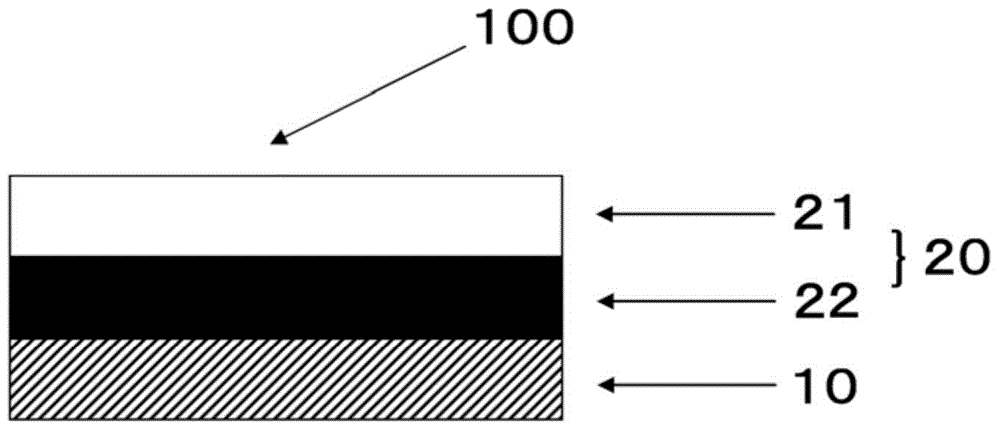

Surface protection film

A technology for protecting film and substrate layers, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problem of surface protection film floating and achieve the effect of suppressing floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

