movement of the substrate (P).

Owner:DAINIPPON SCREEN MTG CO LTD

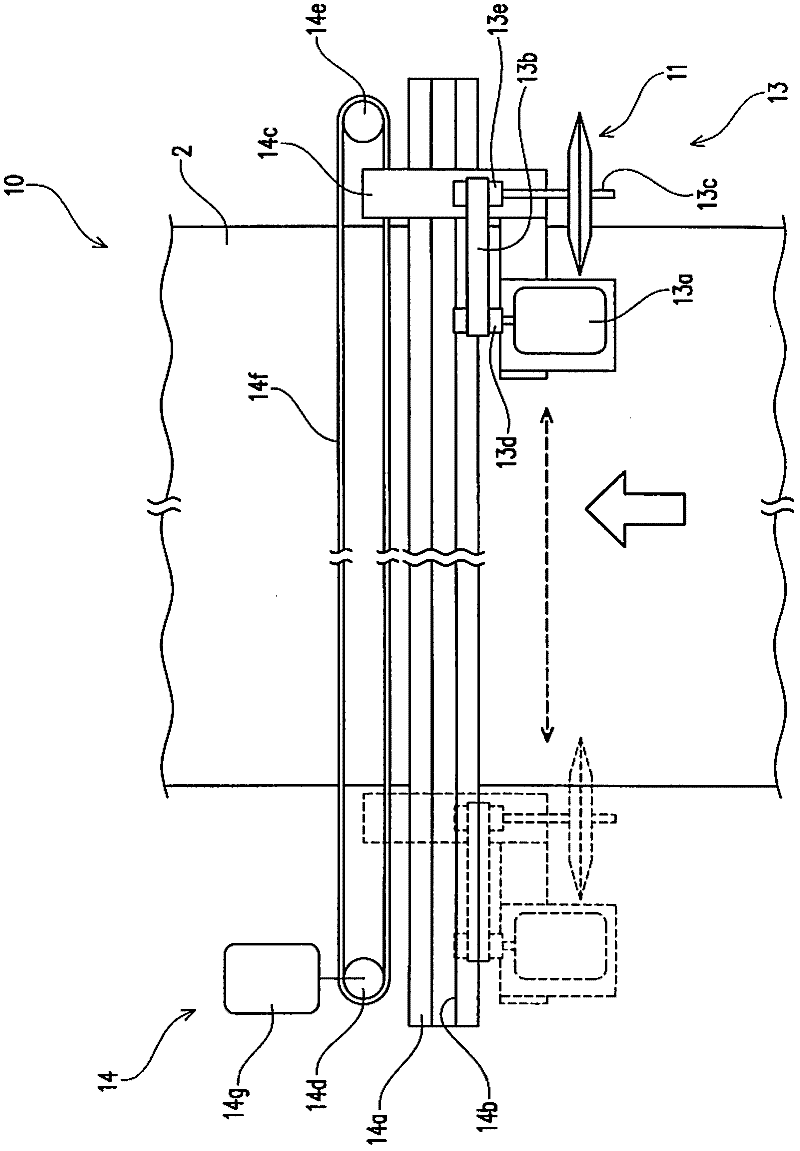

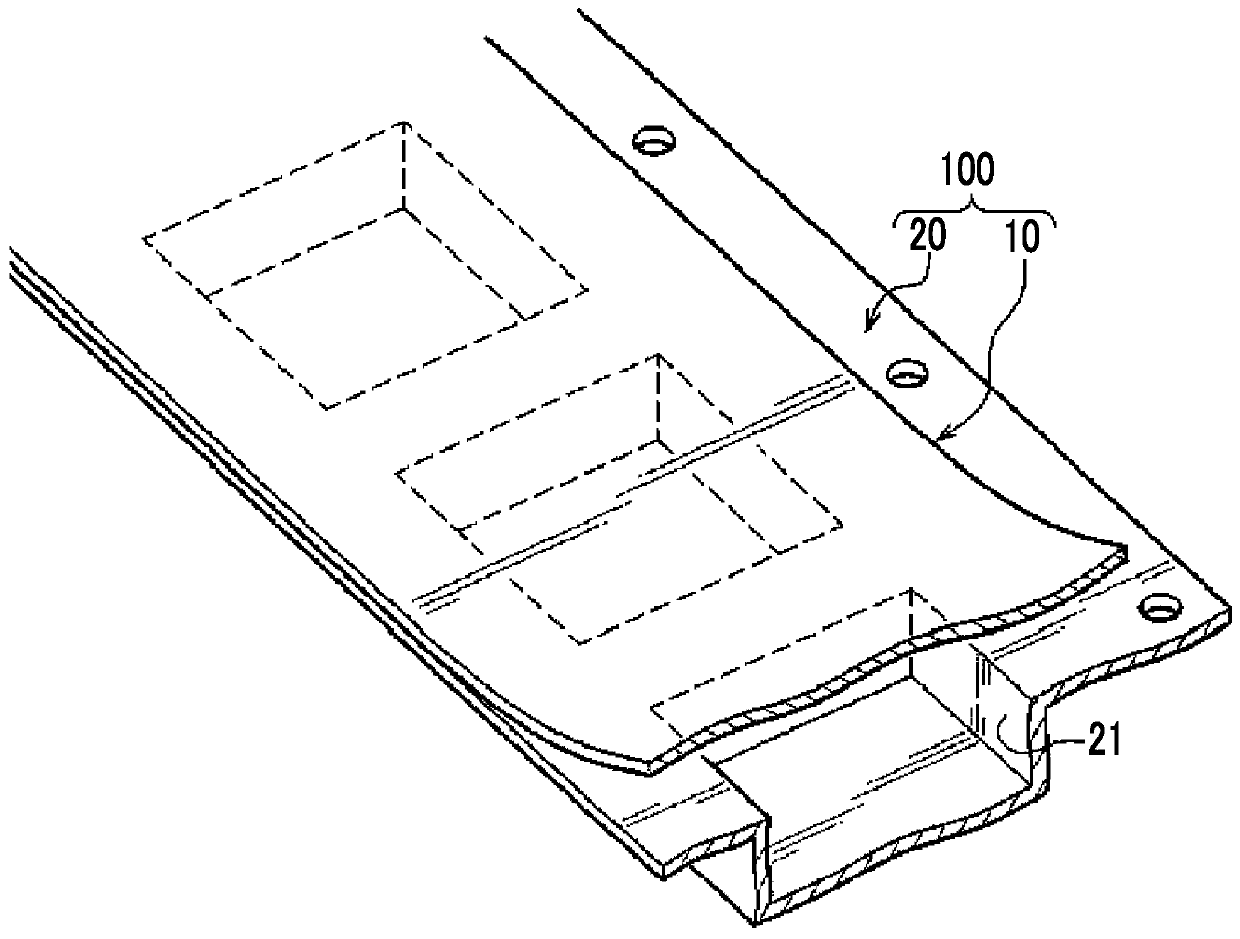

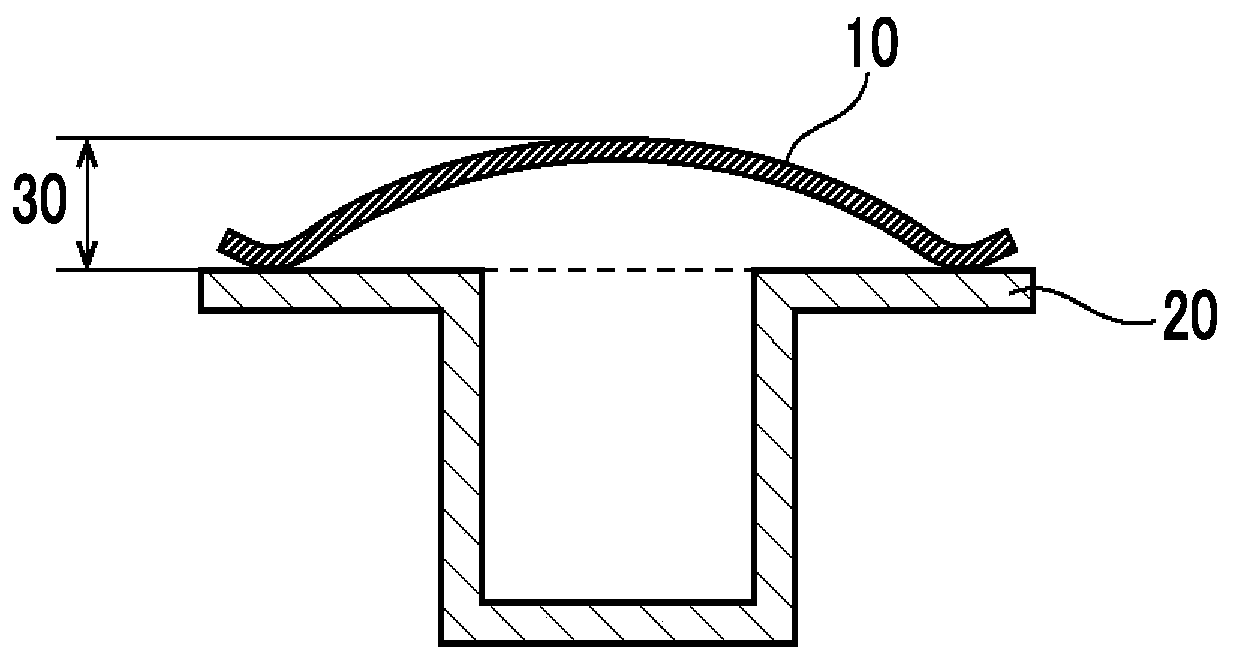

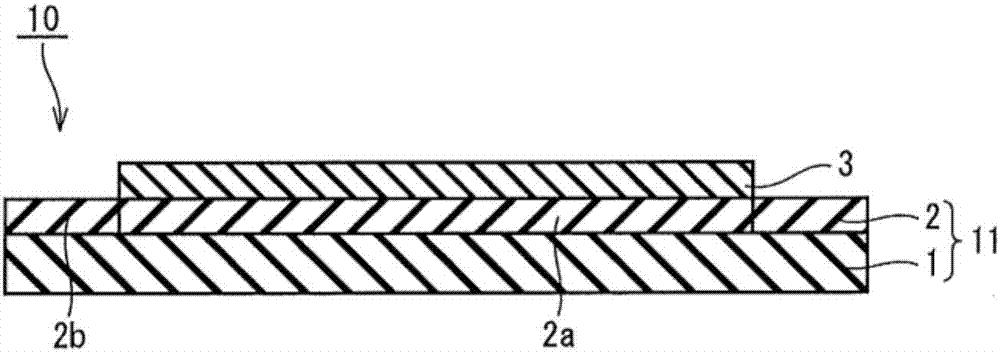

Method for cutting laminated film, cutting device, and method for manufacturing optical display device

ActiveCN102413991ASuppress burrSuppress buoyancyAdhesivesMetal working apparatusDisplay deviceEngineering

A method for cutting a laminated film, adapted to cut the laminated film using a circular cutter having a cutting edge at the peripheral edge thereof. The method cuts the laminated film by rotating the circular cutter by a rotating means in the forward rotational direction relative to the cutting direction at a cutting-edge peripheral speed Vr while causing the laminated film to travel in the cutting direction at a travel speed Vc. The relative cutting speed V obtained by subtracting the peripheral speed Vr from the travel speed Vc is set in the range from minus 50 m / min to 30 m / min inclusive.

