Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

390results about How to "Guaranteed volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

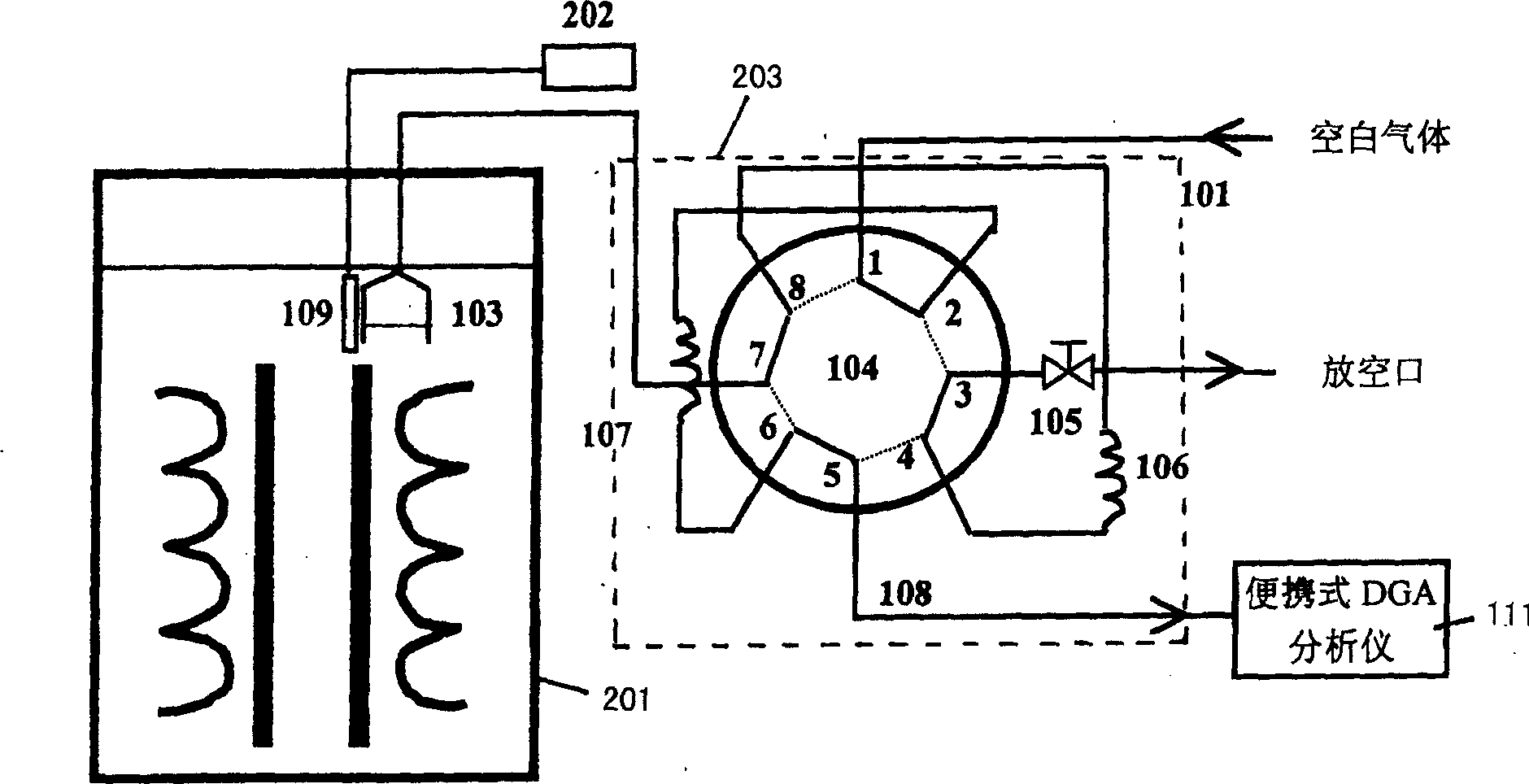

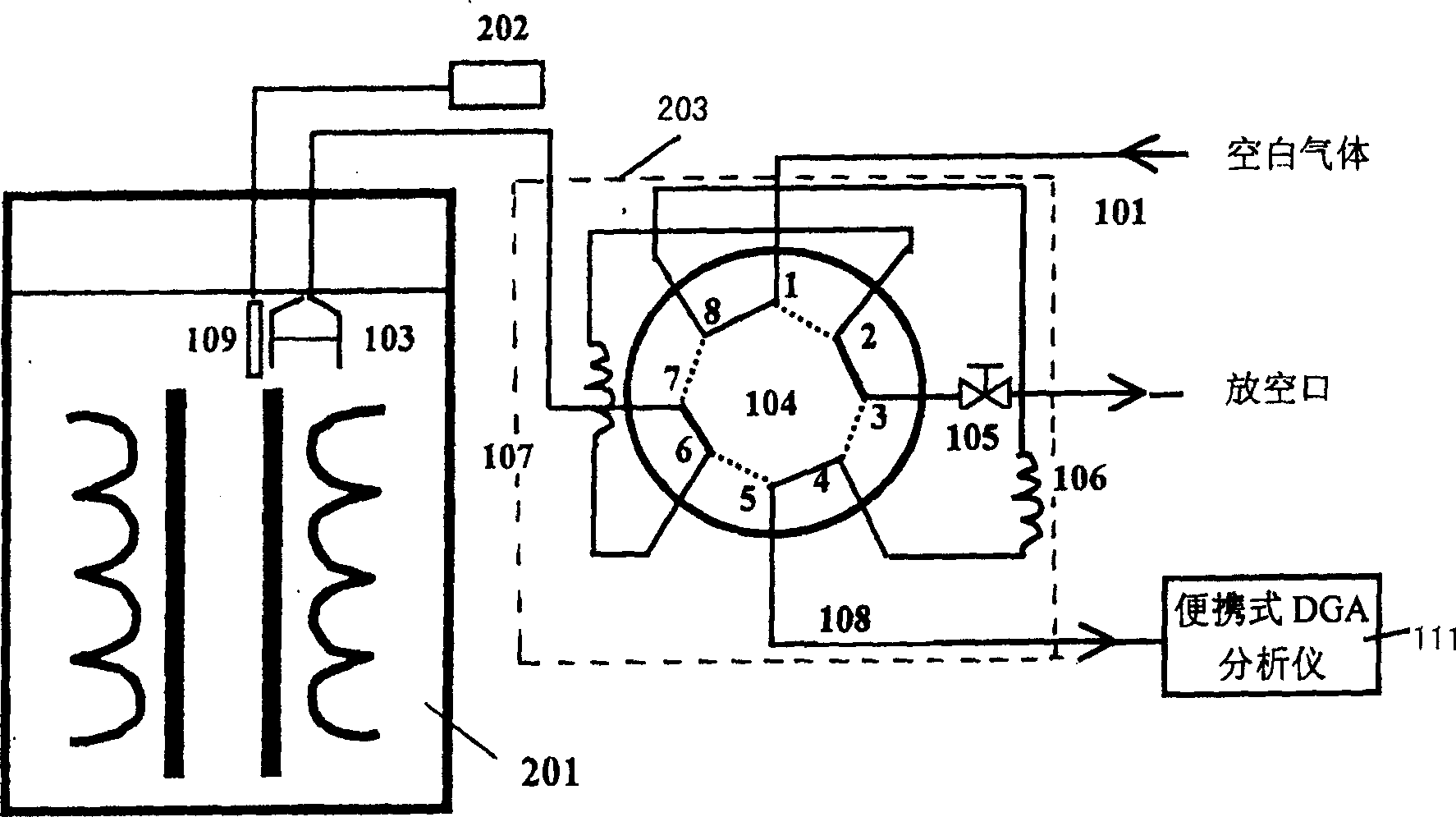

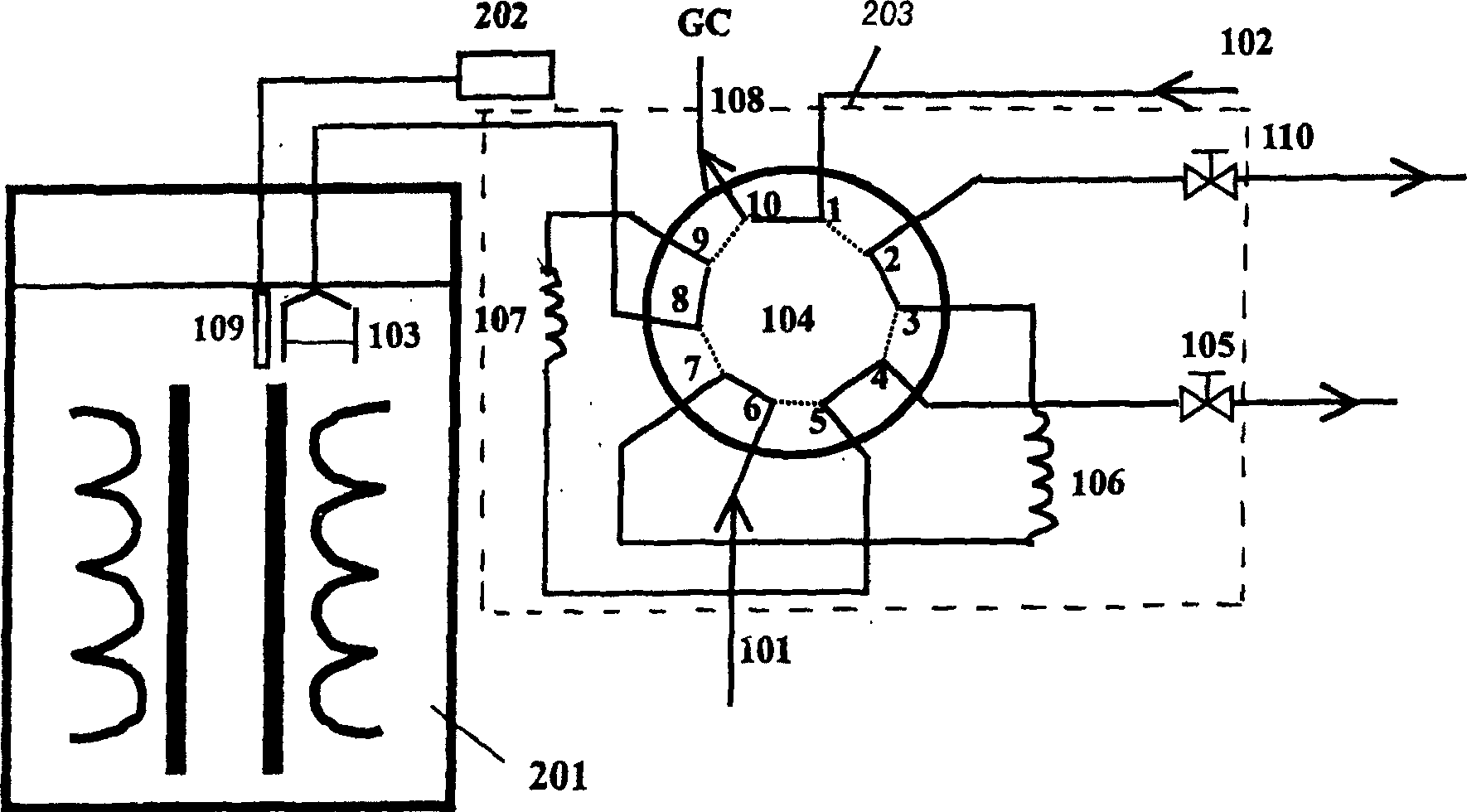

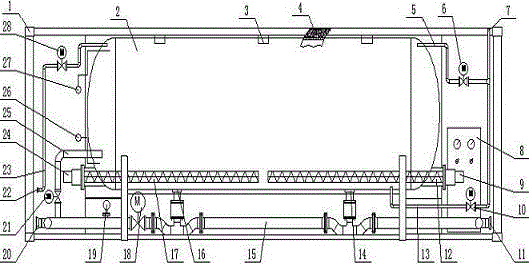

Dissolved gas sampling apparatus and method used in transformer oil gas-chromatography on-line analysis

ActiveCN1721835AGuaranteed volumeGuaranteed repeatabilityWithdrawing sample devicesPreparing sample for investigationGas liquid chromatographicProduct gas

The invention relates to a sampling device and method of gas chromatographic online analysis transformer dissolved gas, which comprises sampling probe, temperature sensor, multi-ported valve, sample quantitative pipe, marginal gas quantitative pipe, cutoff valve and marginal gas regulating system. The method directly inserts sampling probe into transformer oil and presses marginal gas into sampling probe by switching of multi-ported valve; the transformer oil is circulated by oil pump so that the dissolved gas of transformer oil can spill into marginal gas and then it achieves gas-liquid equilibrium in probe.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

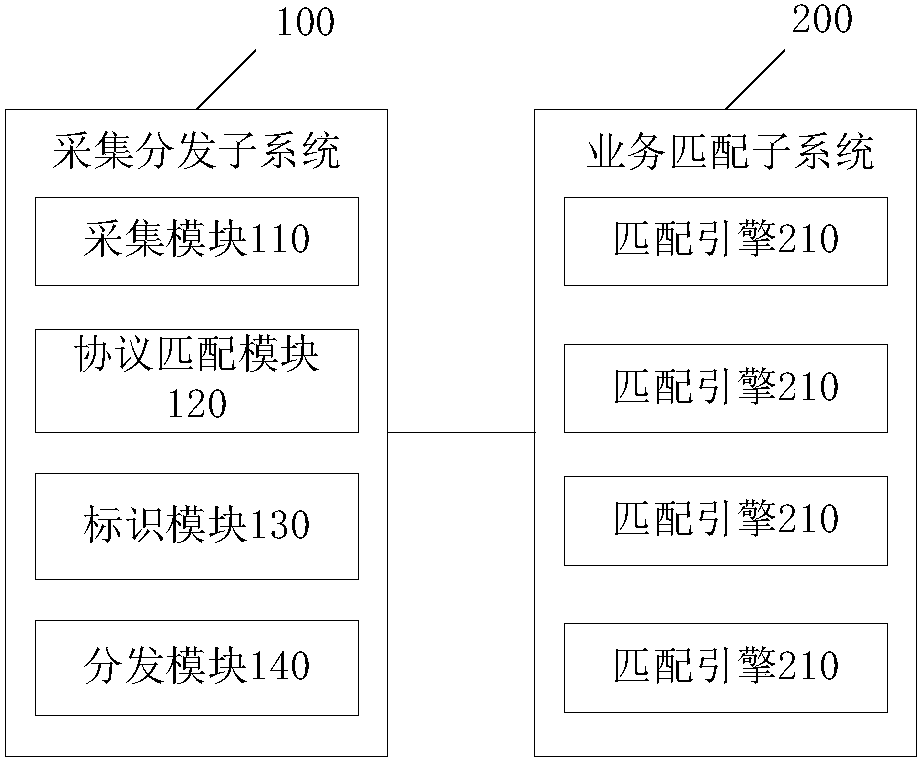

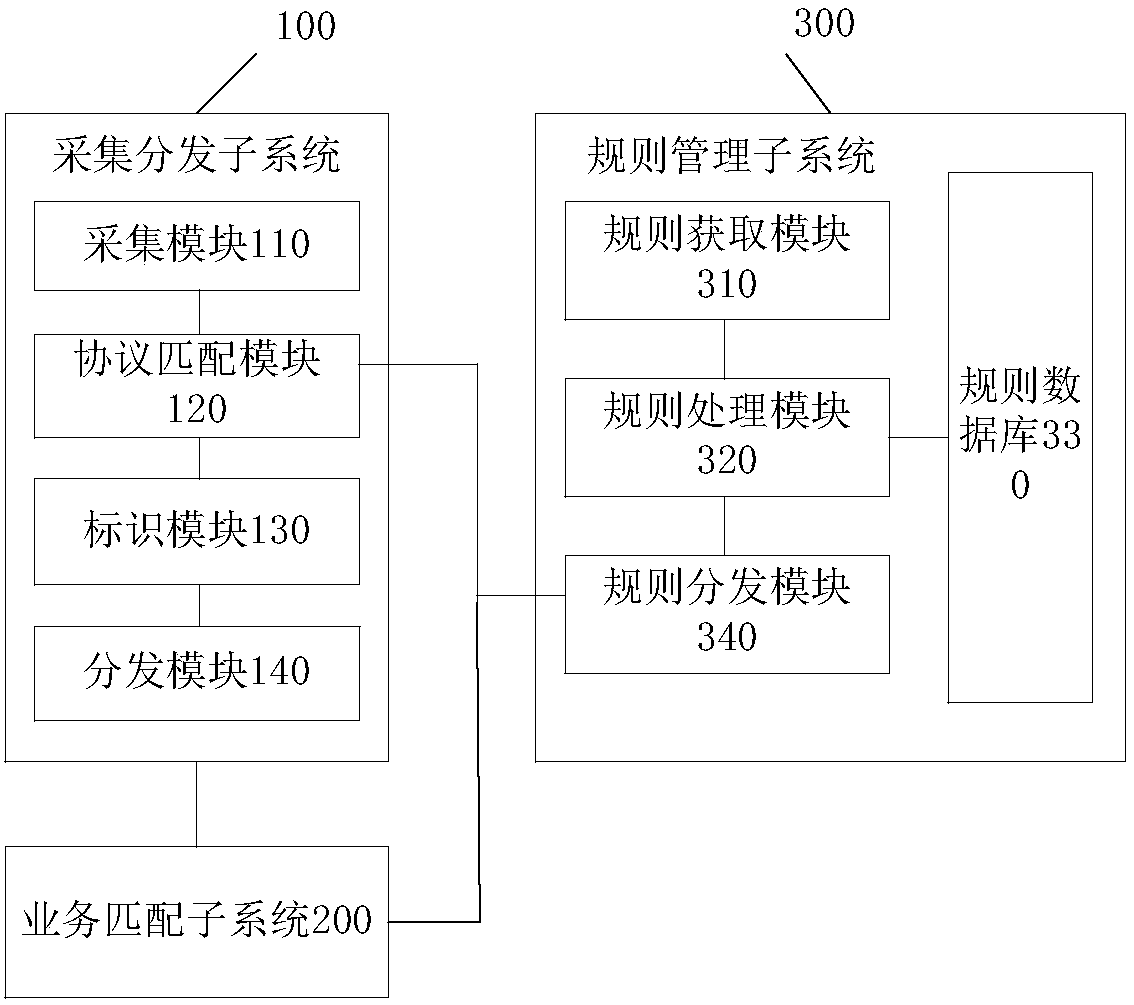

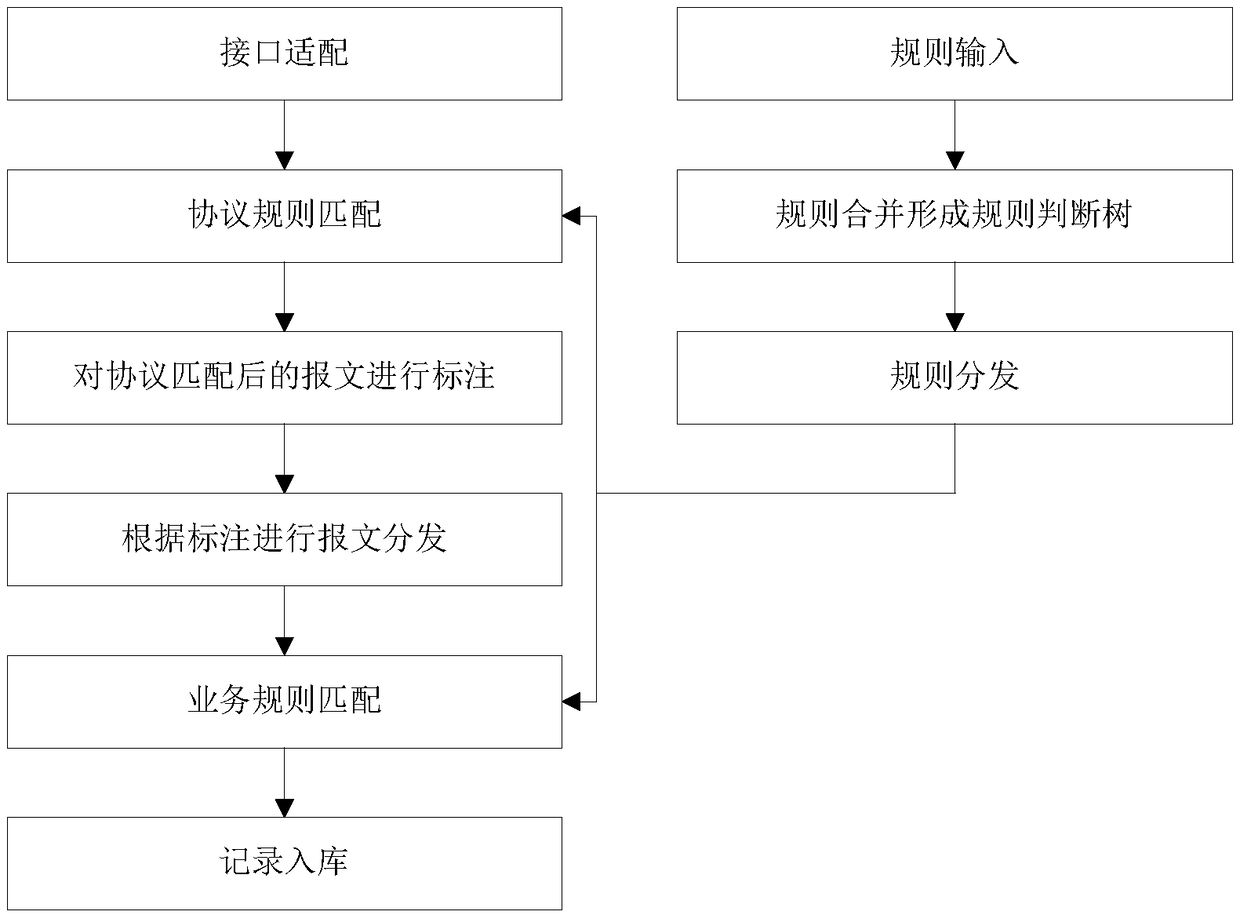

Method and device for network flow data analysis based on stream processing

InactiveCN108259371ATake advantage ofGuaranteed volumeData switching networksTraffic capacityReal time analysis

The present invention provides a method and a device for network flow data analysis based on stream processing. The method comprises the steps of: obtaining original network flow data switched by a signaling transfer device; performing protocol matching of an original message in the original network flow data; marking a classification identifier distributed by the message for the original messageafter protocol matching; and sending the original message after protocol rule matching to a target processing node according to the classifier identifier, wherein the target processing node employs adistributed calculation stream data processing mode to perform business rule matching of the original message to generate XDR (External Data Representation) data in real time. According to the technical scheme disclosed by the embodiment of the invention, the method and the device for network flow data analysis based on stream processing meet the demand of real-time analysis of large-scale flow data in an operator communication device network so as to greatly improve the analysis efficiency and speed.

