Insert, holder, and cutting tool using said insert and holder

A technology of inserts and tool holders, which is applied in the field of cutting tools, can solve the problems of increased repeat installation accuracy, reduced rigidity, and reduced cross-sectional area of inserts, etc., and achieves good repeatability, sufficient rigidity, and vibration suppression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

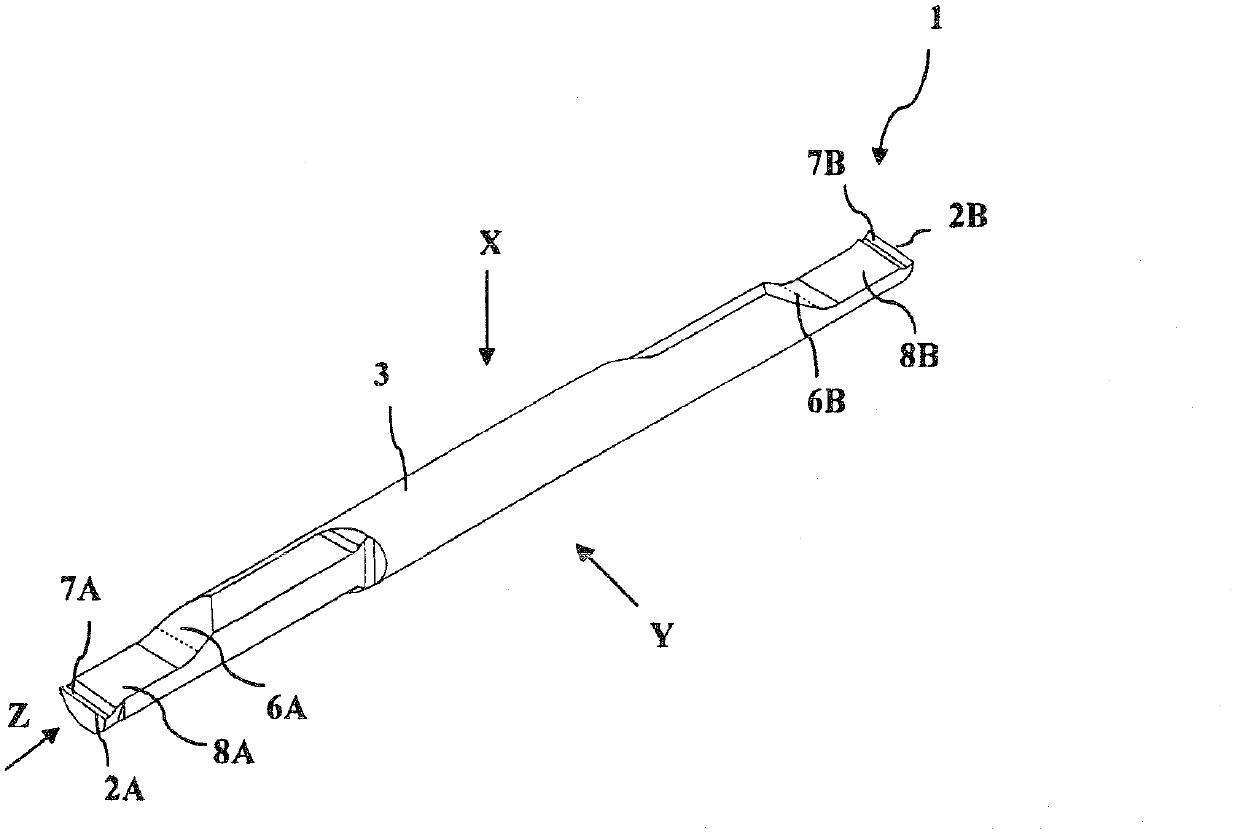

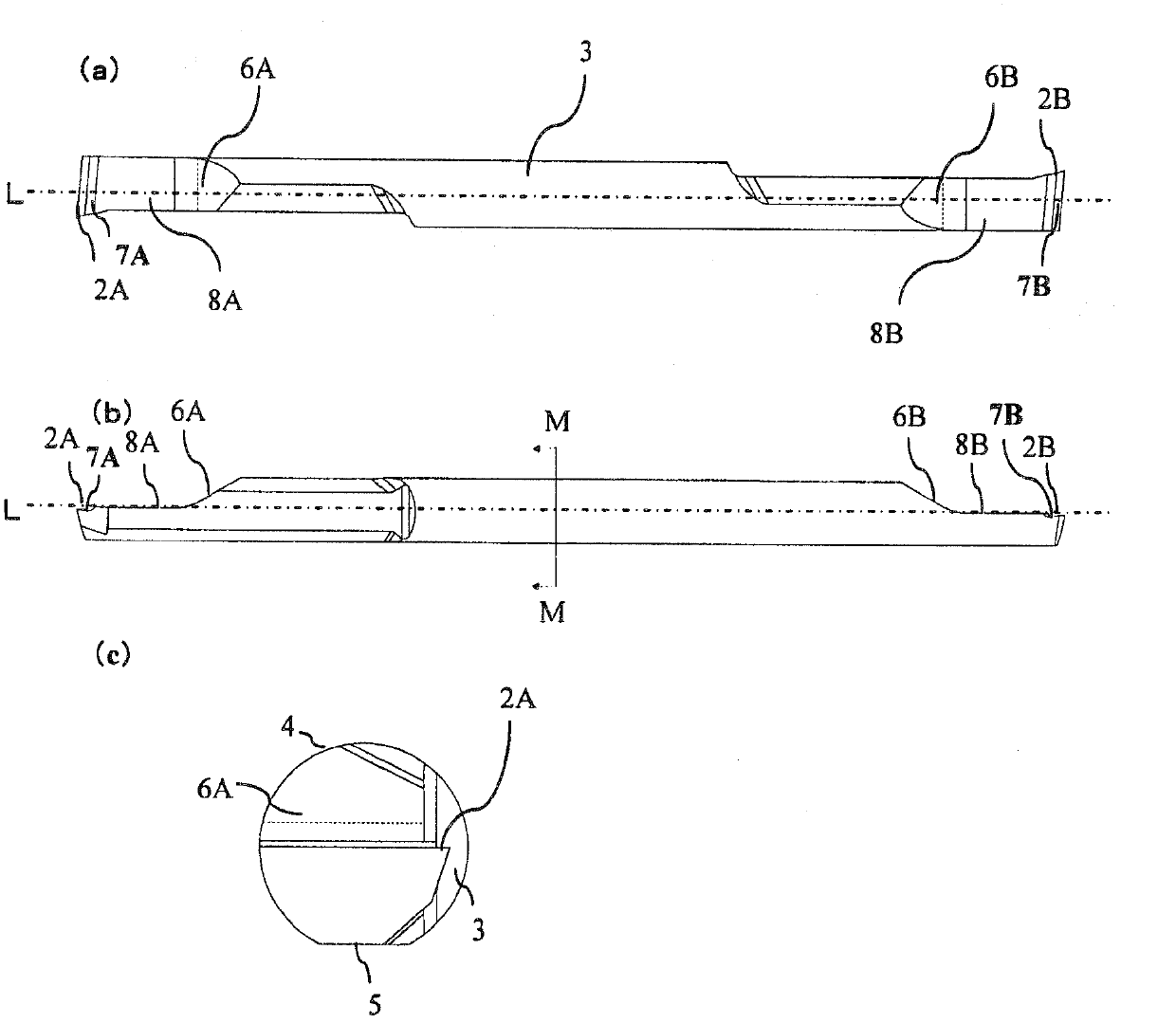