Owner:NITTO DENKO CORP

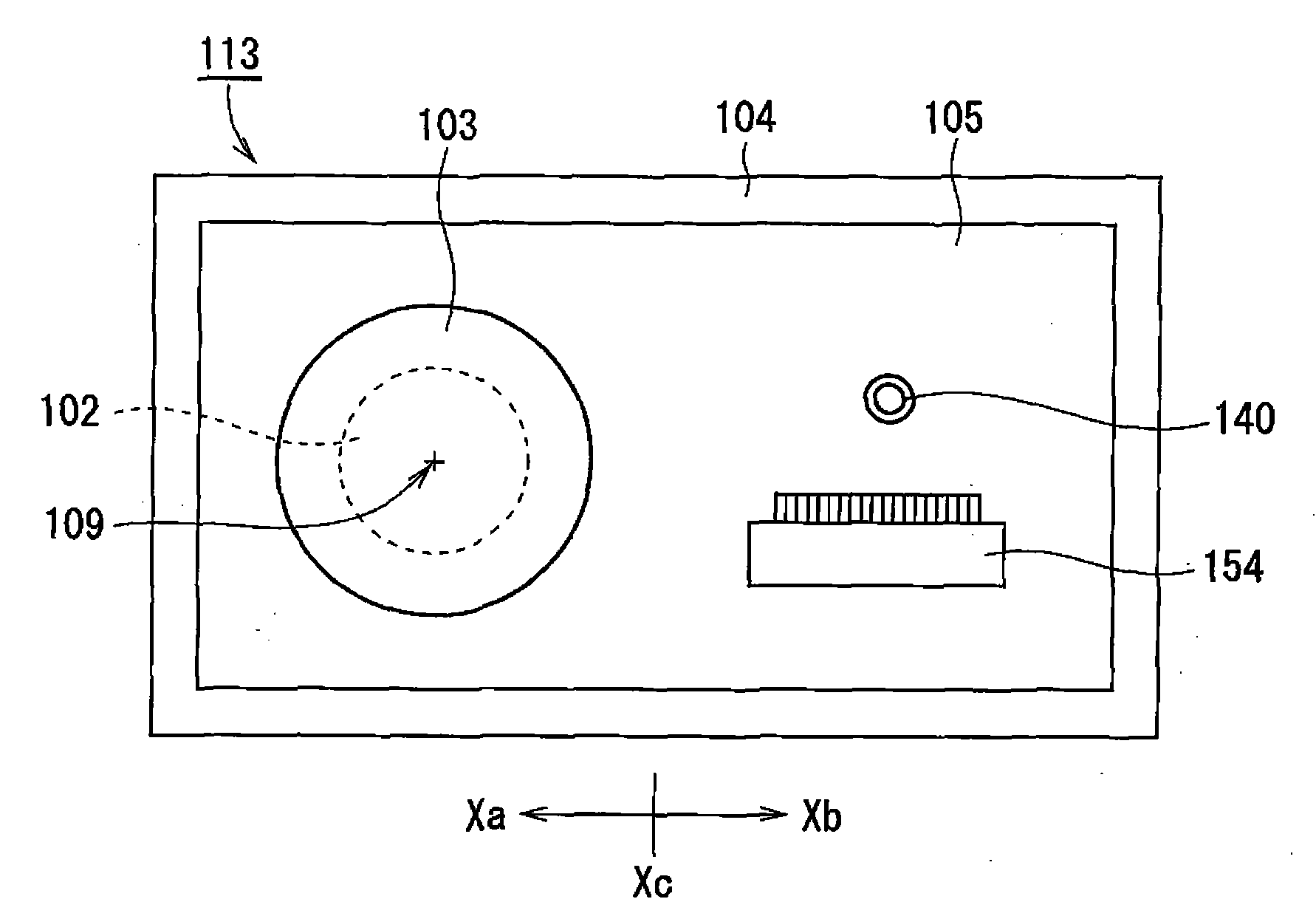

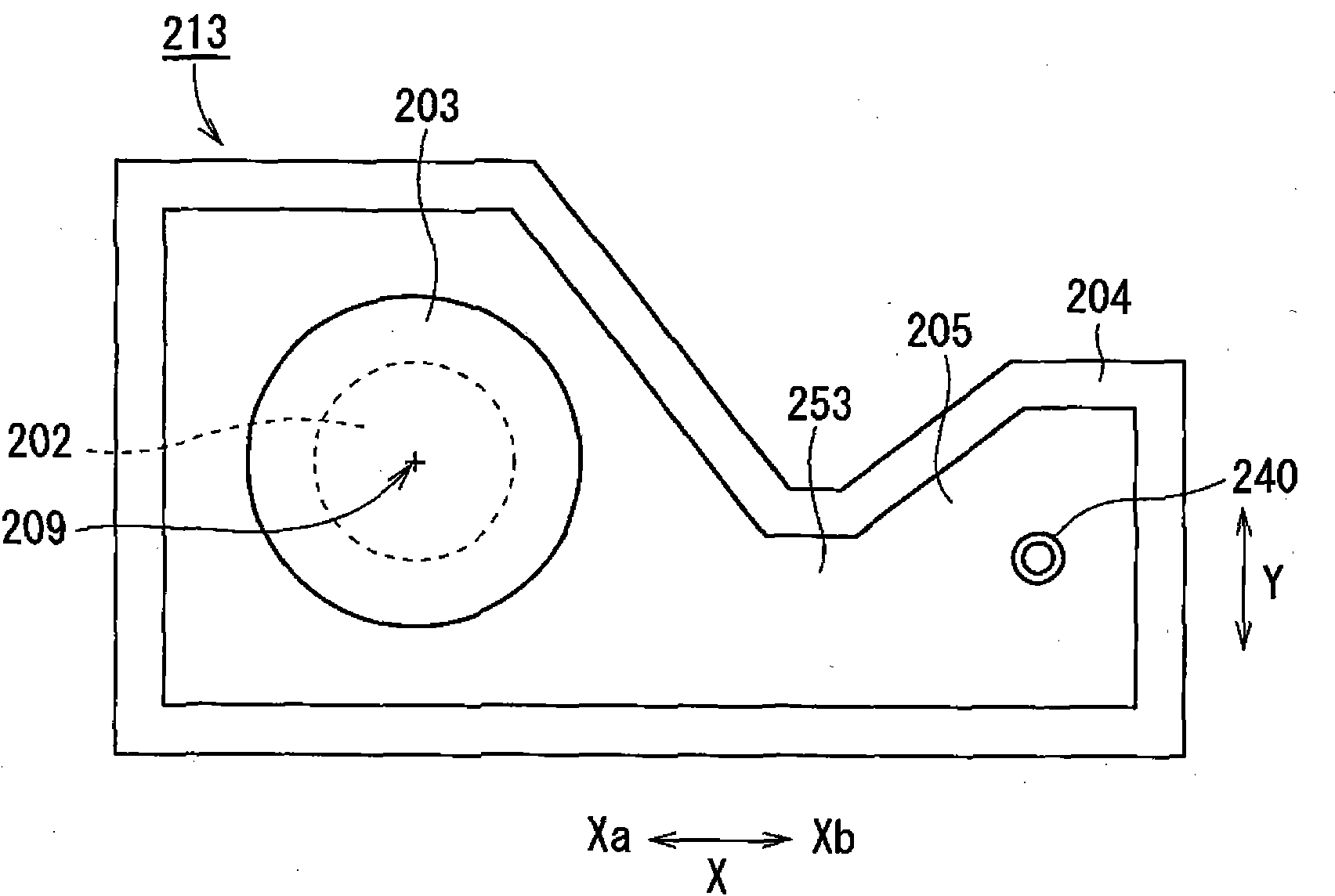

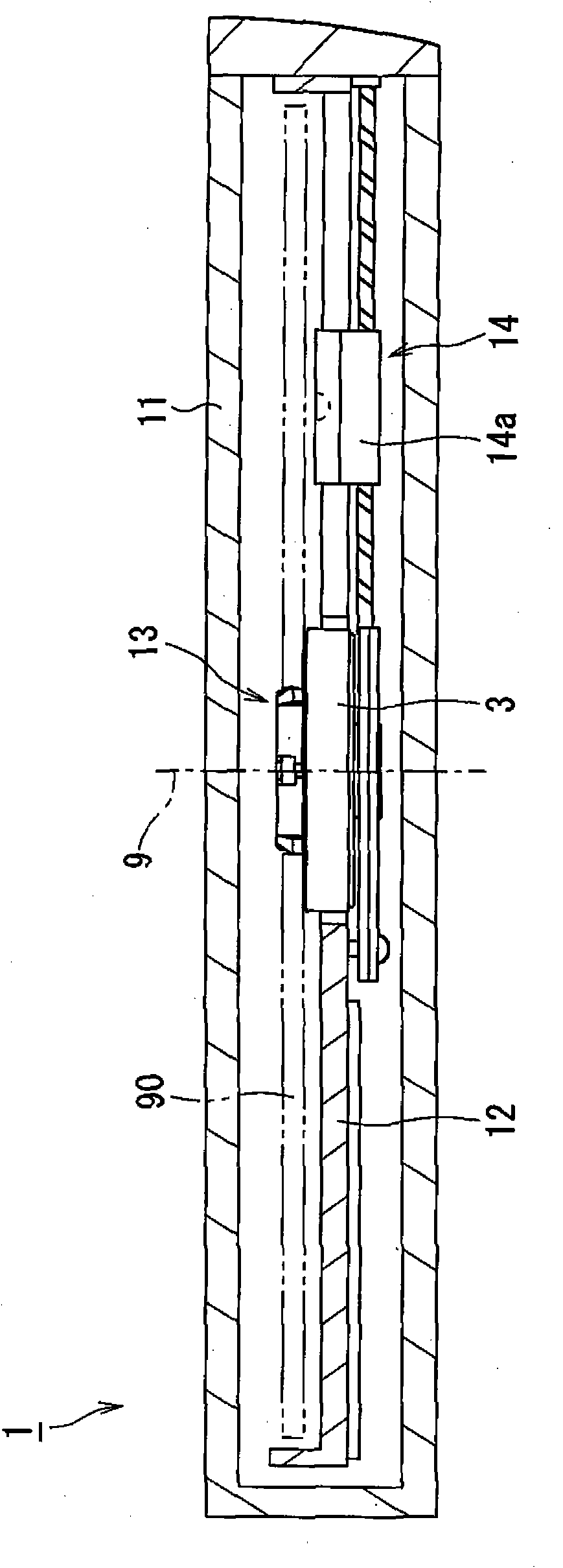

Motor and disk driving device

ActiveCN102044936ASuppress buoyancyAssociation with control/drive circuitsRecord information storageMechanical engineeringElectronic circuit

The present invention provides a motor which comprises the following components: a stationary part, a rotating part which is supported by the stationary part at a state of rotating round a central shaft that extends vertically, a mounting plate for fixing stationary part, and a circuit substrate which is configured at an upper side of the mounting plate and is provided with an electronic circuit that is used for rotatably driving the rotating part relatively to the stationary part. The stationary part is provided at one side of a central position in a length direction of the circuit substrate. The circuit substrate is provided with a connector which is provided at the other side of the central position in the length direction. The mounting plate is provided with a riveting partwhich abuts against an upper surface of the circuit substrate for fixing the circuit substrate. At least one riveting part is configured at a position of the other side of one end at one side of the connector. The circuit substrate is mechanically fixed on the mounting plate at the periphery of the connector where warpage easily generates in the circuit substrate. Therefore, the circuit substrate can be fixed on the mounting plate without pushing the circuit substrate to the upper surface of the mounting plate.