Owner:BOCO INTER TELECOM

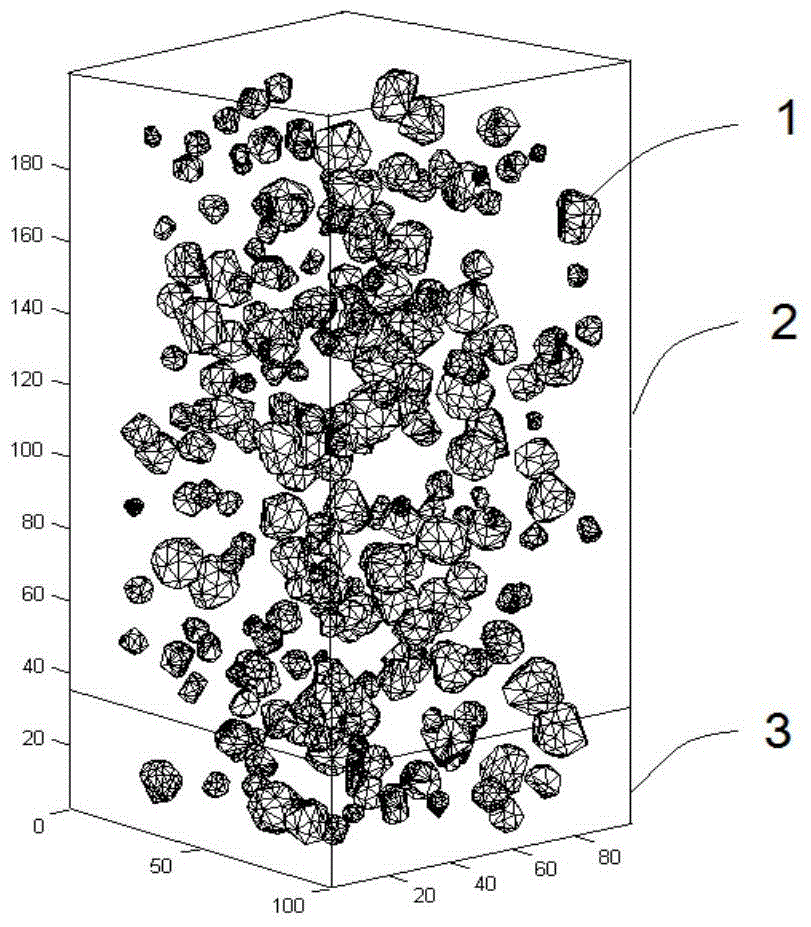

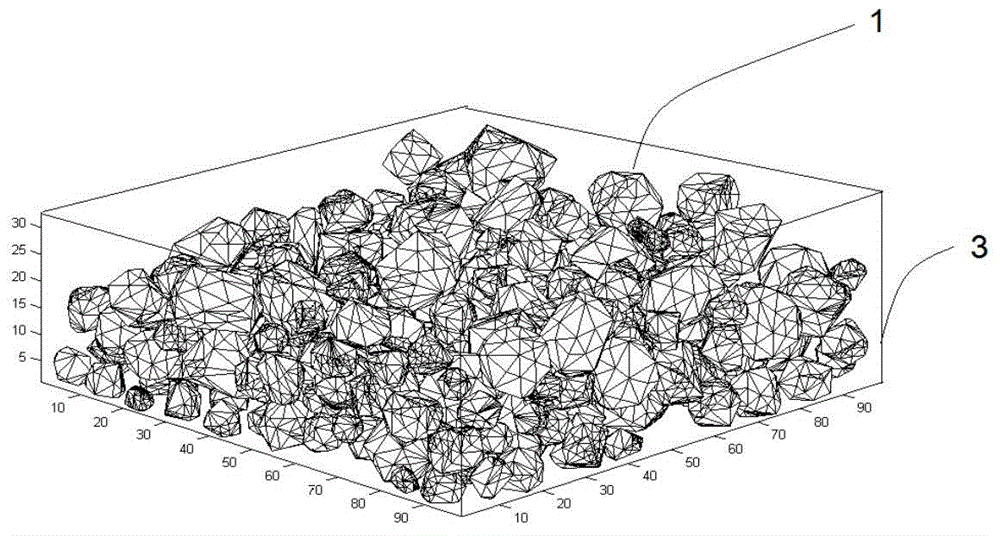

Modeling method of dispersed-phase reinforced composite material meso-structure

ActiveCN104899393AGuaranteed uniformityImprove production efficiencySpecial data processing applicationsElement modelModel method

The invention relates to a modeling method of a dispersed-phase reinforced composite material meso-structure. The modeling method comprises the following steps that the shape and the size of a model of a composite material are prepared, and the boundary of the model is determined; the sum of the volumes of particle reinforced phases in different size ranges in the model is prepared; particle models in all the size ranges are generated; the surface of each particle model is divided into finite element grids, and the prepared boundary of the model is divided into finite element grids; shell element attributes are given to the finite element grids; the mode of contact between the particle models and the mode of contact between the particle models and the boundary of the model are defined, and the descending process of particles in the space is simulated through a finite element method; the internal space of the model can be exactly filled with the particle models in all the size ranges; finite element models of the particle models and a finite element model of a substrate are obtained; modeling of the particle reinforced composite material structure is accomplished through the definition of the mode of constraint between the substrate and the particles and the material attributes of the substrate and the particles.

Owner:SHANDONG UNIV

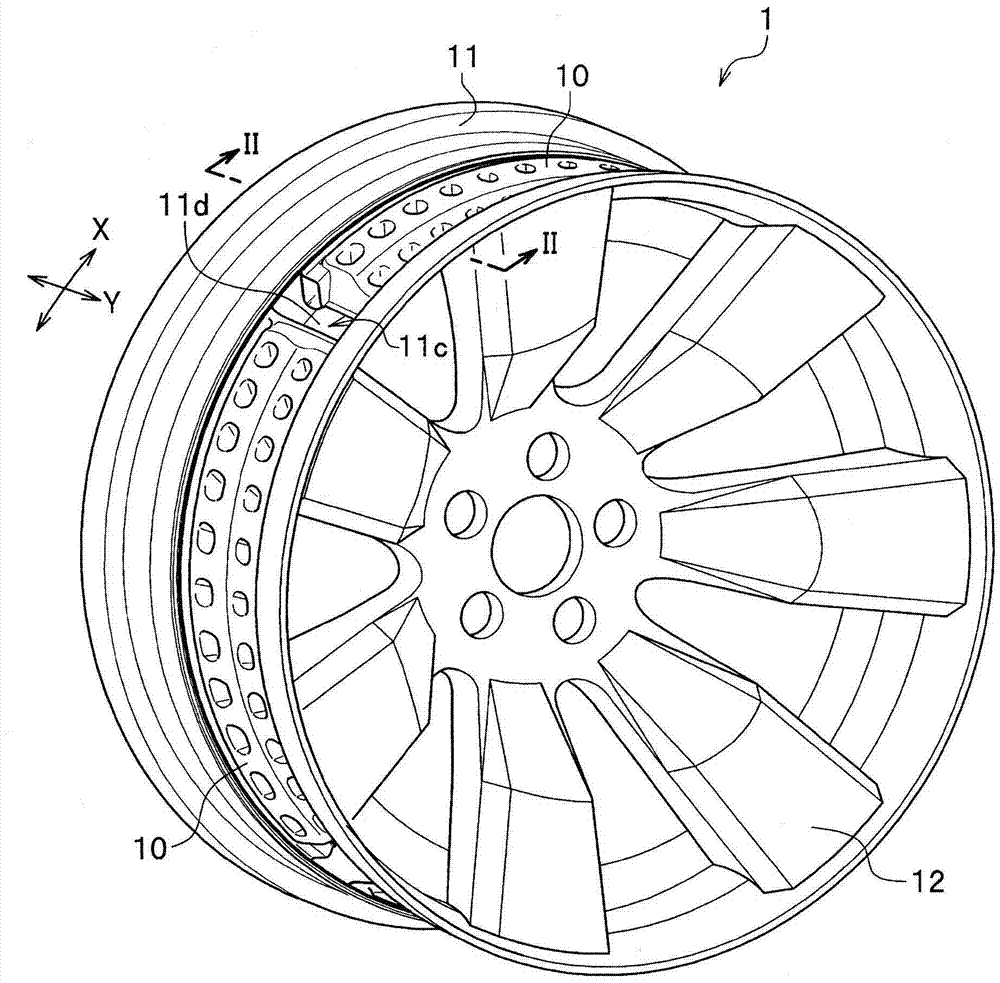

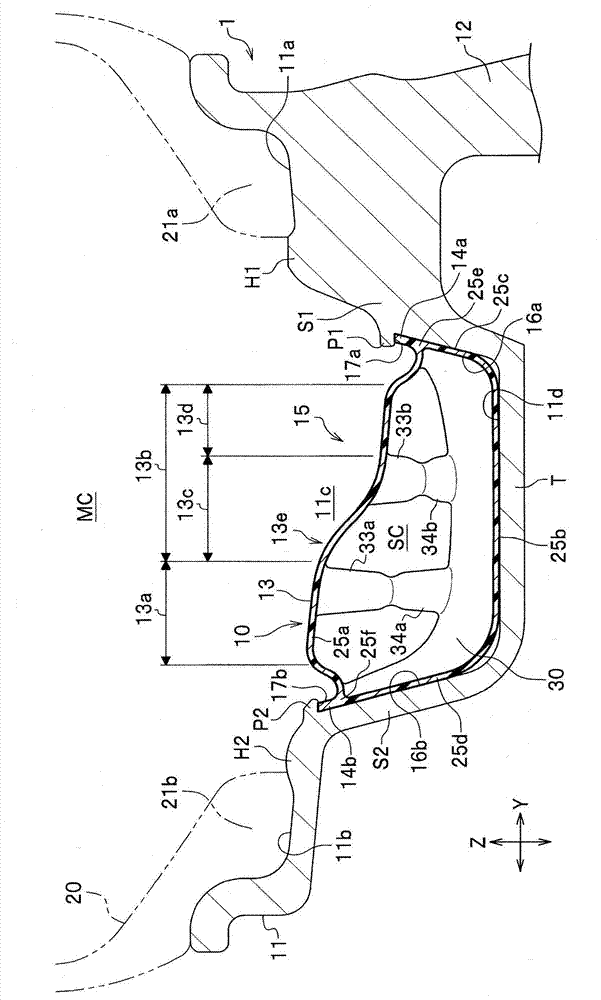

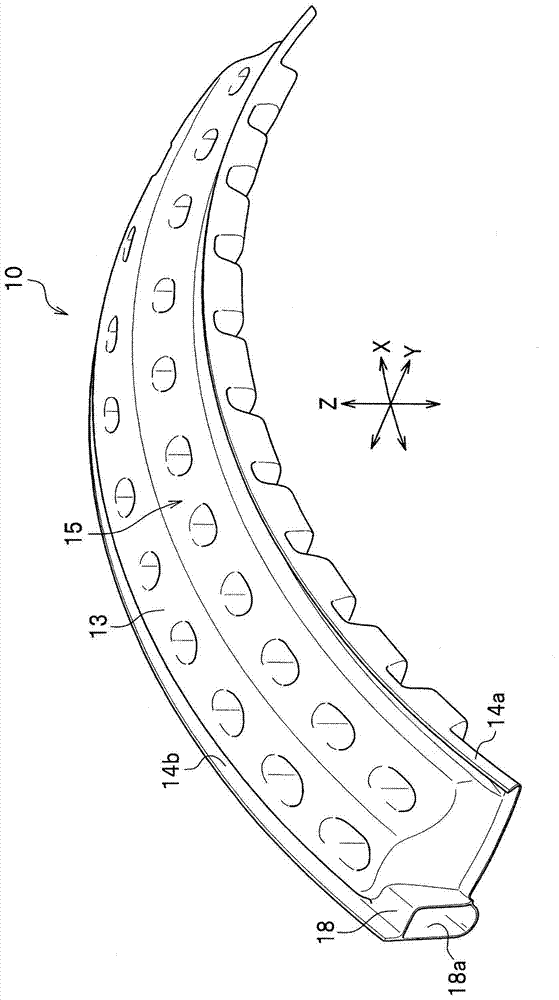

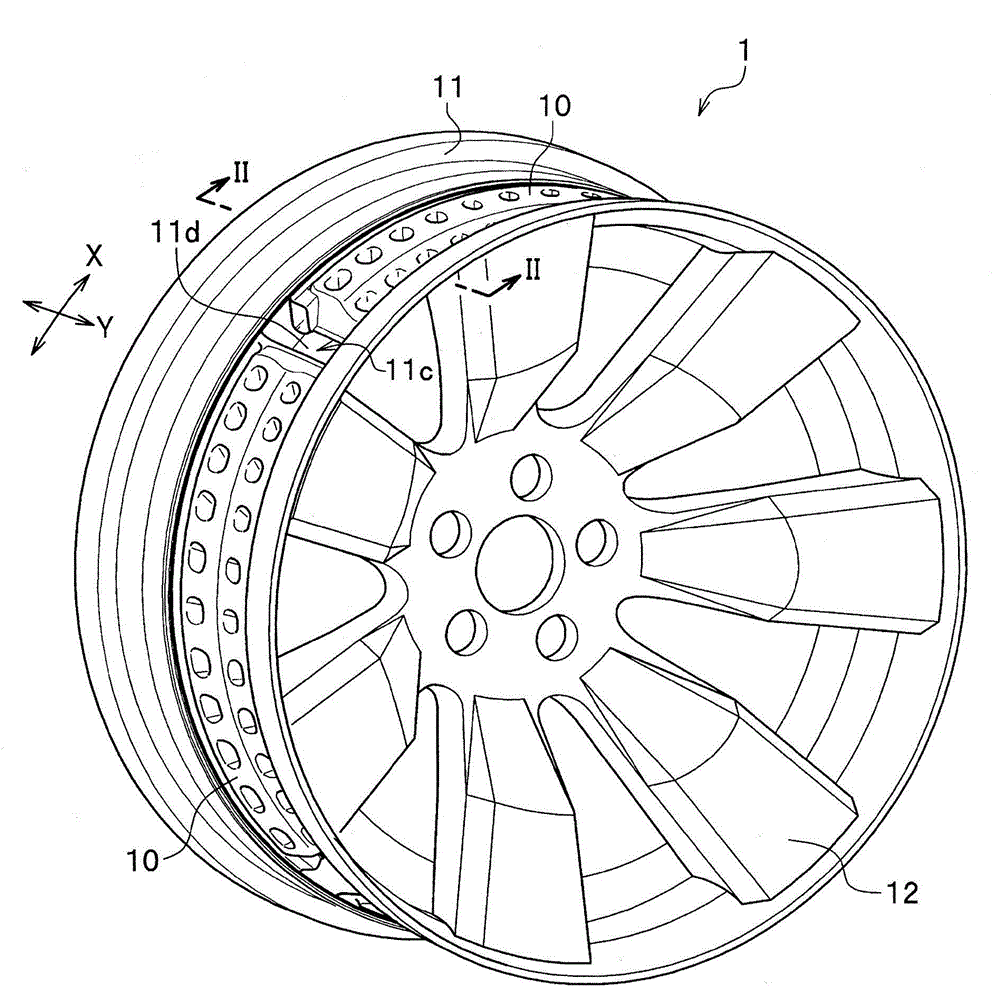

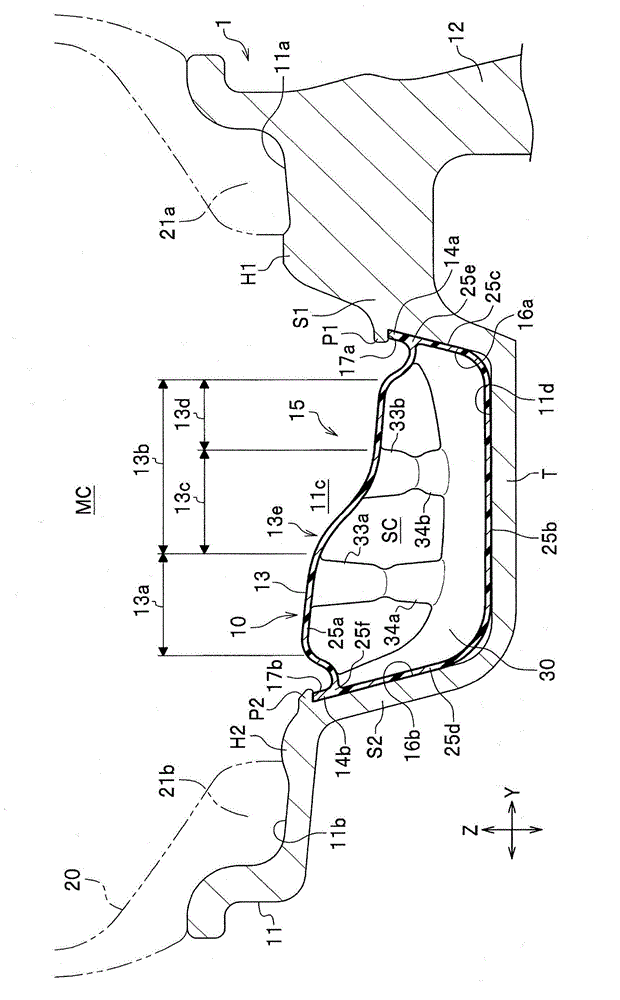

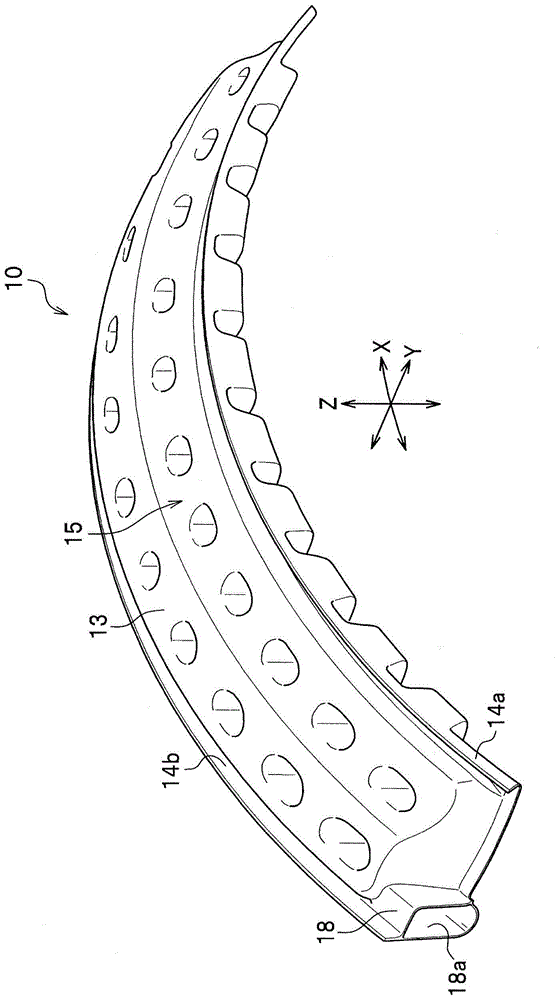

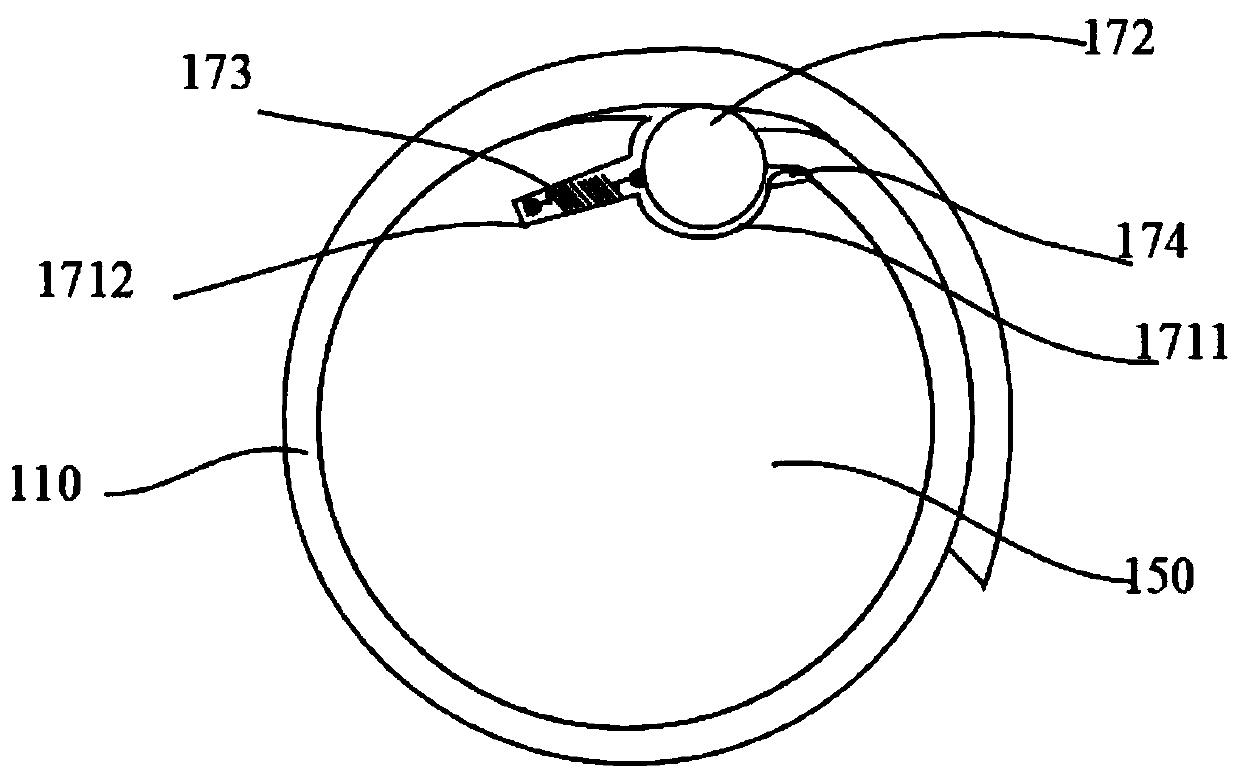

vehicle wheels

The present invention provides a vehicle wheel including a sub-air chamber member capable of securing a sufficiently larger volume of the sub-air chamber than conventional ones. The vehicle wheel (1) of the present invention is characterized in that the main body portion (13) of the auxiliary air chamber member (10) is aligned with one end in the wheel width direction (Y) when viewed in cross section along the wheel width direction (Y). side (second region (13b) side), the other end side (first region (13a) side) on the outer peripheral surface (11d) of the concave portion (11c) is formed higher in height, the main body portion (13) Compared with the position (hel) of the edge portion (14a) on the one end side, the position (he2) of the edge portion (14b) on the other end side is toward the wheel radial direction (Z) of the two edge portions (14a, 14) of Lateral offset.