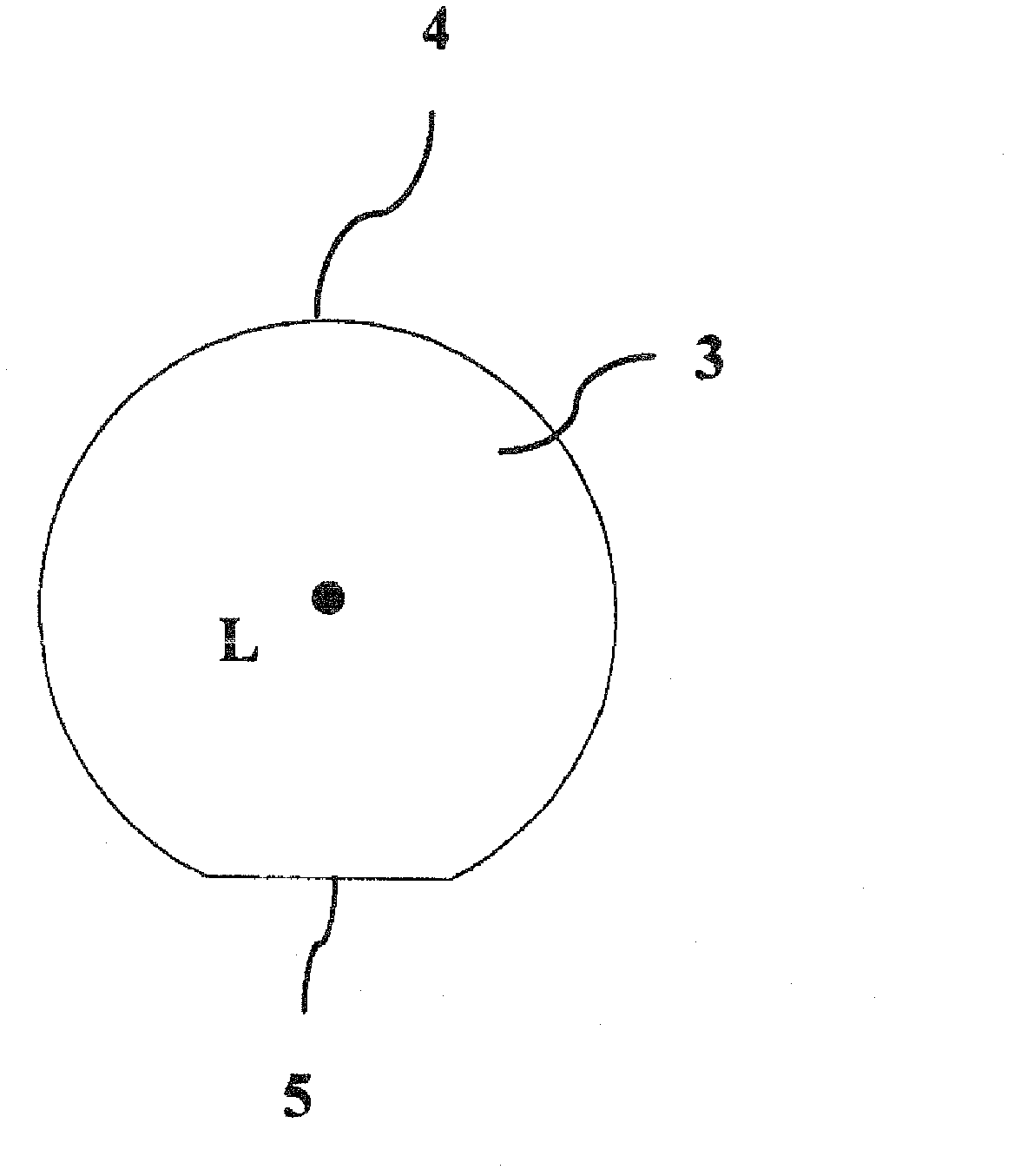

[0031] Below, use Figure 1 to Figure 6 Next, a cutting tool T for machining an inner diameter used by attaching the insert 1 according to one embodiment of the present invention to the holder 10 will be described. figure 1 It is a brief perspective view of insert 1, figure 2 It is viewed from (a) X direction (top view direction) figure 1 (b) is a side view viewed from the Y direction (side view direction), (c) is an end view obtained from the Z direction (front end direction), image 3 yes figure 2 (a) M-M sectional view. and, Figure 4 is a schematic perspective view of a cutting tool T with an insert 1 attached to a tool holder 10, Figure 5 It is viewed from (a) X direction (top view direction) Figure 4 (b) is a side view viewed from the Y direction (side view direction), (c) is an end view obtained from the Z direction (tip direction), Image 6 yes Figure 5 (b) N-N sectional view.

[0032] exist figure 1 Among them, the insert 1 is composed of a rod-shaped b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com