Owner:NIPPON DENSAN CORP

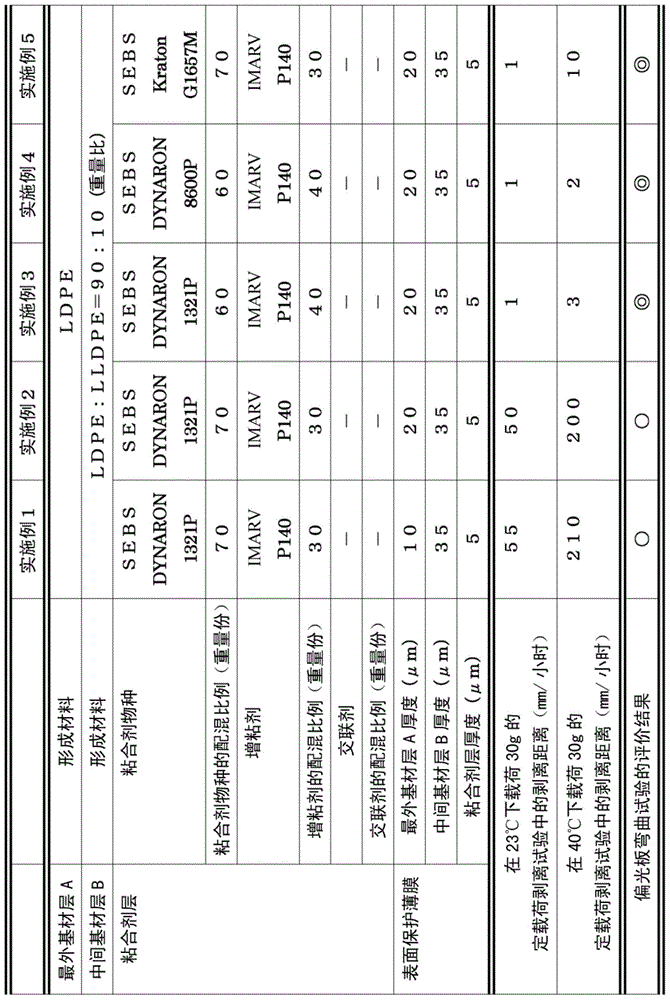

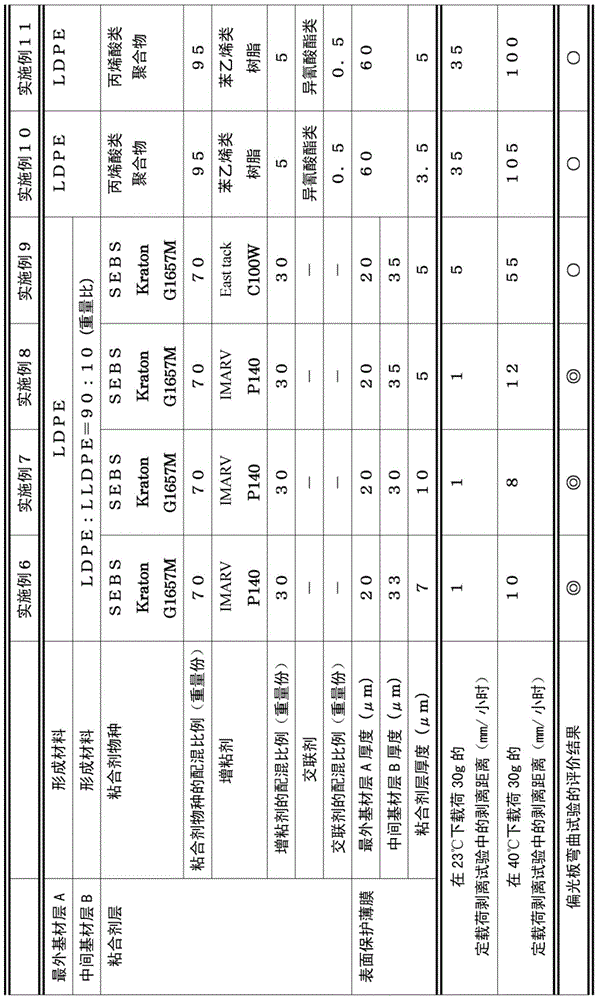

Surface protection film

The invention provides a surface protection film. The surface protection film comprises a base layer and a binder layer. Even if the surface protection film is bonded to a bend plane, the surface protection film can effectively inhibit separation of the surface protection film from the bend plane. The surface protection film comprises the base layer and the binder layer. In a 30g constant load peeling test at a temperature of 23 DEG C, the surface protection film has a peeling distance of 70mm / h or less and In a 30g constant load peeling test at a temperature of 40 DEG C, the surface protection film has a peeling distance of 300mm / h or less.

Owner:NITTO DENKO CORP

Cover tape and electronic component package

Owner:SUMITOMO BAKELITE CO LTD

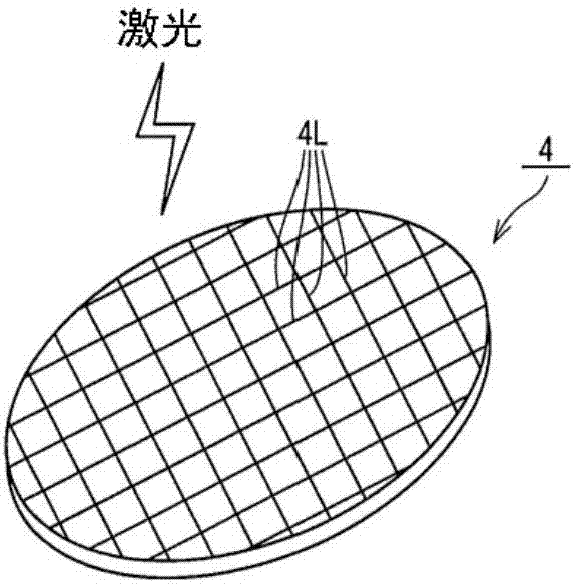

Dicing chip Bonding Film And Method For Manufacturing Semiconductor Device

InactiveCN107227123ASuppress buoyancyNon-macromolecular adhesive additivesFilm/foil adhesivesDevice materialSemiconductor chip

The invention discloses a dicing chip bonding film and a method for manufacturing a semiconductor device, wherein, the dicing chip bonding film can prevent a chip bonding film from floating from a dicing sheet in a cooling and expansion procedure, and can peel a semiconductor chip with the chip bonding film from the dicing sheet suitably in a picking procedure. The dicing chip bonding film comprises a dicing sheet; and a chip bonding film that is overlapped on the dicing sheet. A peeling force A of the dicing sheet and the chip bonding film at 23 DEG C is between 0.15N / 20mm and 0.5N / ;20nm; and the chip bonding film is fractured by extension for usage.