Owner:HONDA MOTOR CO LTD

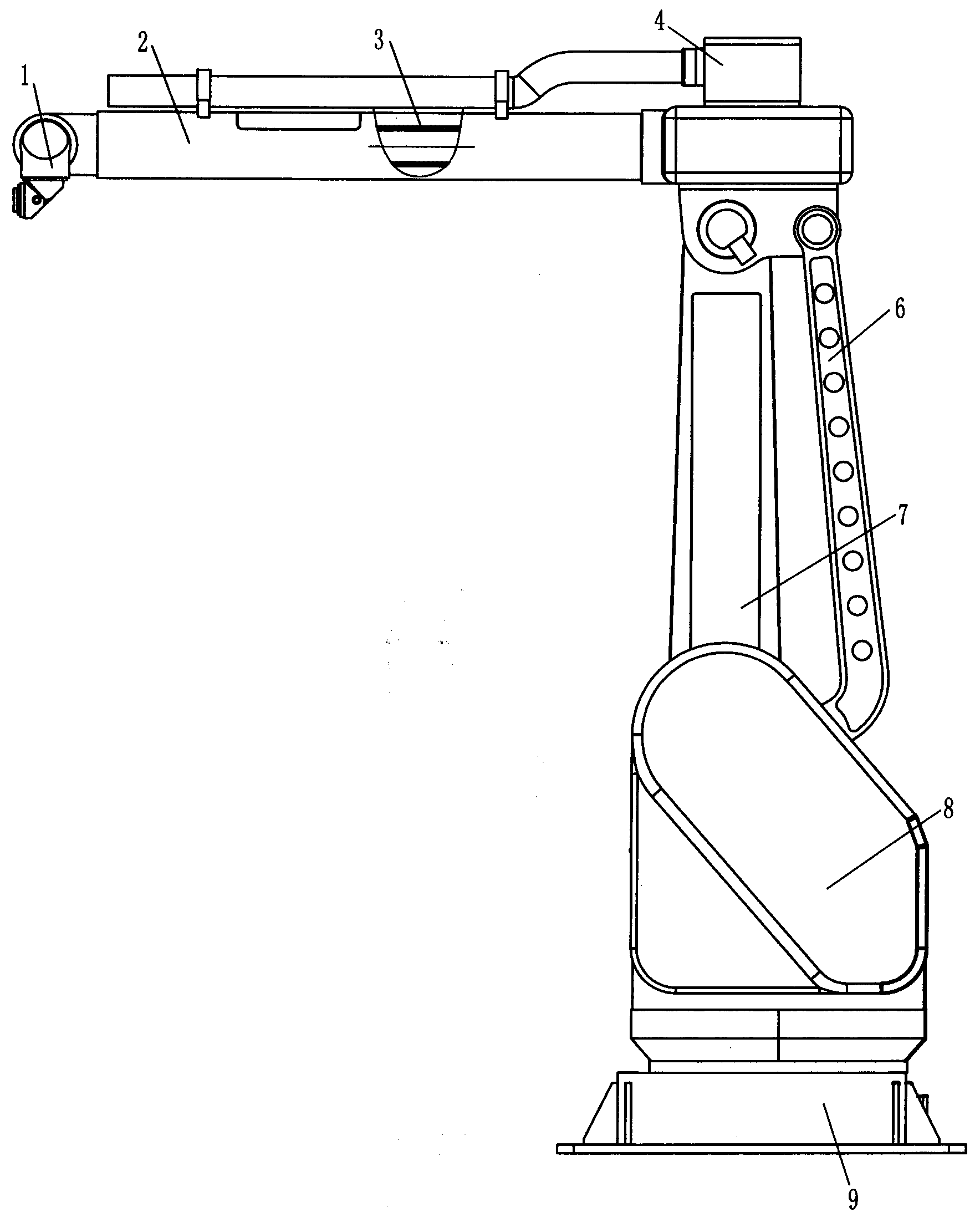

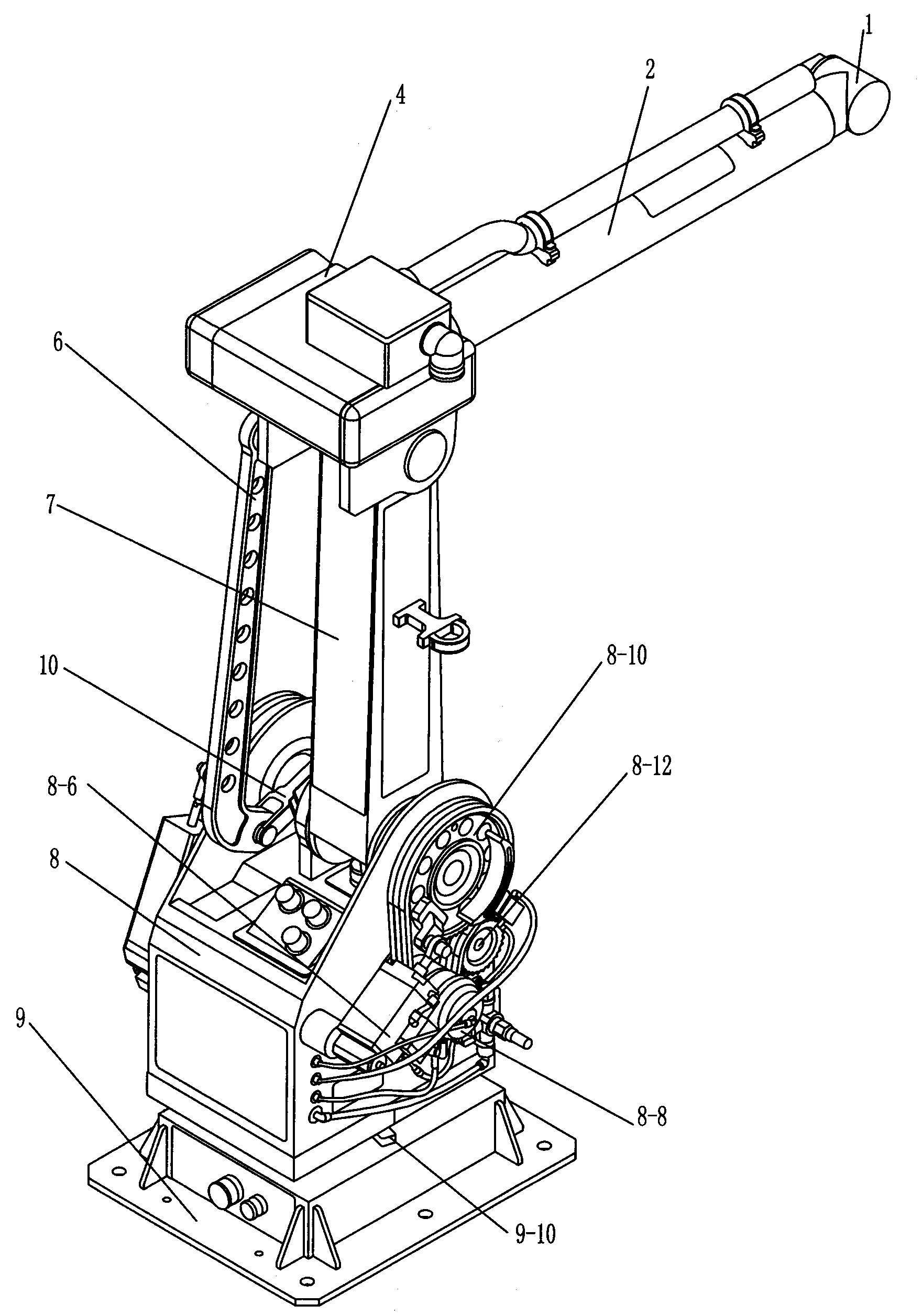

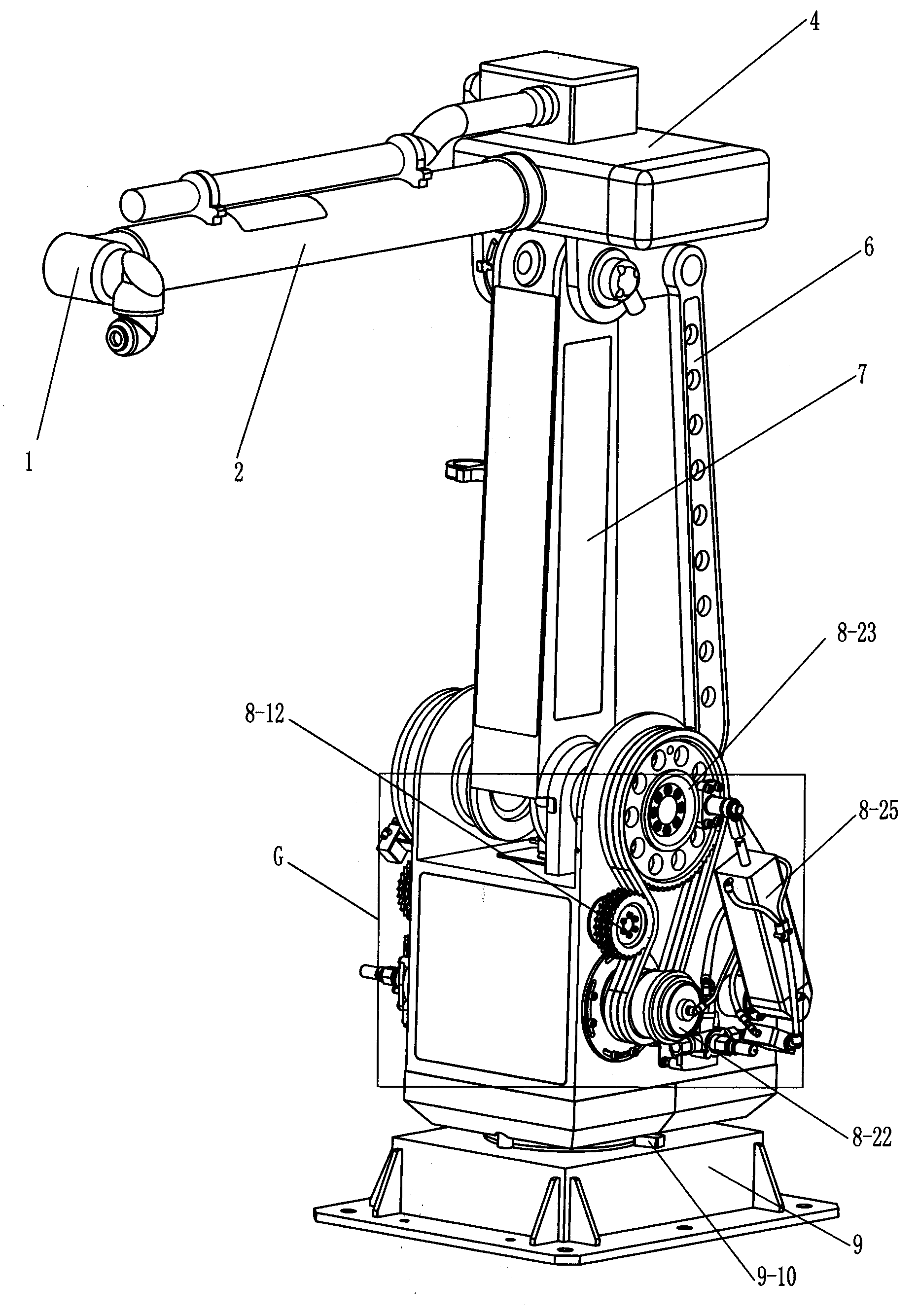

Professional glaze spraying six-axis robot

A professional glaze spraying six-axis robot belongs to the technical field of robot, and solves the problems of expensiveness, complicated operation and difficult maintenance of a foreign glaze spraying robot system in domestic application. The robot wrists are connected to a fourth, fifth and sixth axis motor through wrist transmission chains; the robot wrists, small arms and a fourth, fifth and sixth shaft seat assembly are orderly connected; the upper part of a big arm assembly is connected with the fourth, fifth and sixth shaft seat assembly through a bearing shaft seat one, and the part is connected with second and third axis large chain wheel assemblies; a second axis motor assembly drives the second large chain wheel assembly to rotate; a second axis cylinder assembly is fixed on a second and third axis box bodies and the second axis large chain wheel assembly; upper part of a third axis driving connecting rod through a bearing two is connected with the fourth, fifth and sixth shaft seats assemblies, and the lower part is connected with a third axis drive bracket through a bearing three; the third axis driving bracket is connected with the third large chain wheel assemblies; and the third axis motor assembly through a chain two drives the third large chain wheel assemblies to rotate. The invention is special for glaze spraying.

Owner:杭州钱江机器人有限公司

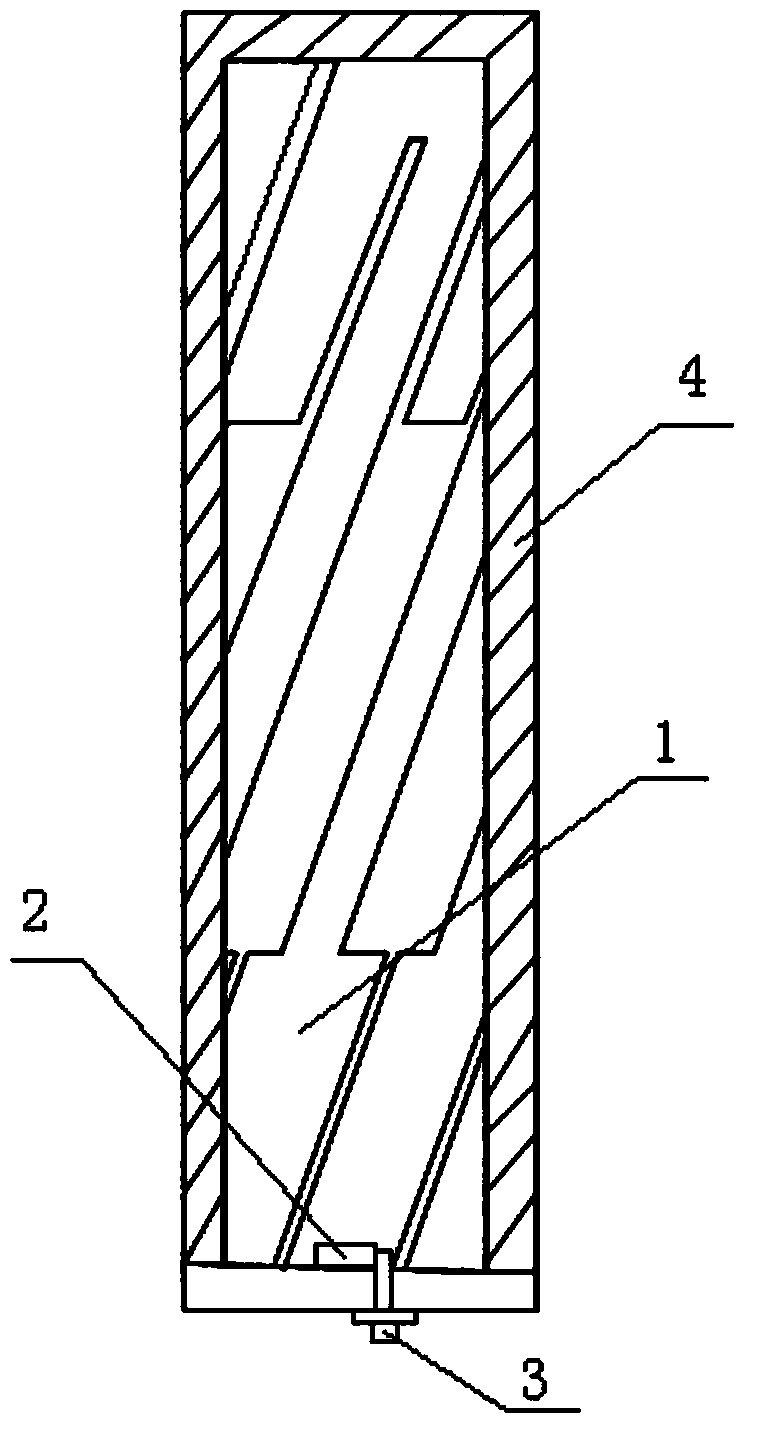

Superconductive heat pipe electric heater

ActiveCN103363571ASimple structureReasonable structureElectric heating systemIndirect heat exchangersHeat conductingEngineering

The invention provides a superconductive heat pipe electric heater, belongs to the field of electrical heating equipment, and particularly relates to an electric heater using a heat pipe as a heat transfer element to dissipate heat. A heat-conducting medium absorbs heat released by a heating element. The heat is dissipated to the air through fins (4). The superconductive heat pipe electric heater is characterized in that a circulation chamber (5) and a heating chamber (1) are installed in a heater shell body (9); the circulation chamber (5) and the heating chamber (1) are communicated through the heat pipe (3) which is used as a heat conduction element; the circulation chamber (5), the heating chamber (1) and the heat pipe (3) form an airtight vacuum space; the circulation chamber (5), the heating chamber (1) and the heat pipe (3) are filled with heat-conducting media respectively; an electrical heating rod (2) is installed in the heating chamber (1). According to the superconductive heat pipe electric heater, the heating method and heat conduction method of a traditional electric heater are changed, superconductive liquid is used as the heat-conducting media, therefore, the temperature rise speed is increased, energy sources are saved, and heat exchange efficiency is improved at the same time.

Owner:山东伟瑞制冷科技有限公司

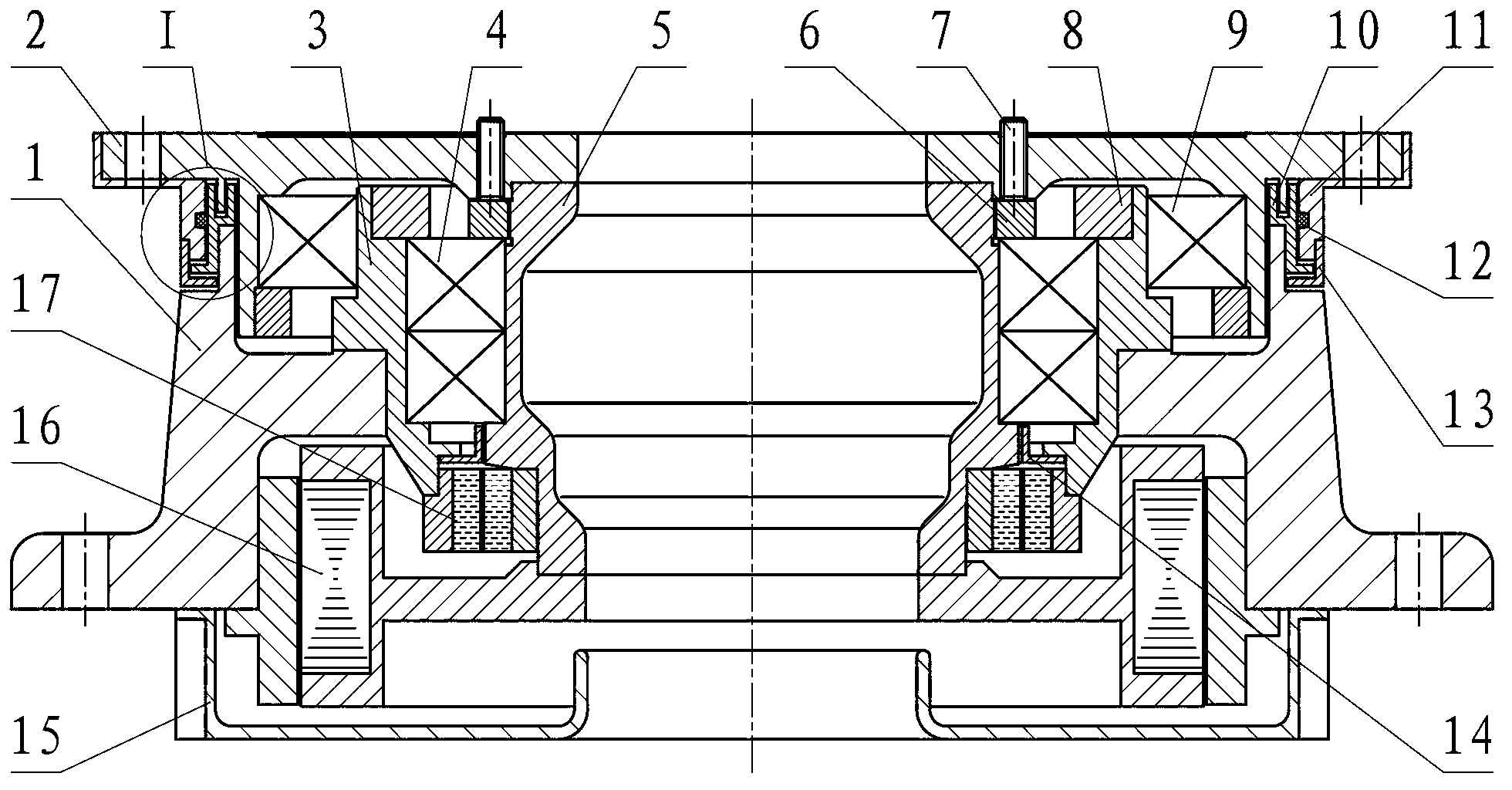

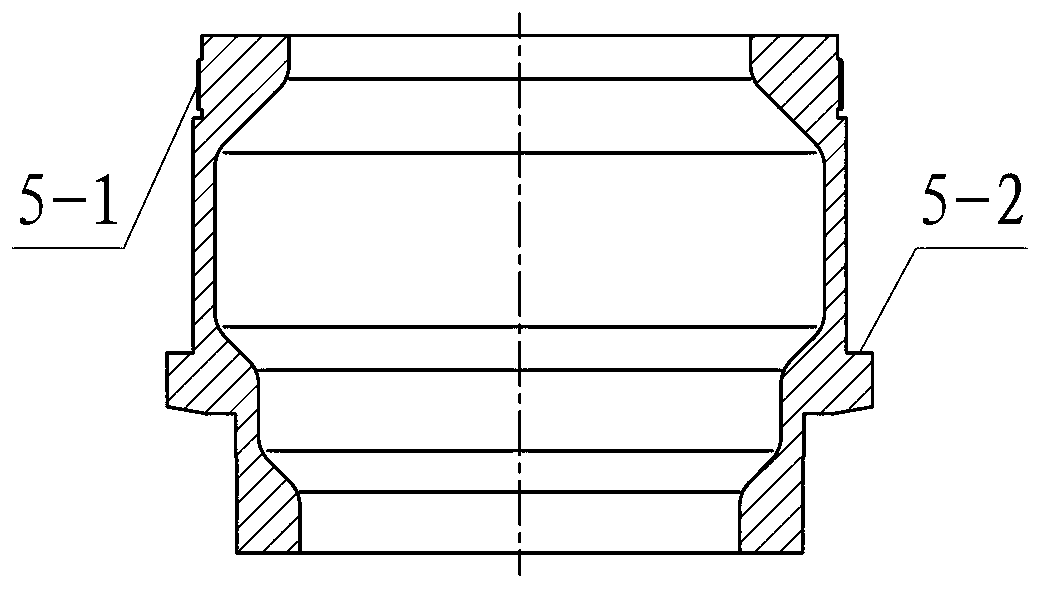

Azimuth device applicable to vehicular photoelectric turntable

ActiveCN103294066AAchieving a modular designImprove maintainabilityPosition/direction controlBiaxial loadMaintainability

The invention discloses an azimuth device applicable to a vehicular photoelectric turntable. The azimuth device comprises a revolving shaft system, an azimuth shell, a rotary transformer and a torque motor. The revolving shaft system comprises an azimuth dead shaft, an azimuth moving shaft, an azimuth rotating adaptor disc and two groups of bearings, the azimuth dead shaft is connected with the azimuth moving shaft and the azimuth rotating adaptor disc respectively via a first bearing and a second bearing, the first bearing bears biaxial loads, the second bearing is larger in diameter and bears radial and tipping loads, and thereby the rotating disc type revolving shaft system borne by the internal and external bearings is formed. The revolving shaft system as well as the rotary transformer and the torque motor are respectively positioned on an upper side and a lower side of an annular transverse plate in the middle of the azimuth shell and are independent to one another. Furthermore, a comprehensive labyrinth felt collar sealing structure is adopted. The azimuth device has the advantages of simple structure, low height, light weight, good maintainability, excellent expansibility, strong environmental suitability and the like, mechanical characteristics and capabilities of resisting shock, vibration and large-angle inclination of the photoelectric turntable are effectively improved, and tracking precision of photoelectric tracking equipment is guaranteed.

Owner:西安应用光学研究所

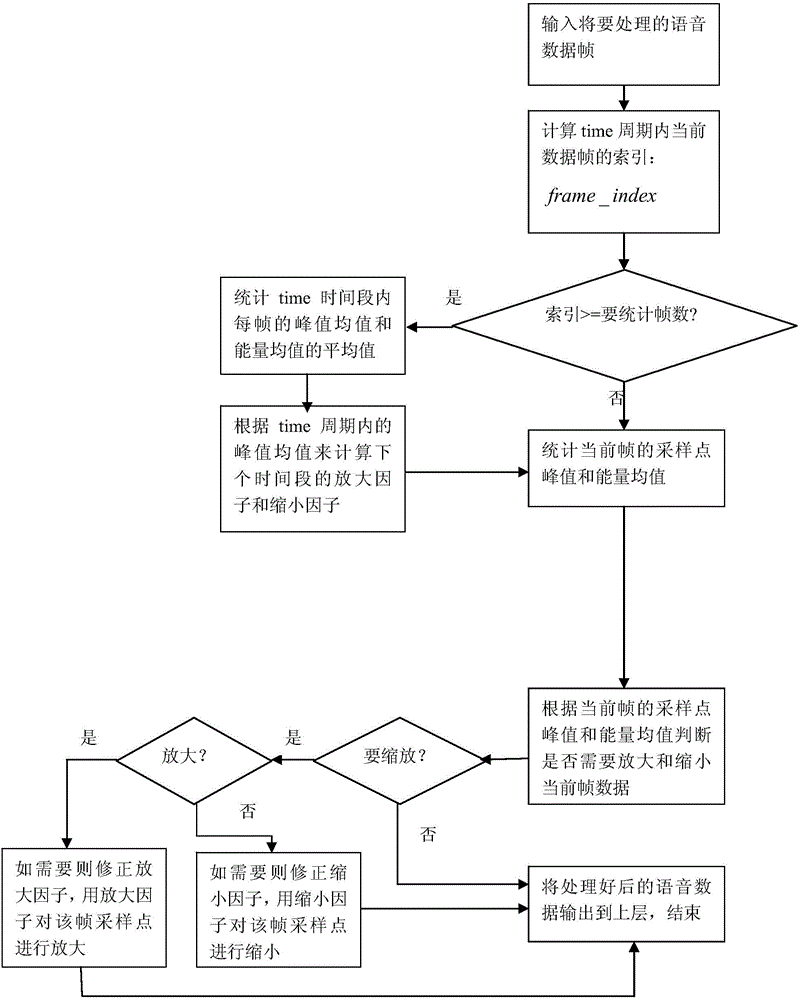

Voice volume automatic adjustment method based on energy statistics

The invention discloses a voice volume automatic adjustment method based on energy statistics. The voice volume automatic adjustment method based on the energy statistics includes the following steps: (1) counting the energy average value energy of the sample point of each point and the maximum peak value peak of the absolute values of the energy values of all the sample points in the frame; (2) calculating the average value energy_avg of the energy average value energy of the sample point of each frame from 0 to frame_index and the average value peak_avg of the maximum peak value peak; (3) calculating the amplification factor factor_max' and the reduction factor factor_min' in the next time quantum time; (4) judging the voice data of each frame in the next time quantum time, and amplifying or reducing through the reduction factor when amplification and reduction are needed; and (5) outputting the processed voice data frame and ending. The voice volume automatic adjustment method based on the energy statistics can predict the amplification factor and the reduction factor needed in the next time quantum by utilization of the similarity and the continuity of the voice data according to the voice data statistic information of the previous period, and meets the requirement of the practicability while reduces the complexity of the algorithm.