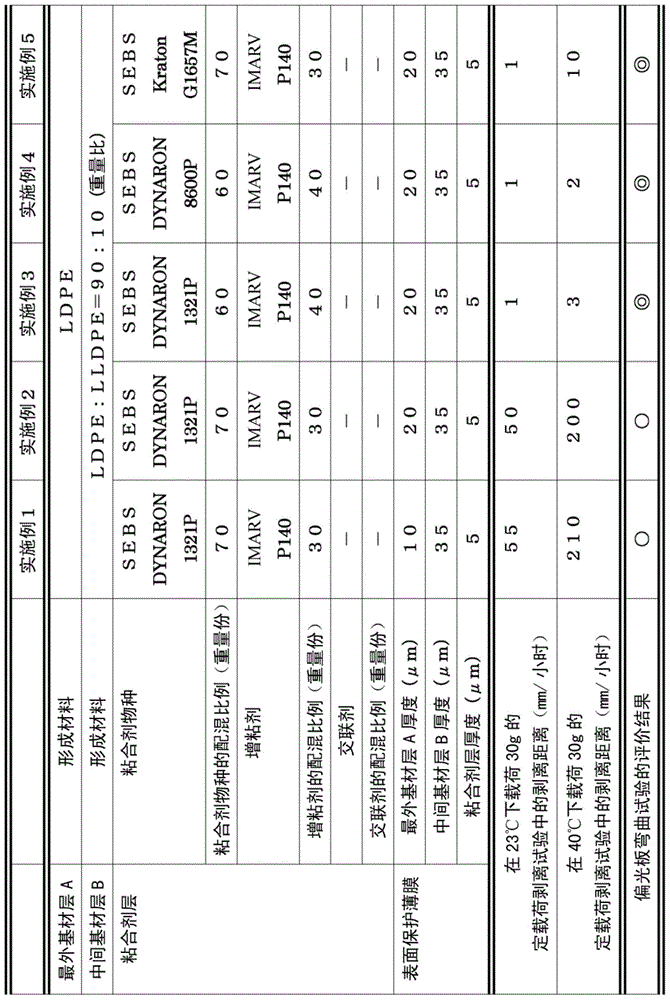

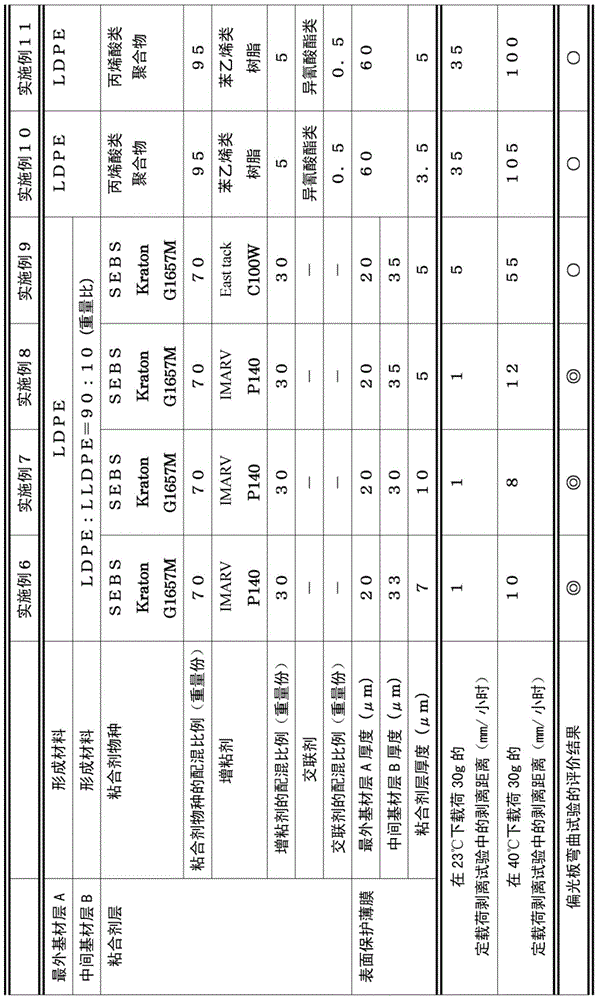

Embodiment 1

[0121] Preparation of substrate layer (1A)

[0122] Low-density polyethylene (manufactured by Japan Polyethylene Corporation, trade name: NOVATEC LD LC720, density=0.922g / cm 3 ) as the substrate layer (1A) forming material.

[0123] Preparation of substrate layer (1B)

[0124] Compounding low-density polyethylene (manufactured by Tosoh Corporation, trade name: Petrothene 186R, density=0.924g / cm 3 ): 90 parts by weight, and linear low-density polyethylene (manufactured by Sumitomo Chemical, trade name: EXCELLEN FX FX307, density = 0.890 g / cm 3 ): 10% by weight, as a material for forming the substrate layer (1B).

[0125] Preparation of Adhesive Layer (1)

[0126] Compounded SEBS (hydrogenated SEBS, manufactured by JSR, trade name: DYNARON1321P, styrene content = 10% by weight): 70 parts by weight and tackifier (C5 type hydrogenated aromatic petroleum resin, manufactured by Idemitsu Kosan, trade name: IMARV P140 , ring and ball method softening point = 140°C): 30 part...

Embodiment 2

[0131] Preparation of substrate layer (2A)

[0132] Low-density polyethylene (manufactured by Japan Polyethylene Corporation, trade name: NOVATEC LD LC720, density=0.922g / cm 3 ) as the substrate layer (2A) forming material.

[0133] Preparation of substrate layer (2B)

[0134] Compounding low-density polyethylene (manufactured by Tosoh Corporation, trade name: Petrothene 186R, density=0.924g / cm 3 ): 90 parts by weight and linear low-density polyethylene (manufactured by Sumitomo Chemical, trade name: EXCELLEN FX FX307, density = 0.890 g / cm 3 ): 10% by weight, as a material for forming the substrate layer (2B).

[0135] Preparation of adhesive layer (2)

[0136] Compounded SEBS (hydrogenated SEBS, manufactured by JSR, trade name: DYNARON1321P, styrene content = 10% by weight): 70 parts by weight and tackifier (C5 type hydrogenated aromatic petroleum resin, manufactured by Idemitsu Kosan, trade name: IMARV P140 , ring and ball softening point = 140°C): 30 parts by wei...

Embodiment 3

[0141] Preparation of substrate layer (3A)

[0142] Low-density polyethylene (manufactured by Japan Polyethylene Corporation, trade name: NOVATEC LD LC720, density=0.922g / cm 3 ) as the substrate layer (3A) forming material.

[0143] Preparation of substrate layer (3B)

[0144] Compounding low-density polyethylene (manufactured by Tosoh Corporation, trade name: Petrothene 186R, density=0.924g / cm 3 ): 90 parts by weight and linear low-density polyethylene (manufactured by Sumitomo Chemical, trade name: EXCELLEN FX FX307, density = 0.890 g / cm 3 ): 10% by weight, as a material for forming the substrate layer (3B).

[0145] Preparation of adhesive layer (3)

[0146] Compounding SEBS (hydrogenated SEBS, manufactured by JSR, trade name: DYNARON1321P, styrene content = 10% by weight): 60 parts by weight and tackifier (C5 type hydrogenated aromatic petroleum resin, manufactured by Idemitsu Kosan, trade name: IMARV P140 , ring and ball softening point = 140°C): 40 parts by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com