Owner:NITTO DENKO CORP

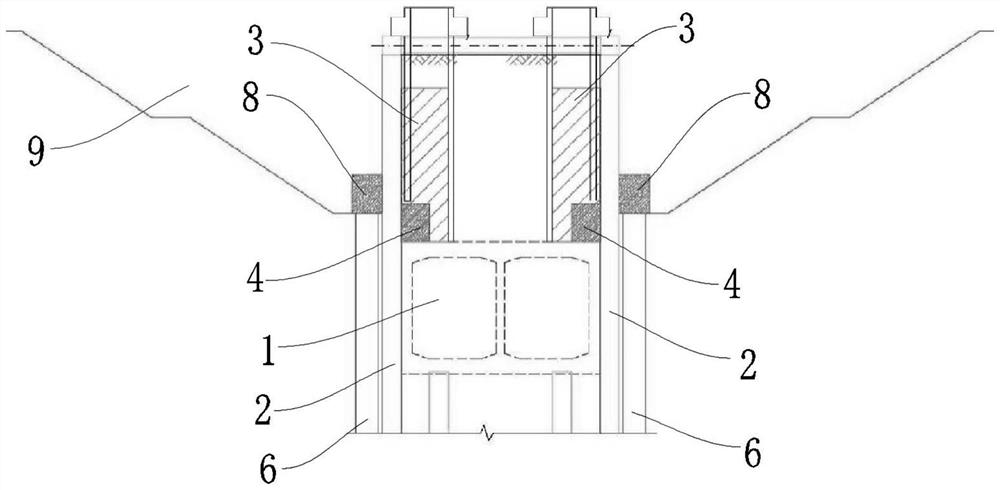

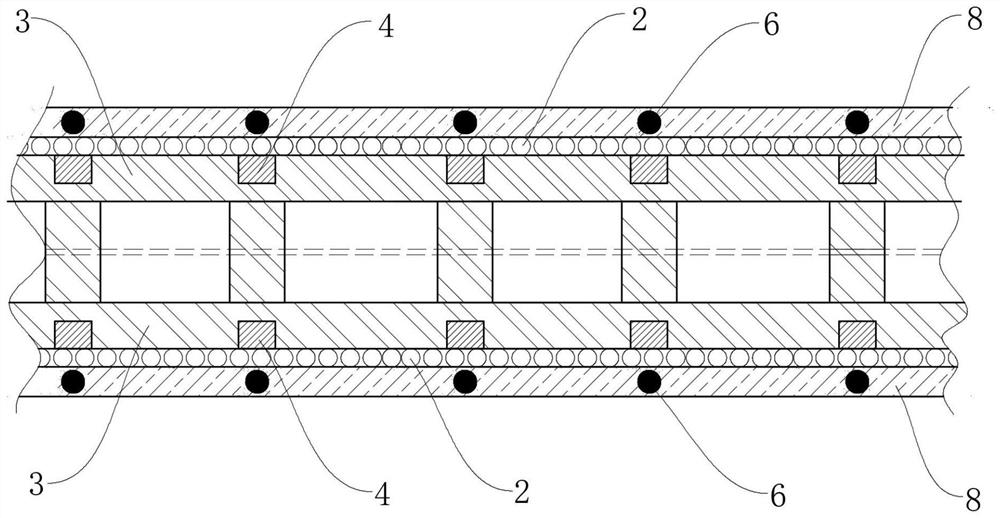

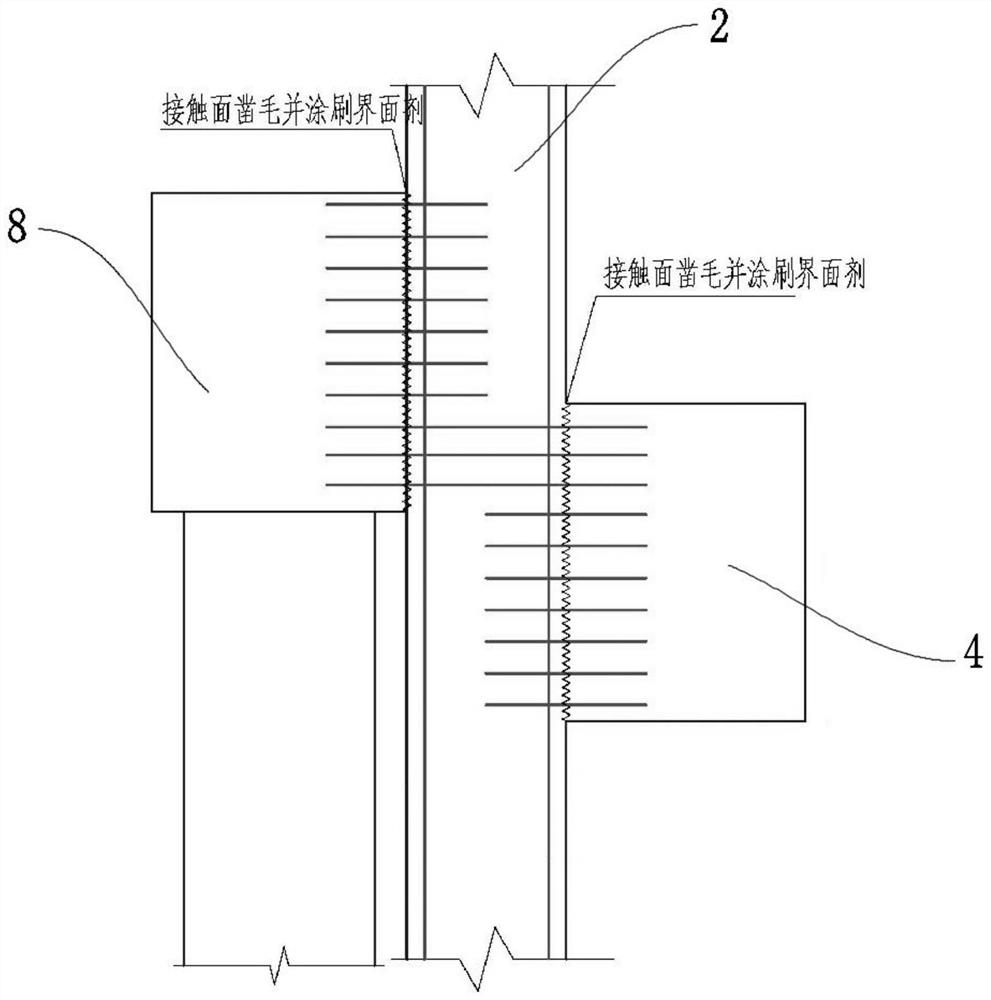

Construction method of combined protection structure of existing tunnel

ActiveCN114809106AStable structureSuppress buoyancyProtective foundationHydro energy generationArchitectural engineeringPier

The invention discloses a construction method of a combined protection structure of an existing tunnel. The construction method comprises the following steps that a top beam and a straining beam are poured above existing fender posts on the two sides of the existing tunnel correspondingly; a grouting reinforcement area is poured on the inner side of the existing fender post; a plurality of vertical shafts are constructed in the grouting reinforcement area to the top plate of the existing tunnel, and coping piers are poured out respectively; uplift piles are constructed on the outer sides of the existing fender posts correspondingly; the outer side of the existing fender post is excavated to the position below the channel foundation pit along the subway in a segmented mode, and connecting beams are poured respectively; channel foundation pits are symmetrically excavated on the two sides of the existing fender posts in a segmented and partitioned mode, and a channel structure is constructed in time and ballasting is carried out; foundation pits between the existing fender posts are excavated in a segmented and partitioned mode, and the existing fender posts are chiseled away; a channel structure is constructed in time and connected with channels on the two sides, and ballasting is conducted according to monitoring data; according to the method, the stability of the existing tunnel is guaranteed, and rapid advancing of earth excavation construction on the upper portion of the subway can be guaranteed.