Owner:ZHEJIANG WANPENG EDUCATION TECH CO LTD

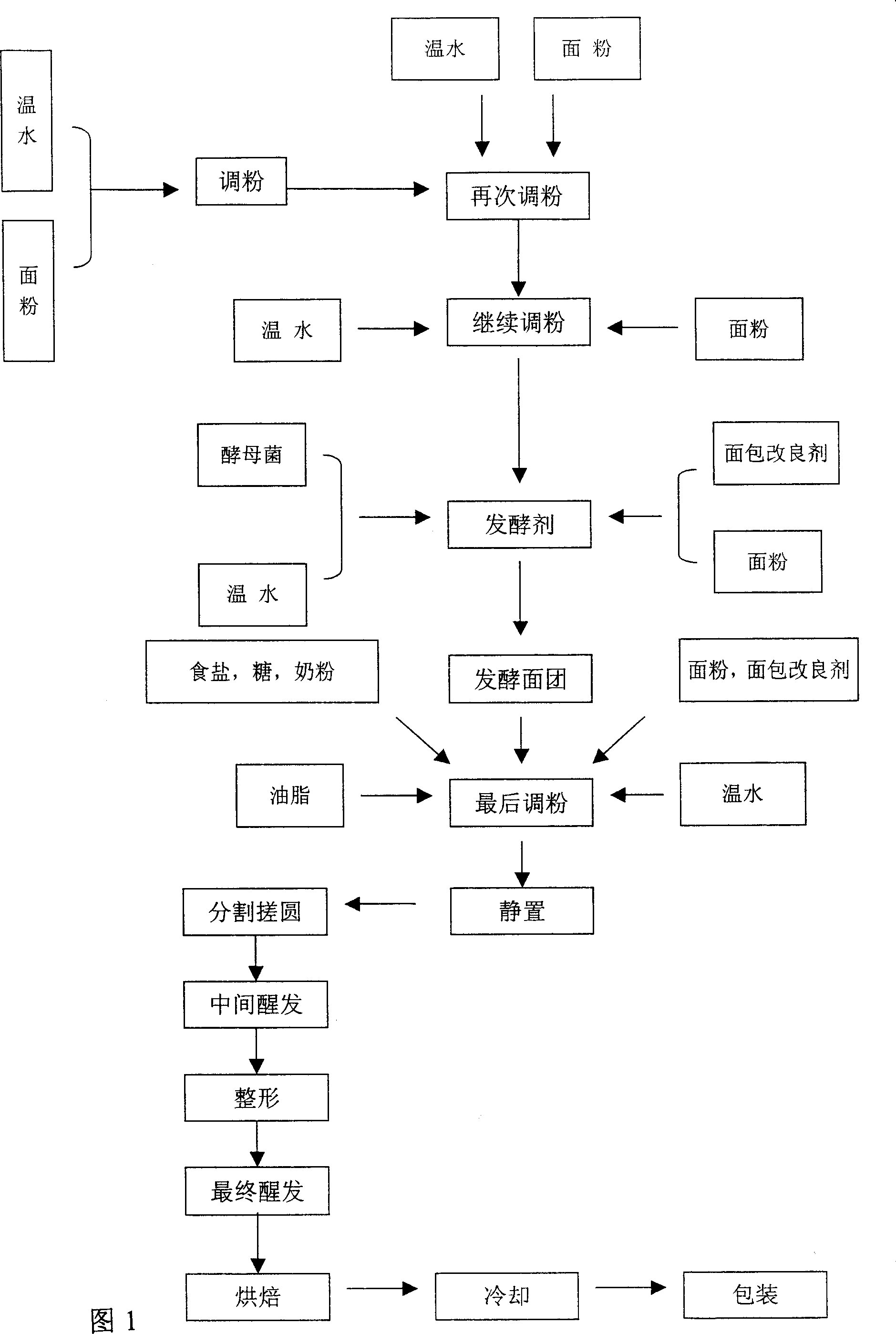

Natural fermented sourdough bread of leaven containing microzyme and its production method

The present invention relates to a naturally-fermented sour bread by utilizing fermenting agent containing yeast and its production method. In the concrete, it utilizes synergistic fermentation of lactic acid bacteria and microzyme to make sour bread. Said invention utilizes flour, water, microzyme, sugar, edible salt, milk powder and bread-improving agent as raw material, and provides the concrete steps of its production method so as to obtain the invented sour bread food with palatable taste.

Owner:JIANGNAN UNIV

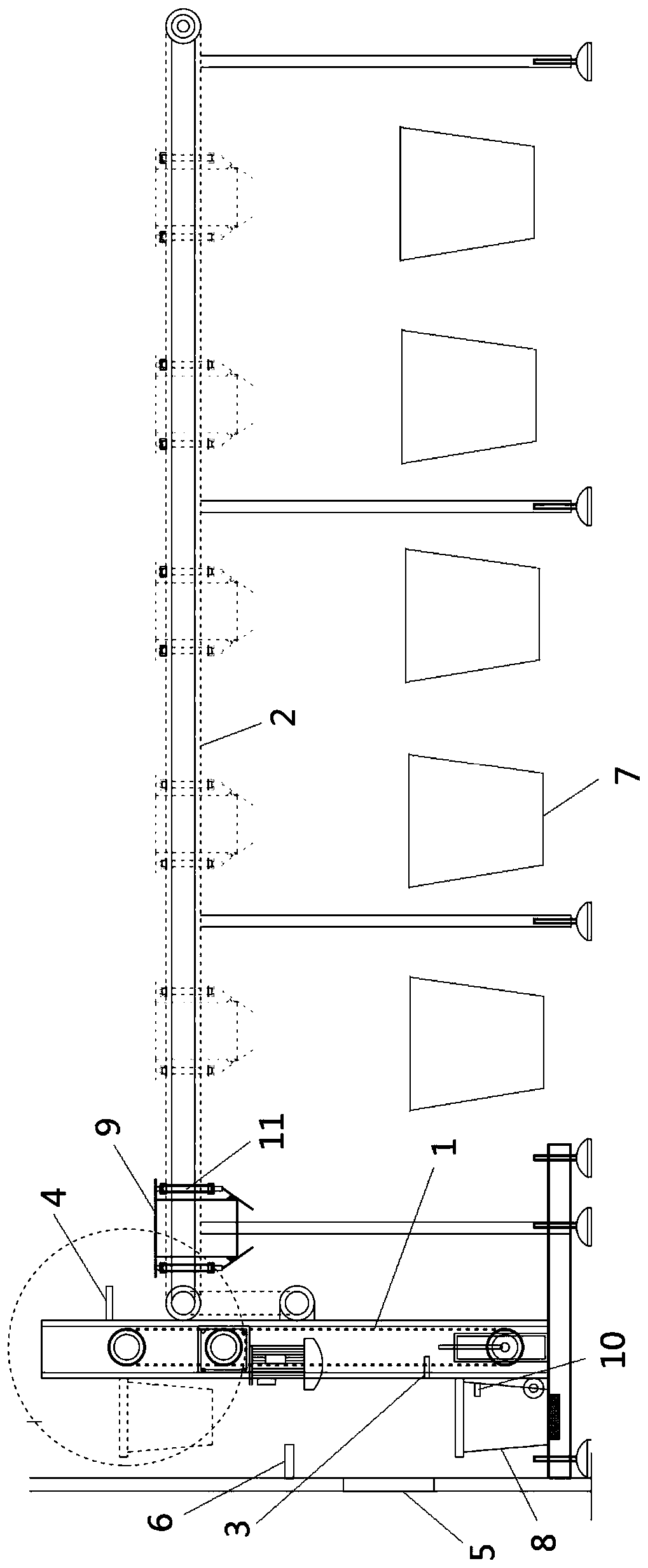

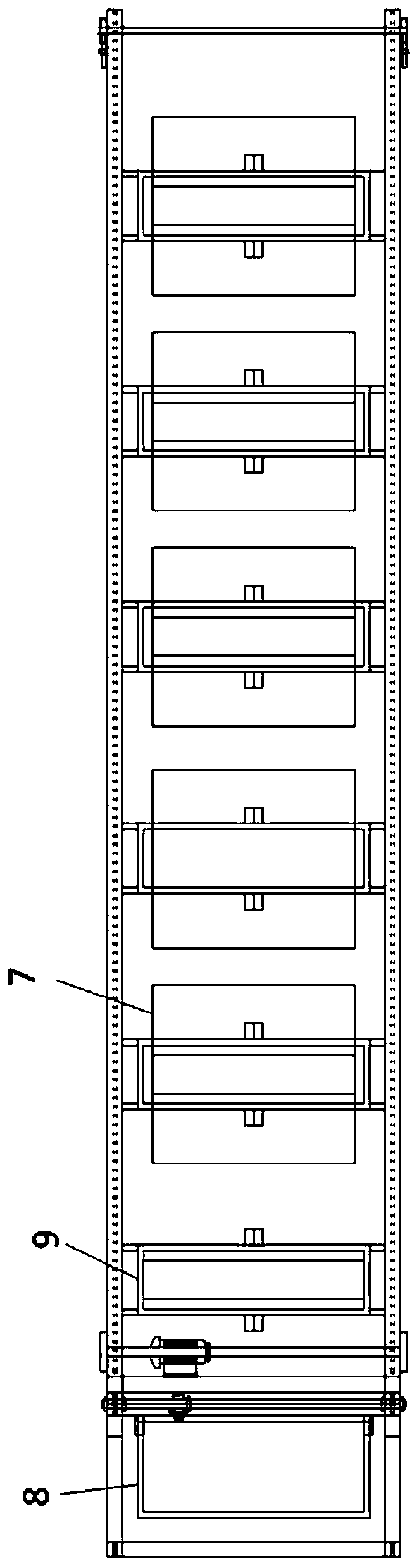

Closed sand mixing device and method

ActiveCN106640024AReduce screw speedIncrease sand delivery speedFlow mixersOther gas emission reduction technologiesGas phaseLiquid state

The invention provides a closed sand mixing device. The closed sand mixing device comprises a frame, a tank body arranged in the frame and a main pipe assembly arranged below the tank body. The tank body is a horizontal pressure tank, a gas phase channel is formed in the top of the tank body, a plurality of sand filling ports are formed in the top, a liquid phase channel is formed in the bottom, a plurality of sand outlets are formed in the bottom, a plurality of sand conveying devices are arranged on the inner bottom surface in the tank body, the sand outlets and the sand conveying devices are in one-to-one correspondence, one ends of the sand outlets communicate with outlets of the sand conveying devices while the other ends of the sand outlets communicate with the main pipe assembly, the sand conveying devices are connected to an electric control cabinet, a gas phase discharge pipe assembly is arranged on the upper portion of the tank body, and a gas phase discharge valve is arranged on the gas phase discharge pipe assembly. Liquid carbon dioxide or other liquefied gas and a supporting agent are mixed in a certain proportion and are output in a closed condition under pressure, thereby providing a sand mixing liquid with a certain sand ratio for a fracturing truck.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

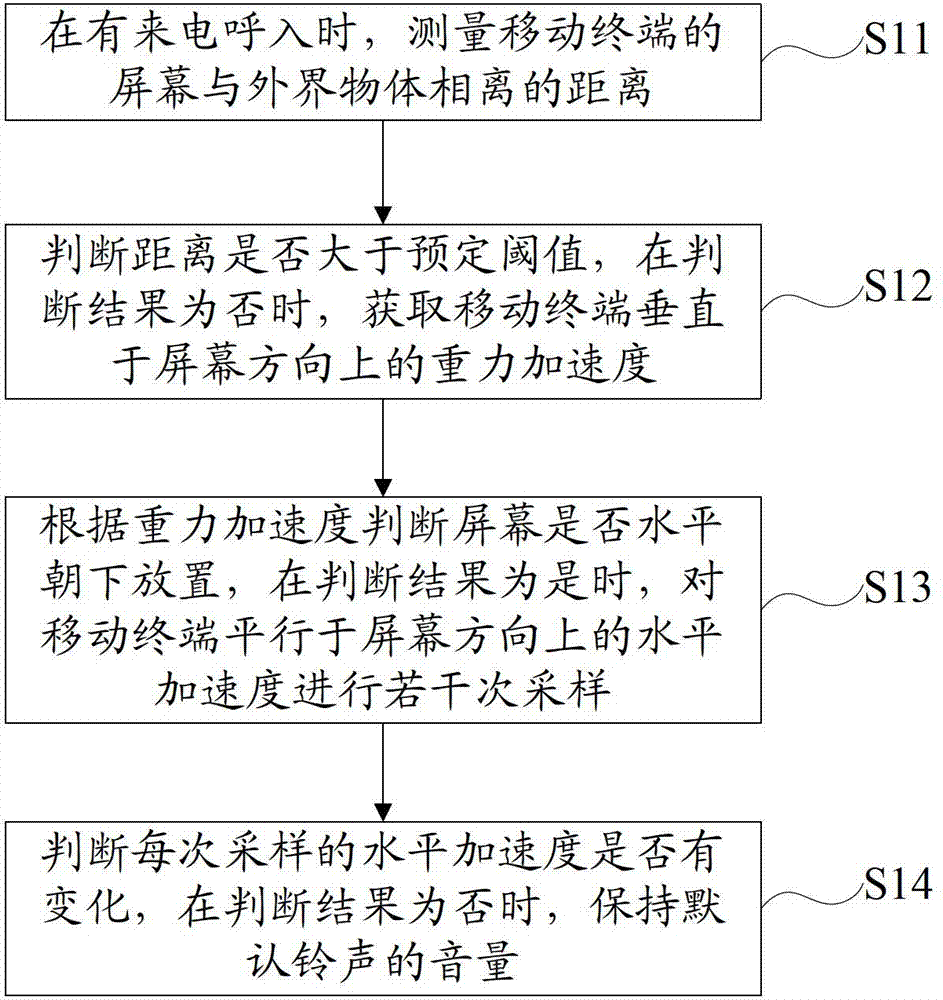

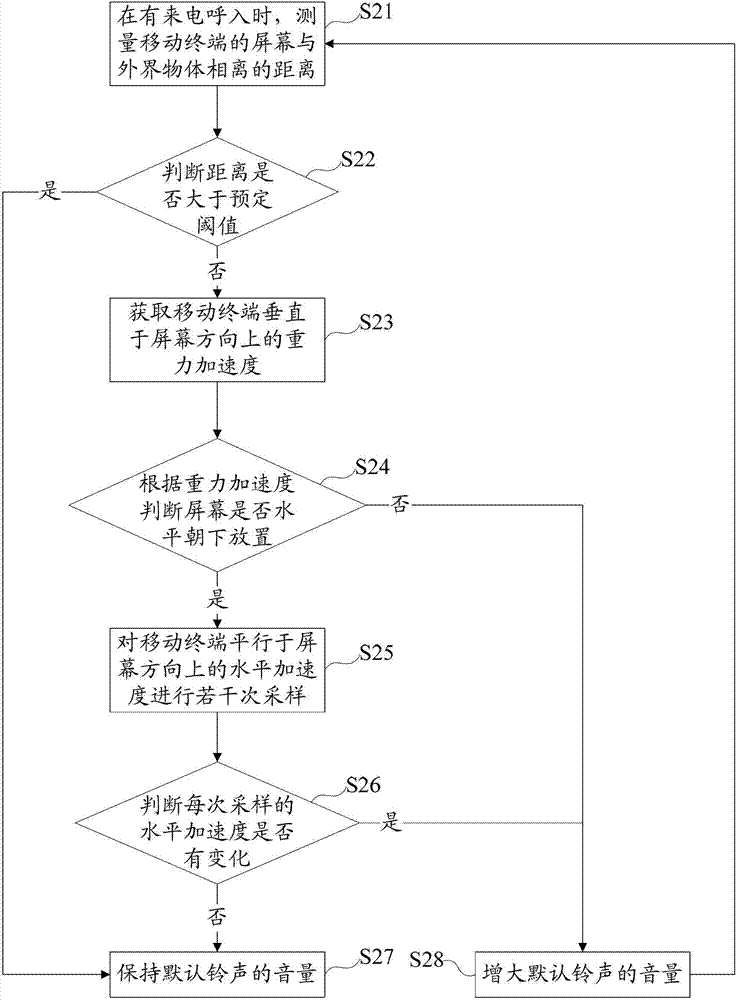

Mobile terminal and volume adjusting method thereof

ActiveCN103051788AImprove experienceGuaranteed volumeSubstation speech amplifiersSimulationAcceleration Unit

Owner:HUIZHOU TCL MOBILE COMM CO LTD

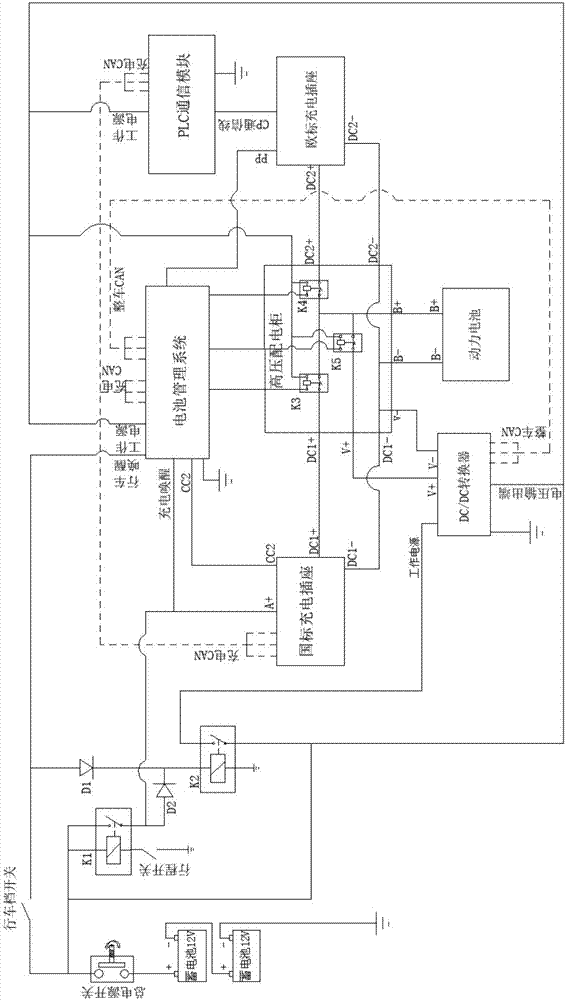

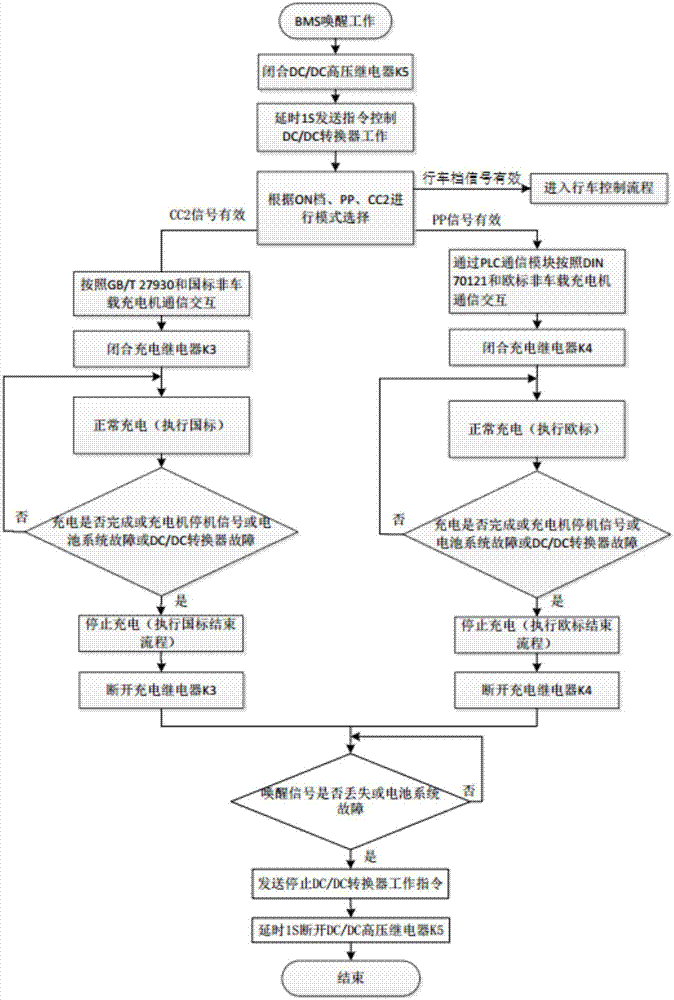

Combined charging system for electric vehicle and control method of combined charging system for electric vehicle

ActiveCN107336632AGuaranteed volumeCharging supportCharging stationsCharging managementElectrical batteryEngineering

The invention discloses a combined charging system for an electric vehicle. The combined charging system comprises a battery management system a high-voltage distribution cabinet, a DC / DC converter, a power battery, a national standard charging socket, an European standard charging circuit and a lead acid battery power source formed by connecting two 12 V storage batteries in series. The battery management system is provided with a running wakeup terminal and a charging wakeup terminal. The national standard charging socket is provided with a wakeup line and a national standard connecting signal line. The wakeup line is electrically connected with the charging wakeup terminal. The national standard connecting signal line is connected with the battery management system. The European standard charging circuit comprises a stroke switch, a low-pressure replay, a PLC communication module and a European standard charging socket. The battery management system is electrically connected with the DC / DC converter, the PLC communication module and the national standard charging socket through a CAN bus. The combined charging system for the electric vehicle is convenient to use and good in charging effect.

Owner:XIAMEN GOLDEN DRAGON BUS

Inner cycle collision mixed type soil repair device

InactiveCN108114971AGuaranteed volumeImprove discretenessContaminated soil reclamationGrain treatmentsHybrid typeSpray cone

The invention discloses an inner cycle collision mixed type soil repair device which comprises a processing box, wherein the processing box is a cylindrical barrel, wherein a lifting barrel is arranged at the middle position of the upper end of the processing box in a penetrating manner, a rotating bearing matched with the lifting barrel is arranged at the upper end of the processing box, a supporting ring is arranged in the bottom of the processing box, a material collecting box is arranged in the middle position of the supporting ring, the lower end of the lifting barrel stretches into the material colleting groove, and a lifting shaft is arranged in the axis position in the lifting barrel. By crushing materials circumferentially and screening the materials through a filter barrel, the sizes of the materials are qualified when the materials are repaired, so that the materials are in full contact with a repair solution in the later period; the materials then upwell along the lifting barrel through lifting blades and collide with a material spraying cone which sprays the repair solution, so that the dispersion degree of the materials is enhanced; the materials are in contact with the repair solution sprayed from the nozzle conveniently, so that the repair effect is improved and the practicality is high.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Vehicle wheel