Owner:中铁建设集团南方工程有限公司 +1

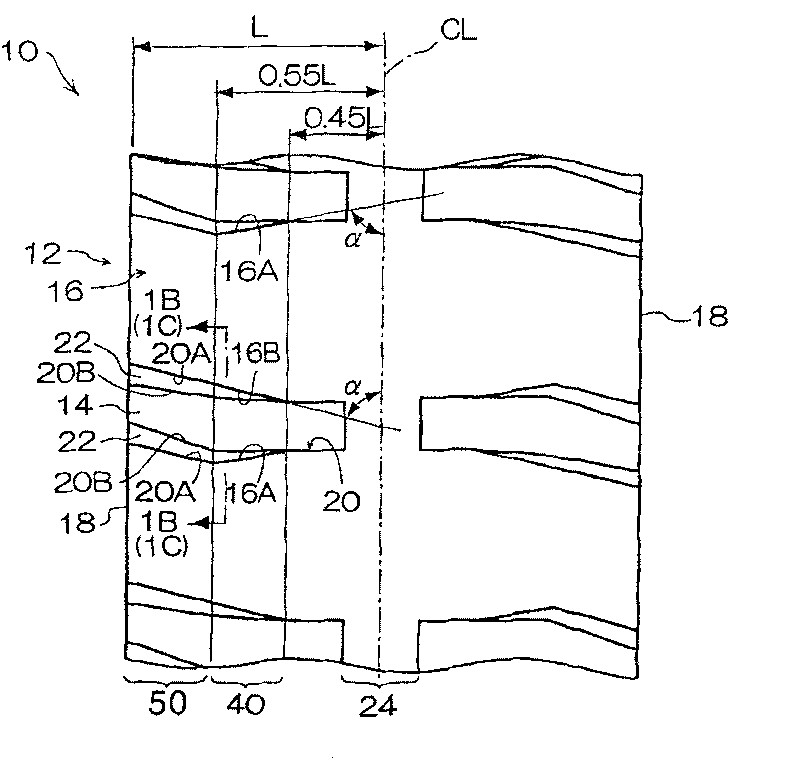

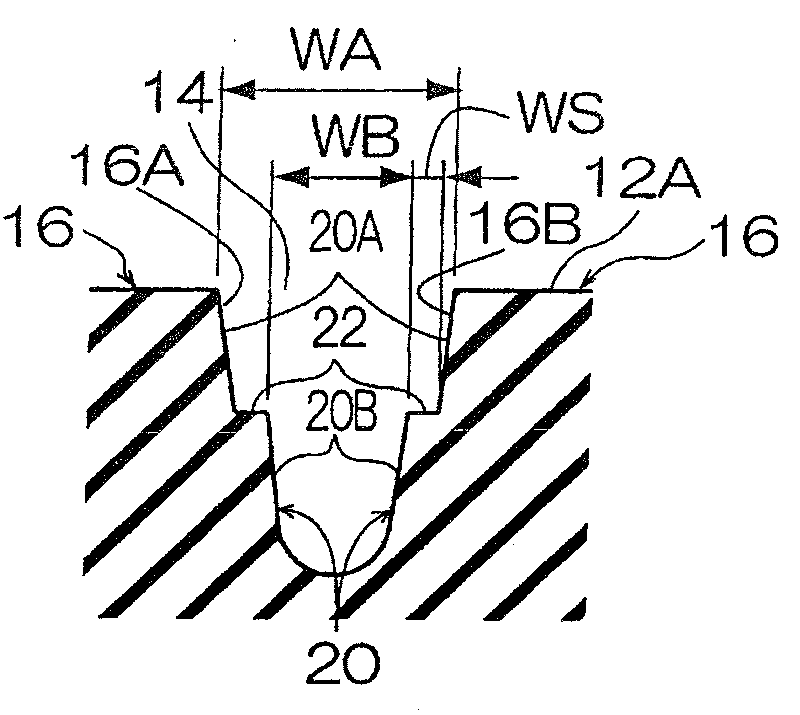

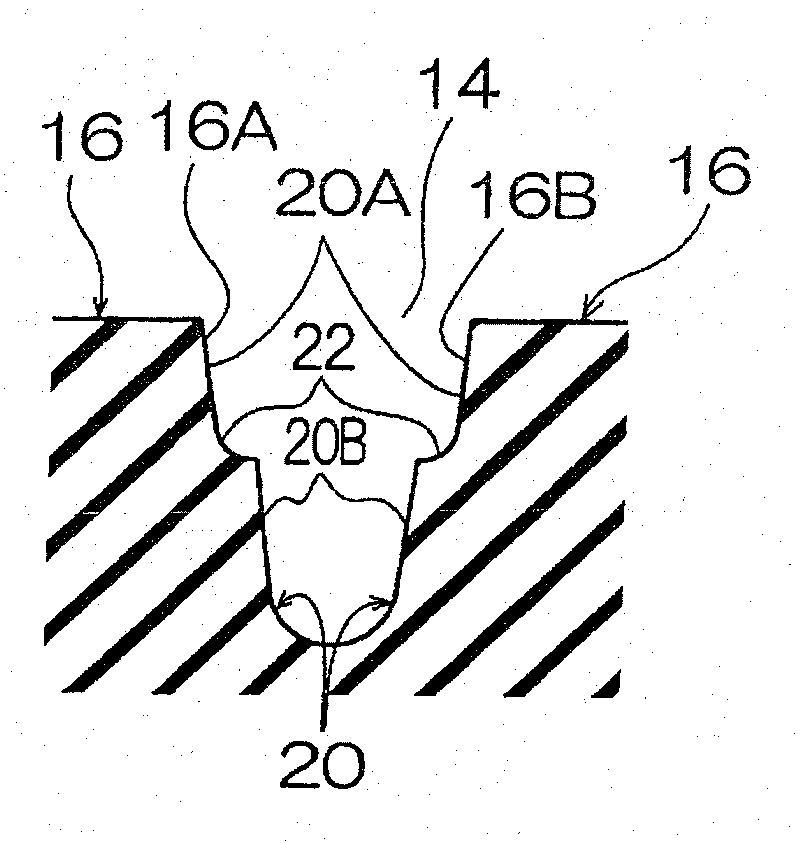

Pneumatic tire

ActiveCN101111398BGuaranteed volumeImprove rigidityHeavy duty tyresTyre tread bands/patternsGroove widthRoad surface

A pneumatic tire for heavy duty enabling an increase in the biased abrasion resistance of a tread while maintaining durability. A component (Fin) in the axial inner direction of the tire which is opposite to the axial outer direction of the tire is added to a force acting on the kicking end (16B) of a land portion (16) to suppress wear at the kicking end of the land portion so as to increase the biased abrasion resistance. Also, step parts (22) are formed on the groove walls (20) of a lug groove (14), tread side groove widths (WA) on the tread sides of the step parts are increased toward the axial outside of the tire, and the widths (WS) of the step parts (22) are increased toward the axial outside of the tire. Thus, the rise of the land portion (16) from a road surface (26) at a tread-inend (16A) can be suppressed.