Owner:HONDA MOTOR CO LTD

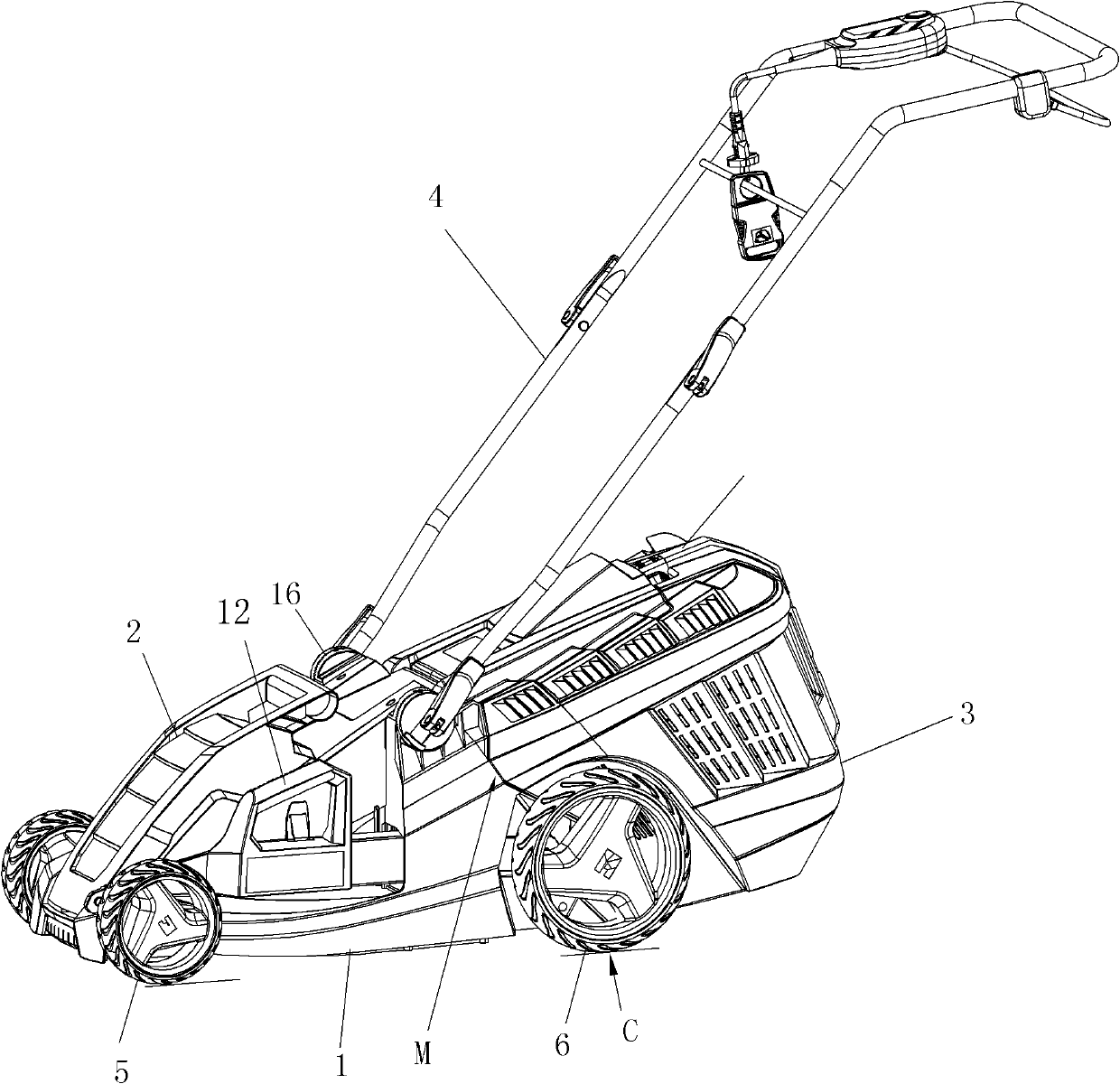

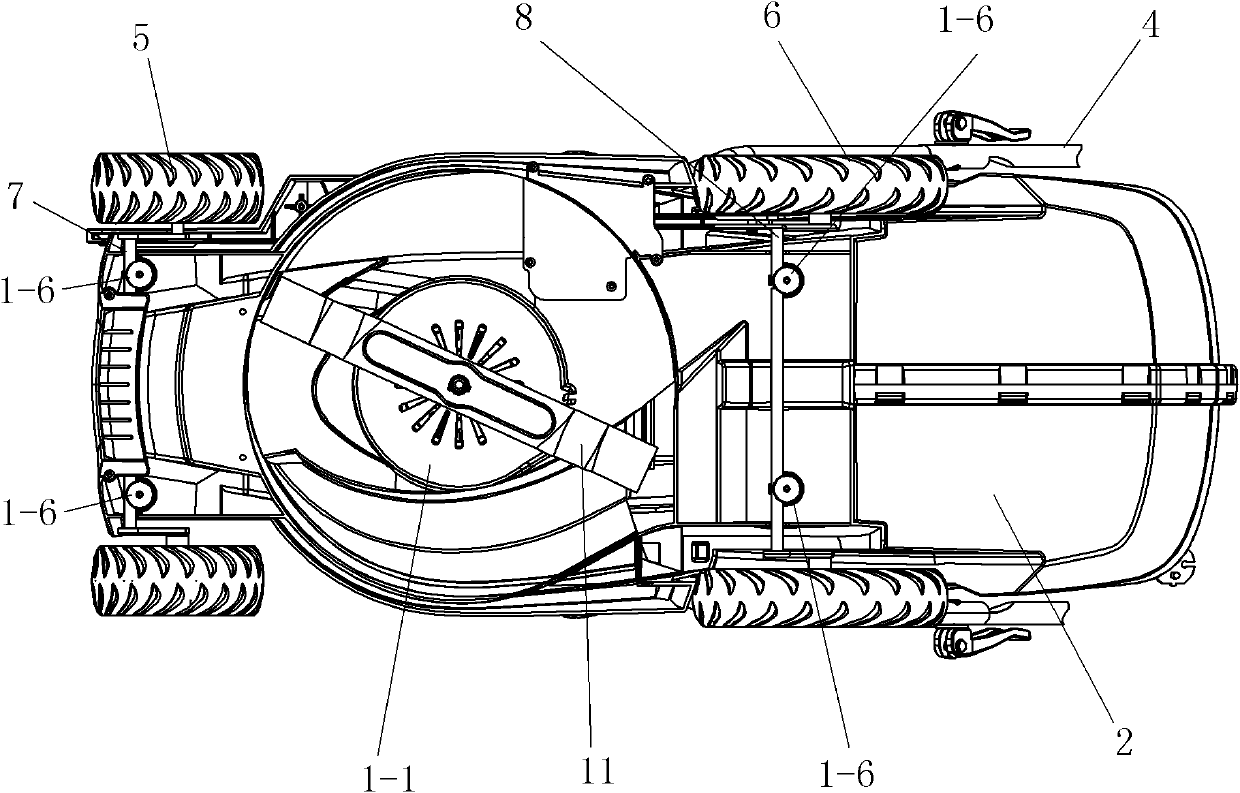

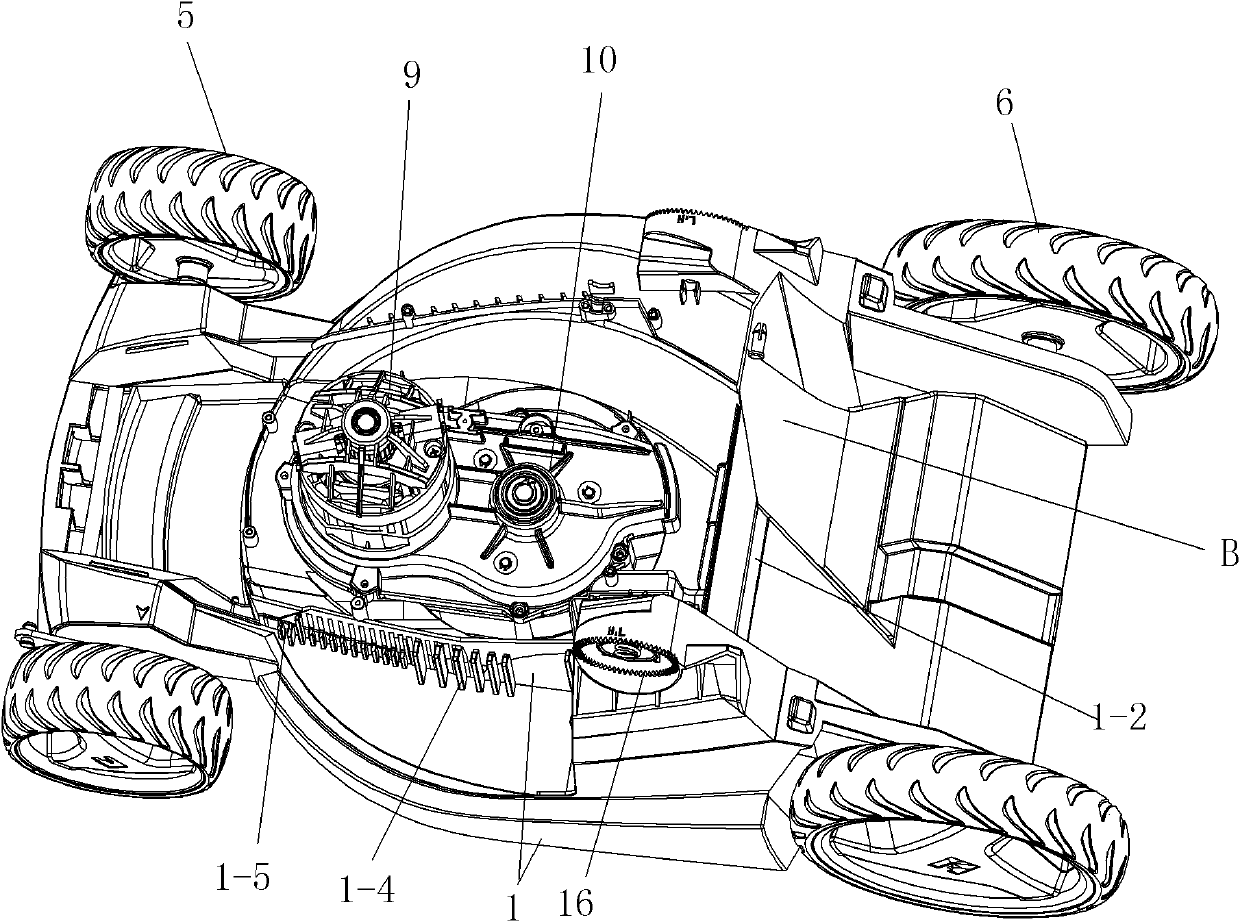

Anti-dumping hand-push electrical mower

The invention relates to an anti-dumping hand-push electrical mower which is provided with a machine casing, a power mechanism, an upper cover, a handrail, a grass collecting hopper, a front travelling wheel unit and a rear travelling wheel unit, wherein the upper cover and the handrail are connected with the upper part of the machine casing; the grass collecting hopper is connected with the rear part of the machine casing; and the front travelling wheel unit and the rear travelling wheel unit are connected with the bottom of the machine casing. The power mechanism is in a forwards arranged type. A motor can perform a certain whole machine weight balancing function after arranged on the front part. Part of the grass collecting hopper is arranged in the front space of the rear wheel, so that the grass collecting hopper is arranged on the front part as much as possible, the volume of the grass collecting hopper is ensured, and simultaneously, the distance between the rearest end of the grass collecting hopper and the furculum of the rear wheel is shortened. An adjusting handle, a triangular front connecting component and a triangular connecting component form the connecting rod mechanism. When the machine casing is adjusted to the highest position, i.e. the machine is in the highest cutting position, the machine moves forwards and moves backwards relative to the furculum of the rear wheel, thereby being beneficial to balancing the whole machine.

Owner:CHANGZHOU CREATE ELECTRIC APPLIANCE

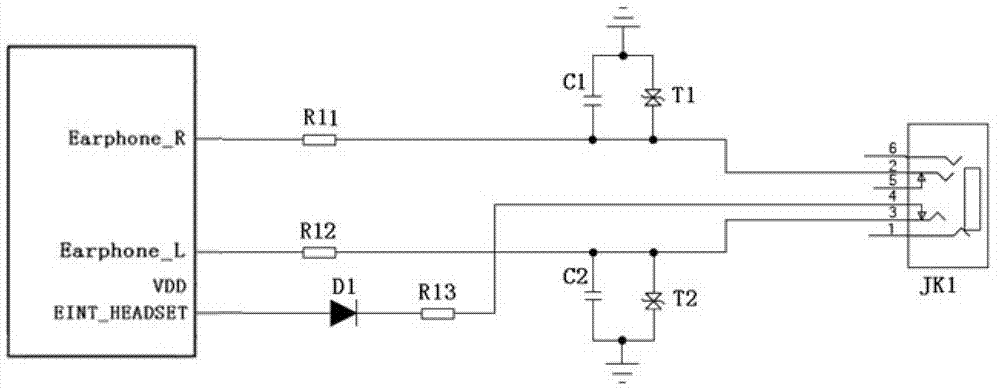

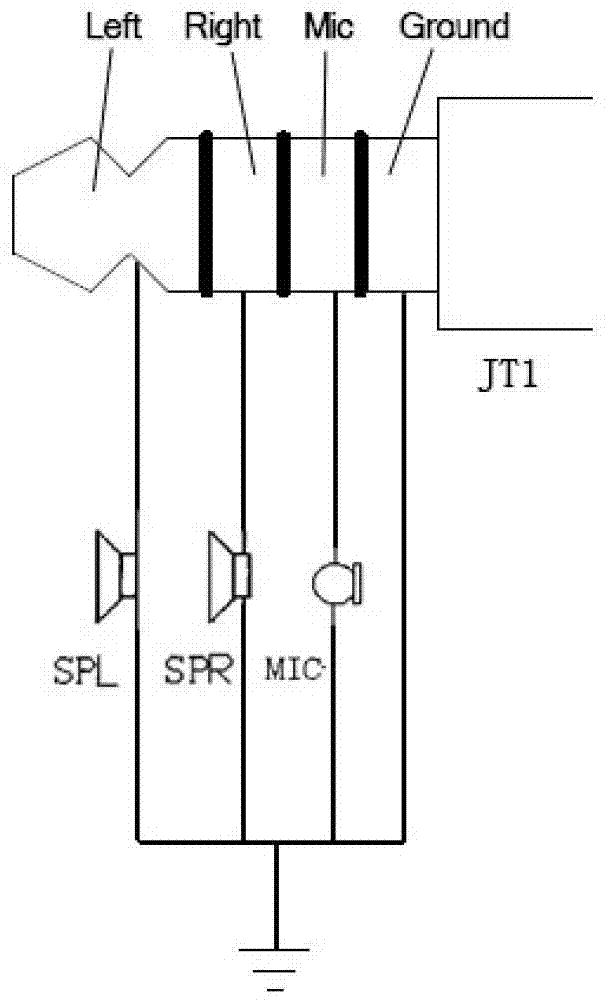

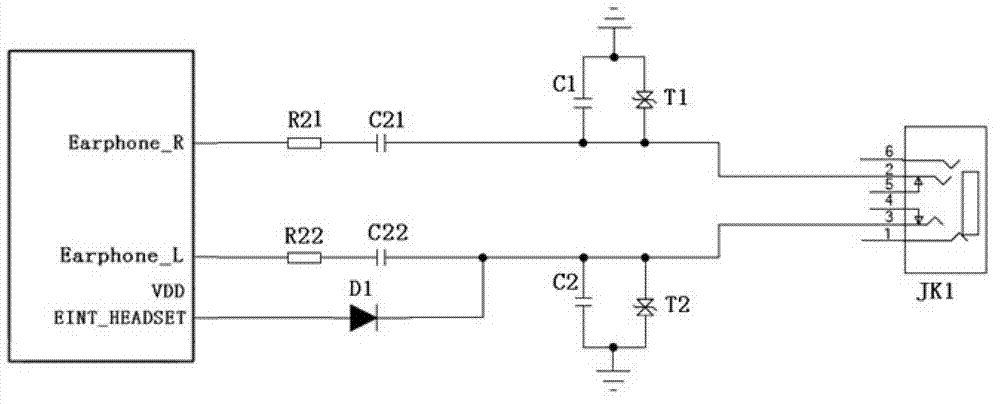

Earphone interface circuit and electronic equipment

ActiveCN102740181ALower Detection LatencyEasy to useStereophonic circuit arrangementsTransducer protection circuitsEngineeringHeadphones

The invention relates to the field of electronic equipment, and provides an earphone interface circuit and electronic equipment. The earphone interruption detection end of the earphone interface circuit is connected to a right sound channel pin or a left sound channel pin of an interface; and the earphone interface circuit also comprises an earphone plug-in detection circuit which has the same level as the earphone interruption detection end, clamps the earphone interruption detection end, and is connected to the right sound channel pin or the left sound channel pin. Because the earphone plug-in detection circuit is arranged, earphone detection delay is reduced, and the quality and volume of sound are ensured simultaneously; and the earphone interface circuit is used in the electronic equipment, and a good using effect of the electronic equipment can be ensured.

Owner:DONGGUAN JINGSHENG ELECTRONICS TECH CO LTD

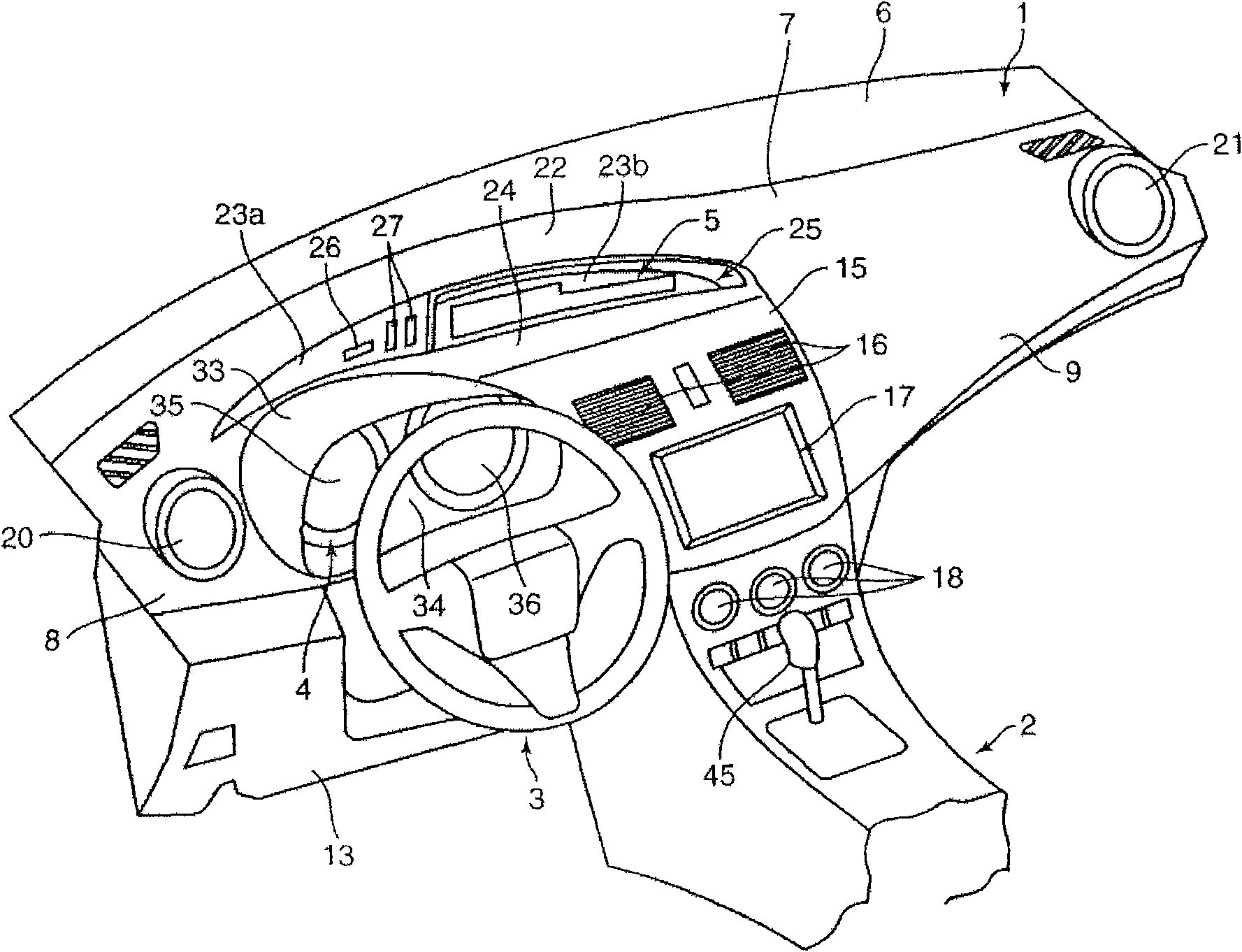

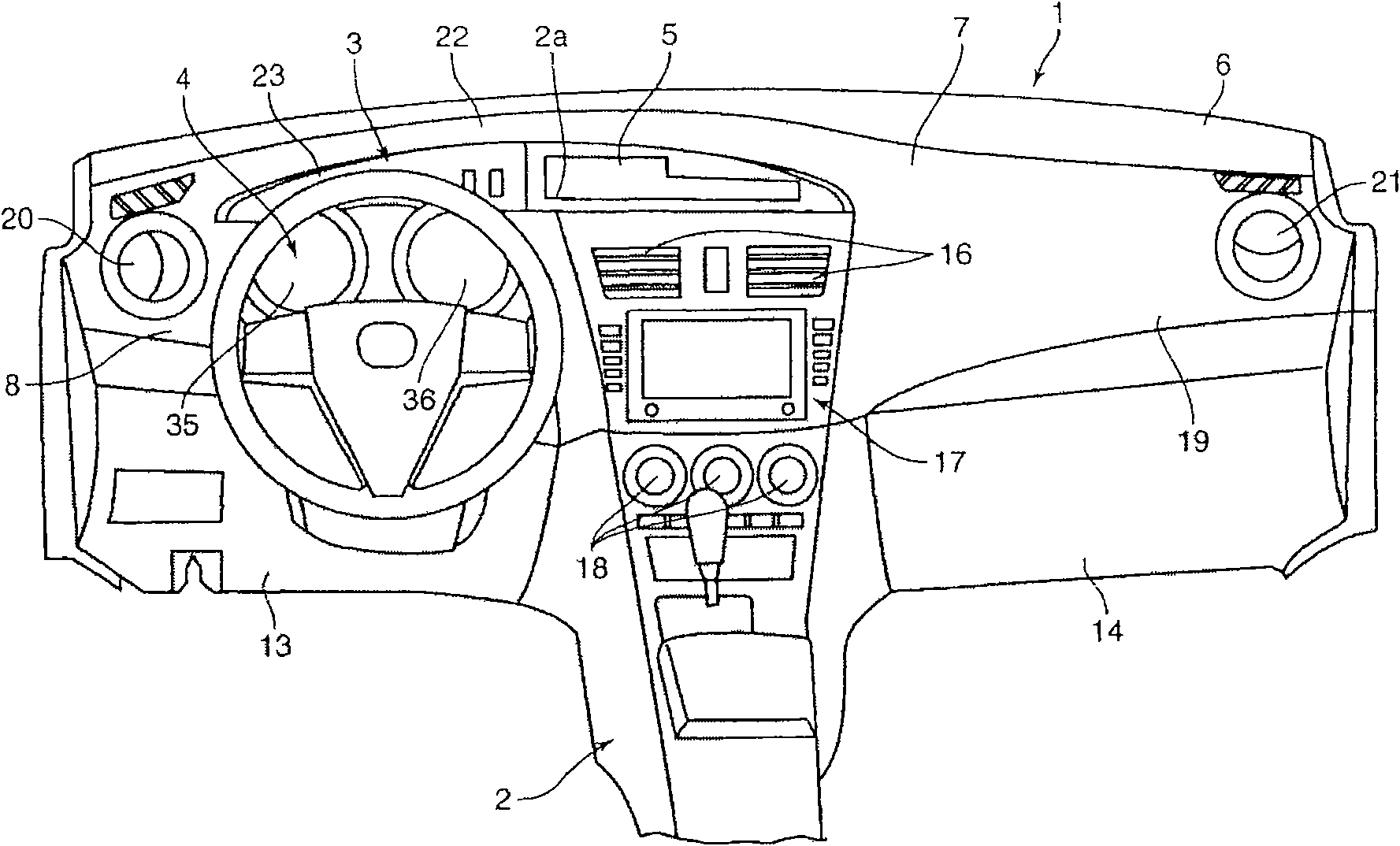

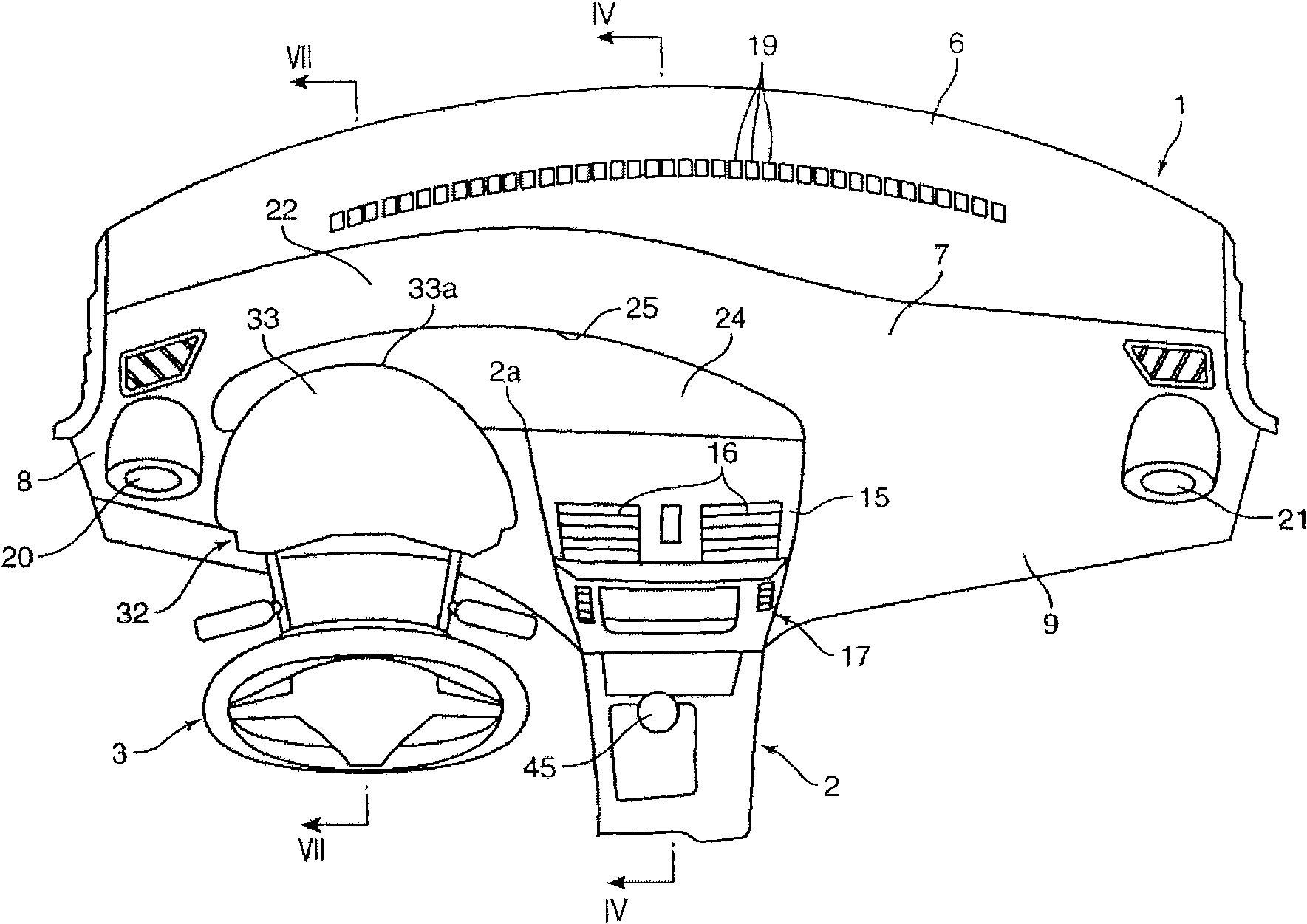

Instrument panel device

InactiveCN101565000AAvoid interferenceGuaranteed volumeSuperstructure subunitsInstrument arrangementsSteering wheelEngineering

An instrument panel device for automobile comprises an instrument panel body 1, a meter cluster portion 4, a display indication portion 5, an instrument-panel recess portion 25 comprising a bottom face portion 24 extending from a central portion of the recess portion to a driver's-seat-side end portion of the recess portion and a portion of difference in level 23 which rises upward from a front end portion of the bottom face portion, a projection portion provided in front of the steering wheel, the projection portion being formed in such a manner that a specified portion of the bottom face portion of the recess portion which is located in front of the steering wheel projects upward. A meter-panel face portion of the meter cluster portion is provided at the projection portion. The display indication portion is provided at a central portion of the portion of difference in level.

Owner:MAZDA MOTOR CORP

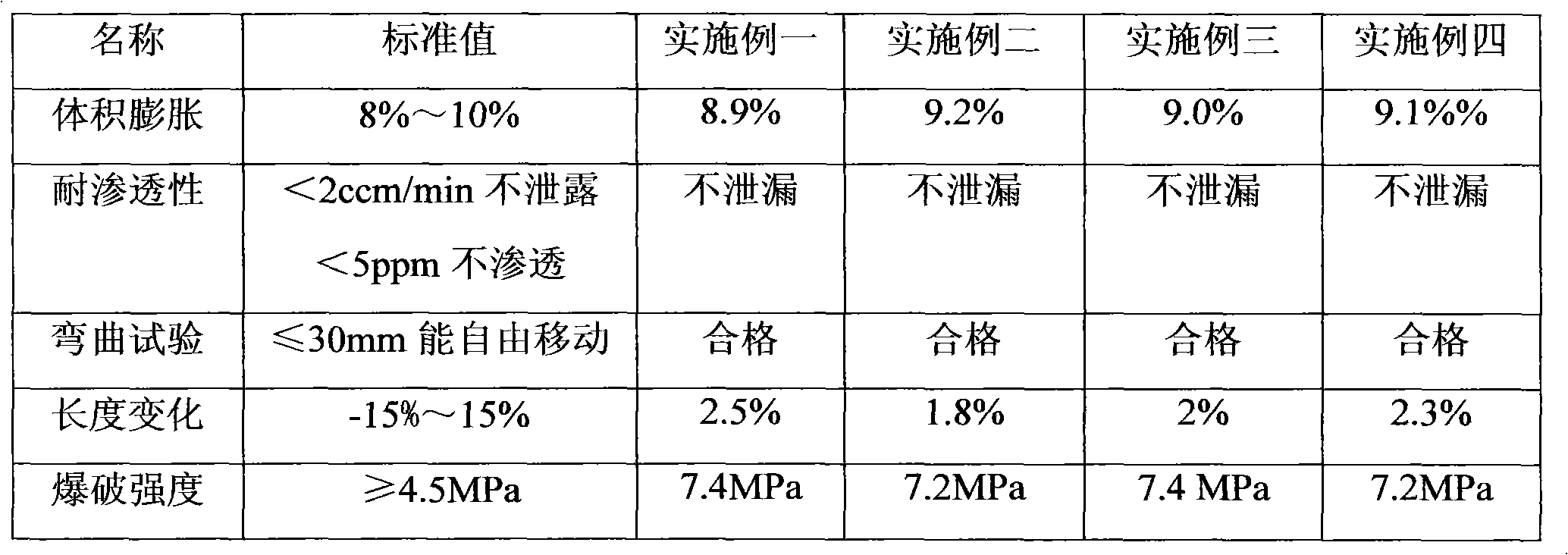

Urea tube and production process thereof

The invention relates to a urea tube resisting heat, automotive urea and lubricating oil. The urea tube is mainly made from ethylene propylene diene monomer rubber. The urea tube has the beneficial effects that a frequently-used vulcanization system of sulphur is utilized to ensure the comprehensive performance of a rubber material; zinc oxide and stearic acid are utilized to activate the physical properties of the rubber material, and at the same time phenolic resin is added to improve the bonding of the rubber material and yarns and ensure burst pressure and volume expansion; reactive type long-acting antiager is utilized to prevent heat aging and ozone aging; and a plasticizer DOS (dioctyl sebacate) is utilized to replace the previous paraffin oil to improve cleanness and prevent permeating leakage of urea and other media, and at the same time white carbon black and light calcium are added to reinforce the strength of the ethylene propylene diene monomer rubber. The obtained flexible tube has good heating resisting, automotive urea resisting and lubricating oil resisting performances, and has the parameters of fastness and permeation resistance less than 2 ccm / min without leakage and less than 5 ppm without permeation, volume expanded by 8%-10% and the bending radius less than or equal to 30 mm so as to move freely.

Owner:QINGDAO SUNSONG CO LTD

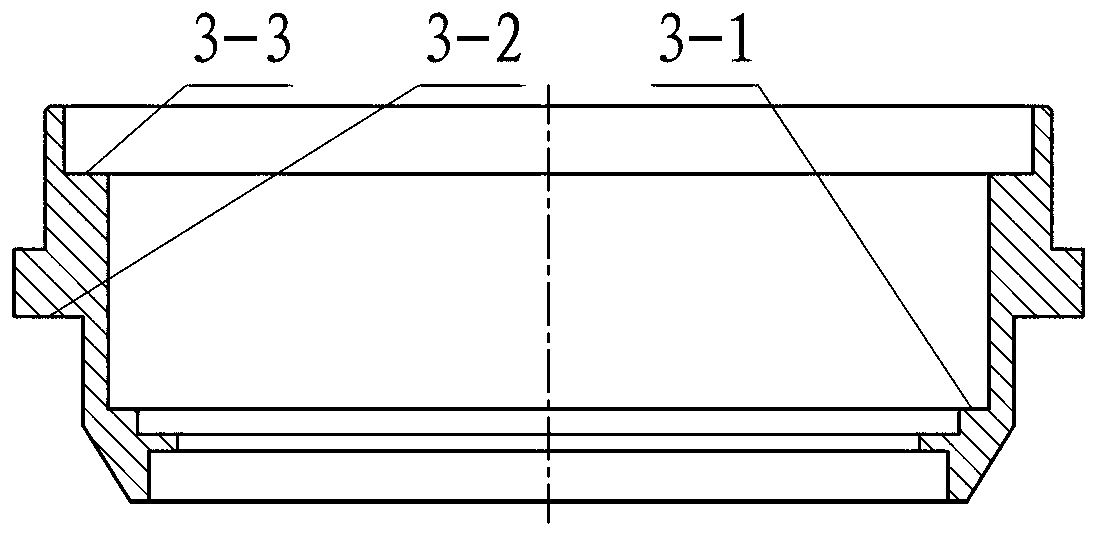

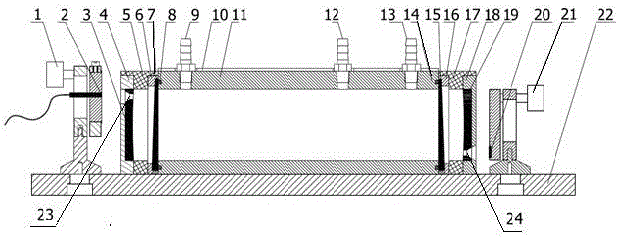

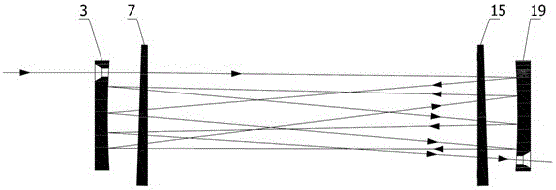

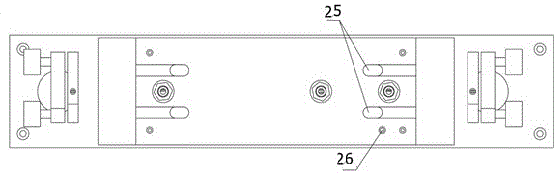

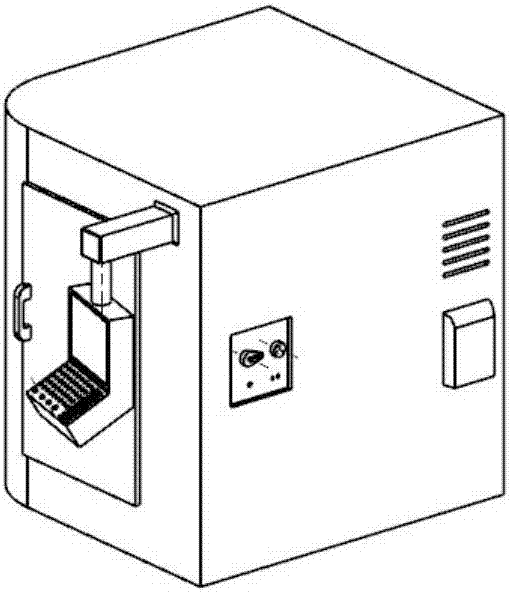

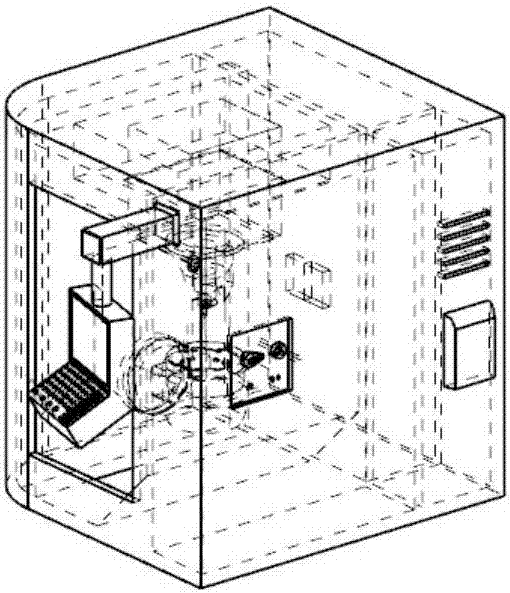

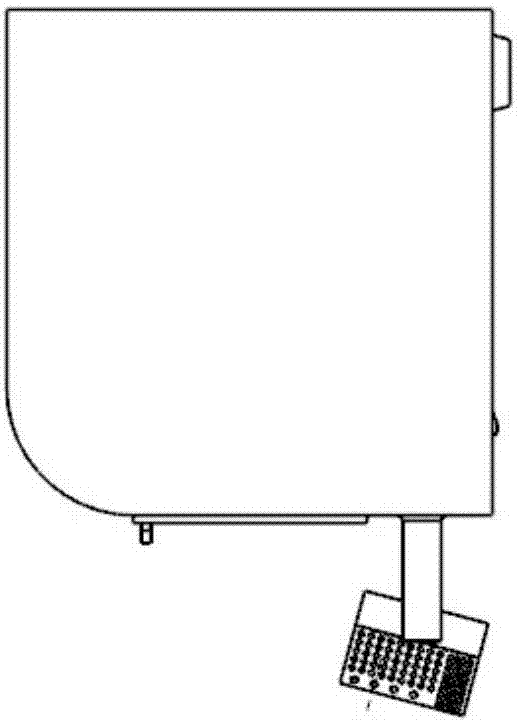

Laser gas detection platform with multiple-reflection long-optical-path high-temperature sample chamber

InactiveCN105758803AGuaranteed volumeLow costColor/spectral properties measurementsOptoelectronicsOptical pathlength

The invention relates to a laser gas detection platform with a multiple-reflection long-optical-path high-temperature sample chamber.The laser gas detection platform comprises a platform base (22), a sample chamber shell (11), an optical path adjusting device (1), a laser emitting device (2), a receiving device installation base (21), a laser receiving device (20) and a conjugate laser reflecting device.A gas inlet (9) is formed in the upper portion of one side of the sample chamber shell (11), a gas outlet (13) is formed in the upper portion of the other side of the sample chamber shell (11), and an incidence window (7) and an emergence window (15) are arranged at the two ends of the sample chamber shell (11) respectively.The laser emitting device (2) is installed on the optical path adjusting device (1), and the laser receiving device (20) is installed on the receiving device installation base (21).The conjugate laser reflecting device comprises a concave reflecting mirror (3) and a concave reflecting mirror (19).The gas detection platform is high in measuring precision; as laser spots are small, a sample gas optical path through which detection lasers pass is prolonged to 10-30 times through multiple reflection; the size is small, and the length of the long-optical-path sample chamber is reduced due to the multiple reflection structure; the cost is low, a complex optical-mechanical structure is simplified, and the structural member cost of a measuring system is reduced.

Owner:中钢集团武汉安全环保研究院有限公司

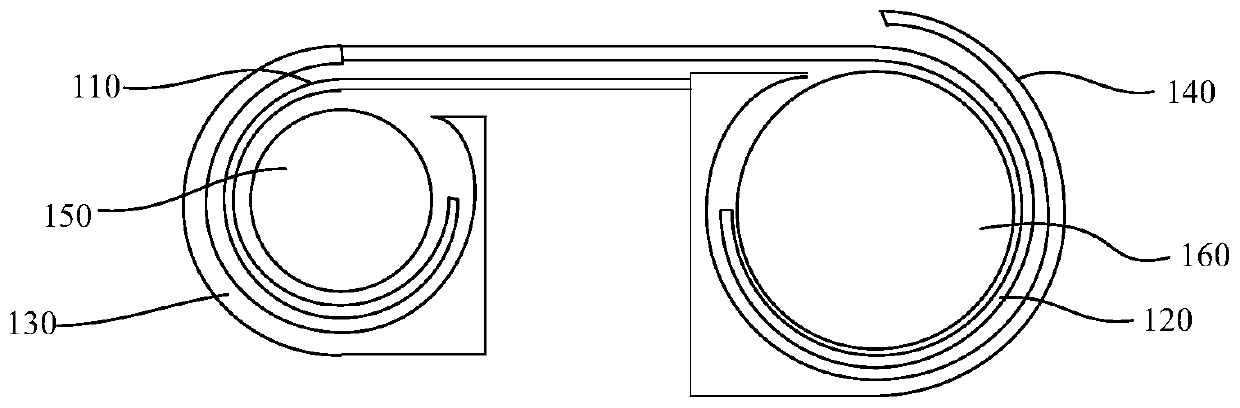

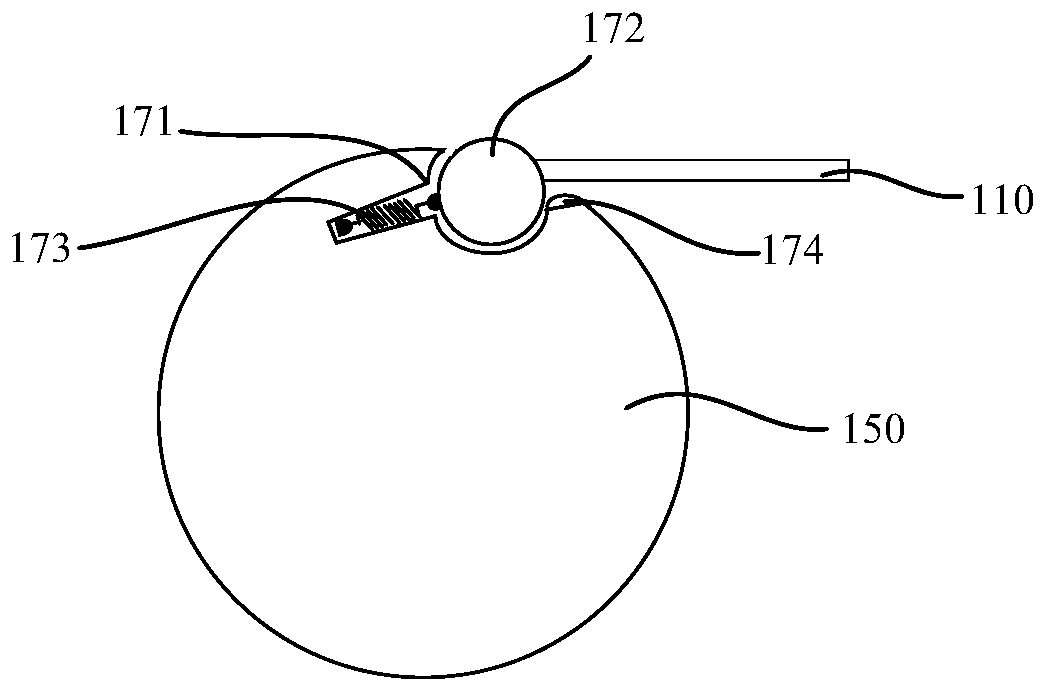

Flexible display device

ActiveCN111583802AGuaranteed hardnessHigh hardnessCasings with display/control unitsCasings/cabinets/drawers detailsEngineeringFlexible display

The invention discloses a flexible display device, which comprises a display component, including a flexible screen body and a flexible cover plate; and a shell comprising a first shell and a second shell, wherein the first shell is provided with a first opening, the second shell is provided with a second opening, and the first opening and the second opening are oppositely arranged; a first scrollis arranged in the first shell and is used for rolling or unfolding the flexible screen body; a second scroll is arranged in the second shell, and the second scroll is used for winding or unwinding the flexible cover plate in cooperation with the first scroll to wind or unwind the flexible screen body; the flexible screen body penetrates through the first opening to be connected to the second shell, and the flexible cover plate penetrates through the second opening to be connected to the first shell. The size of the flexible display device can be reduced while hardness requirement of the flexible cover plate is met.

Owner:HEFEI VISIONOX TECH CO LTD

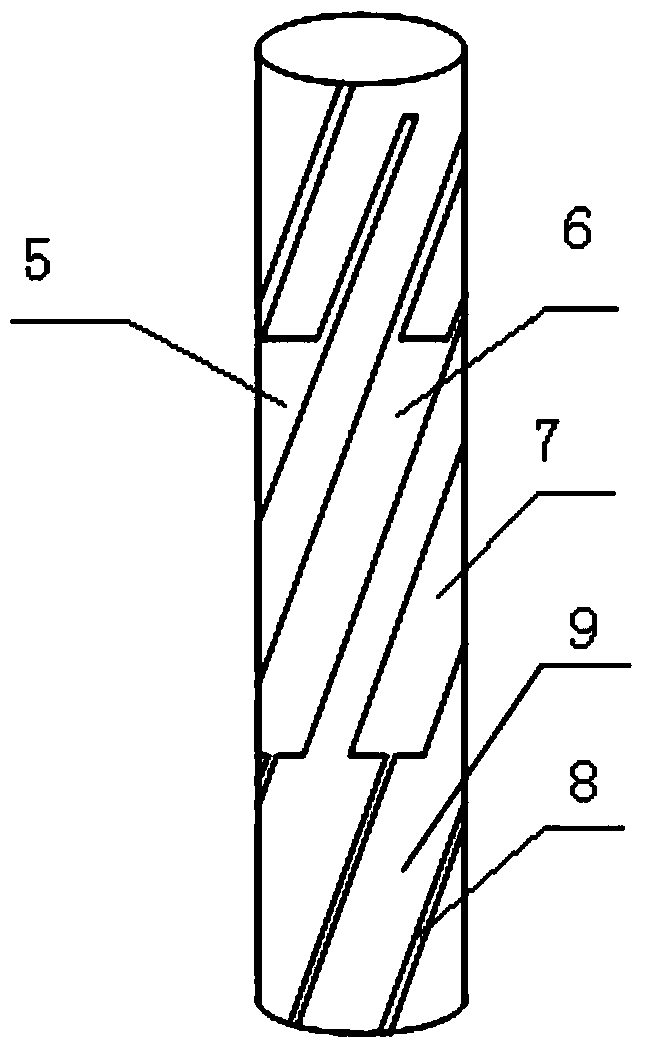

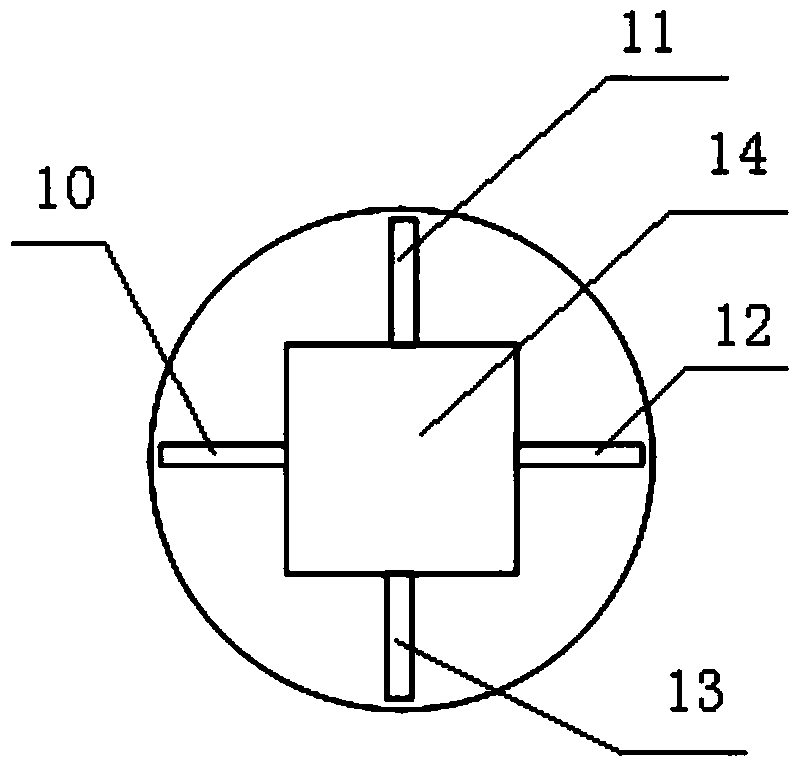

Handset terminal antenna for mobile satellite communication system

ActiveCN104332704AGuaranteed volumeGuaranteed weightSimultaneous aerial operationsRadiating elements structural formsDielectric cylinderComputer terminal

The invention discloses a handset terminal antenna for a mobile satellite communication system. The handset terminal antenna comprises a four-arm spiral antenna, a circular polarization network component and an antenna shell, wherein the four-arm spiral antenna comprises first to fourth helical arm patches and a dielectric cylinder; the first to fourth helical arm patches are printed on the outer wall of the dielectric cylinder; the dielectric cylinder is fixedly arranged on the circular polarization network component; the antenna shell is arranged on the outer side of the dielectric cylinder; the circular polarization network component comprises first to fourth micro-strip patches and an LTCC (Low Temperature Co Fired Ceramic) circular polarization network; certain ends of the first to fourth micro-strip patches are connected with four output ports of the LTCC circular polarization network respectively, and the other ends of the first to fourth micro-strip patches are connected with the first to fourth helical arm patches respectively; an input port of the LTCC circular polarization network is a radio frequency connector; the radio frequency connector is connected with a radio frequency circuit of a handset terminal.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Five-axis ultrasonic vibration numerical control machine tool for composite laser machining

ActiveCN107443075AImprove processing efficiencyImprove finished productsOther manufacturing equipments/toolsMovement controlEngineering

The invention relates to a five-axis ultrasonic vibration numerical control machine tool for composite laser machining. The numerical control machine tool has the mechanical machining function and the laser machining function simultaneously. The numerical control machine tool comprises a mechanical movement control system and a workpiece machining portion. The workpiece machining portion comprises a motor moving along the X axis, the Y axis and the Z axis, an A-axis motor, a C-axis motor, a tool chuck for mechanical machining, a laser generator for laser machining, a machining platform and a depth detector for laser machining. The mechanical movement control system controls the motors to move. The mechanical numerical control machining manner and the laser machining manner are combined, machining efficiency is improved, machined finished products are improved, and the machining capacity is improved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

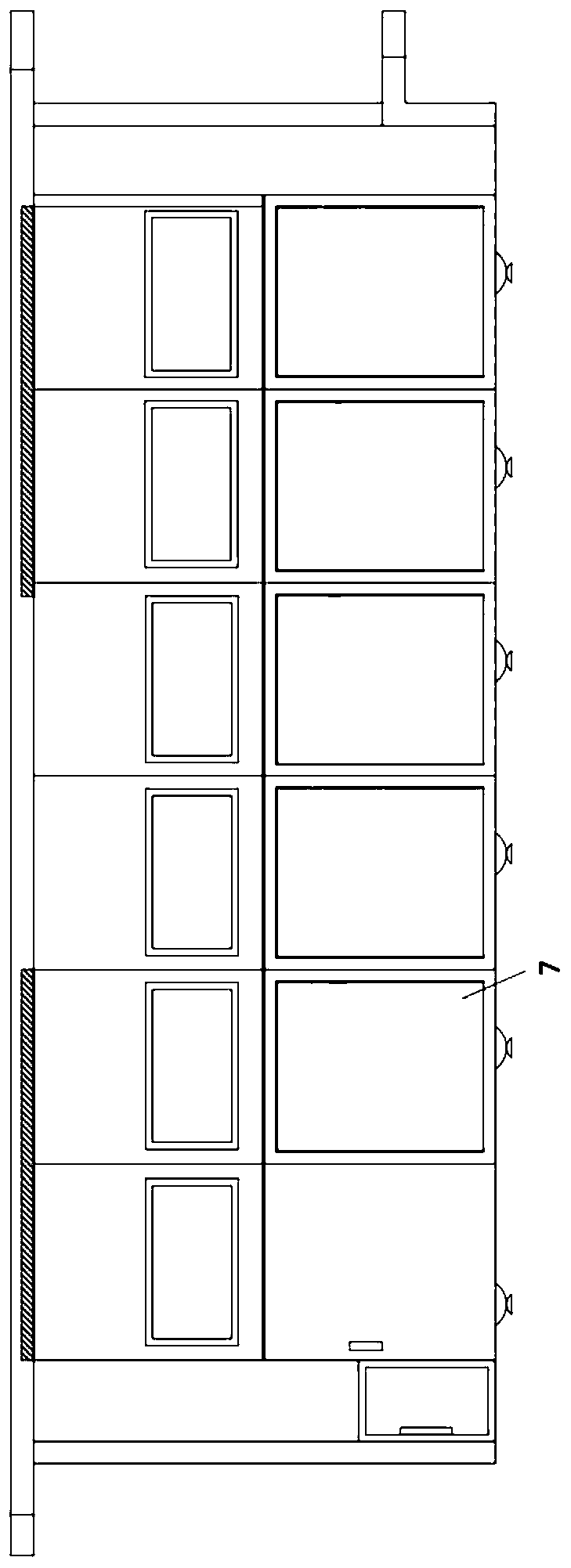

Garbage classification device and garbage classification method

ActiveCN110329672AImprove accuracyAccurate class separationWaste collection and transferRefuse receptaclesClassification methodsEngineering

The invention relates to the technical field of garbage classification, in particular to a garbage classification device and a garbage classification method. The garbage classification device comprises a box body, a humidity sensor, an image collecting mechanism and a controller, wherein a vertical conveying mechanism and a horizontal conveying mechanism are arranged in the box body; a discharge port of the vertical conveying mechanism corresponds to a feed port of the horizontal conveying mechanism; the humidity sensor is arranged at a feed port of the vertical conveying mechanism; a materialgrabbing mechanism is arranged at a position, close to the humidity sensor, of the vertical conveying mechanism; the image collecting mechanism is arranged at the feed port of the horizontal conveying mechanism; the controller is in signal connection with the humidity sensor, the material grabbing mechanism and the image collecting mechanism; different types of garbage identification codes are prestored in the controller; and garbage on the horizontal conveying mechanism is conveyed to different storage boxes after image information is collected by the image collecting mechanism and corresponding identification codes are identified by the controller. The garbage classification device and the garbage classification method have the advantage of high accuracy.