Owner:BRIDGESTONE CORP

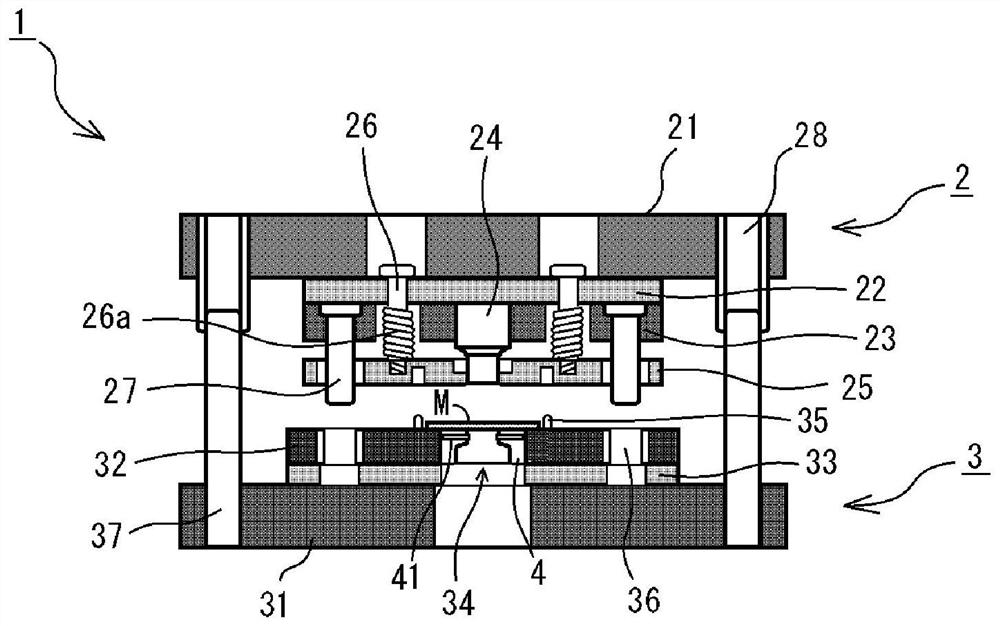

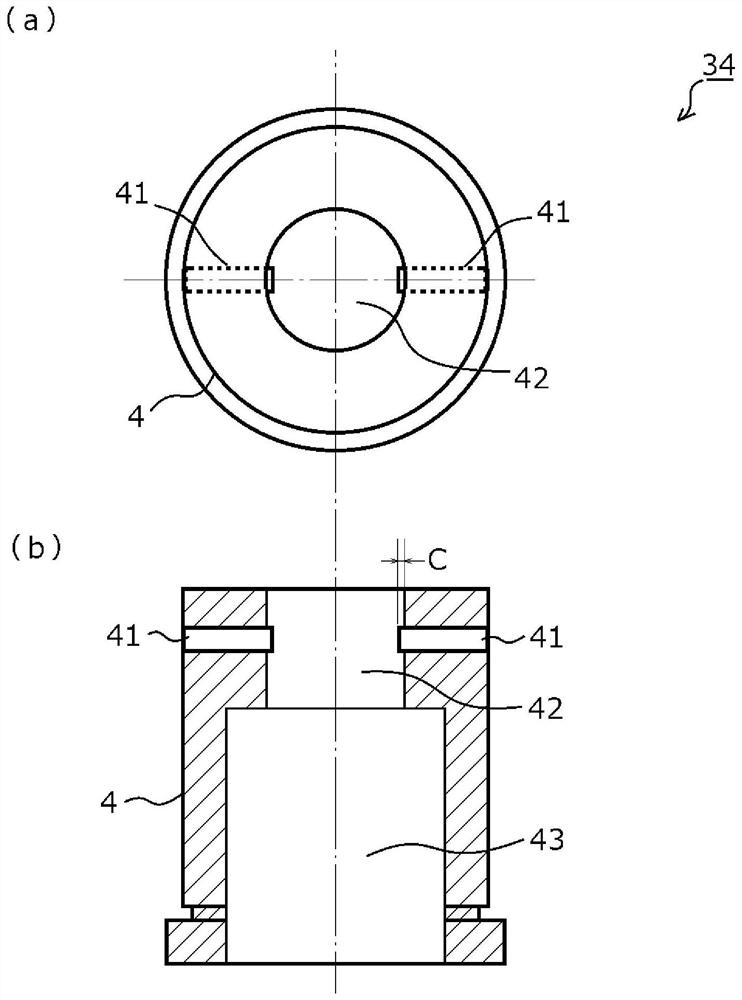

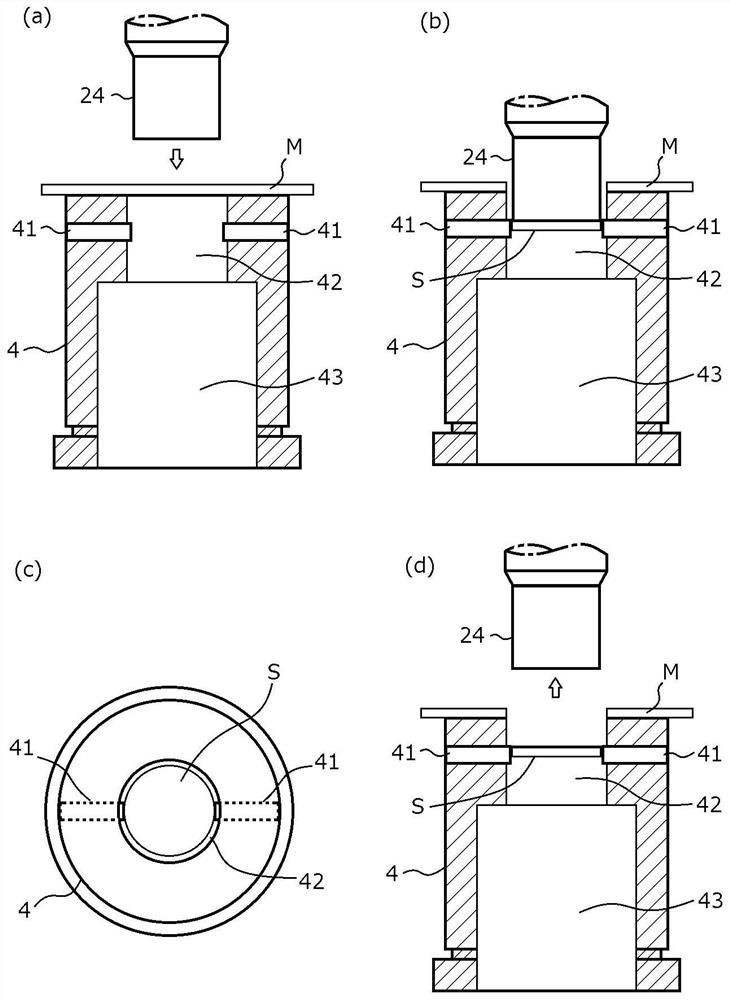

Punching die of die

PendingCN113385577ALess difficult to makeIncreased durabilityStripping-off devicesPunchingClassical mechanics

The invention provides a novel punching die of a die and capable of suppressing waste floating generated during punching. The punching die is composed of a punching die body (4) and slender resistance members (41); a punched hole (42) provided with a gap (C) relative to the peripheral surface of a punch (24) is formed in the punching direction of a machined material (M); and the slender resistance members (41) are nested inside the punching die body in the direction intersecting with the punching direction at the position lower than the upper surface of the punched hole, and the front ends of the slender resistance members (41) protrude to the positions where the slender resistance members (41) make contact with a part of punched waste (S) when the punch advances and retreats in the punched hole.

Owner:株式会社HARZ

Motor and disk driving device

InactiveCN102044936BSuppress buoyancyAssociation with control/drive circuitsRecord information storageMechanical engineeringElectronic circuit

The present invention provides a motor which comprises the following components: a stationary part, a rotating part which is supported by the stationary part at a state of rotating round a central shaft that extends vertically, a mounting plate for fixing stationary part, and a circuit substrate which is configured at an upper side of the mounting plate and is provided with an electronic circuit that is used for rotatably driving the rotating part relatively to the stationary part. The stationary part is provided at one side of a central position in a length direction of the circuit substrate. The circuit substrate is provided with a connector which is provided at the other side of the central position in the length direction. The mounting plate is provided with a riveting partwhich abuts against an upper surface of the circuit substrate for fixing the circuit substrate. At least one riveting part is configured at a position of the other side of one end at one side of the connector. The circuit substrate is mechanically fixed on the mounting plate at the periphery of the connector where warpage easily generates in the circuit substrate. Therefore, the circuit substrate can be fixed on the mounting plate without pushing the circuit substrate to the upper surface of the mounting plate.

Owner:NIDEC CORP

Solenoid fuel jet valve

ActiveCN100489296CAvoid it happening againFirmly connectedFuel injection apparatusMachines/enginesSynthetic resinFuel injection