Owner:北京绿博伟业环保科技有限责任公司

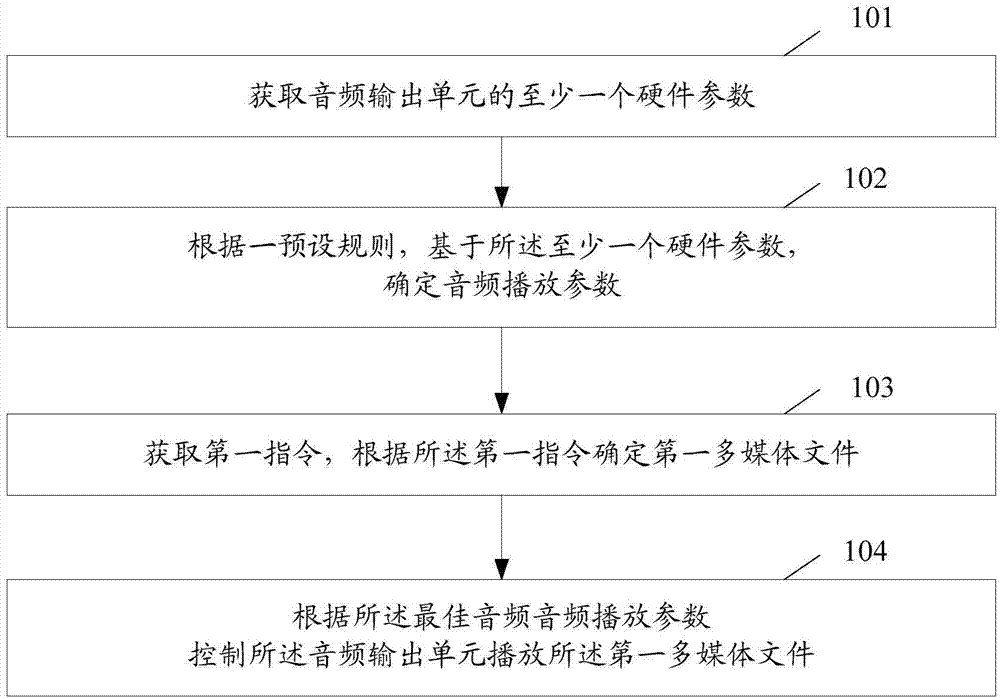

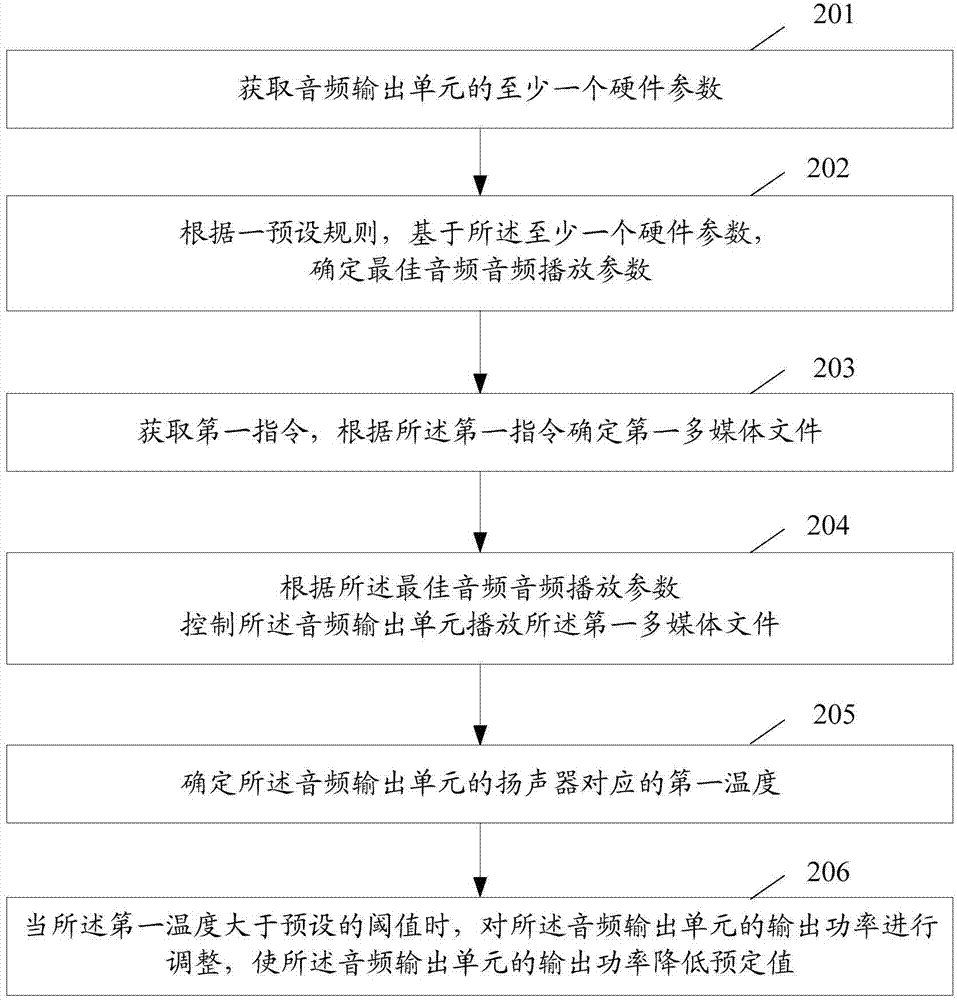

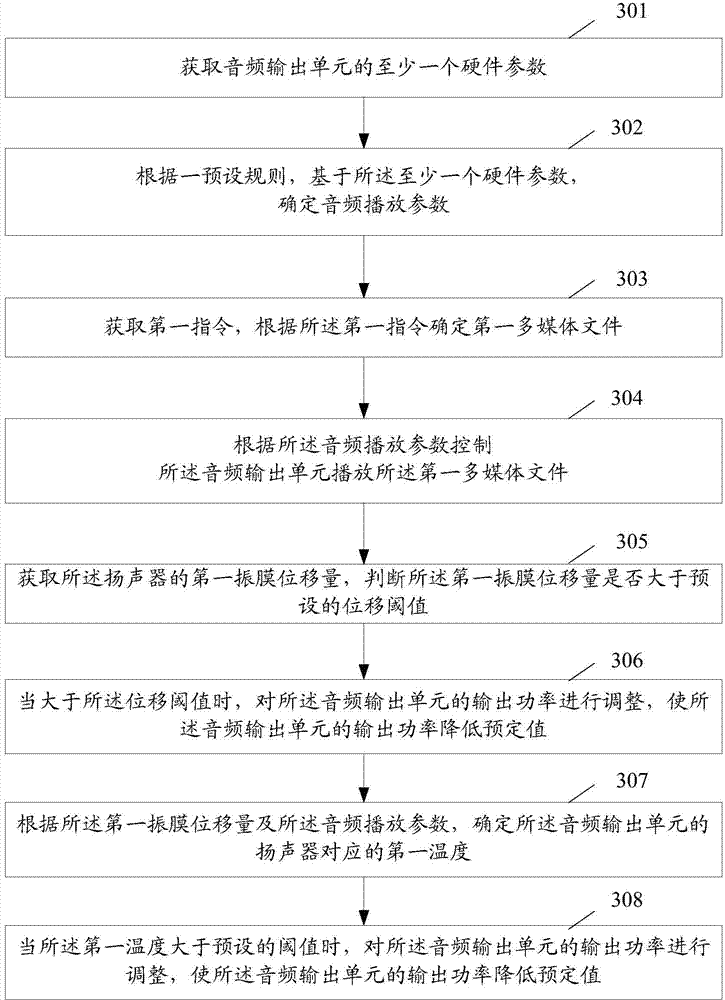

Method for processing audio information and electronic device

ActiveCN103929692AMonitor temperatureBest Playing StatusFrequency/directions obtaining arrangementsParameter controlAudio frequency

The invention discloses a method for processing audio information and an electronic device. The method includes the steps of obtaining at least one hardware parameter of an audio output unit; based on the at least one hardware parameter, determining a set of audio playing parameters according to a preset rule, wherein the audio playing parameters are matched with the hardware parameter of the audio output unit; obtaining a first instruction, and determining a first multimedia file according to the first instruction; controlling the audio output unit to play the first multimedia file according to the audio playing parameters. By means of the method and the electronic device, it can be guaranteed that the audio output unit can be kept in the optimal playing state.

Owner:LENOVO (BEIJING) CO LTD

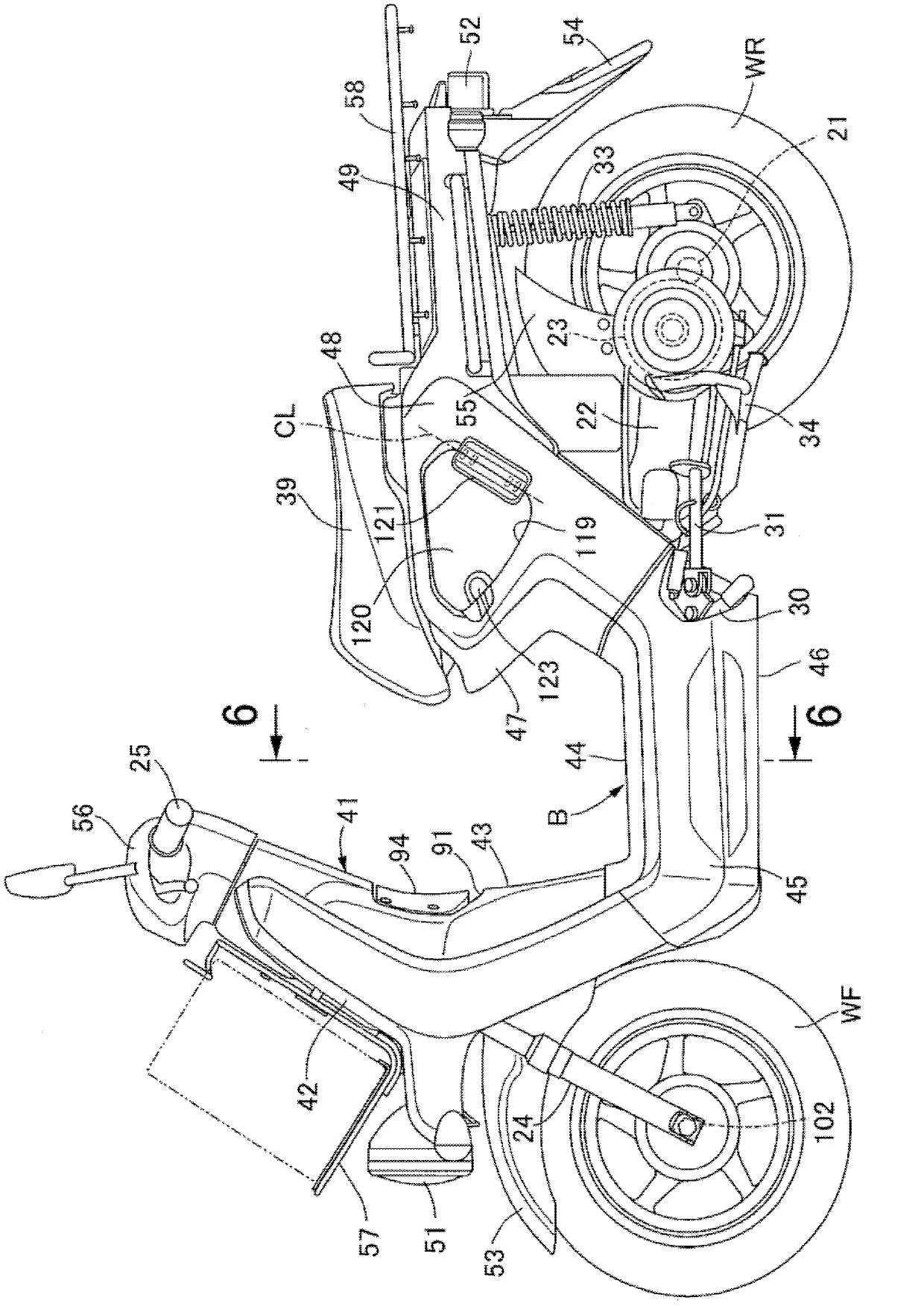

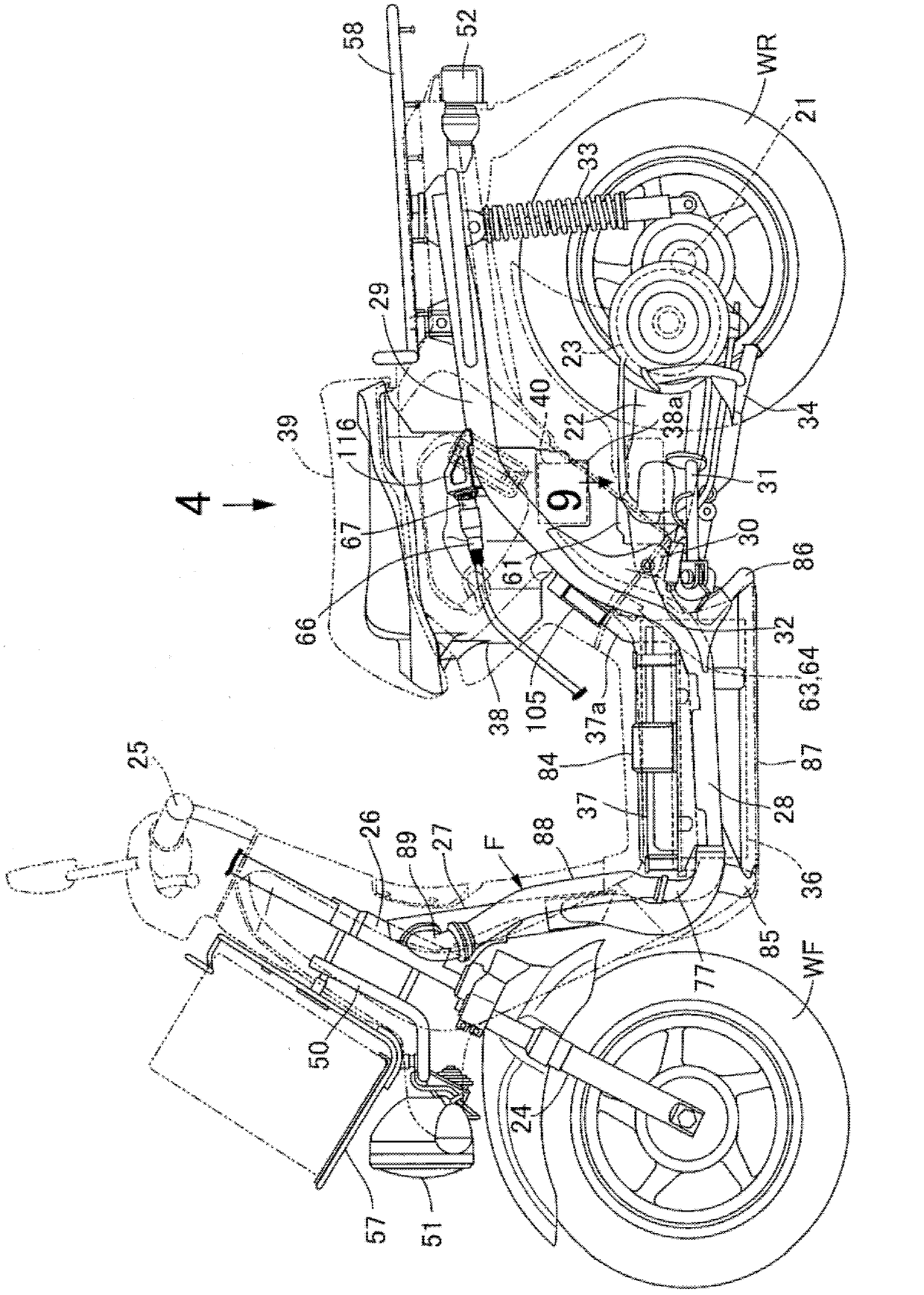

Electrically driven two-wheeled vehicle

ActiveCN102498031AEasy to chargeImprove convenienceCycle standsMotorised scootersElectricityEngineering

An electrically driven two-wheeled vehicle provided with an electric motor which generates power for driving the rear wheel, a battery which supplies electric power to the electric motor, a sitting seat on which the occupants sits, a containing box which is disposed below the sitting seat, and a side cover which covers the containing box at a position below the sitting seat, wherein the battery is rechargeable. An opening (118) which is covered with an openable / closable lid member (120) is provided in the side cover (48), and an electricity receiving-side connector (67) which can be inserted into an electricity supply-side connector which connects to an external electric power source is affixed and disposed between the containing box and the outer surface of the side cover (48) so as to be exposed at the opening (118). The configuration eliminates the need of opening the sitting seat in order to recharge the battery, and as a result, the recharging operation is facilitated.

Owner:HONDA MOTOR CO LTD

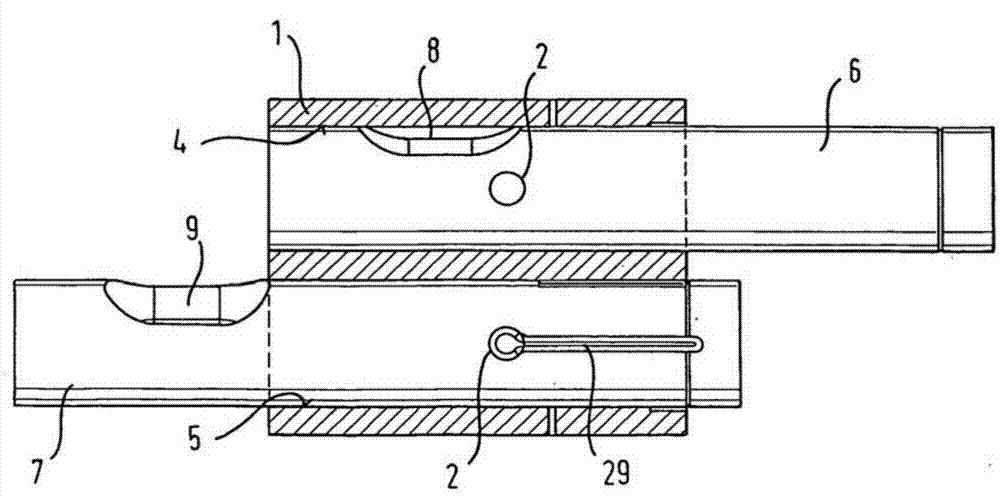

Device for filtering a fluid

InactiveCN104203364AEnsure continuous melt flowGuaranteed volumeStationary filtering element filtersAxial displacementEngineering

The invention relates to a device for filtering a thermoplastic melt, comprising a housing (1) having at least one fluid feed channel (2) and at least one fluid discharge channel (3) and having at least two bores (4, 5) which are in fluid communication with the fluid feed channel and the fluid discharge channel, respectively. In each of the bores a respective bolt (6, 7) is axially movable, radially rotatable and mounted in a fluid-tight manner, and each of the bolts is provided with a filter unit (8, 9) having an inflow side and an outflow side. The bolts can each be moved at least between a filtering position and a back-flushing position, and each of the bolts can be moved into a filling position in which via a respective clean fluid channel (12, 13) fluid flows from the outflow side of the respective filter unit to a storage space (14, 15) produced by the movement of the respective bolt in the respective bore. As the respective bore is moved into the back-flushing position the fluid again flows through the respective filter unit to the at least one back-flushing channel and out of the housing.