Owner:HITACHI ASTEMO LTD

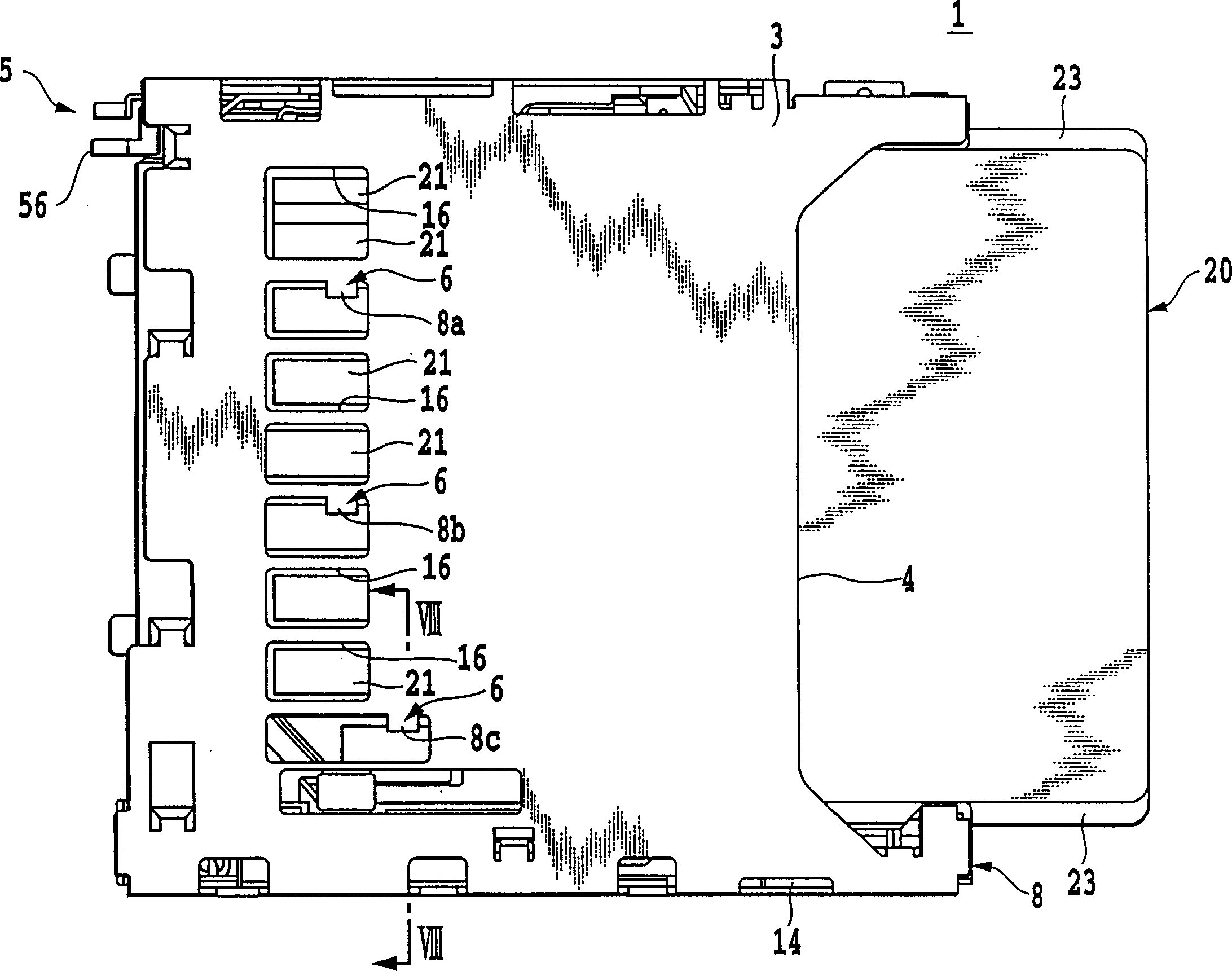

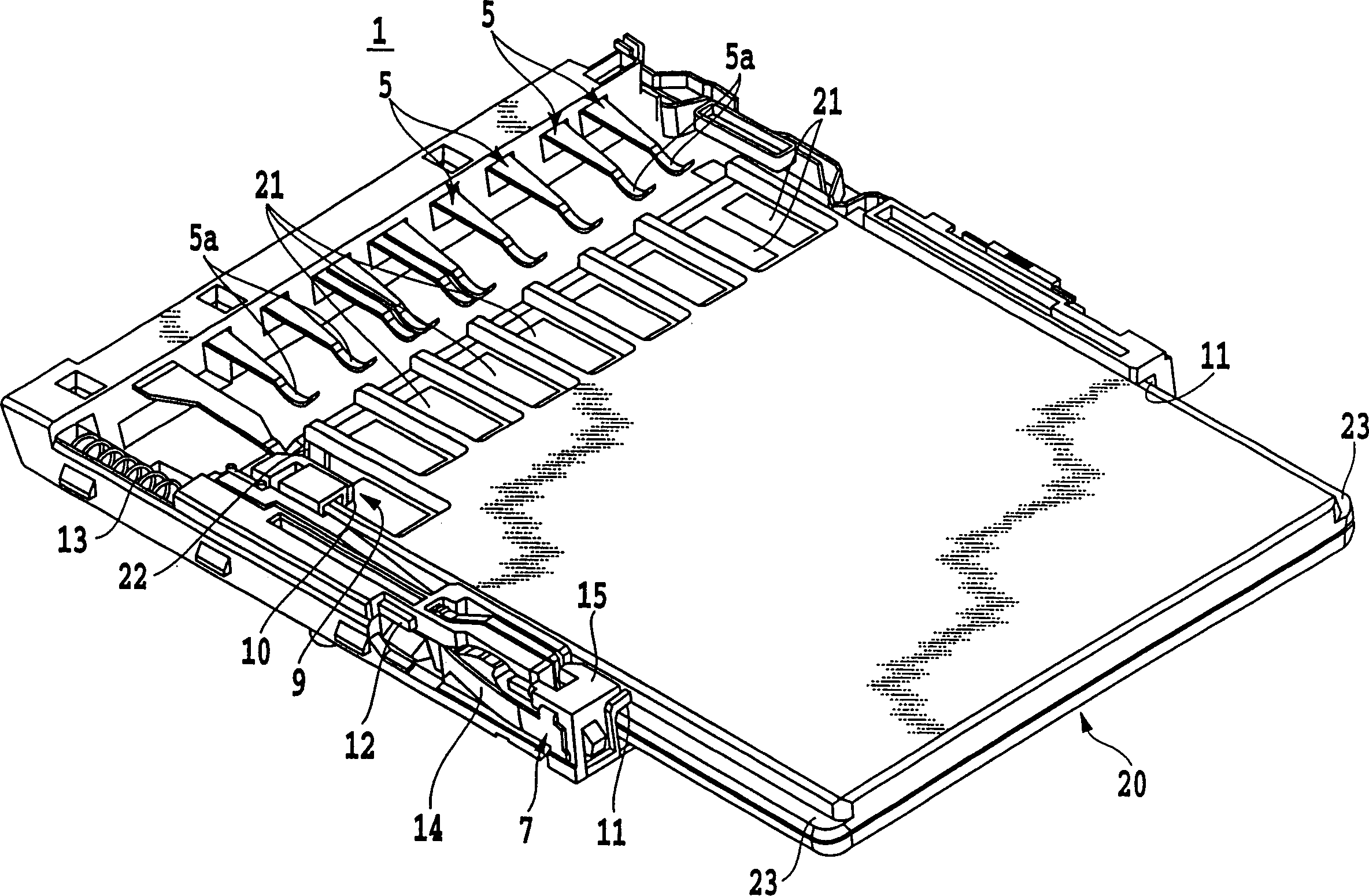

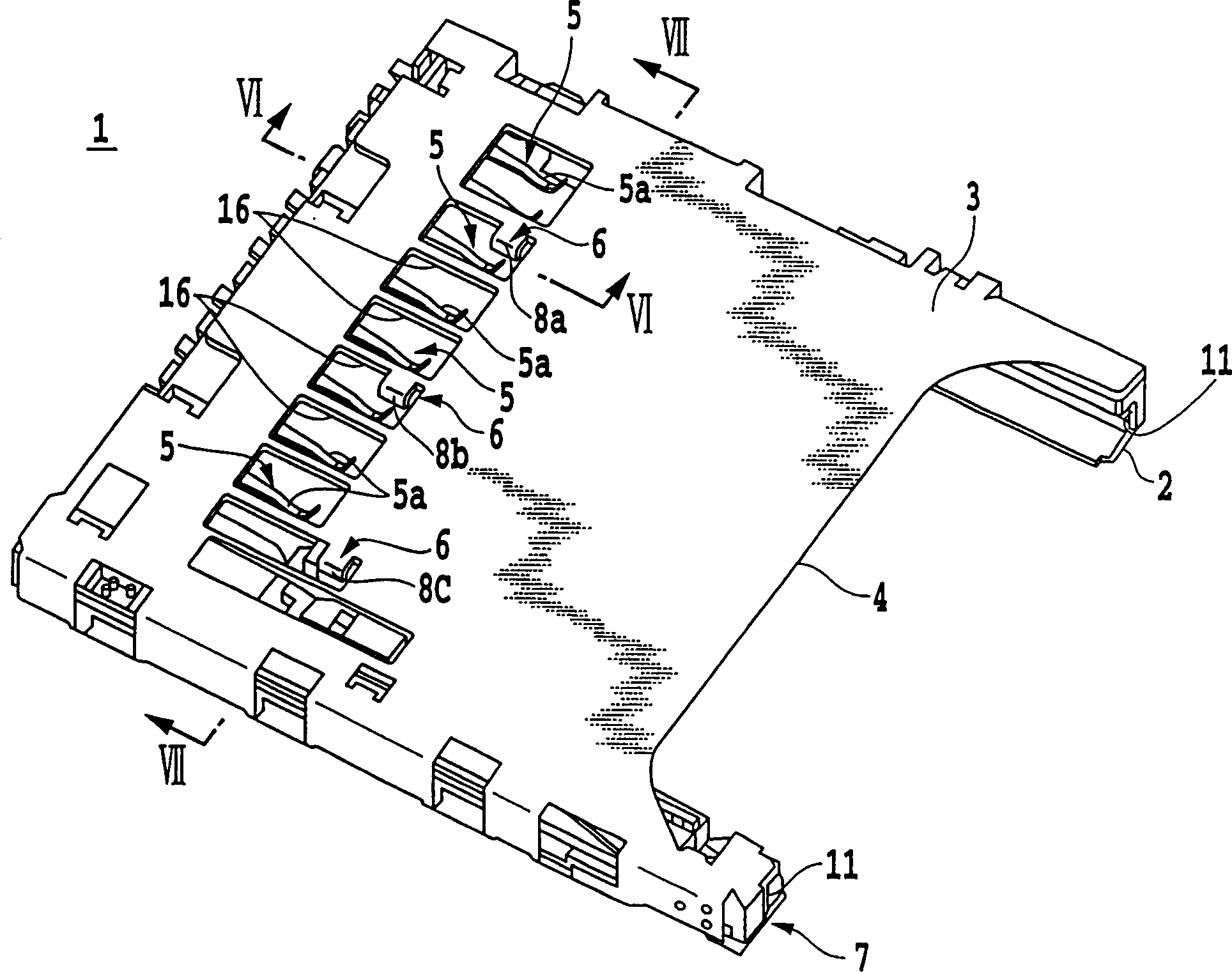

Card connector

InactiveCN1295816CNo short circuitWrong insertionOther printing matterConveying record carriersEngineeringMetal sheet

A card connector for an IC card according to the present invention is provided with a preventive wall of an anti-floating mechanism in an ejector mechanism on a substrate, for suppressing the floating-up of the inserted IC card. Also, projections of an erroneous insert prevention mechanism for inhibiting the opposite insert of the card are provided with a sheet metal cover to prevent the IC card from floating up or being erroneously inserted, so that the IC card is not damaged and no short-circuit accident occurs. The card connector for an IC card is constructed into a hollow flat housing formed of a substrate and a metal sheet cover combined therewith, having the anti-floating mechanism for suppressing the floating-up of the IC card and the erroneous insert prevention mechanism for preventing the IC card from being inserted in such a manner that the rear end is directed forward.

Owner:YAMAICHI ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com