Owner:马格自动化有限责任公司

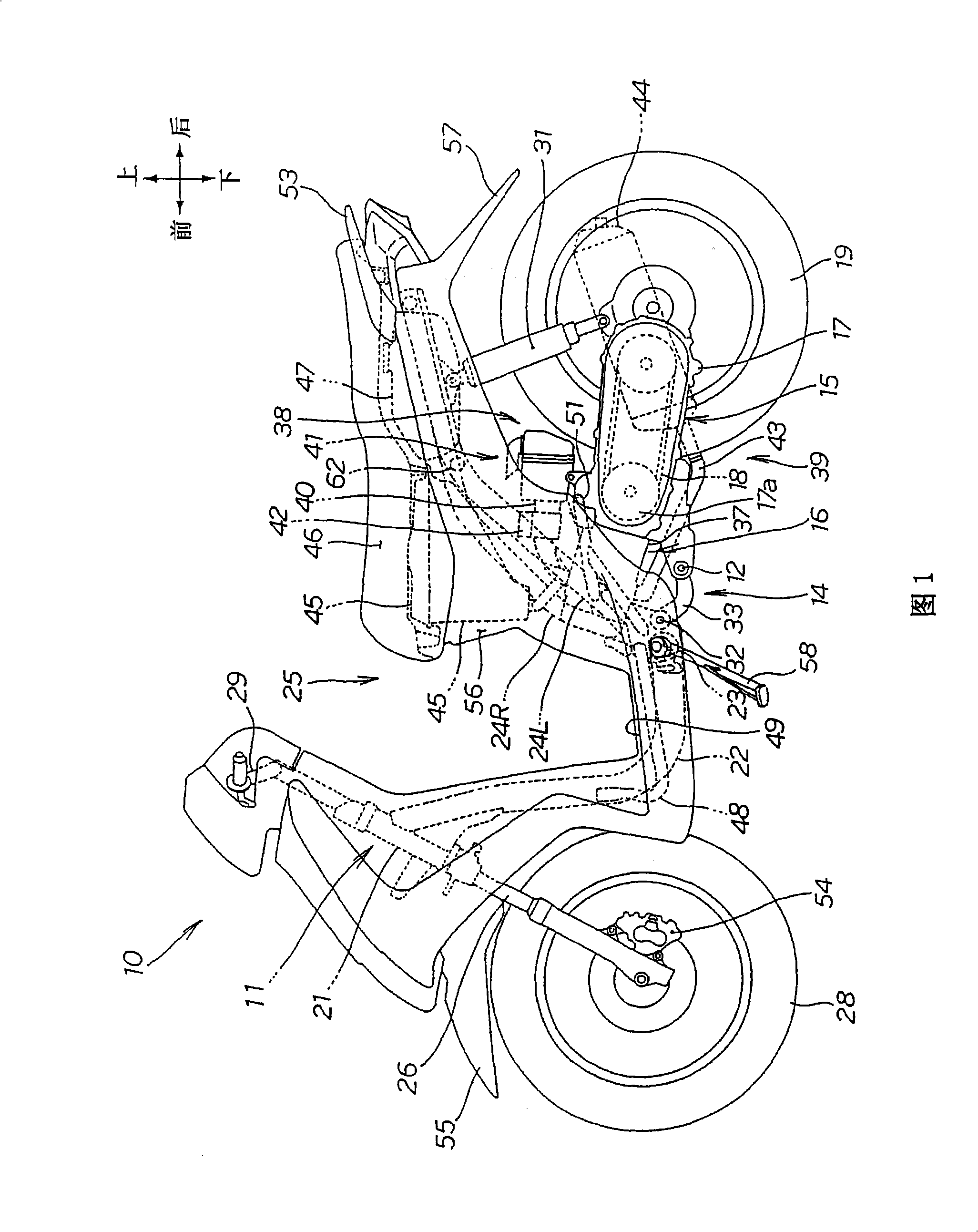

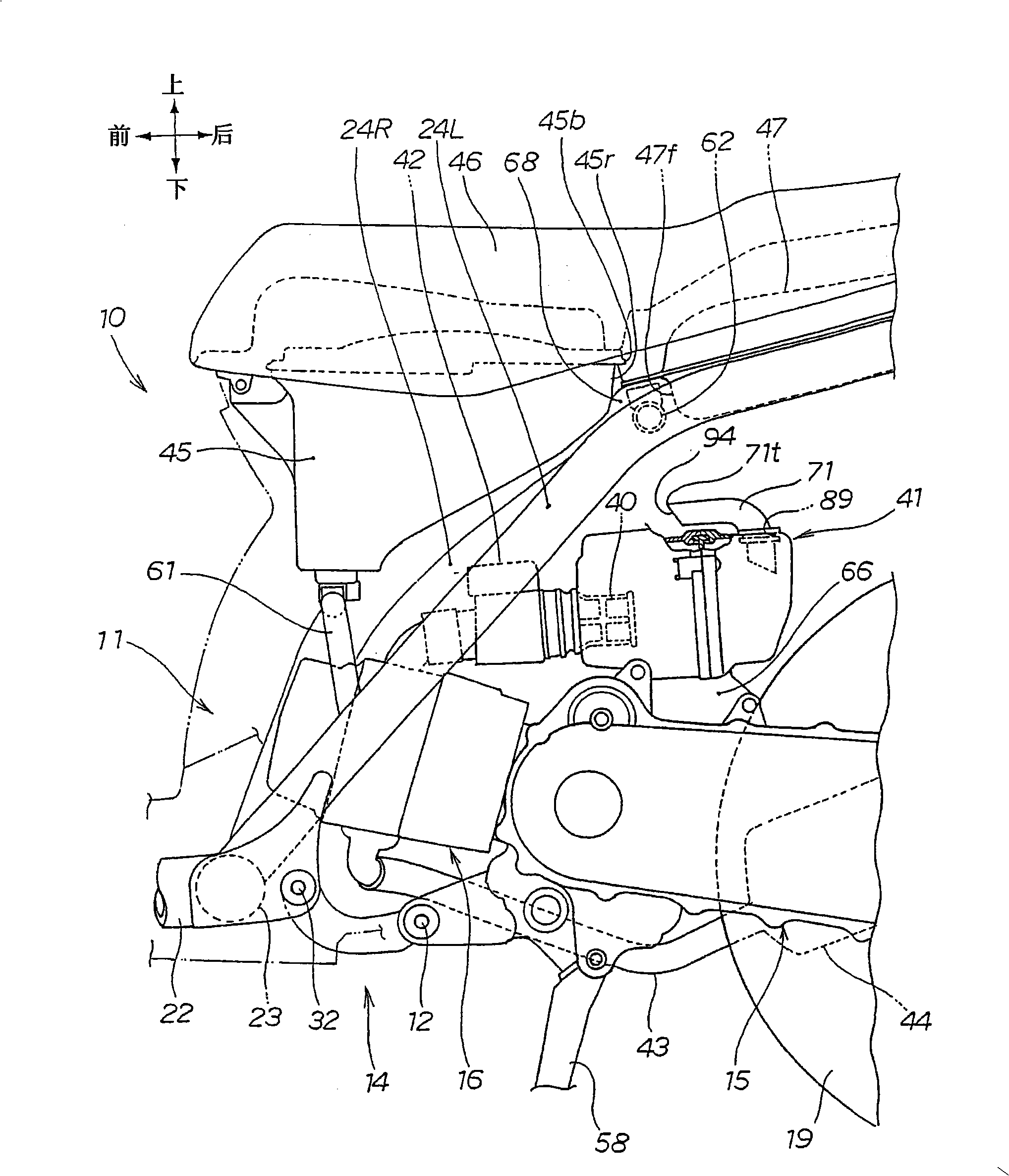

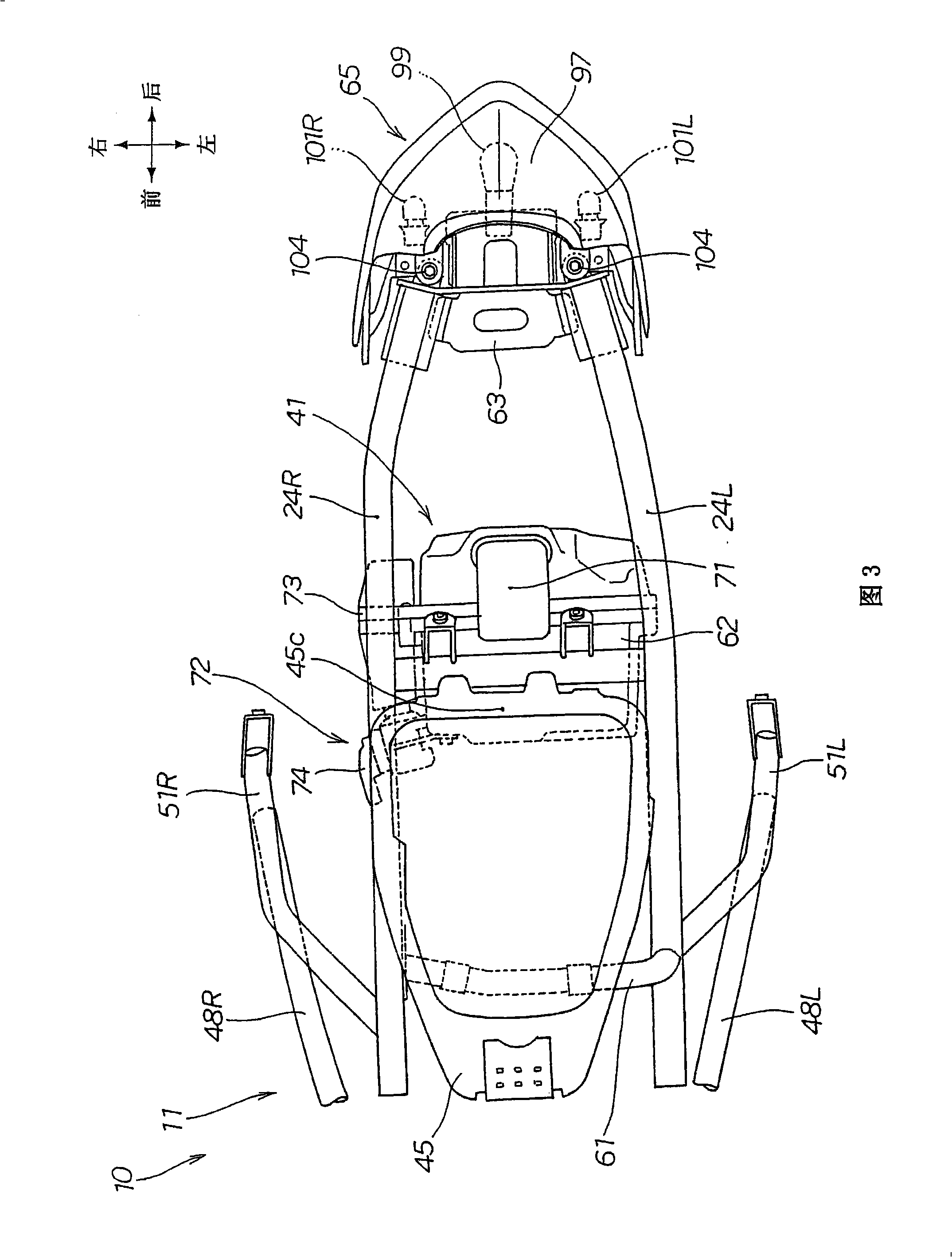

Scooter-type vehicle

InactiveCN101333987ASmall volumeFully inhaled performanceExhaust apparatusSilencing apparatusAir filterFuel tank

The present invention provides a scooter-type vehicle which ensures that the air cleaner has a required and sufficient intake performance, and also ensures that the storage box (45) has a sufficient storage capacity. A scooter-type vehicle includes an air cleaner (41) that is arranged between a power unit (15) and a storage box (45) as seen from the lateral side and is supported on the power unit (15). A fuel tank (47) is arranged in rear of the storage box (45). A gap (68) is provided between the rear side surface of the storage box (45) and the front side surface of the fuel tank (47). When the power unit (15) swings and the air cleaner (45) approaches the storage box (45), a duct (71) is located near the gap (68).

Owner:HONDA MOTOR CO LTD

Nutritional and healthy health care product

The invention relates to an orally taken nutritional and healthy health care product which comprises 16 groups of foods which are not same completely, wherein each group of foods comprises one type of aquatic seafood materials, one type of animal-based materials and two types of vegetables, fruits and beans. The nutritional and healthy health care product provided by the invention has the functions of supplementing qi and blood, nourishing yin and yang, tonifying internal organs and benefiting brain, and is a nutritional and healthy health combination meeting a healthy and scientific diet method requiring food diversity and outstanding vegetarian foods matched with meat.

Owner:杨明华

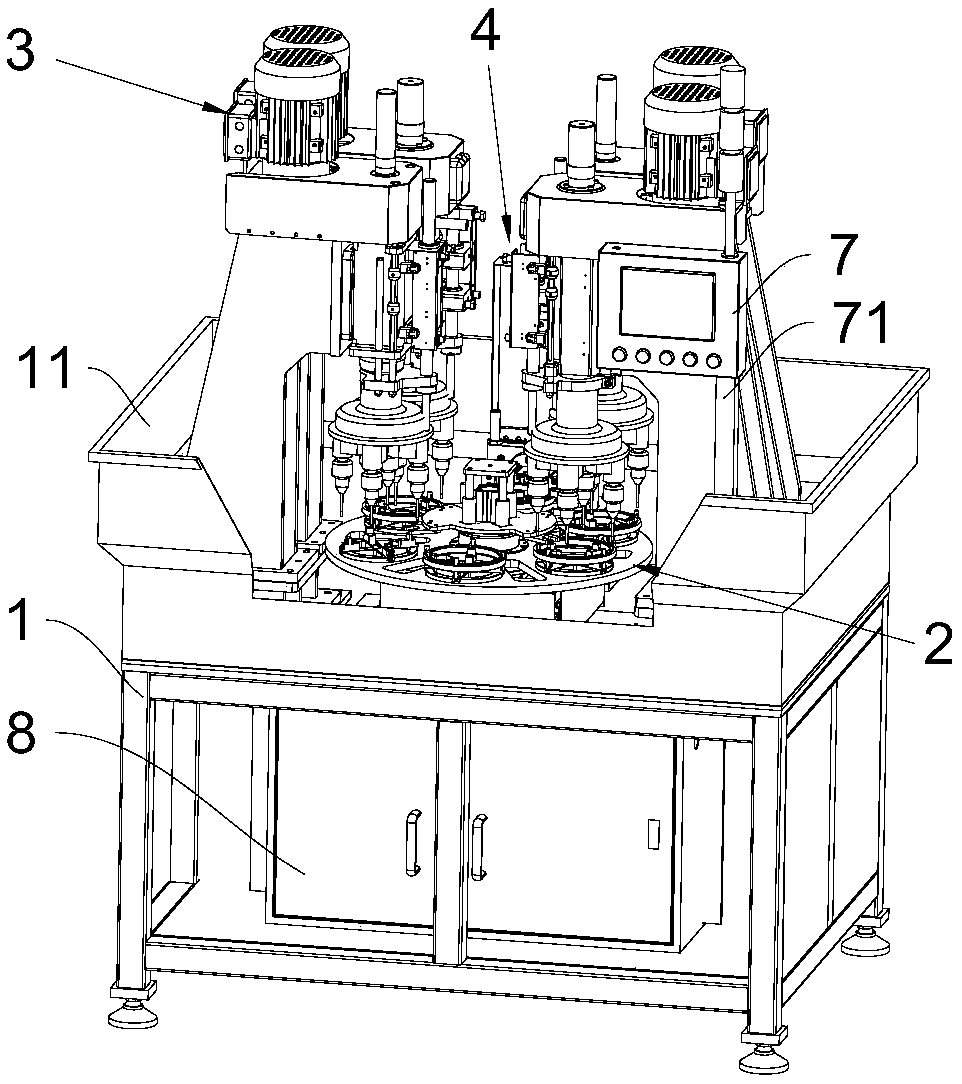

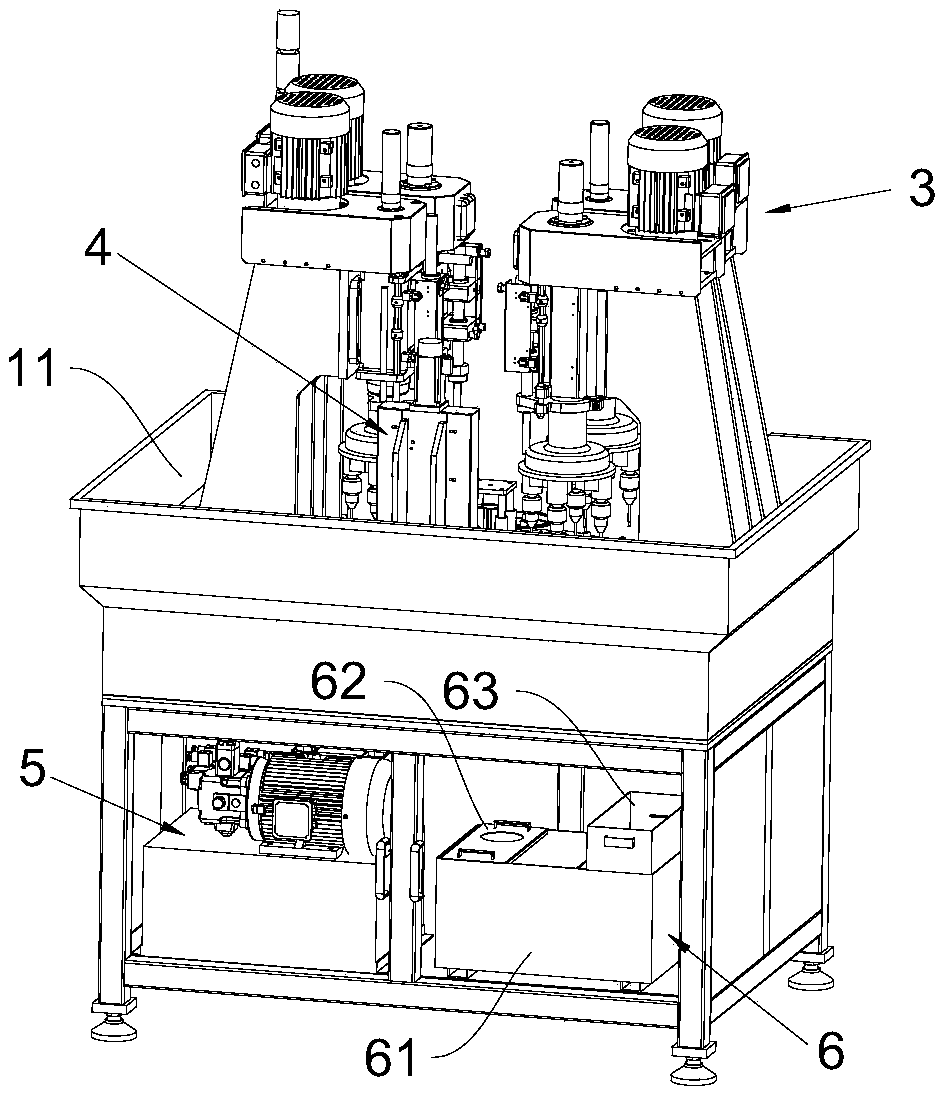

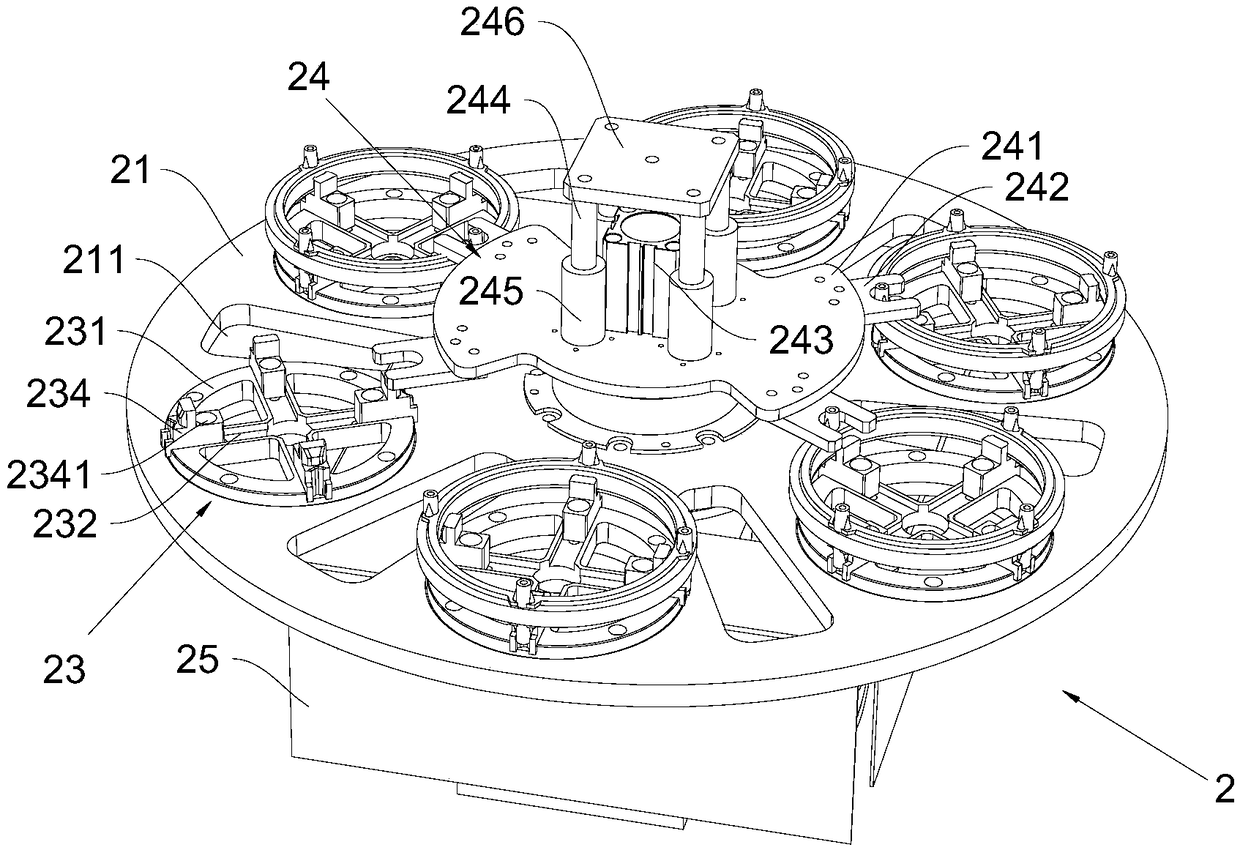

Drilling-tapping all-in-one machine

PendingCN109454457AReduce dependenceImprove processing efficiencyPrecision positioning equipmentOther manufacturing equipments/toolsTransport timeWorking environment

The invention provides a drilling-tapping all-in-one machine which solves the problem that an existing motor ring processing process is complex. According to the technical scheme, the key point is that the drilling-tapping all-in-one machine comprises a rack and an oil supply system, wherein an indexing positioning device which is rotatably connected with the rack is arranged on the rack; a turnover device for turning over workpieces is arranged on the rack; processing devices are arranged on the positions, at the two sides of the turnover device, of the rack; and each processing device comprises a drilling device and a tapping device. The indexing positioning device, the processing devices and the turnover device are arranged on the rack, so that the workpieces are transported to each station through the indexing positioning device, one workpieces is clamped once and processing of positive and negative surfaces is accomplished, multi-time calibration is not needed, processing time isshortened, and processing efficiency is improved; and moreover, the turnover device can automatically turn over the workpiece, equipment processing speed is increased, transportation time is saved, workpiece collision is avoided, working environment of a worker is improved, working strength is reduced, fatigue of the worker is reduced, and processing quality of the workpiece is guaranteed.

Owner:广东顶固集创家居股份有限公司

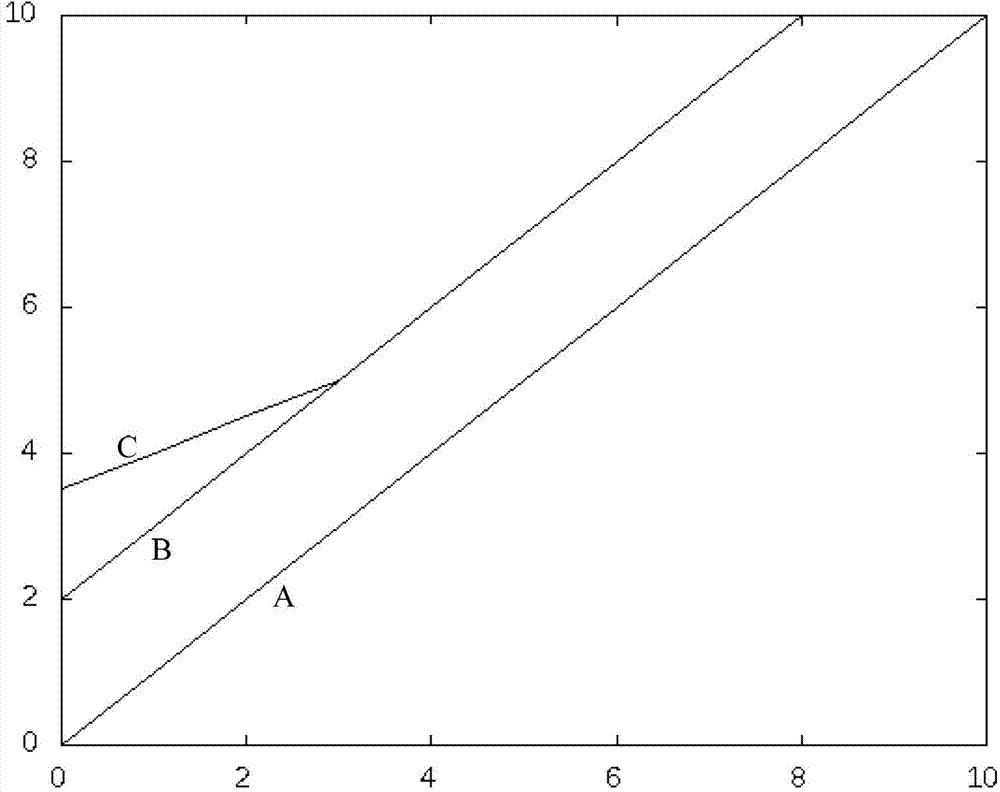

Method and device for generating customizable dynamic graphs

InactiveCN104574483ARich dynamic effectsGuaranteed sizeTexturing/coloringAnimationMultiple frameComputer graphics (images)

The embodiment of the invention provides a method and device for generating customizable dynamic graphs. The method includes the steps that dynamic information is read from dynamic interaction files; the dynamic interaction files comprise script objects and static images; at least part of pixel points in the static images are mapped to distorted images of one frame or multiple frames through the script objects according to the dynamic information so as to drive the dynamic images to change frame by frame. According to the method and device, the customizable dynamic graphs are achieved through the dynamic information, the dynamic effect can be assigned by users, and the dynamic effect mode is richened; due to the fact that the static images are small in size change, only information, such as the dynamic information and the scrip objects with the size being smaller is added, and the size is reduced greatly while the dynamic effect is guaranteed.

Owner:BEIJING QIHOO TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com